Rapid joint semi-automatic assembling line

An assembly line, semi-automatic technology, applied in the direction of assembly machines, measuring devices, welding equipment, etc., can solve the problems of low work efficiency and achieve the effect of processing guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

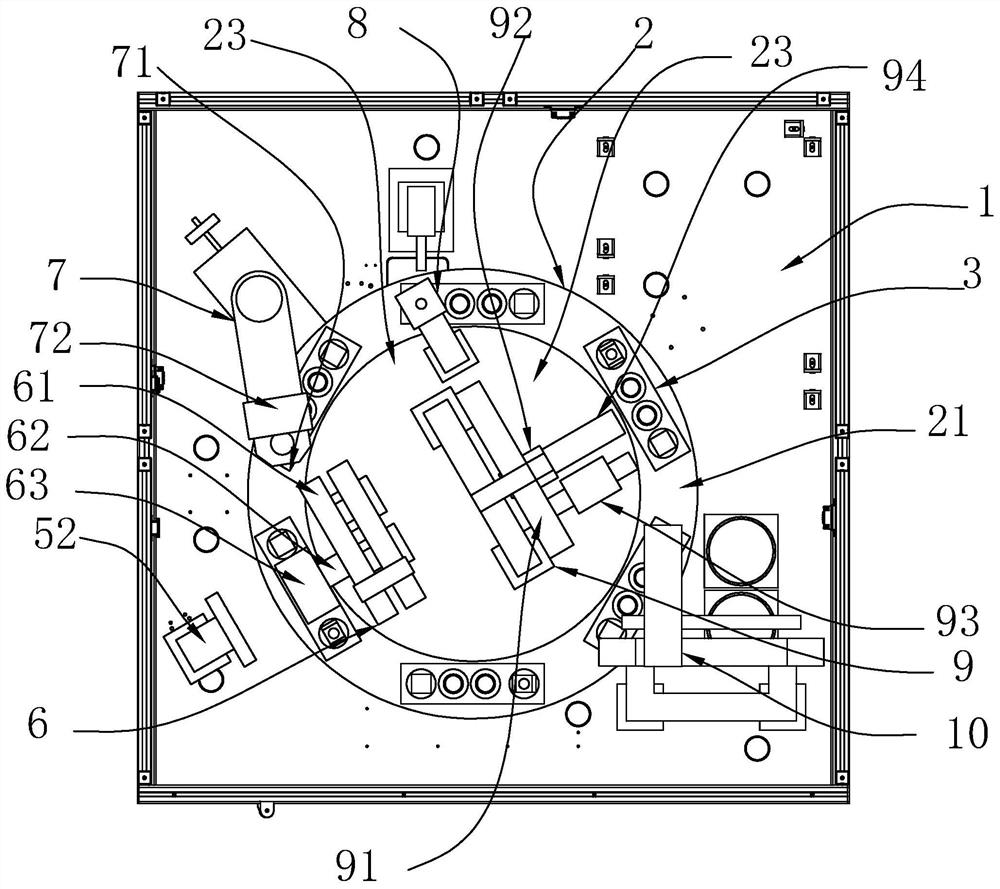

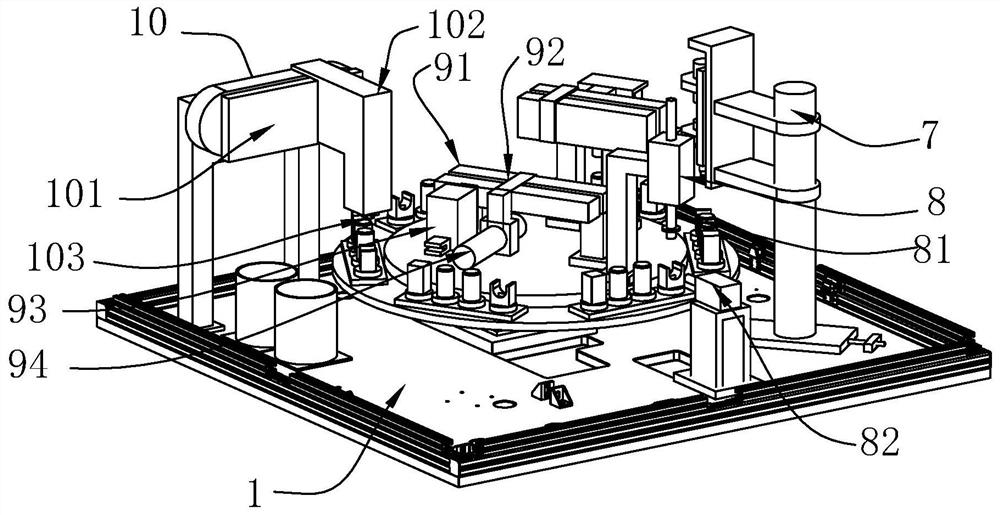

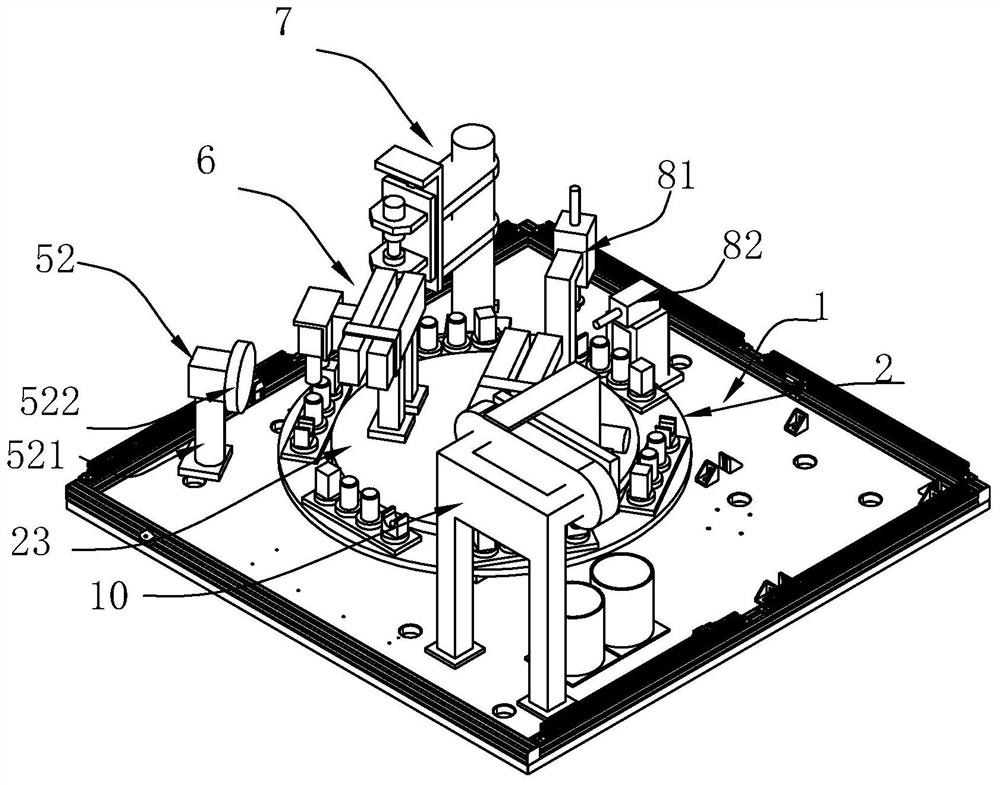

[0050] refer tofigure 1 , a semi-automatic assembly line for quick joints, including a work panel 1, which is supported by a support frame mechanism below it; a turntable unit 2 capable of indexing and rotating is provided at the middle position of the upper end of the work panel 1, and other places are provided with The product detection unit 5, the welding unit 7 and the blanking and sorting unit 10 are to be installed; the periphery of the turntable unit 2 is provided with six workpiece supports 3 of six equal parts, and the fixed disc 23 located directly above the turntable unit 2, The first assembly unit 6 , the air tightness detection unit 8 , and the second assembly unit 9 are installed on the fixed disk 23 .

[0051] refer to figure 1 and Figure 4 The turntable unit 2 includes a rotatable disk 21 and a rotating assembly 22 respectively supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com