Automatic assembly device for piston rod sealing element

An automatic assembly and sealing technology, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of high labor intensity for operators, unguaranteed product quality, and easy scratching of sealing rings, etc. Stable and reliable, small deformation, high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

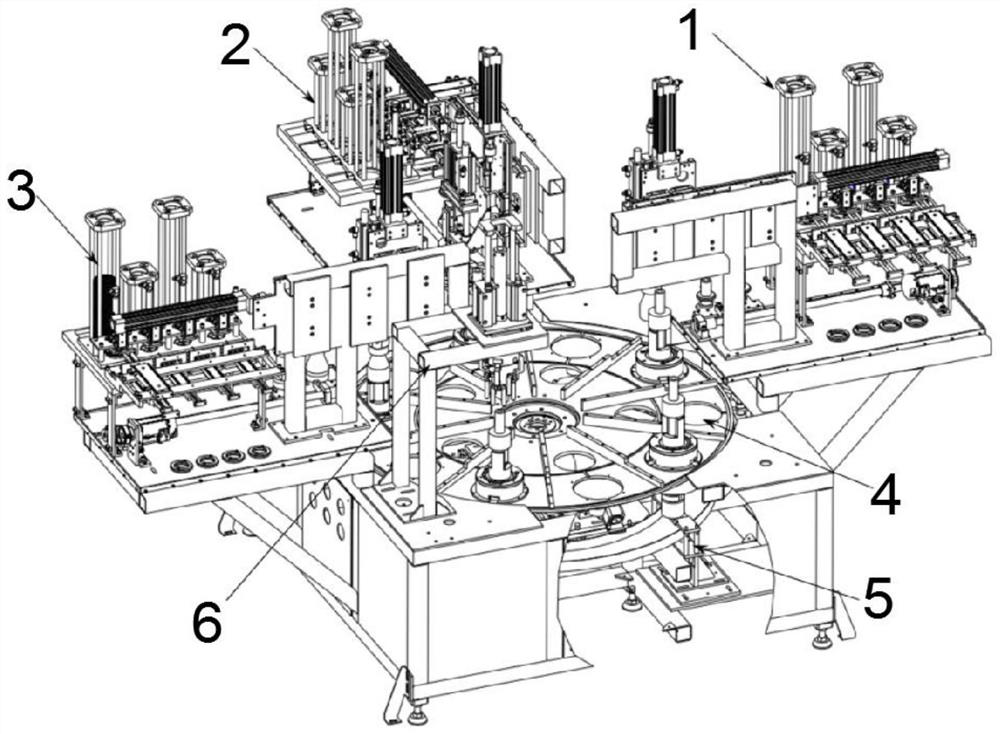

[0034] An automatic assembly equipment for piston rod seals, comprising seal assembly unit one 1, seal assembly unit two 2, seal assembly unit three 3, servo rotation unit 4, pneumatic jacking unit 5, and shaping unit 6, the servo The rotating unit 4 is arranged on the top side of the pneumatic jacking unit 5, the shaping unit 6 is arranged on the left side of the top front of the servo rotating unit 4, and the seal assembly unit 1 is arranged on the top of the servo rotating unit 4. On the left side of the surface, the second seal assembly unit 2 is arranged on the rear side of the top surface of the servo rotation unit 4 , and the third seal assembly unit 3 is arranged on the right side of the top surface of the servo rotation unit 4 .

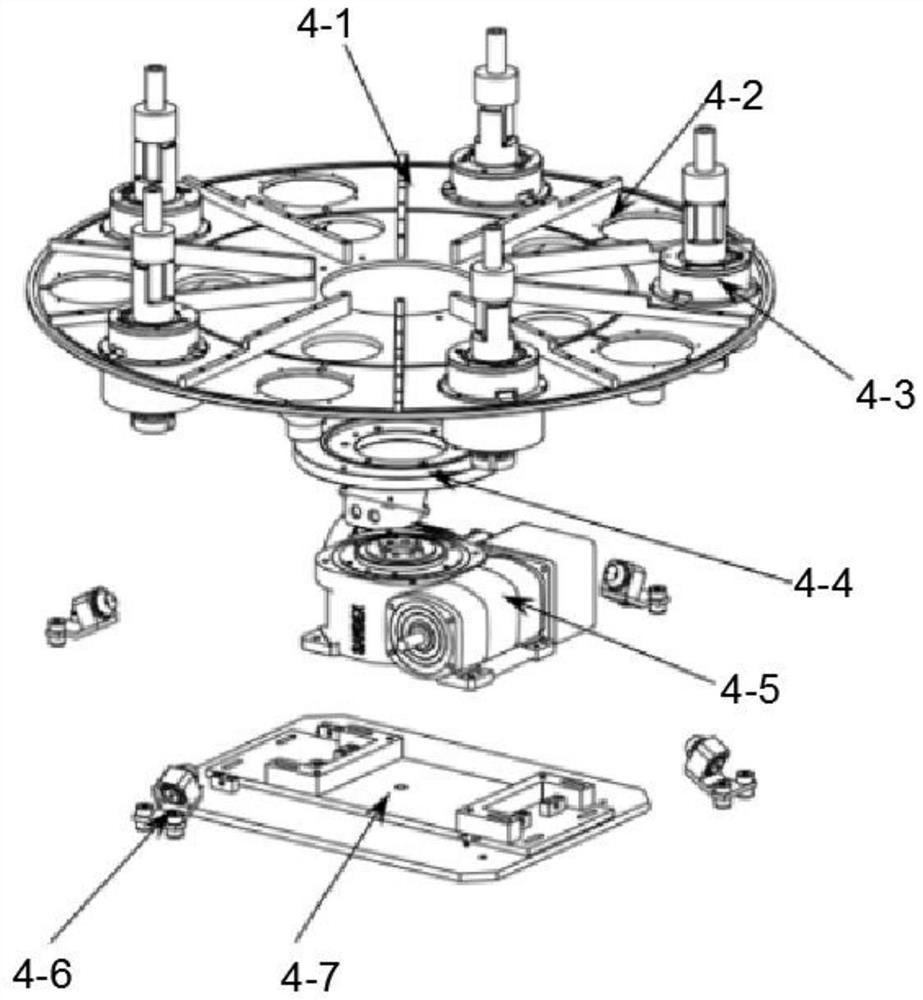

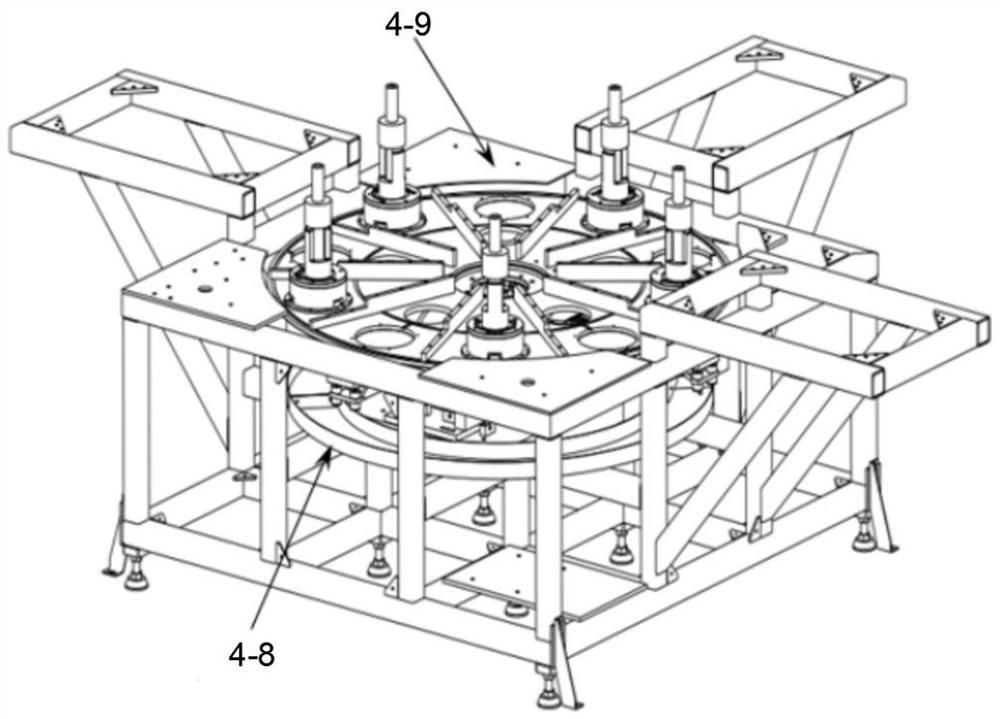

[0035] The servo rotation unit 4 is composed of a reinforcing rib 4-1, a rotary table 4-2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com