Container assembly method, container assembling apparatus and setting method thereof

An assembly device and assembly method technology, applied in packaging, transportation and packaging, containers, etc., can solve problems such as reducing production efficiency, threatening the life safety of operators, increasing container production costs, etc., to improve safety, safe and reliable storage space , the effect of improving production efficiency and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

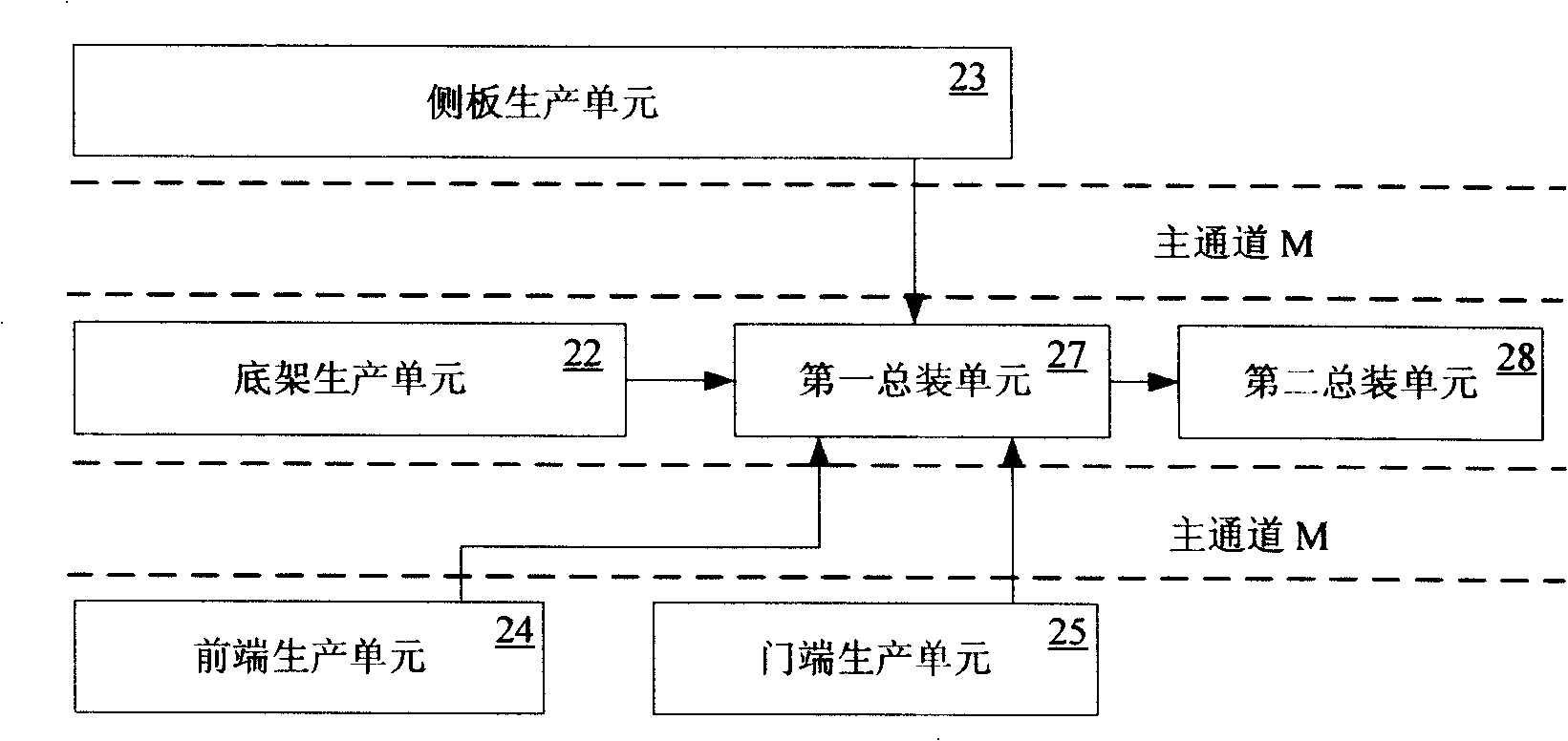

[0026] Optionally, each longitudinal conveying device is also provided with a lifting mechanism for lifting the corresponding longitudinal conveying device to avoid interference with the transverse conveying device.

[0027] Optionally, the underframe conveying unit includes four longitudinal conveying devices and two lateral conveying devices.

[0028] Optionally, the first lifting unit includes: a rail extending from the production upstream of the assembling unit to the assembling unit; and a sling set on the rail.

[0029] Optionally, the first lifting unit includes two rails that are parallel to each other and spaced a predetermined distance apart.

[0030] Optionally, a side panel storage unit is provided between the side panel processing unit and the assembling unit, and the side panel storage unit has at least one pair of storage spaces for storing processed side panels. The two tracks of the first lifting unit correspond.

[0031] Optionally, a conveyor belt for conveying the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com