One-component silicone conductive adhesive, and preparation method and application thereof

A technology of silicone and conductive adhesive, applied in the field of conductive adhesive, can solve problems such as inapplicability and failure, and achieve low interface resistance, low cost, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

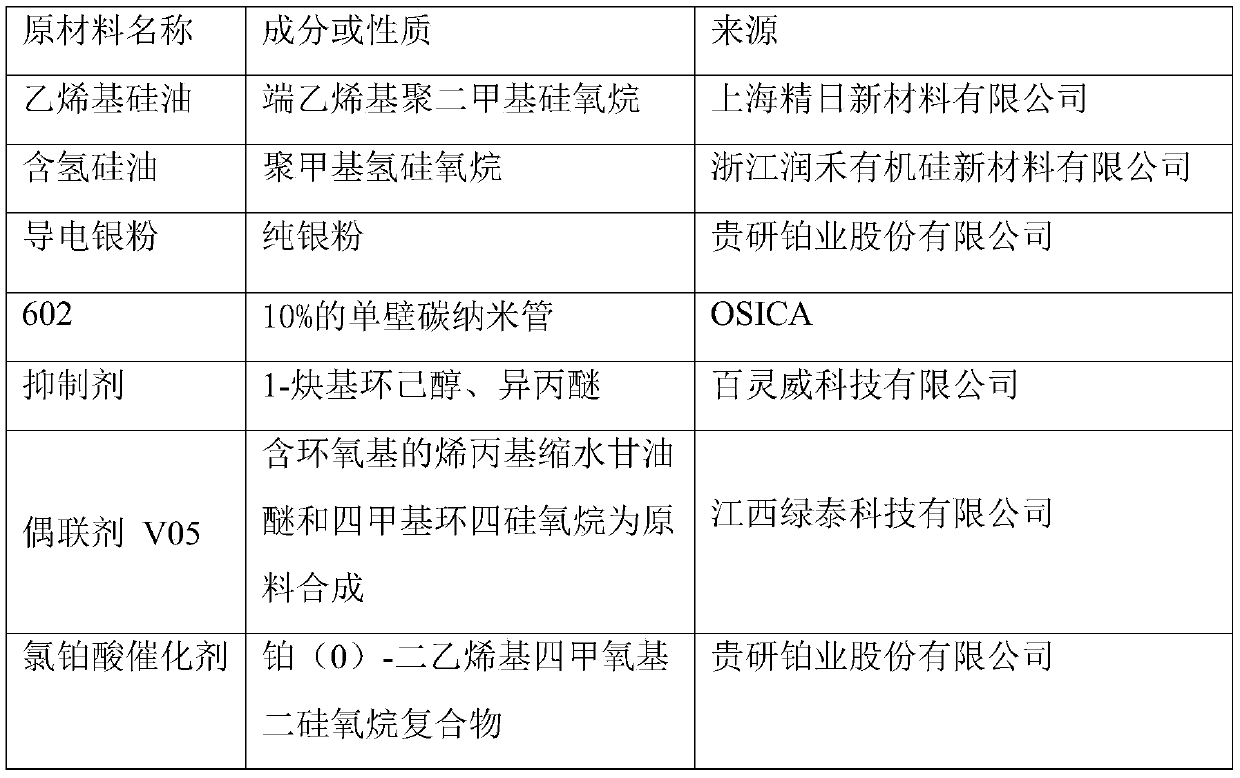

Method used

Image

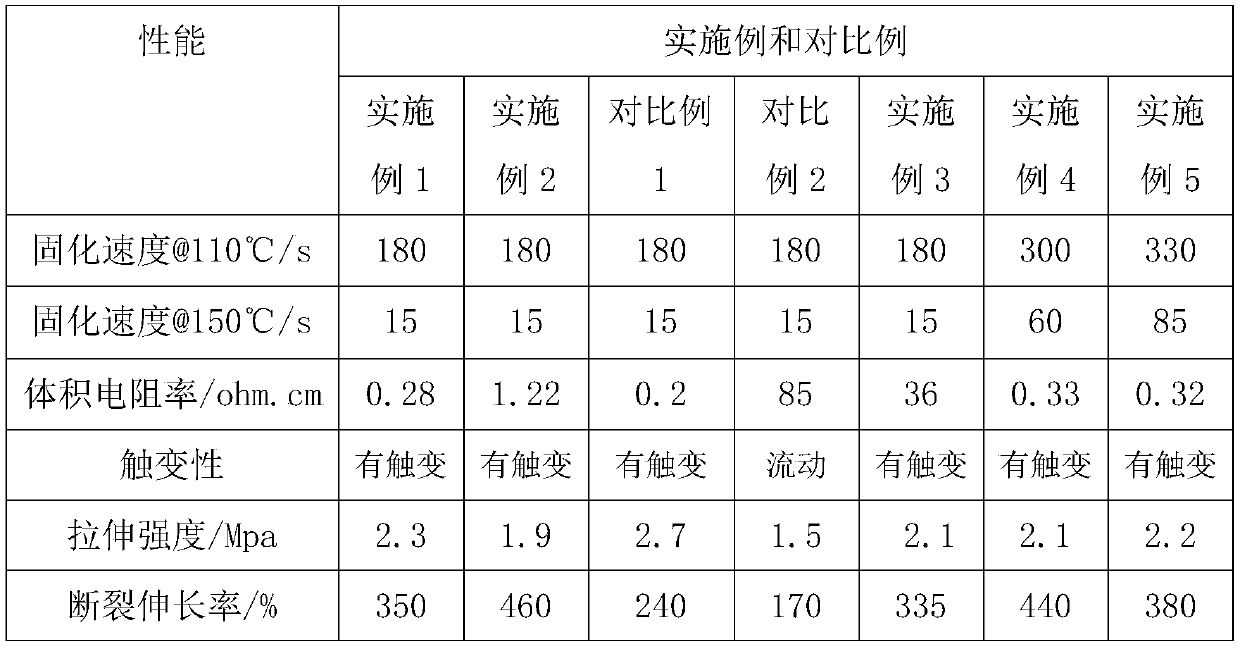

Examples

Embodiment 1

[0021] Add 100 parts of vinyl-terminated silicone oil with a vinyl content of 0.46% and a viscosity of 500mpa.s, and 10 parts of single-walled carbon nanotubes with a solid content of 10% in a planetary dispersion mixer, and disperse and stir at a high speed at a stirring speed of 1000rpm. After stirring for 0.5h Grind 6 times with a three-roll mill. After grinding, add 5 parts of hydrogen-containing silicone oil with a silicon hydrogen content of 1.6% and 40 parts of flake silver powder with an average particle size of 10 μm in the mixer, stir evenly and heat up to 100°C, keep in a vacuum state (<-0.08Mpa), and stir After cooling for 1 h, the stirring speed was 1000 rpm to obtain the base material. In the base material cooled to room temperature, 1 part of coupling agent V05, 0.5 part of 1-alkynyl cyclohexanol, 0.5 part of 1-alkynyl cyclohexanol, 0.2 parts of chloroplatinic acid catalyst with a content of 5000ppm was introduced into dehydrated compressed air, stirred and mix...

Embodiment 2

[0023] Add 60 parts of vinyl-terminated silicone oil with a vinyl content of 1.5% and a viscosity of 50mpa.s and 5 parts of single-walled carbon nanotubes with a solid content of 10% in a planetary dispersion mixer, and disperse and stir at a high speed at a stirring speed of 100rpm. After stirring for 1 hour, use Three-roll mill grinding 4 times. After grinding, add 1 part of hydrogen-containing silicone oil with a silicon hydrogen content of 1.6% and 20 parts of flaky silver powder with an average particle size of 10 μm in the mixer. Stir evenly and heat up to 120 ° C. Keep in a vacuum state (<-0.08Mpa), stir After cooling for 1 h, the stirring speed was 100 rpm to obtain the base material. In the base material cooled to room temperature, 0.2 parts of coupling agent V05, 1.5 parts of 1-alkynyl cyclohexanol, 1.5 parts of 1-alkynyl cyclohexanol, 0.5 parts of chloroplatinic acid catalyst with a content of 3000ppm was introduced into dehydrated compressed air, stirred and mixed...

Embodiment 3

[0025] Add 80 parts of vinyl-terminated silicone oil with a vinyl content of 1% and a viscosity of 500mpa.s and 8 parts of single-walled carbon nanotubes with a solid content of 10% in a planetary dispersing mixer, disperse and stir at a high speed at a stirring speed of 500rpm, and stir for 0.5h Grind 8 times with a three-roll mill. After grinding, add 3 parts of hydrogen-containing silicone oil with a silicon hydrogen content of 1.6% and 30 parts of flaky silver powder with an average particle size of 10 μm in the mixer, stir evenly and heat up to 110°C, keep in a vacuum state (<-0.08Mpa), and stir After cooling for 1 h, the stirring speed was 500 rpm to obtain the base material. In the base material cooled to room temperature, 2.5 parts of coupling agent V05, 3 parts of 1-alkynyl cyclohexanol, 3 parts of 1-alkynyl cyclohexanol, 1 part of chloroplatinic acid catalyst with a content of 4000ppm is introduced into the dehydrated compressed air, stirred and mixed, and after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com