Industrial robot teaching system

An industrial robot and teaching system technology, applied in the field of industrial robot teaching system, can solve the problems of simulated laser cutting, poor integrity and compactness, poor automation assembly precision, etc., and achieve high automation assembly precision, high structural integrity and compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

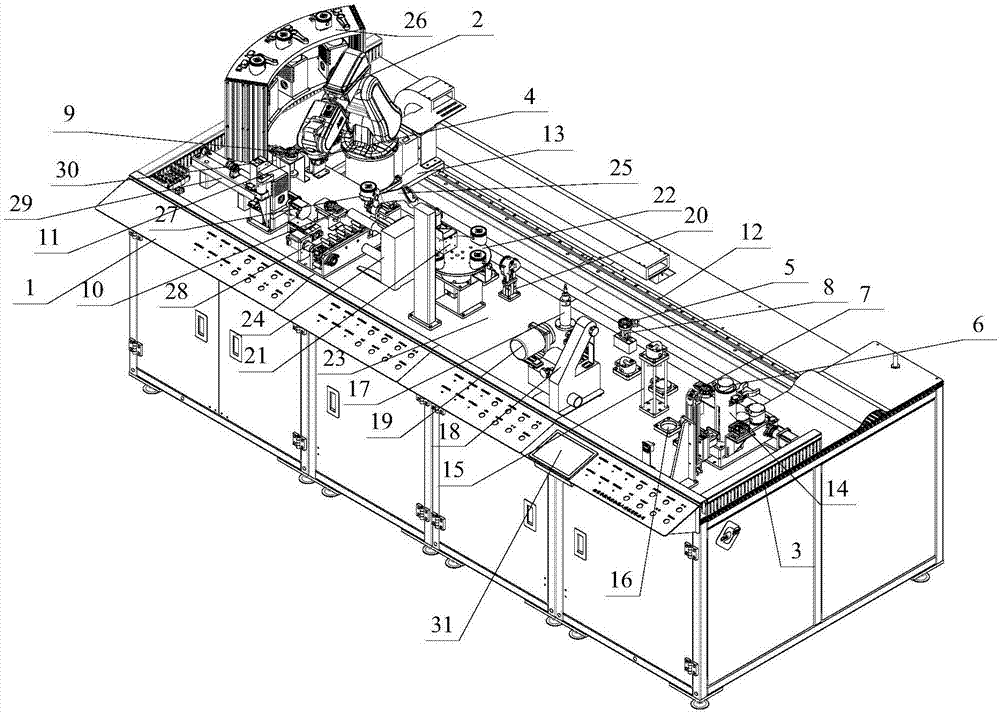

[0050] Embodiment 1 proposes a preferred industrial robot teaching system, such as figure 1As shown, the industrial robot teaching system includes a workbench 1 and an industrial robot teaching device. The workbench 1 is equipped with an industrial robot body 2, a piston feeding and rough machining unit, a piston finishing unit, a piston mechanism assembly unit, and an industrial robot control unit. Components such as device, robot body walking unit, tool quick change unit, piston vision detection unit, PLC controller and display unit. The industrial robot teaching pendant communicates with the industrial robot controller, and the industrial robot teaching pendant stores action commands of the industrial robot body 2 to indirectly control the motion of the industrial robot body 2 . The industrial robot controller is connected with the process robot body 2, and is used to control the industrial robot body 2 to complete action instructions. The industrial robot body 2 operates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com