Method for fabricating sheet metal product having three-dimensional shape, and product

A manufacturing method and three-dimensional shape technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, engine frames, etc., can solve problems such as thermal deformation, harsh environmental requirements, and difficulty in improving work efficiency, and achieve high precision and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

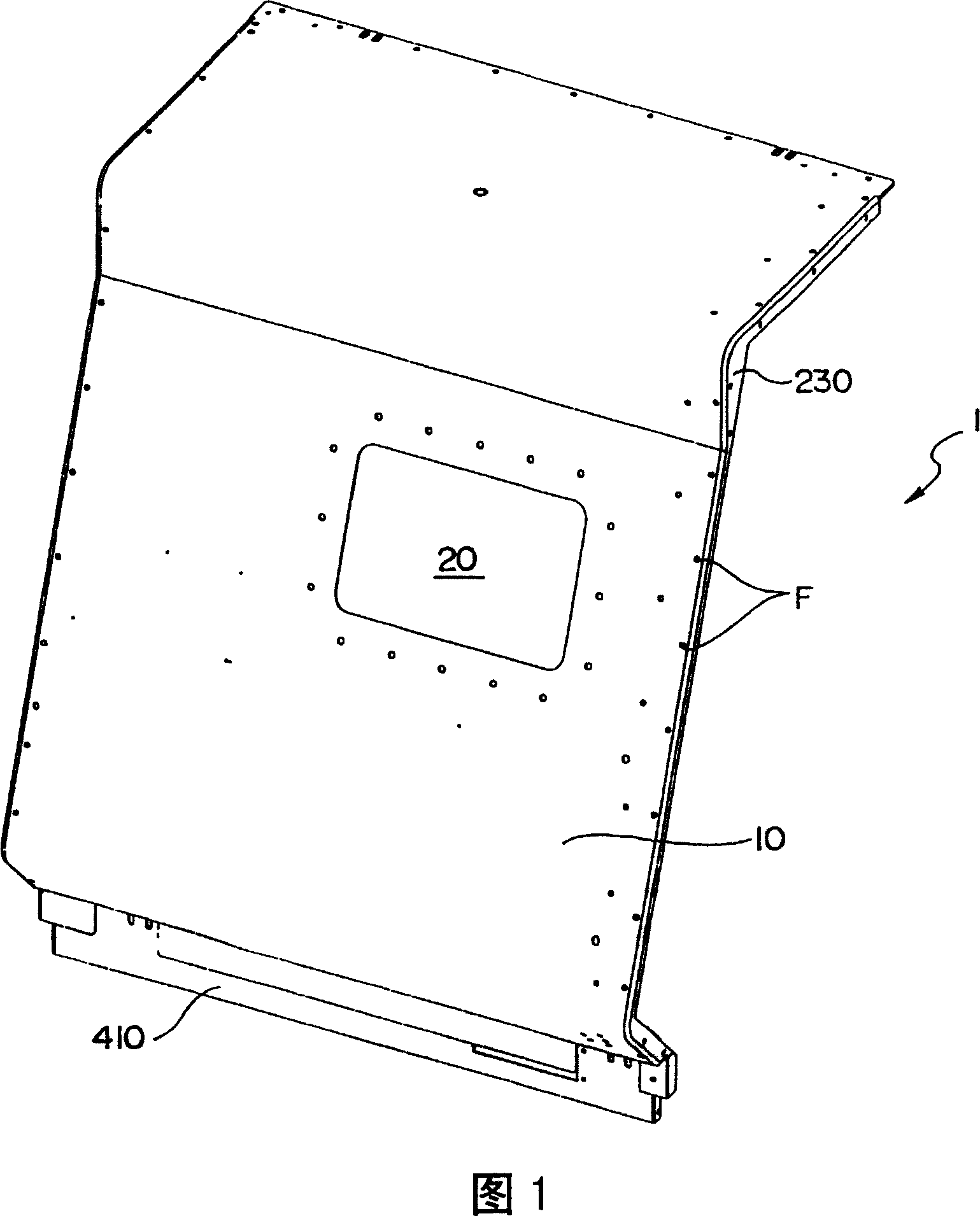

[0030] FIG. 1 is a perspective view showing an example of a sheet metal product according to an embodiment of the present invention.

[0031] The overall sheet metal product denoted by reference numeral 1 is, for example, a cover assembly equipped at the front of the machine tool.

[0032] The cover unit 1 is composed of a cover sheet 10 formed by molding a metal plate, and corner members 230 , 410 , which will be described later, mainly mounted around the cover sheet 10 .

[0033] The cover sheet 10 is provided with an opening 20 and the like, and a window for observing the machining part of the machine tool from the outside of the cover is attached thereto.

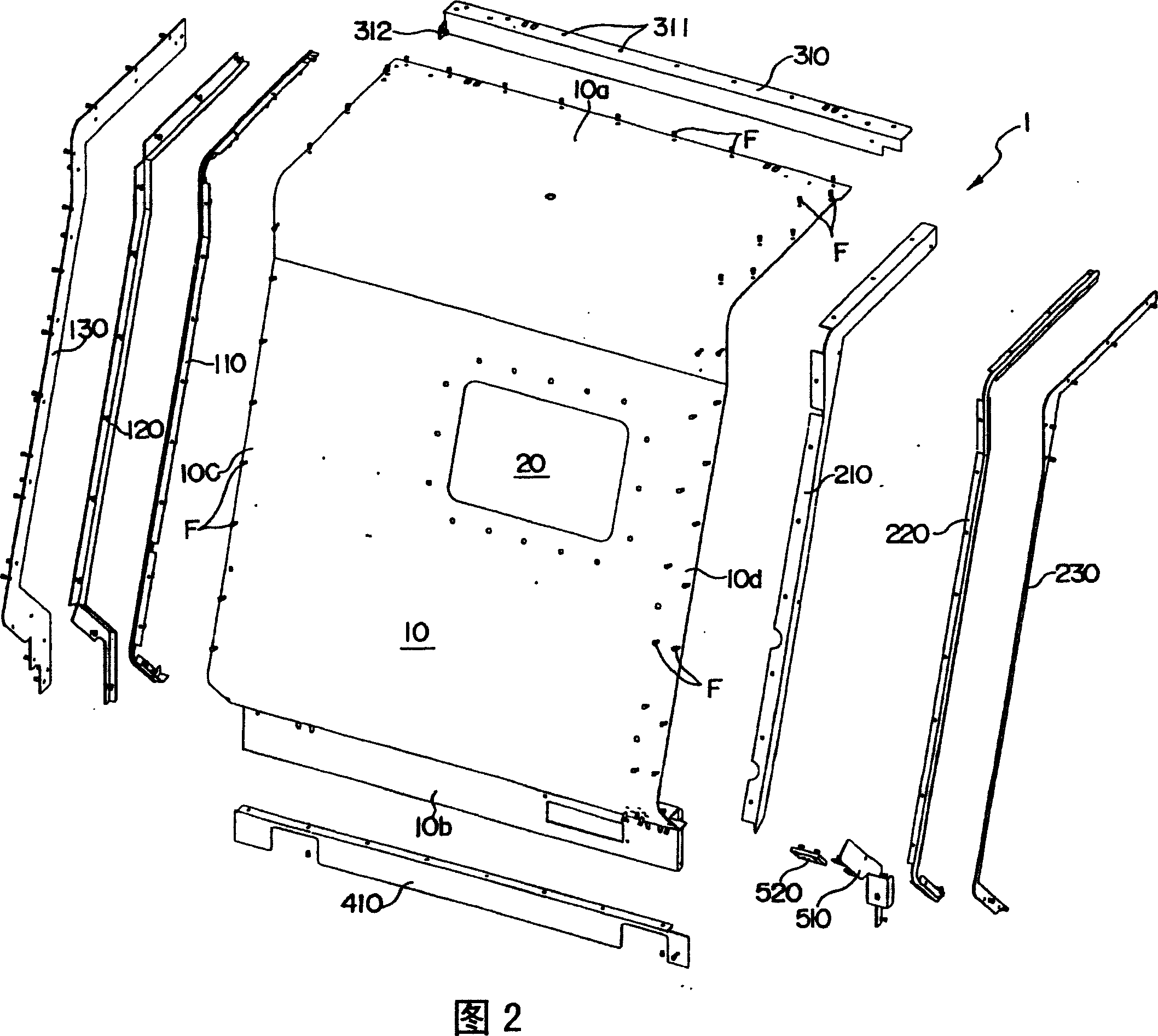

[0034] FIG. 2 is an exploded view of main components constituting the cover assembly 1 .

[0035] Fig. 2 is a view of the cover sheet 10 viewed from the front, but the upper edge 10a, the lower edge 10b, the left edge 10c, and the right edge 10d of the cover sheet 10 are respectively fixed with reinforcing parts to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com