Concrete composite shear wall with embedded steel plates and production method thereof

A technology of combining shear walls and concrete, applied in the direction of walls, building structures, building components, etc., can solve the problem that the ductility of concrete has not been significantly improved, and achieve high structural stability and reliability, improve strength and ductility, and save construction. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

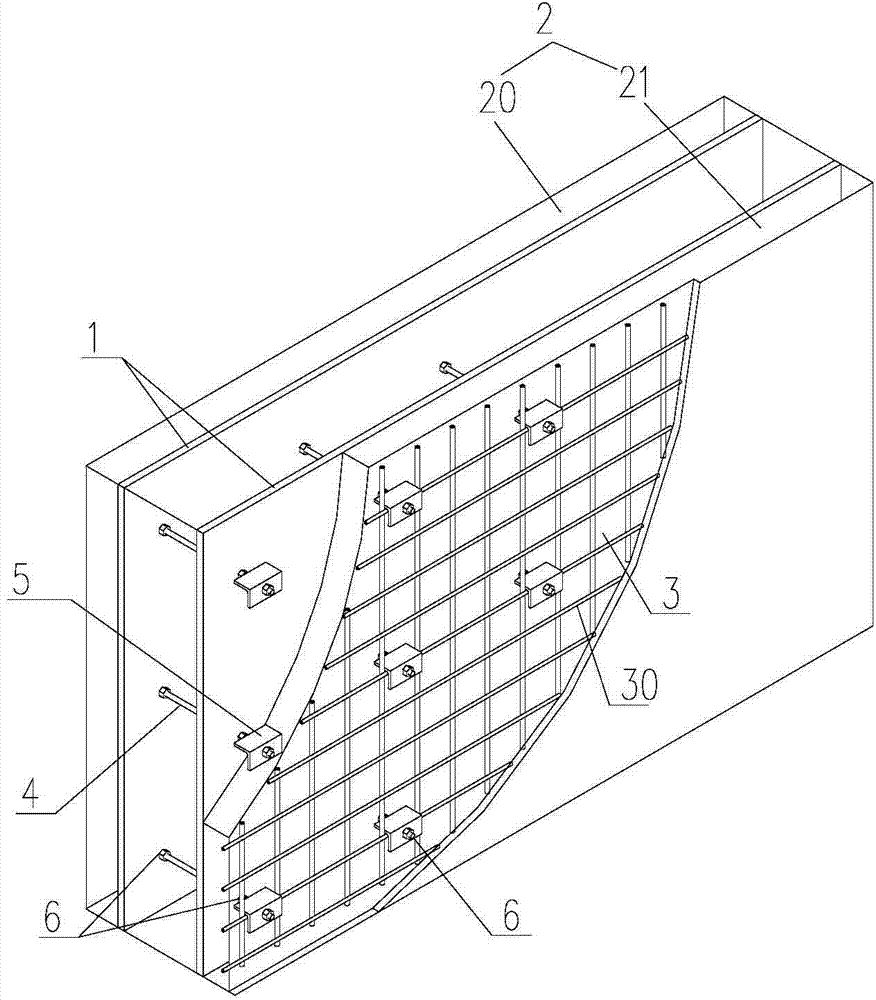

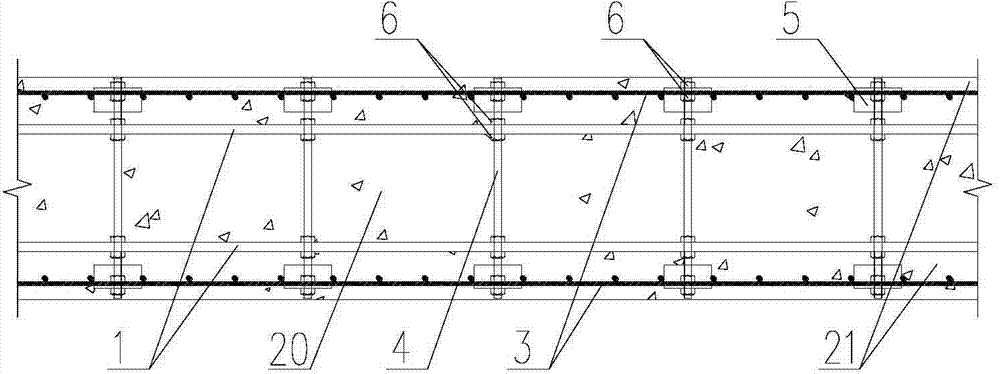

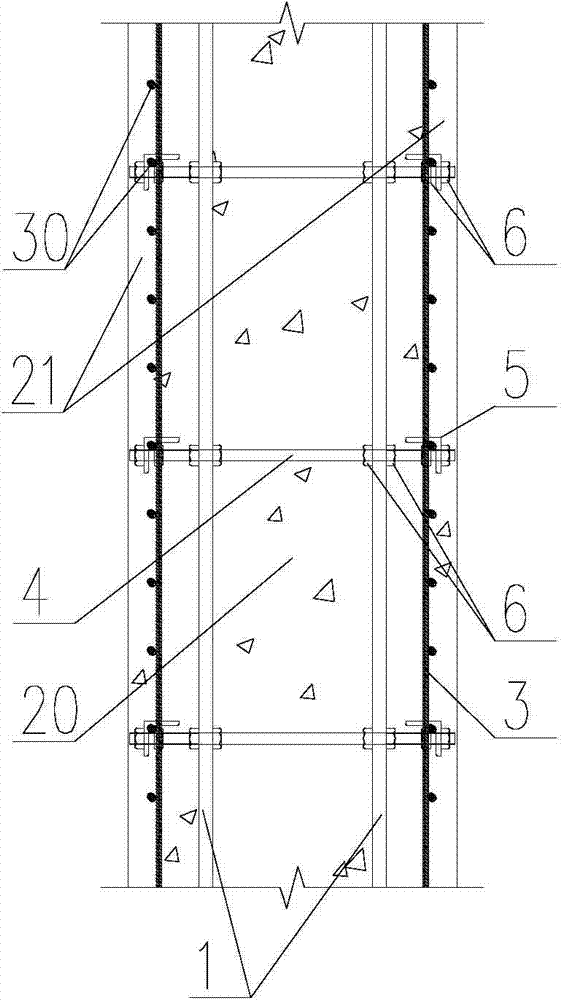

[0028] refer to Figure 1-6 As shown, in the construction industry, in order to realize the rapid prototyping and combined installation of the shear wall, and solve the problems of cumbersome and time-consuming building construction procedures, the invention provides a concrete composite shear wall with embedded steel plates. For civil engineering, wherein the shear wall includes at least one set of steel plates 1 and a concrete layer 2 mixed with each other, the concrete layer 2 is filled between the steel plates 1 and wrapped around the outer periphery of the steel plates 1, and sandwiched by the concrete layer 2 The steel plate 1 is combined to strengthen the support of the overall shear wall, and the overall strength of the shear wall is improved through the concrete layer 2 interlaced with the steel plate. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com