Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Assembly cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

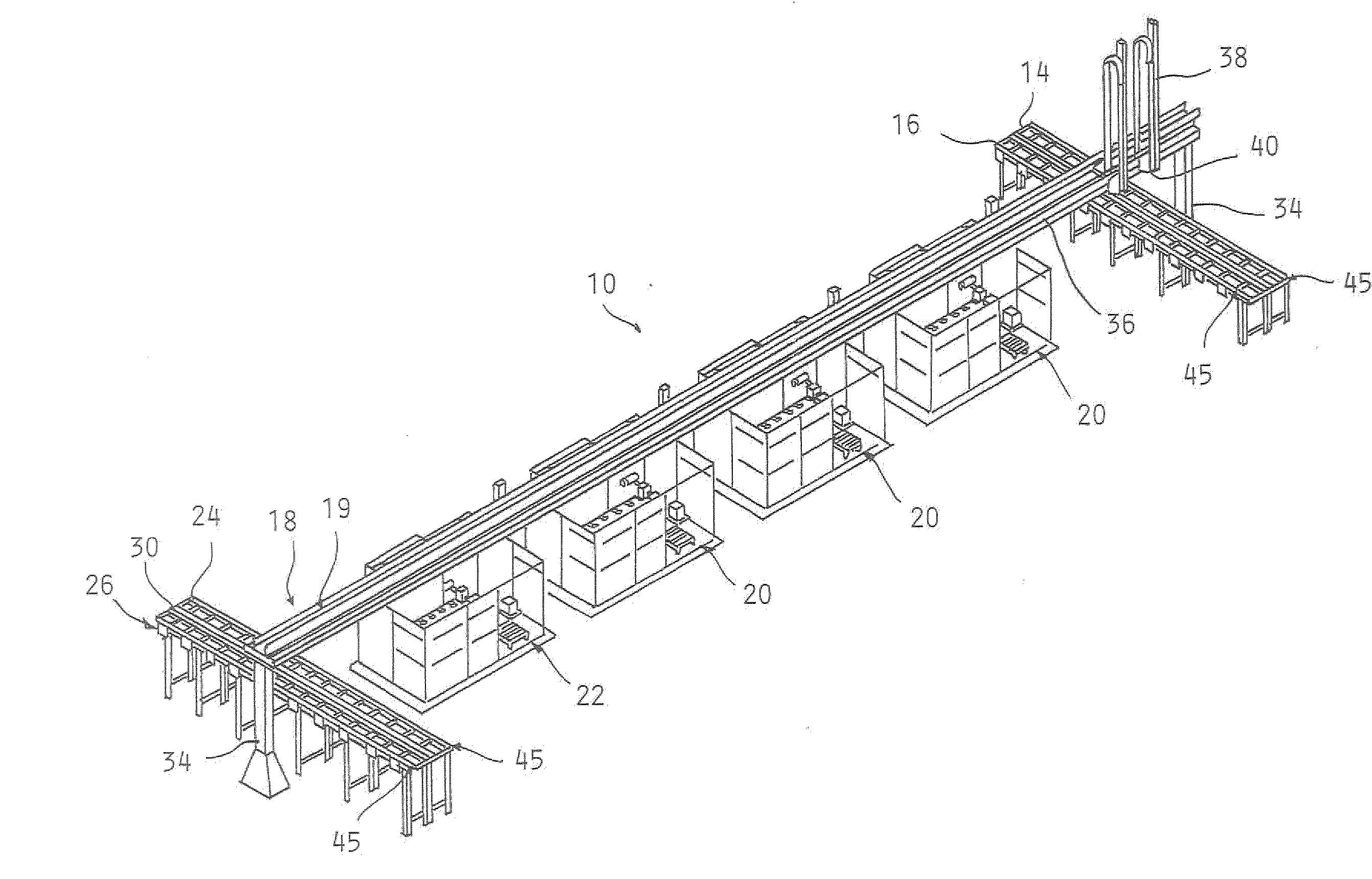

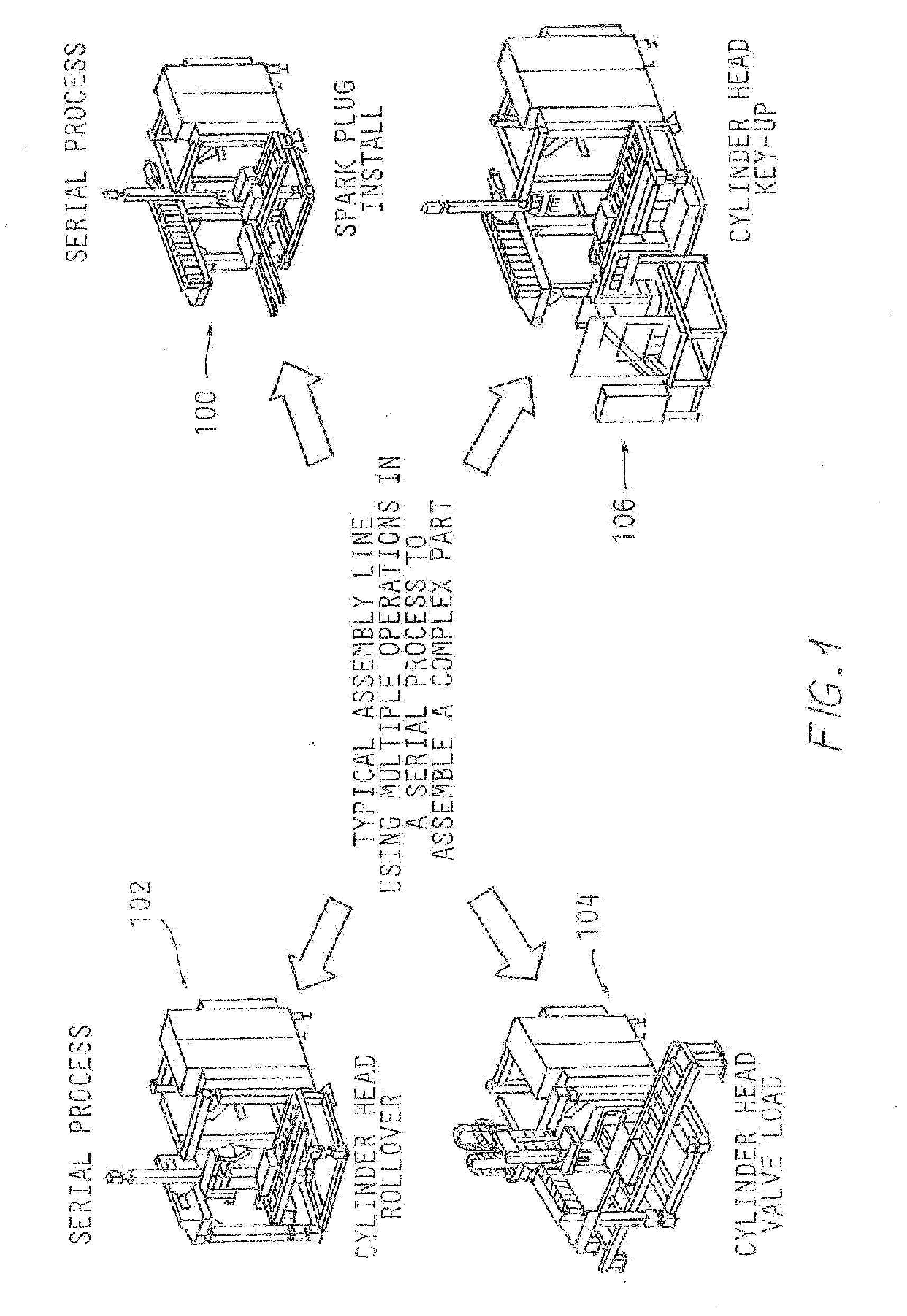

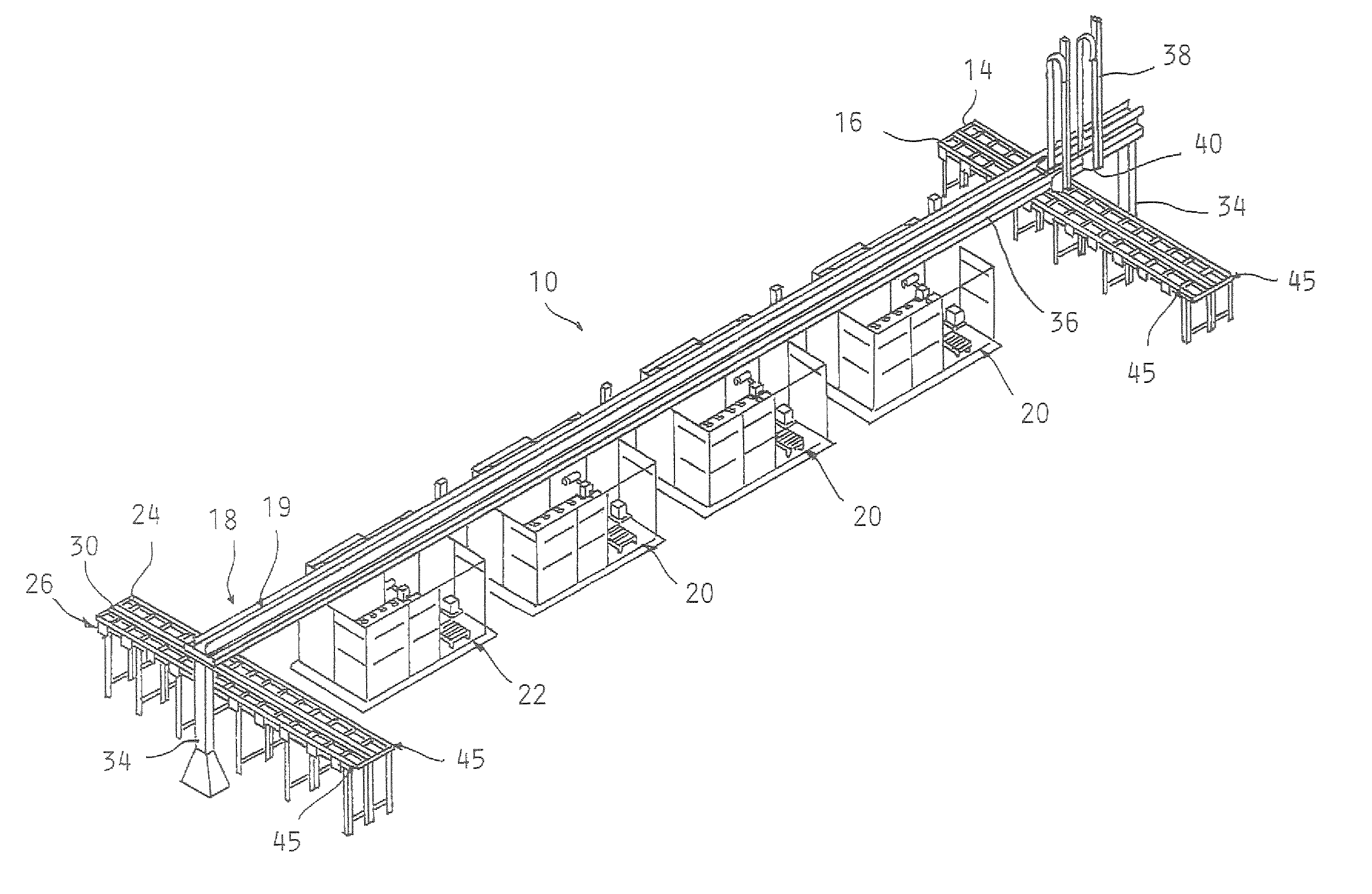

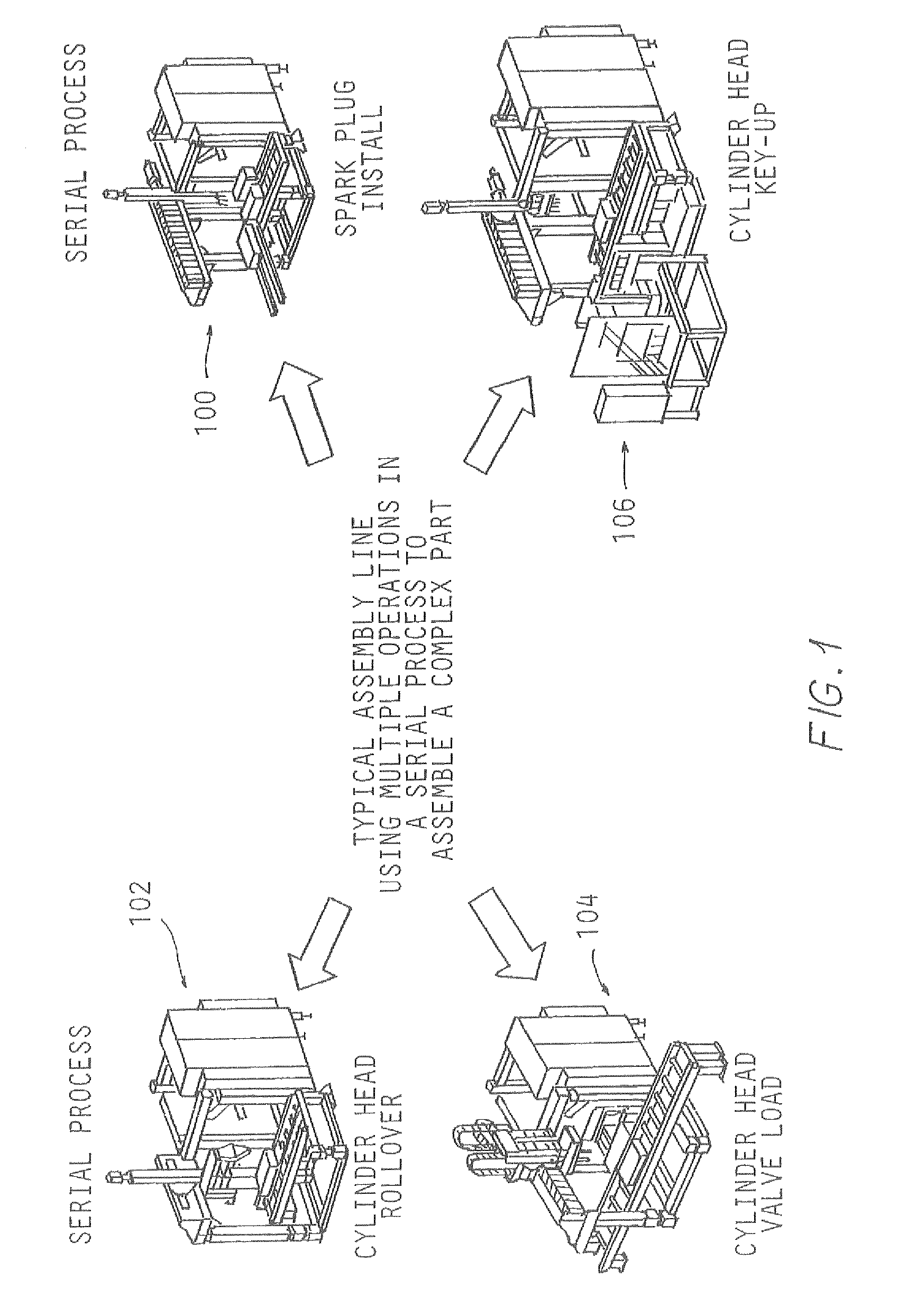

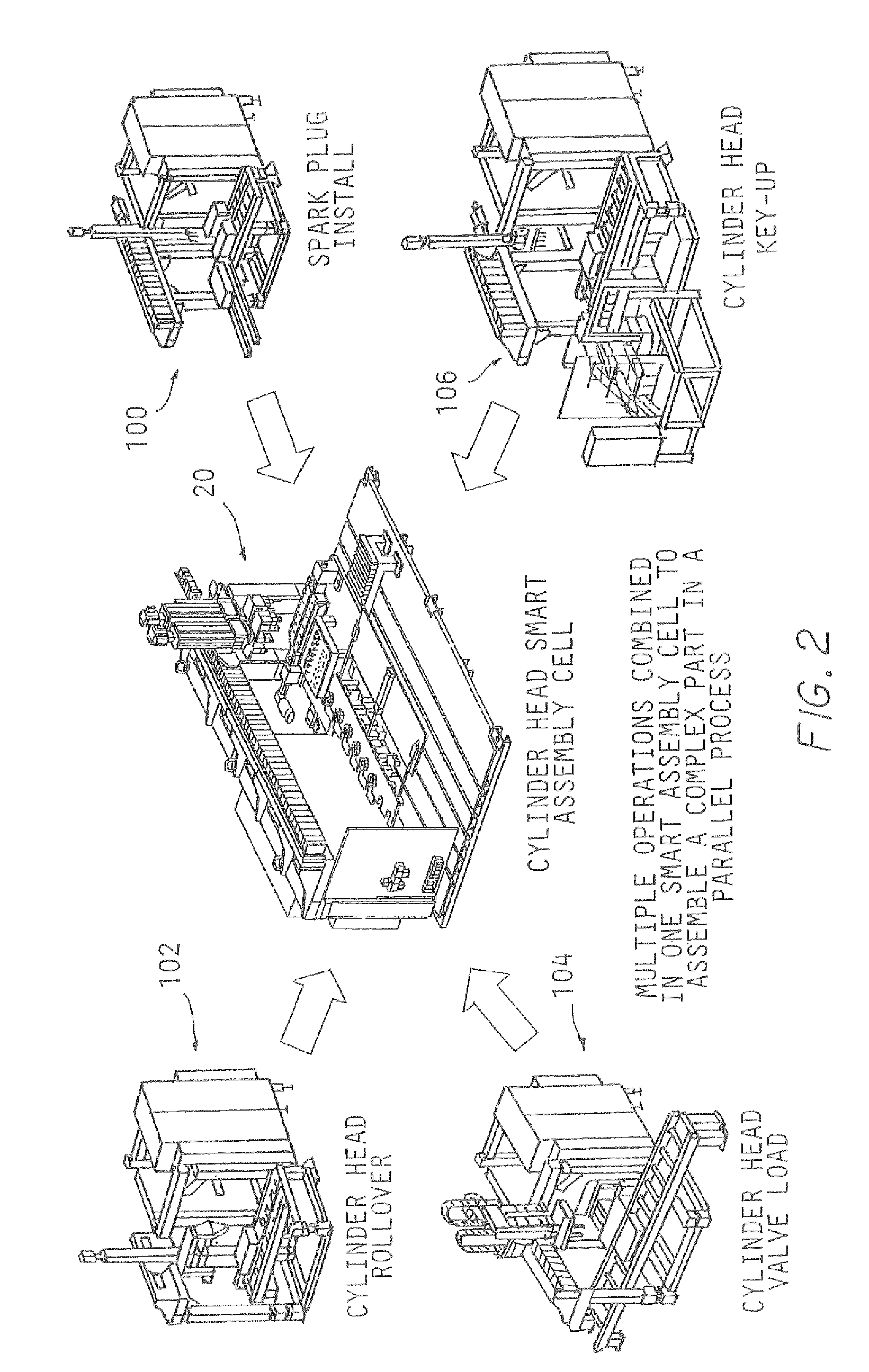

Method and apparatus forassembling a complex product ina parrallel process system

A method and apparatus for assembling a complex product in a parallel process system wherein a collection of components are provided for assembling the complex product. The present invention involves transferring the collection of the components to one of a plurality of similar computerized assembly cells through the use of a transport system. The collection of components is automatically assembled into the complex product through the use of the computerized assembly cells. The complex product is then transferred from one of the assembly cells to a computerized test cell, where the complex product is tested to ensure for the proper dimensioning and functioning of the complex product. The complex product is then transferred from the test cell via the transport system to either a part reject area or conveyor, if the complex product is defective, or to an automatic dunnage load or part return system, if the complex product is not defective.

Owner:COMAU LLC

Method and apparatus for assembling a complex product in a parallel process system

A method and apparatus for assembling a complex product in a parallel process system wherein a collection of components are provided for assembling the complex product. The present invention involves transferring the collection of the components to one of a plurality of similar computerized assembly cells through the use of a transport system. The collection of components is automatically assembled into the complex product through the use of the computerized assembly cells. The complex product is then transferred from one of the assembly cells to a computerized test cell, where the complex product is tested to ensure for the proper dimensioning and functioning of the complex product. The complex product is then transferred from the test cell via the transport system to either a part reject area or conveyor, if the complex product is defective, or to an automatic dunnage load or part return system, if the complex product is not defective.

Owner:COMAU LLC

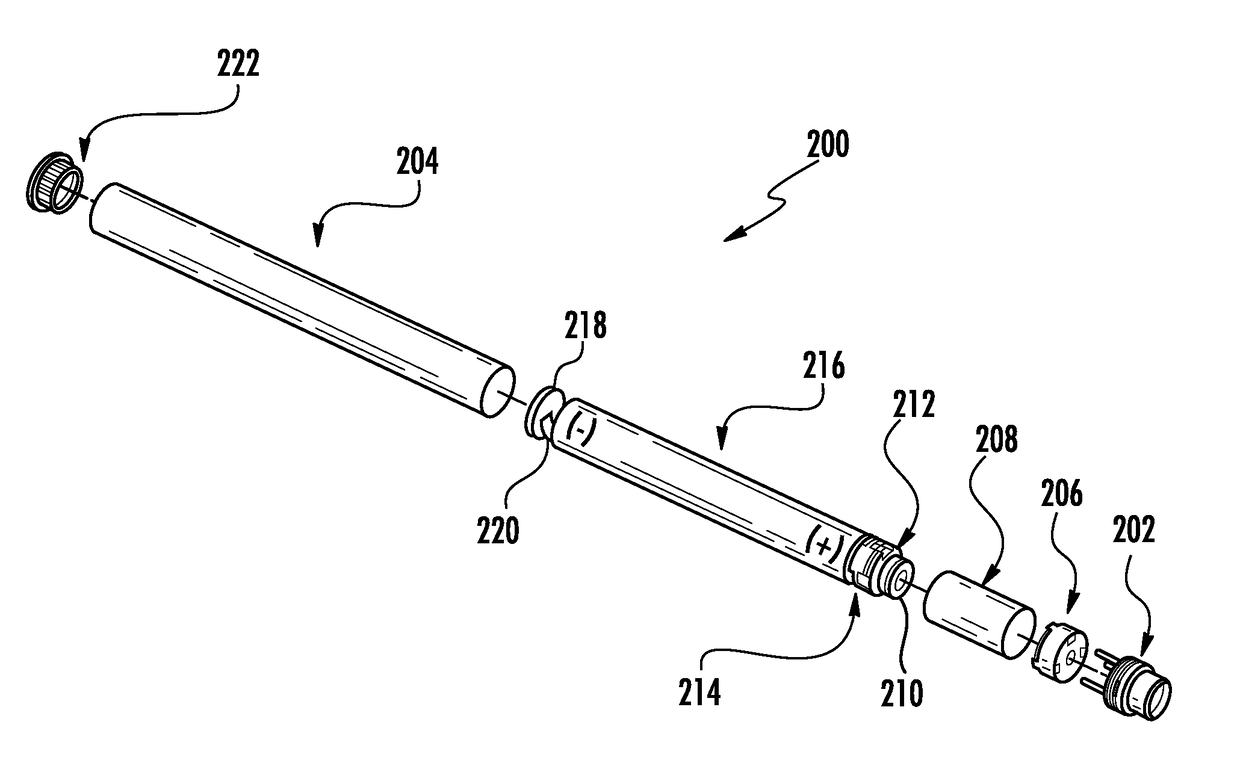

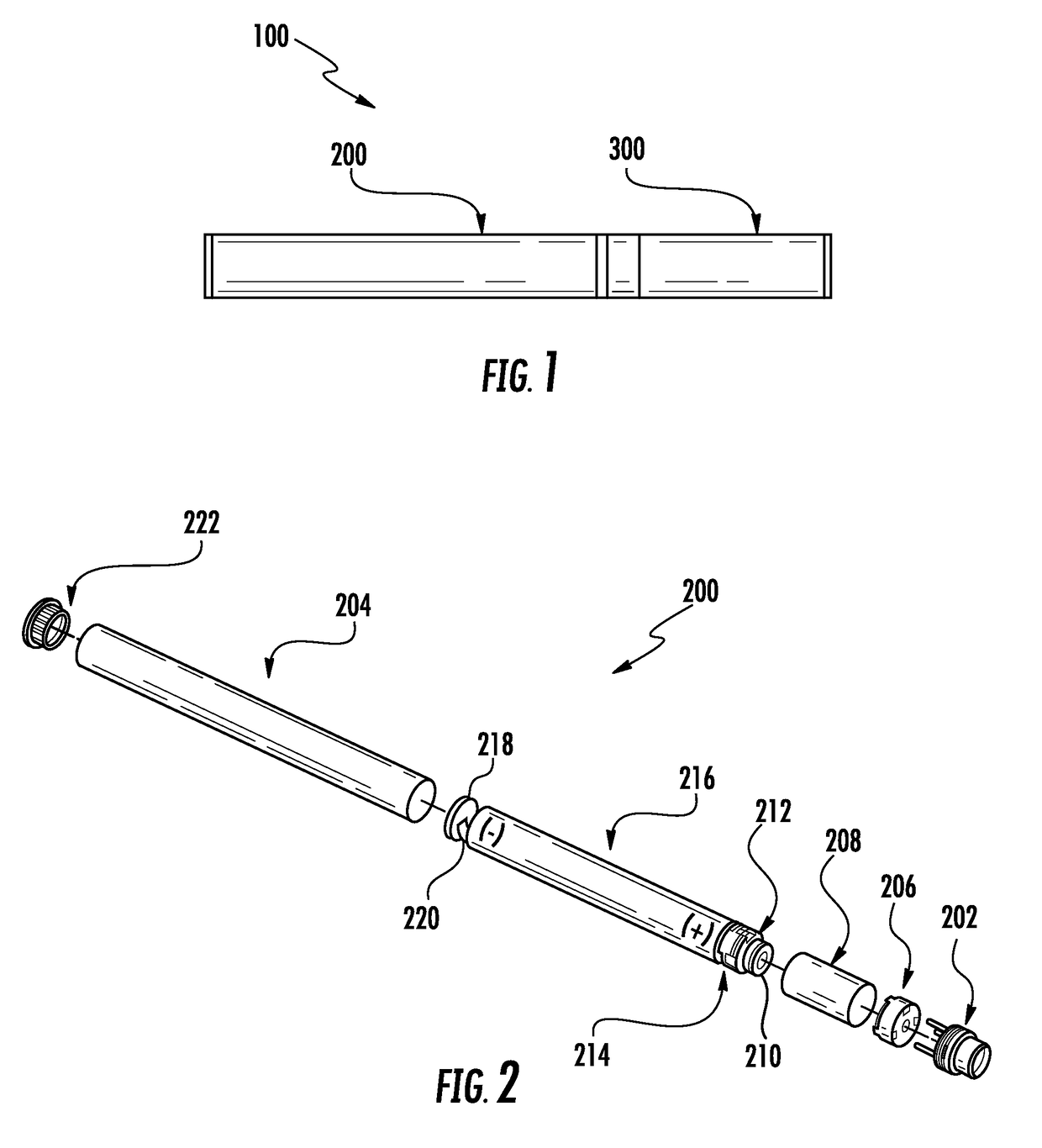

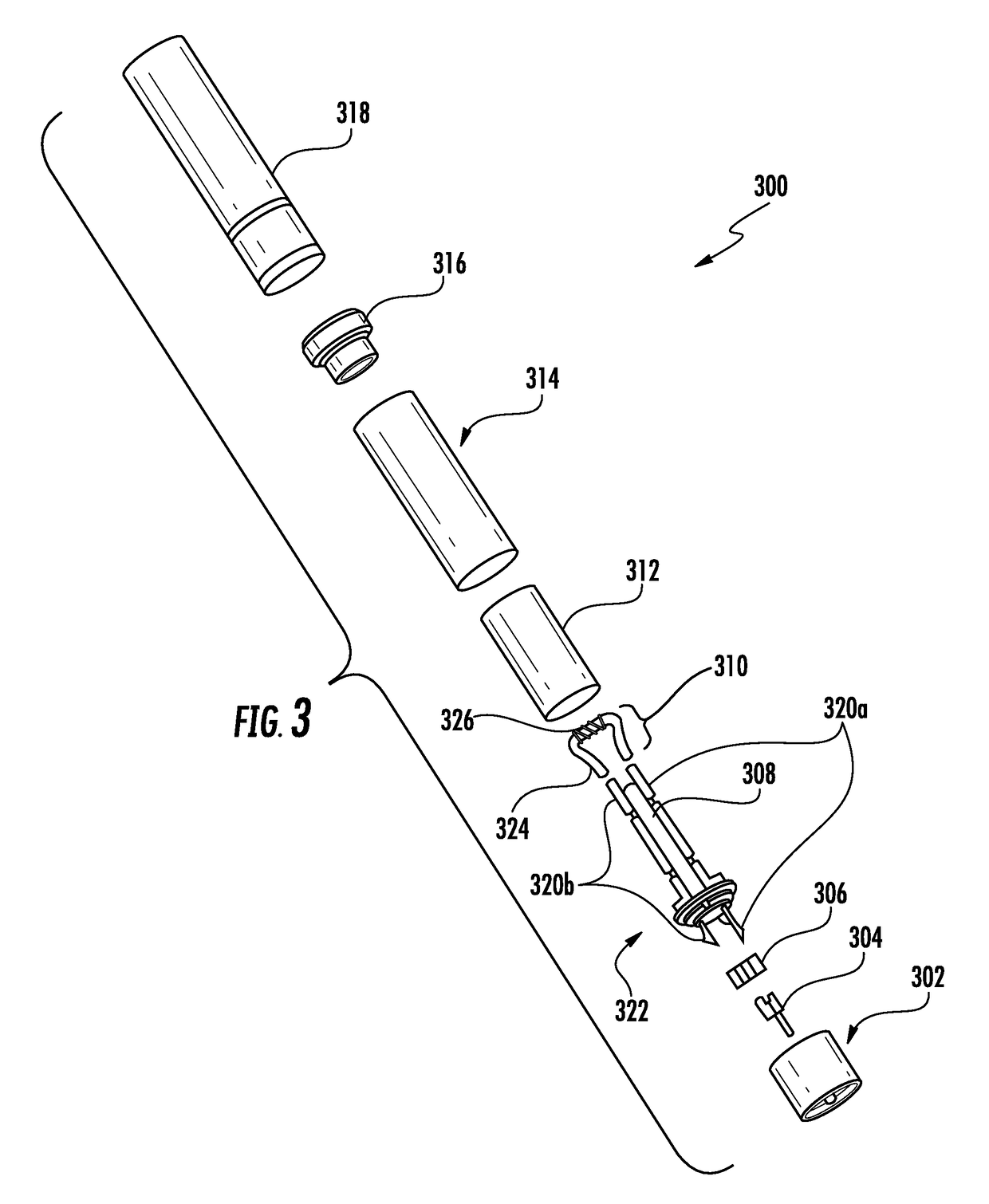

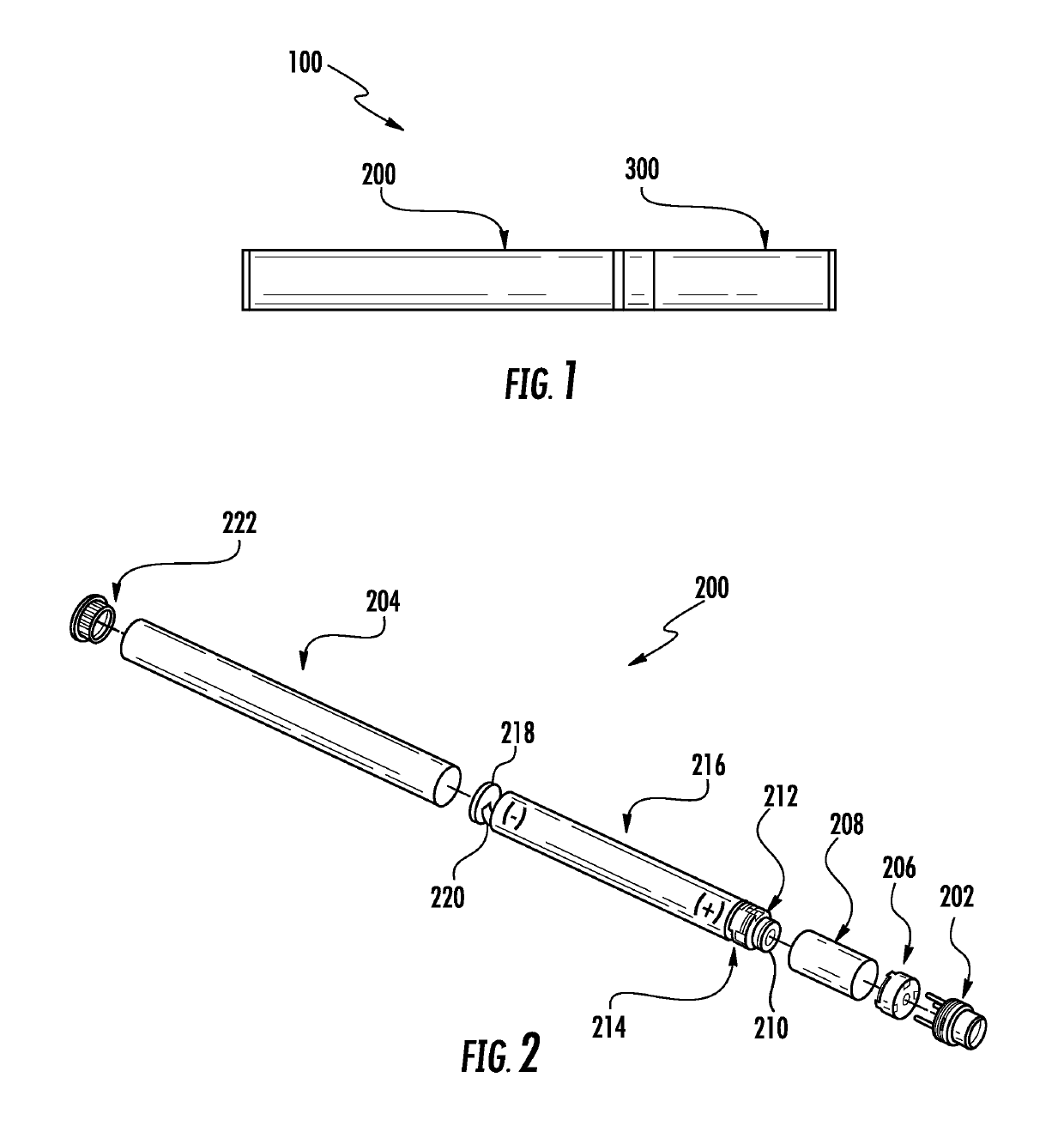

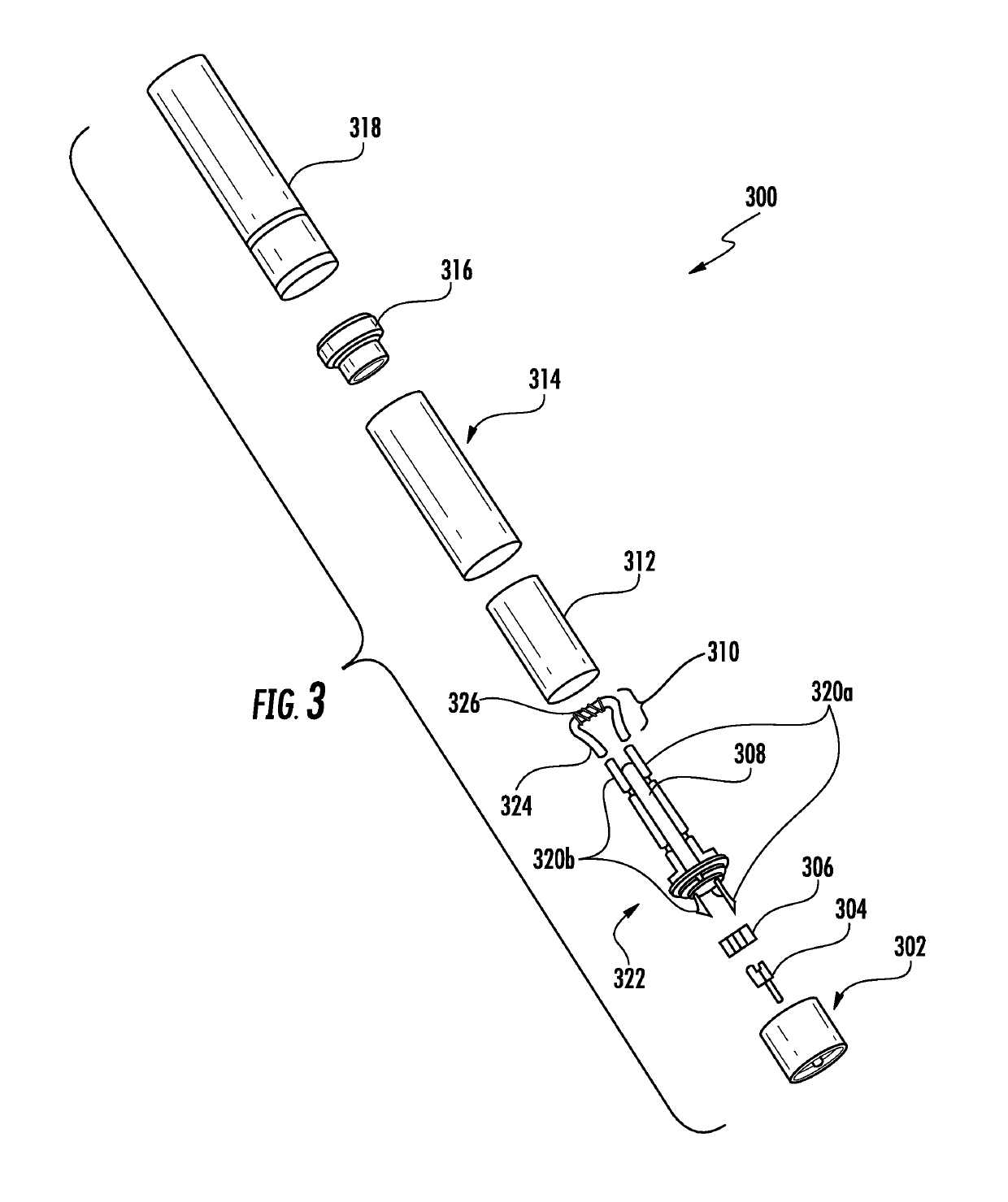

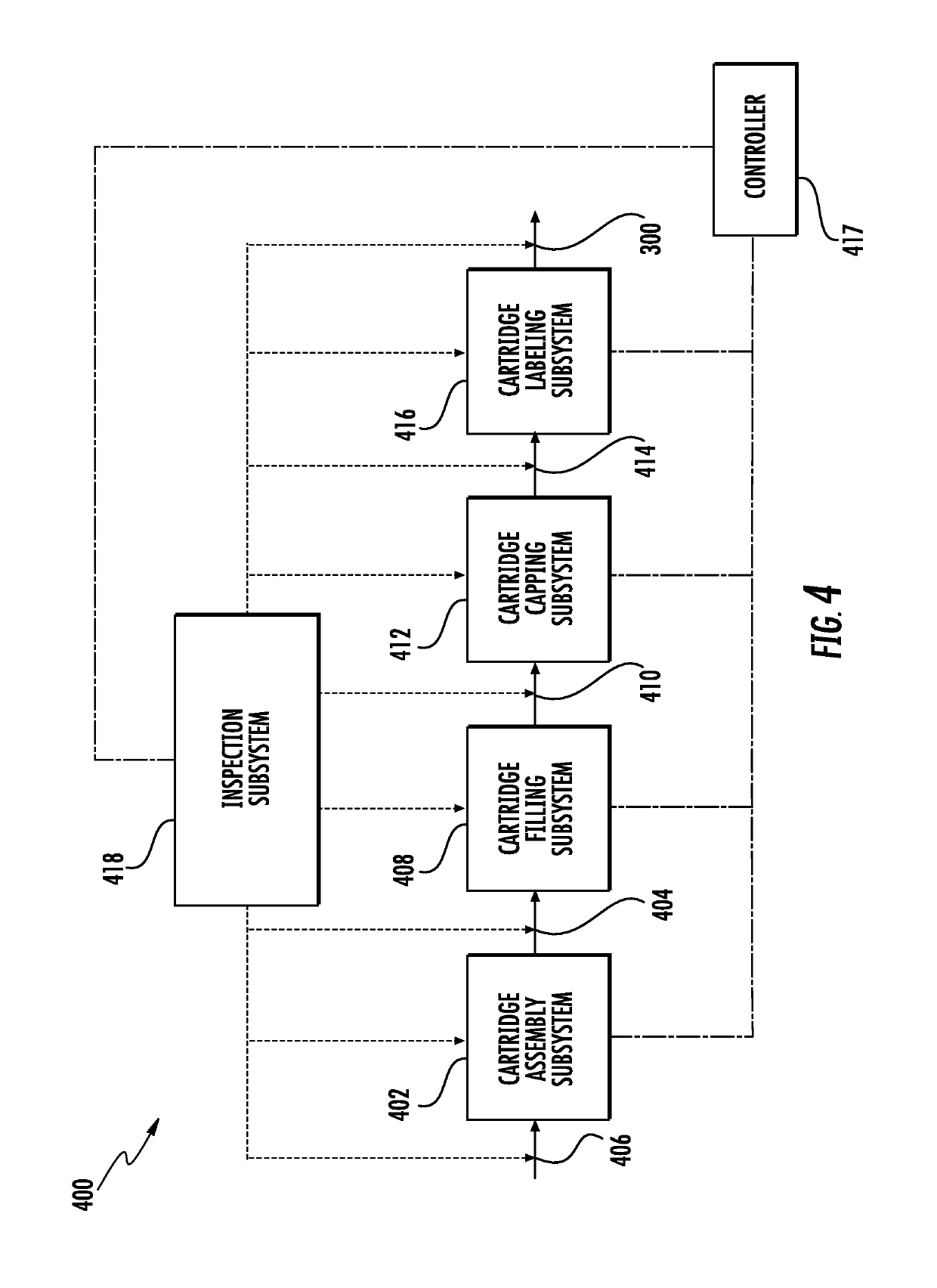

Methods for assembling a cartridge for an aerosol delivery device, and associated systems and apparatuses

The present disclosure relates to systems, apparatuses, and methods for assembling cartridges for aerosol delivery devices. A system may include assembly cells each including an assembly track and assembly carriages that ride thereon and which engage components of partially-assembled cartridges. A transfer apparatus may transfer partially-assembled cartridges between the assembly cells. In another example system, cartridges may be assembled on platforms on a rotary track. The platforms may include assembly grippers with sequentially-opening clamps configured to receive the components of the partially-assembled cartridges. Related methods are also provided.

Owner:RAI STRATEGIC HLDG INC

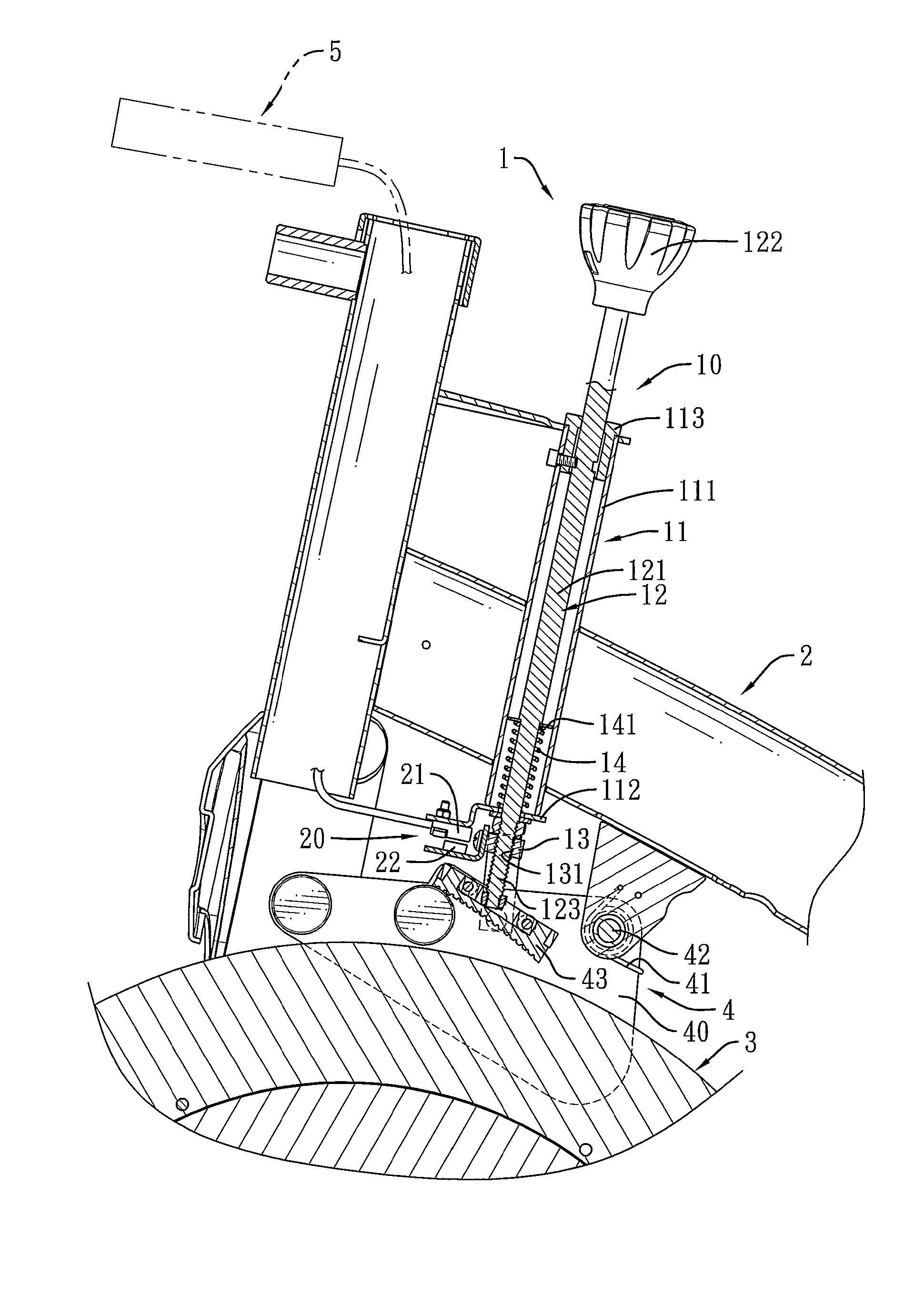

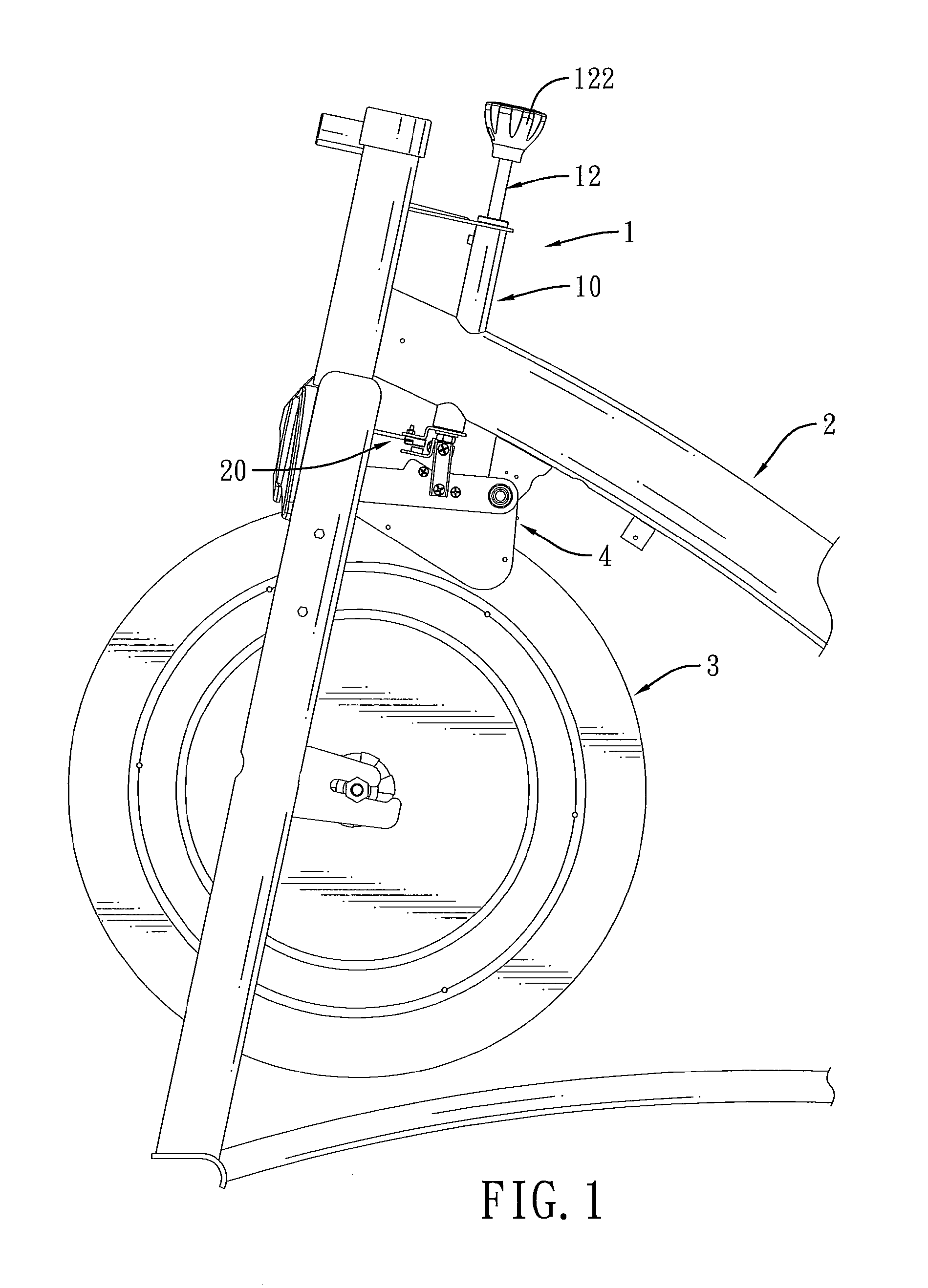

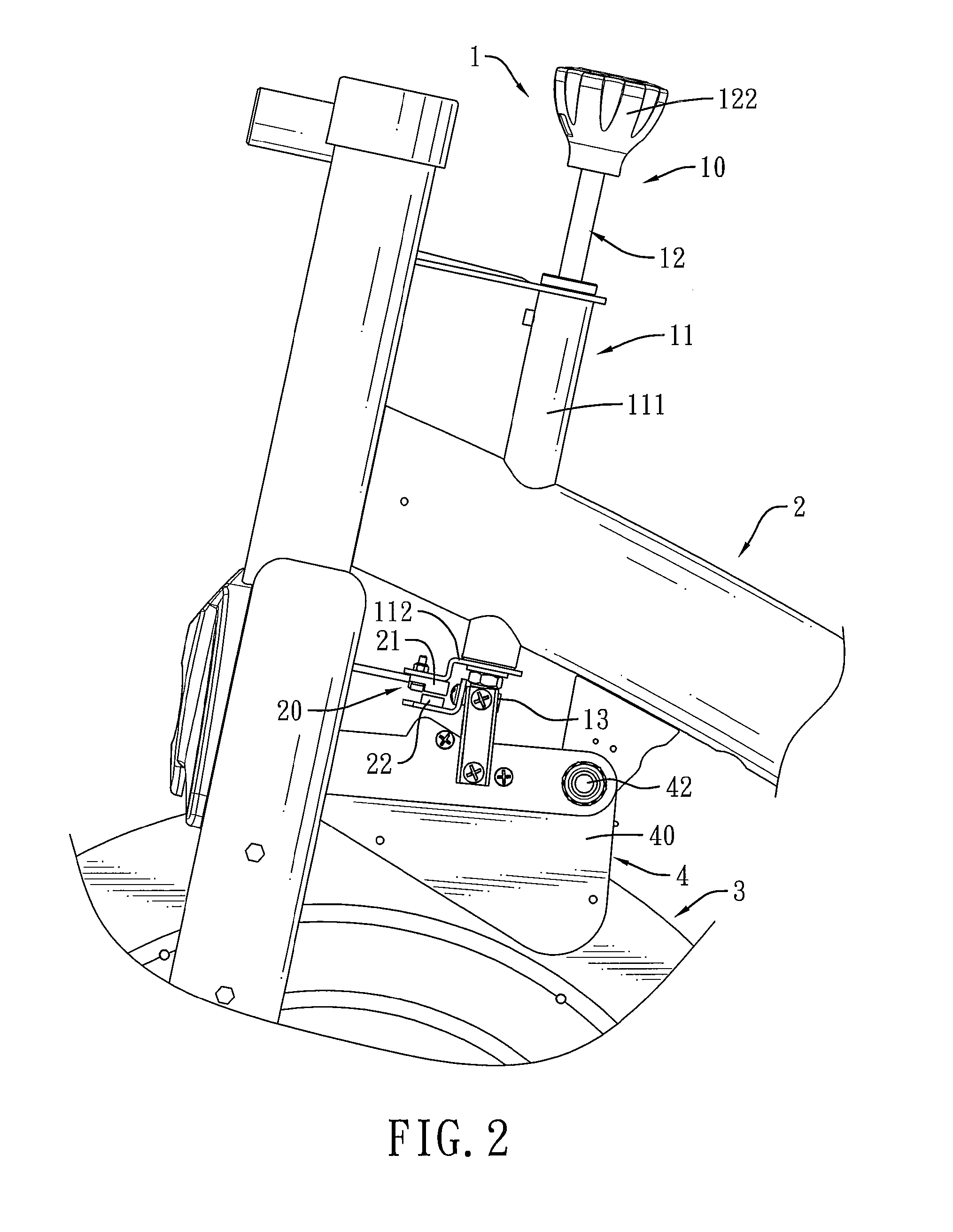

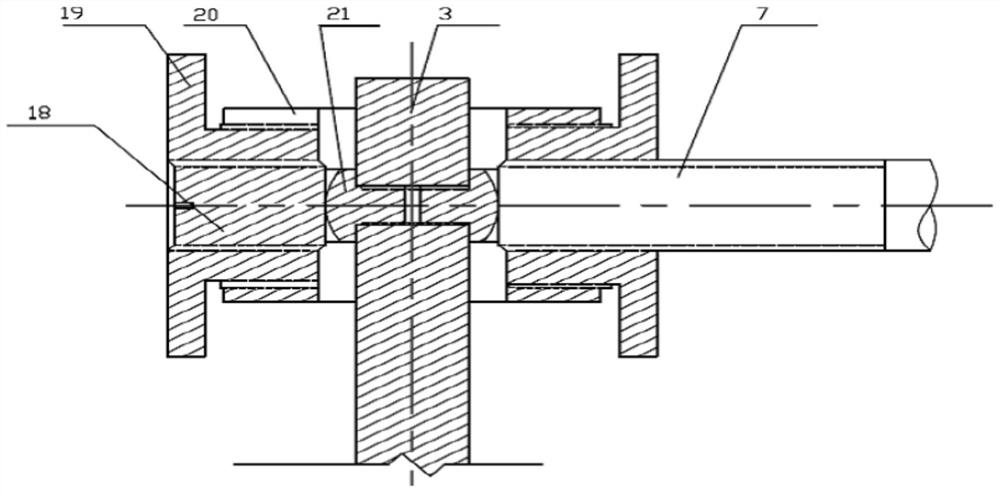

Torque sensing apparatus

ActiveUS20140013861A1High precisionWork measurementTorque measurementTorque regulationControl theory

A torque sensing apparatus has a torque adjusting assembly and a non-contact sensing assembly. The torque adjusting assembly has a fitting unit, a regulating rod and a regulating seat. The non-contact sensing assembly has a first device and a second device. The regulating rod is rotatably mounted through the fitting unit. The regulating seat is movably mounted on the regulating rod and located outside the fixed plate of the fitting unit. The first device is mounted on the fixed plate. The second device is mounted on the regulating seat and kept from contacting the first device. The non-contact sensing assembly detects a change of the distance between the first device and the second device and generates a signal to a controller, and the controller gauges a torsional value of the torque adjusting assembly. Therefore, the non-contact sensing assembly is not abraded and increases the precision of the torque sensing apparatus.

Owner:WU MU CHUAN

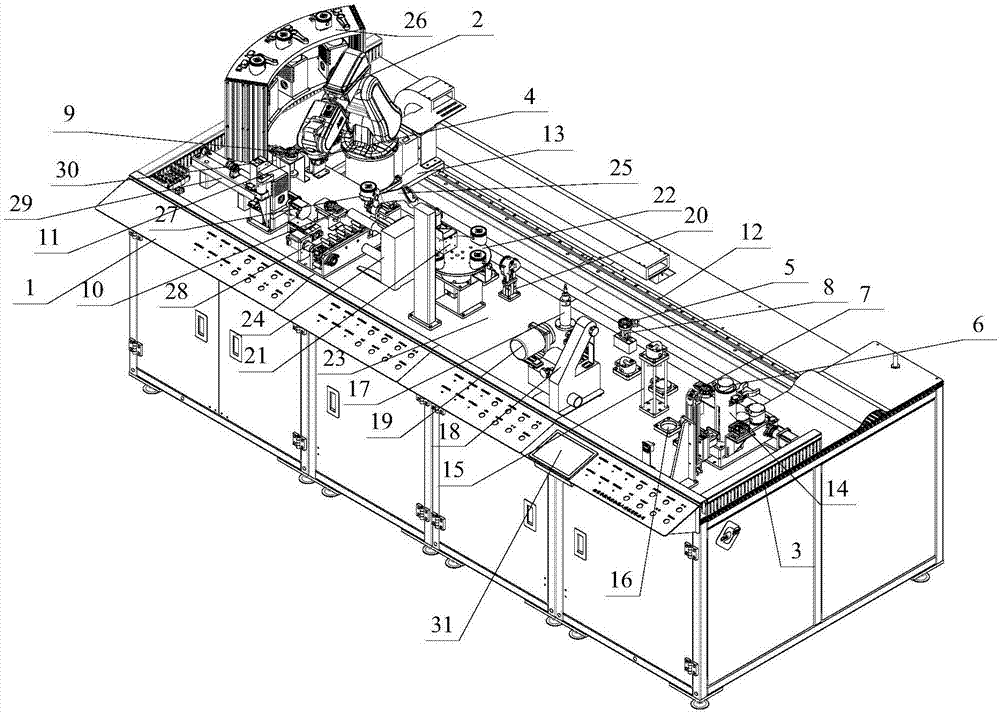

Industrial robot teaching system

InactiveCN106971662ARealize autonomous operationSimple structureCosmonautic condition simulationsEducational modelsMachined surfaceAssembly cells

The invention discloses an industrial robot teaching system, and relates to the field of teaching equipment. The system comprises a workbench, an industrial robot teaching demonstration device, an industrial robot body, a material supply and rough machining unit, a finish machining unit, a mechanism assembly unit, and an industrial robot controller. The interior of the industrial robot teaching demonstration device stores an operation instruction of the industrial robot body. The industrial robot controller is connected with a technological robot body, and is used for controlling the industrial robot body to execute the operation instruction. The industrial robot body operates at the places of the material supply and rough machining unit, the finish machining unit and the mechanism assembly unit, so as to respectively simulate the technologies of supply, taking and laser cutting of a machined object, burring, grinding and polishing technologies of a machined surface and the high-precision assembly technology of the machine object and a semi-finished product mechanism. The system is high in structural integrity and compactness, is high in automatic assembly precision, can simulate various types of operations, and fully meets the demands of a school for carrying out the industrial robot education for students.

Owner:BEIJING C H L ROBOTICS CO LTD

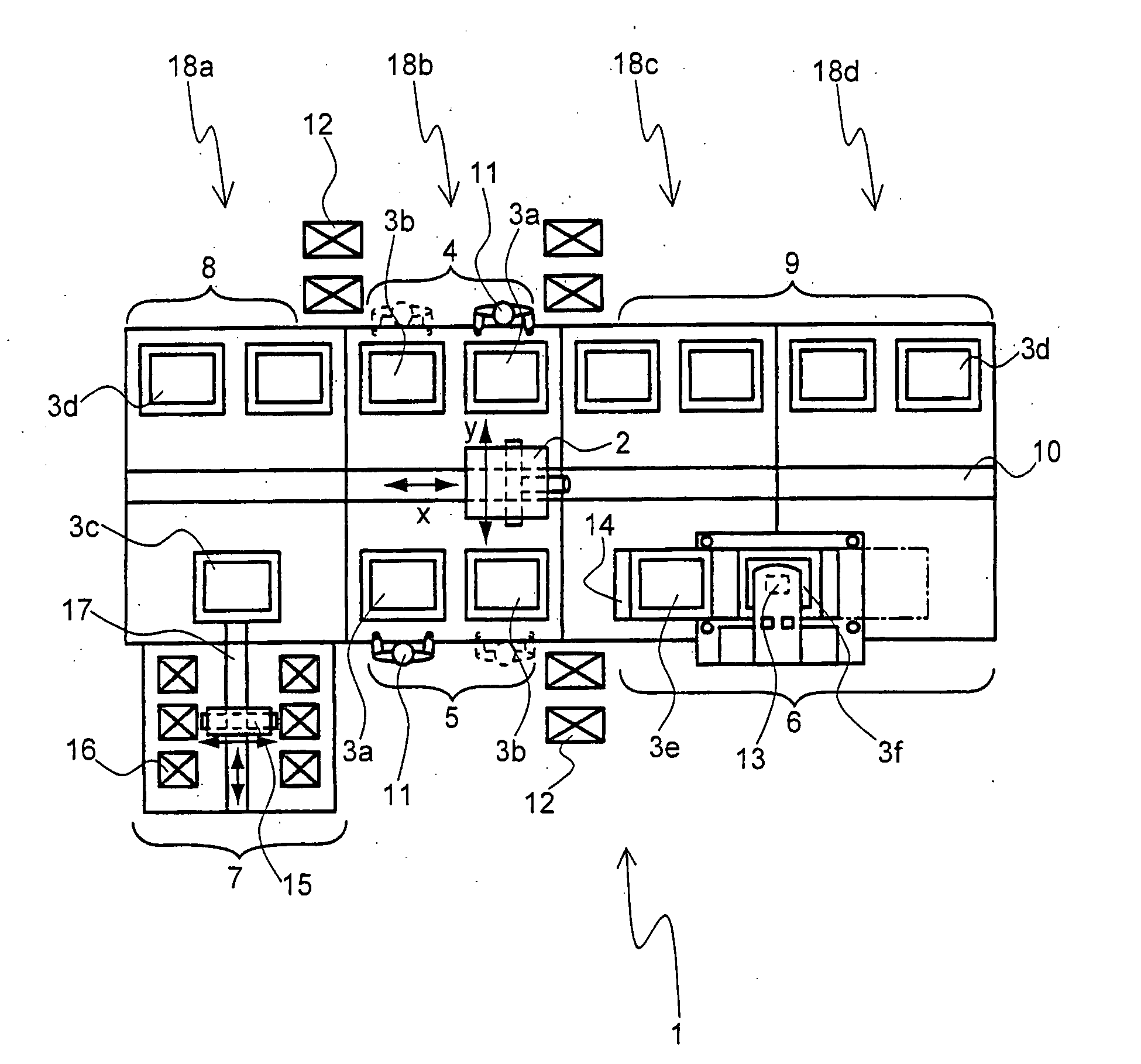

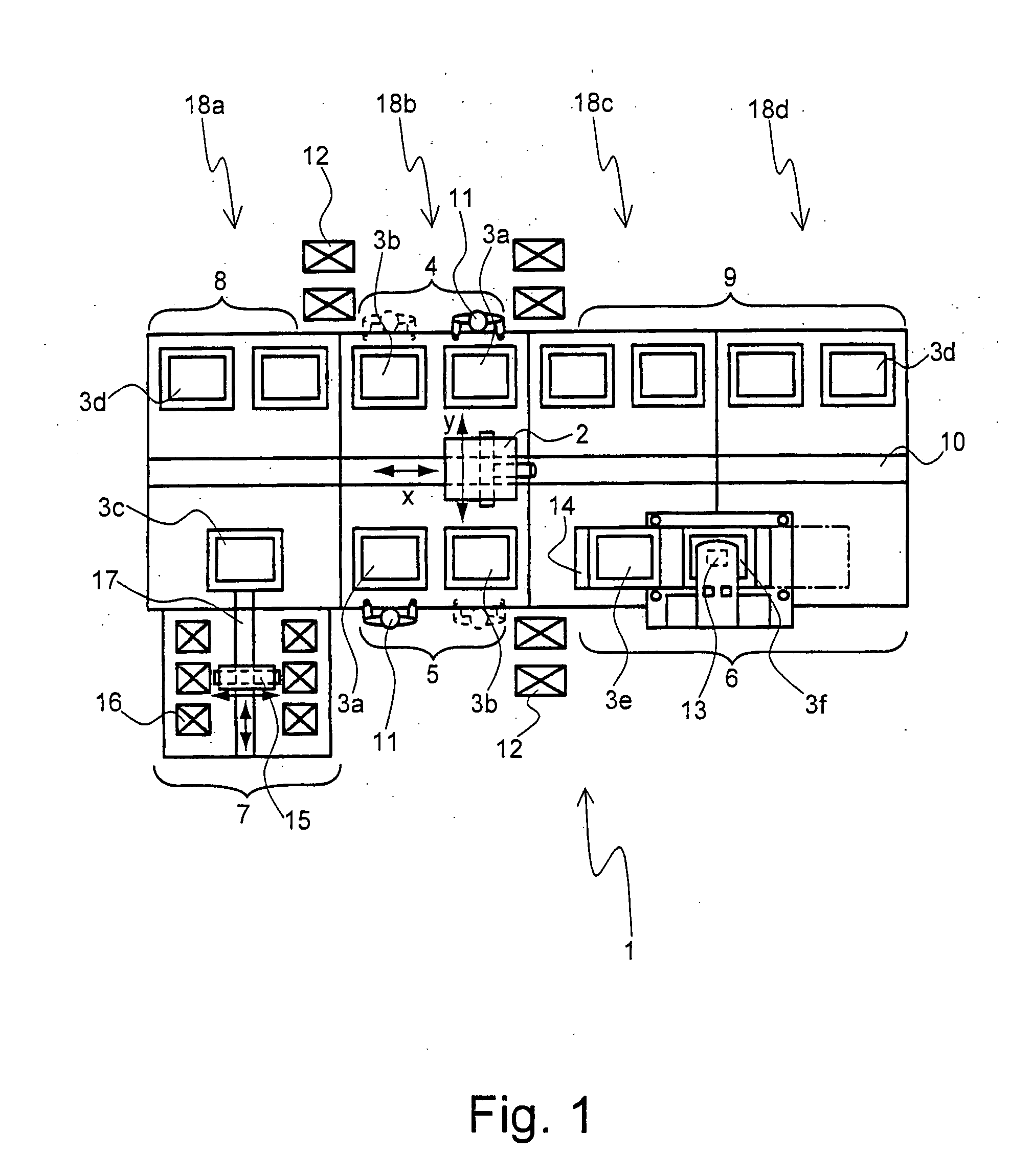

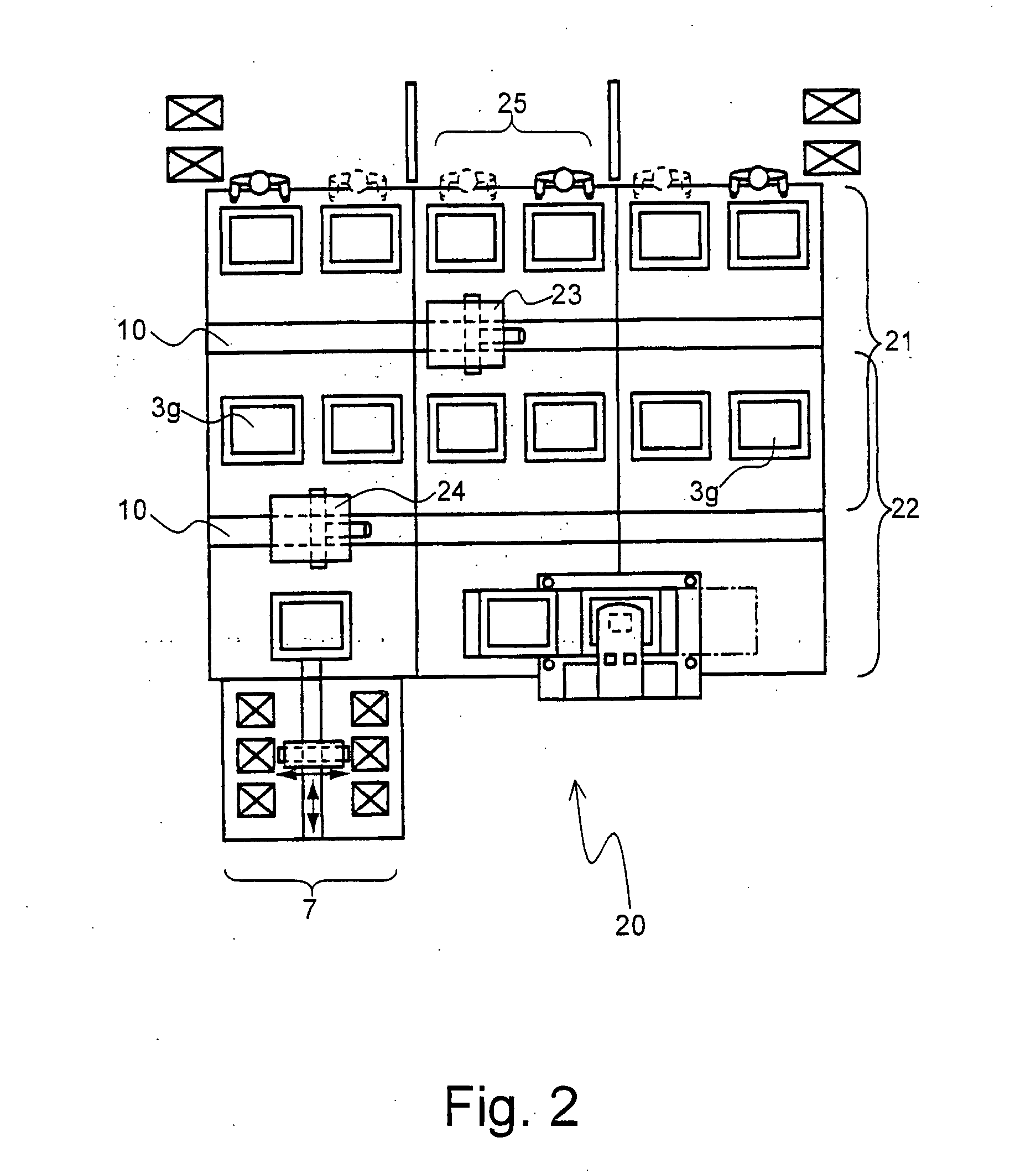

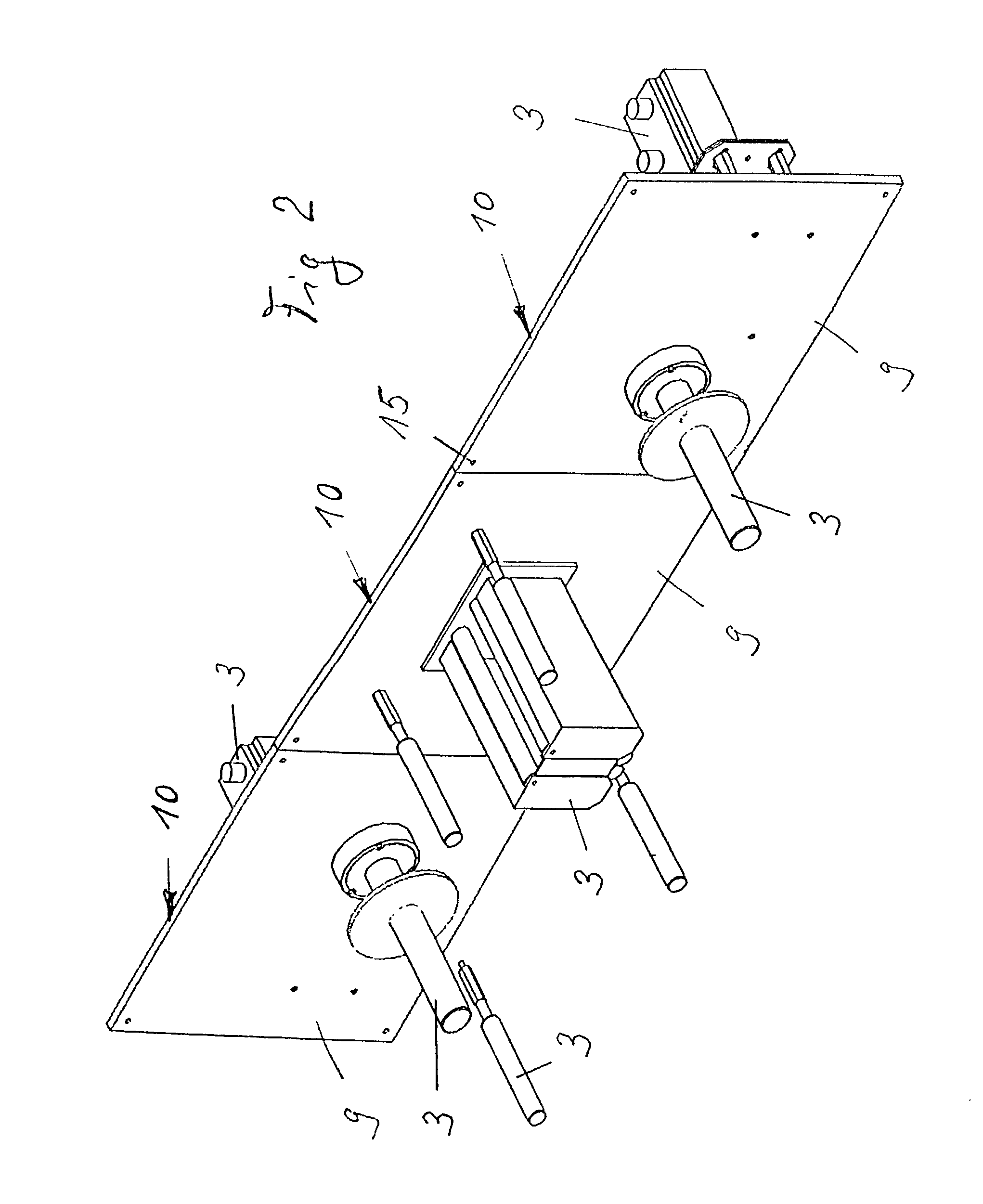

Assembly Cell For Assembling Modules From Work Pieces On Pallets, As Well As Method For Its Operation

InactiveUS20080015097A1Shorten the space distanceAssembly machinesTool changing apparatusAssembly cellsEngineering

The invention pertains to an assembly cell (1; 21, 22) that is suitable for the assembly of modules (55) from work pieces (35) on pallets (33; 42, 43; 54; 68, 69) and features several pallet stations (3a, 3b, 3c, 3d, 3e, 3f, 3g, 3h), in which pallets can be positioned, wherein at least some of the pallet stations are realized in the form of assembly stations for carrying out assembly work on the modules on the pallets., and with at least one transport device for transporting the pallets between the pallet stations. The invention is characterized in that the transport device is realized in the form of a triaxial module (2; 23, 24) that is able to transport an individual pallet from any pallet station within the assembly cell to any other unoccupied pallet station within the assembly cell. The invention therefore makes available an assembly cell, by means of which modules can be assembled independently of the spatial arrangement of the assembly stations, wherein said assembly cell requires fewer pallets and makes it possible to realize a faster transport of the pallets from assembly station to assembly station.

Owner:FELSOMAT

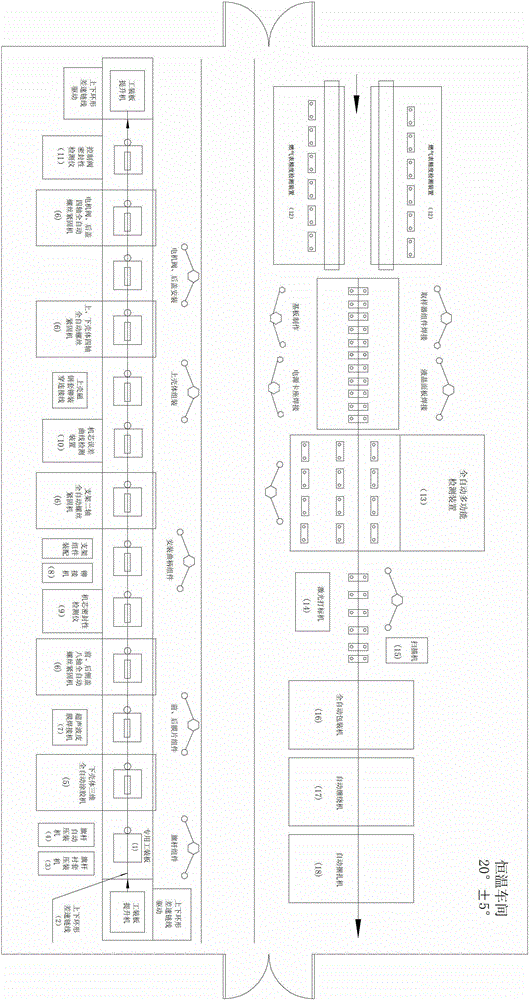

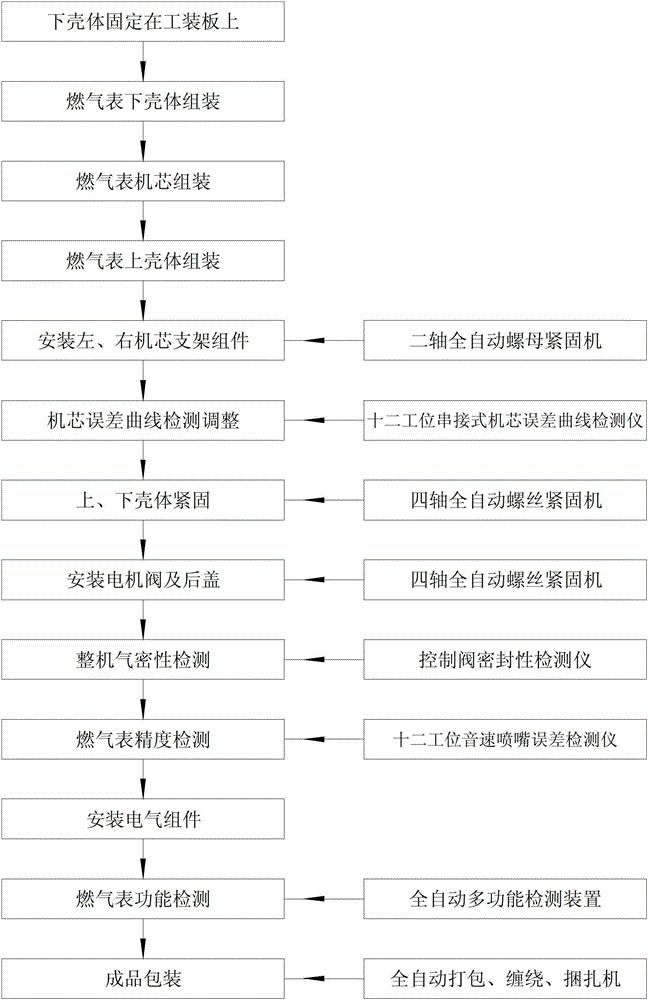

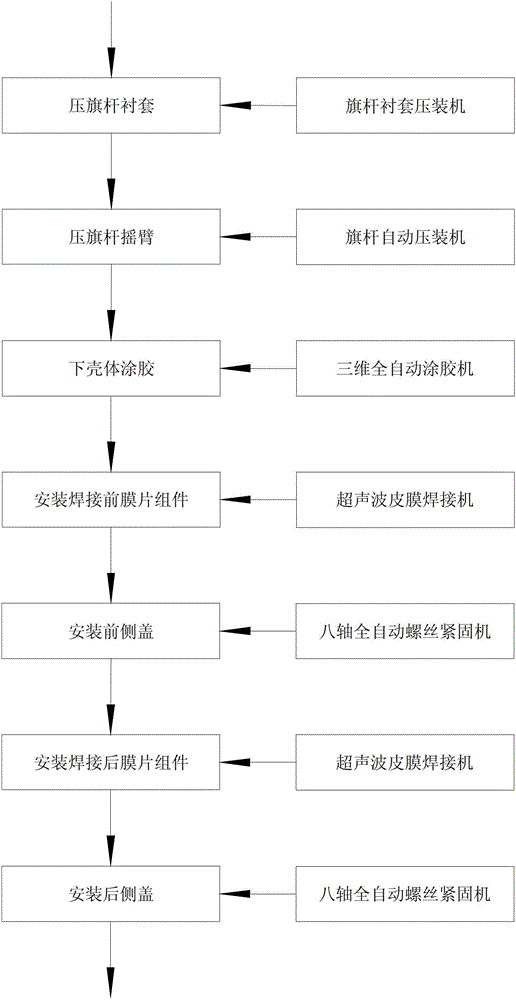

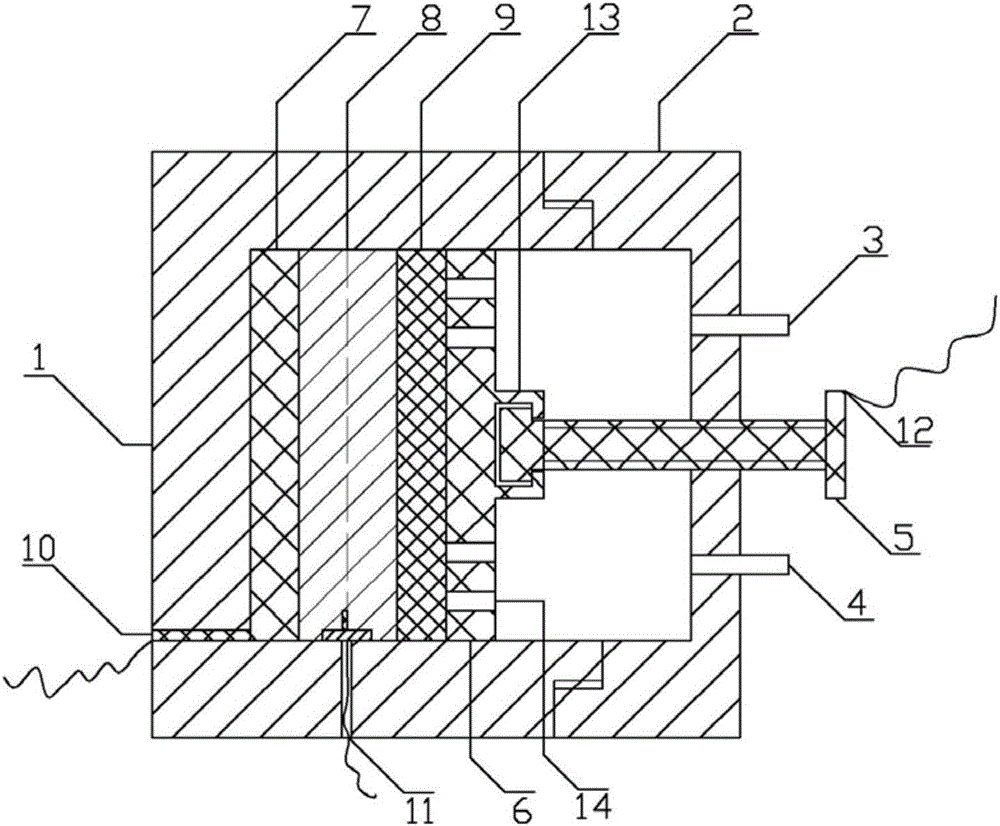

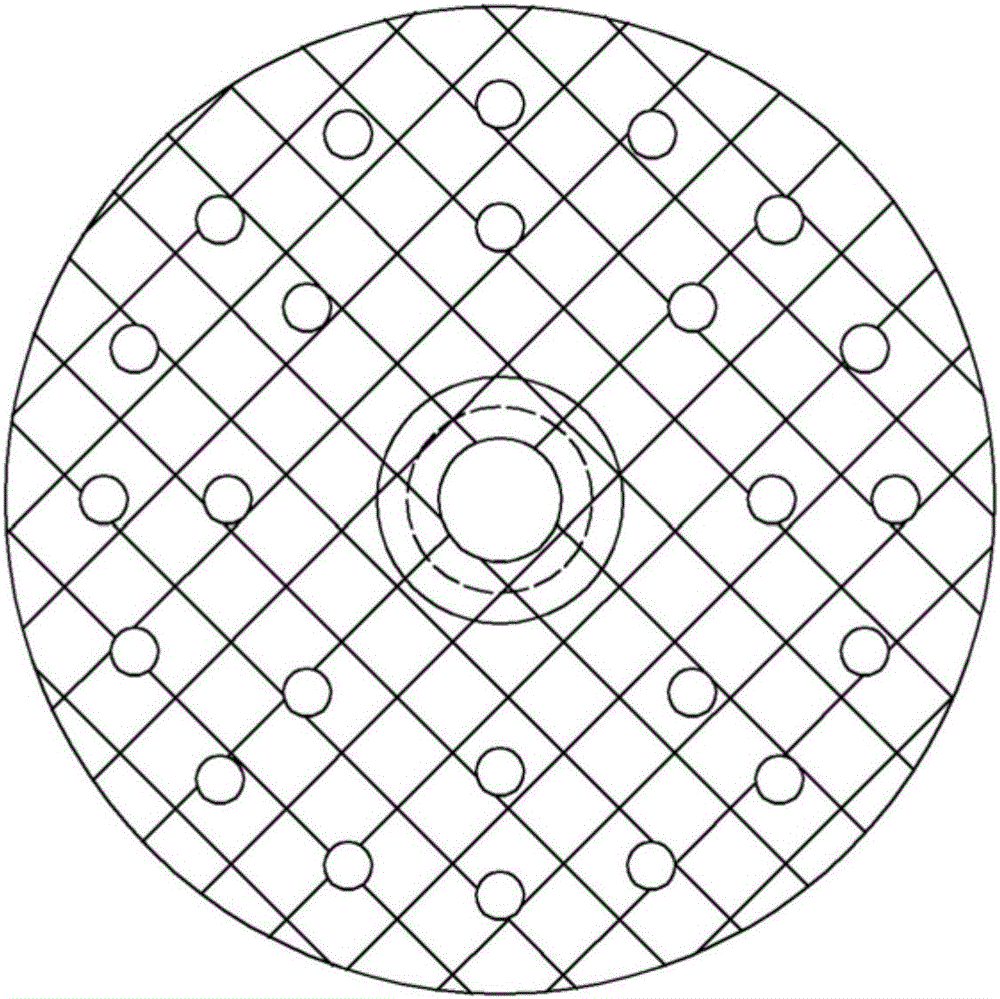

Continuous production line for gas meter and production process flow

ActiveCN102749112AEliminate time-consuming and labor-intensive detection methodsShorten detection timeTesting/calibration apparatusVolume meteringProduction lineConnection type

The invention discloses a continuous production line for a gas meter and a production process flow. The production line is arranged in a constant temperature workshop and comprises an assembling unit, a detection unit and a packaging unit. A lower casing of the gas meter is fixed on a special tooling plate and transmitted to each process through an upper annular differential chain line and a lower annular differential chain line, accurate positioning between a part and a processing device is achieved, consistency of a product is good, the production cycle is shortened, only a sound velocity nozzle is used in a twelve-station series-connection type machine core error curve detector, investment in detection devices is reduced, continuous completion of initial correction and repeated detection is achieved, a full-automatic multifunctional detection device can detect various functional parameters of the gas meter simultaneously in parallel, detection time is saved, detection precision is improved, and continuous and massive production of the gas meter is achieved.

Owner:金卡智能集团(杭州)有限公司

Three-electrode lithium air cell test die

ActiveCN106340700AConvenient electrochemical testingMeet contact needsFuel and secondary cellsElectrical testingThroatElectrical battery

A three-electrode lithium air cell test die is a novel lithium air cell die. The three-electrode lithium air cell test die is a test die adopting a three-electrode test method, and a reference electrode is added, so that the electrode process in the cell charging and discharging course can be detected and analyzed in real time. A reference electrode component is formed by combining an elastic insulating sheet and a replaceable reference probe, and not only meets different test requirements, but also solves the sealing problem of a casing after the adding of the reference electrode. A regulating rod with a thread is adopted to conveniently regulate pressure inside an assembly cell so as to control an internal cell test environment; finally a positive electrode is provided with a hole and a throat to facilitate pressure regulation and gas contact and avoid pole piece deformation in the squeezing process, and it is guaranteed that the cell test is performed normally.

Owner:BEIJING UNIV OF TECH

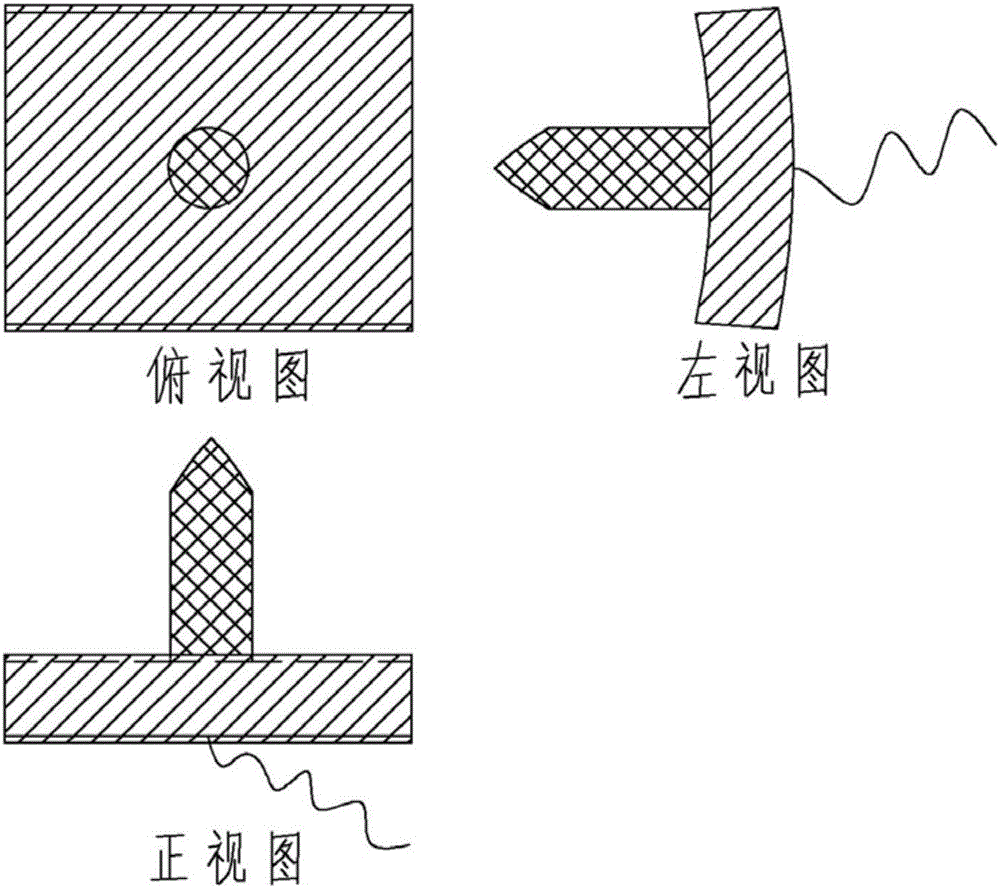

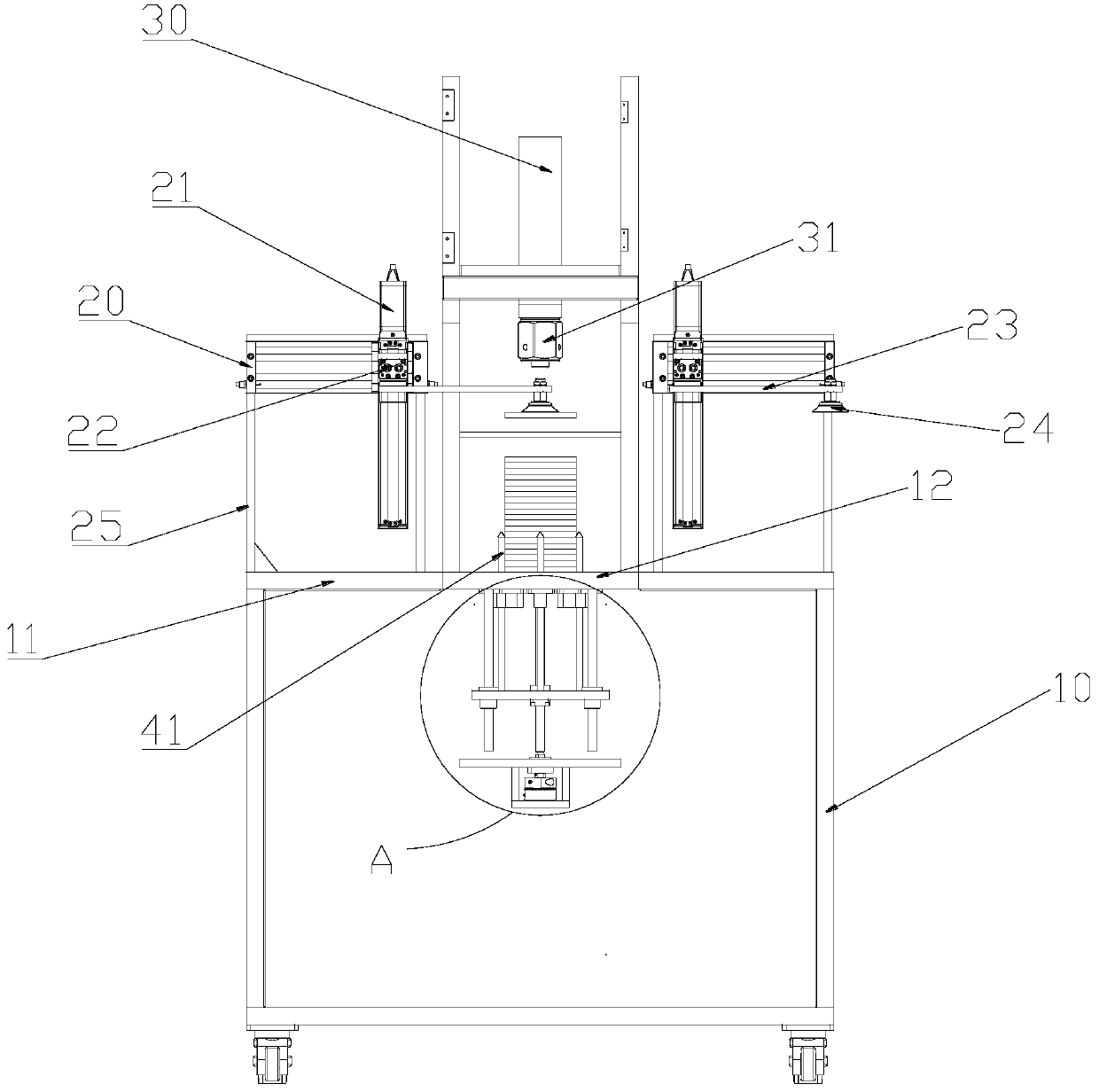

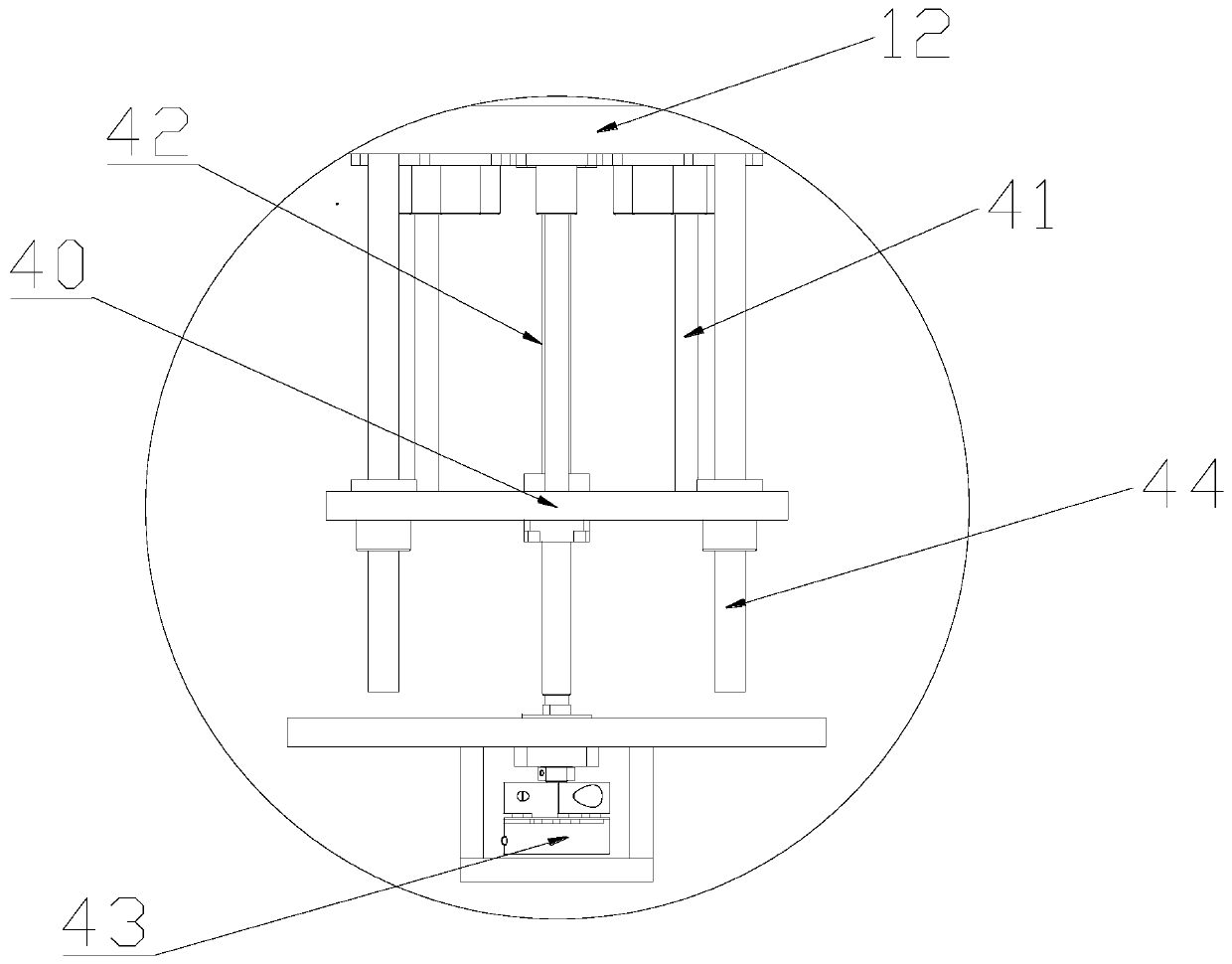

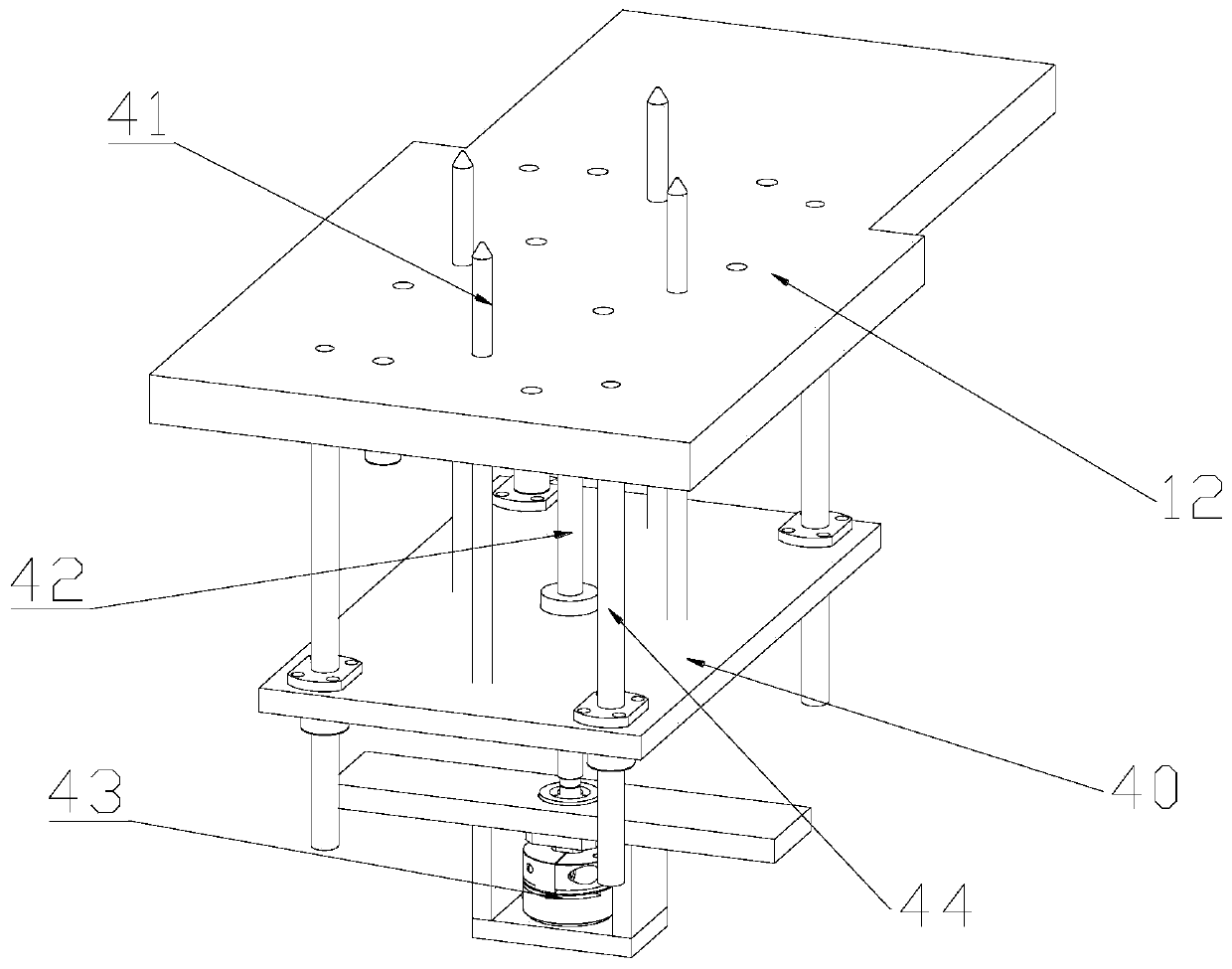

Assembly equipment of fuel cell stack

ActiveCN109768311AReduce work intensityEasy to produceFinal product manufactureFuel cellsFuel cellsAssembly cells

The invention relates to the technical field of an assembly cell, and particularly discloses assembly equipment of a fuel cell stack. The assembly equipment comprises a support, a press device and twogroups of loading device, wherein the support is hollow in interior, a working platform is arranged at an upper part of the support and is horizontally arranged, a stack position is arranged at a middle part of an upper end of the working platform, the press device is arranged above the stack position, the two groups of loading devices are respectively arranged at a left side and a right side ofthe stack position, one group of the loading device is used for transmitting a bipolar plate to the stack position, the other group of the loading device is used for transmitting MEA to the stack position, and the press device is used for pressing the stack on the stack position. The assembly equipment of the fuel cell stack has the advantages of rapid working speed, high production efficiency, labor saving and the like, the working intensity of a worker is reduced, and the production quality is improved.

Owner:武汉喜玛拉雅光电科技股份有限公司

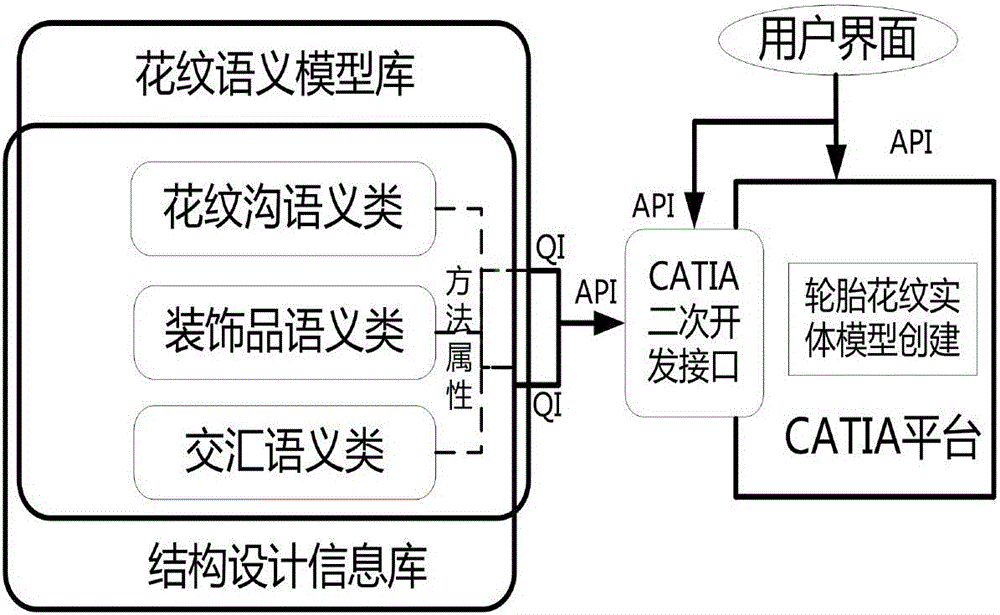

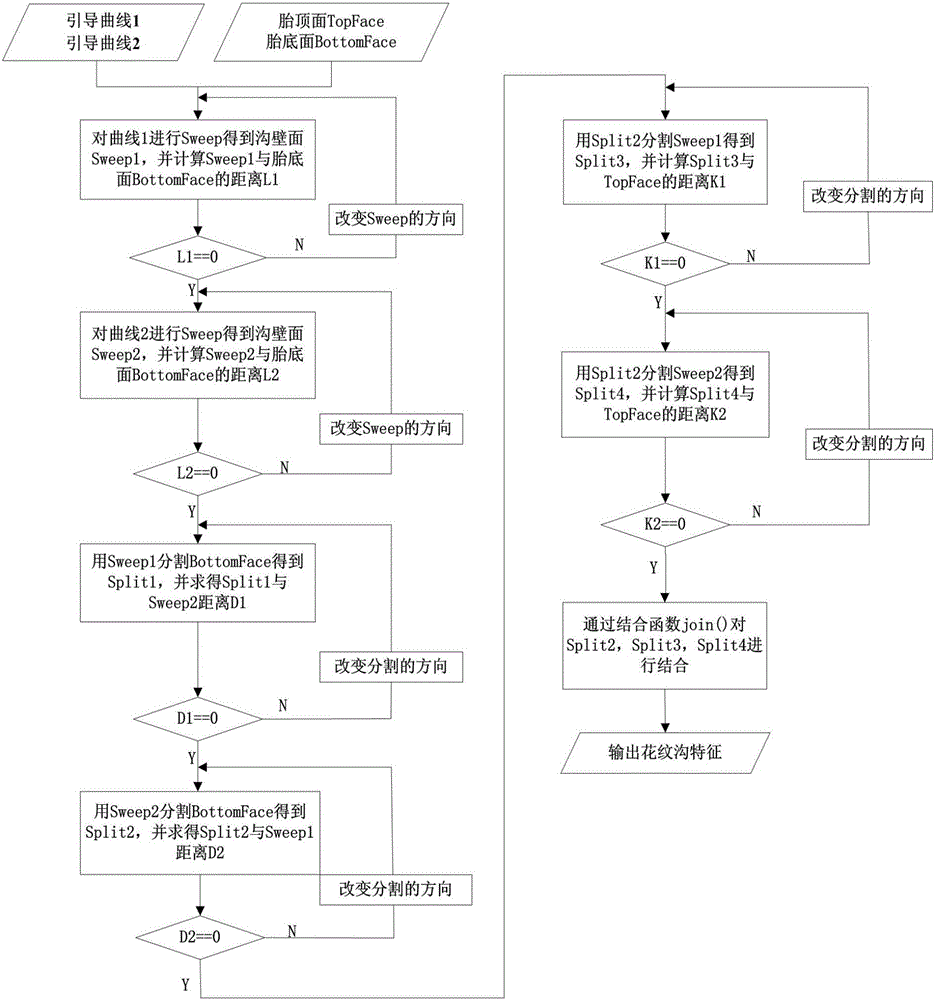

Parametric design system and method for tire patterns

InactiveCN106021669AStandardize the design processReduce duplicationGeometric CADSpecial data processing applicationsAssembly cellsStructural engineering

The invention discloses a parametric design system and method for tire patterns. The system comprises a pattern groove design module, a pattern groove intersection design module, a decoration design module and an auxiliary modeling module; the pattern groove design module comprises a first layer pattern groove design unit, a second layer pattern groove design unit, a third layer pattern groove design unit, a multi-segment pattern groove design unit and a tire should pattern groove design unit; the pattern groove intersection design module comprises an X type intersection processing unit, a T type intersection processing unit and a V type intersection processing unit; the decoration design module comprises a steel sheet characterization design unit, a groove bottom boss characterization design unit, a groove bottom rib characterization design unit, a new tire identification line characterization design unit, an attrition mark characterization design unit and a steel sheet intersection processing unit; and the auxiliary modeling module comprises an automatic assembly unit. The system disclosed by the invention can regulate the design flows of the tire patterns and improve the tire design efficiency and quality.

Owner:HEFEI UNIV OF TECH +1

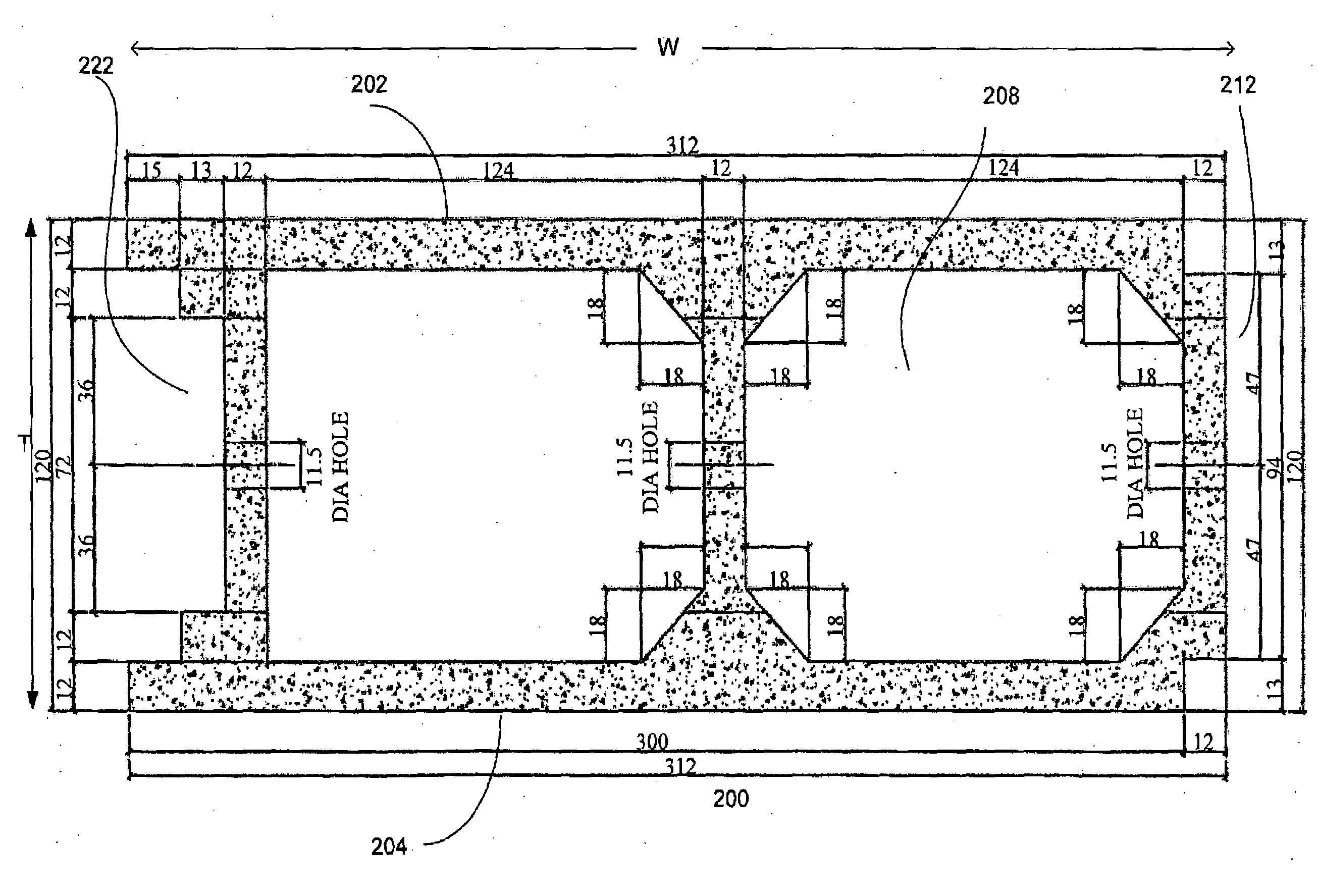

Stable and efficient building system

A plurality of different types of modules are used to form external and internal walls of a building system. Adjacent modules are interlocked by first and second fitting surfaces of respective adjacent modules. First and second adjacent modules are attached using a fastening system which includes a fixing rod and wall fitting unit. A fitting surface of the first adjacent module is fitted with the wall fitting unit and the fixing rod is inserted through the second adjacent module.

Owner:LIM MATAKII OGOSHI

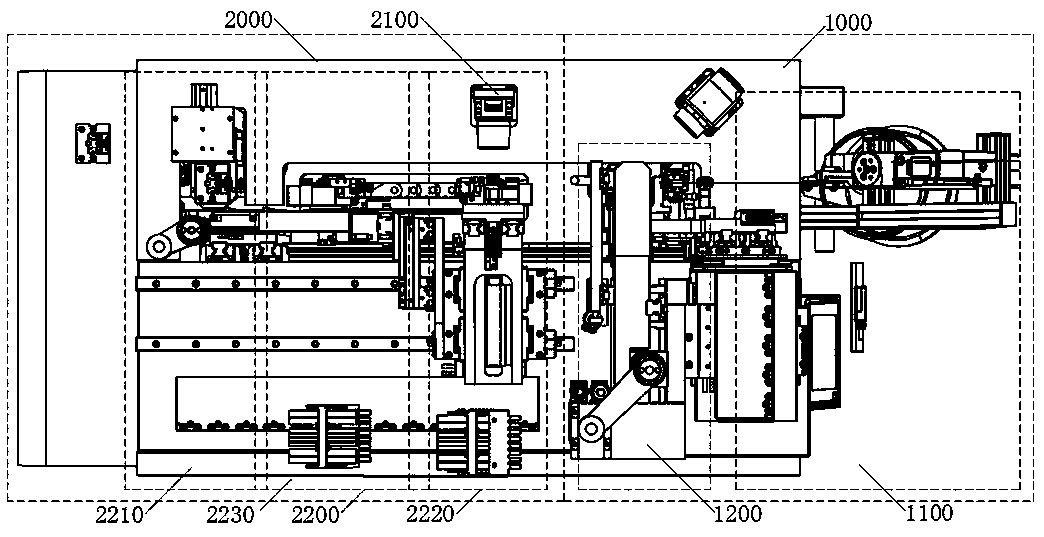

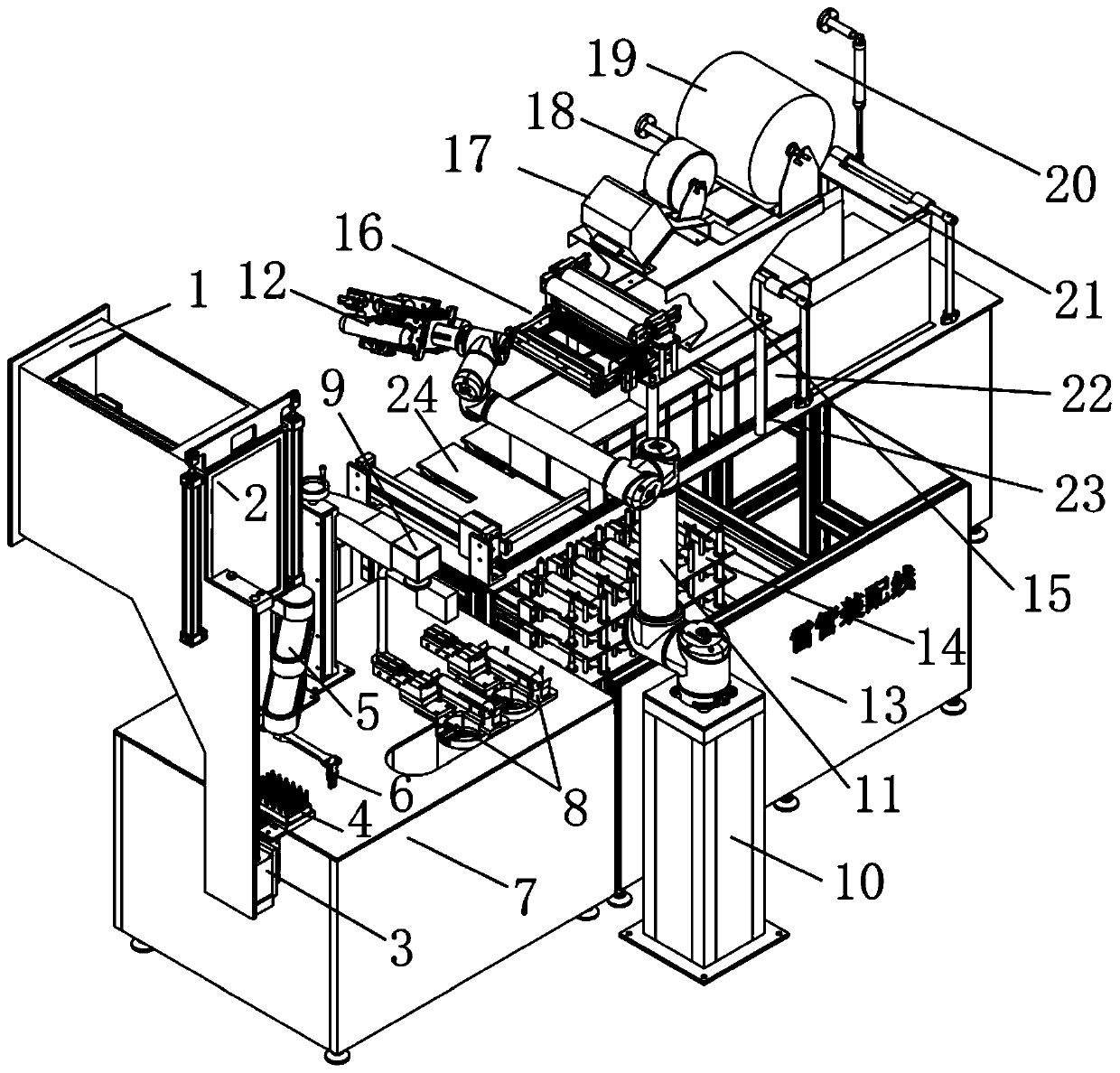

A voice coil winding and assembly device

PendingCN107659877AHigh precision voice coilFlux stabilizationElectrical transducersMagnetic fluxEngineering

The invention provides a voice coil winding and assembly device used for voice coil winding and assembly of a voice coil and a carrier. The voice coil winding and assembly device comprises a wire incoming unit, a winding unit, a temperature control unit, a detection camera and a transfer and assembly unit, which are integrated into a whole. The voice coil winding and assembly device enables rectangular or quasi-rectangular voice coils to be formed directly without correction; the voice coils are high in precision and stable in magnetic flux; the voice coil winding and assembly device integrates voice coil winding, voice coil detection and voice coil assembly, so that the production efficiency is increased; the voice coil winding and assembly device has a specially-shaped voice coil windingfunction, so that the adaptability of the device is improved; the device can perform fine adjustment of voice coils according to error of carrier assembly grooves, so that the matching connection between the voice coils and carriers is better; a turning mechanism meets the requirement for turning in voice coil assembly and can be adaptive to double-side turning adjustment assembly; with a heatingunit, enameled wires of voice coils can be stably and reliably bonded; the device is high in intelligence degree and smart in overall structure; manpower cost is reduced and the yield of products isincreased; the mechanisms are smoothly connected and run stably.

Owner:马斯利自动化技术(苏州)有限公司

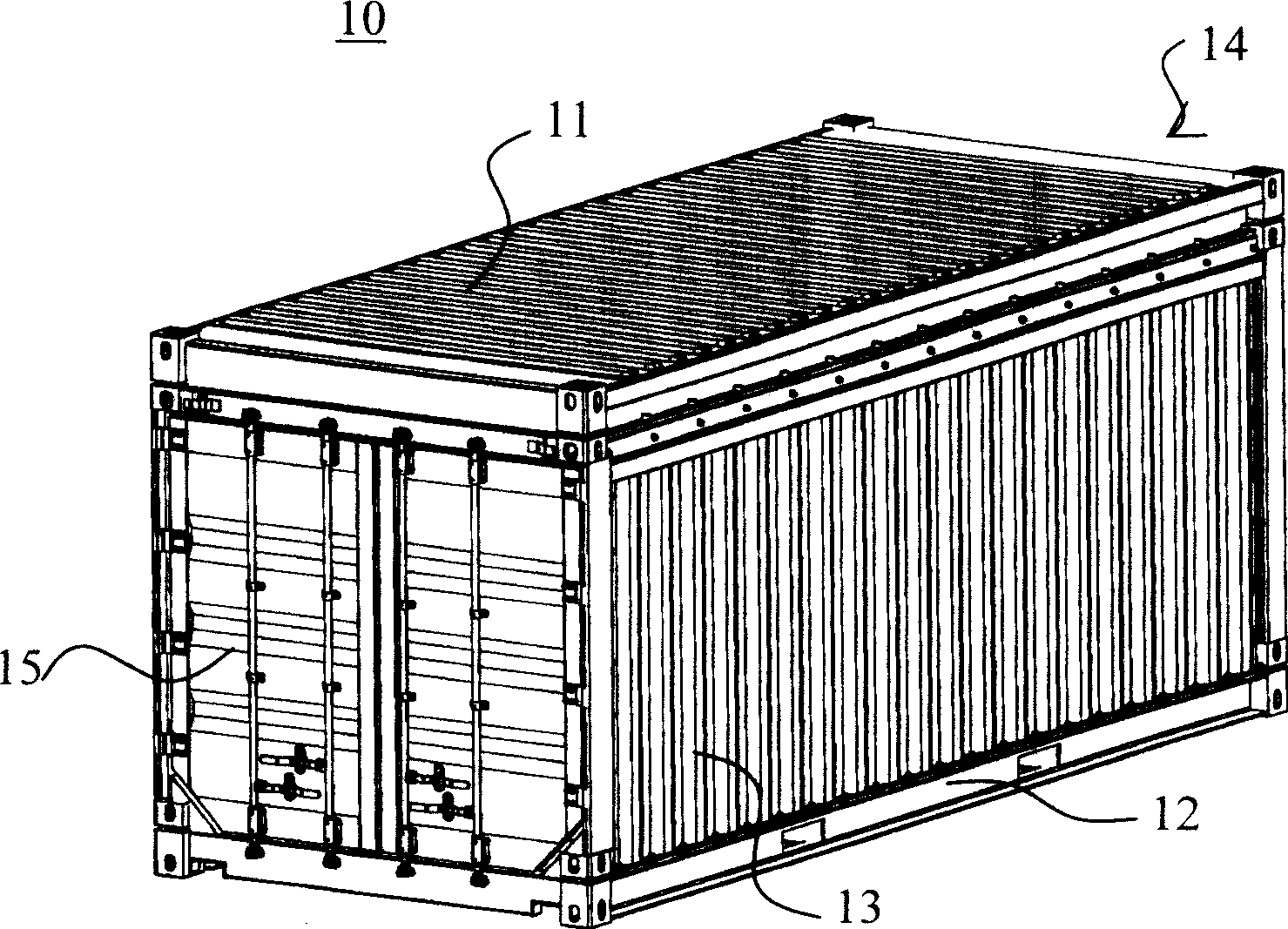

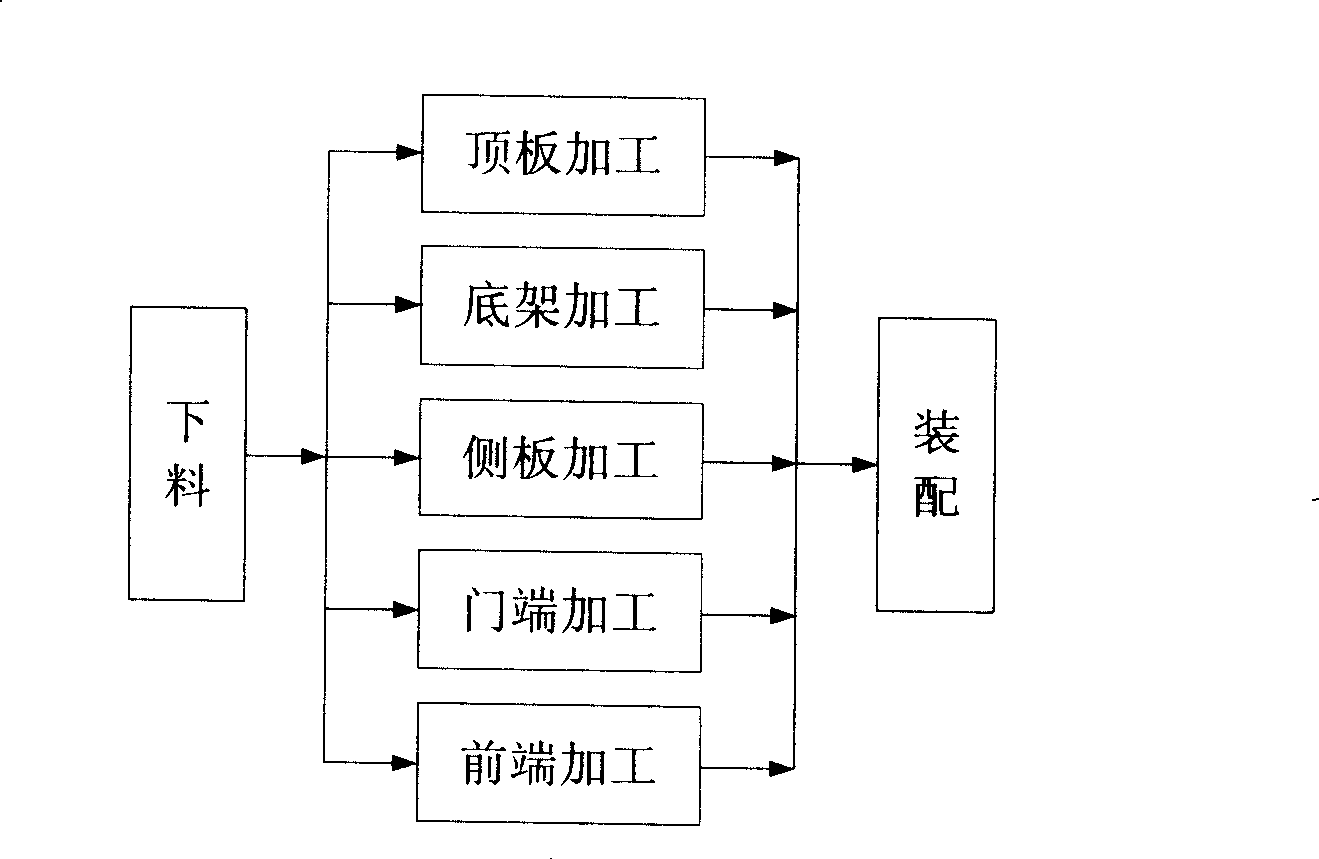

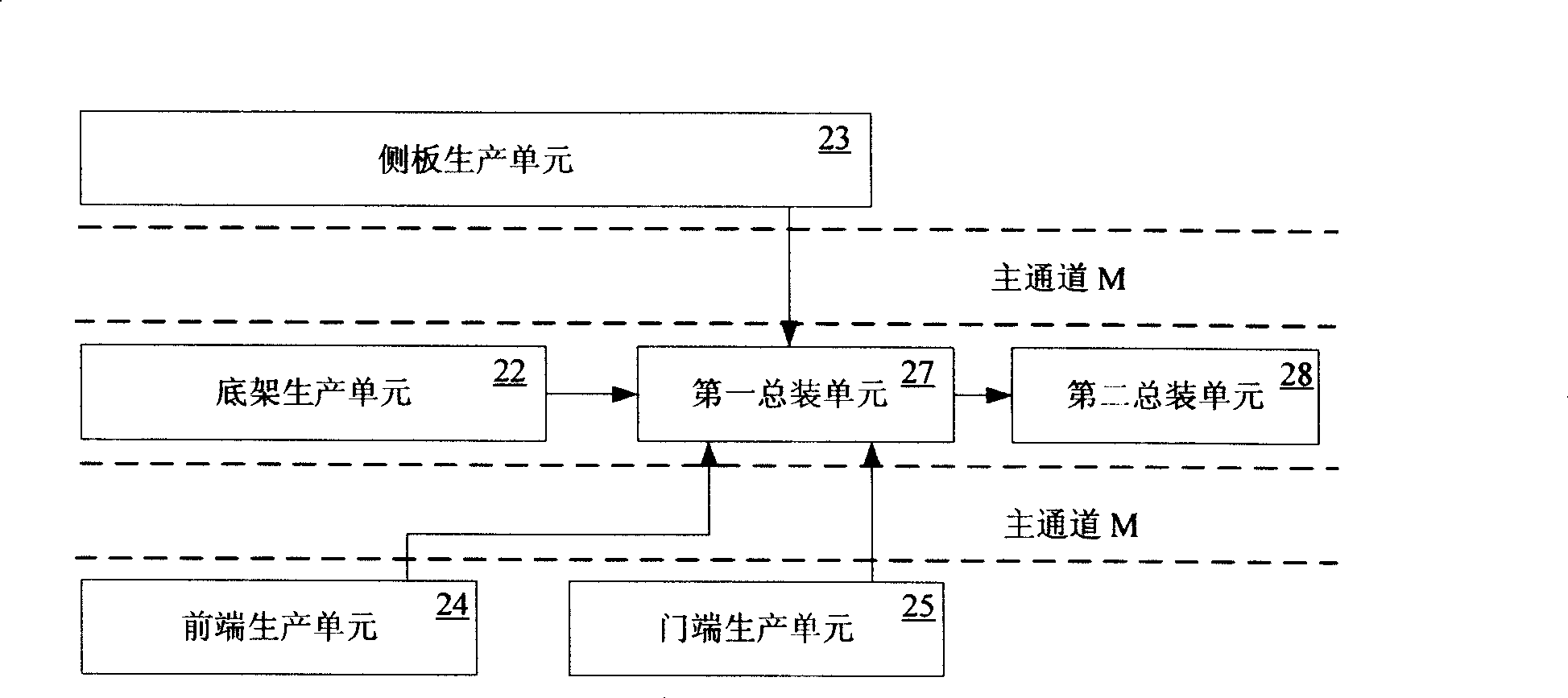

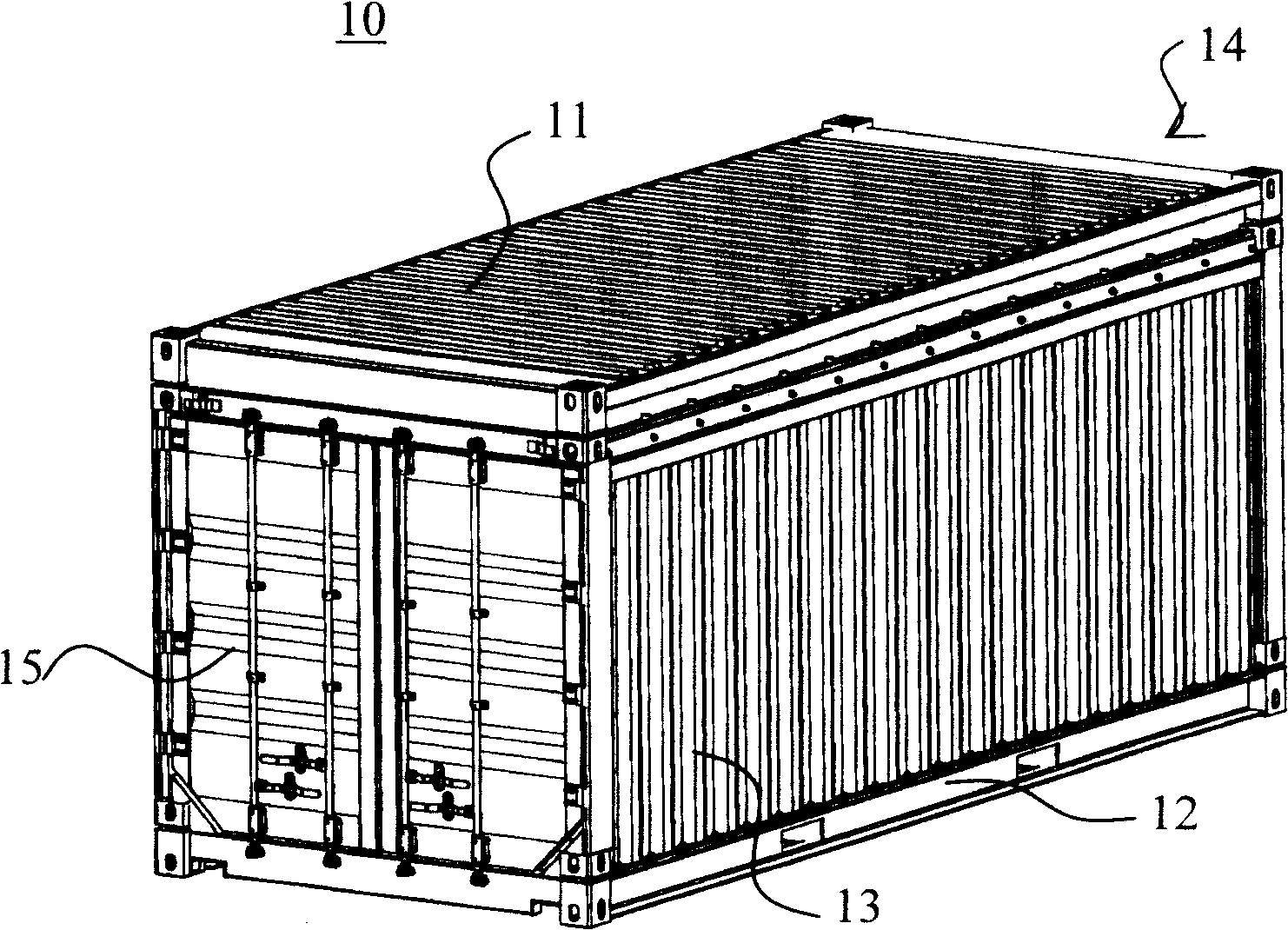

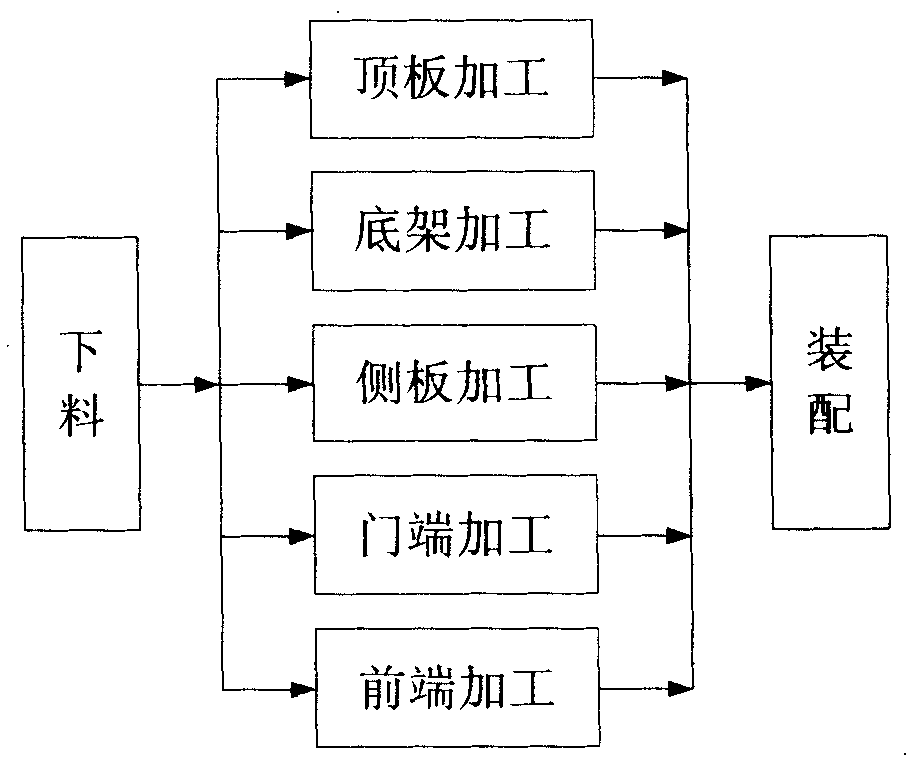

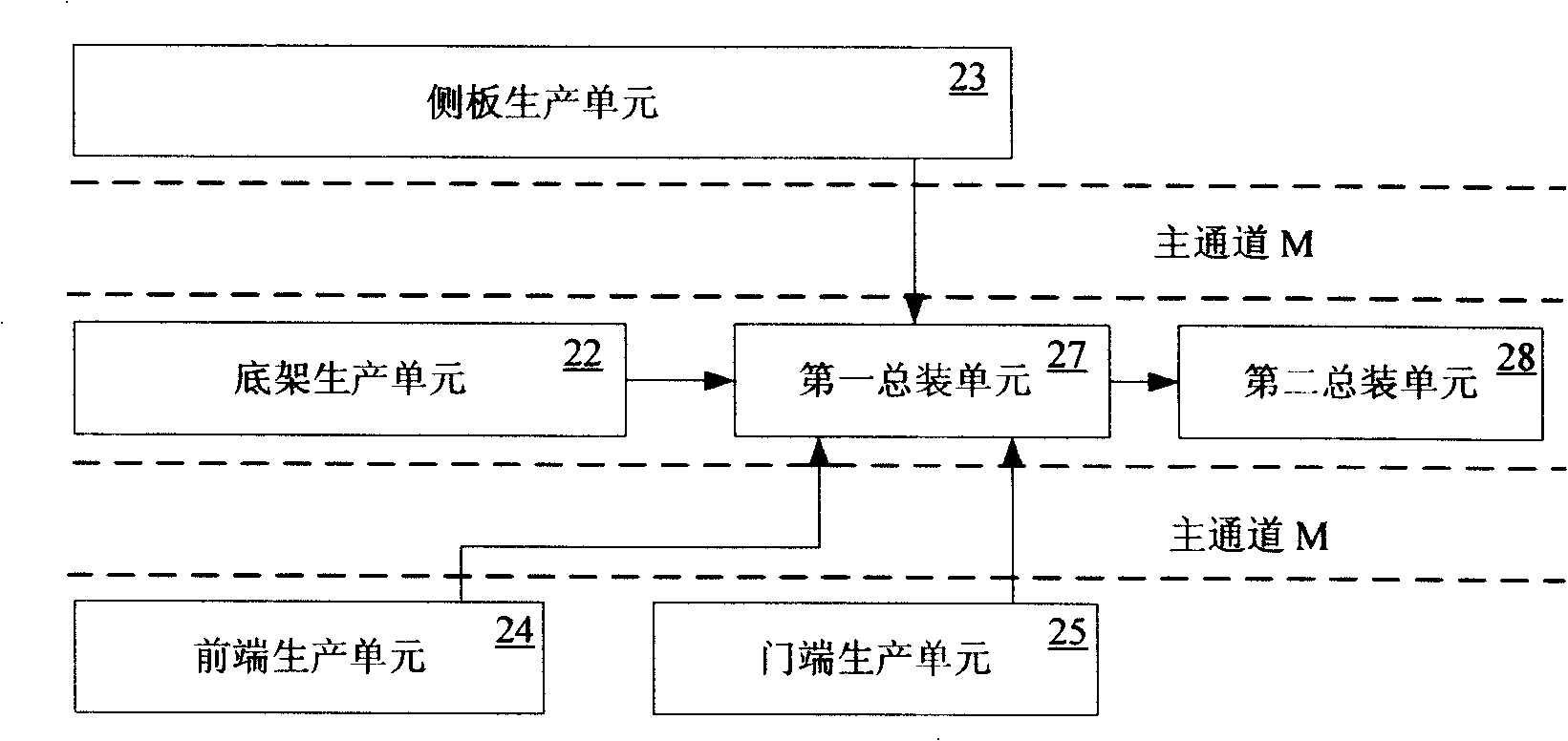

Container assembly method, container assembling apparatus and setting method thereof

The invention discloses a container assembling method and a container assembling apparatus. The method comprises the following steps: an assembling unit is arranged; a chassis conveying unit is arranged at the manufacturing upstream side of the assembling unit; a first hoisting unit is arranged above the assembling unit; the chassis conveying unit is adopted to convey the chassis to a preset position in the assembling unit; the first hoisting unit is adopted to convey two side plates to the preset position in the assembling unit; a front end and a door end are respectively conveyed to the preset position in the assembling unit; a top plate is conveyed to the preset position in the assembling unit; the assembling process is carried out in the assembling unit to form an integrated container. By adopting the method, the side plates can be conveyed to the assembling unit without passing through the main channel of the manufacturing plant, thus enhancing the safety of container manufacturing.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

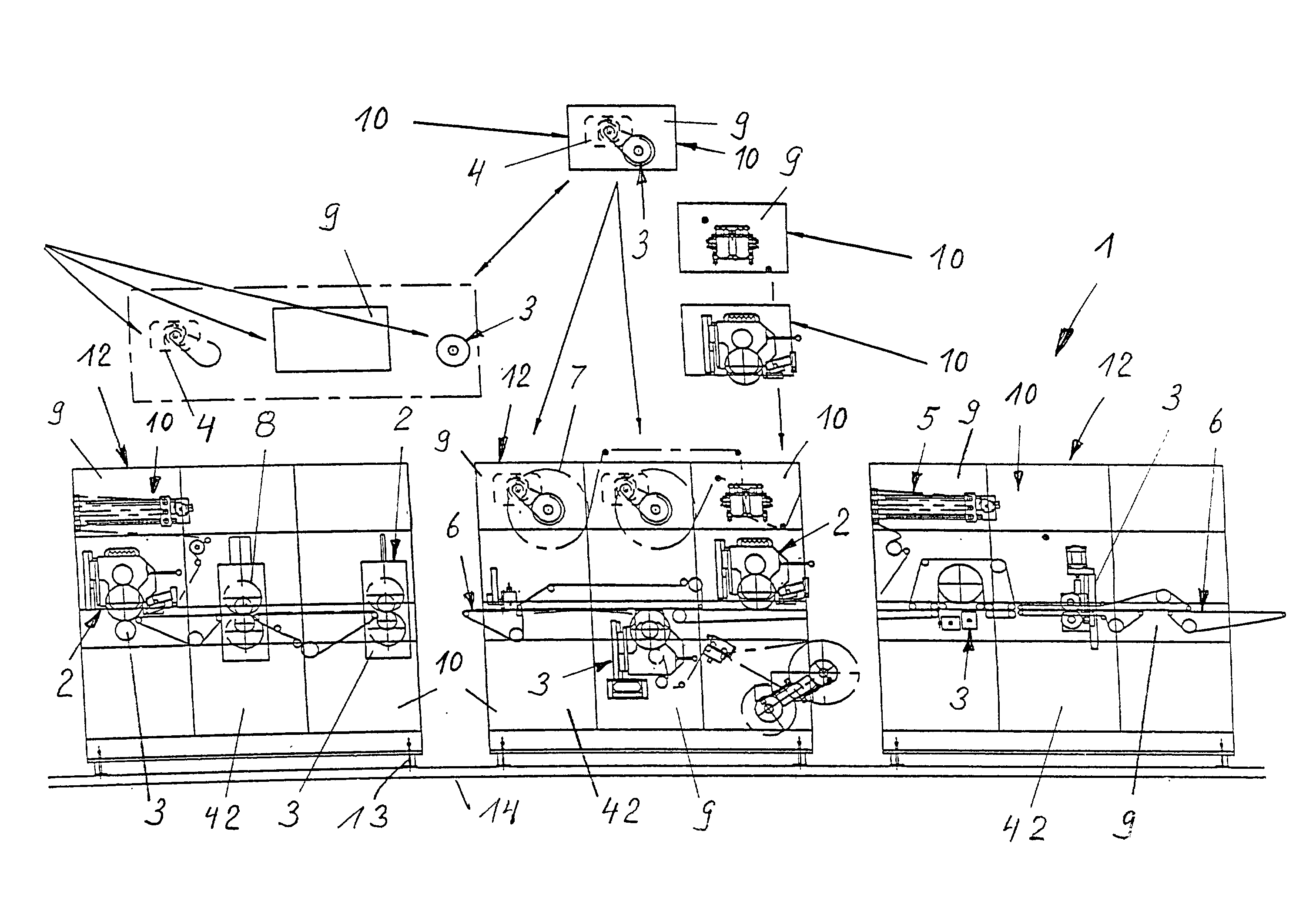

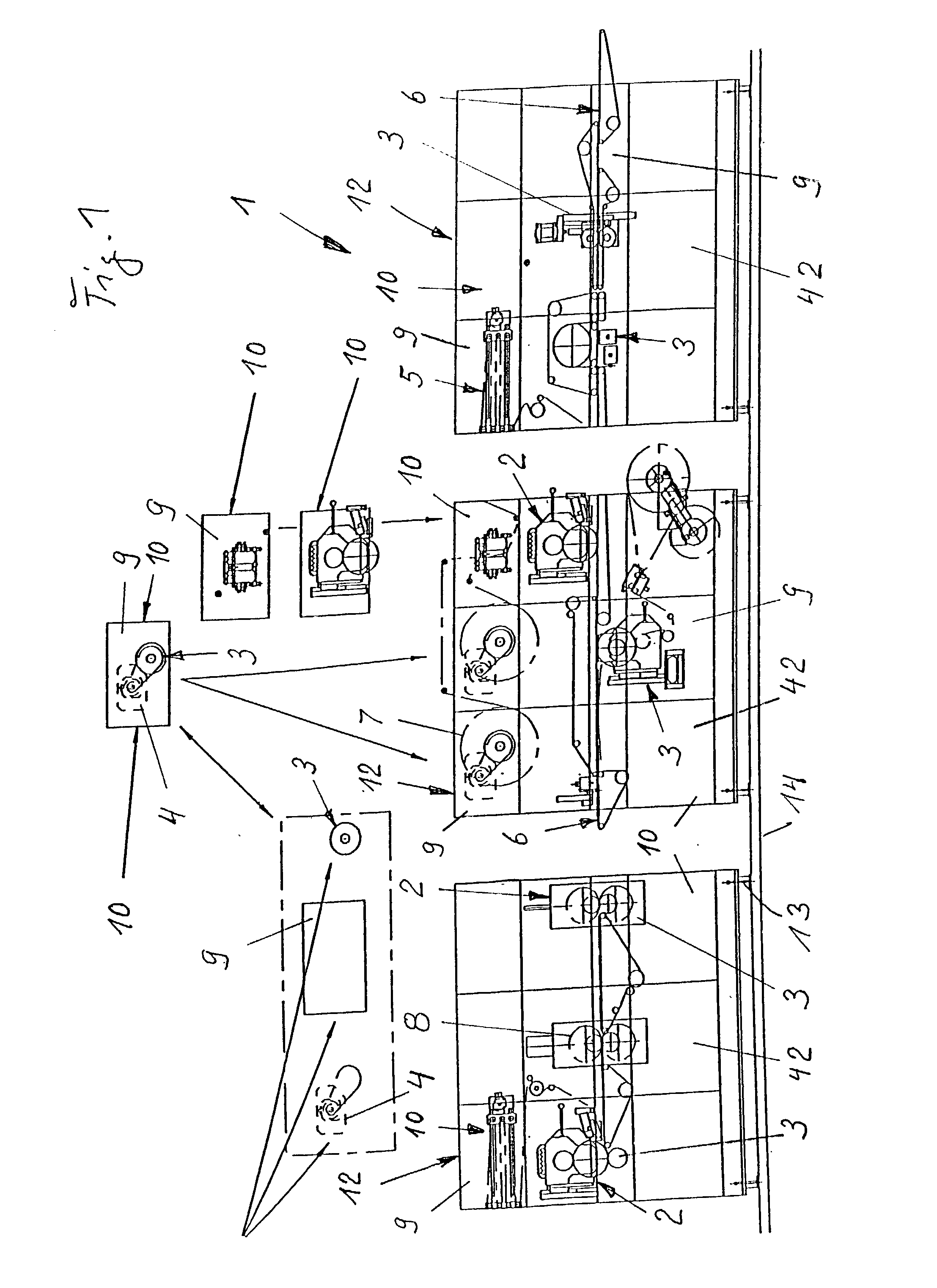

Apparatus for producing hygiene products

An apparatus for producing hygiene products includes several stations (2) with at least partially differing machine components (3) and predominantly separate independent drives (4). The machine components (3) and the drives (4) are assembled together on carrier plates (9) to form assembly units, and are securely mountable in a machine frame, which includes vertical upright supports (18) and horizontal connecting struts (17, 19, 20). The assembly units are provided as small modules (10) assembled from the machine components (3), drives (4) and carrier plates (9), which in turn at least partially are assembled together to form large modules (12) in the manner of large assembly units, which further in turn are assembled and connected together to form the apparatus including the machine frame, the machine components (3), and their drives (4).

Owner:WINKLER DUNNEBIER GMBH

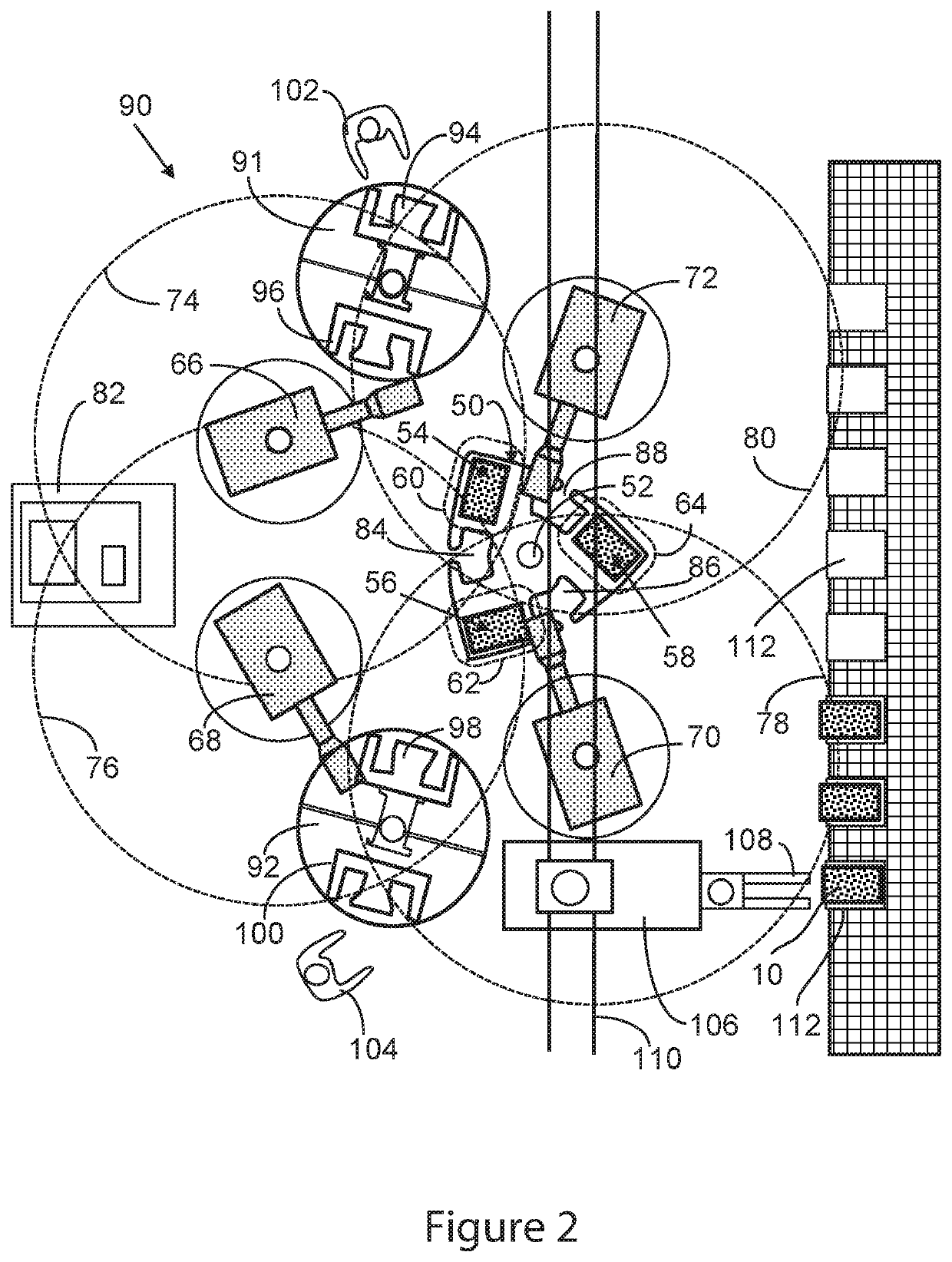

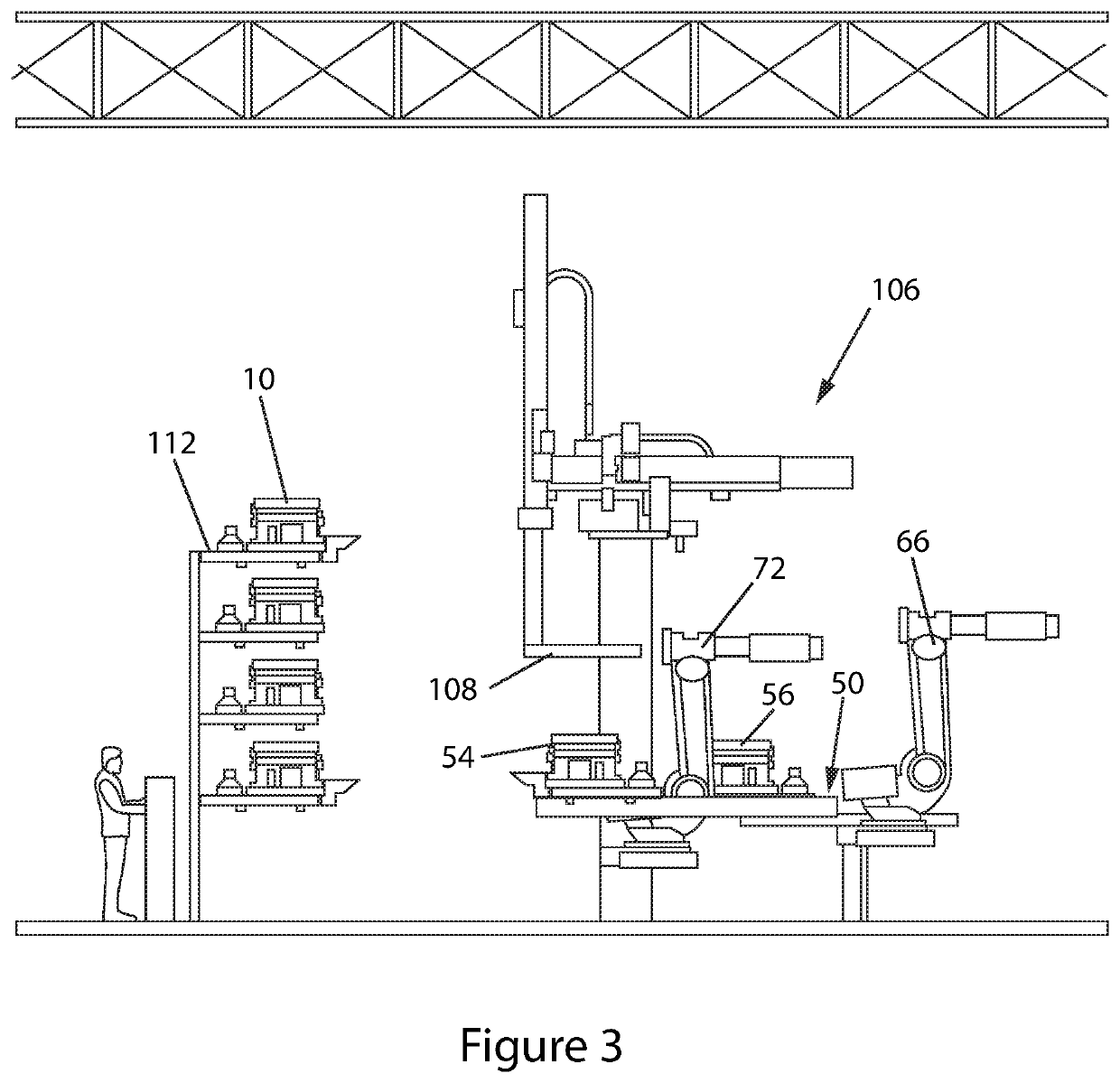

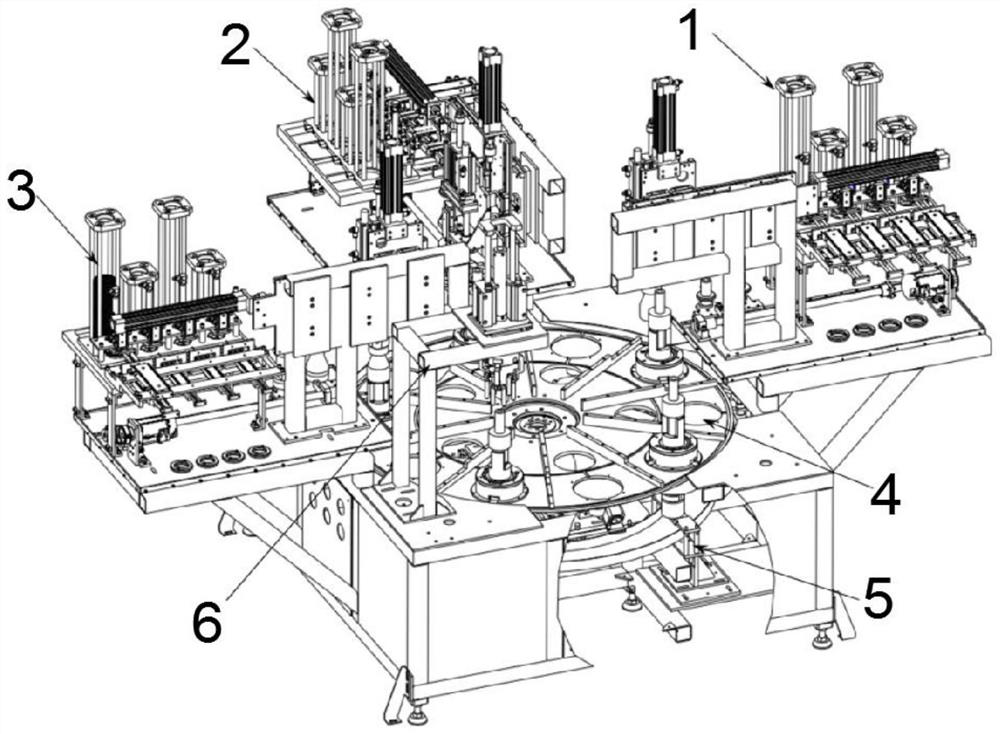

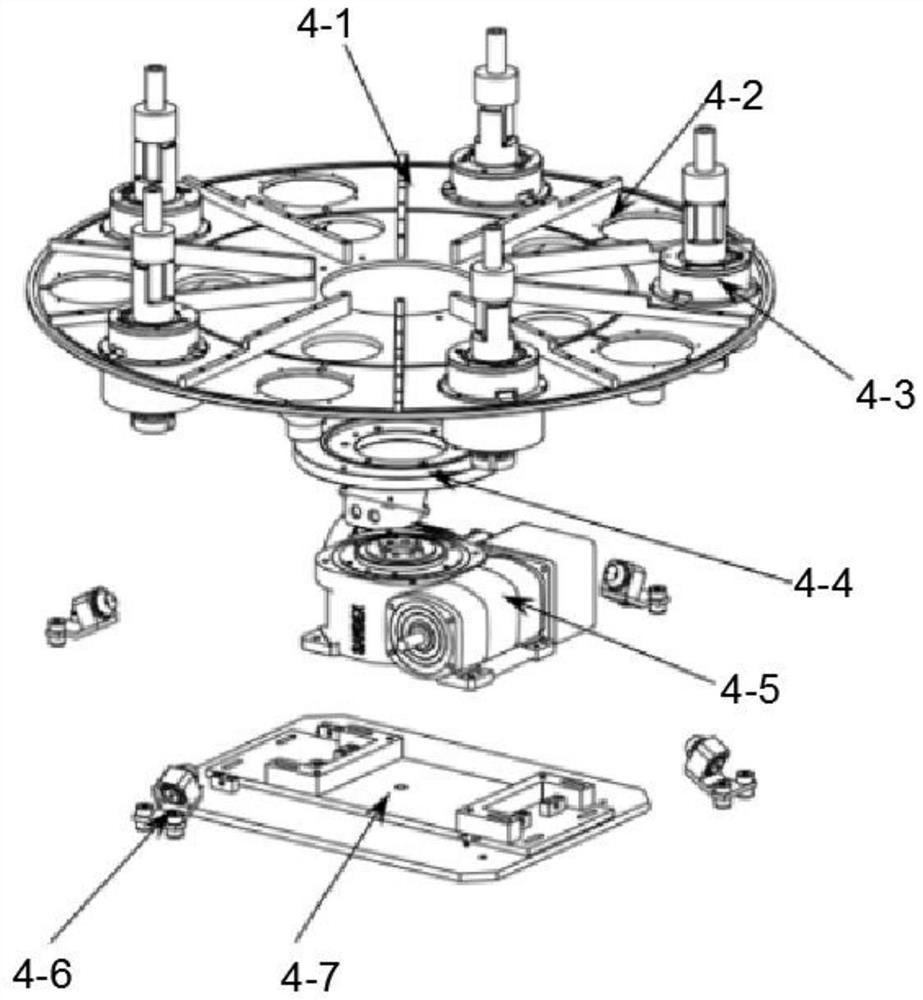

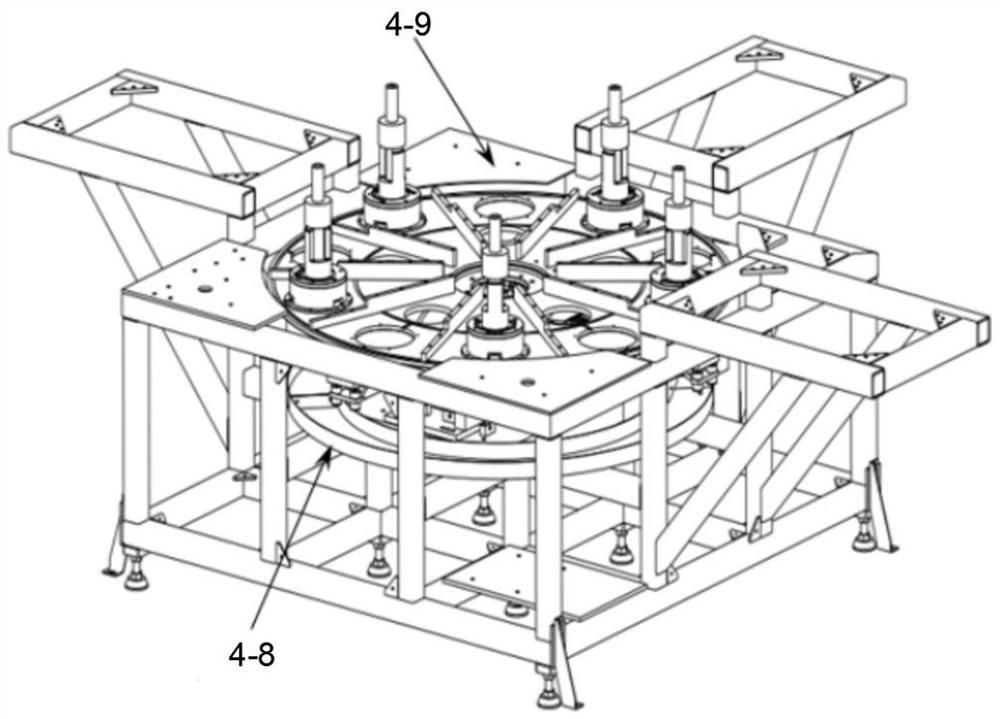

Automated assembly cell and assembly line for producing sand molds for foundries

ActiveUS20200316675A1Improve efficiencyLower cost of capitalCasting plantsMoulding toolsFoundryCylinder head

A mold assembly cell for sand mold production comprising a turntable wherein sand cores and other mold parts (which together cooperate to define the casting cavity of the sand mold) are automatically and progressively assembled following a sequential pre-programmed schedule by programmable robots located in proximal relationship with the turntable and a core shooting machine. The assembly turntable rotates clockwise or counterclockwise to permit placement of progressively more-complete mold packages in each of at least three assembly stations to allow the robots to reach the molds being assembled at different angles for simultaneously setting the sand cores and other parts of the mold according to said pre-programmed assembly schedule. Also a mold assembly line comprising a plurality of the foregoing assembly cells to form sand molds for casting complex-geometry aluminum parts, such as aluminum engine blocks and cylinder heads, with greater flexibility, efficiency and productivity.

Owner:NEMAK S A B DE

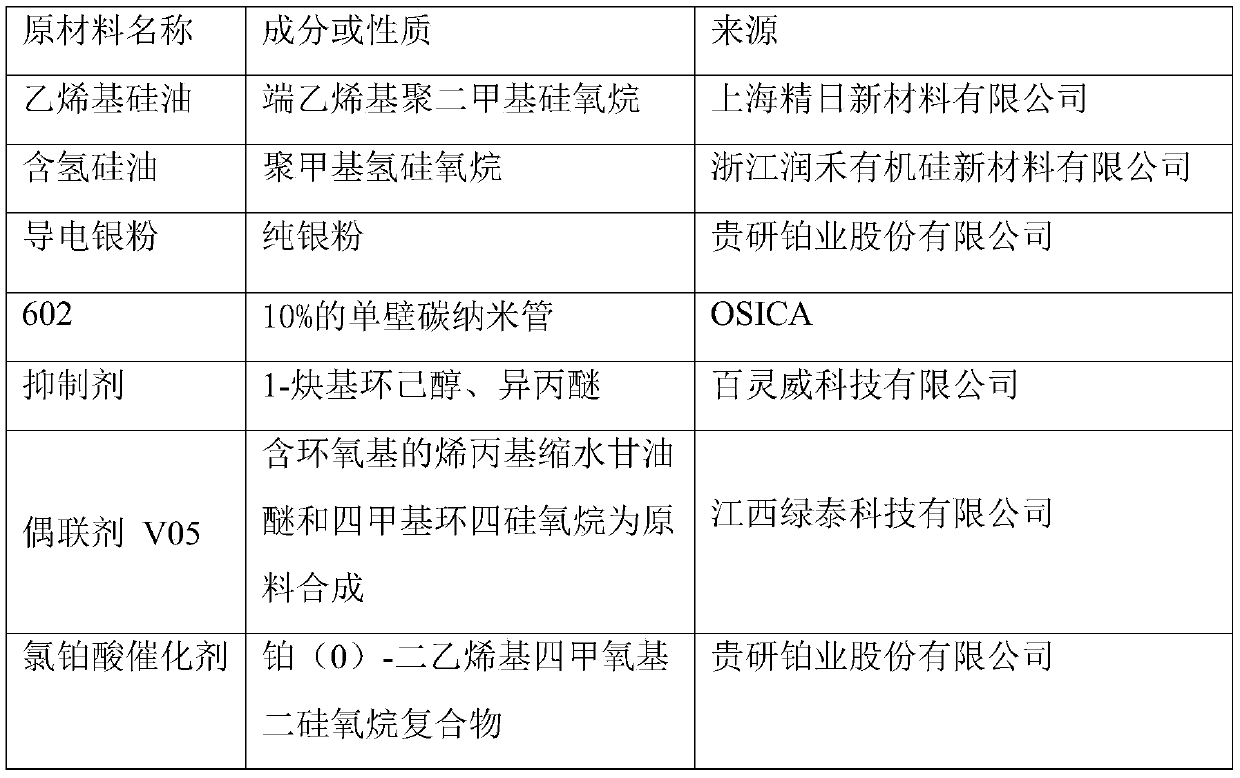

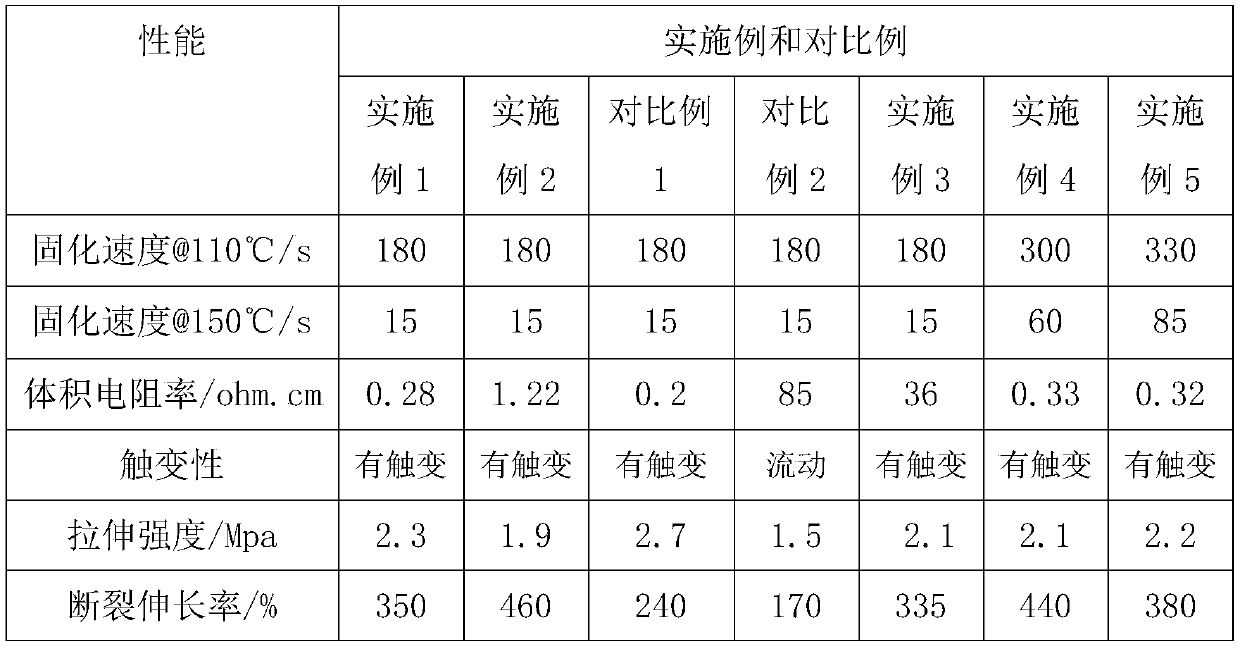

One-component silicone conductive adhesive, and preparation method and application thereof

ActiveCN109705803AReduce interface resistanceLow costNon-macromolecular adhesive additivesElectrically-conducting adhesivesConductive pasteHydrogen

The invention discloses a one-component silicone conductive adhesive. The one-component silicone conductive adhesive comprises, by weight, 60-100 parts of vinyl-terminated silicone oil, 1-5 parts of hydrogen-containing silicone oil, 20-40 parts of silver powder, 5-10 parts of single-walled carbon nanotubes, 0.2-5 parts of a coupling agent, 0.2-1 part of a catalyst and 0.5-3 parts of an inhibitor.The invention also discloses a preparation method and an application of the one-component silicone conductive paste. The one-component addition type silicone conductive adhesive prepared in the invention has the advantages of good electrical conductivity, low interface resistance and good toughness, and can be widely applied to conductive bonding of photovoltaic stacked assembly cell pieces, electronic components and electric conduction of printed circuit boards.

Owner:镇江博慎新材料有限公司

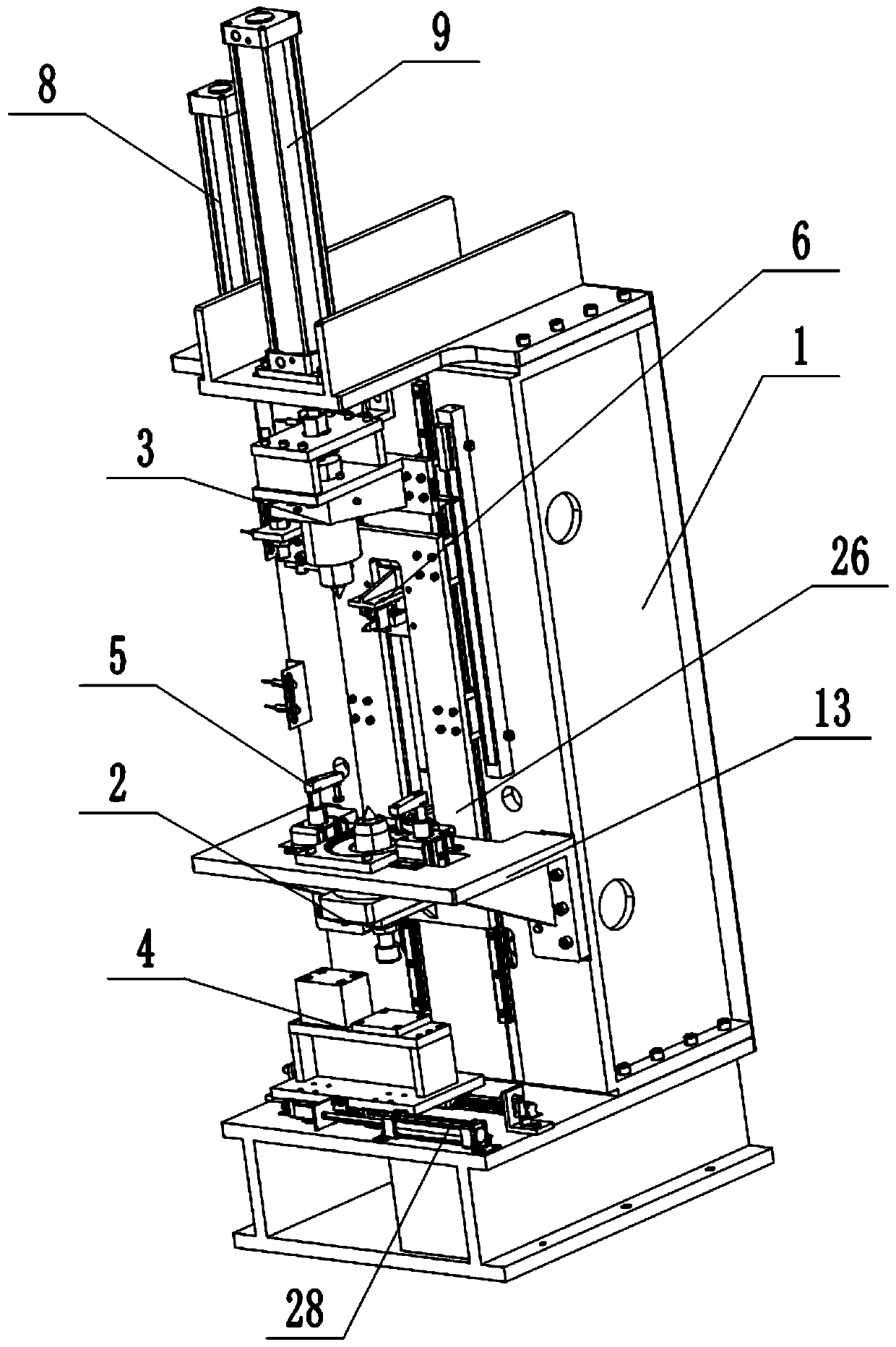

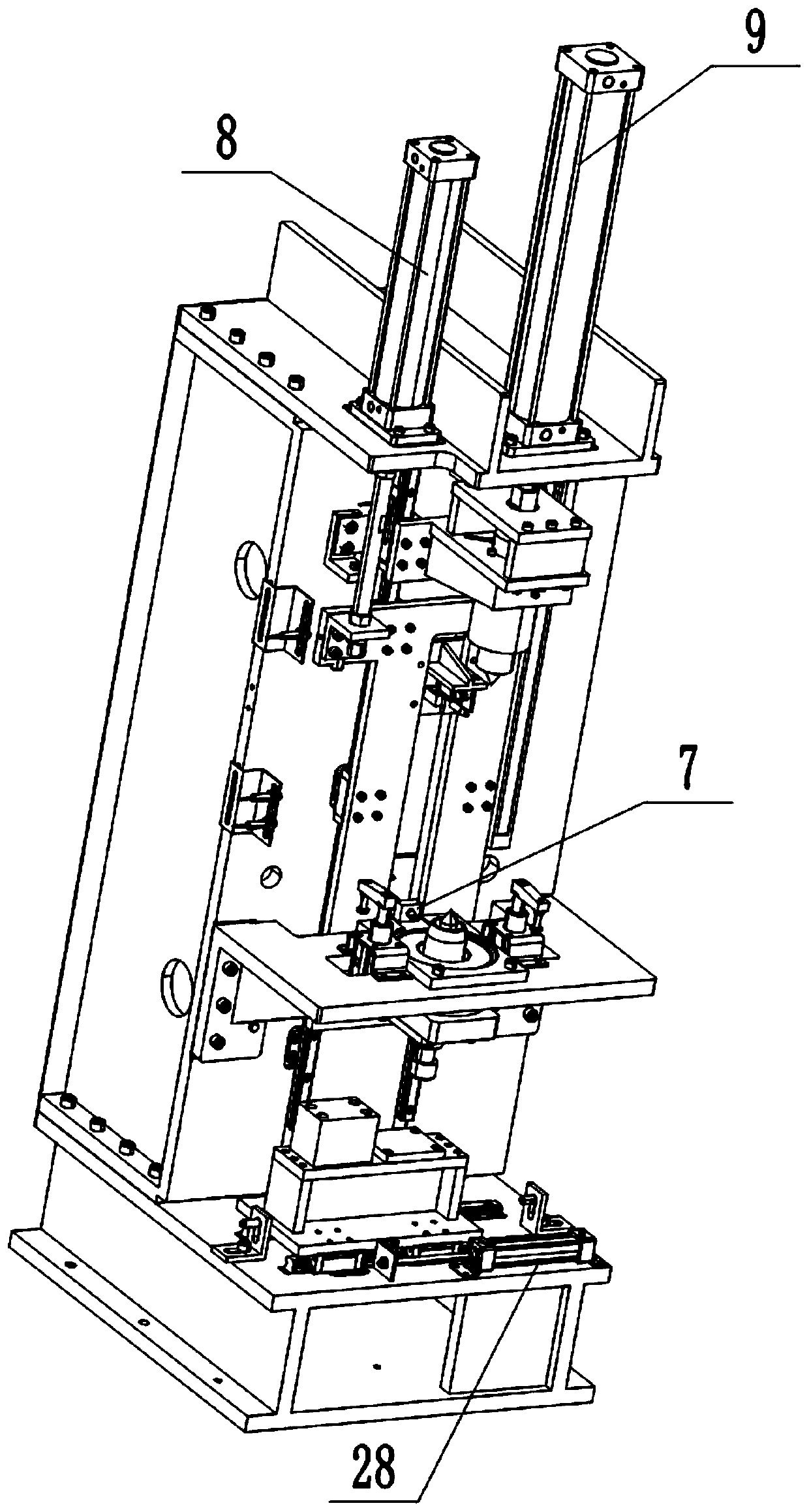

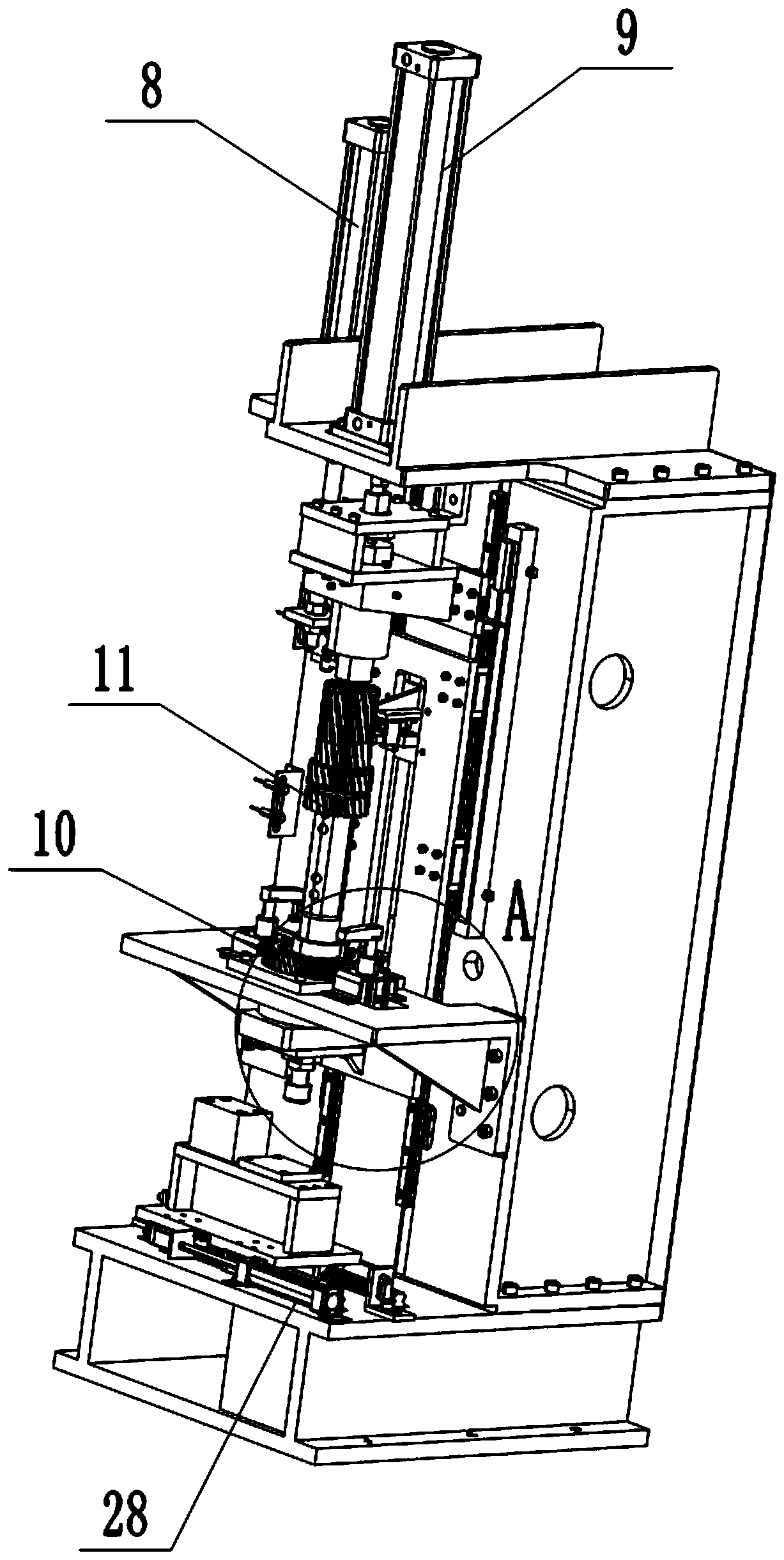

Automatic assembling equipment for gear shaft

PendingCN111390553AMeet axial size requirementsPrecise positioningAssembly machinesGear wheelAssembly cells

The invention belongs to the technical field of assembling equipment, and particularly discloses an automatic assembling equipment for a gear shaft. The automatic assembling equipment for the gear shaft comprises a controller, a machine frame, and a positioning unit, an assembling unit, a tooth aligning unit and a limiting unit which are arranged on the machine frame; the positioning unit is usedfor supporting and centering a gear; the assembling unit is positioned above the positioning unit; the assembling unit and the positioning unit are used for centering and clamping the gear shaft; thetooth aligning unit is used for aligning teeth of the gear and the gear shaft; and the limiting unit is used for limiting the positioning unit. By using the assembling equipment, the problems of low production efficiency and high labor intensity caused by adopting a manual assembling mode in the prior art can be solved.

Owner:CHONGQING ROBOT

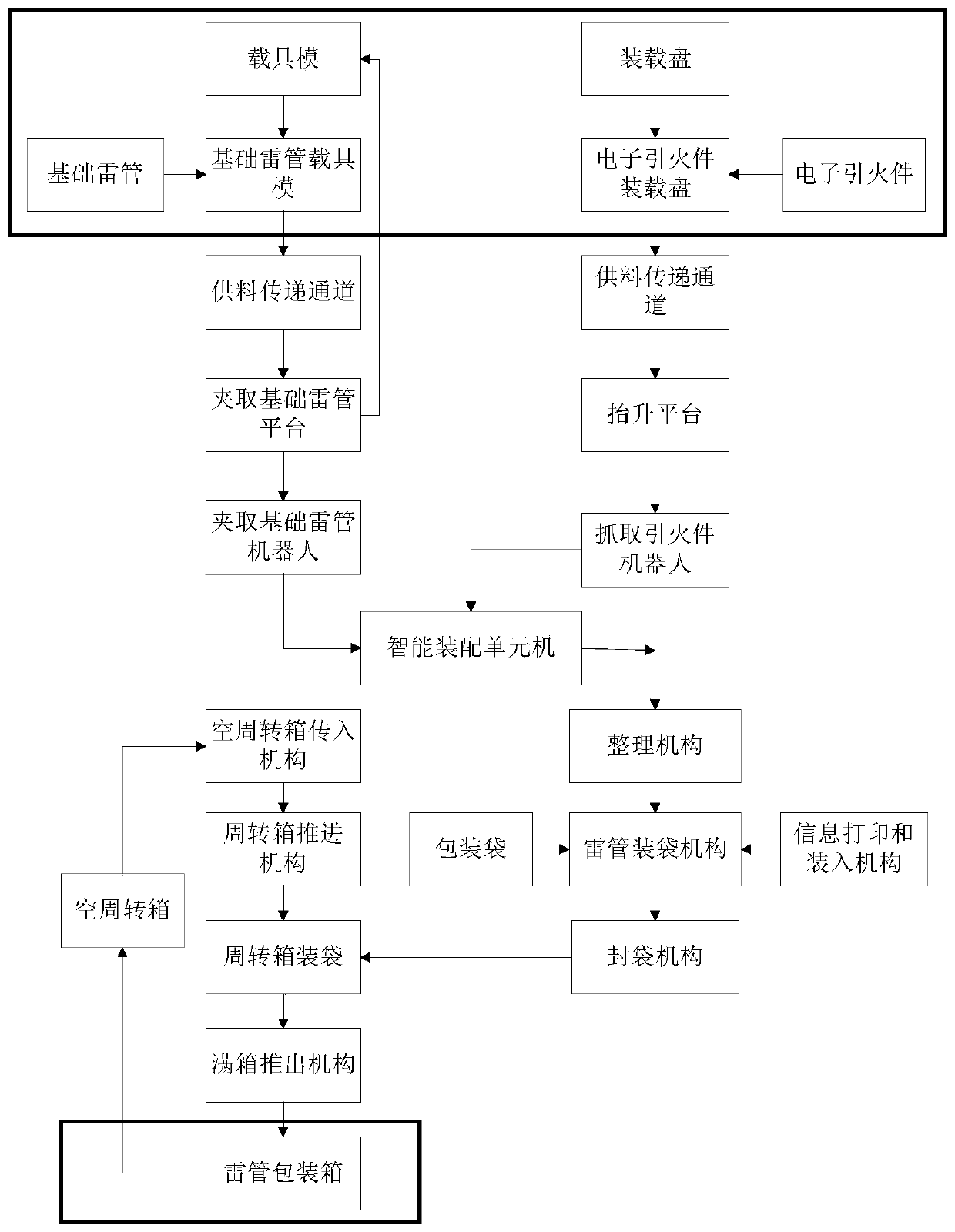

Electronic detonator assembling and production unit line

PendingCN111521077AQuick assemblyImprove time utilizationAmmunitionPackaging automatic controlAssembly cellsMachine

The invention provides an electronic detonator assembling and production unit line which comprises a basic detonator feeding module, an electronic ignition part feeding module, a basic detonator clamping robot, an ignition part grabbing robot, a full-automatic assembling unit machine, an intermediate packing machine and a finished product transfer box conveying module. The basic detonator clampingrobot clamps basic detonators provided by the basic detonator feeding module to be conveyed into a closing device of the full-automatic assembling unit machine. The ignition part grabbing robot clamps electronic ignition parts provided by the electronic ignition part feeding module to be conveyed into the closing device where the basic detonators are already placed. The full-automatic assemblingunit machine is used for completing assembling of the basis detonators and the electronic ignition parts in the closing device. The ignition part grabbing robot conveys the assembled electronic detonators into the intermediate packing machine to complete intermediate packing. The finished product transfer box conveying module is used for loading electronic detonator finished products with intermediate packing completed and conveying the electronic detonator finished products out of the assembling and production unit line. By means of the electronic detonator assembling and production unit line, unmanned and full-automatic assembling of electronic detonators is achieved, and production efficiency and safety are high.

Owner:北京凯米迈克科技有限公司 +2

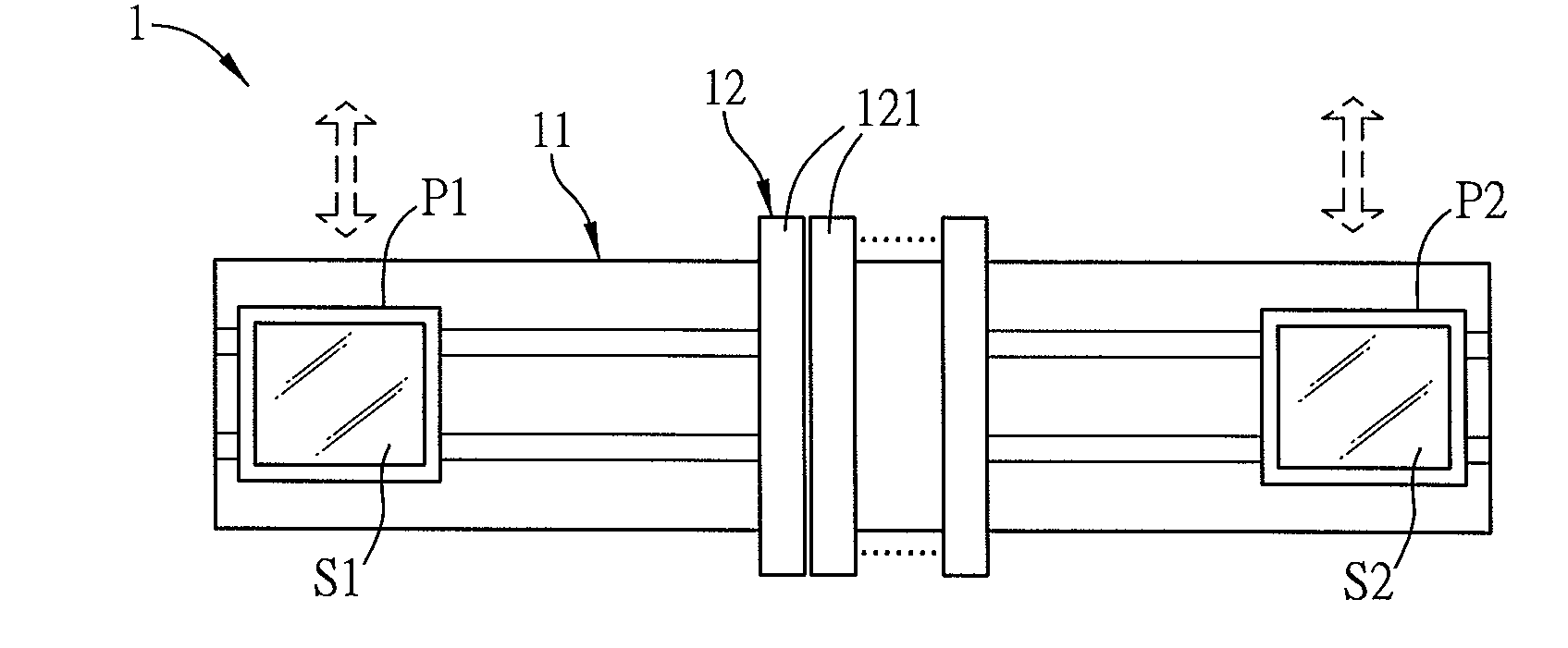

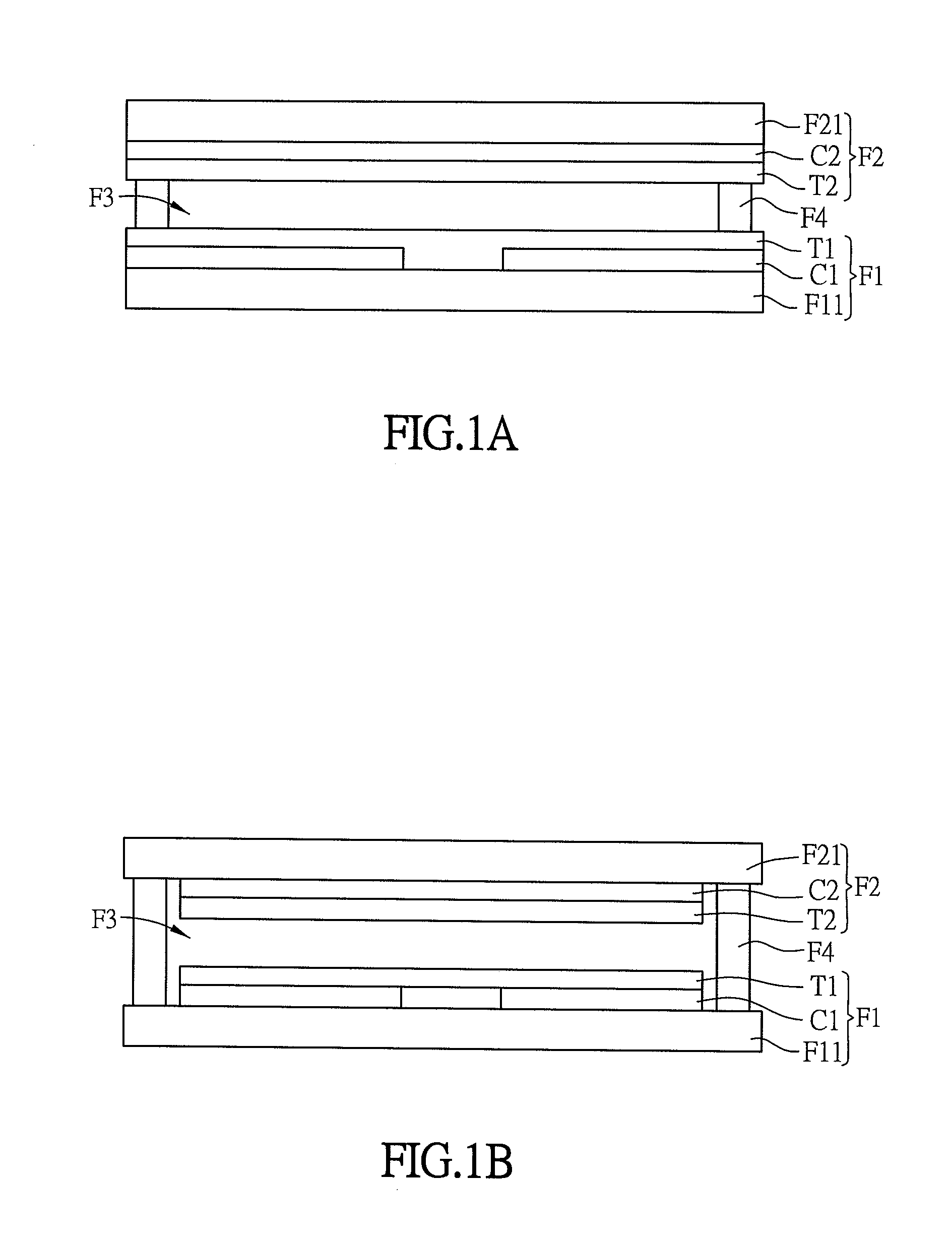

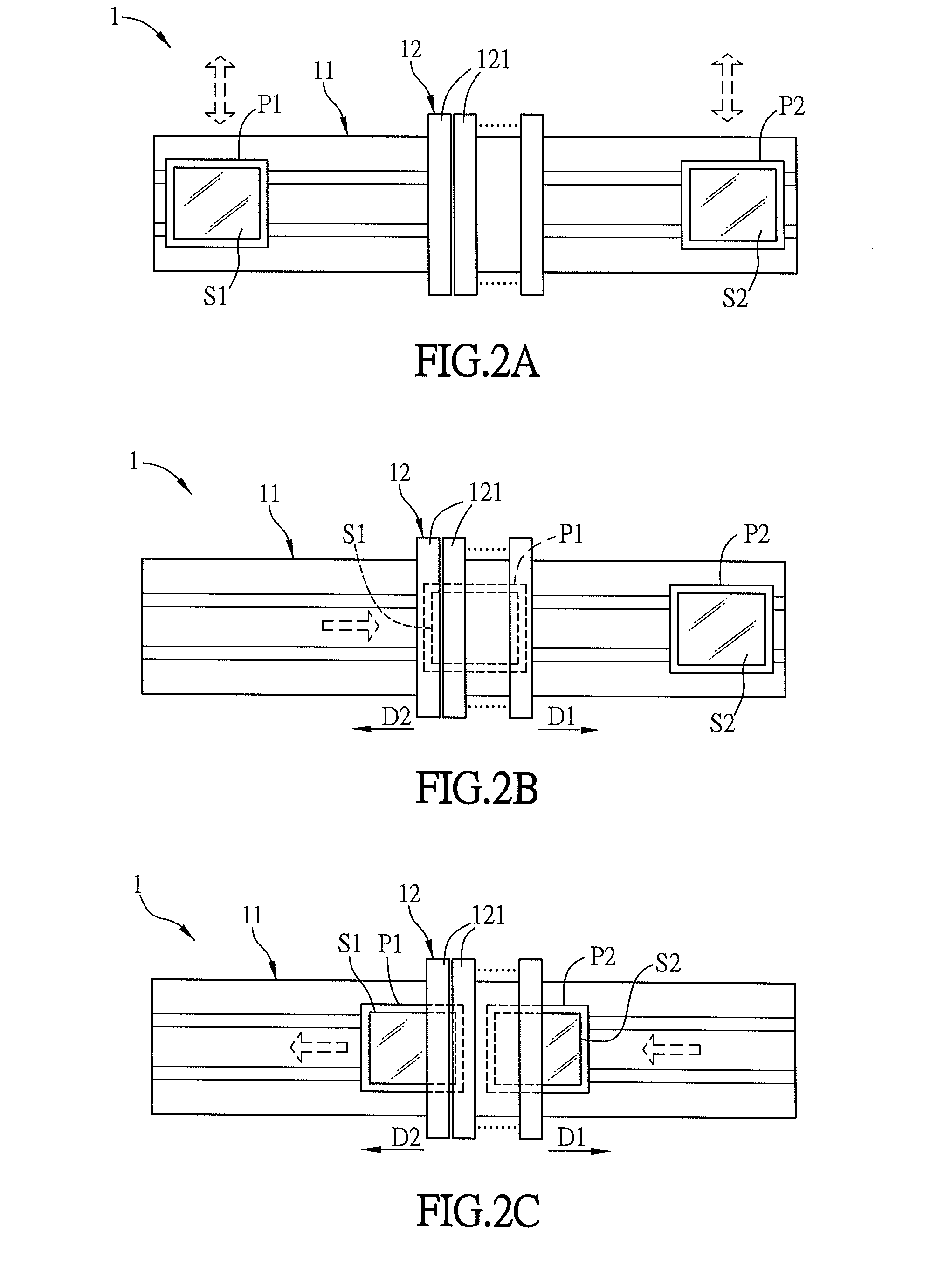

Light exposure system and light exposure process

ActiveUS20140368748A1Shorten the timeReduce manufacturing costPhotomechanical exposure apparatusMicrolithography exposure apparatusAssembly cellsLight exposure

A light exposure system executes a light exposure process to an assembly cell, which includes a first substrate, a second substrate and a liquid crystal layer disposed between the first and second substrates. The light exposure system comprises a transmission device, two moving stages and a light source module. The moving stages are disposed on the transmission device and at least one of the moving stages carries the assembly cell. The light source module includes at least a light emitting element. The transmission device moves at least one of the moving stages carrying the assembly cell or the light source module and the light emitting element emits the light to the assembly cell. A light exposure process applied to the light exposure system is also disclosed.

Owner:INNOLUX CORP

Rapid joint semi-automatic assembling line

InactiveCN111958236AGuaranteed normal processingAssembly machinesFluid-tightness measurement using fluid/vacuumCircular discAssembly cells

The invention relates to a rapid joint semi-automatic assembling line, and belongs to the technical field of medical machines. The rapid joint semi-automatic assembling line comprises a work panel. The work panel is supported by a supporting frame mechanism on the lower portion of the work panel. A rotating disc unit capable of achieving indexing rotating is arranged at the middle position of theupper end of the work panel, and a to-be-mounted product detection unit, a welding unit and a discharging and sorting unit are arranged on the rest of places. Six workpiece supports distributed in sixequal parts are arranged on the periphery of the rotating disc unit. A fixed disc is located over the rotating disc unit, and a first assembling unit, an airtightness detection unit and a second assembling unit are mounted and arranged on the fixed disc. A rotatable disc is made to reasonably rotate in a six-equal-part indexing manner through a cam divider, and the machining precision of six stations is guaranteed.

Owner:ZHEJIANG JUNHE RUBBER TECH

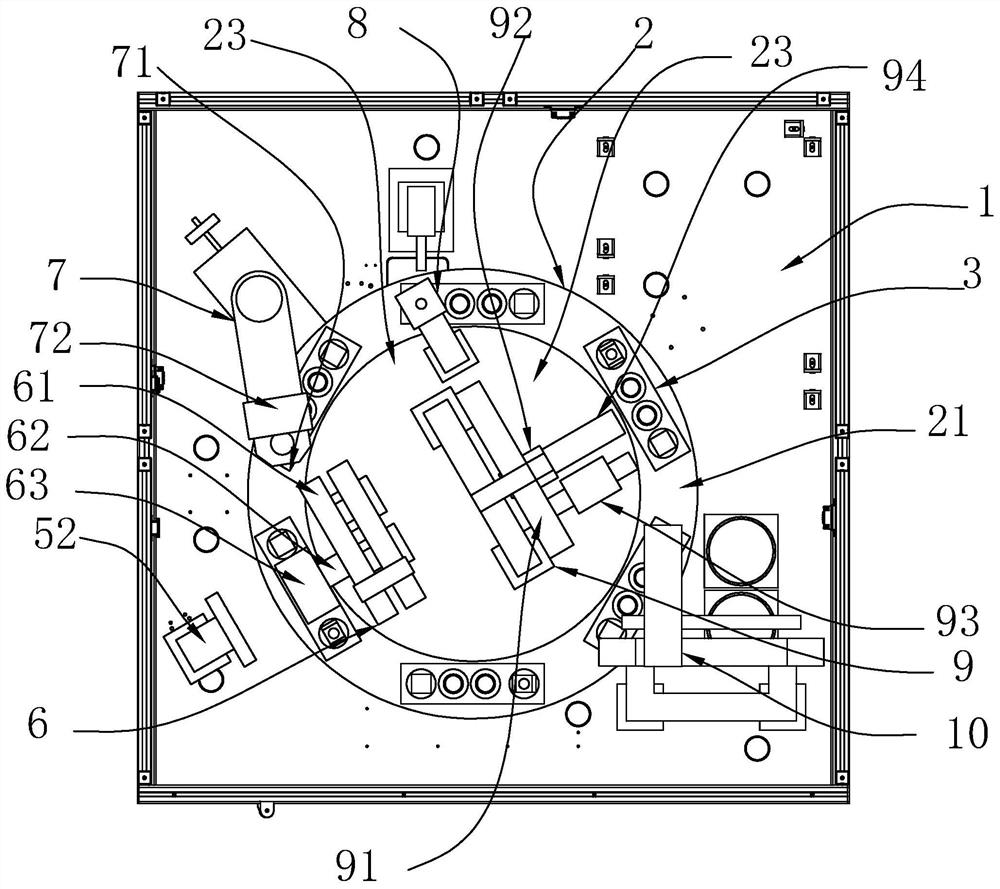

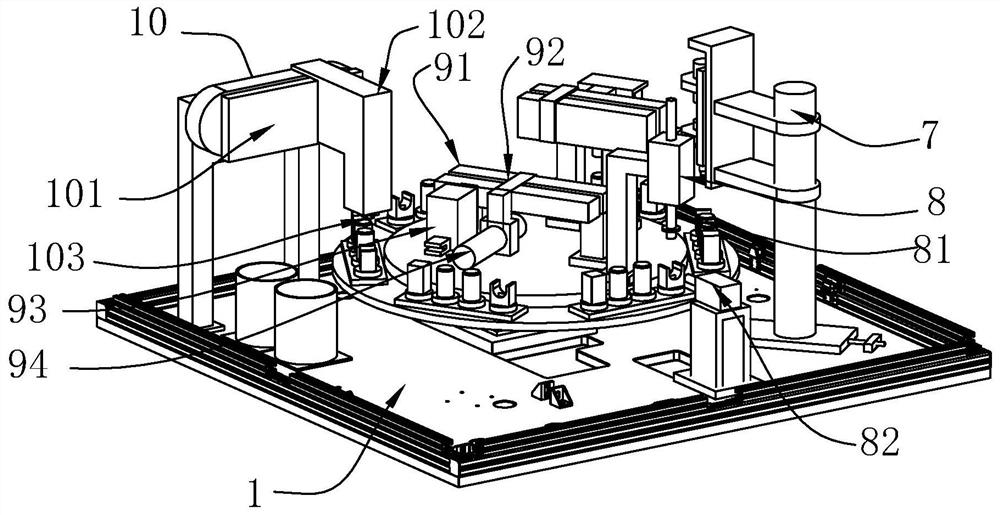

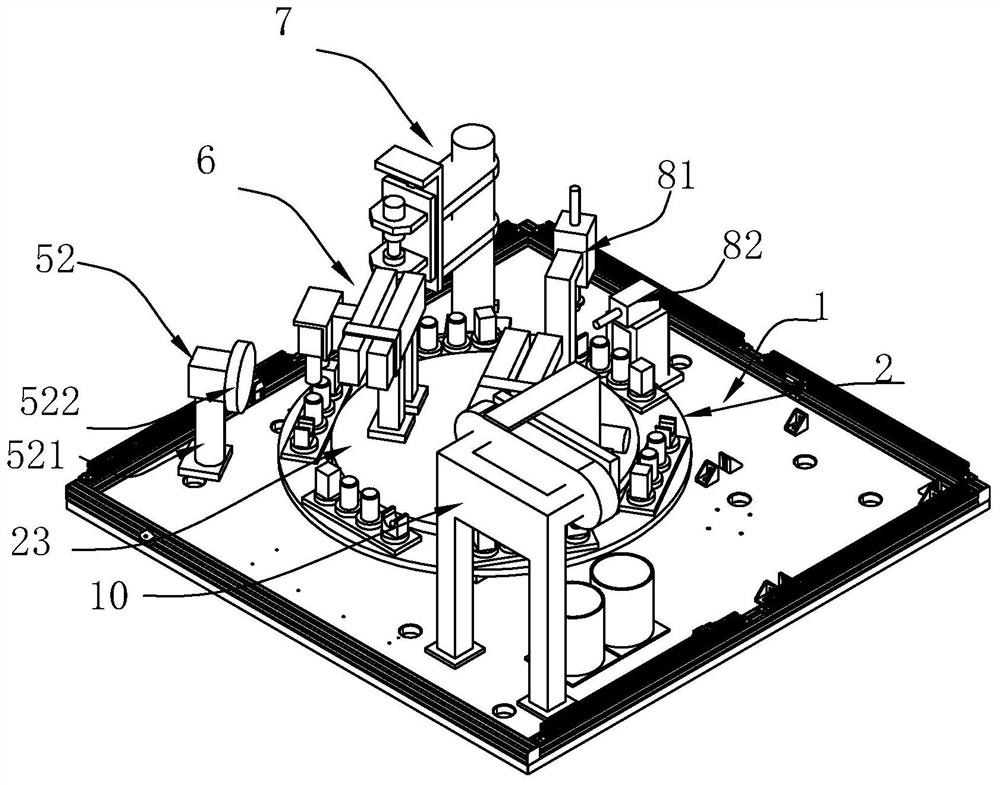

Automatic assembly device for piston rod sealing element

ActiveCN112077558AReduce distortionAvoid damageAssembly machinesMetal working apparatusAssembly cellsPiston rod

The invention relates to an automatic assembly device for a piston rod sealing element, comprising a first sealing element assembly unit, a second sealing element assembly unit, a third sealing element assembly unit, a servo rotating unit, a pneumatic jacking unit and a shaping unit. The servo rotating unit is arranged on the top side of the pneumatic jacking unit; the shaping unit is arranged onthe front left side of the top surface of the servo rotating unit; and the first sealing element assembly unit, the second sealing element assembly unit and the third sealing element assembly unit arearranged on the top surface of the servo rotating unit. The whole layout is high in automation degree; labor is completely released; the assembly efficiency is high; the assembly process is stable, reliable and safe; the layout is reasonable; a taper sleeve is adopted for sealing member assembly; the sealing member deformation is small; the stress concentration is avoided; the sealing member damage is small; the blocking sheet assembly is achieved; quick loading of sealing members can be achieved; the sleeve is elastically pressed; and the structure design is reasonable. In the process that asealing ring is pressed and pushed downwards along the taper sleeve, the sealing ring cannot distort and deform and is suitable for application and popularization.

Owner:SHANDONG ATAW IND ROBOT TECH

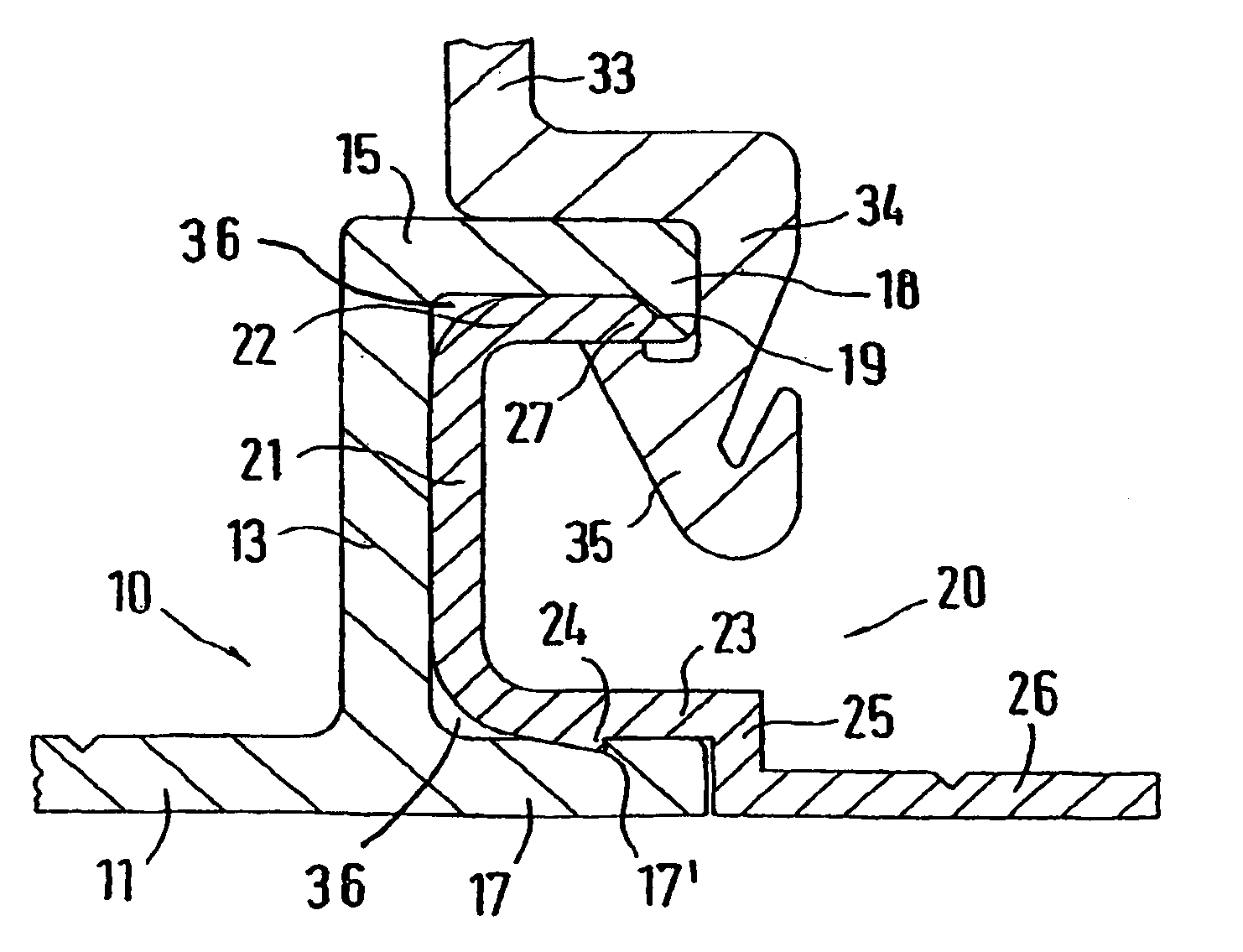

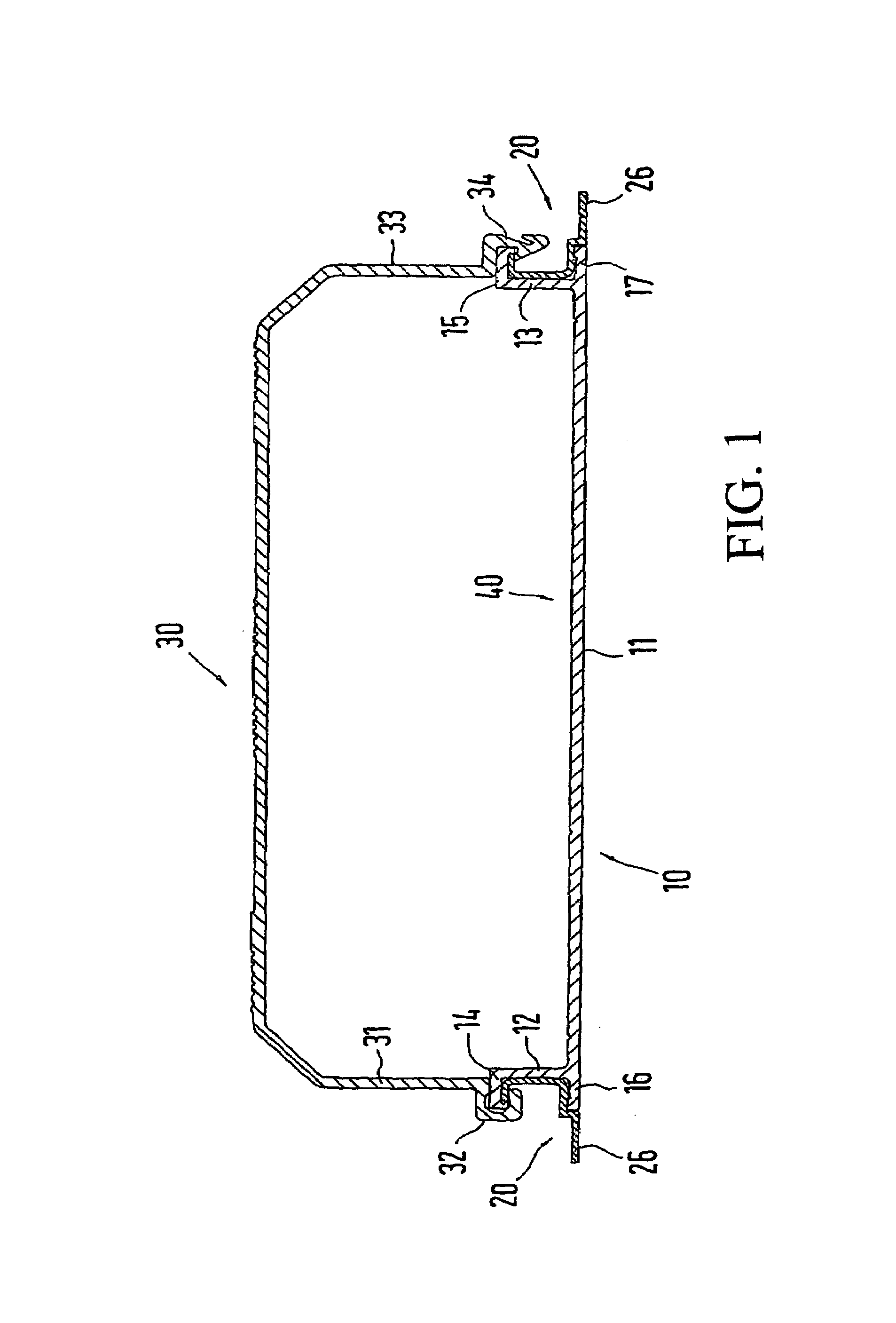

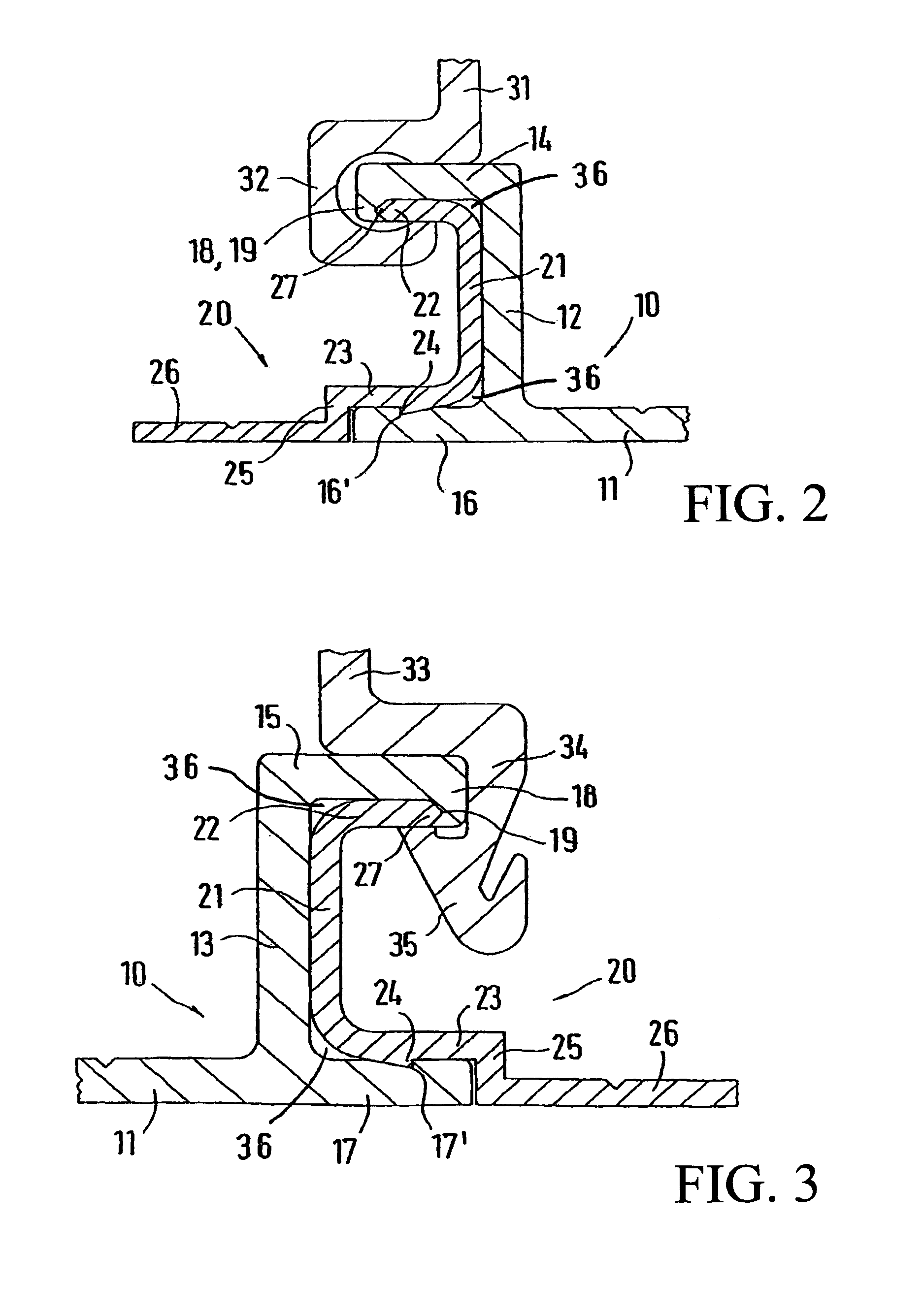

Bus bar system with assembly unit consisting of a base plate and fixing items

InactiveUS7638711B2Reduce manufacturing costEasy to assembleNon-enclosed substationsCouplings bases/casesEngineeringFunctional requirement

A bus bar system with an assembly unit having a base plate with side limbs and fixing items which are connected to the assembly unit. The assembly unit forms a receiving element for a bus bar holder and bus bars which are covered with cover elements and / or adapters for peripheral devices. The covers and / or adapters are mechanically connected to the bus bars by plug-in receiving elements and / or locking receiving elements and the adapters are also electrically connected to the bus bars. An assembly unit, which can be produced and mounted at low cost without impeding functional requirements, is provided and the assembly unit forms locking receiving elements together with retaining flanges, which protrude at a distance on the outer sides of the side limbs, and fixing flanges, wherein bar-shaped fixing items can be inserted into and / or locked inside the receiving elements. The plug-in and / or locking receiving elements of the covers and / or adapters receive the retaining flanges and the connected side limbs of the bar-shaped fixing items.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Container assembly method, container assembling apparatus and setting method thereof

The invention discloses a container assembling method and a container assembling apparatus. The method comprises the following steps: an assembling unit is arranged; a chassis conveying unit is arranged at the manufacturing upstream side of the assembling unit; a first hoisting unit is arranged above the assembling unit; the chassis conveying unit is adopted to convey the chassis to a preset position in the assembling unit; the first hoisting unit is adopted to convey two side plates to the preset position in the assembling unit; a front end and a door end are respectively conveyed to the preset position in the assembling unit; a top plate is conveyed to the preset position in the assembling unit; the assembling process is carried out in the assembling unit to form an integrated container. By adopting the method, the side plates can be conveyed to the assembling unit without passing through the main channel of the manufacturing plant, thus enhancing the safety of container manufacturing.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Assembly system for thin parts

PendingCN113120581ALayout stitching and changesHave diversityAssembly machinesOther manufacturing equipments/toolsVisual inspectionAssembly cells

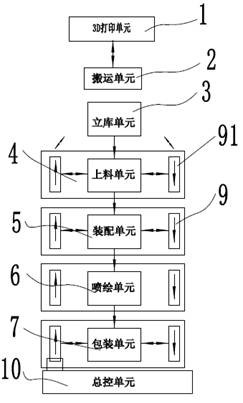

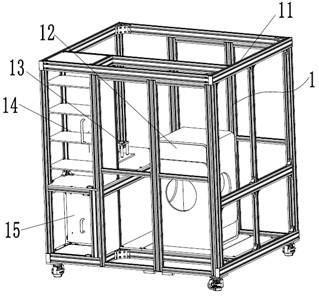

The invention discloses an assembly system for thin parts. The assembly system comprises a 3D printing unit, a carrying unit, a three-dimensional warehouse unit, a feeding unit, an assembling unit, a spray painting unit, a packaging unit and a master control unit, and the three-dimensional warehouse unit comprises a three-dimensional warehouse frame, a stacking machine and a butt joint mechanism; the feeding unit comprises a gantry carrying mechanism, two picking mechanisms, a gluing mechanism, a jacking mechanism, a visual inspection assembly module and two linear conveying lines; the assembling unit comprises a gantry carrying mechanism, a robot, a movable assembling table, a screw driving mechanism and two linear conveying lines; the spray painting unit comprises a transfer robot assembly, a detection table, an overturning table, spray painting equipment, a lifting and pushing mechanism and two linear conveying lines; the packaging unit comprises a butt joint table, a gantry carrying mechanism, a spider hand robot, a material transferring mechanism and two linear conveying lines; and the linear conveying lines on all the units sequentially communicate with one another. The assembly system is formed by a plurality of independent units which are convenient to assemble or disassemble, and is convenient to use and high in automation degree.

Owner:YALONG INTELLIGENT EQUIP GRP CO LTD

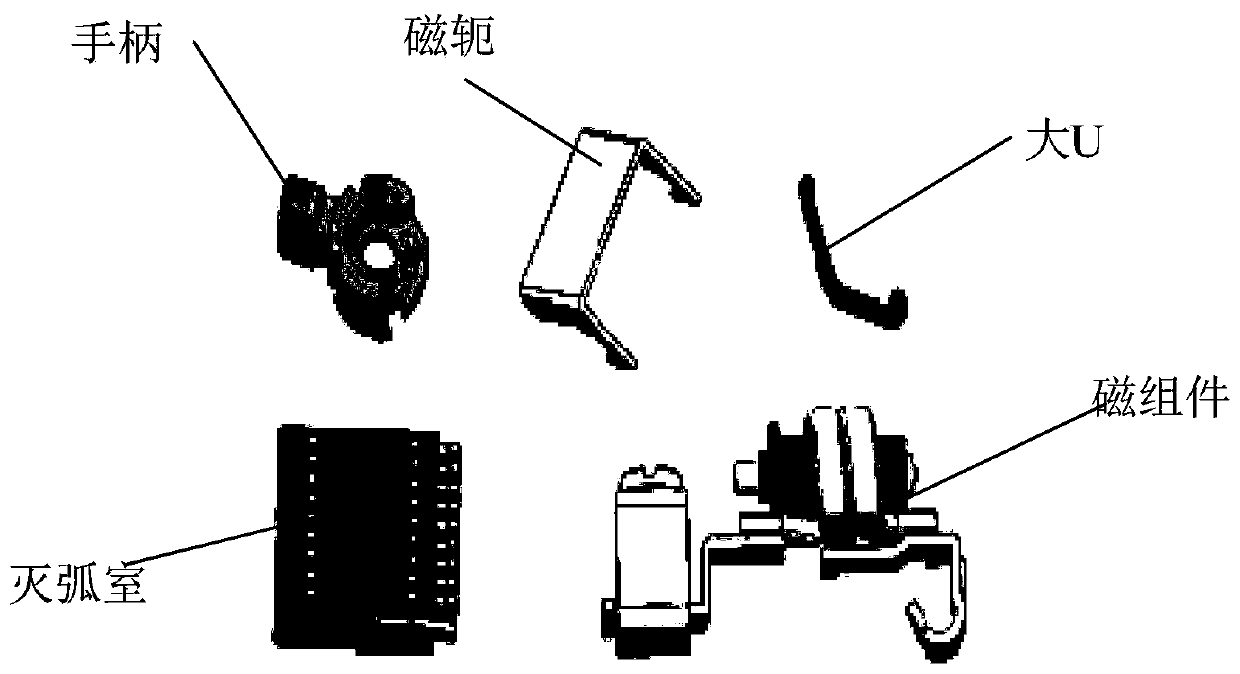

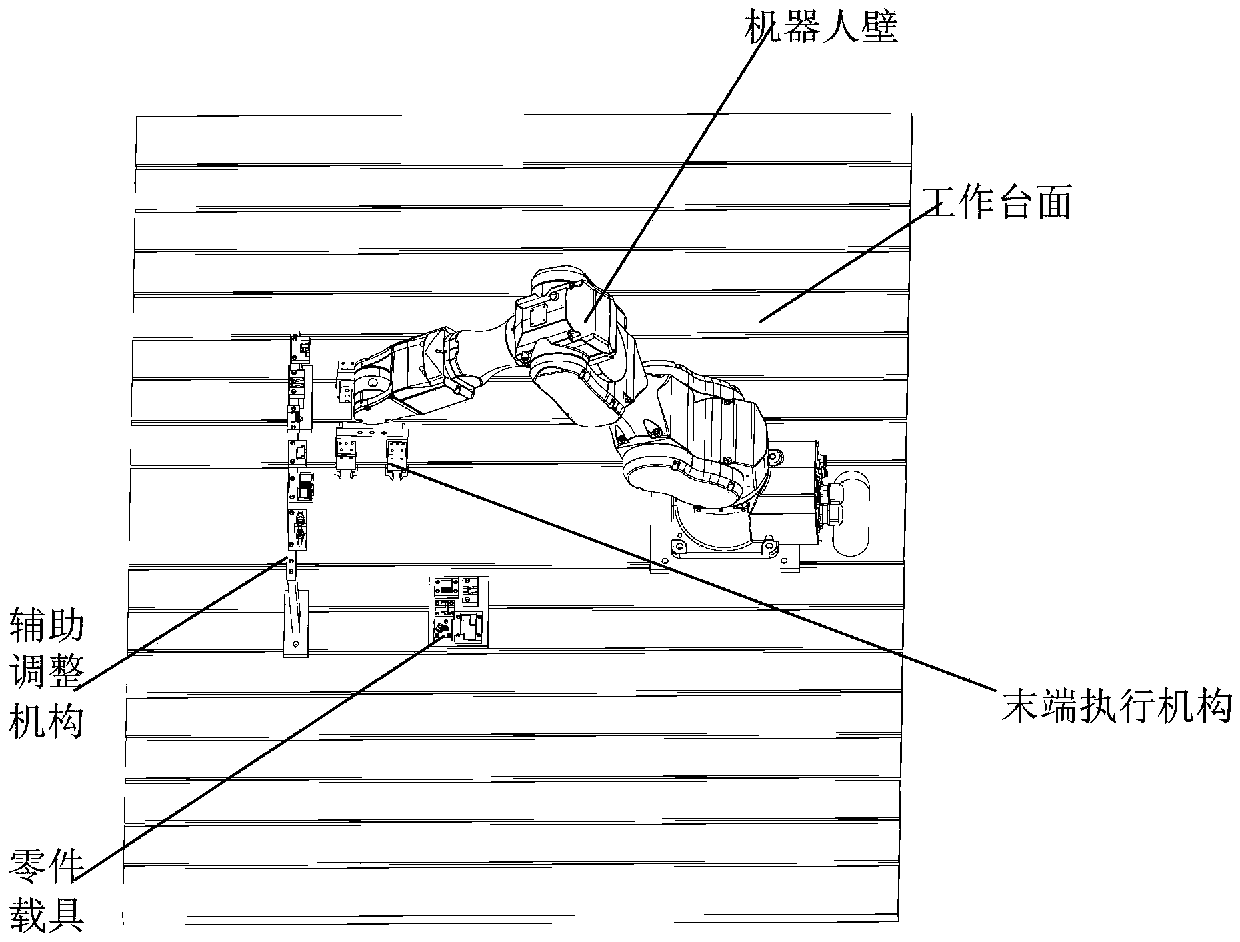

Circuit breaker flexible automatic assembly manufacturing process and matched production line thereof

ActiveCN111161981ASimple processReduce processEmergency protective device manufactureProduction lineAssembly cells

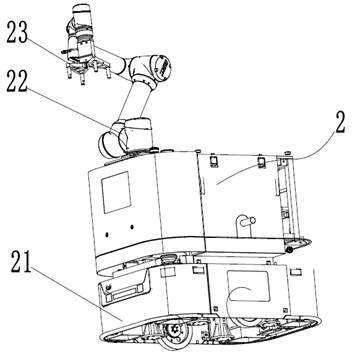

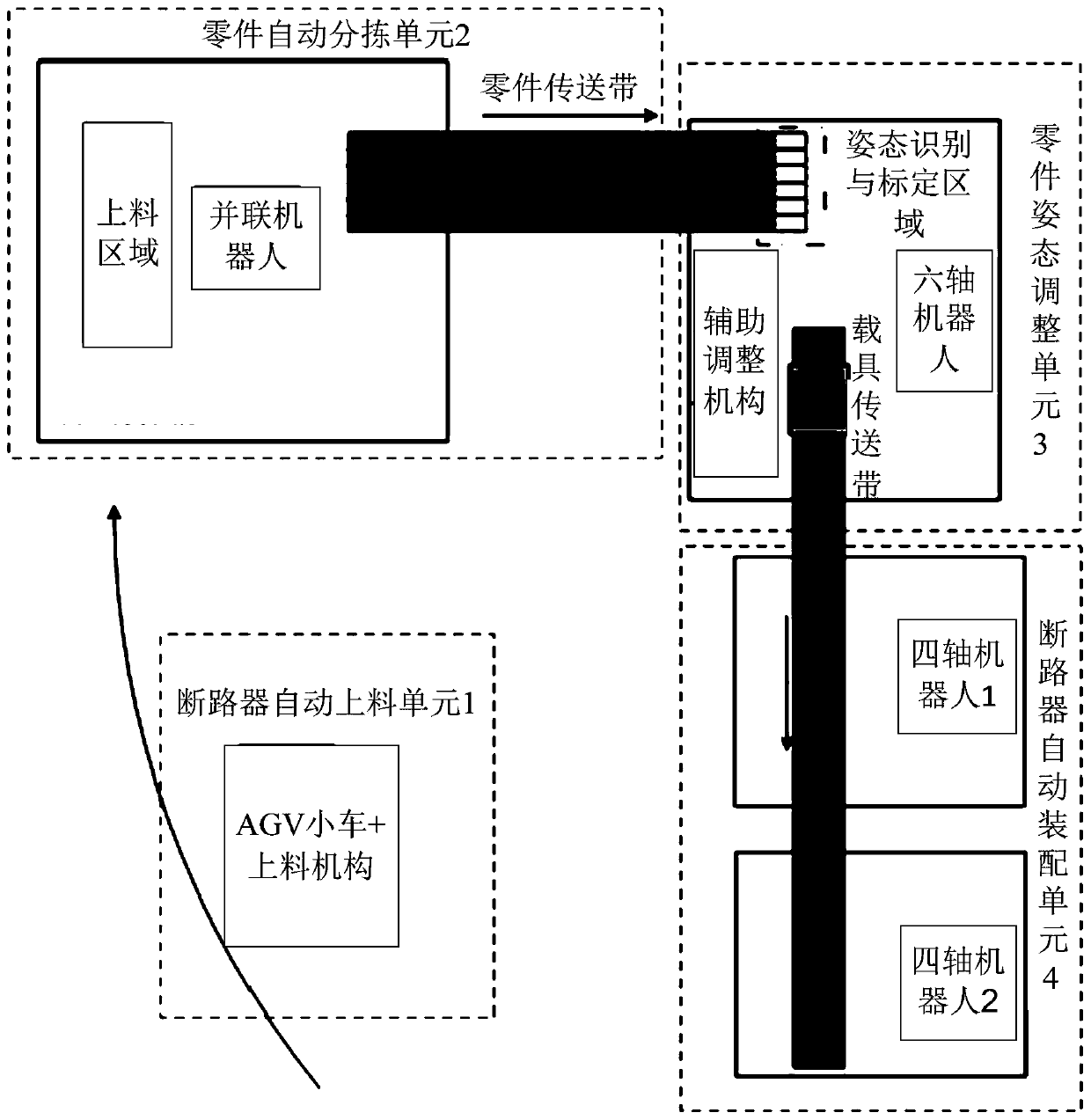

The invention provides a circuit breaker flexible automatic assembly manufacturing process and a matched production line thereof. The manufacturing process and the matched production line comprise a circuit breaker automatic feeding unit, a part automatic sorting unit, a part posture adjusting unit and a circuit breaker automatic assembly unit. The circuit breaker automatic feeding unit conveys various to-be-assembled parts through an AGV and places the parts in a feeding area in cooperation with a feeding mechanism, the part automatic sorting unit performs category sorting through a parallelrobot and puts the sorted parts into a part conveying belt to be conveyed in different grooves, in a posture recognition and calibration area, the part posture adjusting unit randomly clamps all to-be-assembled parts through a six-axis robot, automatically adjusts or is matched with an auxiliary adjusting mechanism to adjust the target postures of the parts needed by assembly, and then places theparts into a designated carrier tray, and the circuit breaker automatic assembly unit assembles a complete circuit breaker product through each four-axis robot. By implementing the invention, the rigid production problem existing in the existing circuit breaker assembling and manufacturing is solved, the manufacturing process is suitable for the automatic assembling production of products of different specifications, and benefits are increased and loads are reduced for enterprises.

Owner:WENZHOU UNIVERSITY

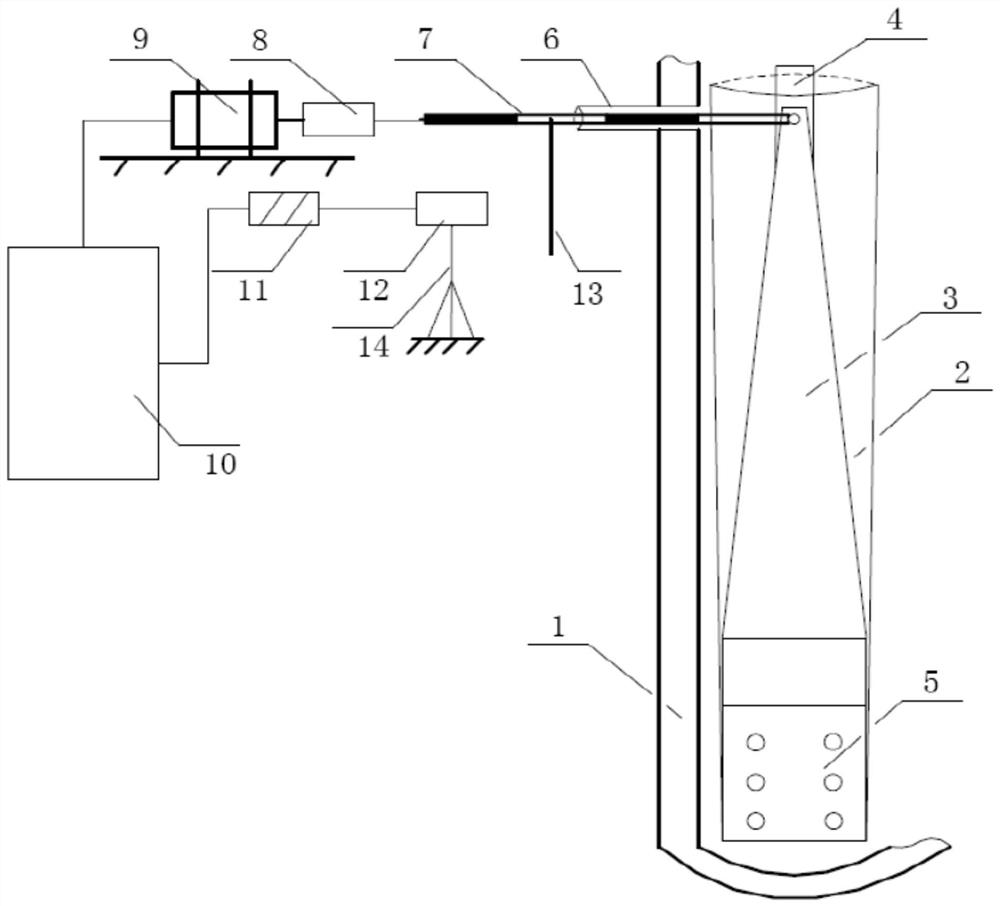

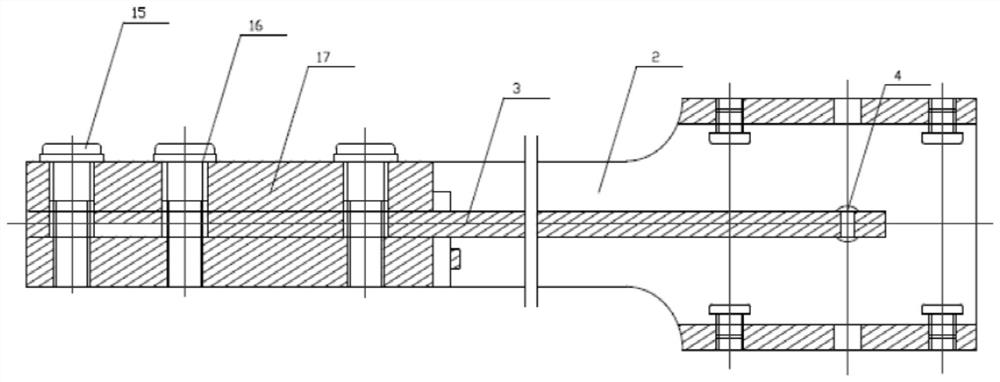

Displacement loading system applied to strain calibration device

ActiveCN111678799AGuaranteed accuracyRealize displacement loadingMaterial strength using tensile/compressive forcesElectric machineryAssembly cells

The invention discloses a displacement loading system applied to a strain calibration device. The system comprises a strain assembly unit, a displacement loading unit and a displacement control unit,wherein the strain assembling unit comprises a supporting cylinder, a calibration beam, a beam fixing piece and a beam centering piece, the displacement loading unit comprises a loading rod, a transmission mechanism, a high-precision stepping motor and a dynamic sealing piece, and the displacement control unit comprises a laser displacement sensor, a transmitter, a controller and an upper computer. The beam fixing piece and the beam centering piece are designed in the system. The vertical centering precision of calibration beam installation is ensured, the designed dynamic sealing piece can achieve displacement loading under high temperature and high pressure, the adopted high-precision stepping motor carries out displacement loading and real-time measurement and feedback control of the laser displacement sensor, and accurate displacement loading of the calibration device under the working conditions of high temperature and high pressure can be achieved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Methods for assembling a cartridge for an aerosol delivery device, and associated systems and apparatuses

Owner:RAI STRATEGIC HLDG INC

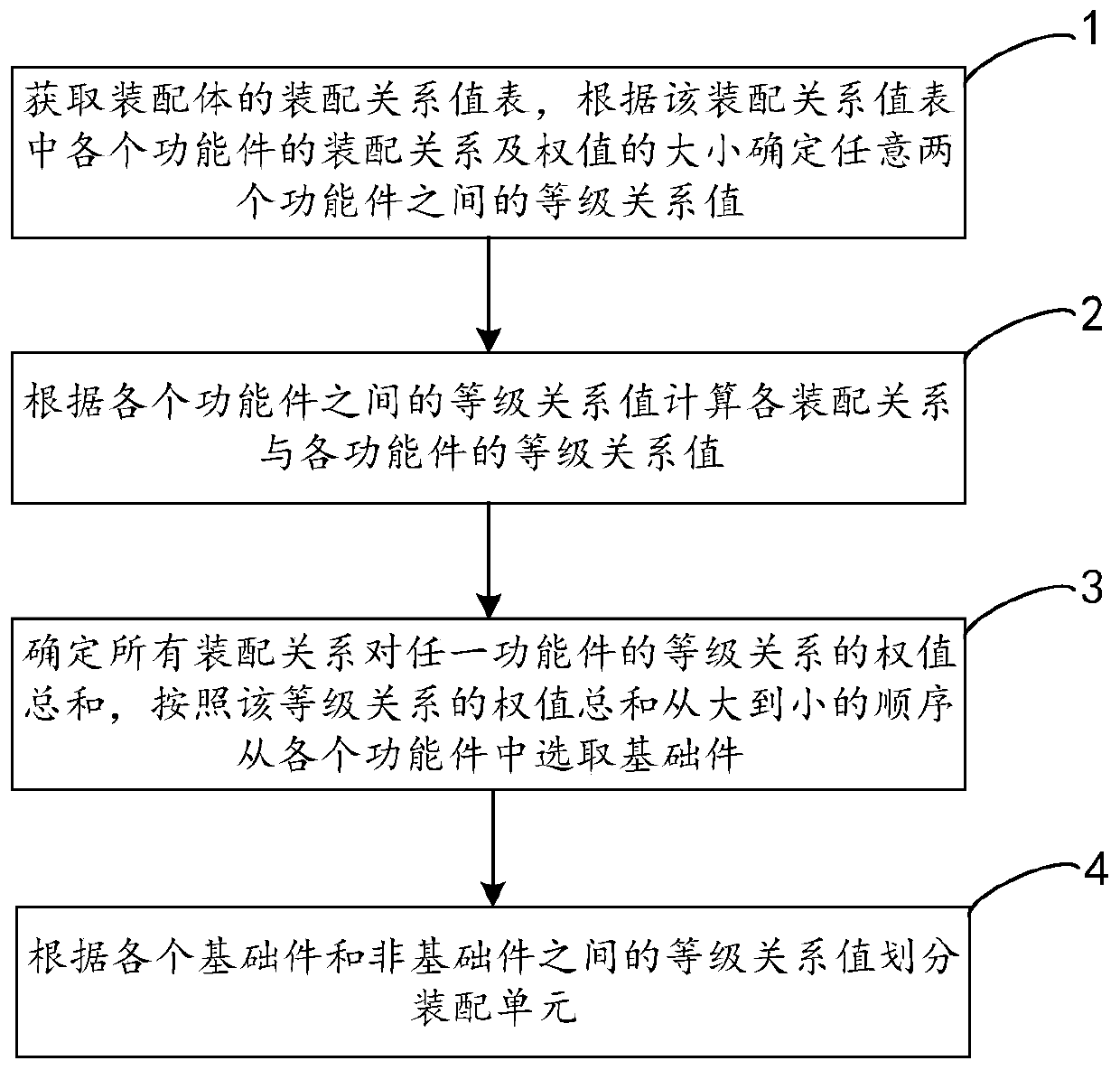

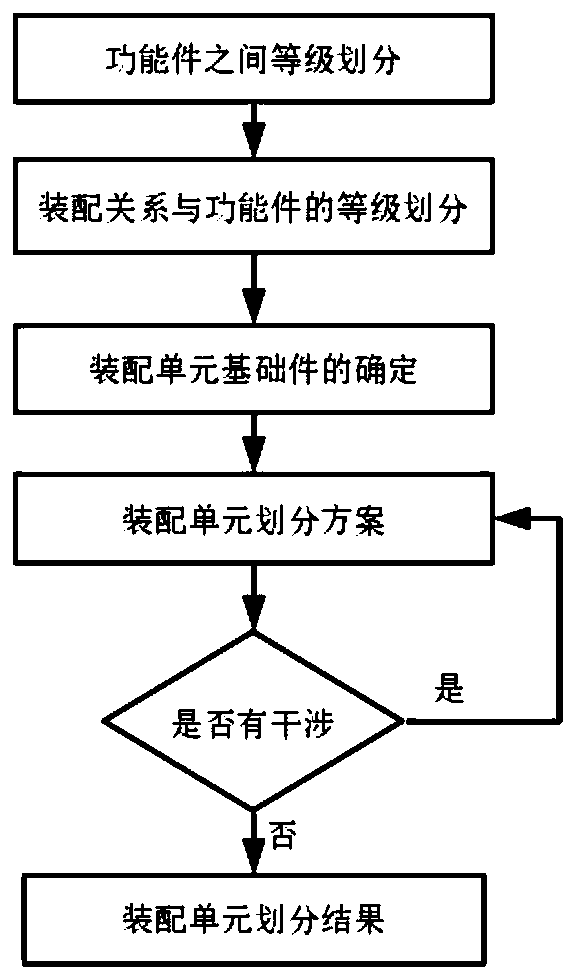

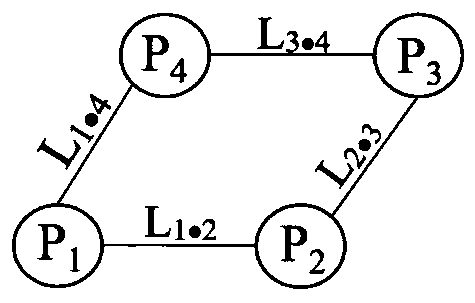

Assembly unit division method based on assembly relationship grading

ActiveCN110889173AEasy to implementHigh feasibilityGeometric CADManufacturing computing systemsGraphicsAssembly cells

The invention discloses an assembly unit division method based on assembly relation grading, and the method comprises the steps: 1, obtaining an assembly relation value table of an assembly body, anddetermining a grade relation value between any two functional parts according to the assembly relation of all functional parts and the values; 2, calculating a grade relationship value of each assembly relationship and each functional part according to the grade relationship value of each functional part; 3, determining the sum of the weights of all the assembly relations to the grade relation ofany functional part, and selecting basic parts from all the functional parts from large to small according to the sum of the weights of the grade relation; and 4, dividing the assembly units accordingto the grade relationship values between the basic parts and the non-basic parts. The division method is simple to implement and high in feasibility; the applicability is high, and functional parts of different assembling bodies can be divided into assembling units through the method; conversion of brawling graph structural features is not needed, conversion into computer language is easy, and the automation degree is high.

Owner:LIUZHOU WULING MOTORS +1

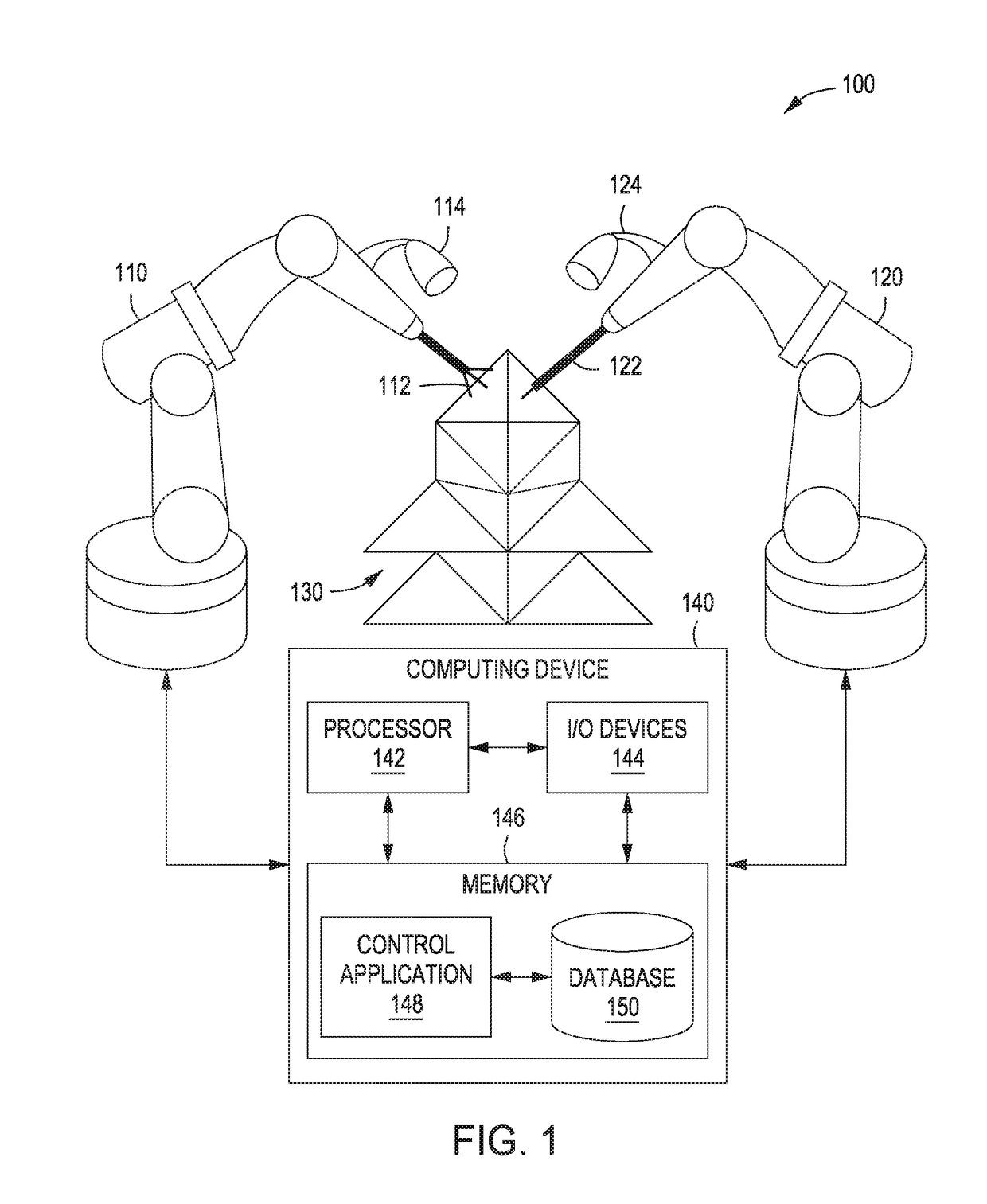

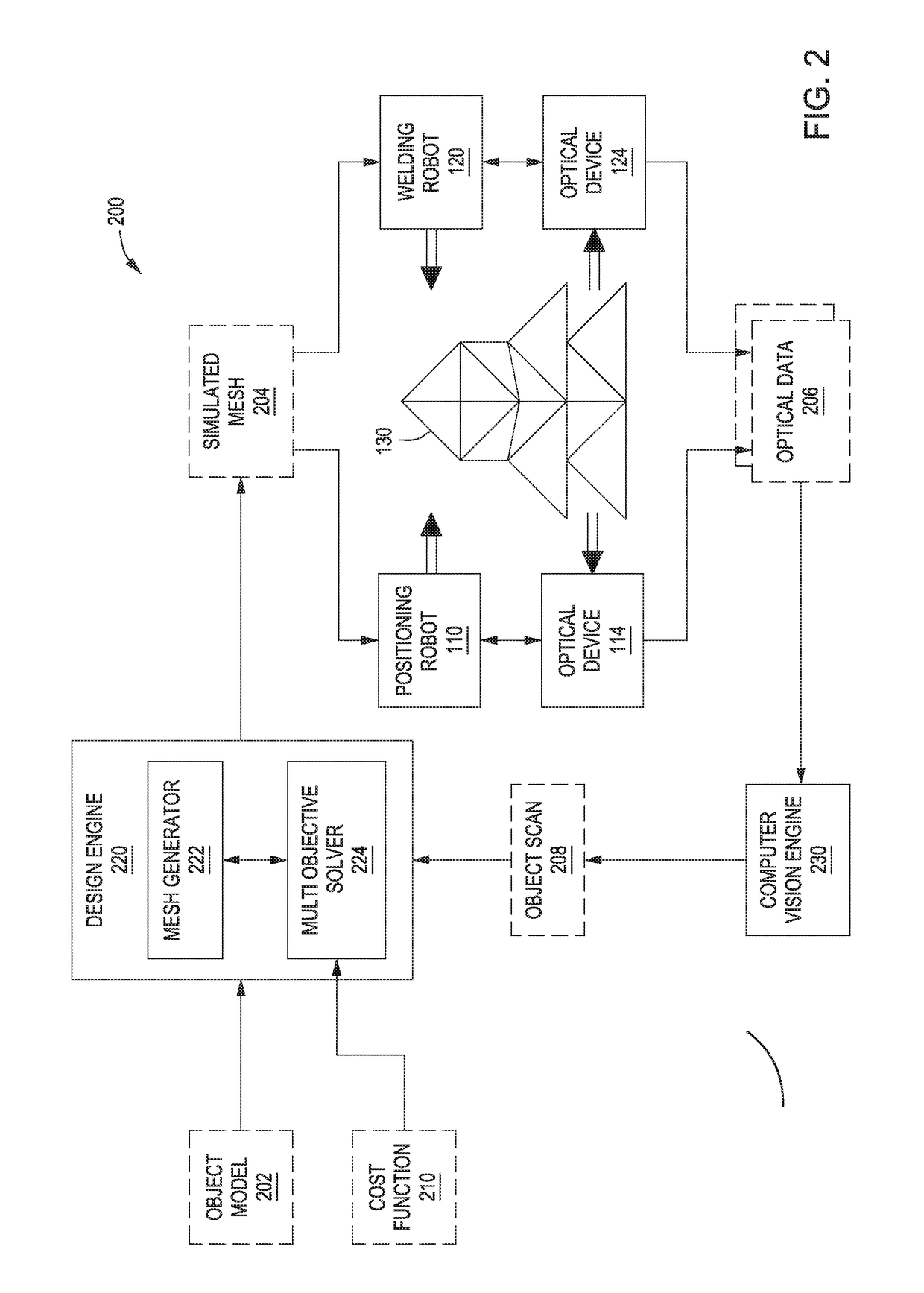

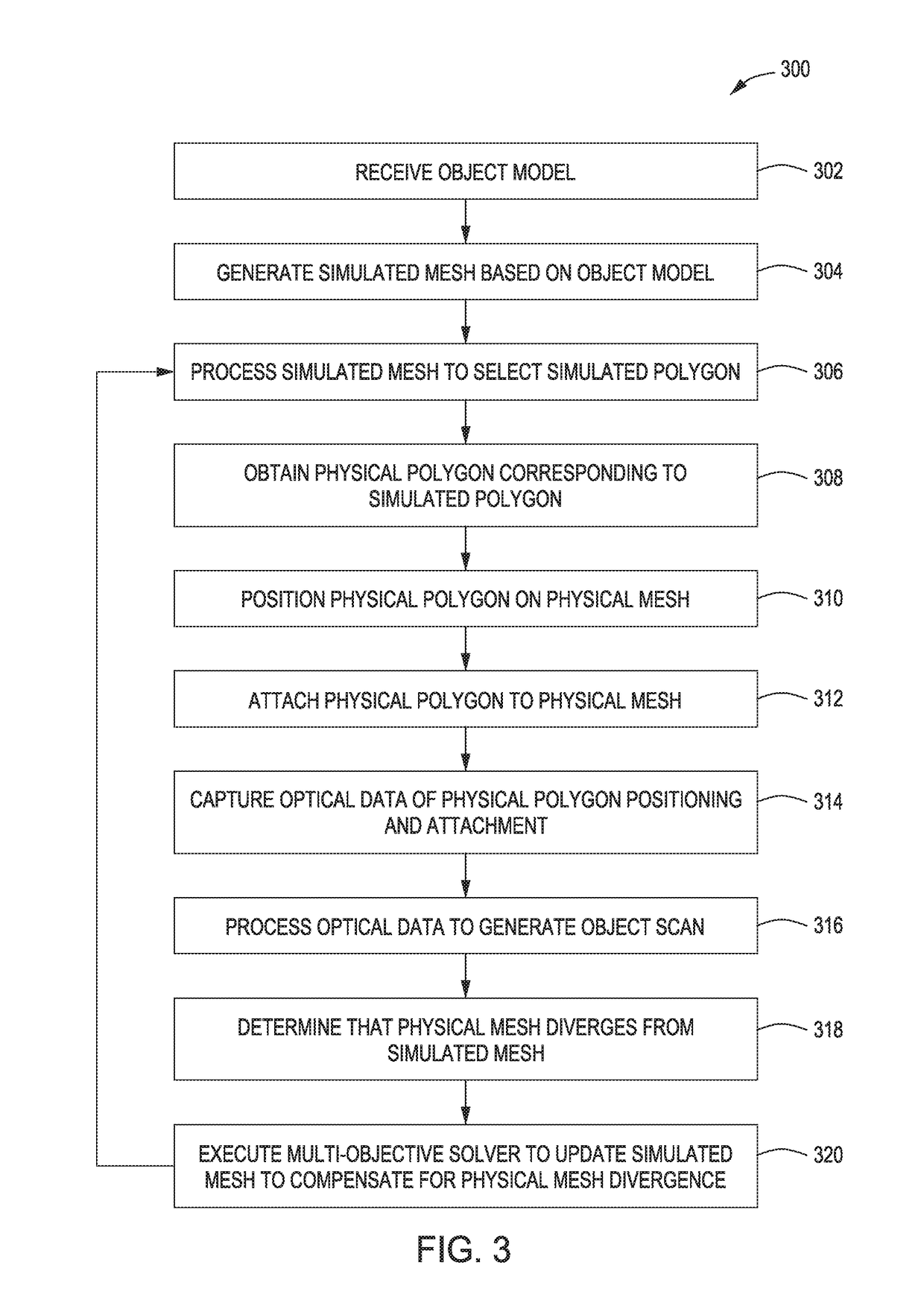

Robotic assembly of a mesh surface

ActiveUS20180341730A1Programme controlProgramme-controlled manipulatorAssembly cellsSimulation based

A robotic assembly cell is configured to generate a physical mesh of physical polygons based on a simulated mesh of simulated triangles. A control application configured to operate the assembly cell selects a simulated polygon in the simulated mesh and then causes a positioning robot in the cell to obtain a physical polygon that is similar to the simulated polygon. The positioning robot positions the polygon on the physical mesh, and a welding robot in the cell then welds the polygon to the mesh. The control application captures data that reflects how the physical polygon is actually positioned on the physical mesh, and then updates the simulated mesh to be geometrically consistent with the physical mesh. In doing so, the control application may execute a multi-objective solver to generate an updated simulated mesh that meets specific design criteria.

Owner:AUTODESK INC

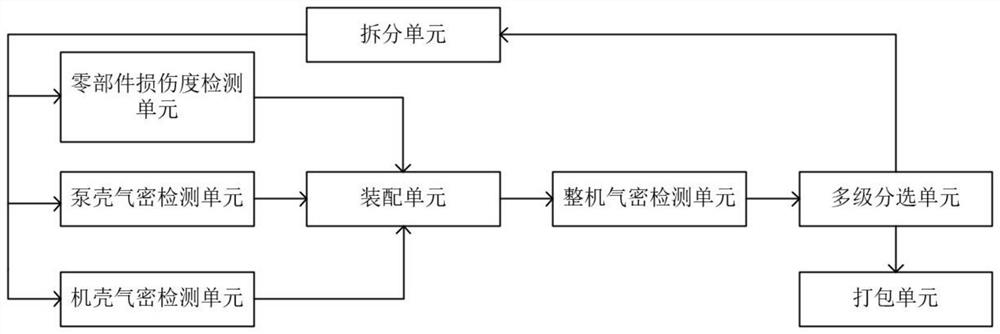

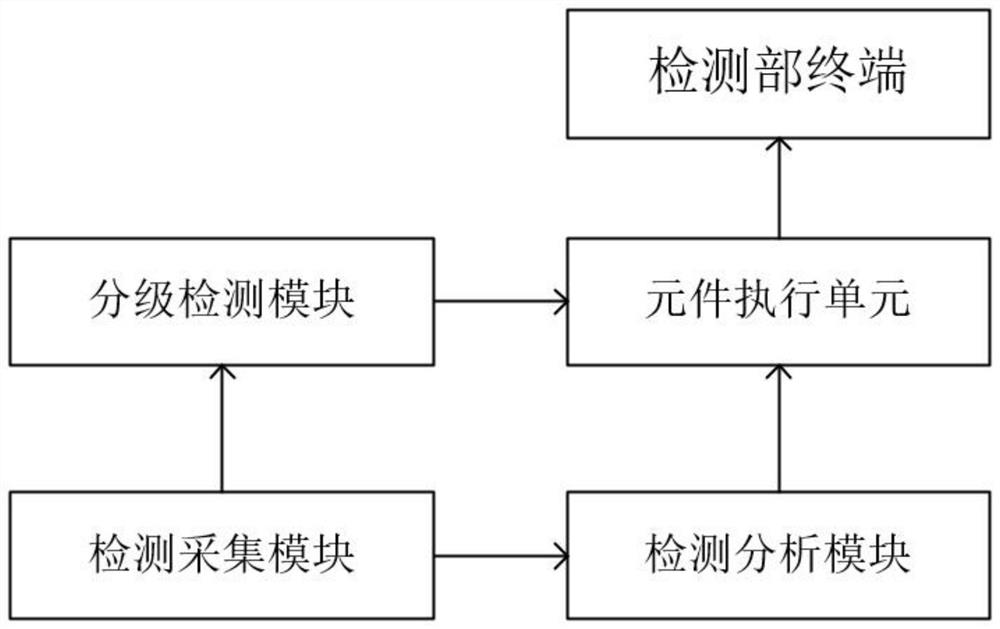

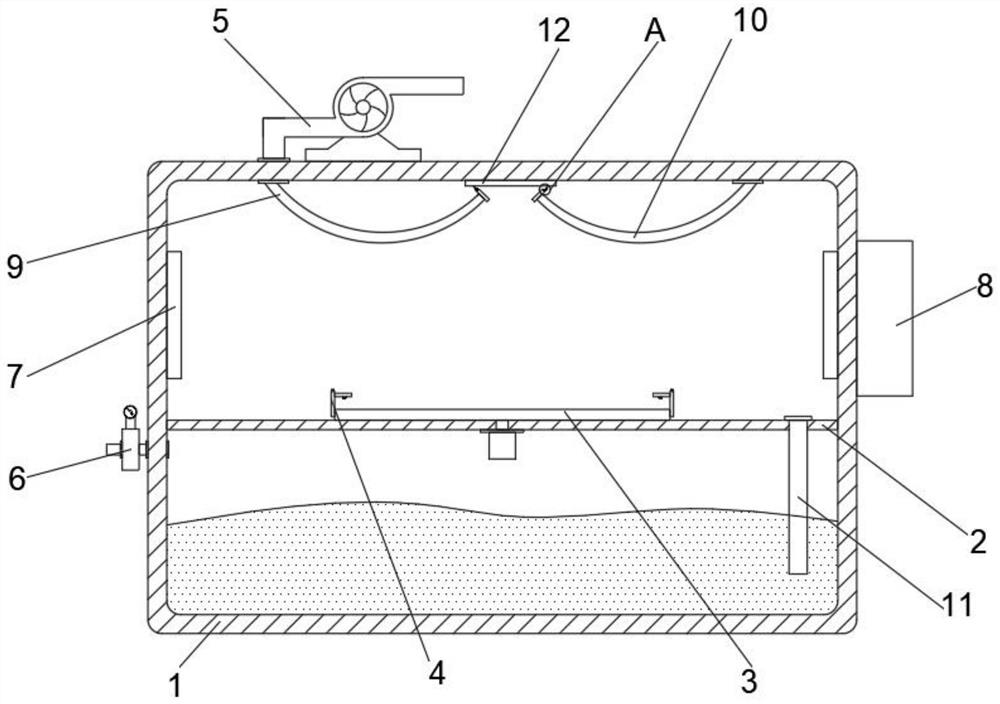

Air tightness detection device for industrial drainage pump and detection method thereof

PendingCN114112231AReduce wear and tearEasy maintenance and correctionPump testingMeasurement of fluid loss/gain rateAir pumpAssembly cells

The invention discloses an air tightness detection device for an industrial draining pump and a detection method thereof, and relates to the technical field of air tightness detection devices, in particular to the technical field of cooperative production of draining pumps and air tightness detection. Comprising a part damage degree detection unit, a pump shell airtightness detection unit, a machine shell airtightness detection unit, an assembling unit, a whole machine airtightness detection unit, a multi-stage sorting unit, a splitting unit, a detection acquisition module and a detection analysis module. According to the invention, the integrated working process of airtightness detection, multistage screening, assembly, part recycling and packaging in the exhaust pump production process is realized, so that the quality of factory products of enterprises is improved, the loss of parts is reduced, the airtightness is detected more accurately through multiple times of detection and screening, and the production efficiency is improved. And through collection, operation, calculation and comparison of information in the exhaust pump production and detection integrated process, a manufacturing part comprehensive rectification text is generated, the part loss in the production process is reduced, and the production efficiency is improved.

Owner:ANHUI JINWAN PUMP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com