Connection structure of cooling system of refrigerating plant

A cooling system and refrigeration device technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of complex connection, uneven liquid separation, etc., and achieve the effect of flexible application, less transitional pipe fittings, and fewer welding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

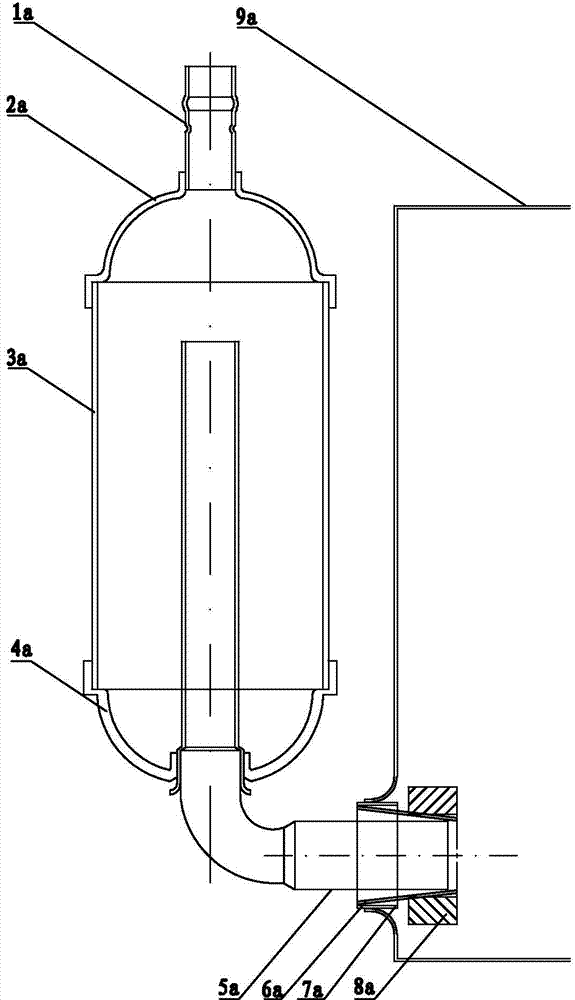

Embodiment 1

[0024] The connection structure of the cooling system of the refrigeration device in this embodiment, combined with figure 2 , including a liquid receiver, a liquid separator and a compressor. The liquid separator includes an air inlet pipe 1, an upper end cover 2, a middle cylinder body 3, a lower end cover 4 and an air outlet pipe 5. The air outlet pipe 5 of the liquid separator is pressed by an interference fit. Into the cylinder hole 8 of the compressor, the first flange 6 is set between the air outlet pipe 5 and the compressor shell 9, and the first flange 6 is connected with the compressor shell 9 and the air outlet pipe 5 by welding. Among them, interference fit In this embodiment, the outer diameter of the air outlet pipe 5 is 0.005mm up and down the inner diameter of the cylinder bore 8 (that is, if the inner diameter of the cylinder bore 8 is 20mm, the air outlet pipe 5 should be precisely shaped so that the air outlet pipe 5 The outer diameter of the end facing the...

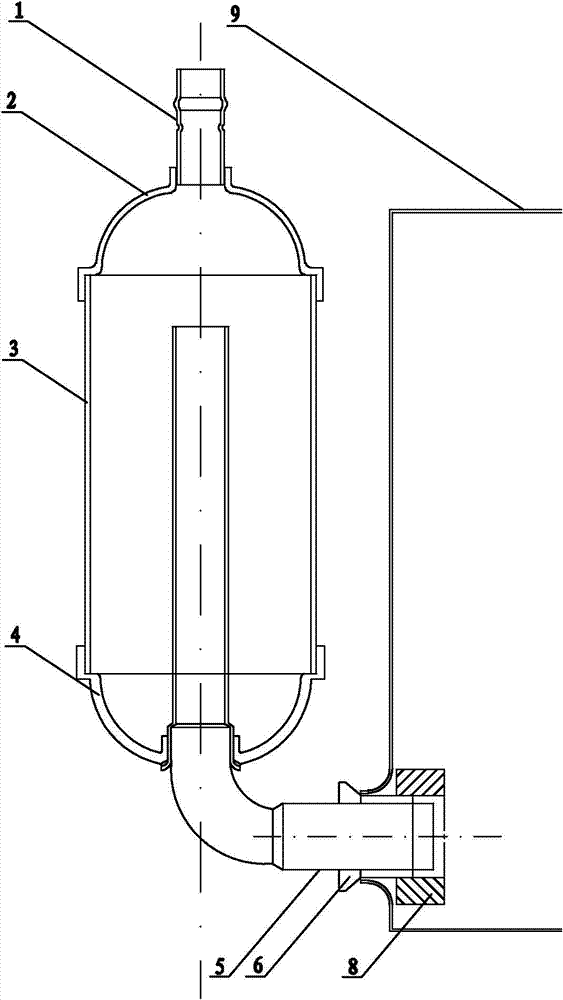

Embodiment 2

[0027] The connection structure of the cooling system of the refrigeration device in this embodiment, combined with image 3 , including a liquid receiver, a liquid separator and a compressor. The liquid separator includes an air inlet pipe 1, an upper end cover 2, a middle cylinder body 3, a lower end cover 4 and an air outlet pipe 5. One end of the air outlet pipe 5 of the liquid separator is an interference fit press into the cylinder hole 8 of the compressor, the first flange 6 is set between the air outlet pipe 5 and the compressor shell 9, and the first flange 6 is connected with the compressor shell 9 and the air outlet pipe 5 by welding; the air outlet pipe The other end of 5 is connected to the lower end cover 4, and the outlet pipe 5 and the lower end cover 4 are connected through the second flange 7, and the second flange 7, the outlet pipe 5, and the lower end cover 4 are connected by resistance welding or furnace brazing connect. Among them, interference fit In t...

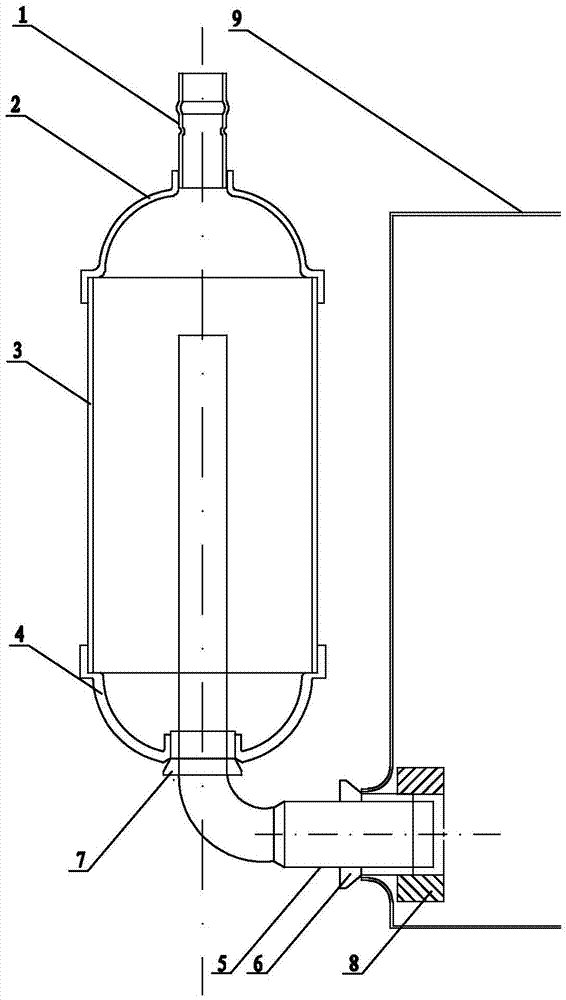

Embodiment 3

[0030] The connection structure of the cooling system of the refrigeration device in this embodiment, combined with Figure 4, including a liquid receiver, a liquid separator and a compressor. The liquid separator includes an air inlet pipe 1, an upper end cover 2, a middle cylinder body 3, a lower end cover 4 and an air outlet pipe 5. The air inlet pipe 1 passes through the third flange 10 and the upper end cover 2 connection, one end of the outlet pipe 5 of the liquid separator is pressed into the cylinder hole 8 of the compressor in the form of interference fit, the first flange 6 is set between the outlet pipe 5 and the compressor shell 9, and the first flange 6 is welded by welding. The flange 6 is connected to the compressor shell 9 and the air outlet pipe 5; the other end of the air outlet pipe 5 is connected to the lower end cover 4, and the second flange 7 is connected between the air outlet pipe 5 and the lower end cover 4, and the second flange 7 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com