Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310 results about "Torque regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

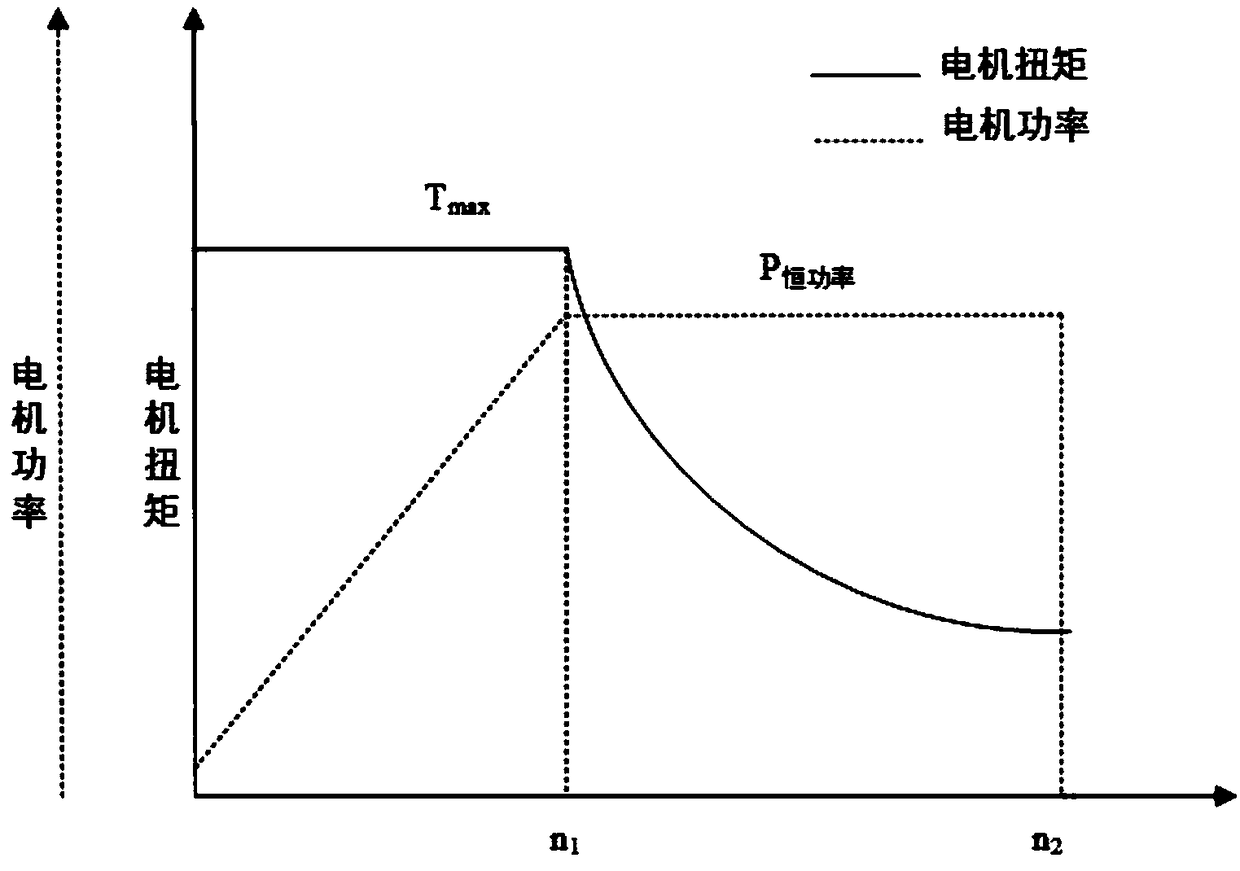

In any motor, torque is the result of the force between two magnetic fields. In a DC motor, torque is easily and directly regulated by regulating the currents that control the flux in the two magnetic fields. The stator flux is the motor’s magne- tizing flux which is held constant by providing a constant field current.

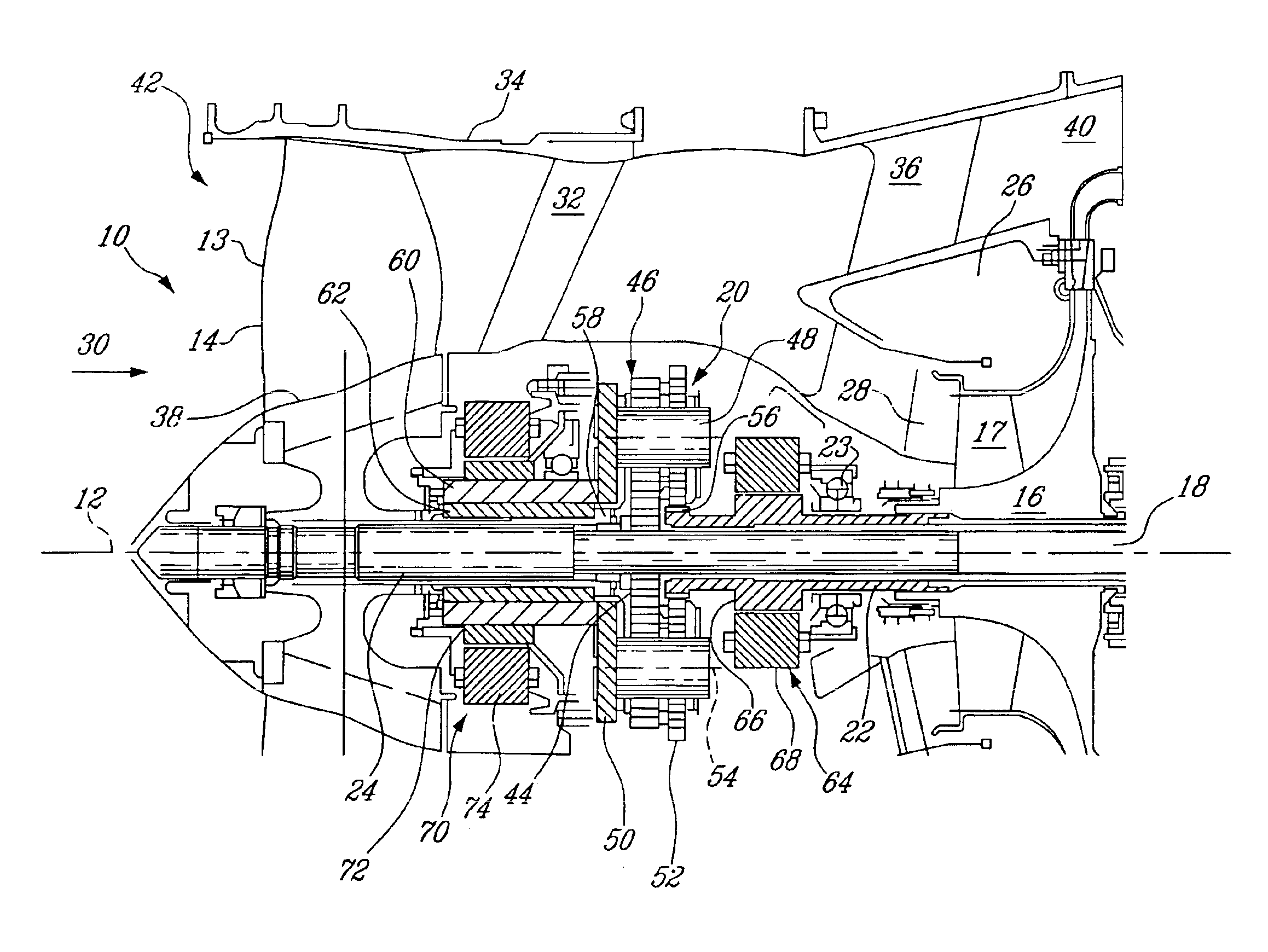

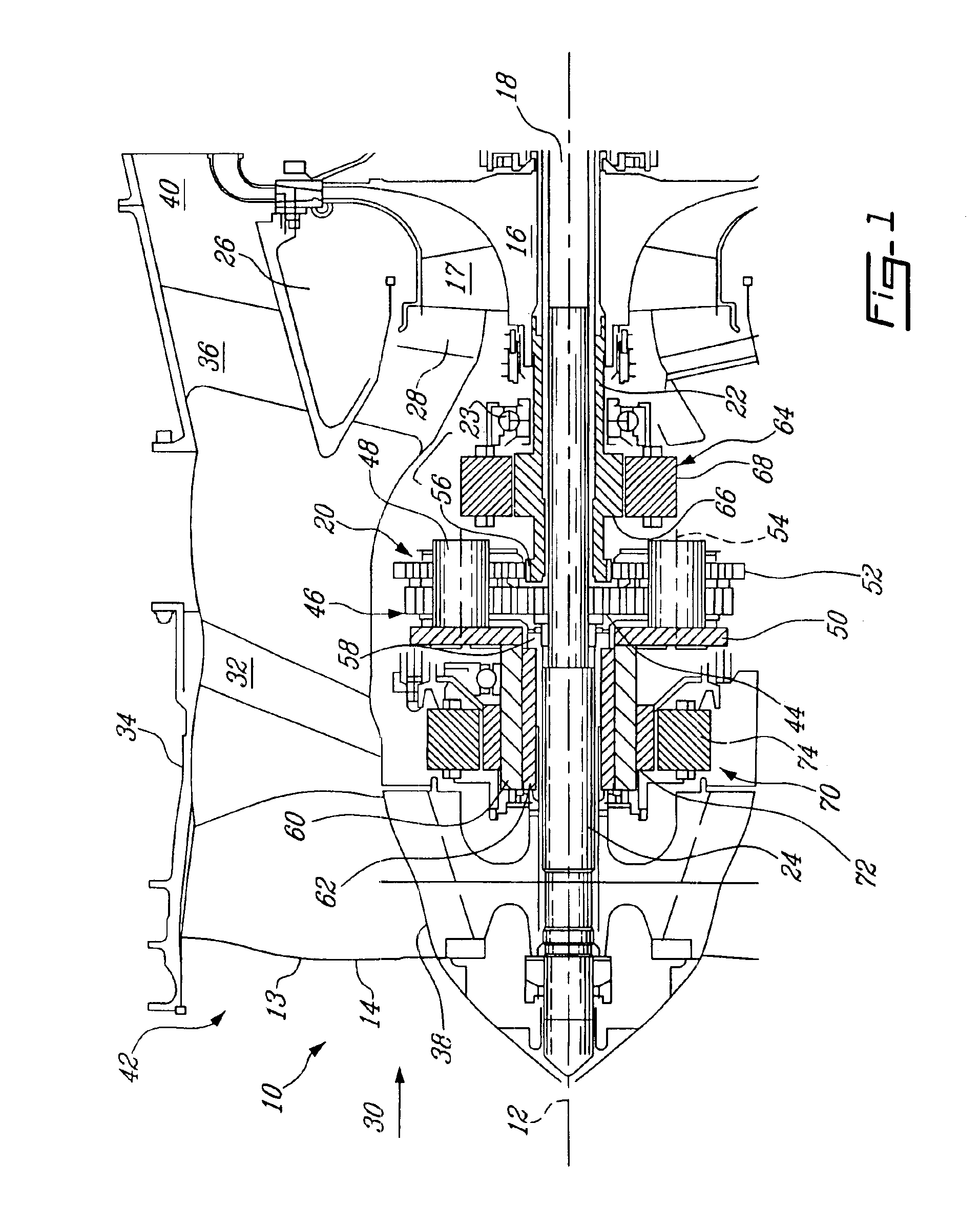

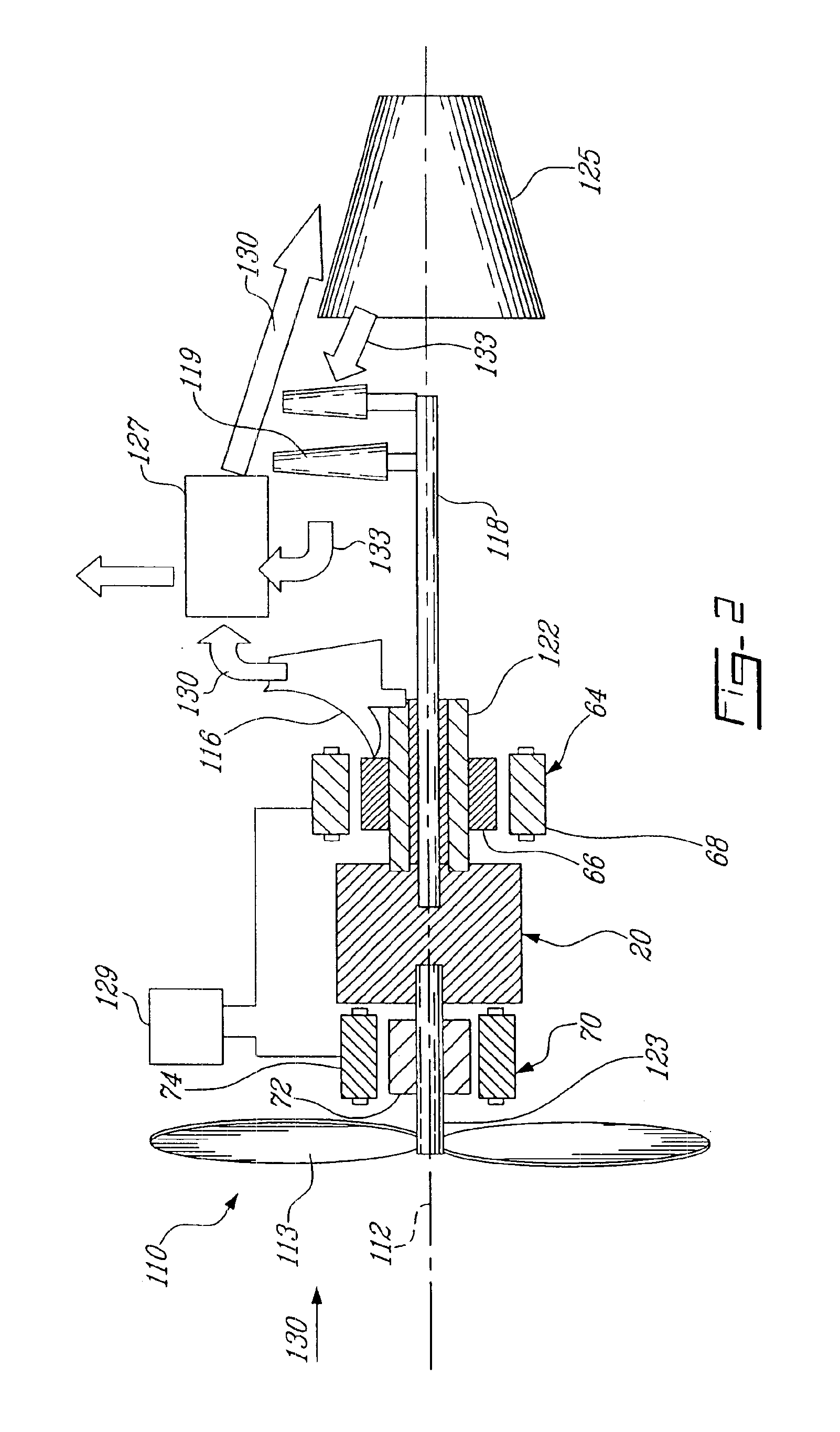

Differential geared turbine engine with torque modulation capability

InactiveUS6895741B2Improve efficiencyMinimal numberEngine fuctionsEfficient propulsion technologiesTorque regulationTurbine

A method and apparatus for controllable distribution of power from a turbine of a gas turbine engine between two rotatable loads of the gas turbine engine, comprises transferring a shaft power of the turbine to the respective rotatable loads using differential gearing operatively coupled with the turbine and the rotatable loads, respectively; and controlling the power transfer using machines operatively coupled with the respective rotatable loads, operable as a generator or a motor for selectively taking power from one of the rotatable loads to drive the other of the rotatable loads, or the reverse.

Owner:PRATT & WHITNEY CANADA CORP

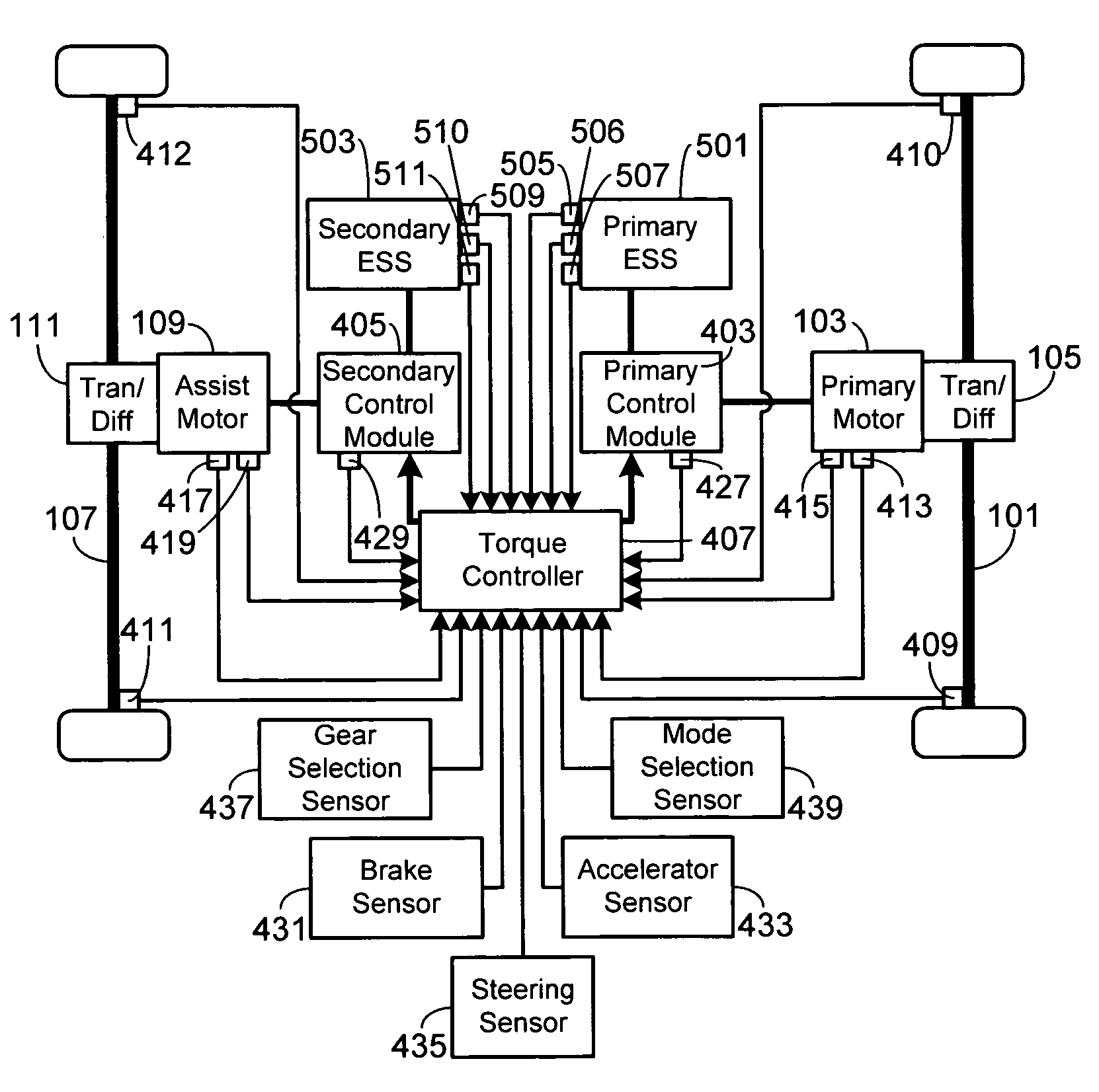

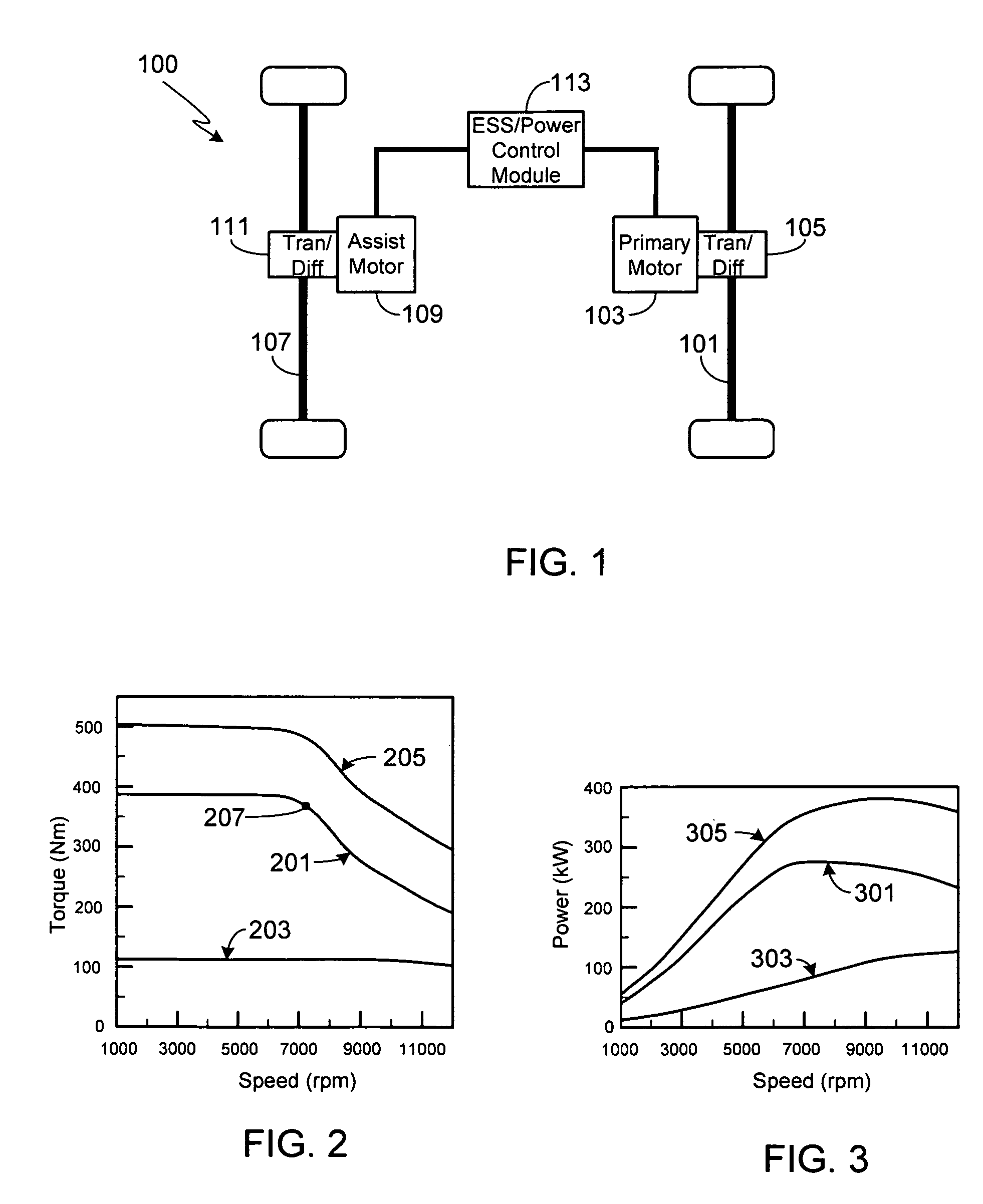

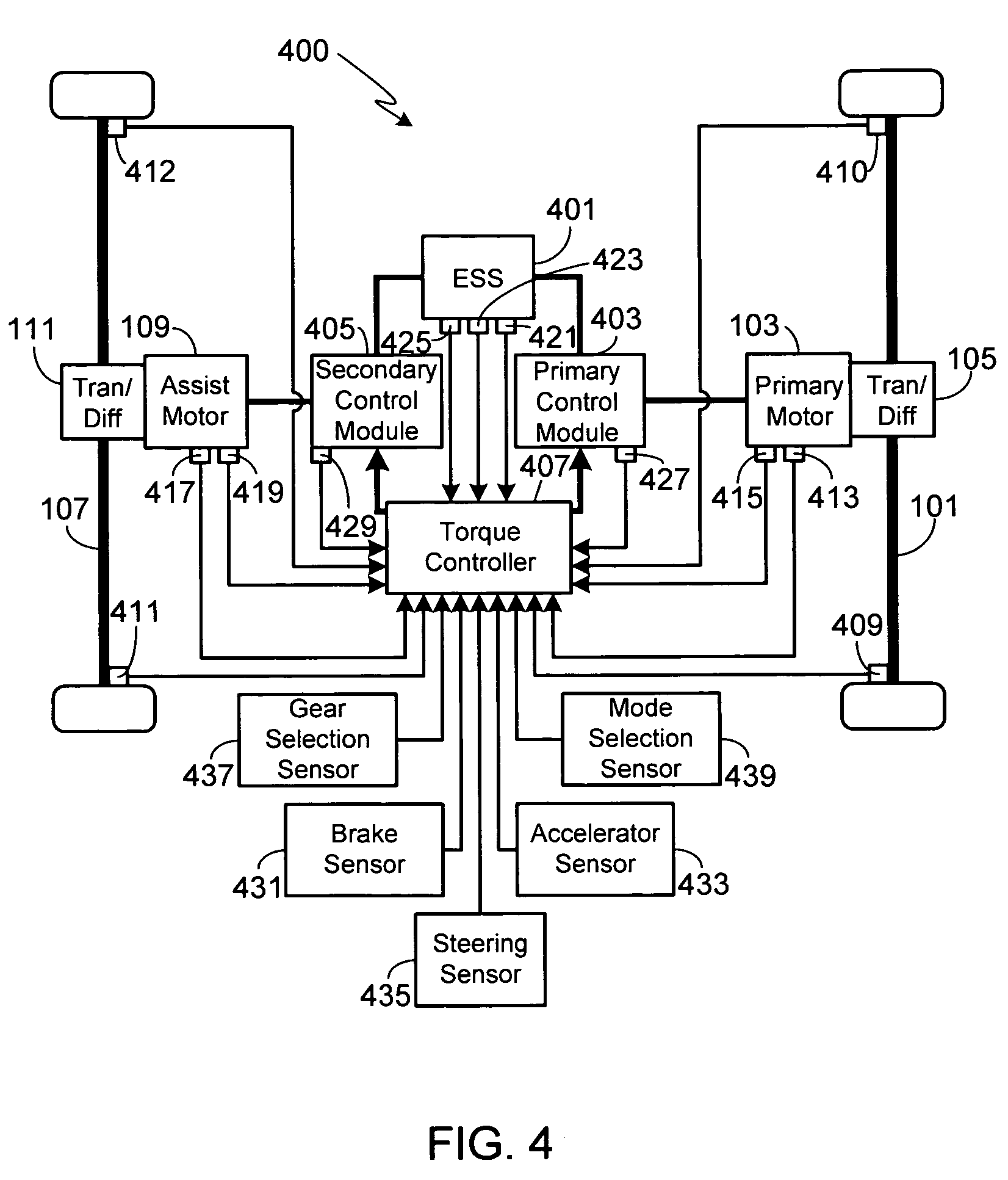

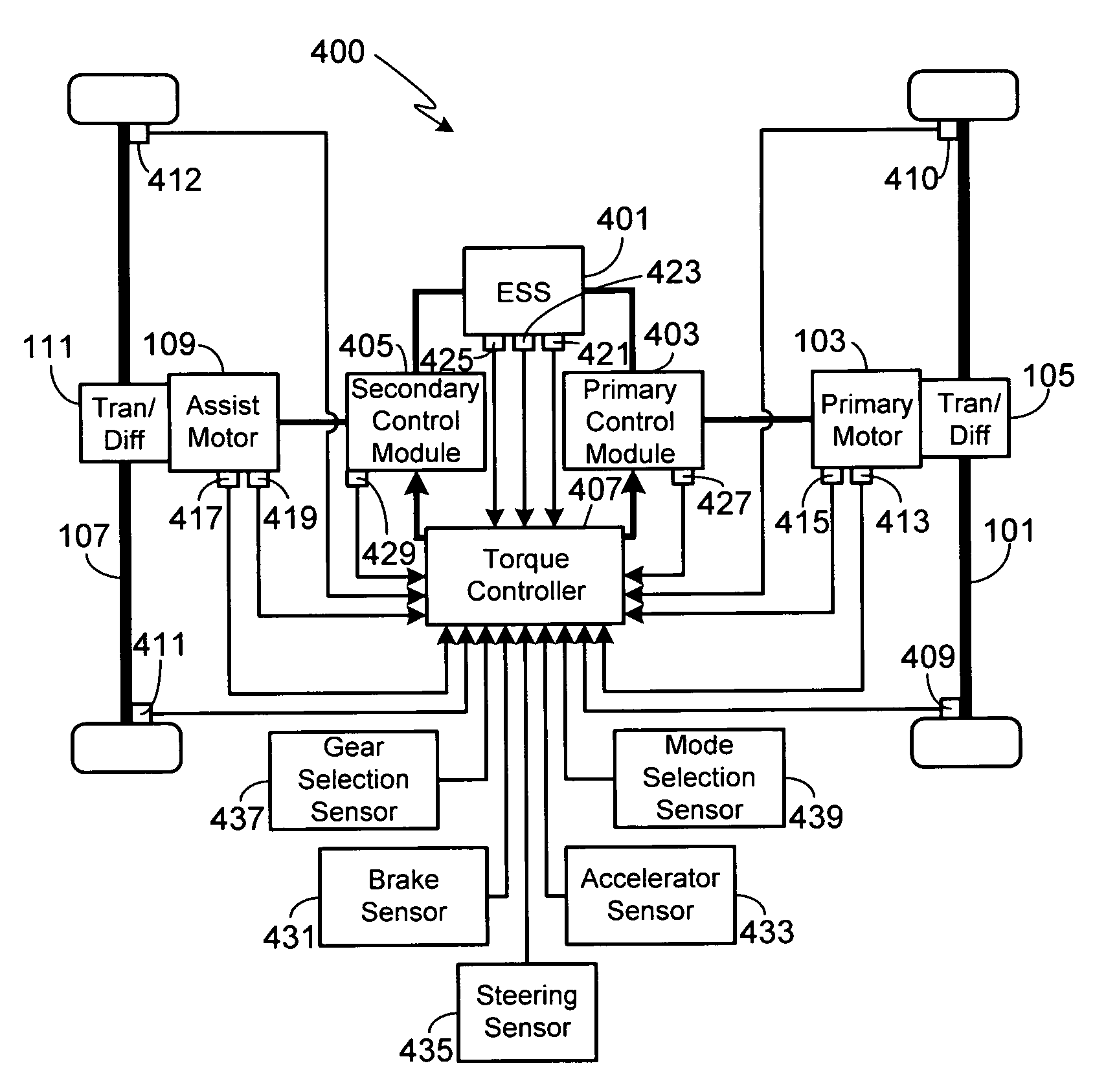

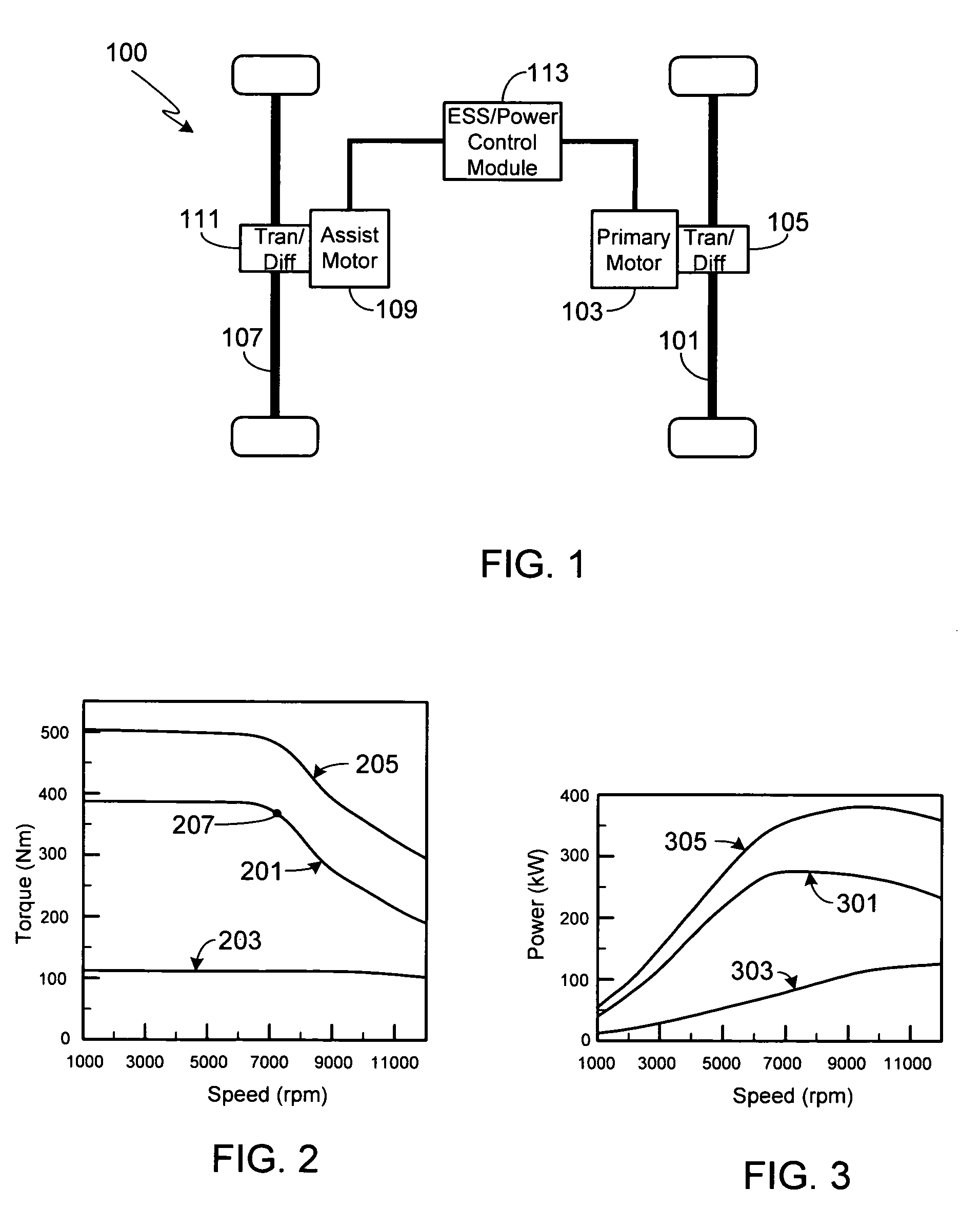

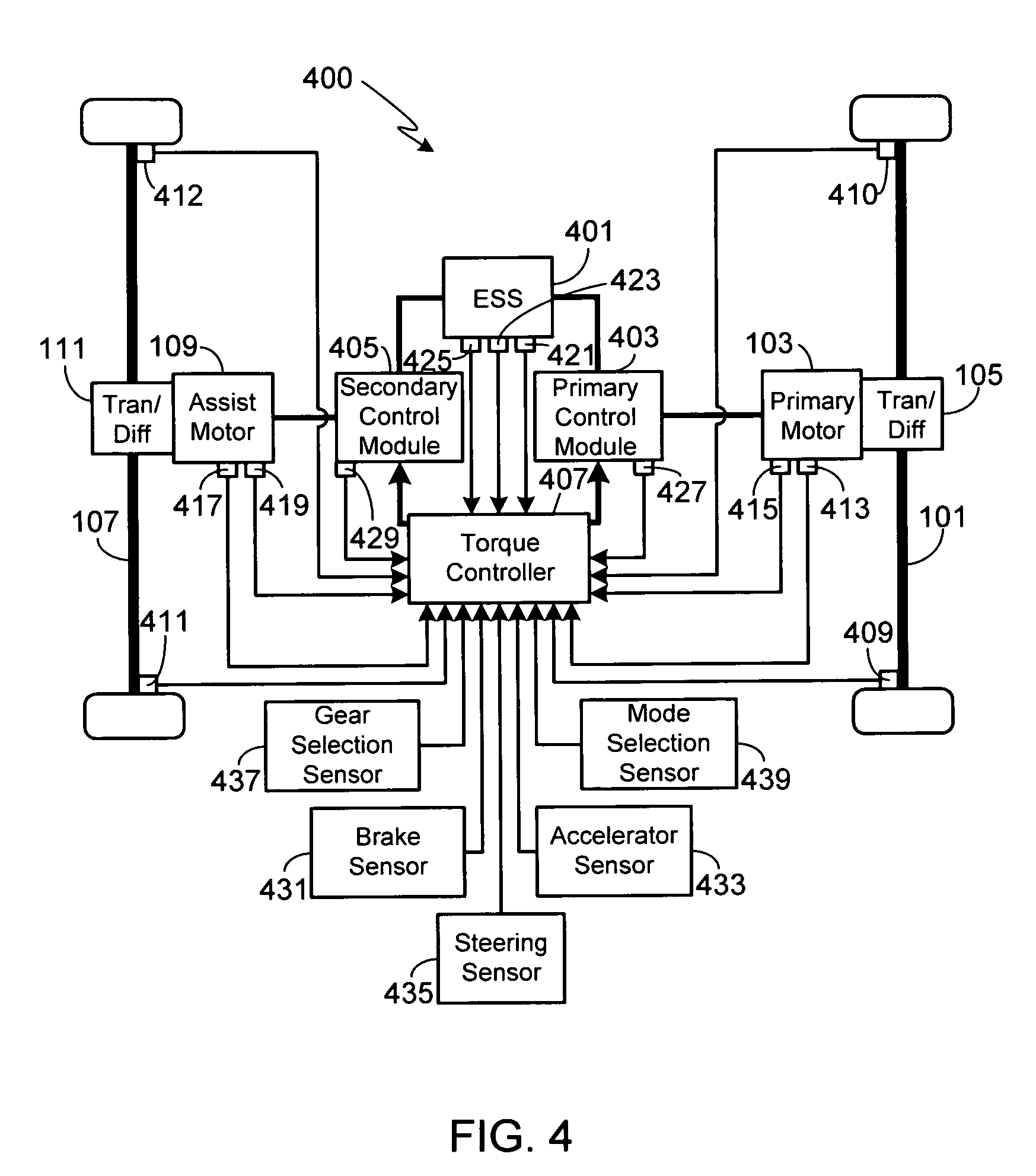

Control system for an all-wheel drive electric vehicle

ActiveUS7739005B1Enhancing electric vehicle tractionGreat tractionDigital data processing detailsPropulsion by batteries/cellsElectric vehicleTorque regulation

A method and apparatus for optimizing the torque applied to the primary and assist drive systems of an all-electric vehicle is provided, the torque adjustments taking into account wheel slip as well as other vehicular operating conditions.

Owner:TESLA INC

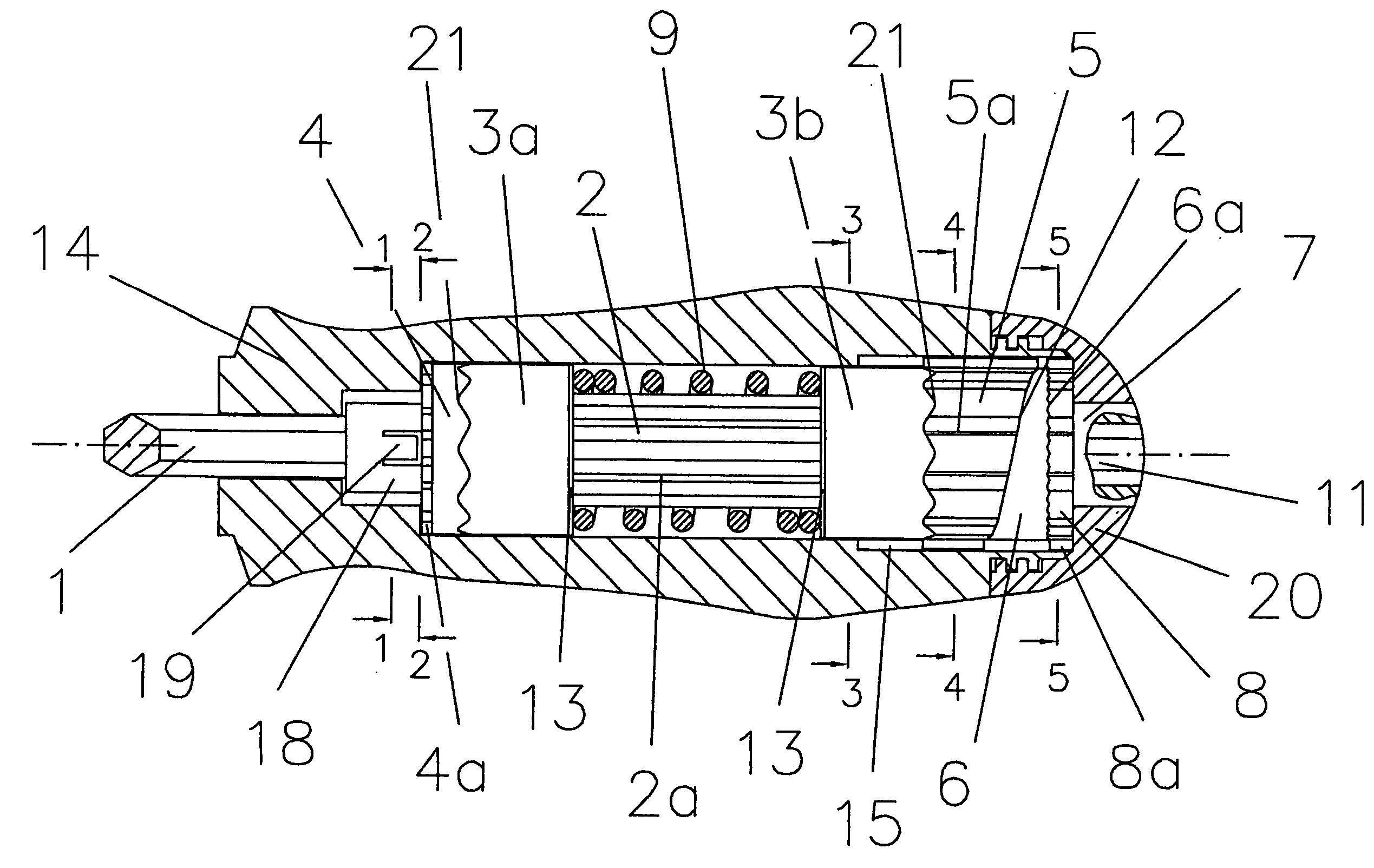

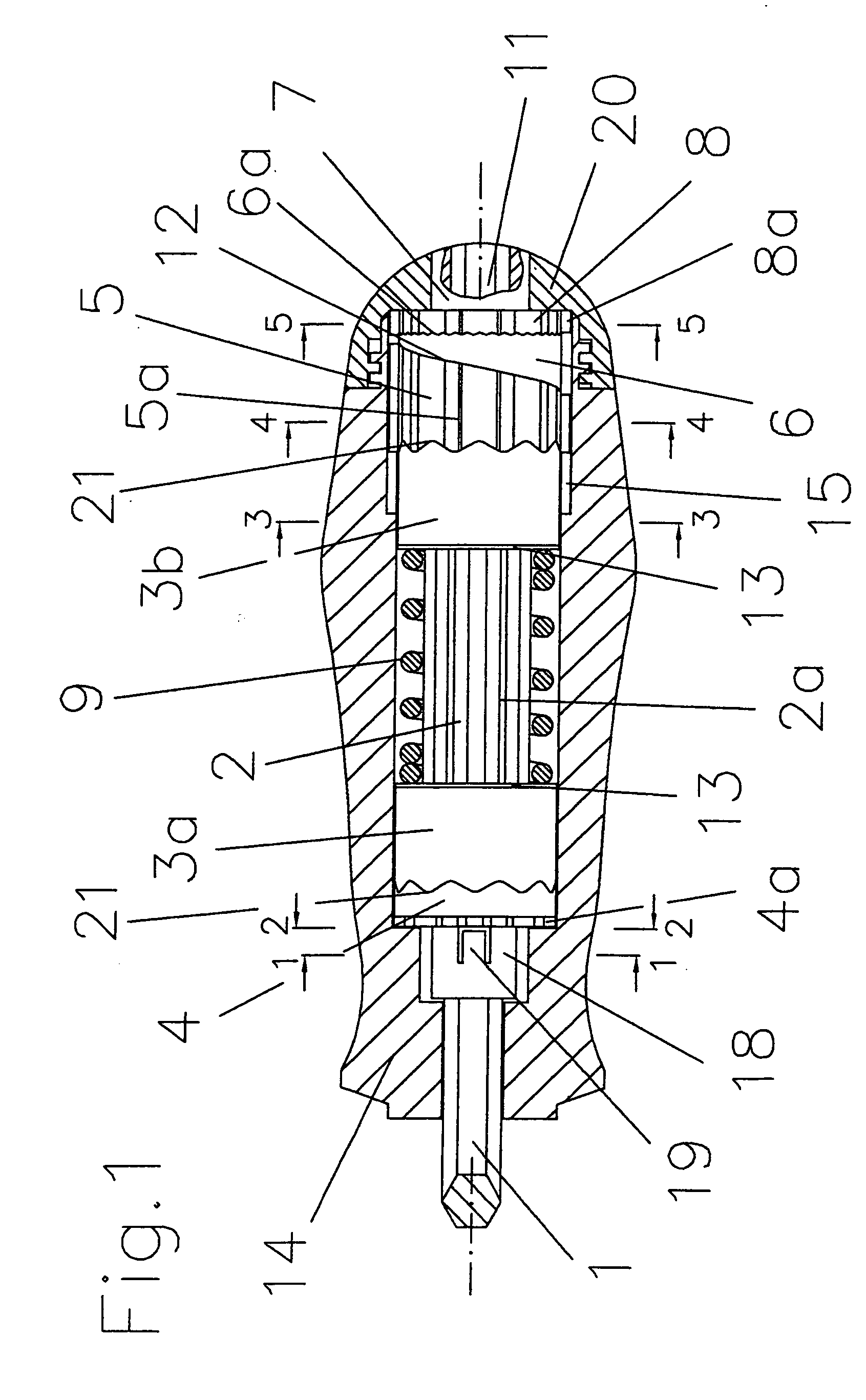

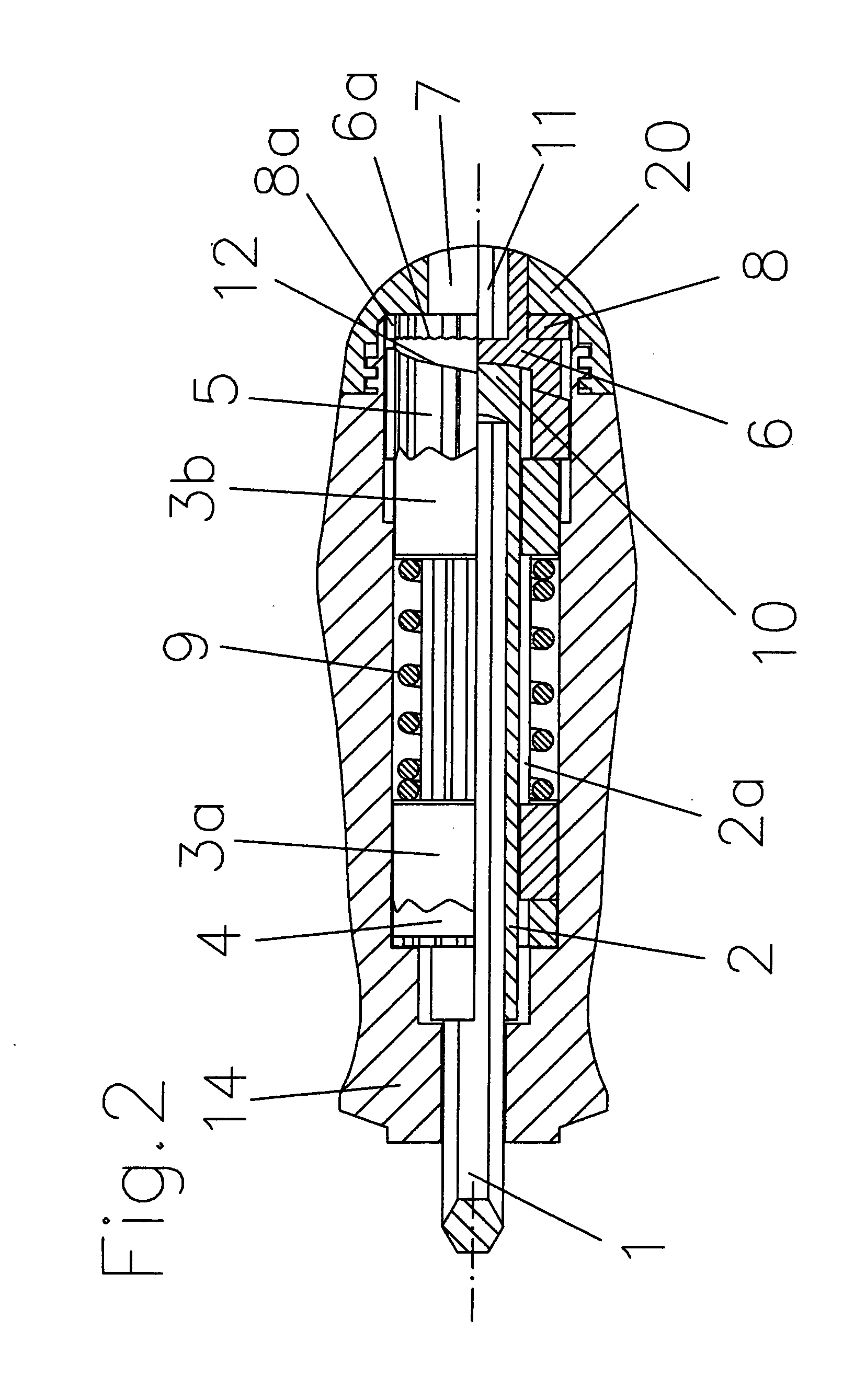

Screwdriver with adjustable device to limit transmitted torque

A screwing-tool with a device to adjust transmitted torque consists of a handle to introduce a torque to the device, which is borne in the hollow of the handle and a driver-shaft as outpout element of the torque. On the driver-shaft inside the handle two separate couplings are assembled, between them a compression spring exerting a spring force onto the two couplings. Each coupling consist of a first and second socket engaging each other by gearings at their opposing faces. The maximum torque at which the torque-transmission will be interrupted cab be adjusted in that way, that by an adjustment-element the distance between the couplings can be changed resulting in a change of the tension of the spring exerting a load on the couplings. The teeth of the gearings slide and the sockets rotate relatively to each other and interrupt the torque-transmission if a pre-adjusted torque is exceeded.

Owner:FELO WERKZEUGFAB HOLLAND LETZ

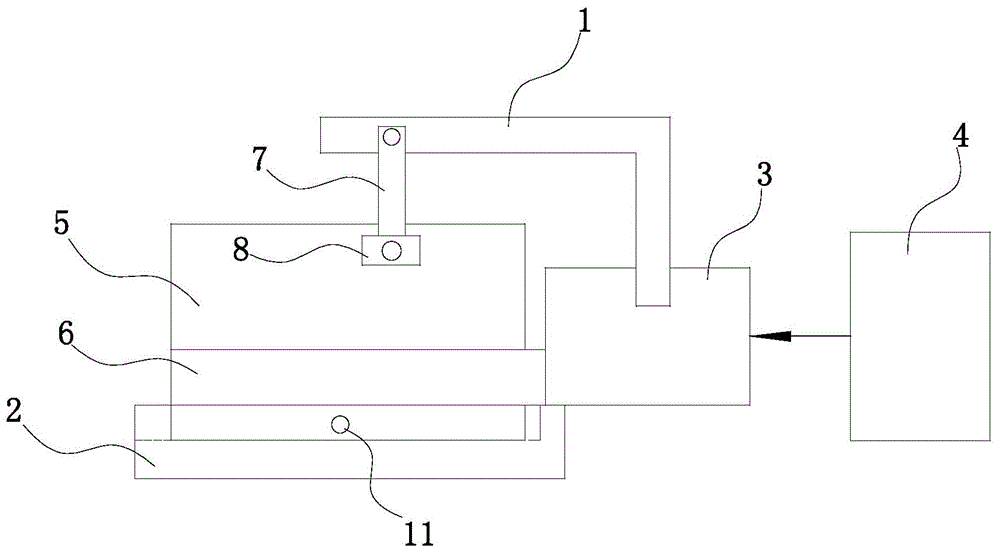

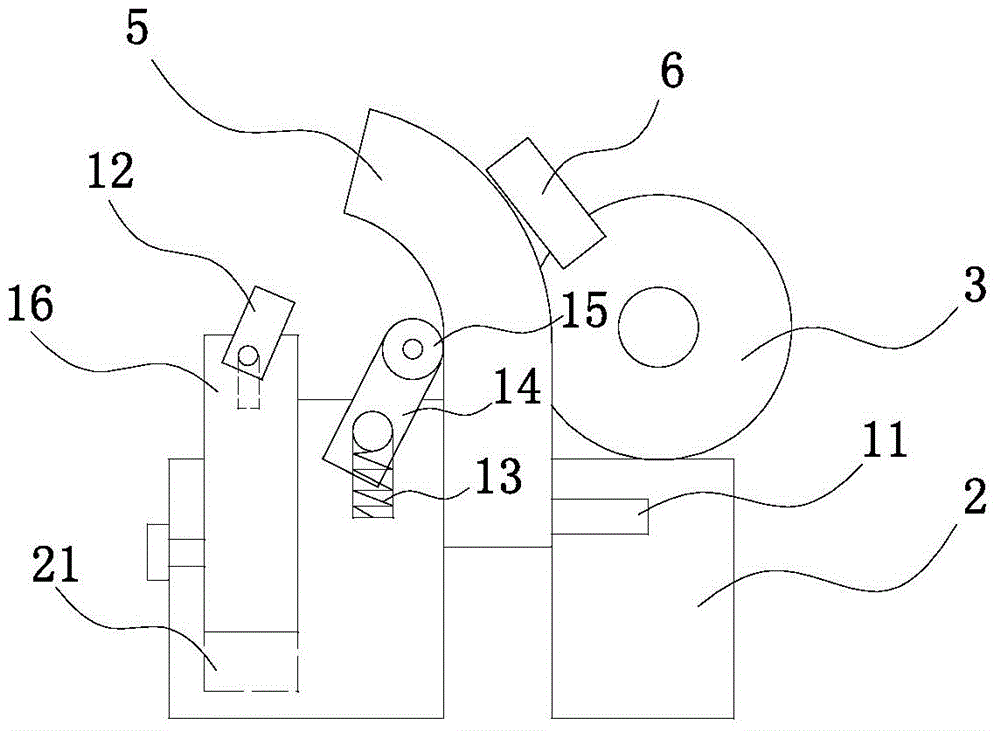

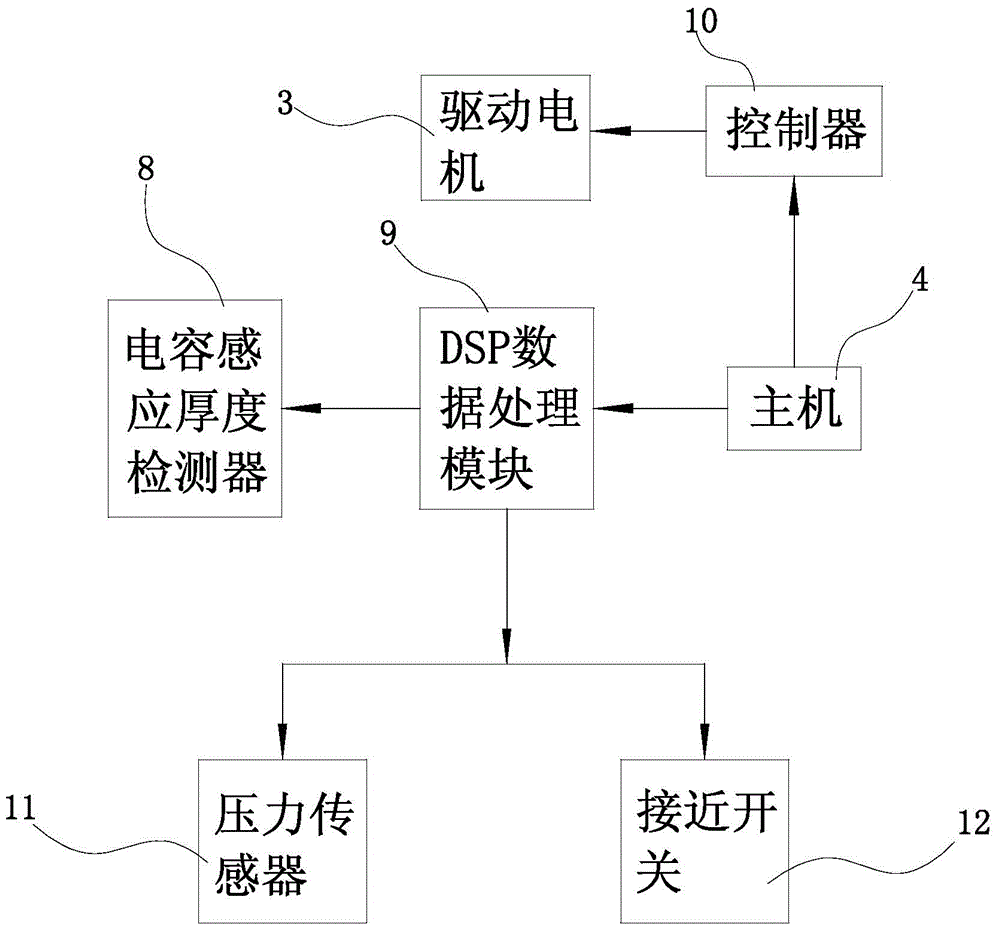

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

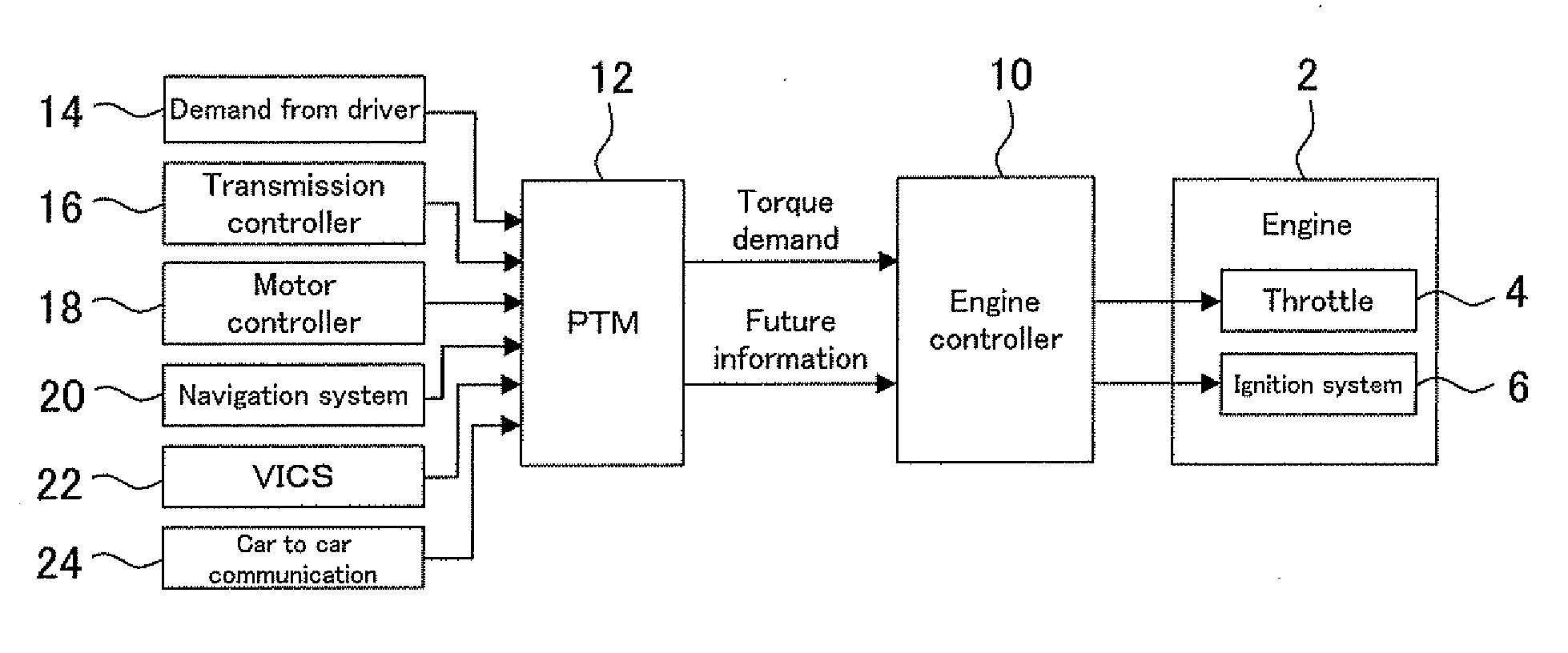

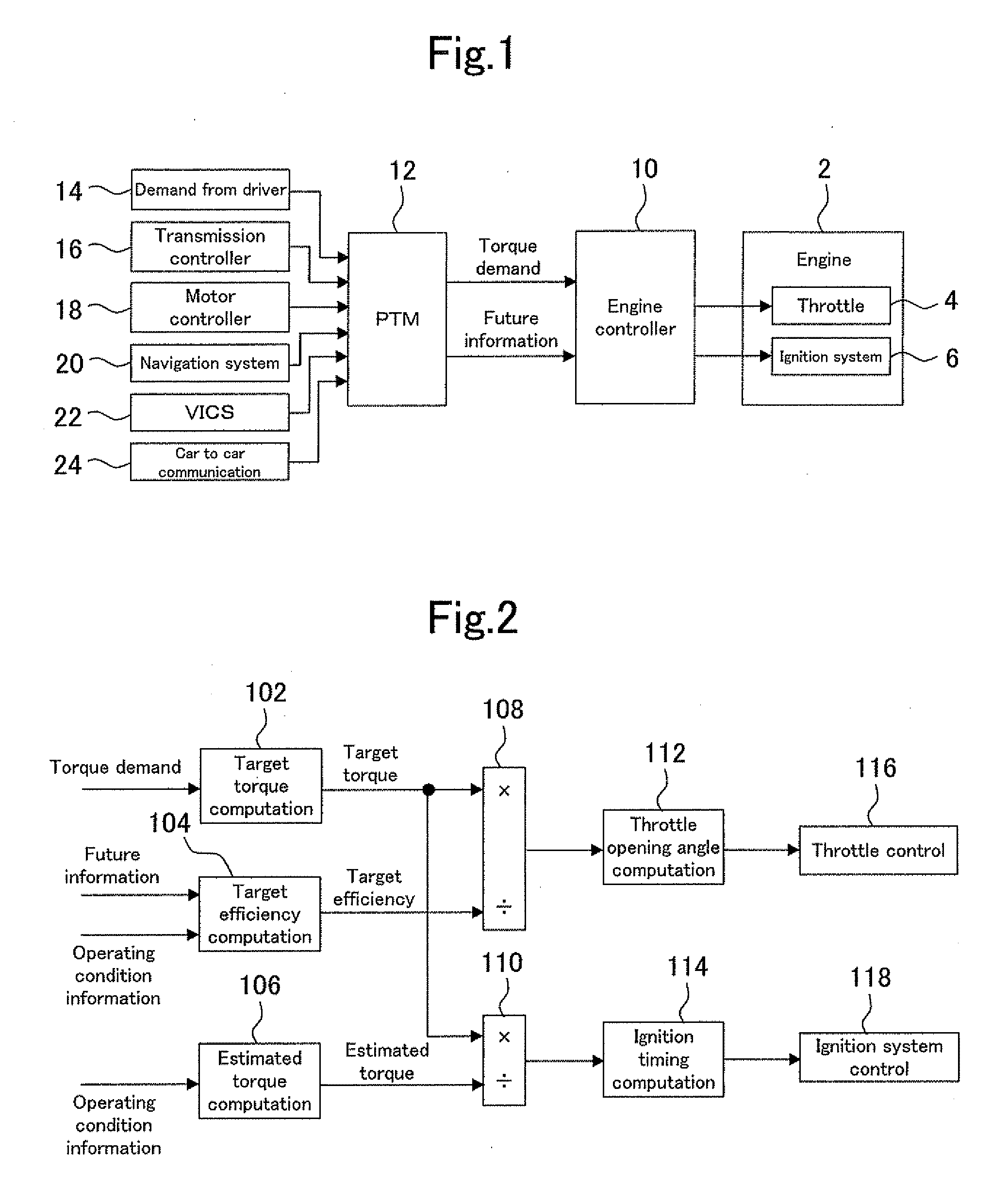

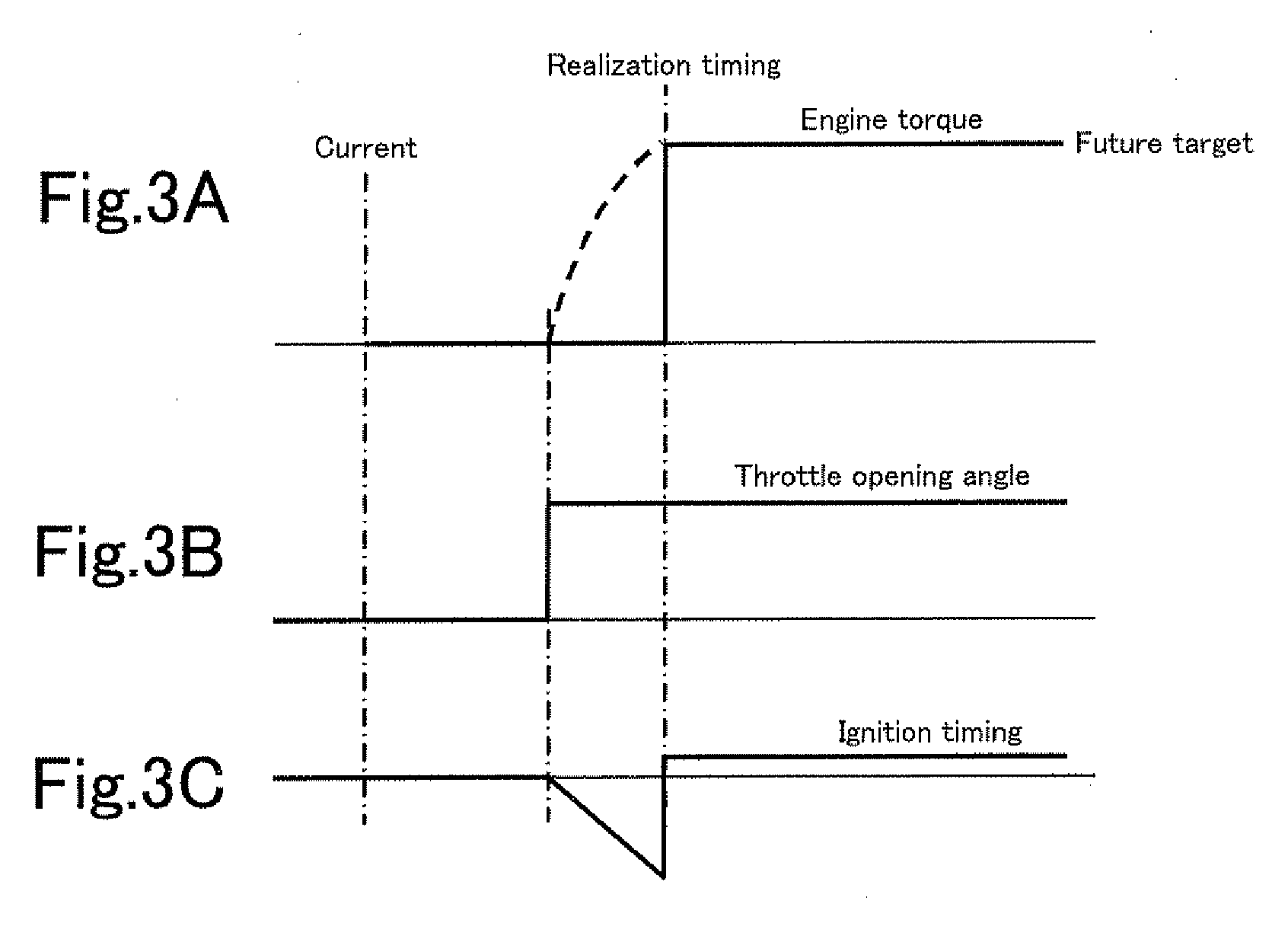

Control device for vehicle drive unit

InactiveUS20100268436A1Minimize operating periodReduce stepsAnalogue computers for vehiclesElectrical controlTorque regulationActuator

This invention is intended to ensure that a control device for a vehicle drive unit is capable of realizing desired torque by making the main-actuator and sub-actuator collaborate adequately while holding the interposition of the sub-actuator as low as possible. For this end, a future target of torque that is going to be output from the engine and a realization timing of the future target are taken as reservation information for reserving engine torque regulation. Next, the required period, which is required to realize the future target when a main-actuator (a throttle) is operated to regulate the torque, is computed from a current engine operating condition. Then, the operation of the main-actuator is started at the timing preceding the realization timing by the required period for realizing the future target. In parallel with that, a sub-actuator (an ignition system) is operated to cancel out a torque change induced by the operation of the main-actuator during the period from the start timing of the operation of the main-actuator to the realization timing.

Owner:TOYOTA JIDOSHA KK

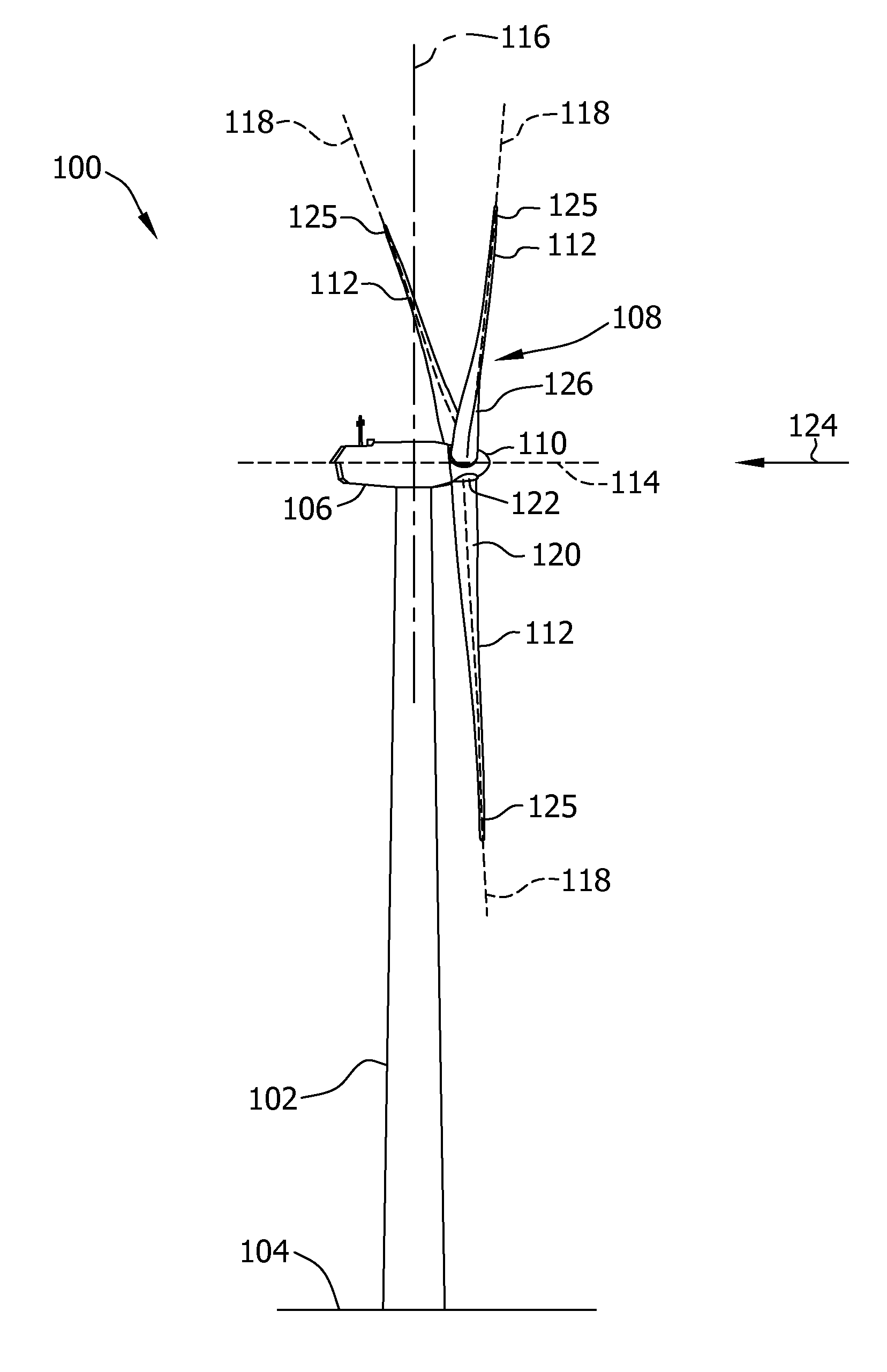

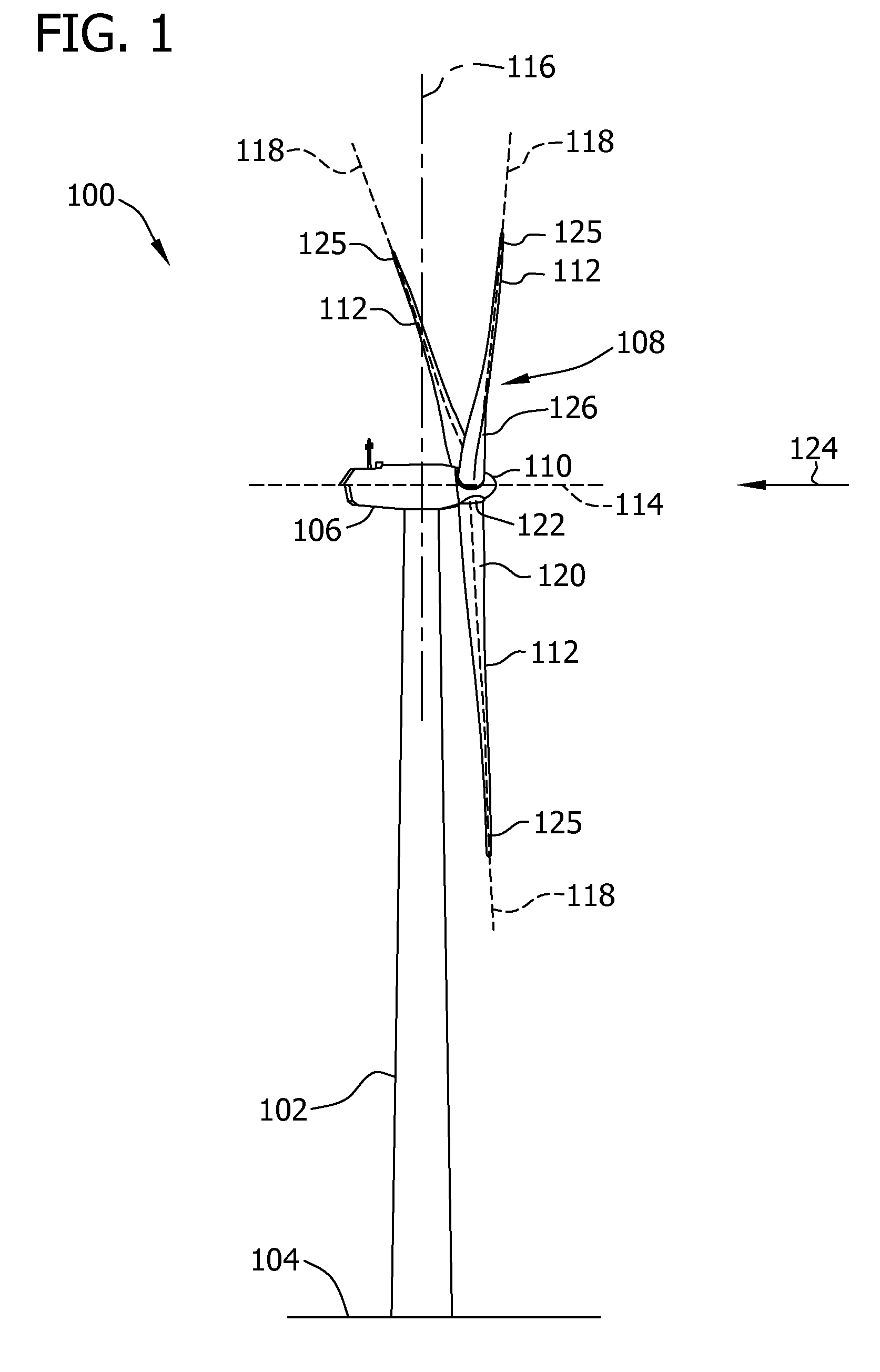

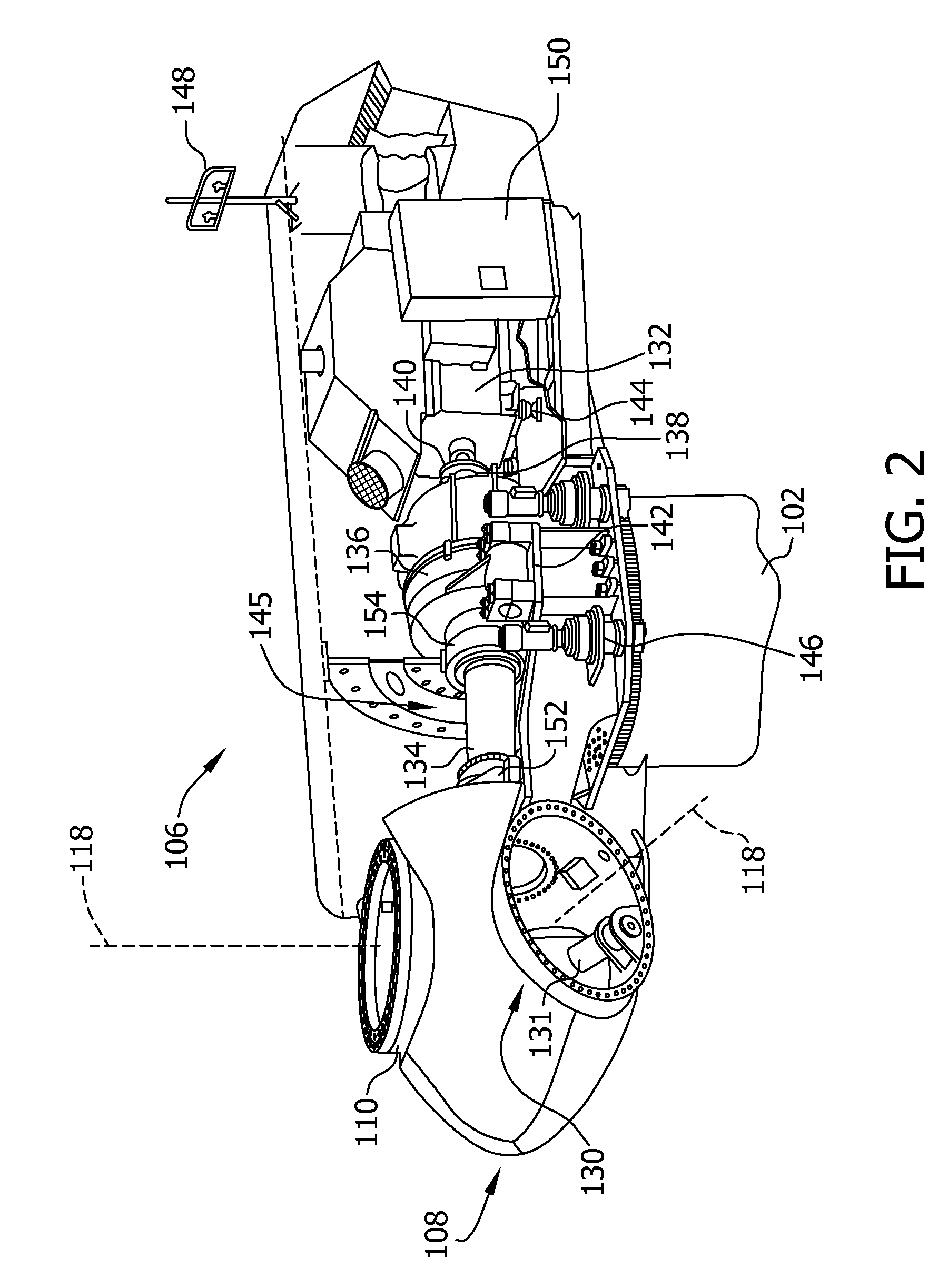

Condition monitoring system for wind turbine generator and method for operating wind turbine generator

A method for operating a wind turbine generator includes generating at least one of a plurality of rotor shaft angular displacement values, a plurality of rotor shaft angular velocity signals, and a plurality of rotor shaft angular acceleration signals. The method also includes determining a torsional moment within a rotor shaft, and modulating at least one of a wind turbine generator yaw orientation and a blade pitch orientation as a function of the determined torsional moment.

Owner:GENERAL ELECTRIC CO

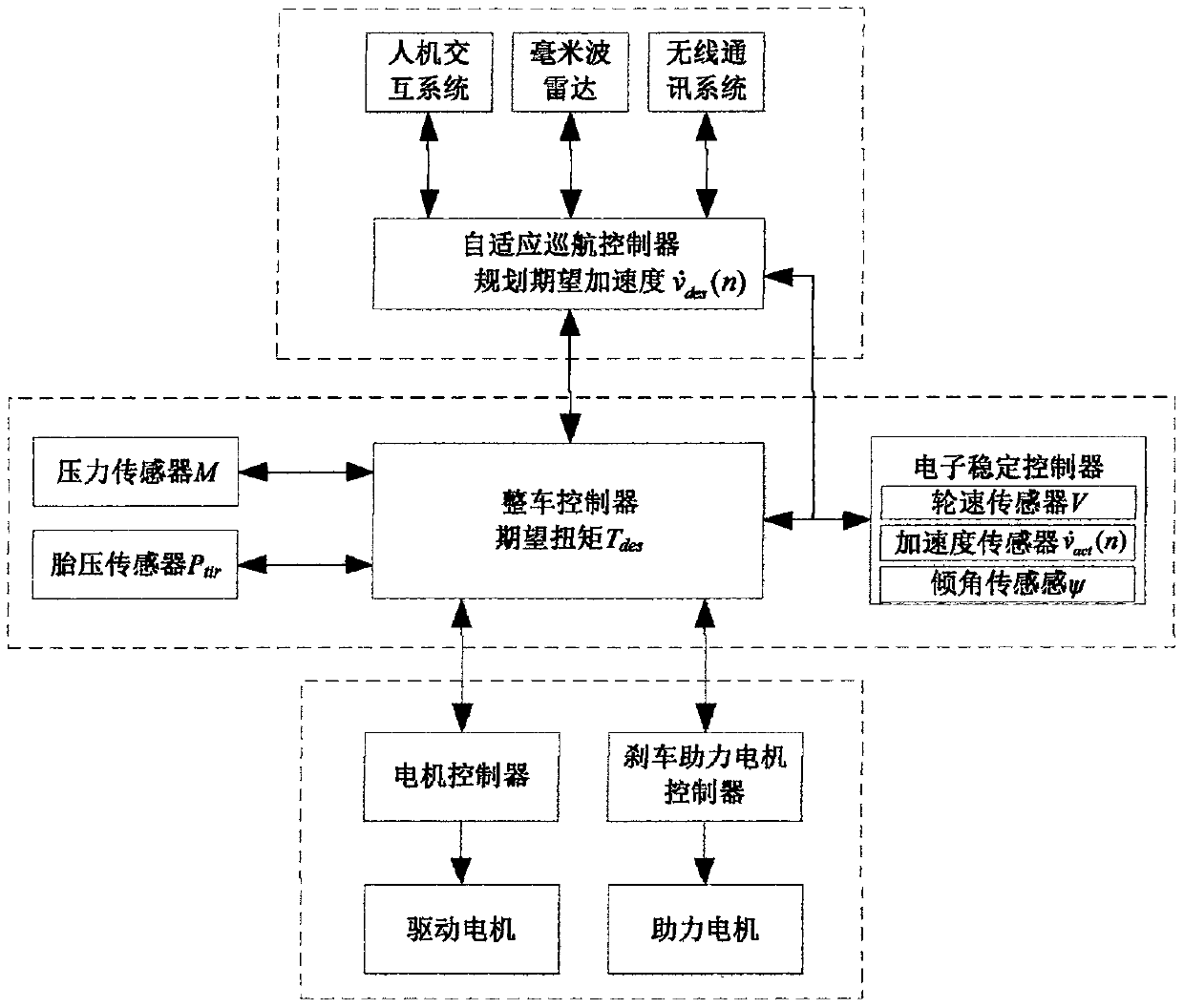

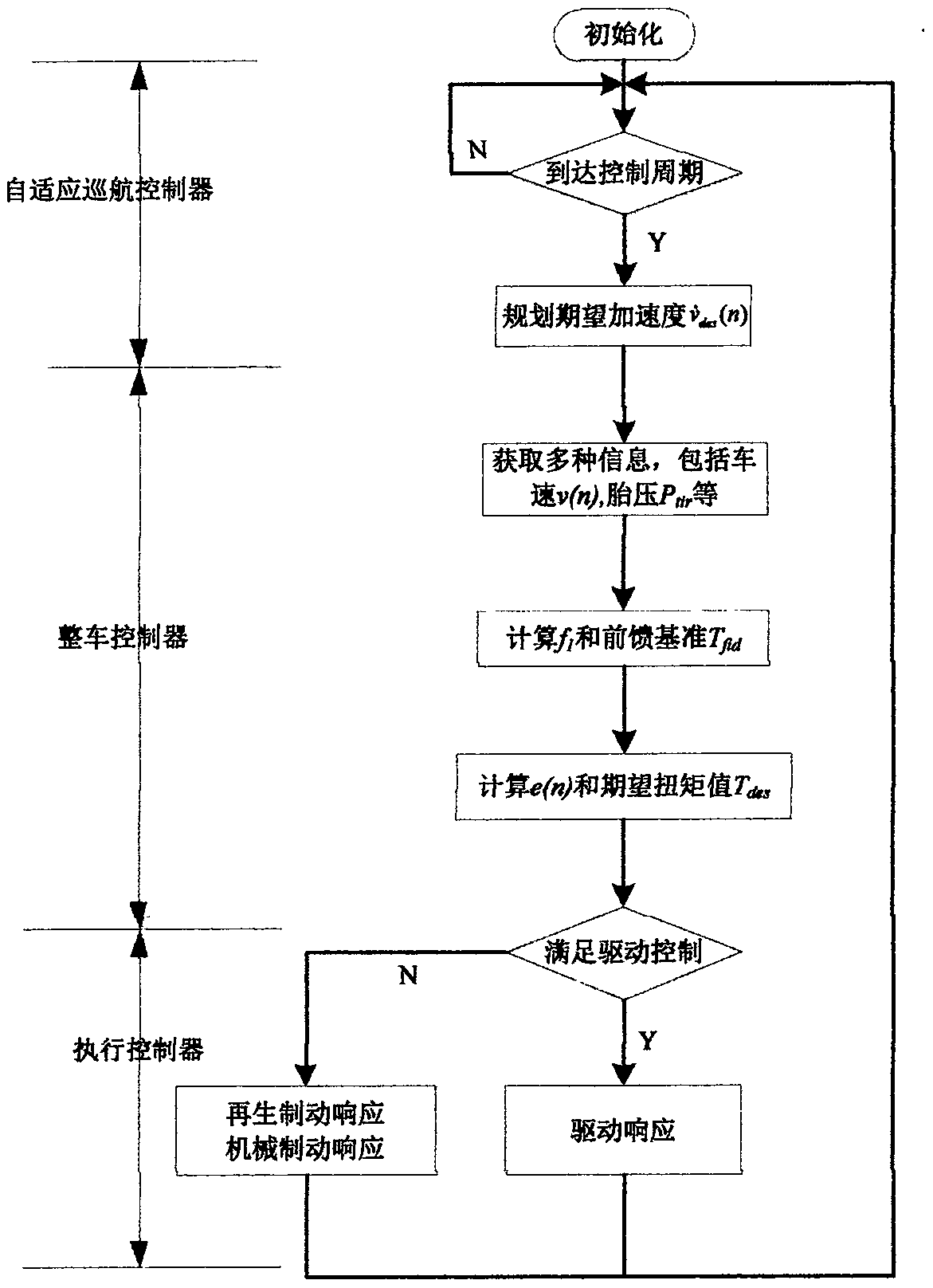

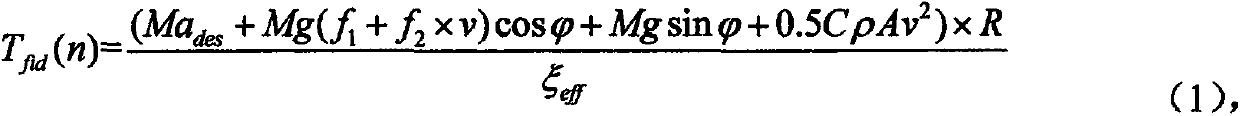

Torque adjusting method of electric automobile adaptive cruise system

ActiveCN108528268AAvoid complex processRealize feed-forward fast adjustmentSpeed controllerExternal condition input parametersBrake controlPressure sensor

The invention provides a torque adjusting method of an electric automobile adaptive cruise system, and relates to the field of automobiles. The method includes the steps: calculating desired acceleration speed Vdes (n) by the aid of an adaptive cruise controller; detecting automobile tire pressure Ptir by the aid of a tire pressure sensor; detecting a road gradient Phi by the aid of a tilt angle sensor; detecting weight M of an integrated automobile by the aid of a pressure sensor; detecting actual speed v(n) of a vehicle by a vehicle speed sensor; detecting actual acceleration speed Vact (n)of the vehicle by an acceleration speed sensor; inputting driving environment information by a man-machine interactive system; acquiring a rolling resistance coefficient according to relation functions among the rolling resistance coefficient, a road and tire pressure; implementing front feed adjustment of a standard torque Tfid(n) through a dynamical model; performing correction through adaptivePID feedback to obtain a desired torque Tdes (n); switching maintaining areas to achieve effective switching of driving control and braking control; implementing adaptive cruise control. According tothe method, adjusting time from stabilization to final target acceleration speed is shortened, and stability of the system is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Control system for an all-wheel drive electric vehicle

ActiveUS7742852B1Digital data processing detailsPropulsion by batteries/cellsControl systemTorque regulation

A method and apparatus for optimizing the torque applied to the primary and assist drive systems of an all-electric vehicle is provided, the torque adjustments taking into account wheel slip as well as other vehicular operating conditions.

Owner:TESLA INC

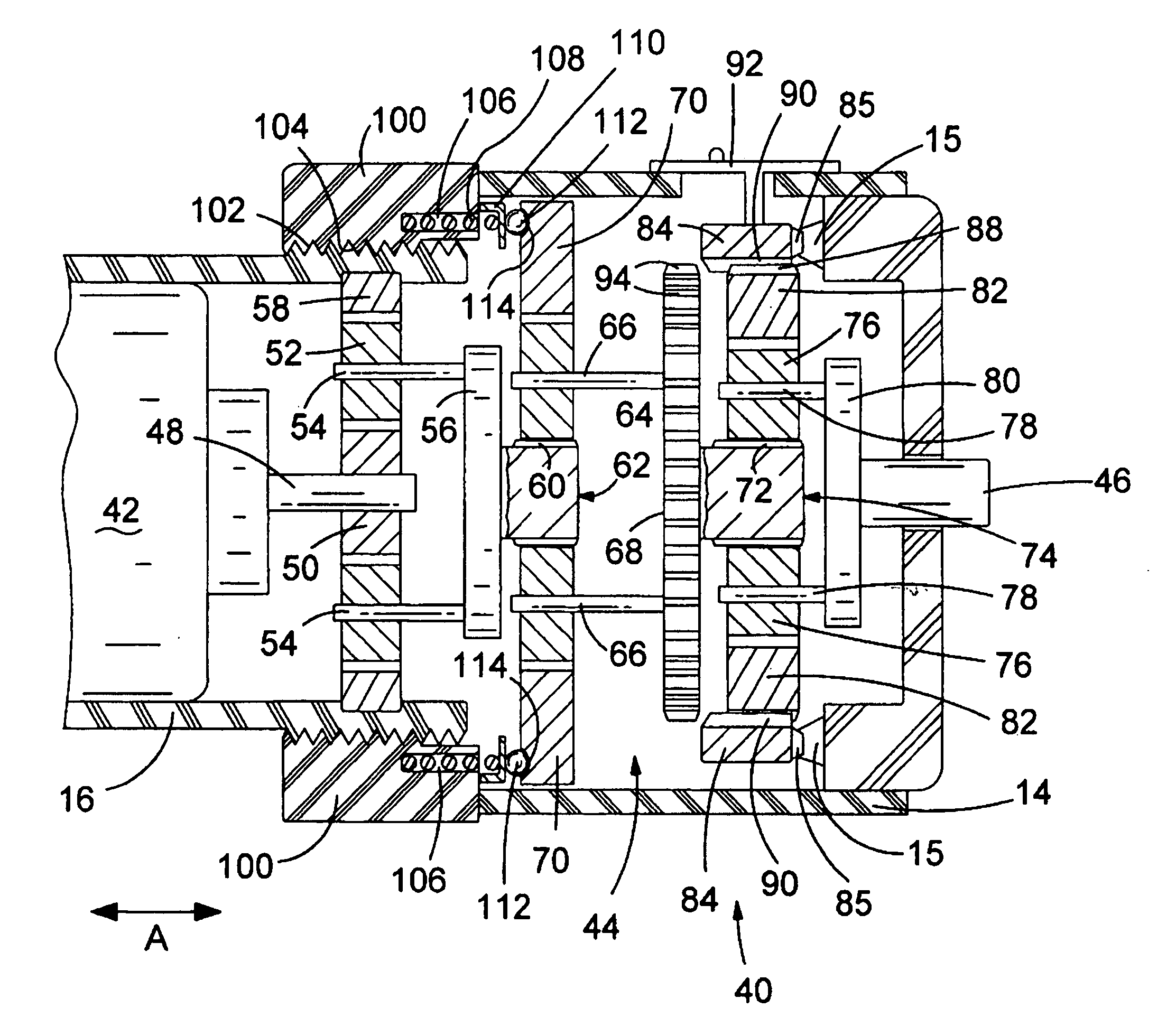

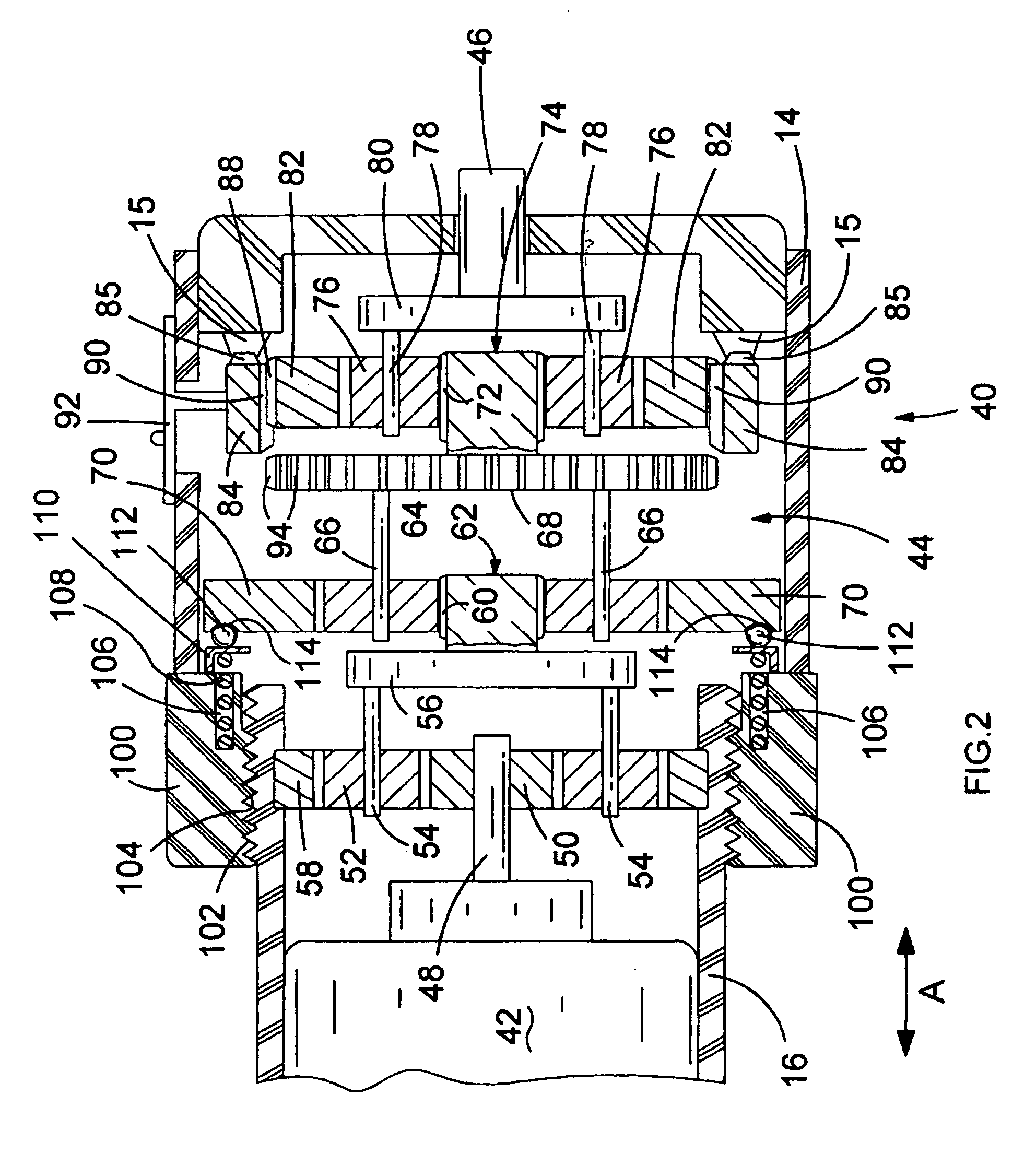

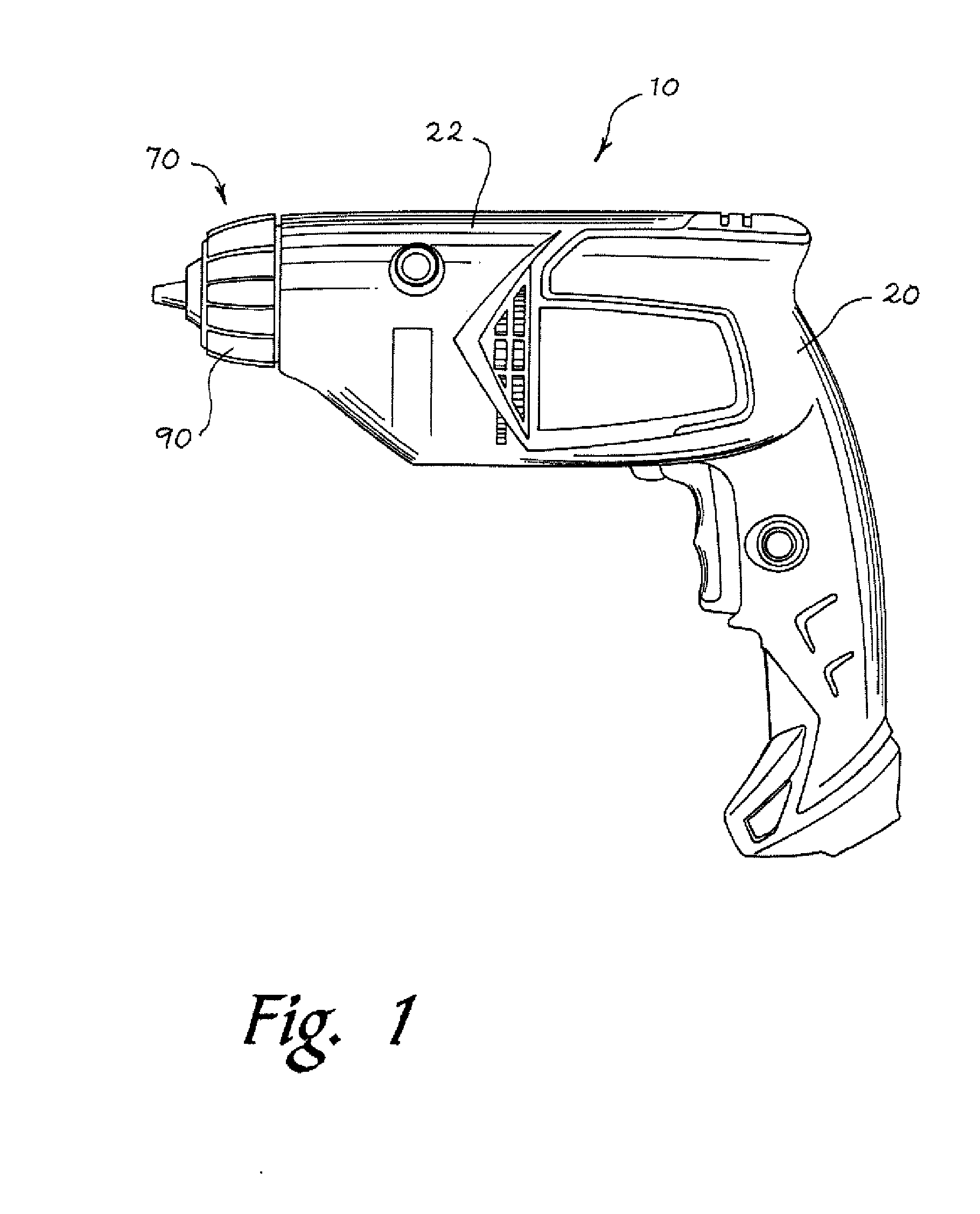

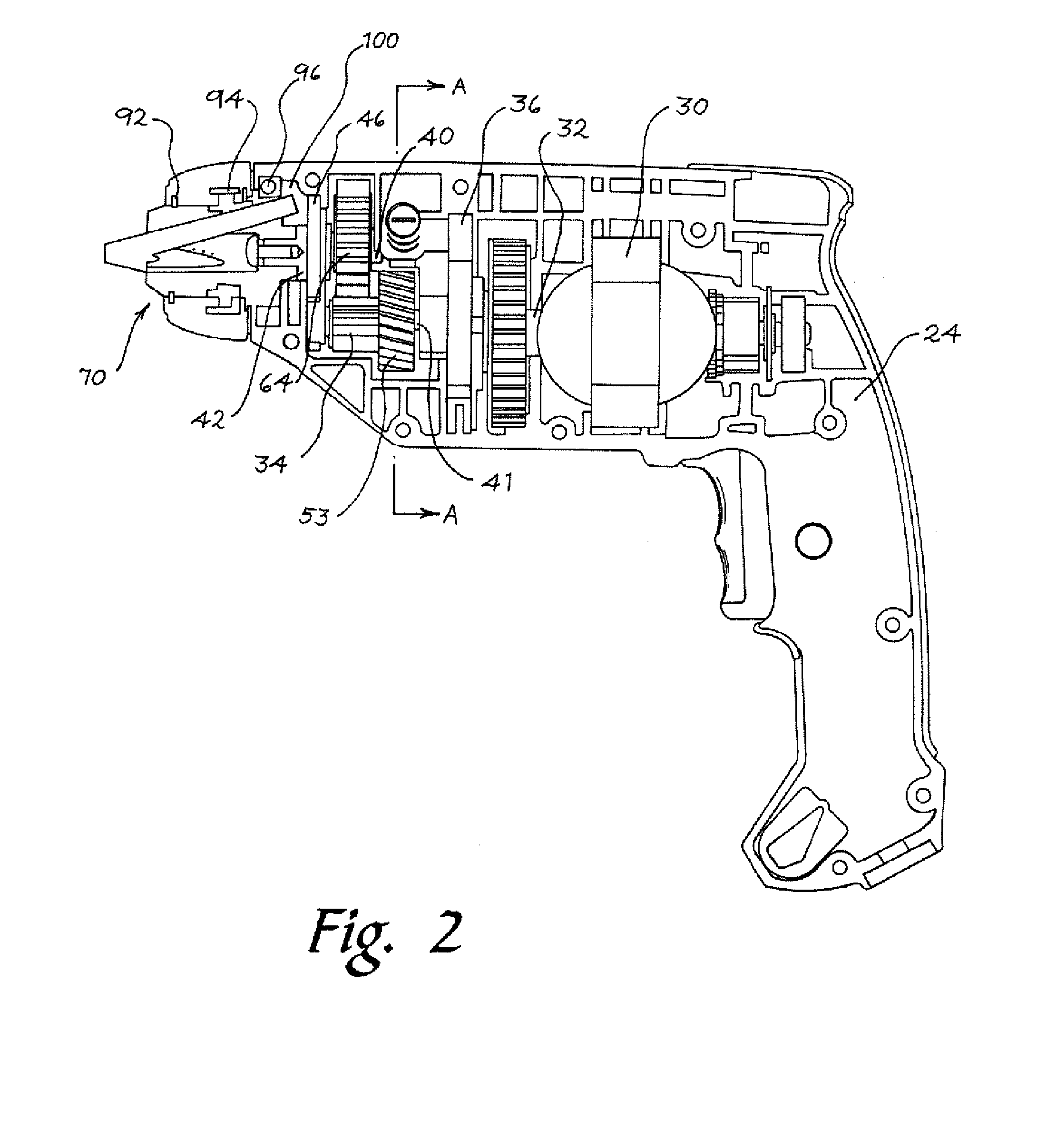

Power tool gear-train and torque overload clutch therefor

ActiveUS20060211534A1Easy to useClosely arrangedDrilling rodsConstructionsElectric machineEngineering

A power tool transmission is described in which an overload clutch mechanism is arranged to provide a relatively compact power tool. A torque adjustment dial is arranged between the visible portions of the motor housing and the gearbox, and the dial is coupled to a compression spring such that rotation of the dial cause the spring to be compressed or decompressed, thereby adjusting the torque at which the clutch overloads and ratchets. The compression spring is arranged at least partially between the motor and gearbox or gear train, in a space which conventional power tools do not utilised for this purpose. Thus, the dimensions of the power tool's transmission can be reduced with respect to conventional power tools. Furthermore, the space on the gearbox immediately behind a chuck can be used for another purpose other than accommodating the adjustment collar, as is the case with conventional power tools.

Owner:BLACK & DECKER INC

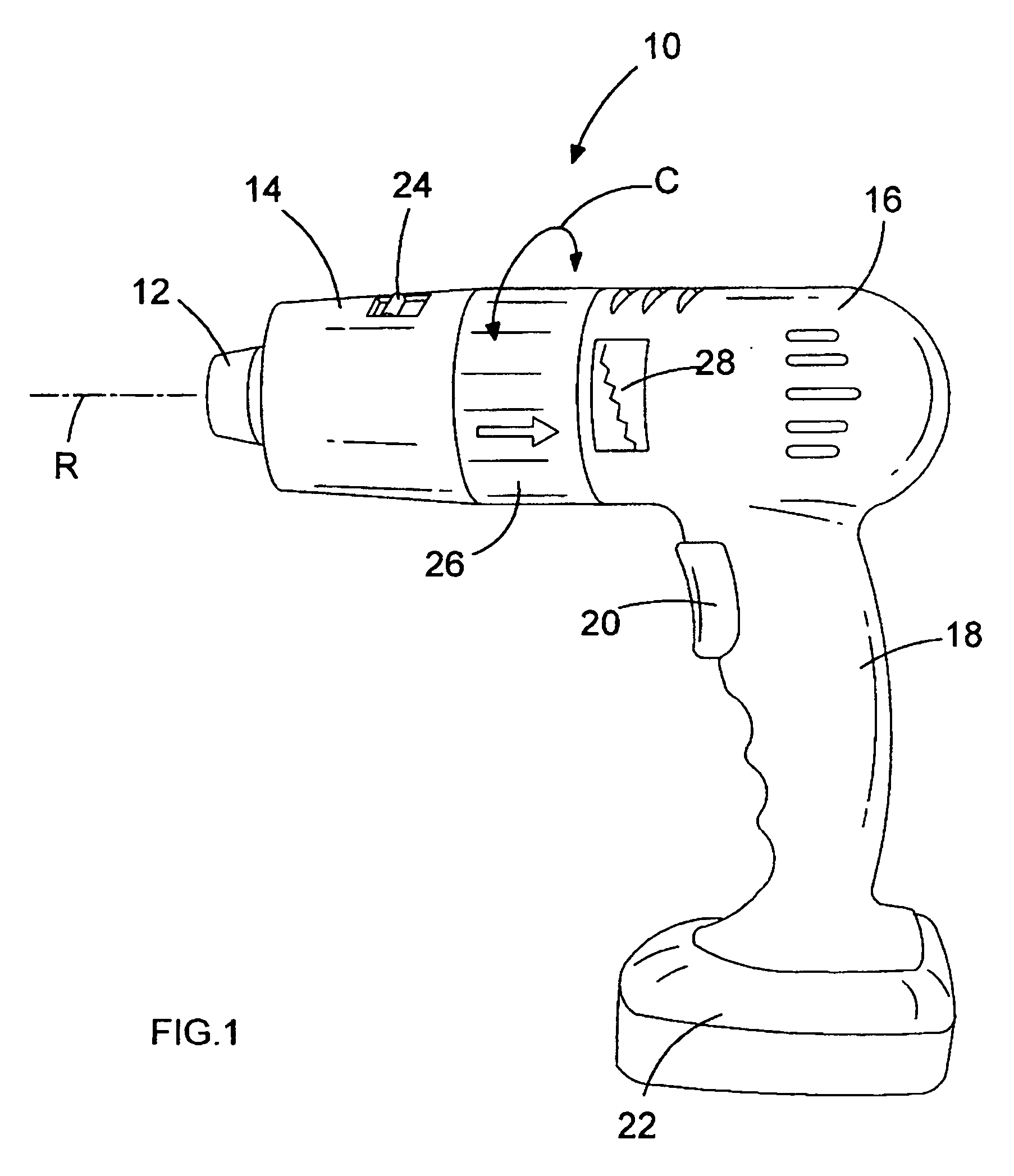

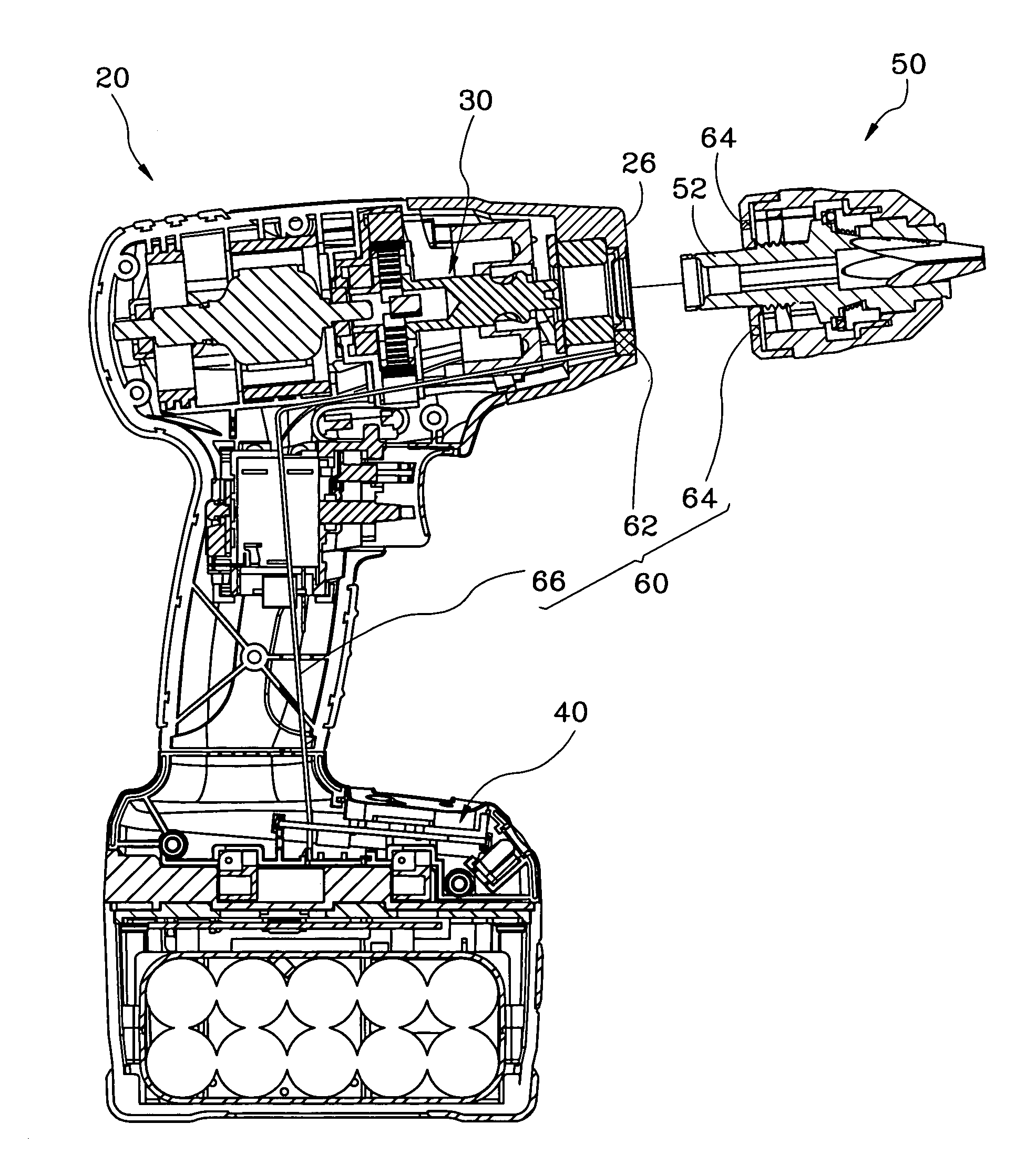

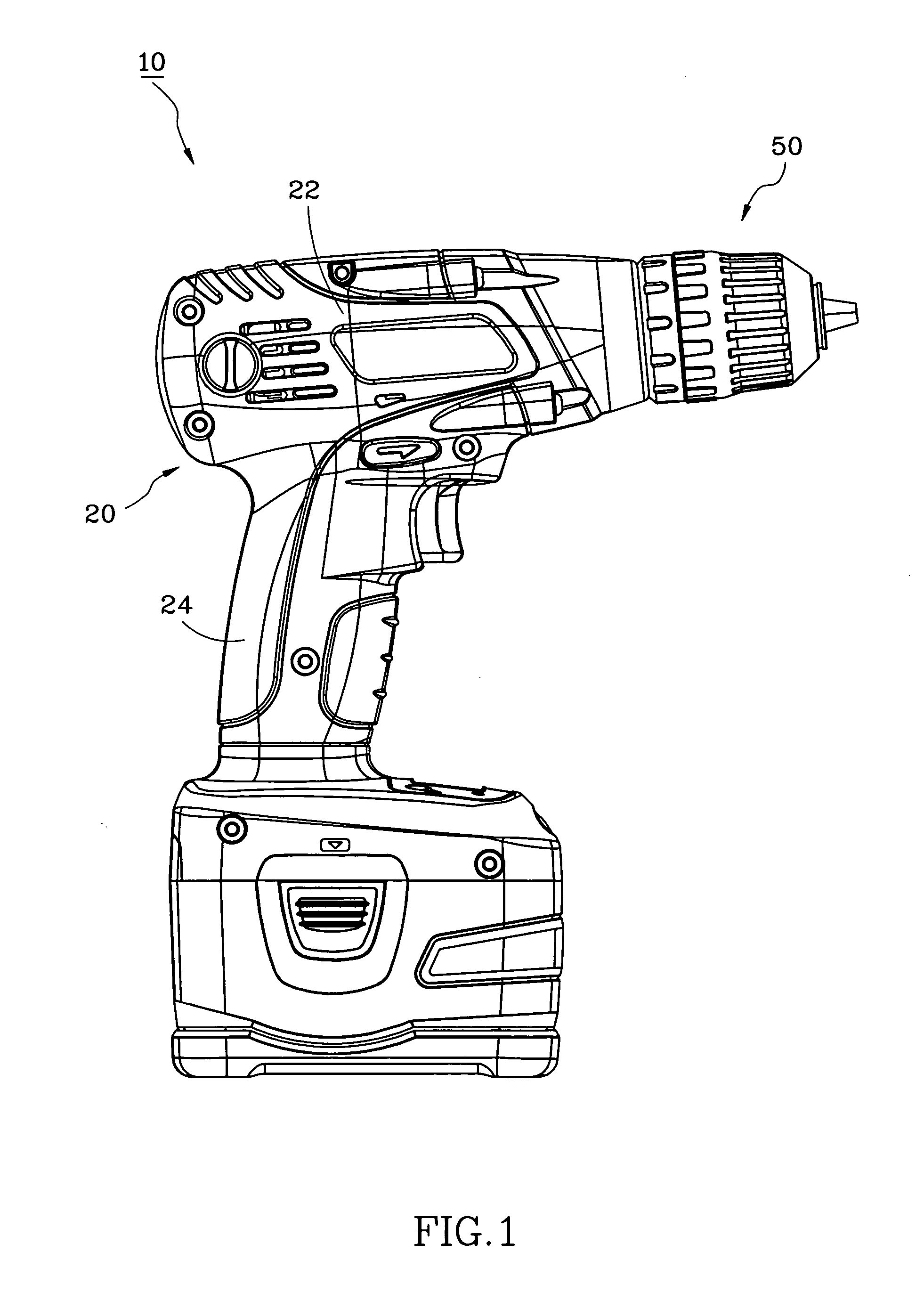

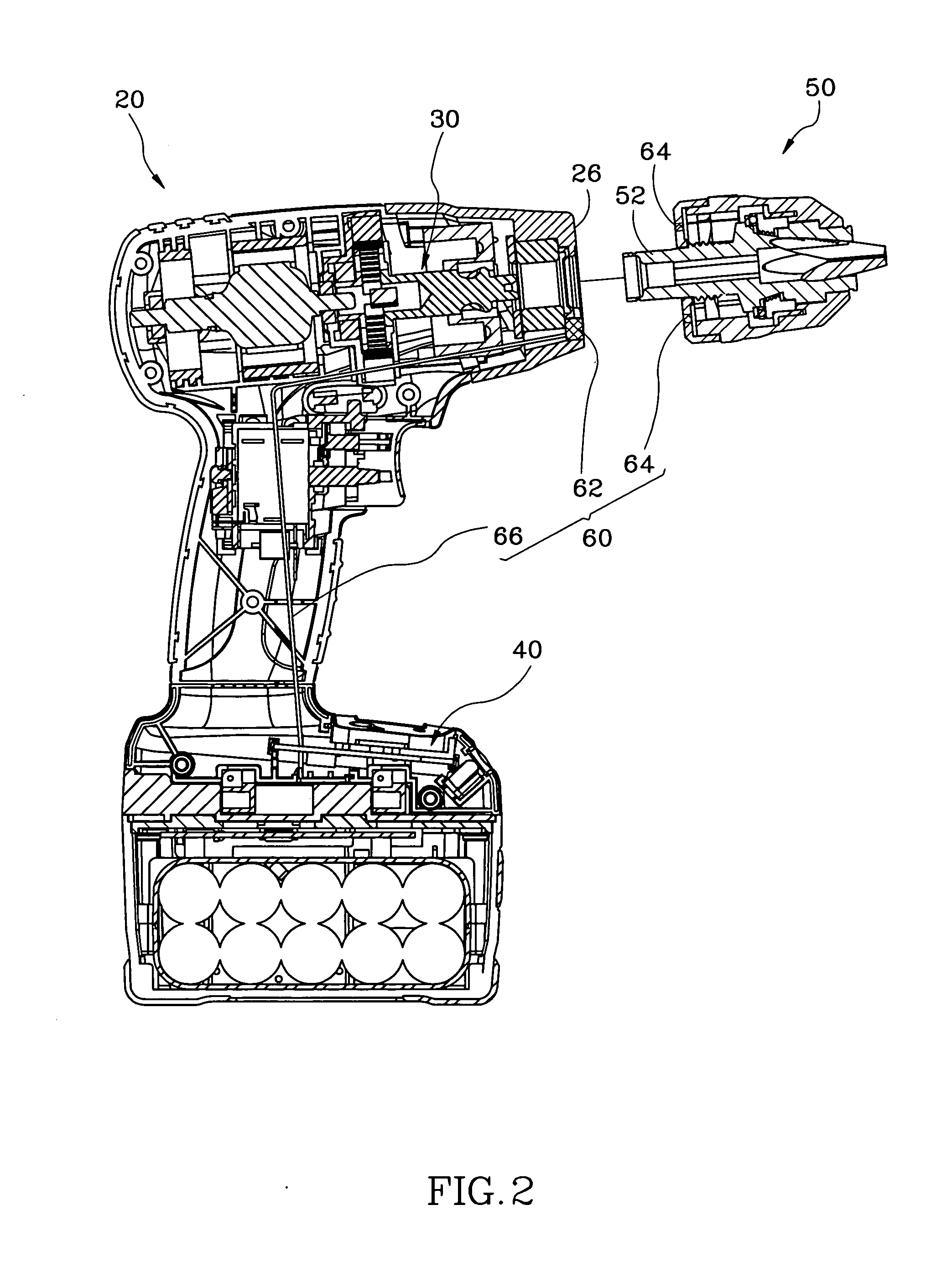

Multi-Speed Drill and Chuck Assembly

ActiveUS20090003950A1Prevent rotationThread cutting machinesThread cutting auxillary apparatusEngineeringDrill bit

A chuck assembly configured to provide a shorter longitudinal profile. The chuck assembly includes a chuck body with a support bearing mounted to a rear portion of the chuck body and mounted to a portion of a housing such that a cavity is defined axially rearward of the support bearing and is configured to receive the jaws when the rear portion of the jaws extend axially rearward. The chuck assembly can be incorporated into a tool driven by a motor. In some aspects, the tool may include a speed change mechanism, a torque adjustment mechanism, or both.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

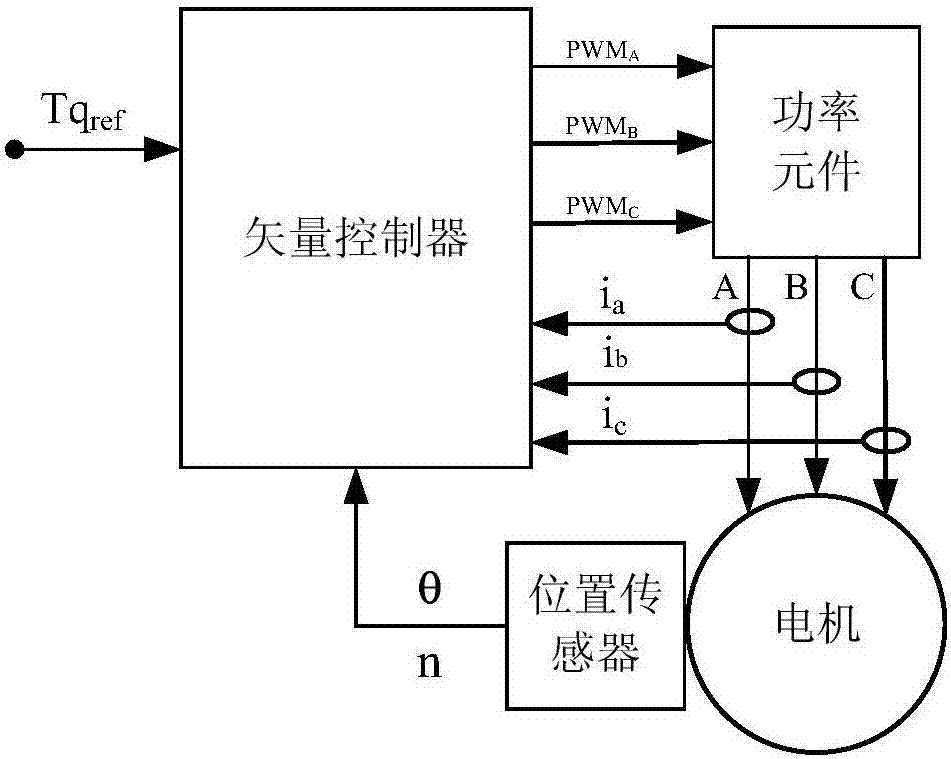

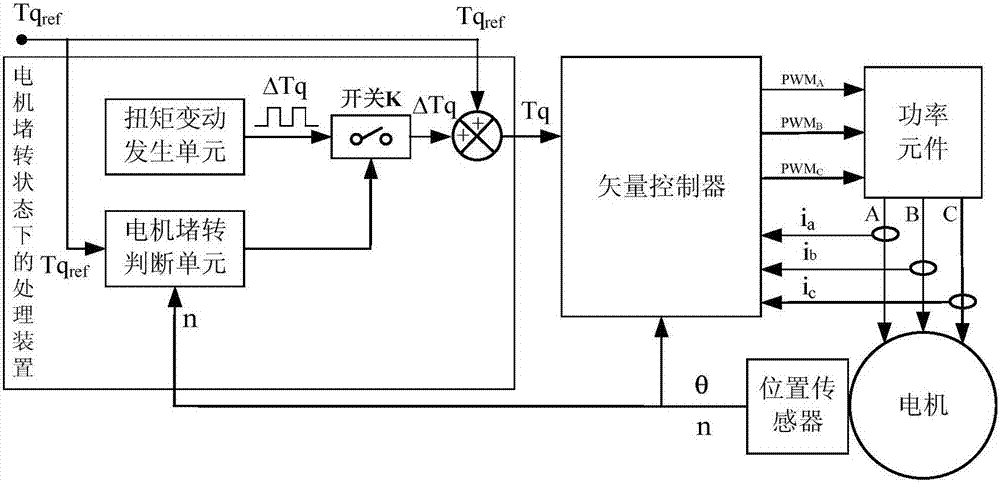

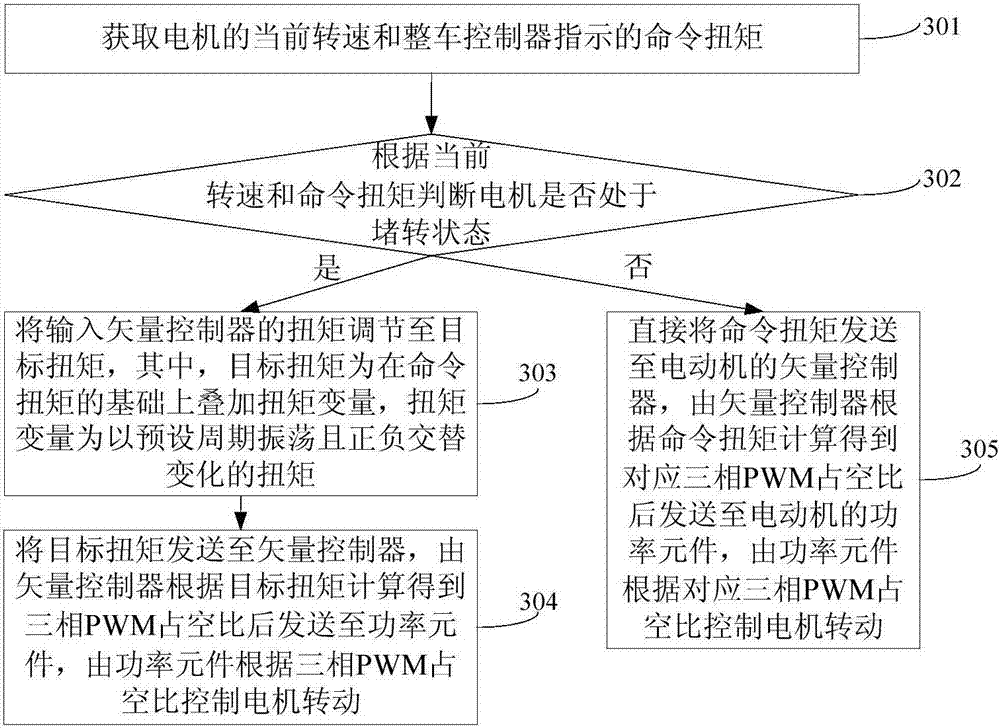

Processing method and device of motor under locked-rotor state

ActiveCN107306108AAvoid damageReduce temperature riseElectronic commutation motor controlSpeed controllerTorque regulationThree-phase

The embodiment of the invention discloses a processing method and device of a motor under a locked-rotor state, and belongs to the field of driving and control of an electric vehicle. A torque input to a vector controller is regulated to a target torque when that the motor is in the locked-rotor state is determined according to a current rotational speed and a command torque, the target torque is in a way that torque change quantity is superposed on the basis of the command torque, the torque change quantity is a torque oscillating in a preset period and changing in a positive-negative alternative way, the target torque is send to the vector controller, a three-phase pulse width modulation (PWM) duty ratio is obtained by calculation of the vector controller according to the target torque and then is sent to a power component, and the power component controls the motor to rotate. According to the method disclosed by the embodiment of the invention, the target torque is in a way that the torque change quantity is superposed on the basis of the command torque, the torque change quantity is the torque oscillating in the preset period and changing in the positive-negative alternative way, so that a rotational angle of a motor rotor changes periodically, a current peak of a single phase of the power component can be correspondingly reduced, and the motor can be prevented from being damaged when in the locked-rotor state due to excessive high temperature rising.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

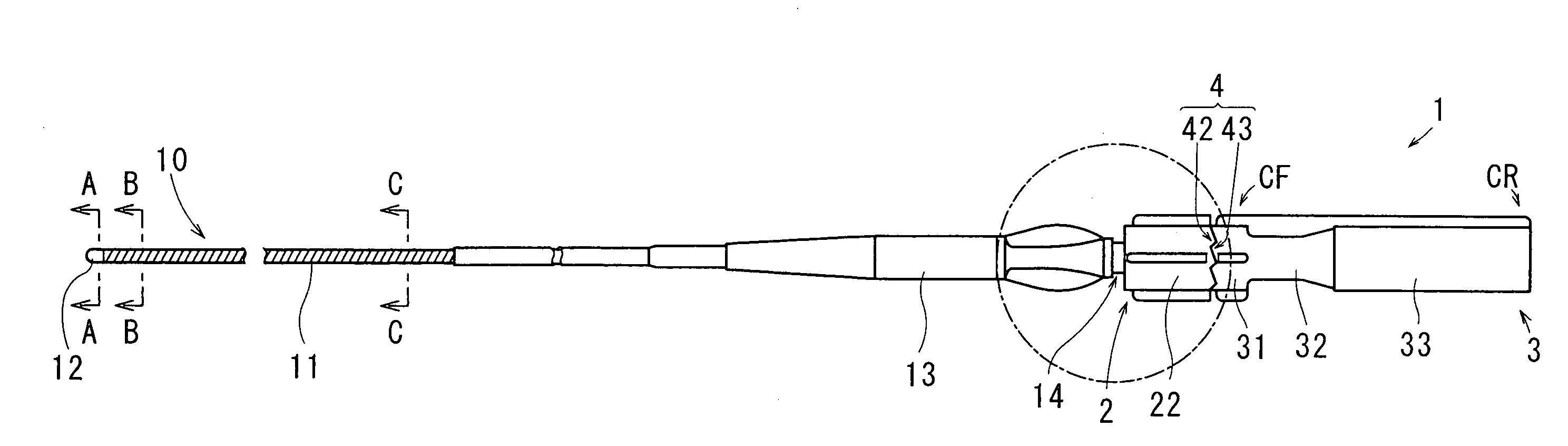

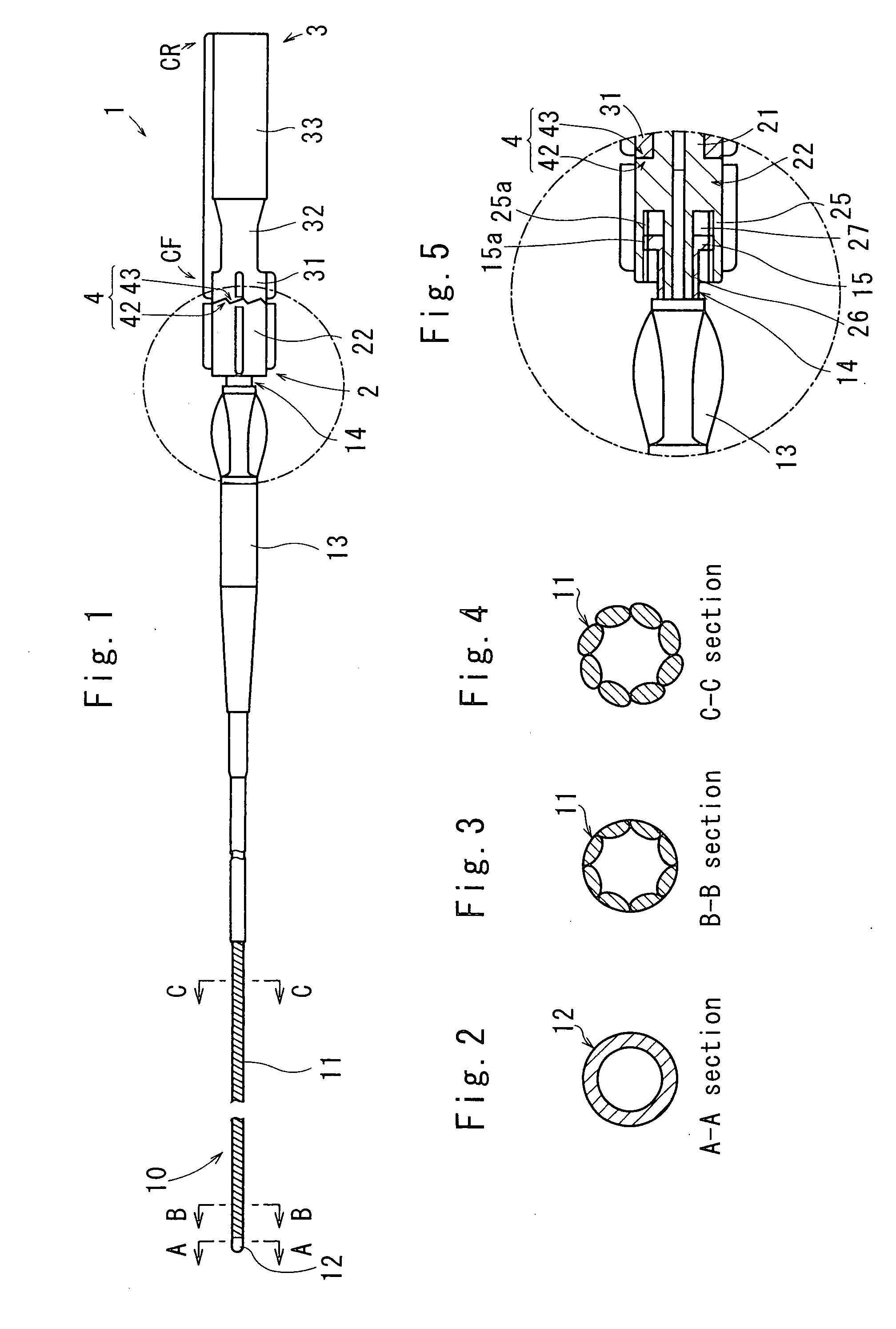

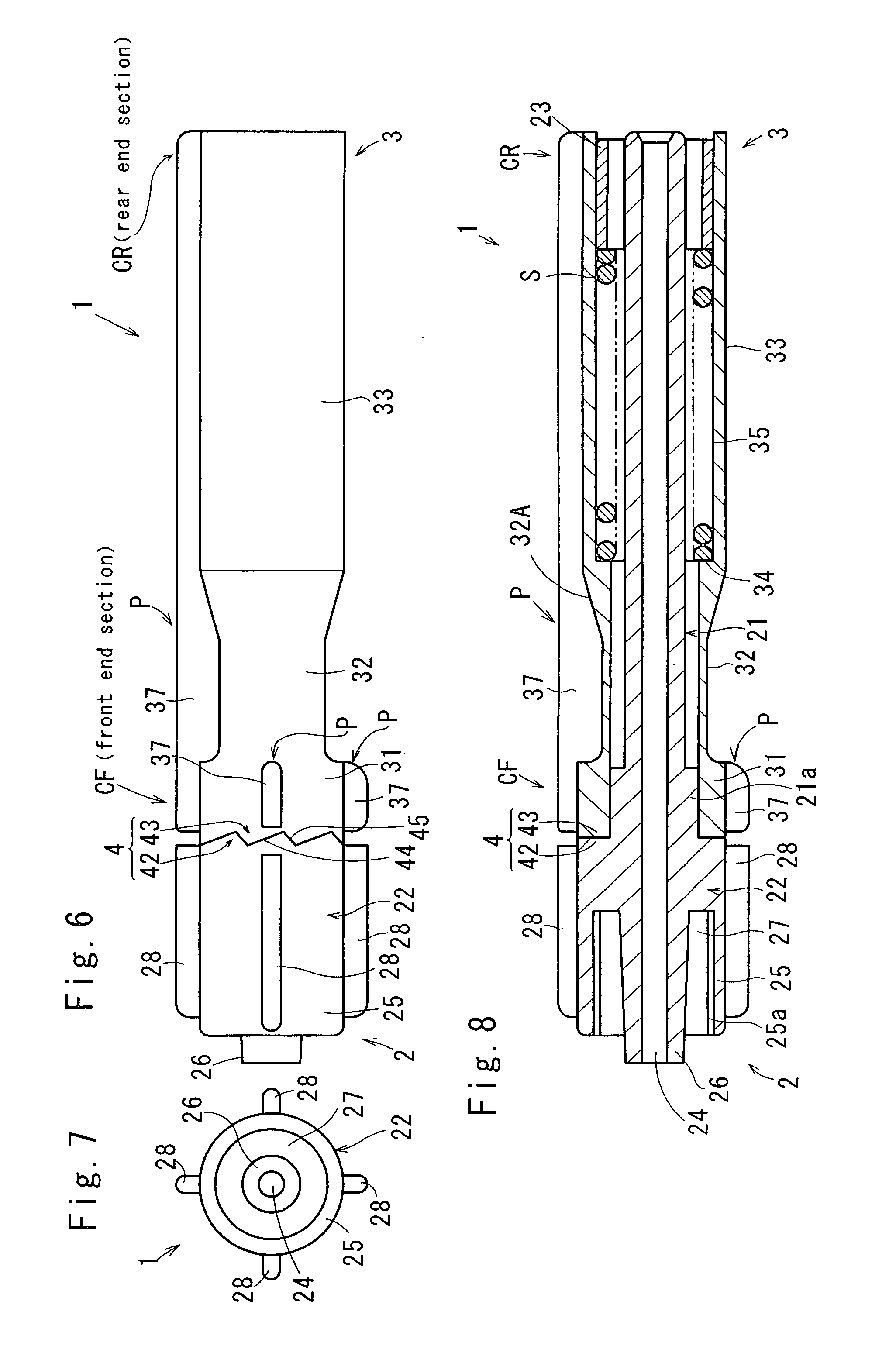

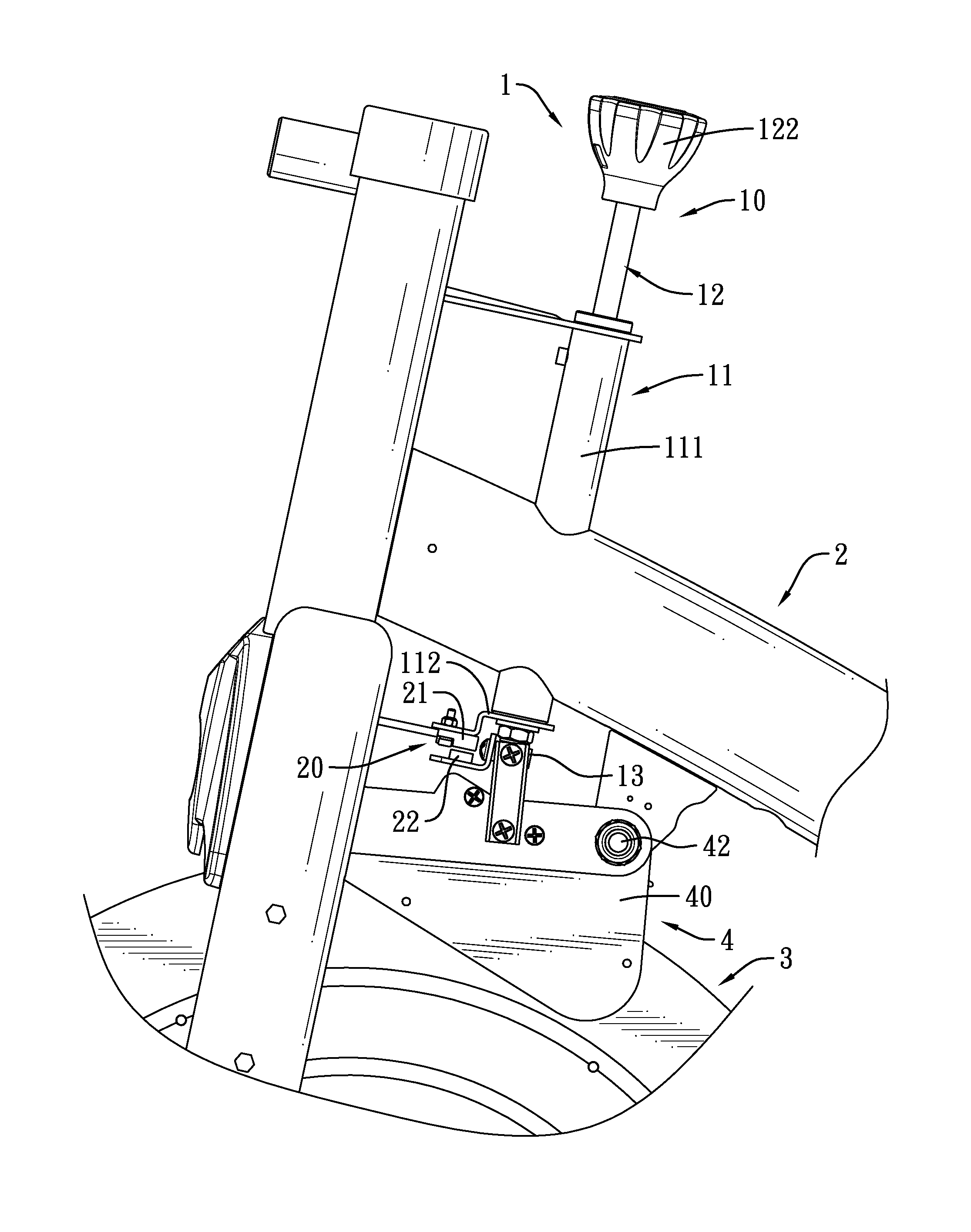

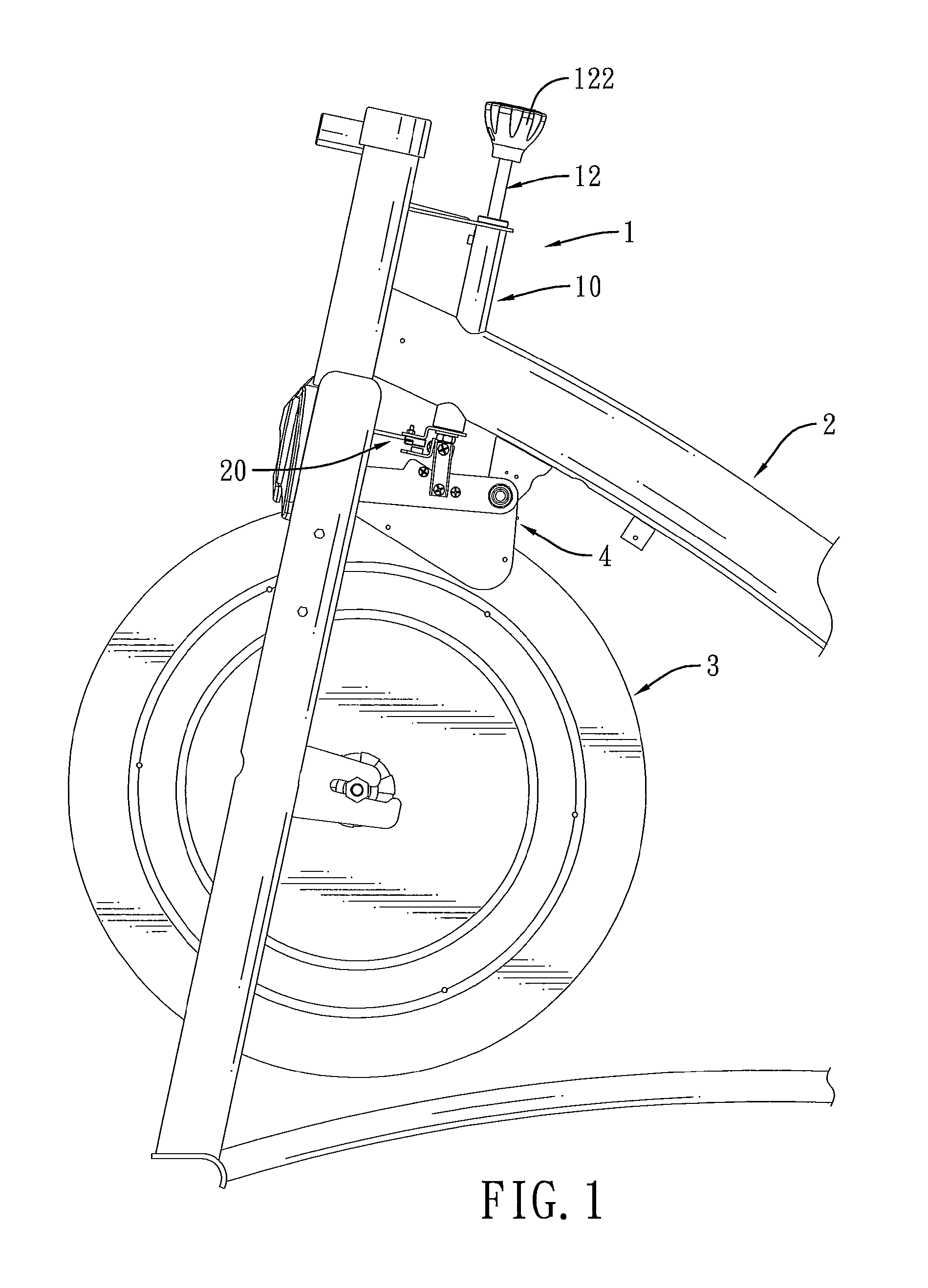

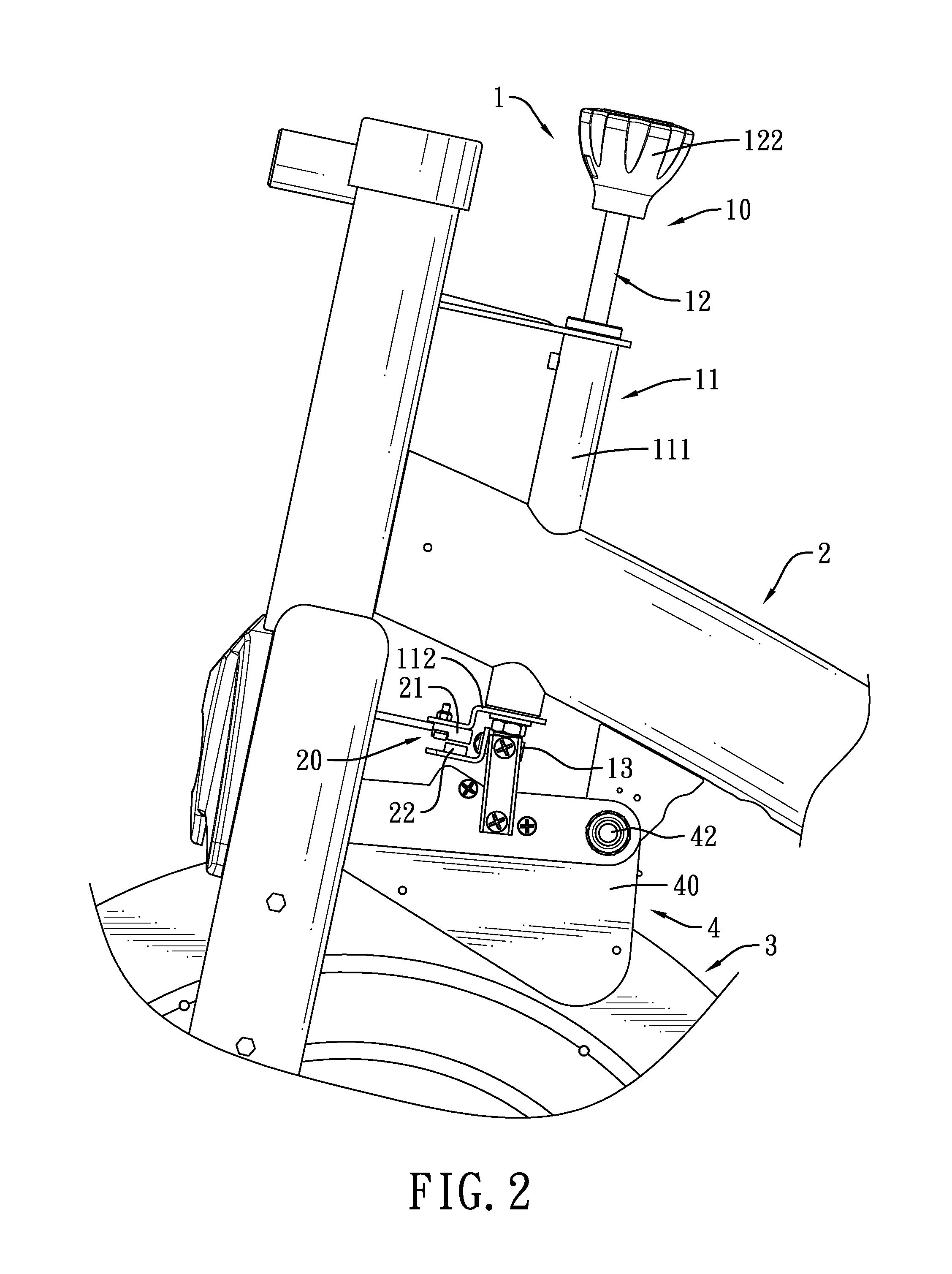

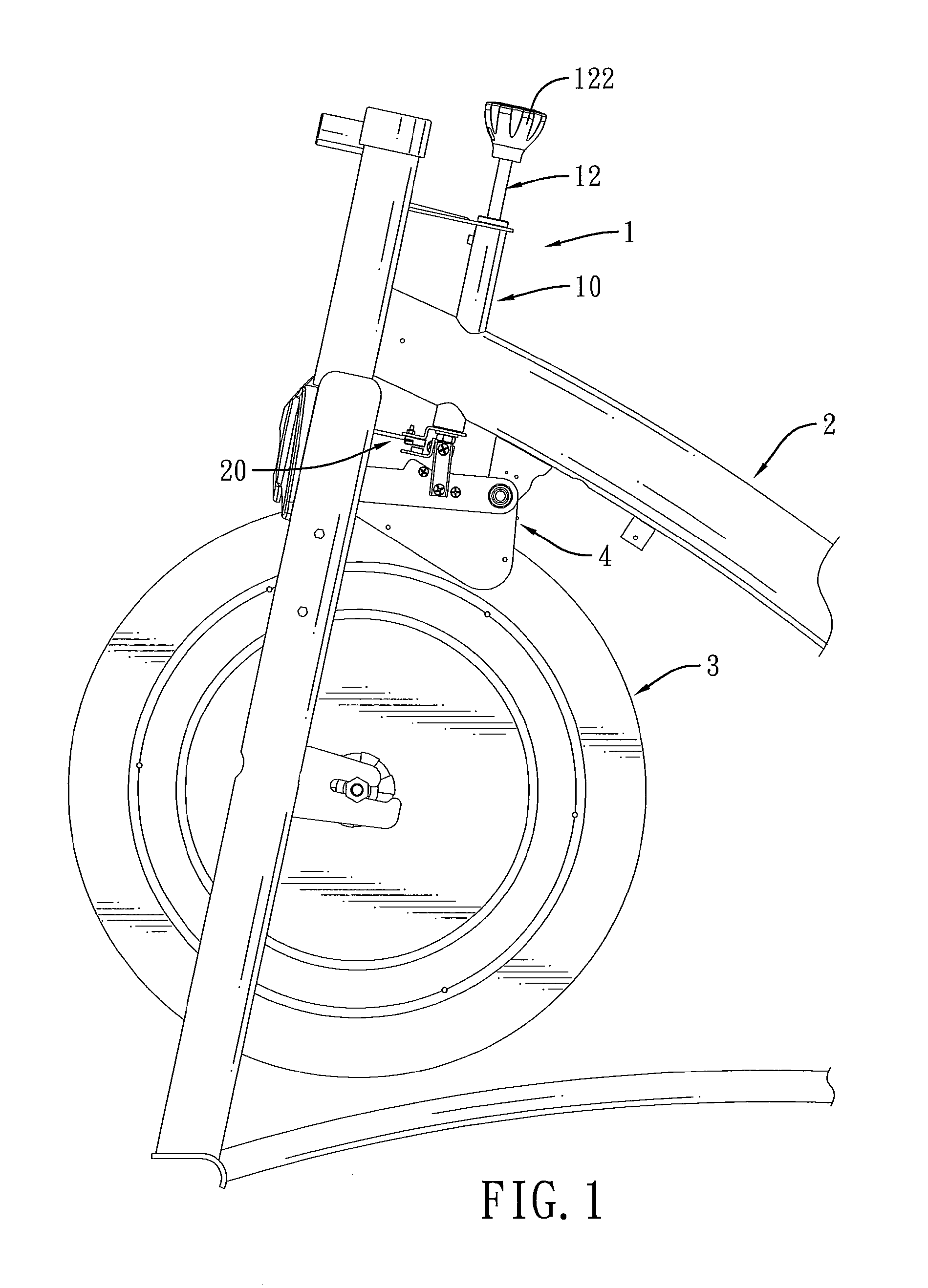

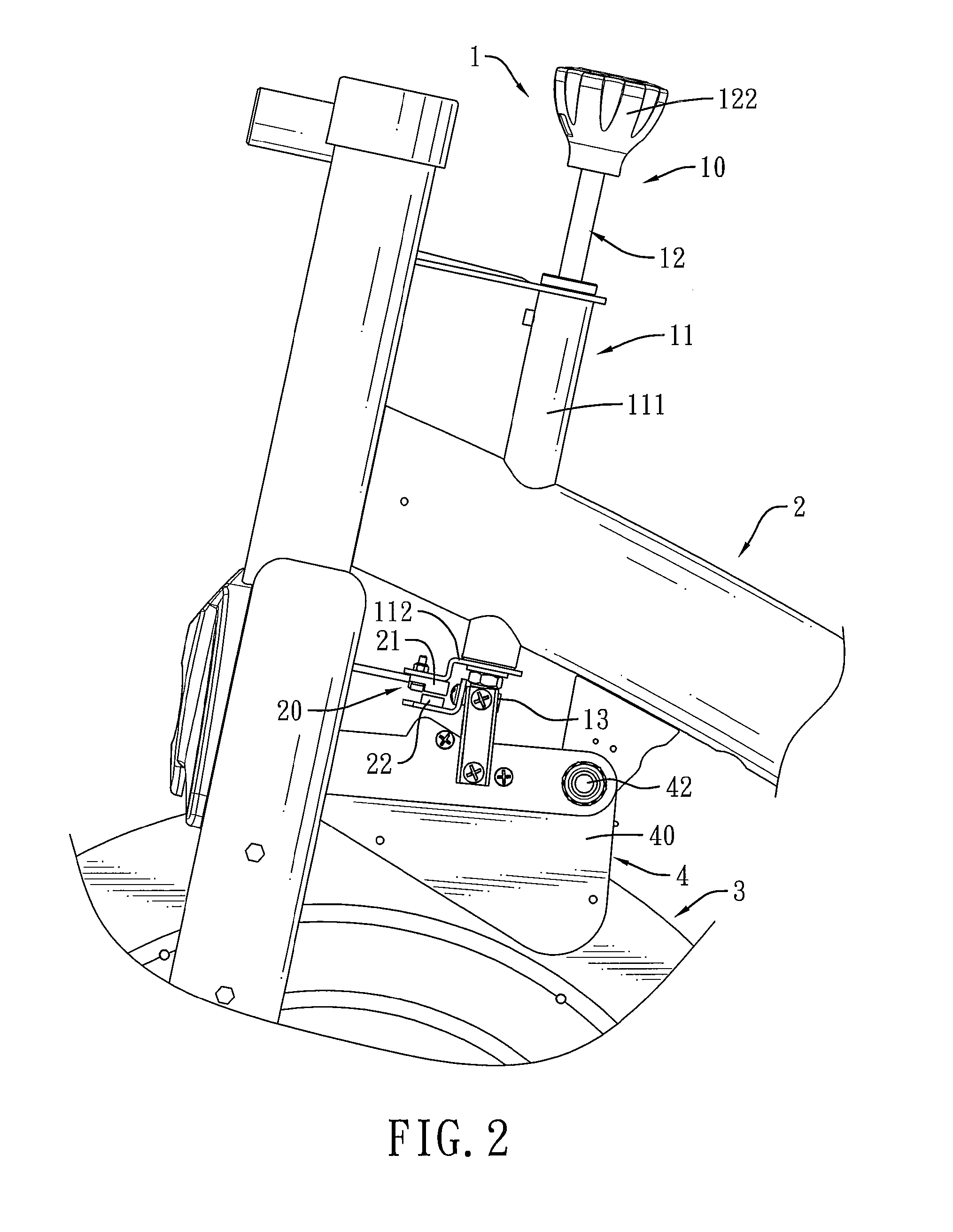

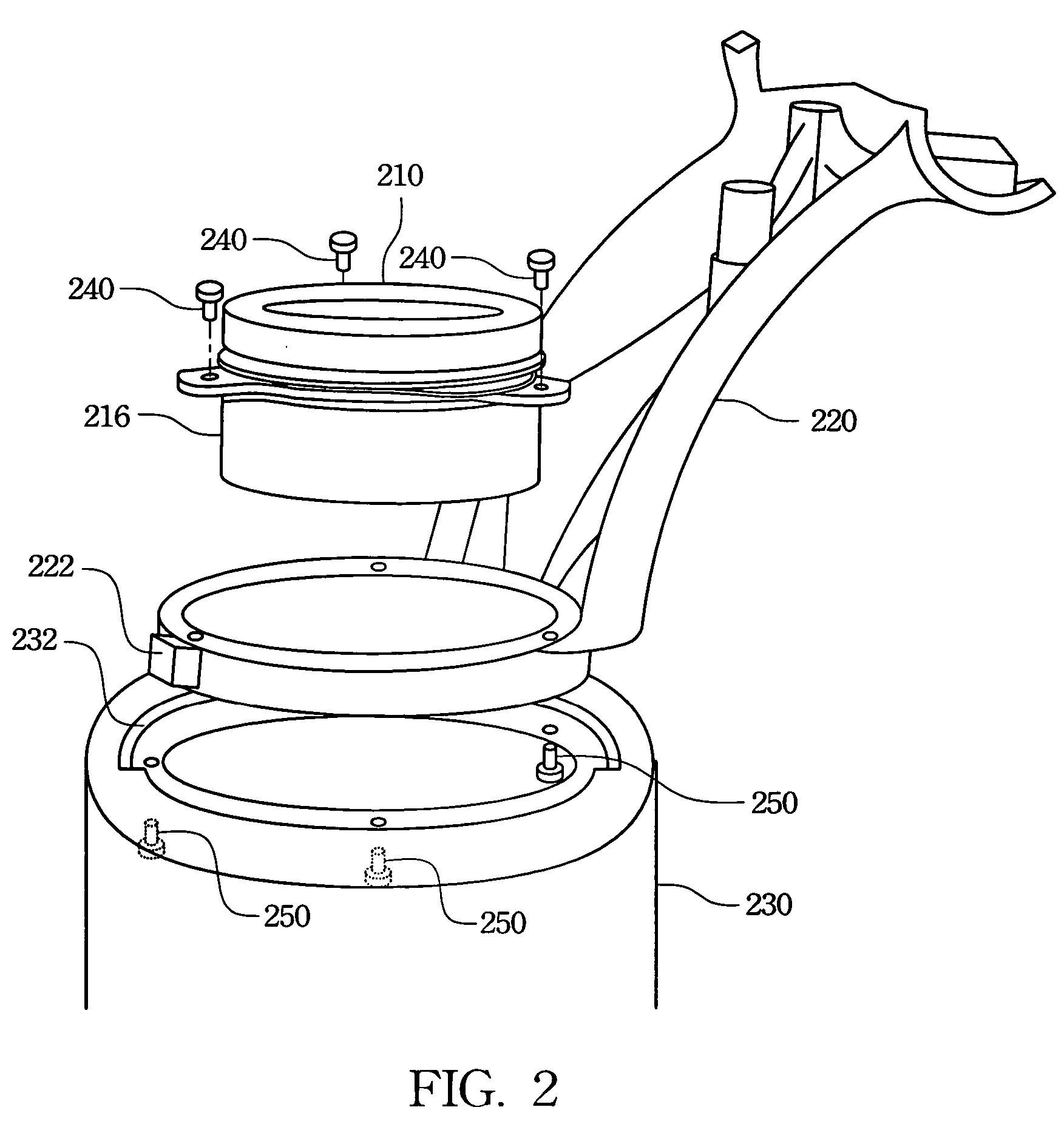

Medical Equipment, Tubular Insertion Device and Tubular Insertion Device Having the Same Medical Equipment

In a medical equipment (1), tubular insertion device (10A) and tubular insertion device having the medical equipment (1), the medical equipment (1) has a main body (2) regulated to rotate around an axis of the tubular insertion device (10A) and having a cylindrical body (3) provided in contact with the main body (2) to rotate integrally with the main body (2). A torque regulation mechanism (4) is provided to release the integral rotation in unison with the main body (2) so as to block a torque transmission to the tubular insertion device (10A) when a torque applied to the cylindrical body (3) is more than a predetermined value. The block of the transmission renders it incapable to further rotate the tubular insertion device (10A), whereby preventing a torsional buckling from being induced on the insertion device (10A), and enabling the operator to quickly perceive an excessive torque.

Owner:ASAHI INTECC CO LTD

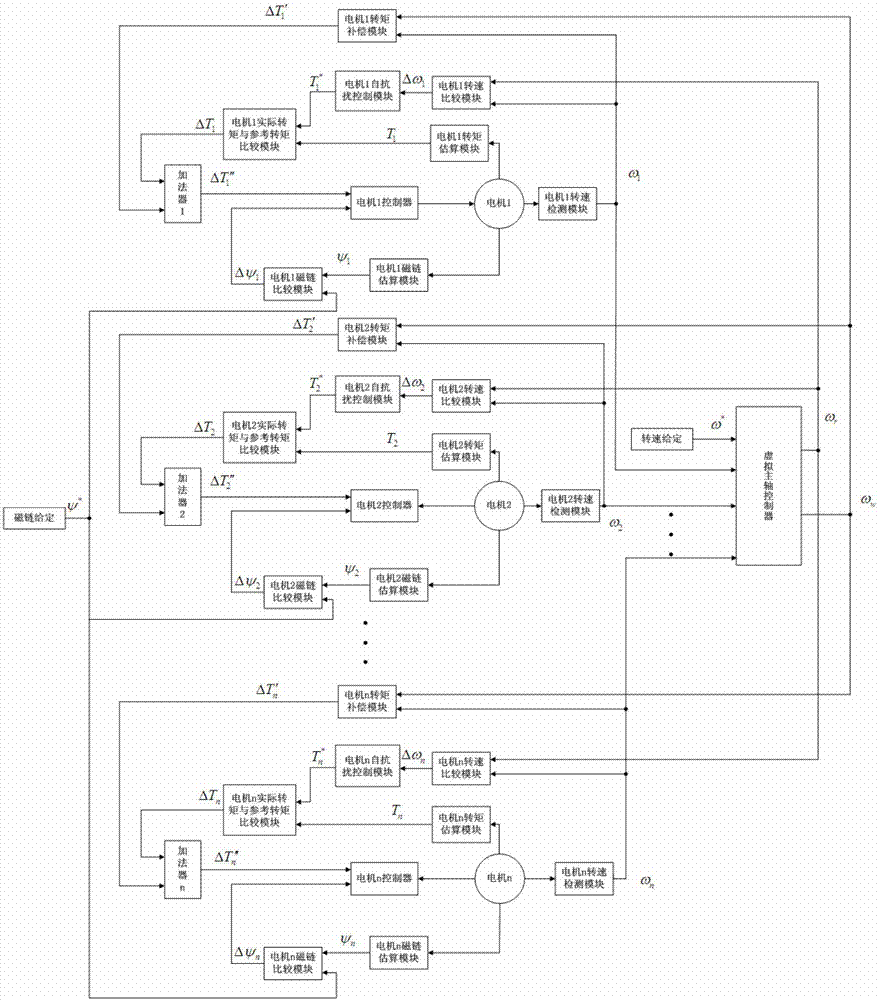

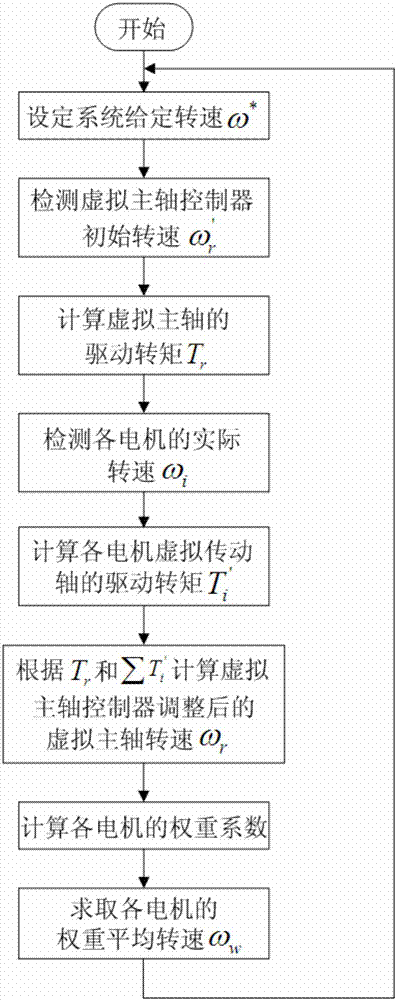

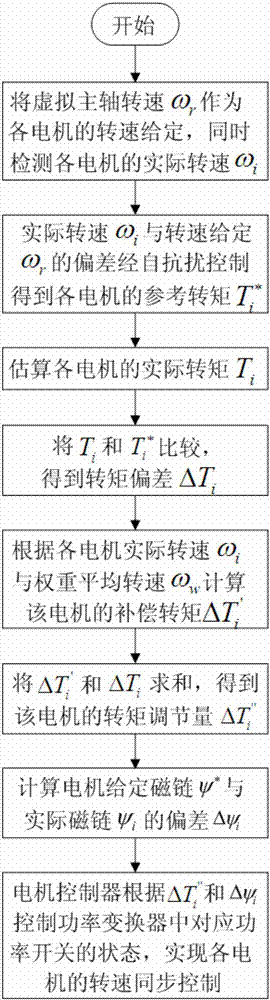

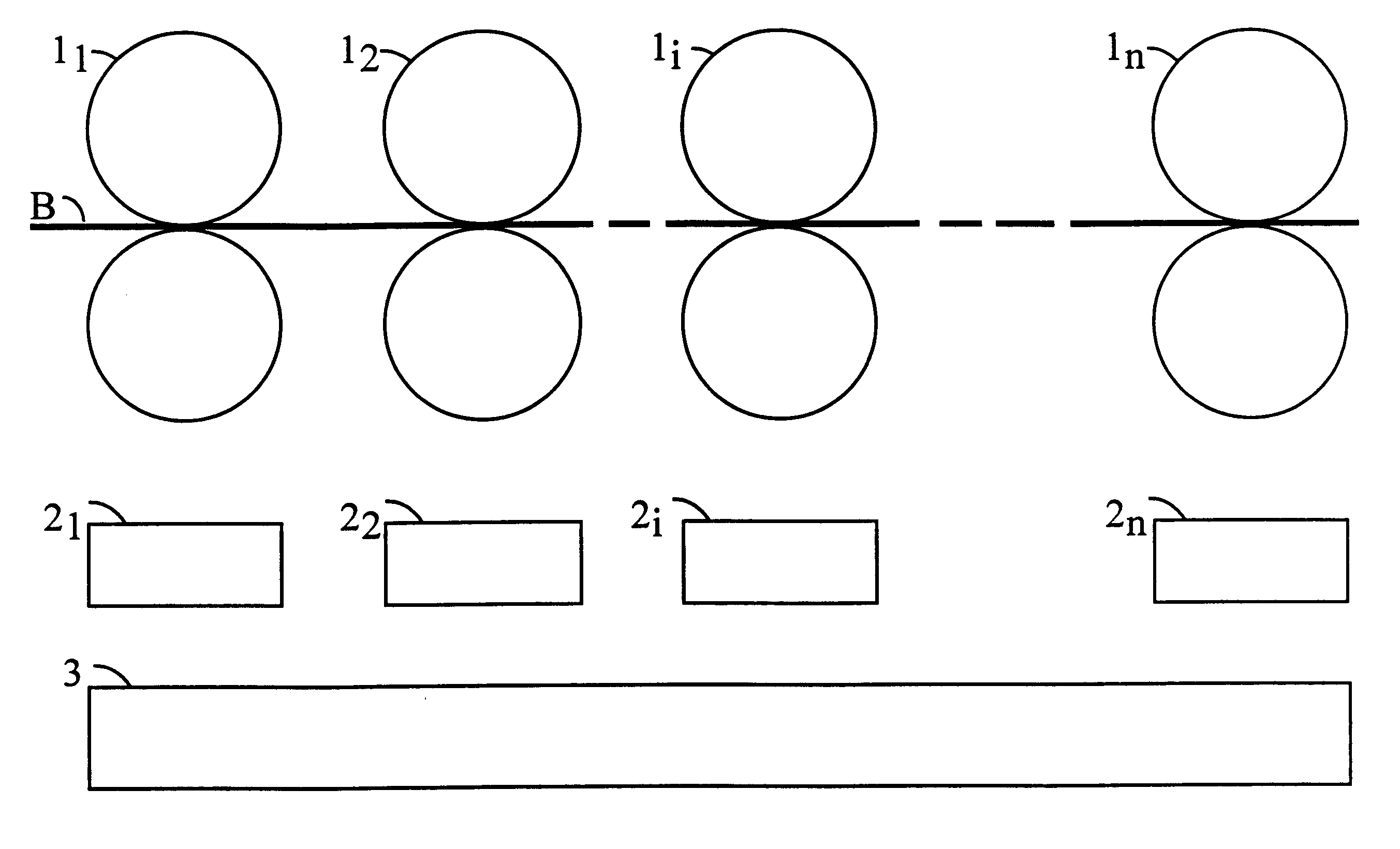

Rotational speed synchronous control device and control method of multi-switch reluctance motor

ActiveCN107070315ATo achieve synchronous operationAccurate trackingAC motor controlVector control systemsMotor speedSynchronous control

The invention discloses a rotational speed synchronous control method of a multi-switch reluctance motor. The rotational speed synchronous control method comprises the following steps of calculating a rotational speed of a virtual main shaft, taking the rotational speed as a given rotational speed of each motor; calculating weight average rotational speed of each motor, and taking the weight average rotational speed as a reference rotational speed of each motor torque compensation module; calculating a reference torque of each motor, and comparing the reference torque with an actual torque of the motor to obtain corresponding torque deviation; calculating a corresponding compensation torque of each motor, and adding the corresponding compensation torque to the torque deviation to obtain torque regulation quantity of each motor; comparing actual flux of the motor with given flux of a system to obtain flux deviation; controlling the motor according to the torque regulation quantity and the flux deviation so that accurate tracking on the given rotational speed of the system by the actual rotational speed of each motor can be achieved and the purpose of synchronous running at various motor rotational speeds is achieved. The invention also discloses a rotational speed synchronous control device of the multi-switch reluctance motor.

Owner:HUNAN UNIV OF SCI & TECH

Torque sensing apparatus

A torque sensing apparatus has a torque adjusting assembly and a non-contact sensing assembly. The torque adjusting assembly has a fitting unit, a regulating rod and a regulating seat. The non-contact sensing assembly has a first device and a second device. The regulating rod is rotatably mounted through the fitting unit. The regulating seat is movably mounted on the regulating rod and located outside the fixed plate of the fitting unit. The first device is mounted on the fixed plate. The second device is mounted on the regulating seat and kept from contacting the first device. The non-contact sensing assembly detects a change of the distance between the first device and the second device and generates a signal to a controller, and the controller gauges a torsional value of the torque adjusting assembly. Therefore, the non-contact sensing assembly is not abraded and increases the precision of the torque sensing apparatus.

Owner:WU MU CHUAN

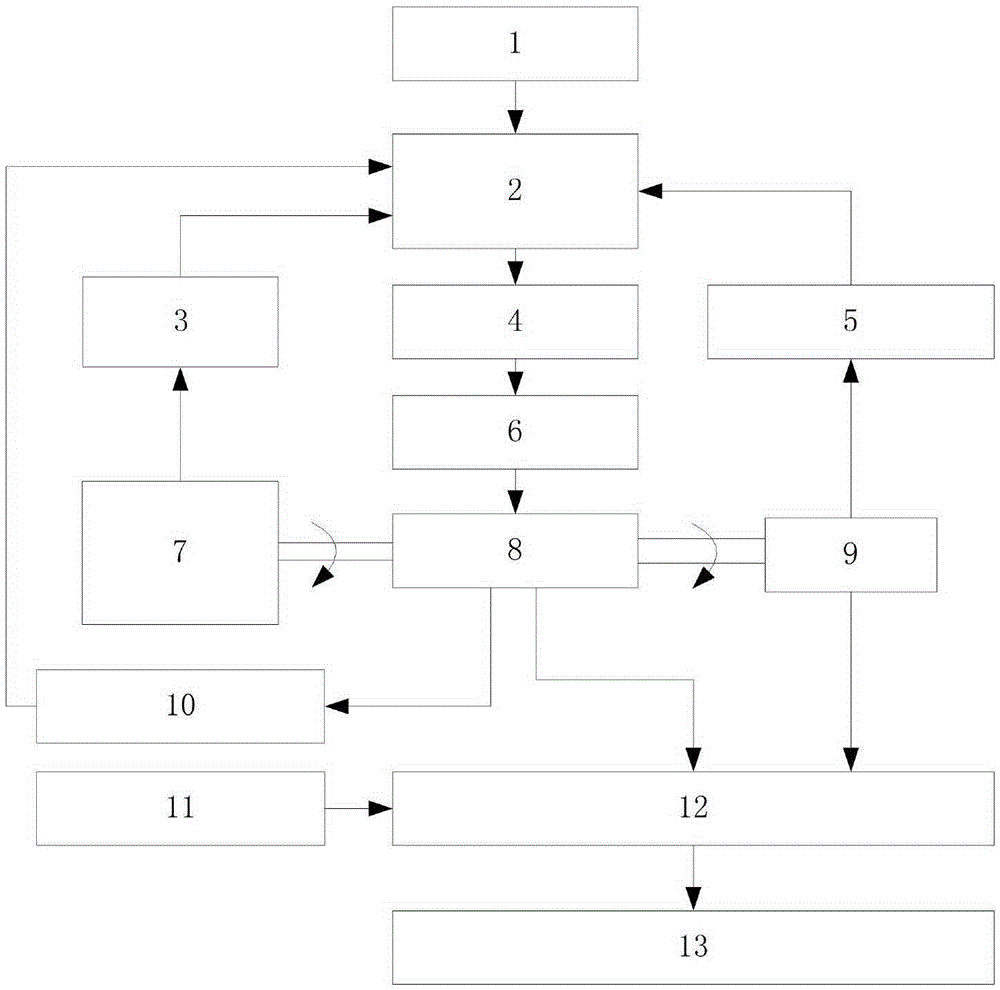

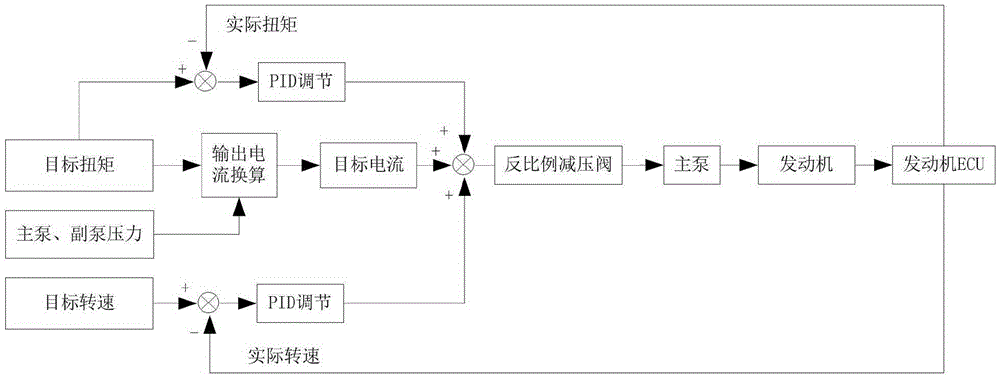

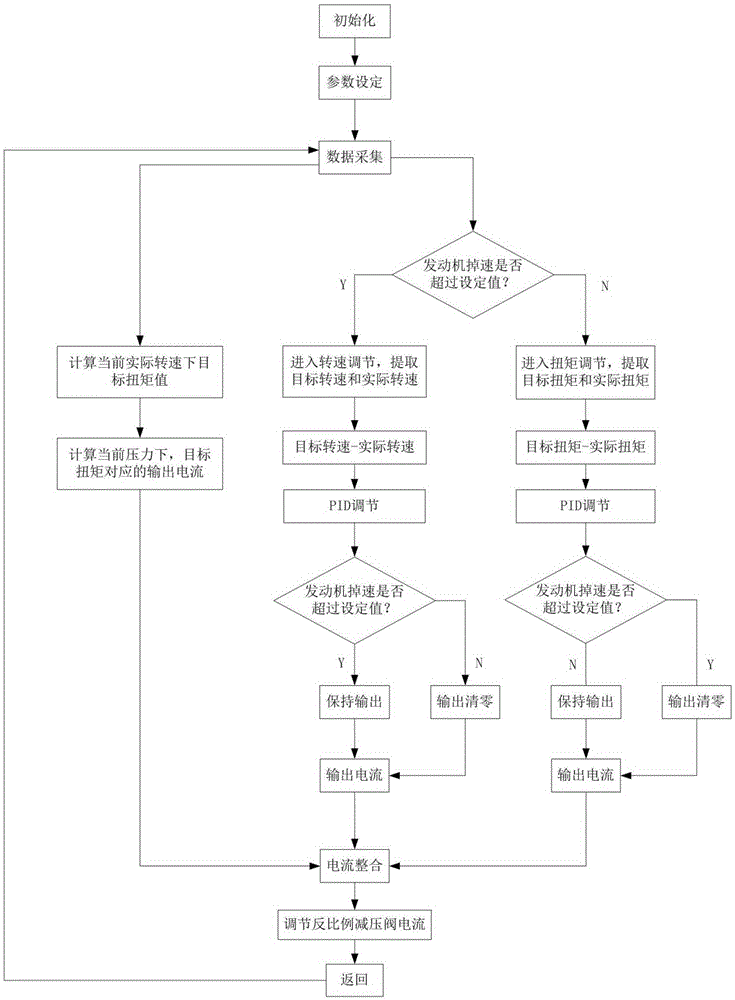

Power matching method based on torque and rotation speed compound control for rotary drilling rig

ActiveCN105402039AReal-time control of input powerAvoid severe slowdownMechanical controlMachines/enginesControl systemComputer module

The invention discloses a power matching method based on torque and rotation speed compound control for a rotary drilling rig. The power matching method comprises the following steps: calculating target current according to pressure of a primary pump and a secondary pump and set target torque percentage; setting a speed drop value during interconversion of a rotation speed regulating module and a torque regulating module; when a real-time speed drop value of an engine is smaller than a set value, adopting the torque regulating module to carry out compensation regulation on target current; when the real-time speed drop value of the engine is greater than the set value, adopting the rotation speed regulating module to carry out compensation regulation on the target current; and outputting a final current value to an inverse proportion pressure-reducing valve to control a displacement regulator to change displacement of the primary pump, thereby controlling input power of the primary pump in real time. The power matching method is simple, reliable and high in practicability, has the characteristics of rotation speed control rapidity and torque control predictability, can effectively avoid severe speed drop of the engine, avoids a shut-down phenomenon, improves operation efficiency of the rotary drilling rig and guarantees operation stability of a control system.

Owner:徐州惠力机械制造有限公司

Power tool and torque adjustment method for the same

InactiveUS20110203819A1Improve work efficiencyAvoid damageSpannersWrenchesDriver/operatorTorque regulation

A power tool includes a detecting member mounted in an output end of a housing, and a to-be-detected member mounted in a driver. When the driver is assembled with the output end of the housing, the detecting member will detect the to-be-detected member and transmit a signal to a torque adjustment unit disposed in the housing so as to enable the torque adjustment unit to automatically adjust the torque applied to the driver to reach a predetermined value, thereby preventing damage to the driver.

Owner:MOBILETRON ELECTRONICS

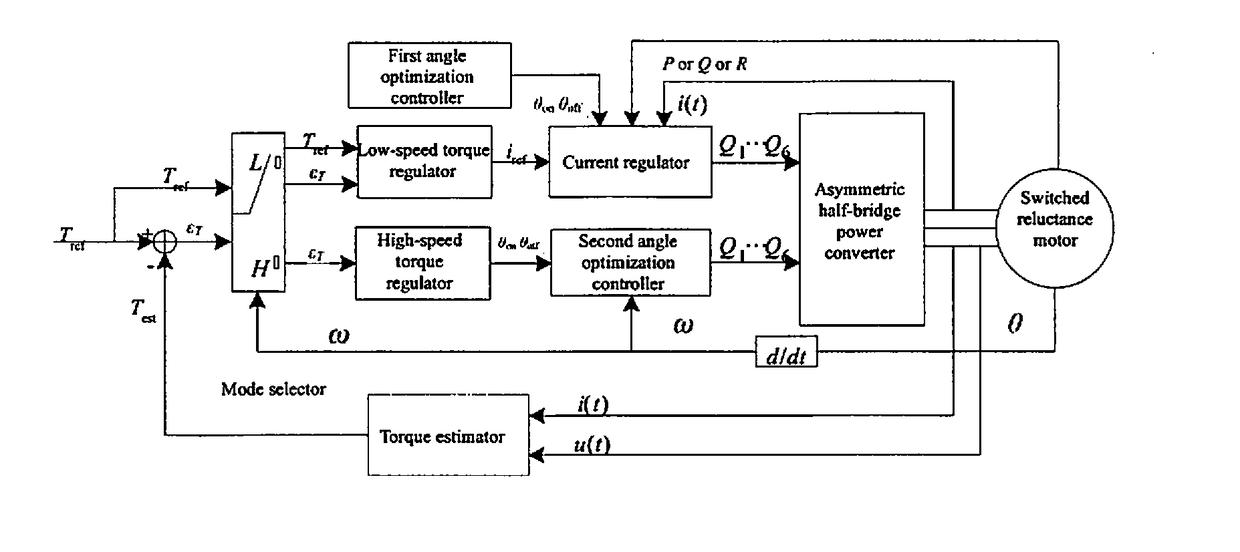

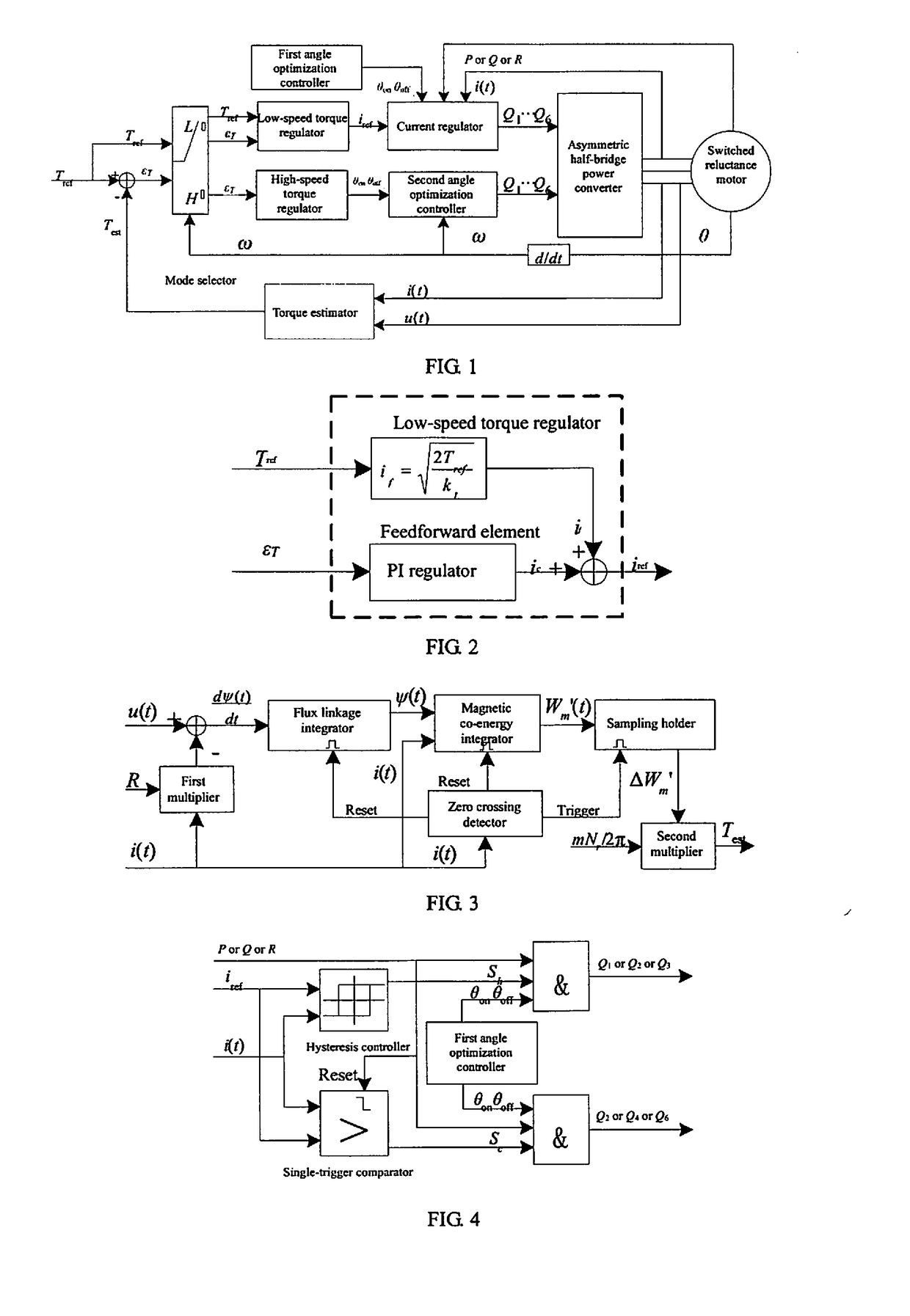

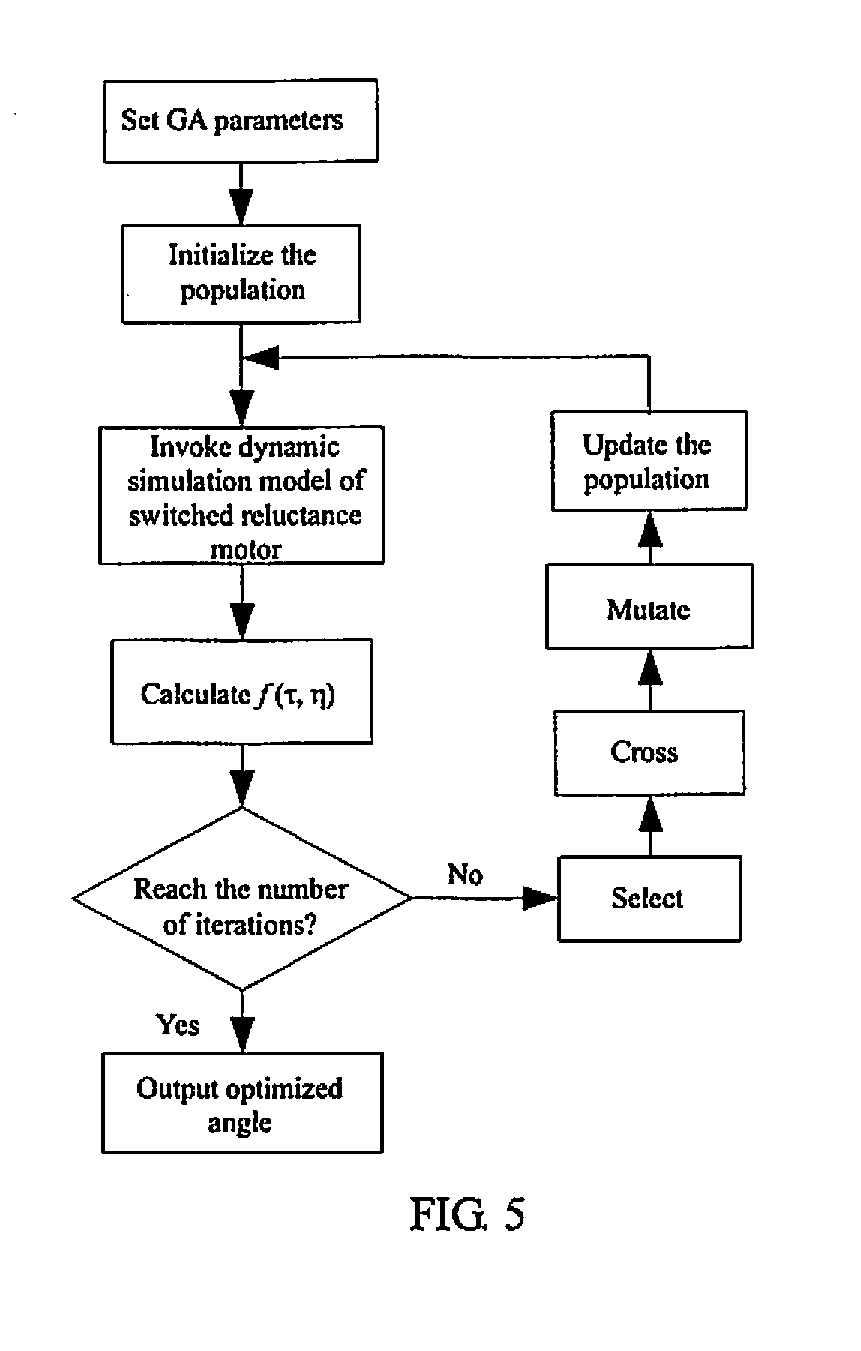

Braking torque closed-loop control system and method for switch reluctance motor

ActiveUS20170250635A1Reduce switching frequencySmall switching lossAC motor controlVector control systemsPhase currentsBrake torque

A braking torque closed-loop control system and method for a switch reluctance motor. The closed-loop control system comprises a torque regulator, a mode selector, a current regulator, an angle optimization controller and a torque estimator. On the basis of the rotating speed of the motor, the mode selector implements a phase current soft chopper control in a low rotating speed region and an angle position control in a high rotating speed region. The current regulator performs soft chopper hysteretic current regulation. The angle optimization controller optimizes a turn-on angle and a turn-off angle of a power converter master switch to reduce torque pulsation and improve braking energy feedback efficiency. The torque estimator conducts an on-line estimation of an actual braking torque estimated value of the motor based on an actual phase voltage and current of the motor to achieve braking torque signal feedback.

Owner:CHINA UNIV OF MINING & TECH

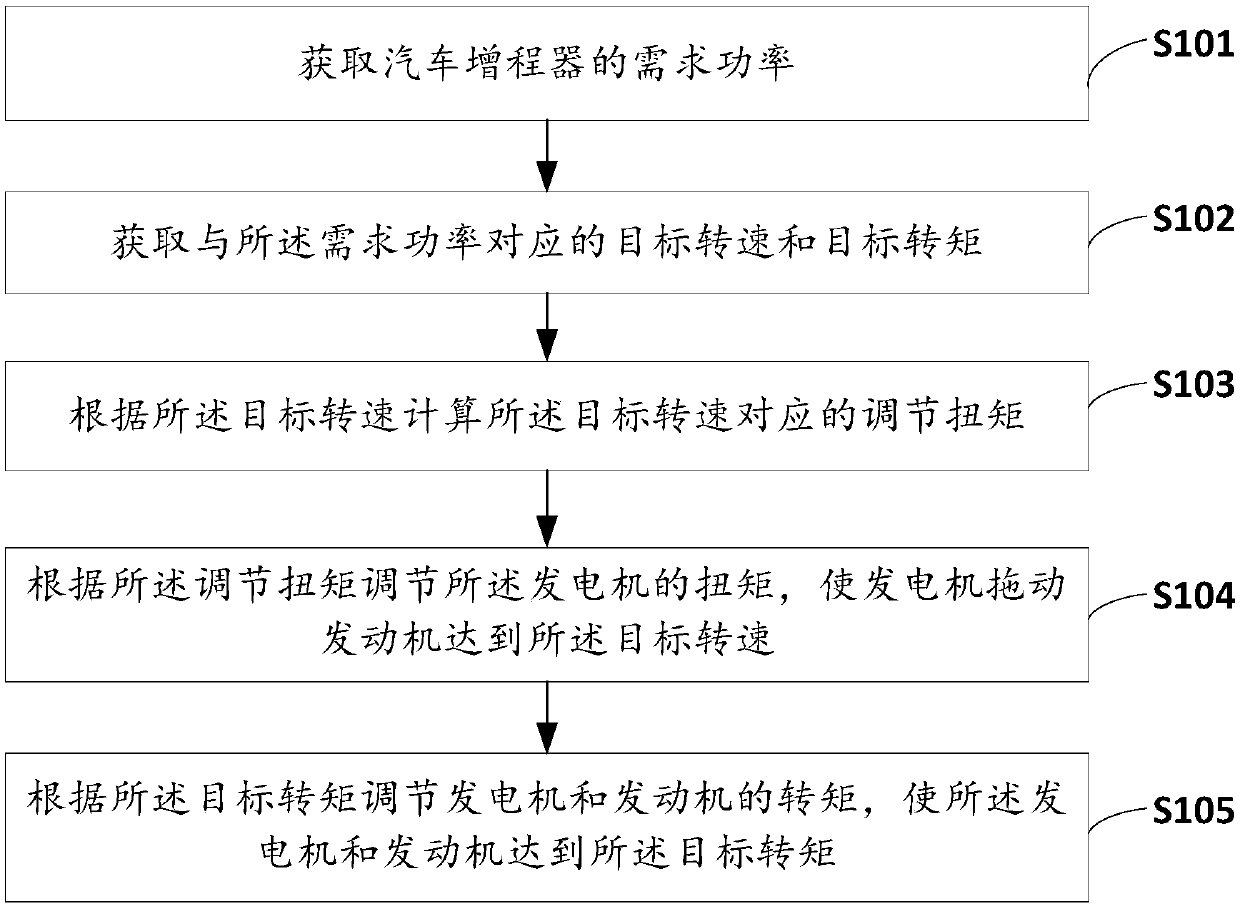

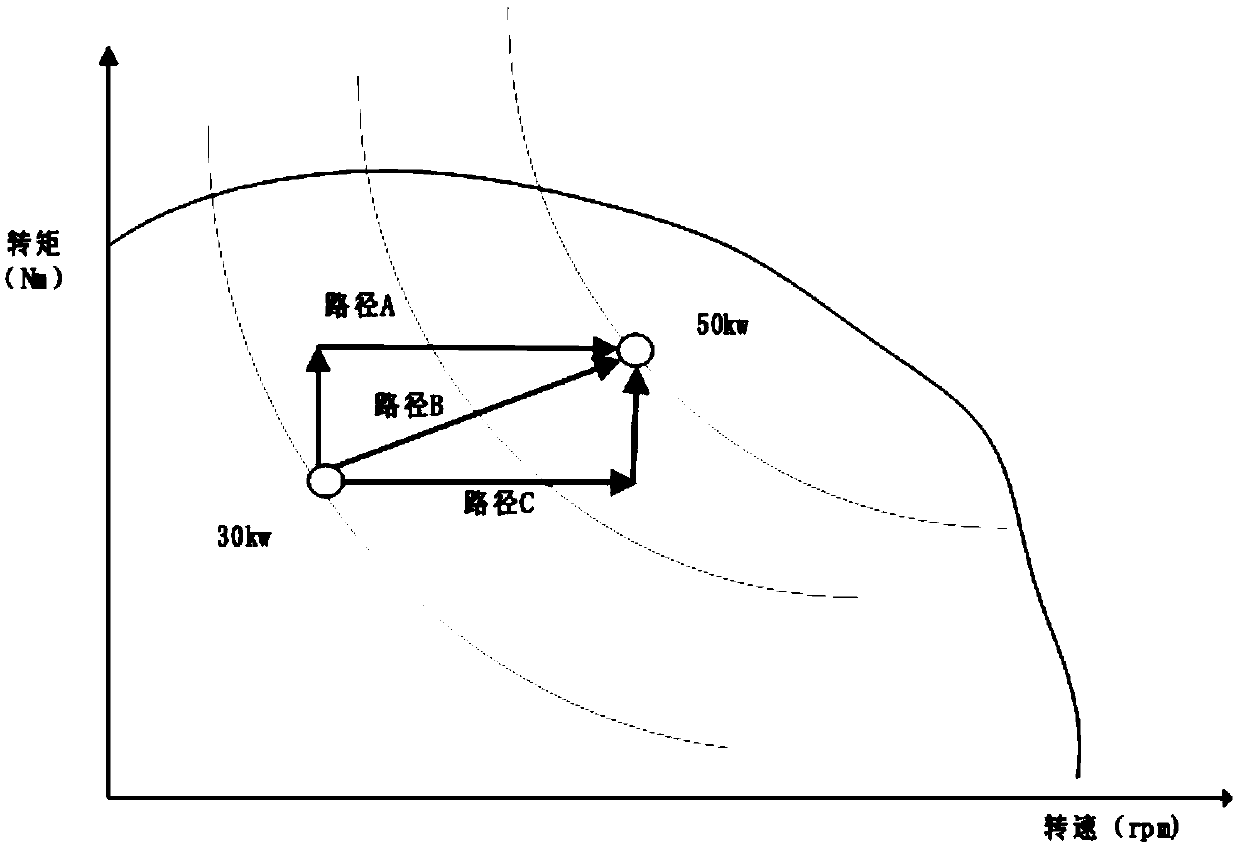

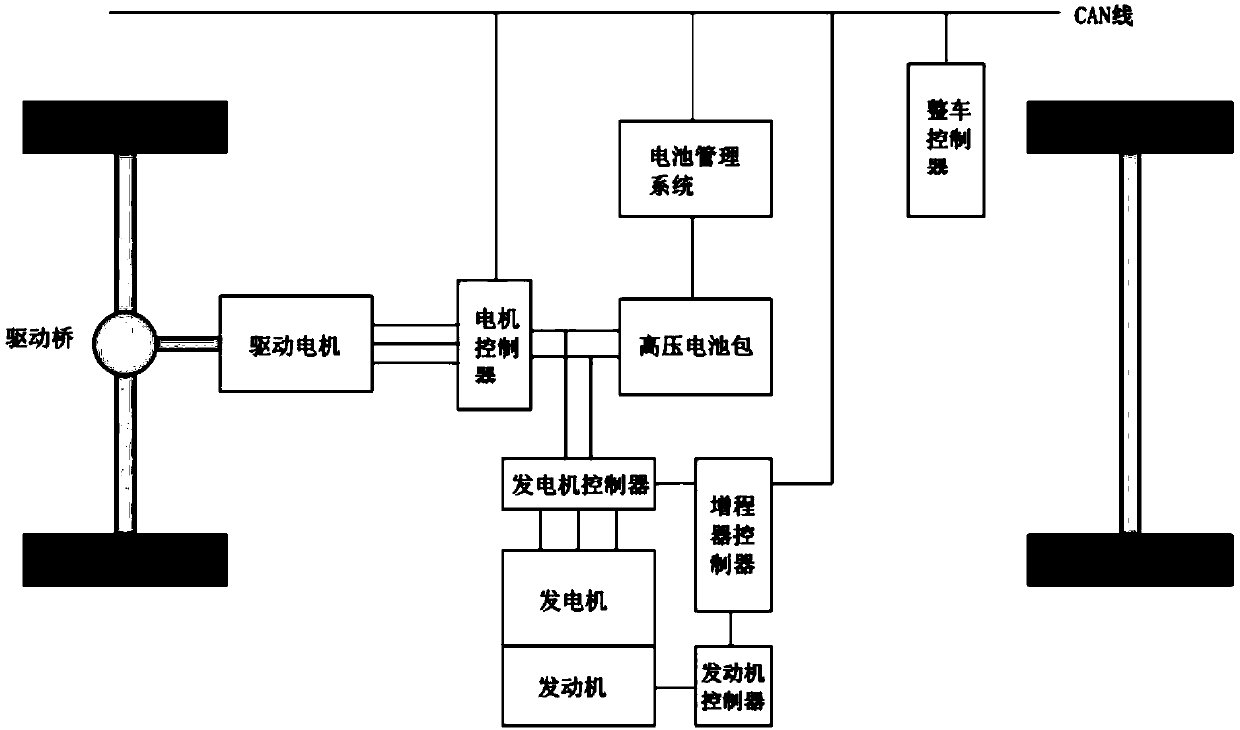

Power switching control method and system of automobile

InactiveCN108674407AExtend your lifeOptimizing the problem of speed overshootHybrid vehiclesPower switchingTorque regulation

The invention relates to the technical field of automobiles, in particular to a power switching control method of an extended-range automobile. The power switching control method comprises the steps that a required power of a range extender of the automobile is obtained; a target rotational speed and a target torque corresponding to the required power are obtained; an adjusting torque corresponding to the target rotational speed is calculated according to the target rotational speed; the torque of a generator is adjusted according to the adjusting torque, so that the generator can drag an engine to reach the target rotational speed; and the torque of the generator and the engine is adjusted according to the target torque, so that the generator and the engine reach the target torque. According to the power switching control method of the extended-range automobile, when the target power is switched, the switching path that target rotational speed adjustment is carried out first and thentarget torque adjustment is carried out is adopted, the problem of rotational speed overshoot in the switching process is optimized, the torque impact and work noise are reduced, the service life of the range extender is prolonged, and at the same time, the hardware cost and mechanical complexity are not increased.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

Method of regulating tension/compression in a multi-frame hot rolling mill, and a corresponding control system

InactiveUS6205829B1Minimal levelRoll force/gap control deviceRolling mill drivesMultiple frameControl system

The value of the rolling torque is measured at each frame through which a metal product passes, and the measurement is performed at the moment when said product reaches the following frame, at which point the frame at which the measurement is performed is switched over to torque regulation. The last frame reached by the product remains in speed regulation and it acts as a controlling frame for all other frames situated upstream therefrom so as to enable them to conserve torque equal to their respective reference torques by adapting their speeds. Once the reference torque measurements have been stored in the control system, regulation is obtained by making use of a distribution key for the stresses between the frames.

Owner:ALSTOM SA

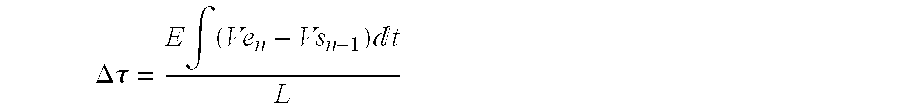

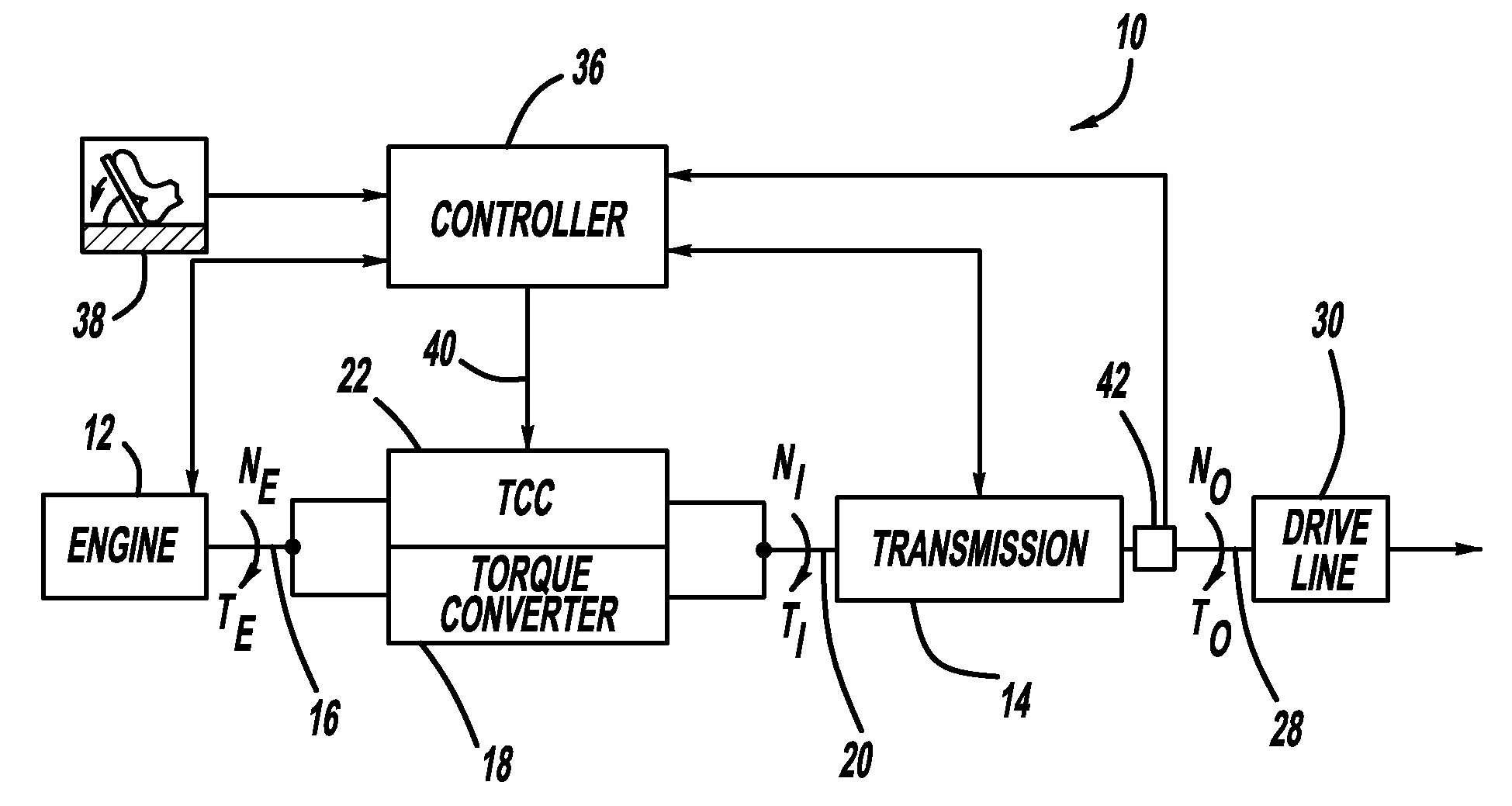

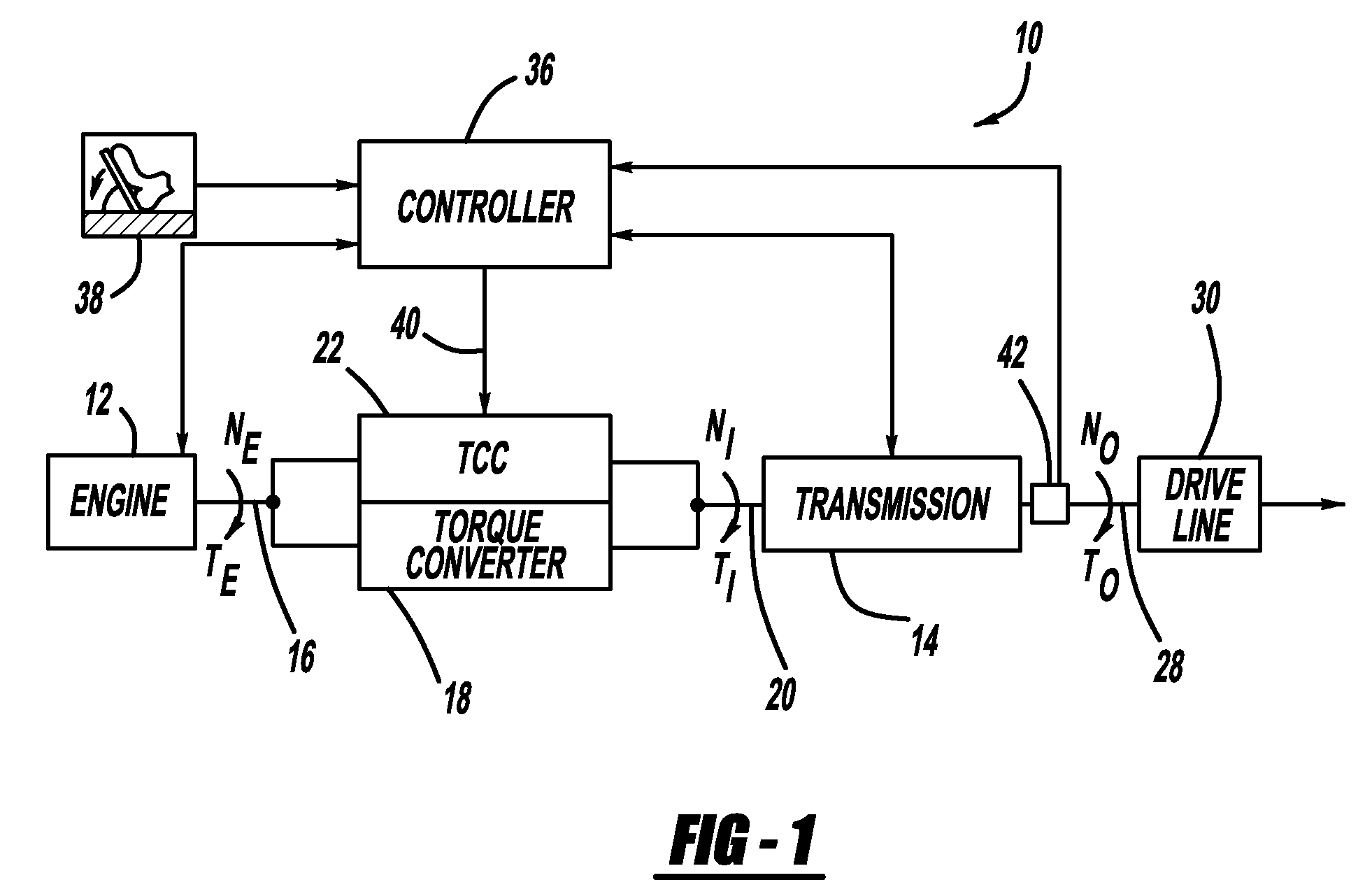

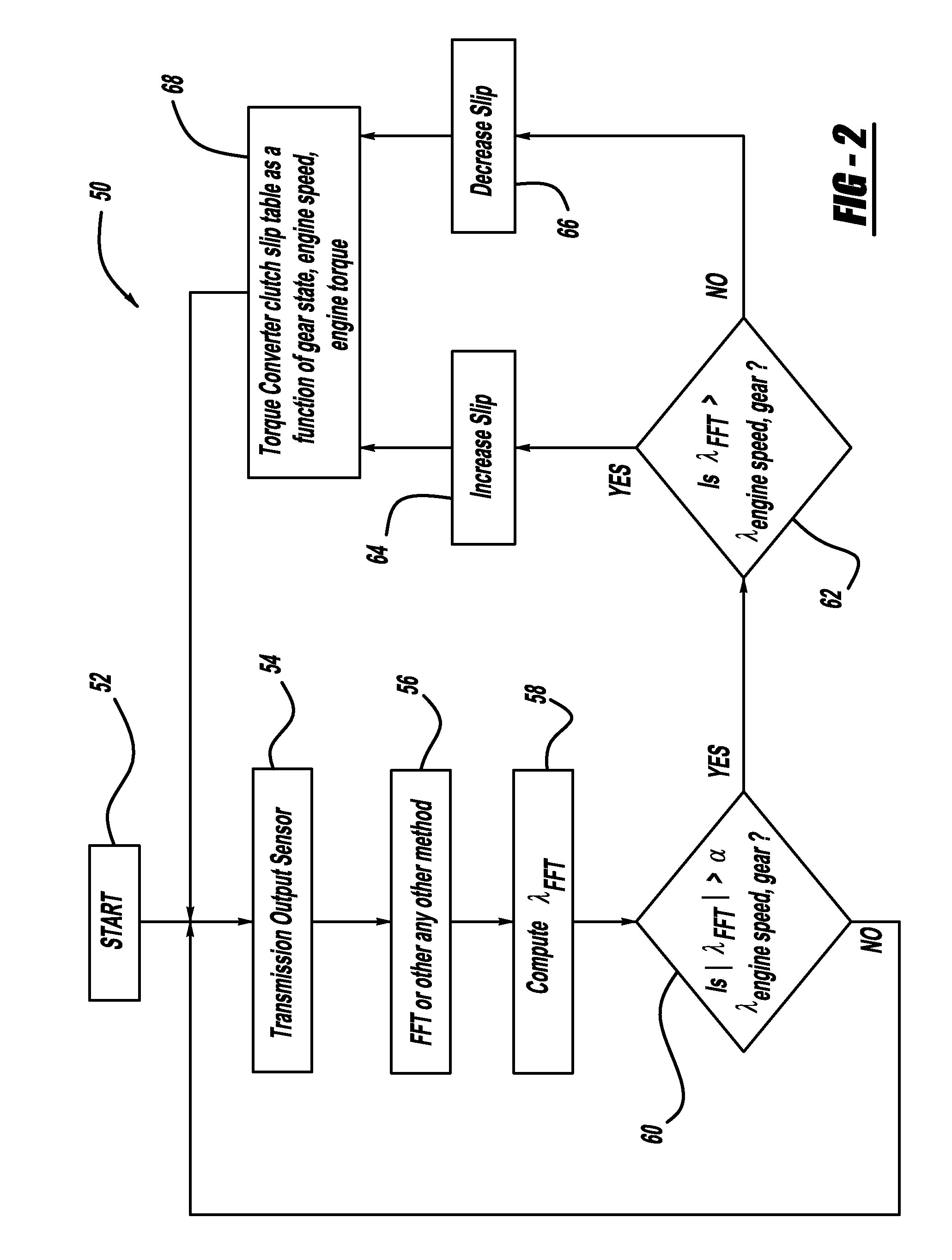

Effective driveline vibration detection algorithm in transmission tcc slip control

ActiveUS20090150032A1Machine part testingDigital data processing detailsTorque regulationVibration detection

A method for adjusting the slip of a torque converter for a plurality of selected engine speeds, transmission gears and engine torque. A sensor is used to determine vibrations transmitted through the torque converter to the driveline of the vehicle. The sensor signal is sent to a controller where it is converted to the frequency domain. If the amplitude of the frequency signal exceeds a threshold, then the algorithm increases / decreases the converter slip until the driveline vibrations equal a threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

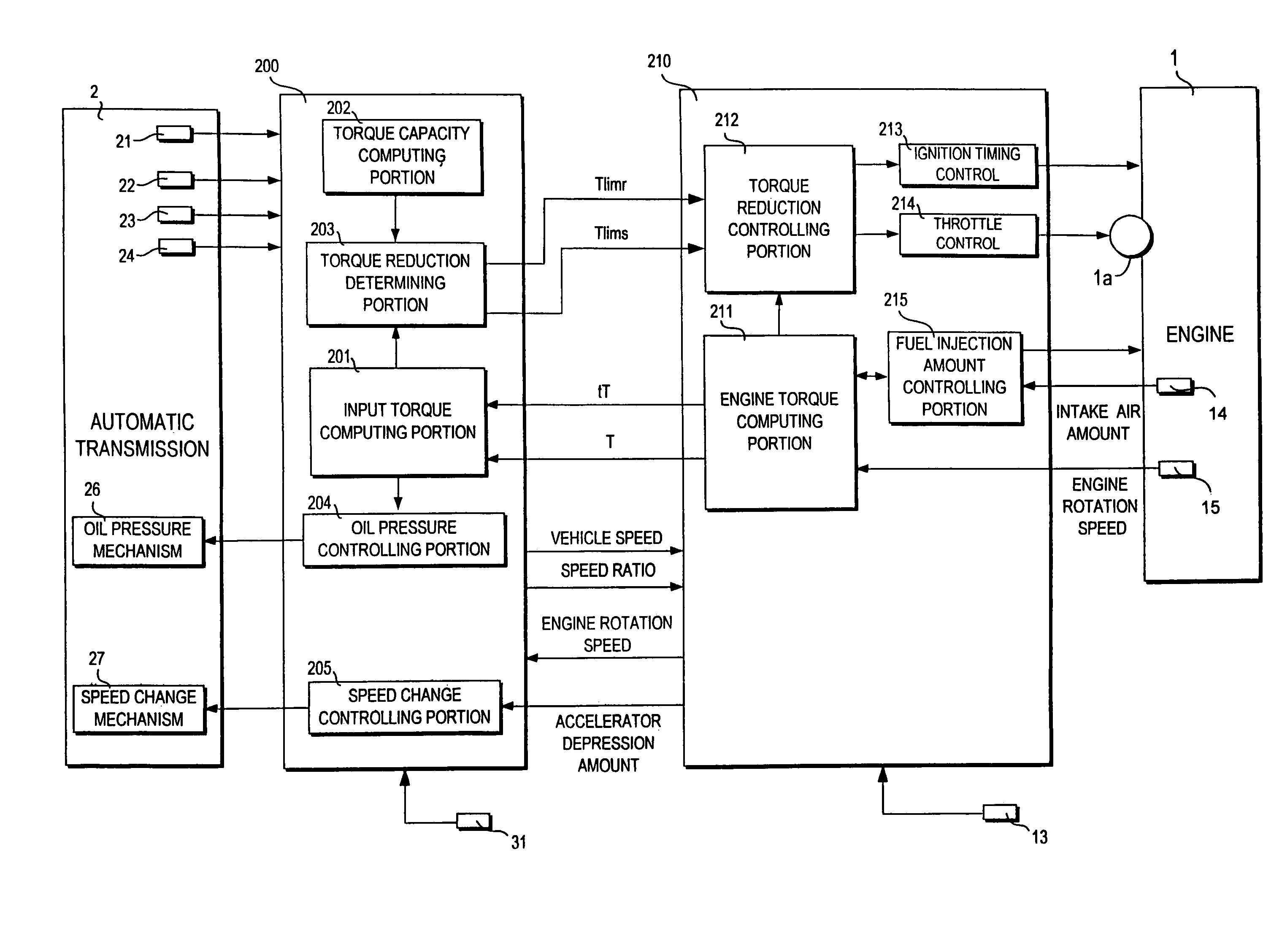

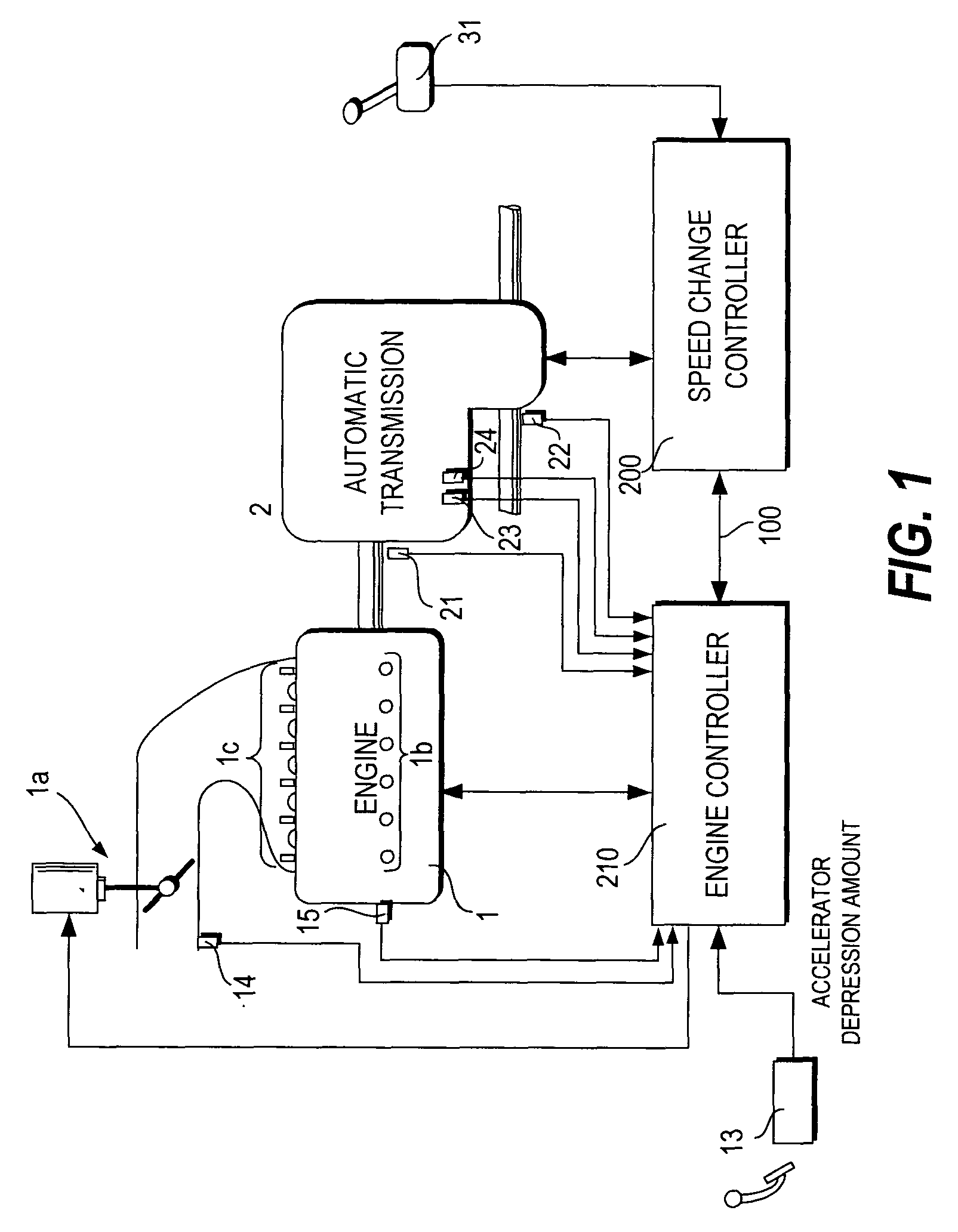

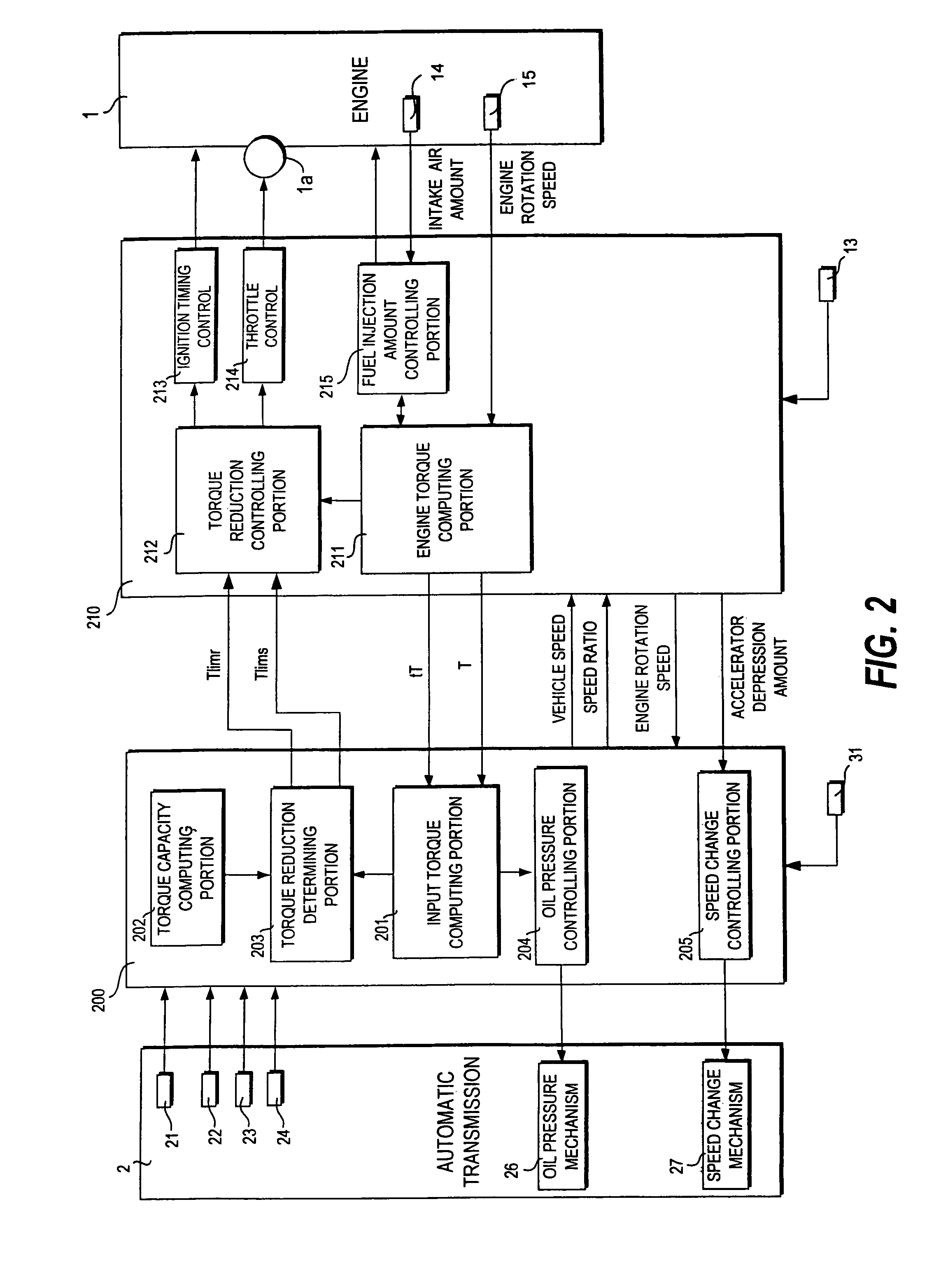

Control apparatus for vehicle provided with an automatic transmission, and method of controlling the same

ActiveUS7024298B2Reduce torqueEngine torqueElectrical controlDigital data processing detailsAutomatic transmissionControl theory

A vehicle is provided with an engine (1), an automatic transmission (2) connected to the engine (1), a detection device (21–24, 31) which detects an operating state of the transmission (2), and a torque regulating mechanism (1a, 1b, 1c) which regulates a torque of the engine. When the operating state of the transmission (2) is in a predetermined drive state and the torque of the engine (1) is to be reduced, a selection is made, based on the operating state of the transmission (2), between a first torque reduction control whereby the torque of the engine (1) is reduced rapidly and temporarily, and a second torque reduction control whereby the torque of the engine (1) is reduced continuously, and more smoothly than in the first torque reduction control. The torque of the engine (1) is then reduced by the selected one of the first torque reduction control and the second torque reduction control.

Owner:JATCO LTD

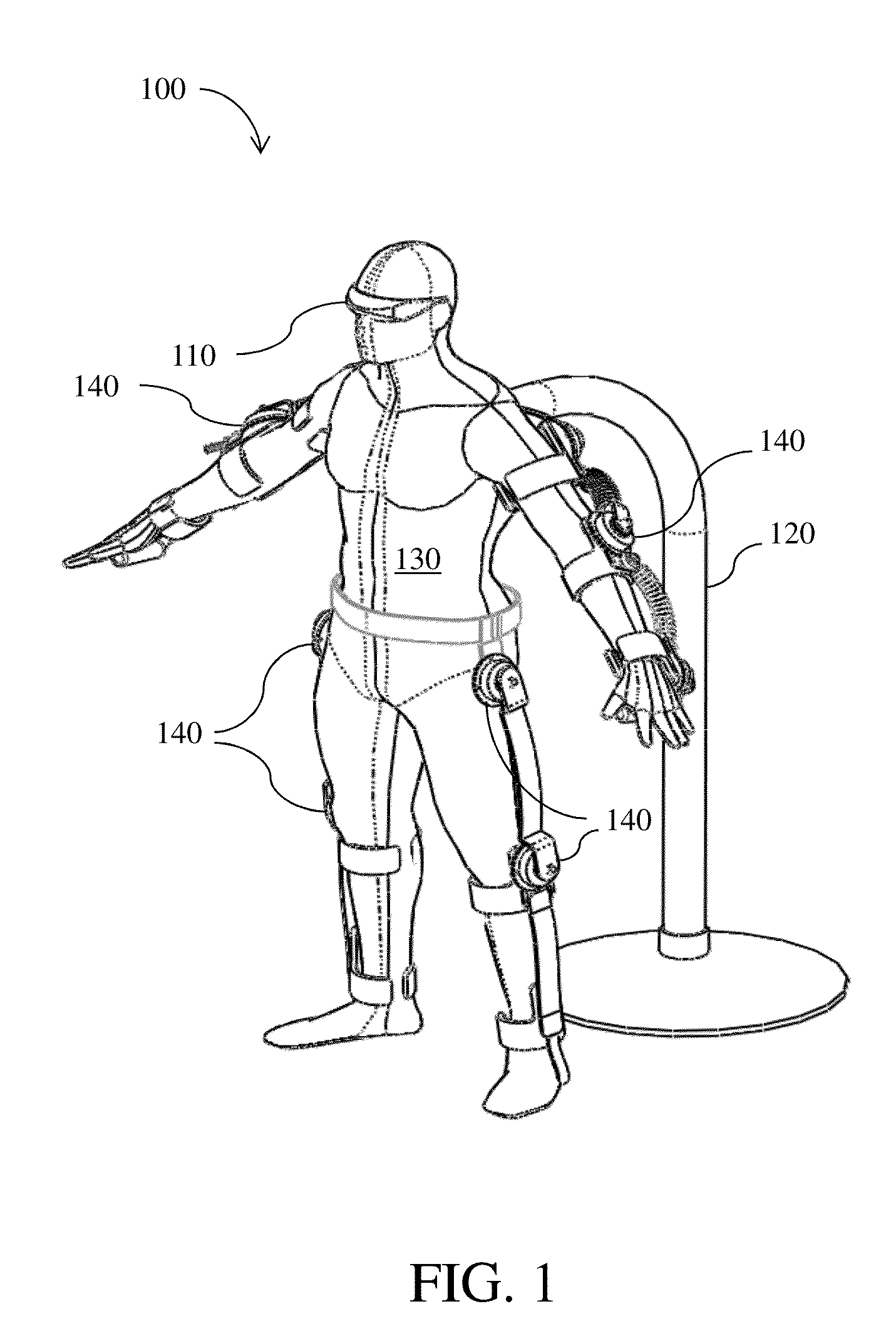

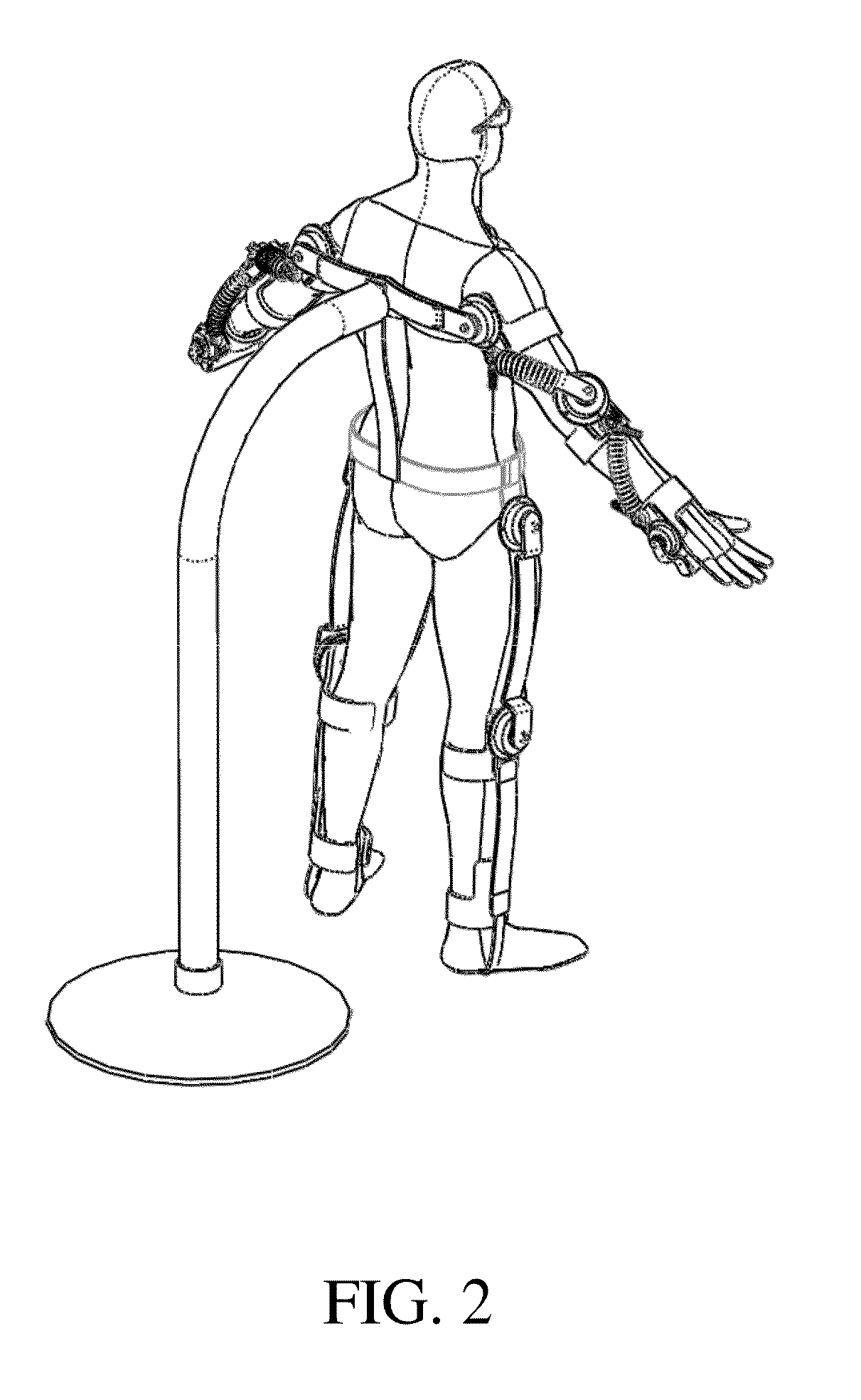

Controllable Training and Rehabilitation Device

InactiveUS20130260968A1Smarter resistanceImprove the immunityMovement coordination devicesMuscle exercising devicesElectrical resistance and conductanceMuscle training

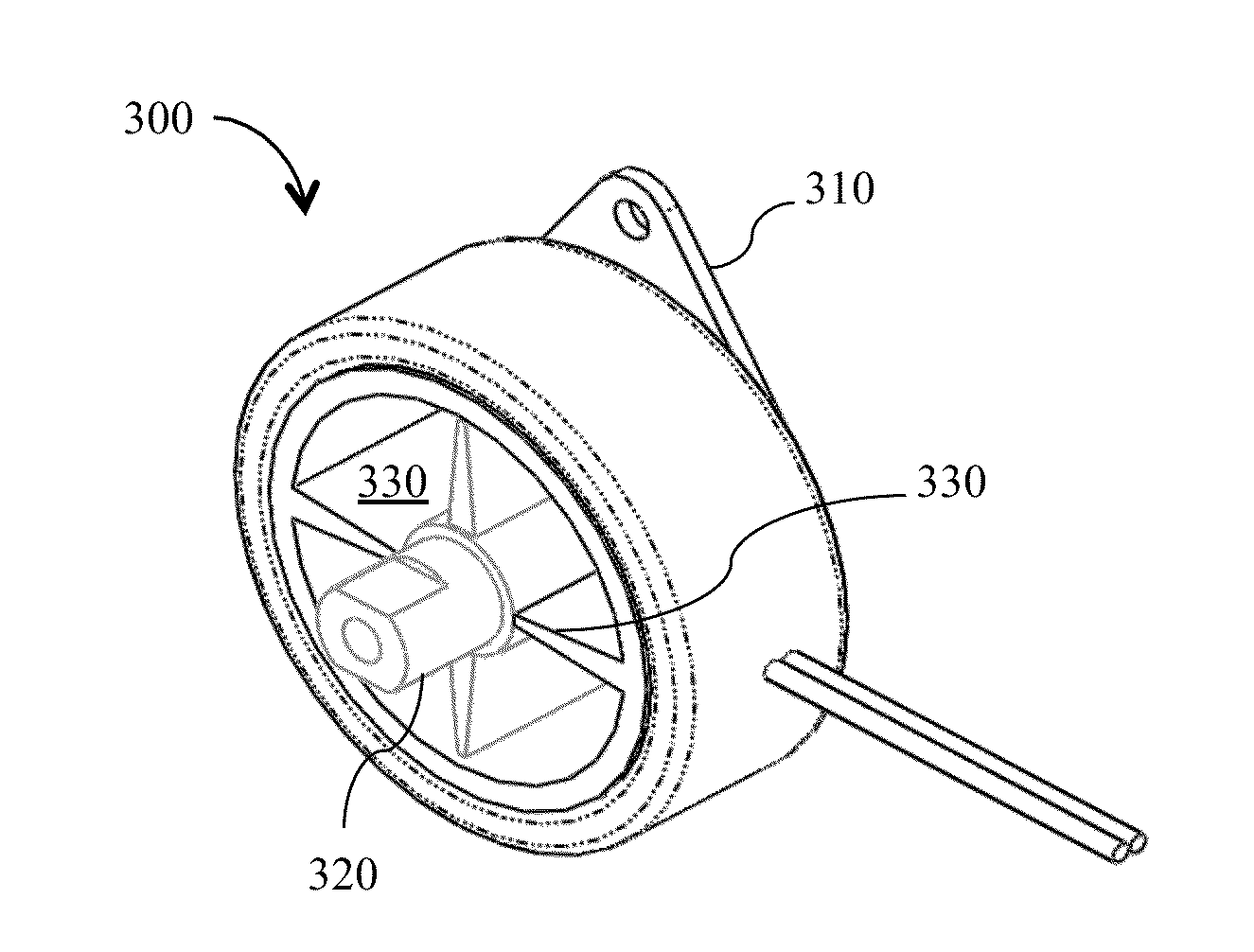

A muscle training and physical rehabilitation device is disclosed. The device is controllable by liquid based resistive units. The liquid based resistive unit utilizes either smart magnetorheological (MR) liquid whose resistance to motion can be adjusted by electromagnetism or by proportional valves with various liquids whose resistance can be controlled by an electronic signal. The MR fluid resistive units comprises a rotor supported by a bearing inside a housing, a stator mounted together with the housing to the mounting plate, and the MR liquid that flows inside the cavity formed by the vane of the rotor and chamber of the stator. The MR liquid is controlled by the applied electromagnetic field to adjust the resistance according to the exerted toque.

Owner:SHKOLNIK ALEXANDR

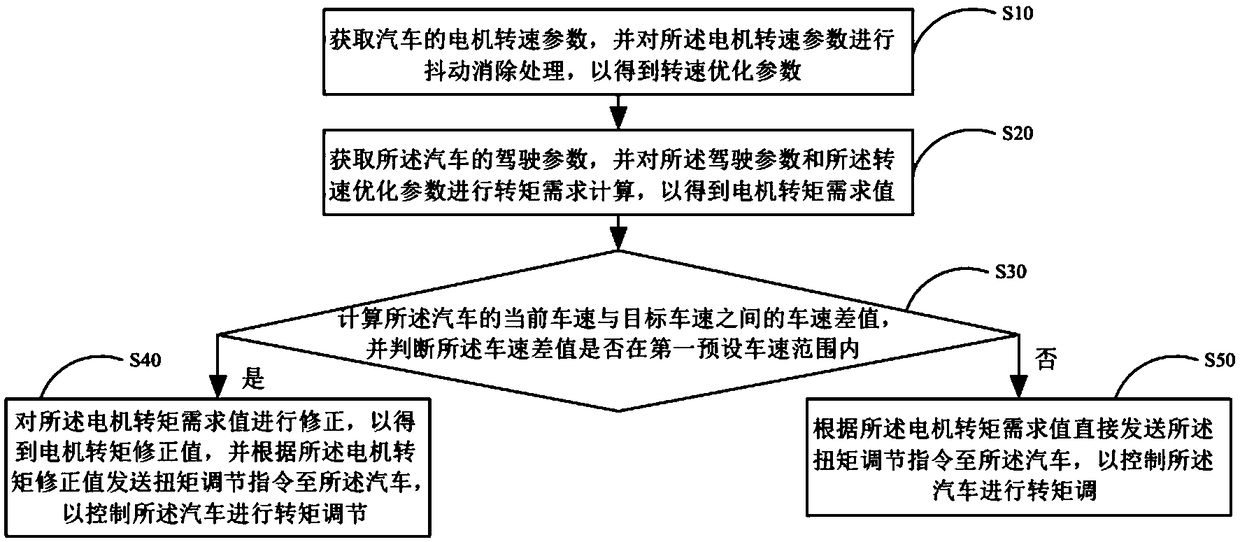

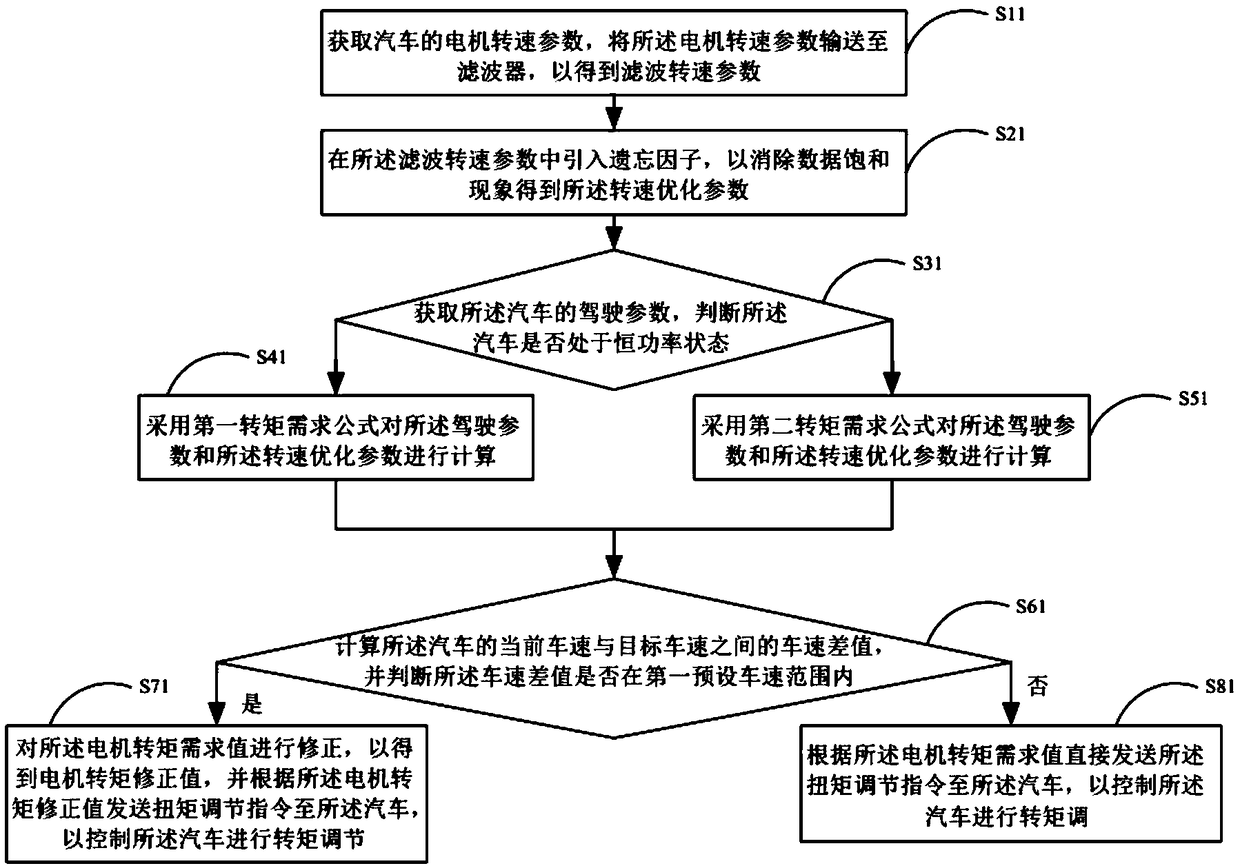

Electric bus torque regulation control method and system, mobile terminal and storage medium

The invention provides an electric bus torque regulation control method and system, a mobile terminal and a storage medium. The electric bus torque regulation control method comprises the steps of obtaining a motor rotation speed parameter of an automobile and performing jitter eliminating processing on the motor rotation speed parameter so as to obtain a rotation speed optimization parameter; obtaining a driving parameter of the automobile and carrying out torque demand calculation on the driving parameter and the rotation speed optimization parameter so as to obtain a motor torque demand value; calculating an automobile speed difference between a current automobile speed and a target automobile speed of the automobile; judging whether the automobile speed difference falls within a firstpreset automobile speed range or not; if the automobile speed difference falls within the first preset automobile speed range, correcting the motor torque demand value so as to obtain a motor torque corrected value, and transmitting a torque regulation instruction to the automobile according to the motor torque corrected value so as to obtain the automobile to regulate the torque; and if the automobile speed difference does not fall within the first preset automobile speed range, directly transmitting the torque regulation instruction to the automobile according to the motor torque demand value so as to control the automobile to regulate the torque. According to the electric bus torque regulation control method and system, the mobile terminal and the storage medium, the stability accuracyof the control process is high, and a phenomenon that abnormal jitter near the target automobile speed is out of control is eliminated.

Owner:JIANGXI B ENERGY SHANGRAO COACH

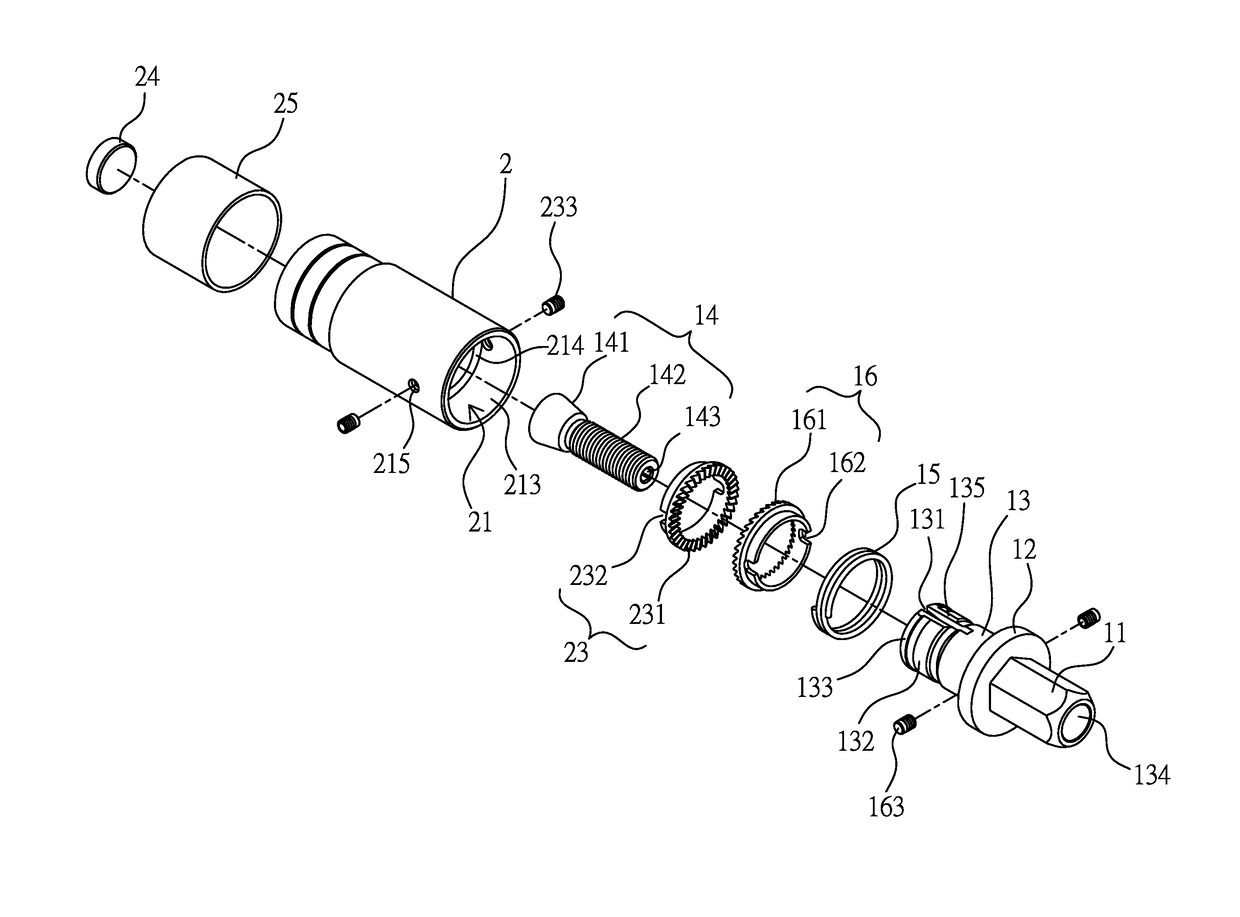

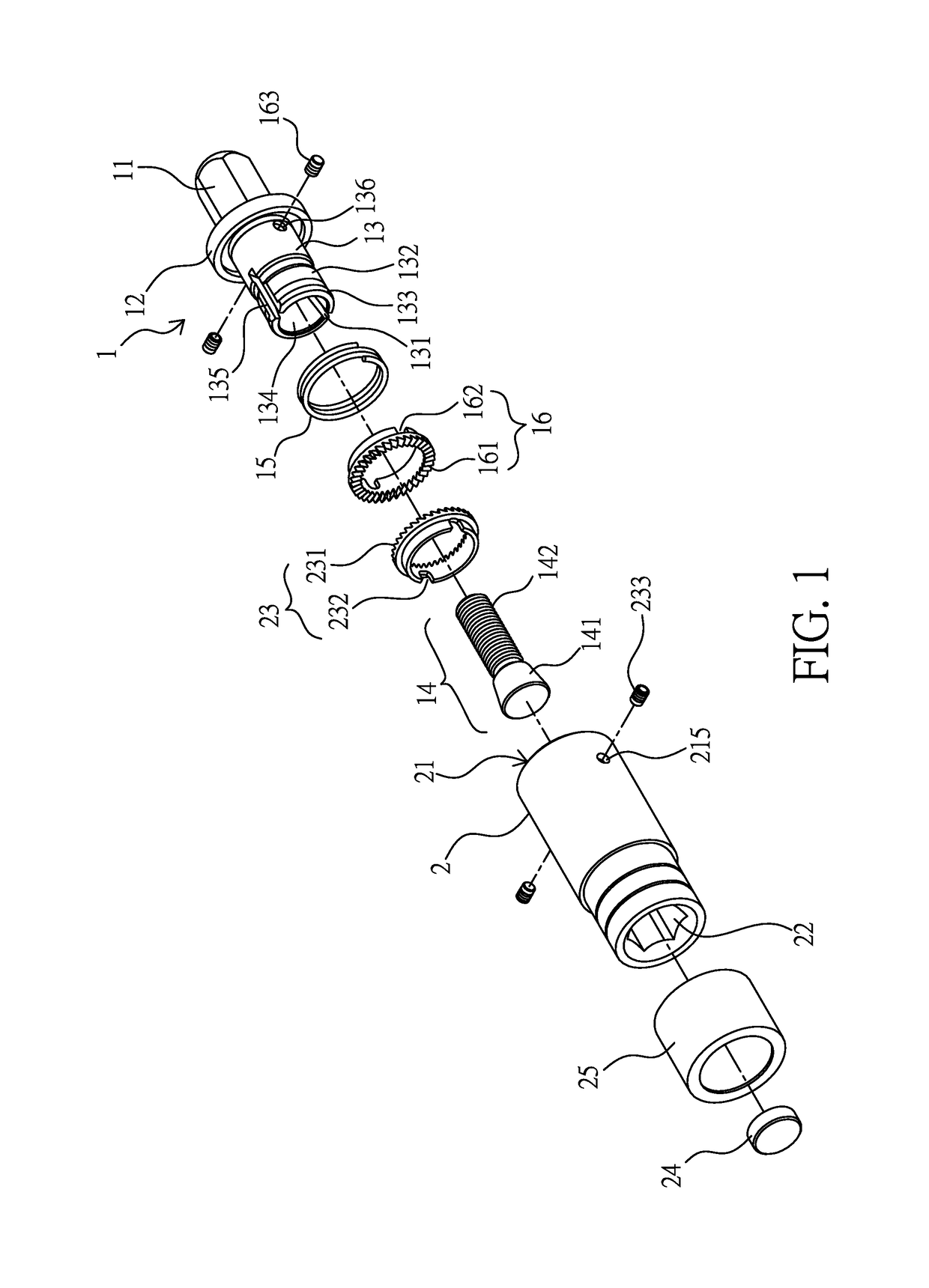

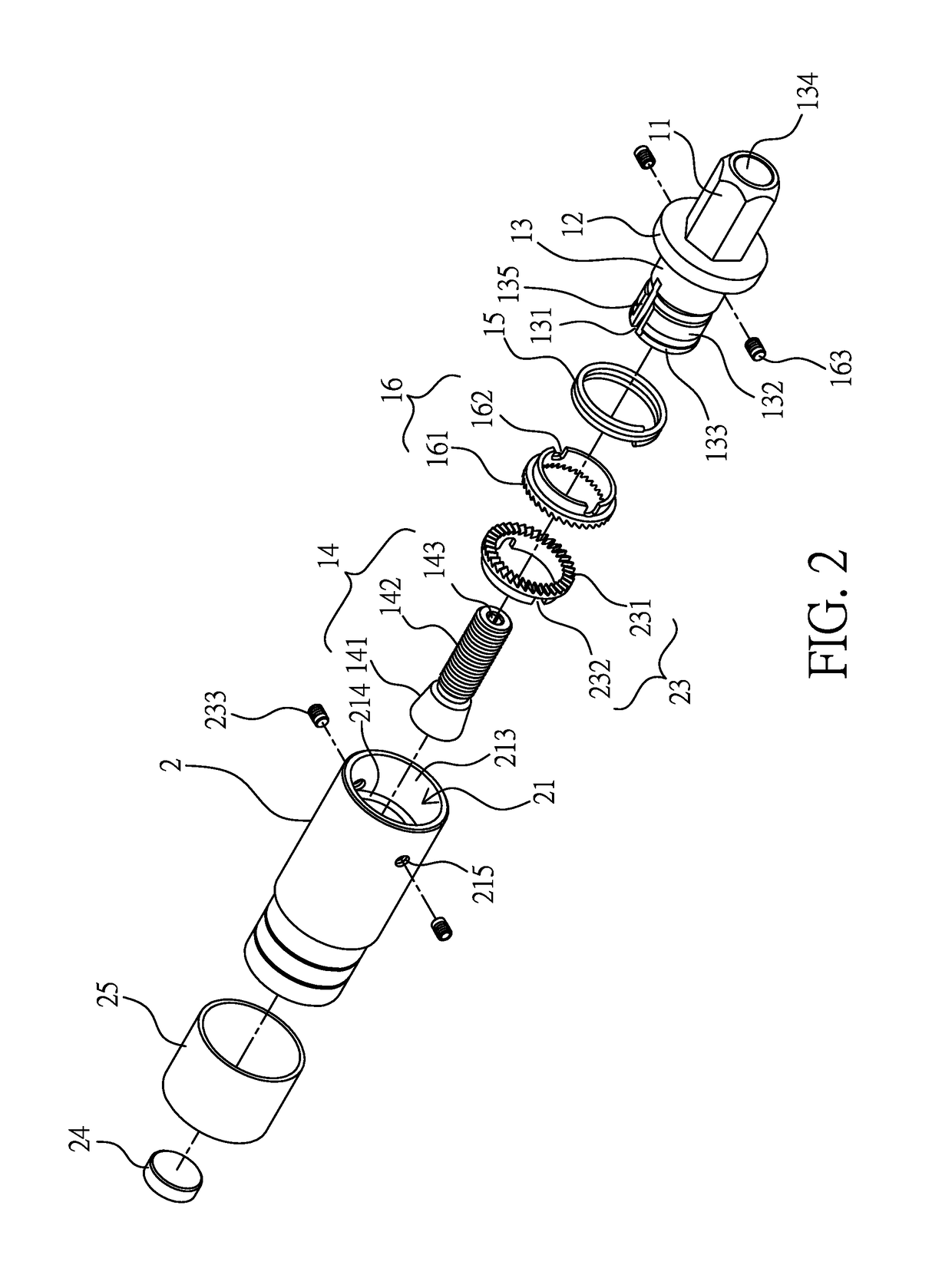

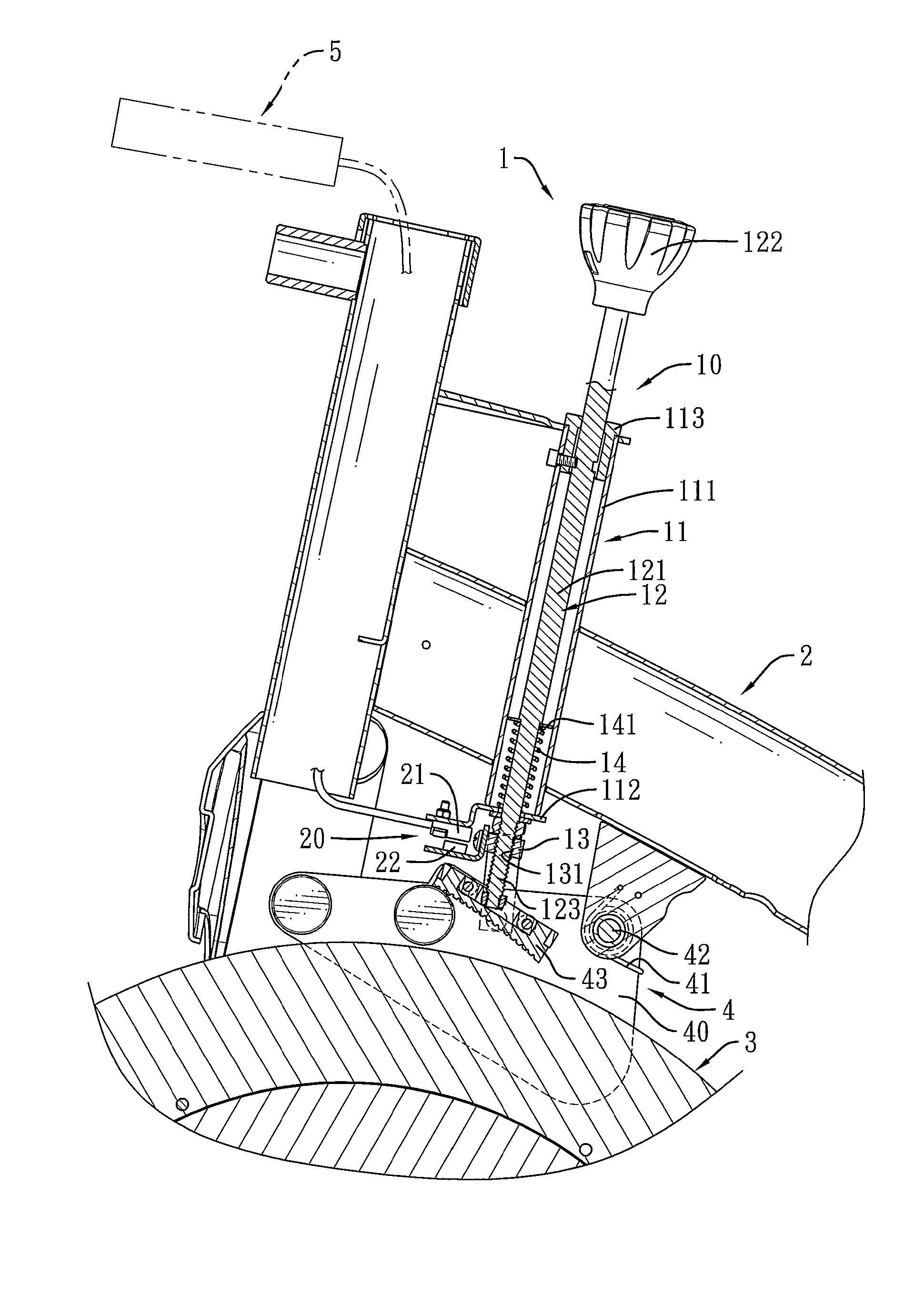

Torque socket having torque adjusting function

A torque socket having a torque adjusting function comprises: a shaft rod having two ends axially extended with an insertion tenon and a core shaft having a shaft hole and having the outer circumference thereof radially formed with a first friction surface; an adjustment member disposed in the shaft hole and having the outer circumference thereof formed with a top connection head and a connecting segment; and a shaft cylinder having two axial ends formed with a shaft slot and a sleeve slot, wherein the interior of the shaft slot is radially formed with a second friction surface being in contact with the first friction surface; when rotating the adjustment member, the outer dimension of the core shaft and the contact area of the first friction surface and the second friction surface can be altered for adjusting the torque.

Owner:CHUANG WEI CHIEH

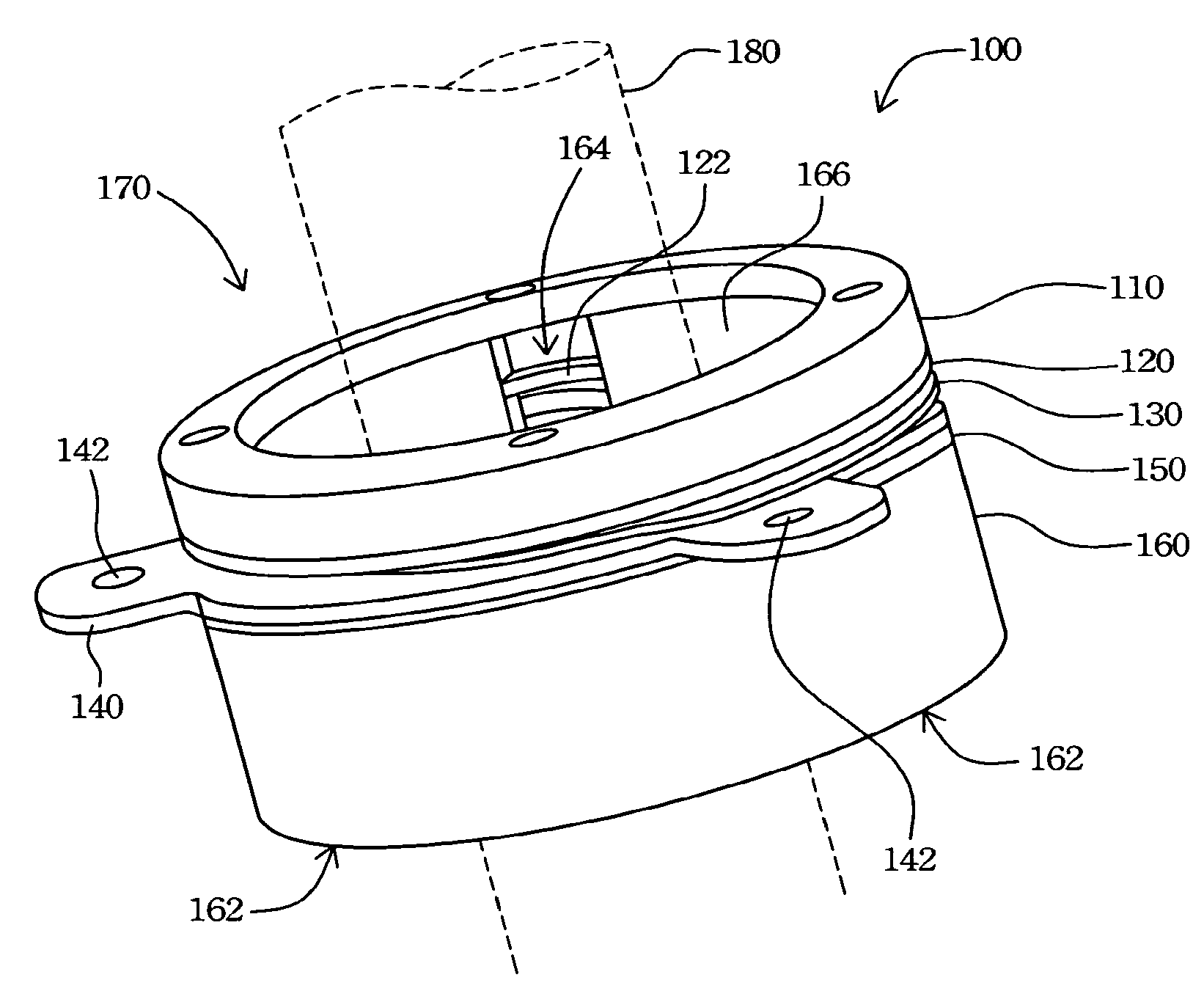

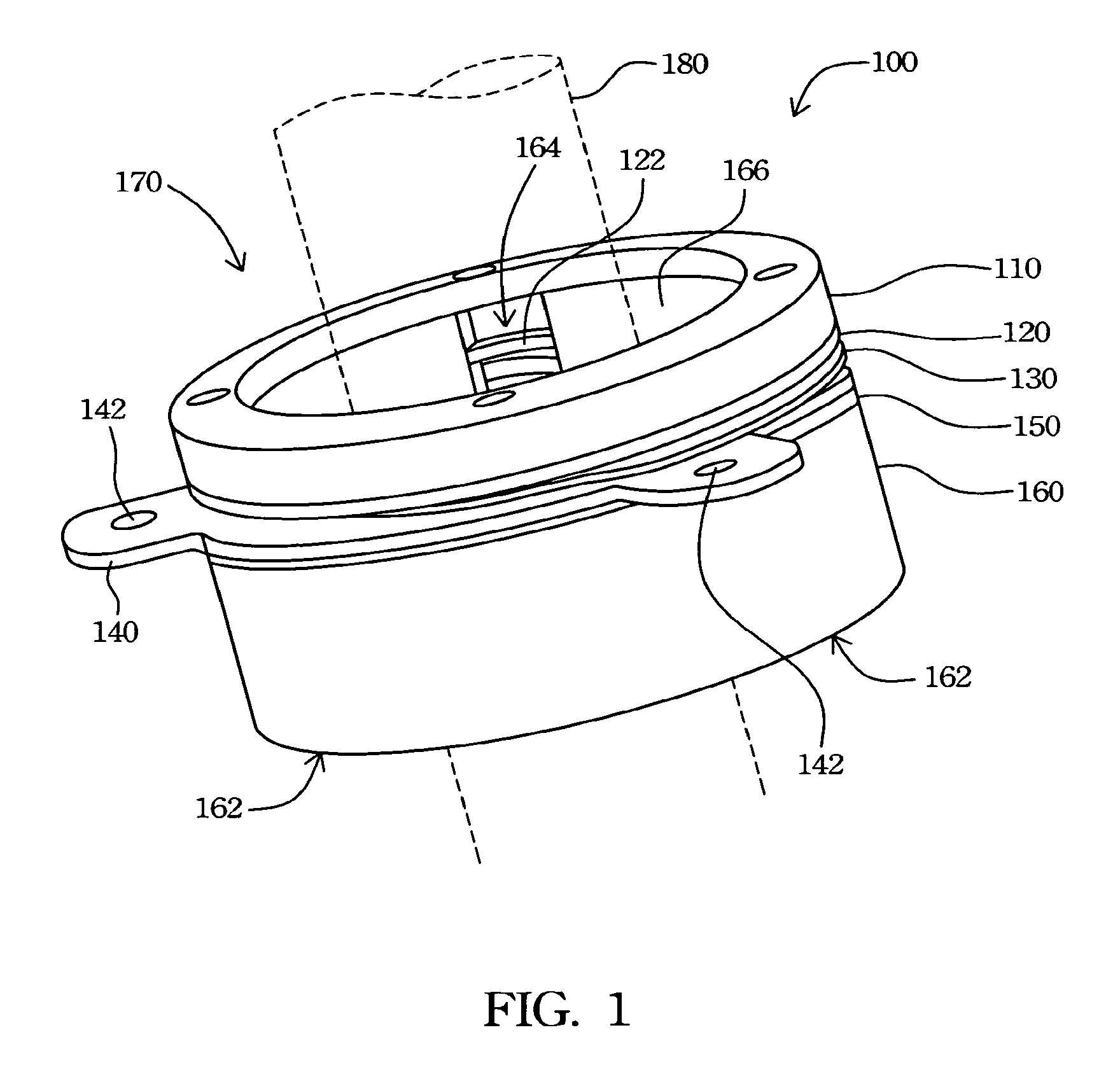

Torque sensing apparatus

ActiveUS20140013861A1High precisionWork measurementTorque measurementTorque regulationControl theory

A torque sensing apparatus has a torque adjusting assembly and a non-contact sensing assembly. The torque adjusting assembly has a fitting unit, a regulating rod and a regulating seat. The non-contact sensing assembly has a first device and a second device. The regulating rod is rotatably mounted through the fitting unit. The regulating seat is movably mounted on the regulating rod and located outside the fixed plate of the fitting unit. The first device is mounted on the fixed plate. The second device is mounted on the regulating seat and kept from contacting the first device. The non-contact sensing assembly detects a change of the distance between the first device and the second device and generates a signal to a controller, and the controller gauges a torsional value of the torque adjusting assembly. Therefore, the non-contact sensing assembly is not abraded and increases the precision of the torque sensing apparatus.

Owner:WU MU CHUAN

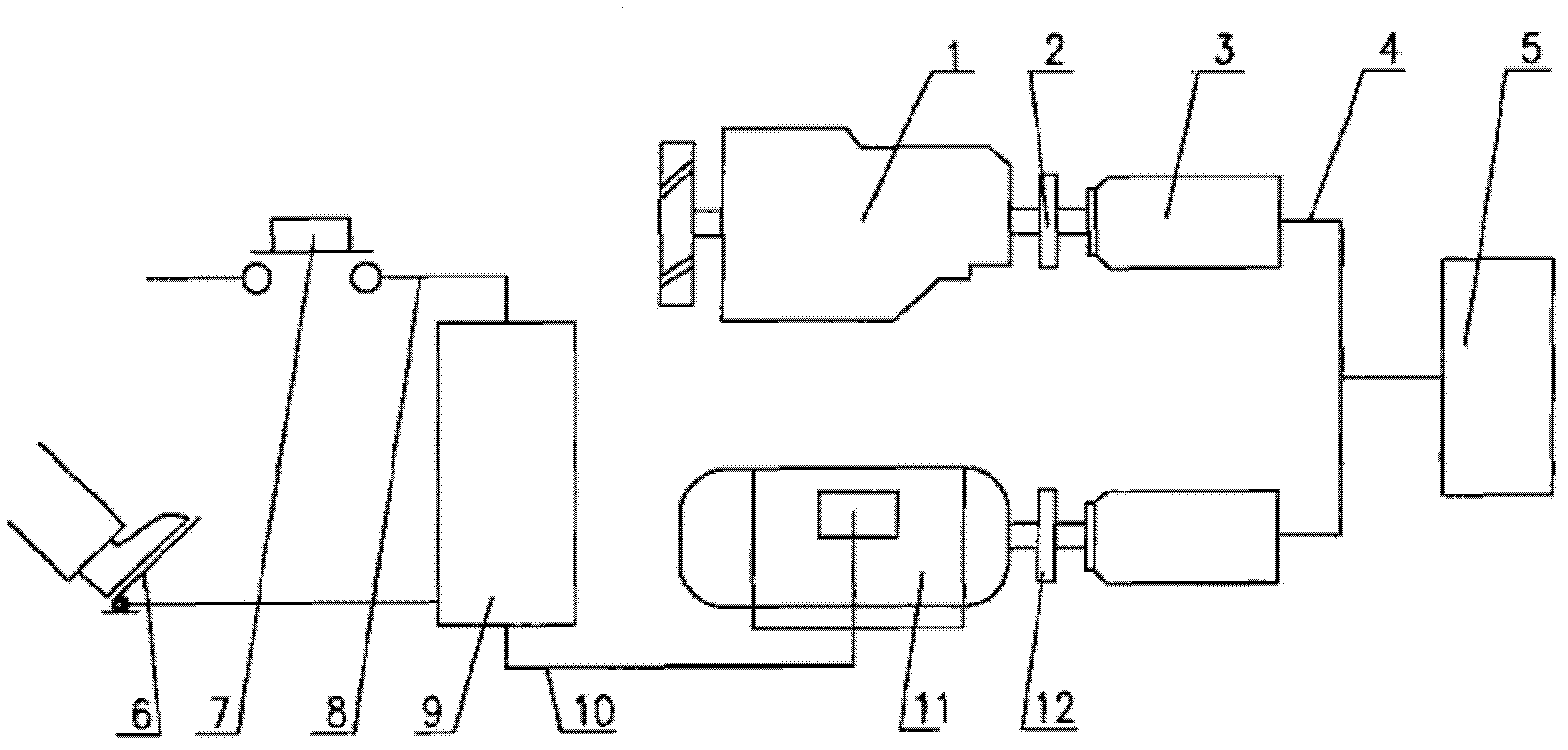

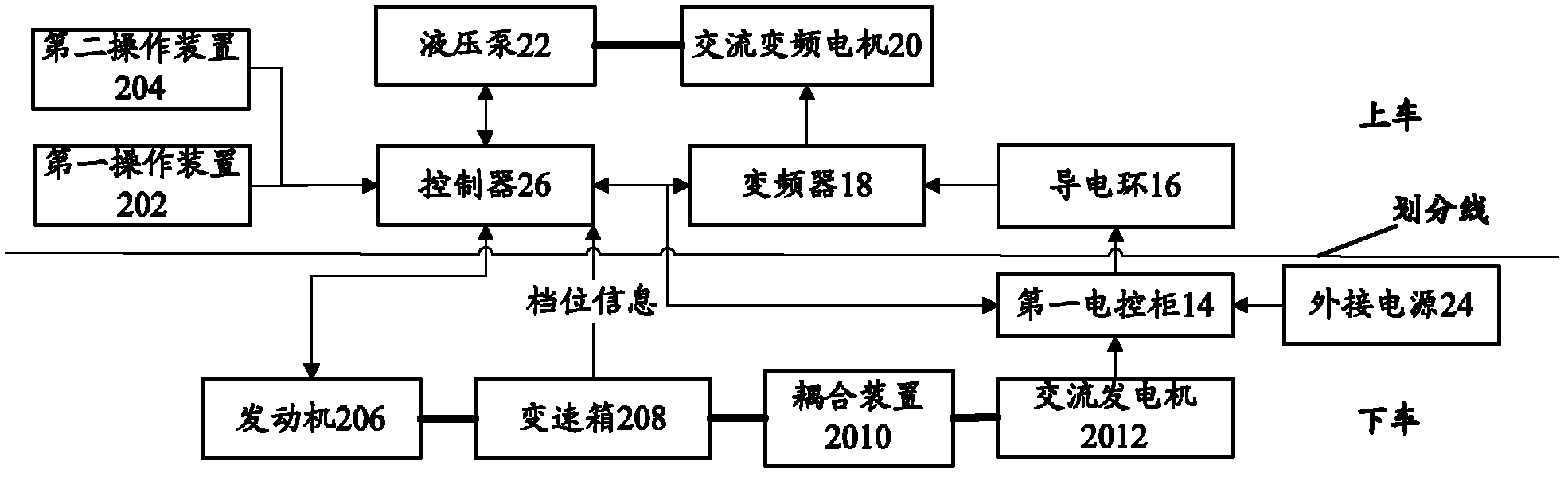

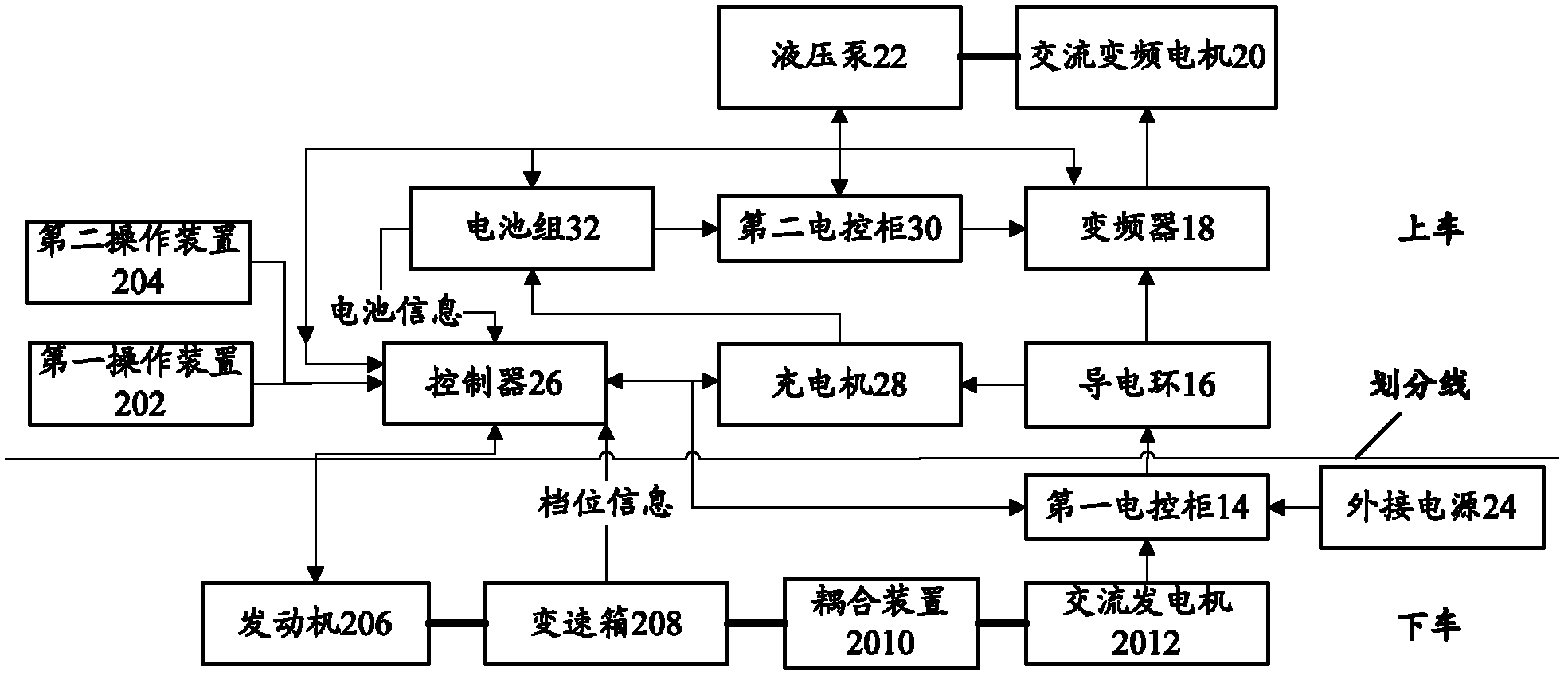

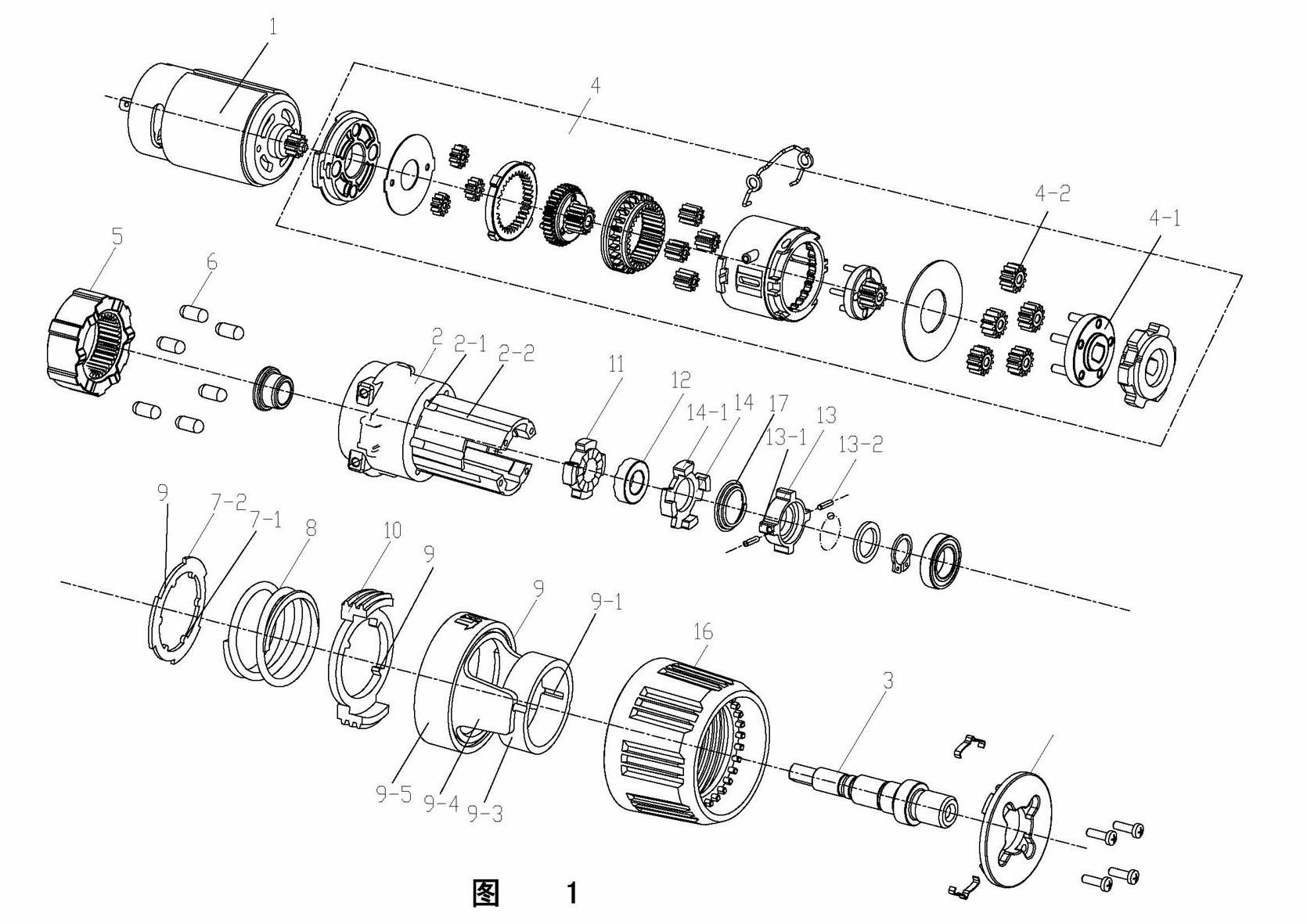

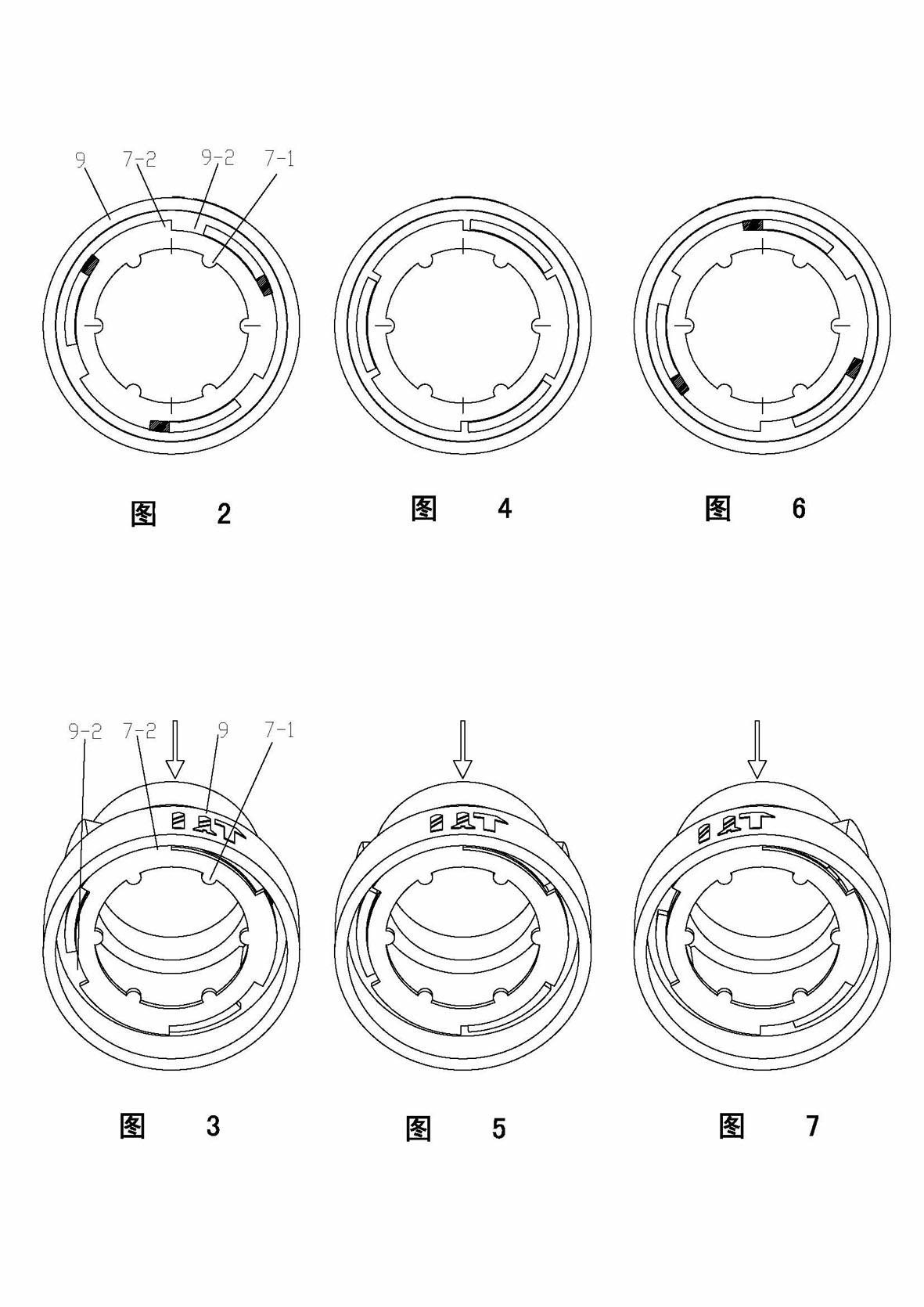

Hybrid power system for hydraulic system and engineering machine

ActiveCN102490583AImprove securityEasy to operate and controlHybrid vehiclesGas pressure propulsion mountingFrequency changerHydraulic pump

The invention provides a hybrid power system for a hydraulic system. The hybrid power system comprises an engine, a gearbox, a coupling device, an alternating-current generator, a frequency converter, an alternating-current frequency conversion motor and a hydraulic pump, wherein the engine outputs a rotating speed and torque and is used for driving the alternating-current generator; the gearbox is connected to the engine, adjusts the rotating speed and torque of the engine and transmits the adjusted rotating speed and torque to the alternating-current generator through the coupling device, so that the alternating-current generator works at a rated rotating speed; the alternating-current generator is connected to the frequency converter, generates electric energy and transmits the electric energy to the frequency converter; the frequency converter controls voltage and current which are output to the alternating-current frequency conversion motor according to the adjusted output frequency; the alternating-current frequency conversion motor is connected to the hydraulic pump, and the rotating speed and torque of the alternating-current frequency conversion motor are adjusted according to the input voltage and current; and the hydraulic pump adjusts the output flow of hydraulic oil according to the rotating speed and torque of the alternating-current frequency conversion motor. The hybrid power system is more convenient to control by a mode that the hydraulic pump is only driven by the alternating-current frequency conversion motor, and the safety and energy-saving efficiency of the system are improved. The invention also provides an engineering machine.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

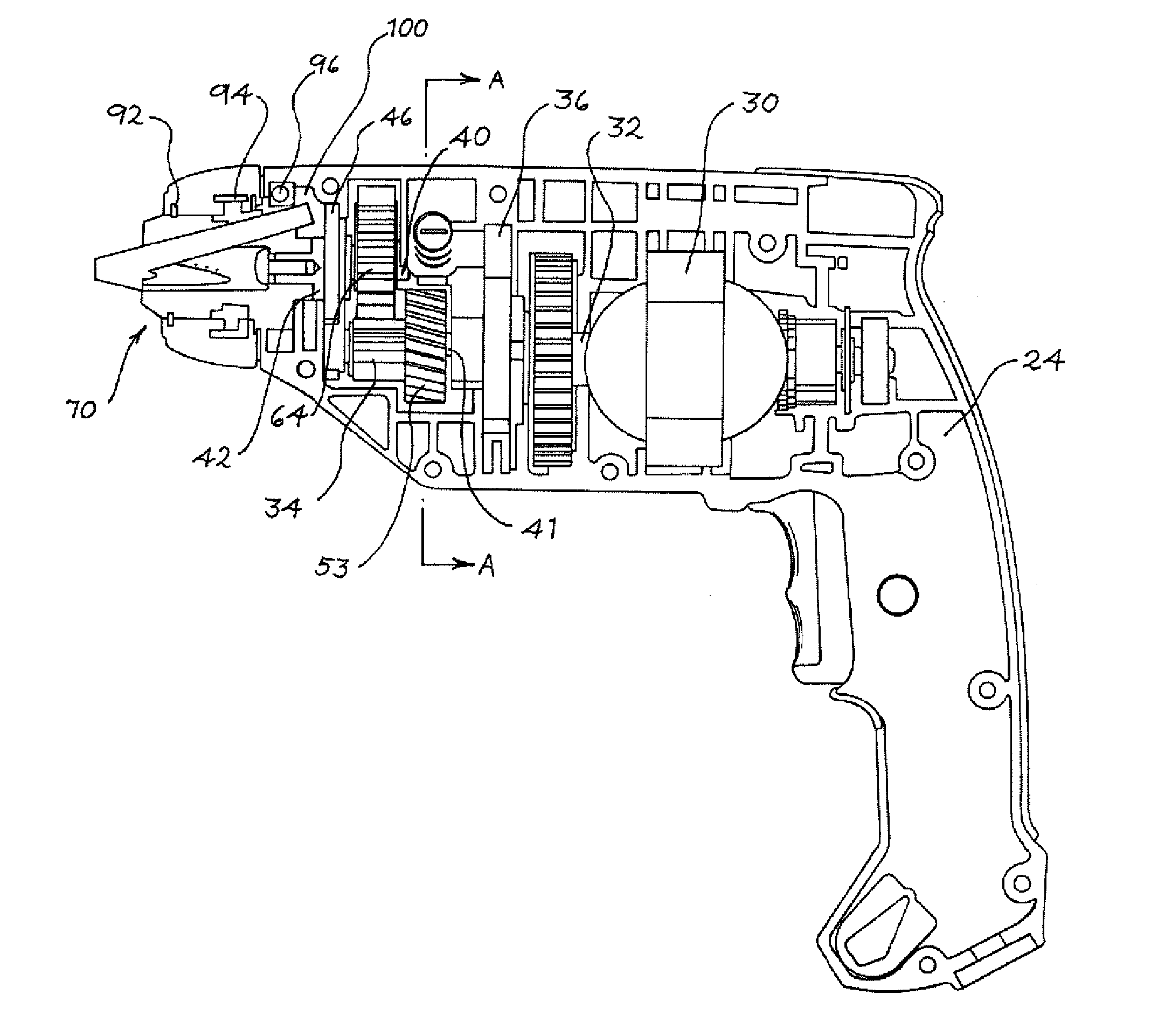

Electric drill with driving mode switching

ActiveCN102431013ARealize drilling modeHighlight substantive featuresPortable power-driven toolsElectric machineAxial pressure

The invention relates to an electric drill with driving mode switching, belonging to the technical field of electric tools. The electric drill comprises a motor, a function switching cup and a torque regulating cup, wherein the motor is connected with an output shaft through a reducing mechanism in transmission mode. The invention is improved in the following ways: the other end of a conjunction piece abuts against one end of a locking ring; the other end of the locking ring is connected with an axial pressure regulating mechanism driven by the torque regulating cup; when the function switching cup is in a first switching position, contrate teeth of the movable and static impact rings are separated, and the locking ring forms axial constraint on the conjunction piece; when the function switching cup is in a second switching position, the contrate teeth of the movable and static impact rings remain separated, and the locking ring loses axial constraint on the conjunction piece; and when the function switching cup is in a third switching position, the contrate teeth of the movable and static impact rings abuts against each other, and the locking ring forms axial constraint on the conjunction piece. The invention can lower the manufacturing and assembly cost, is beneficial to avoiding poor quality caused by accumulated tolerance, and is easier to operate.

Owner:NANJING JIUCHI ELECTROMECHANICAL IND

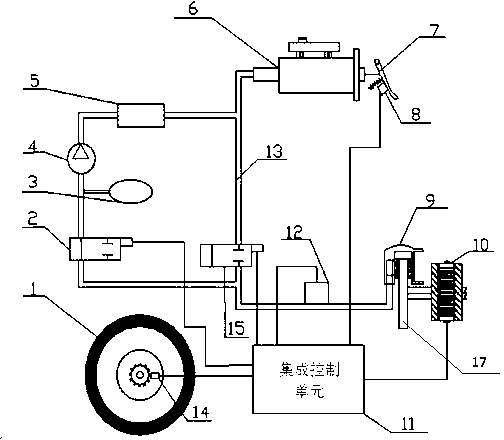

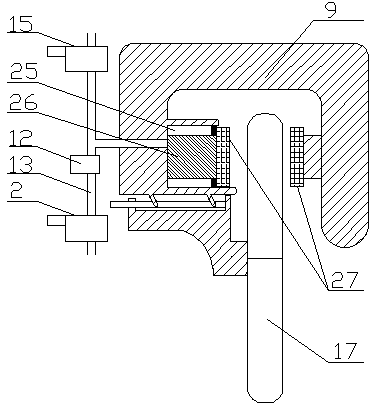

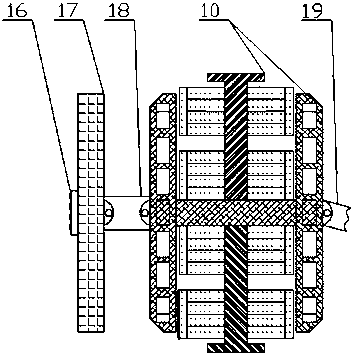

Braking device adopting magnet brake to realize vehicle locking prevention function and control method

InactiveCN102700532AImprove securityImproved resistance to thermal failureBraking systemsFriction reductionWheel speed sensor

The invention discloses a braking device adopting a magnet brake to realize a vehicle locking prevention function and a control method. An oil return solenoid valve, an oil inlet solenoid valve, a braking pipeline pressure sensor, a wheel speed sensor and a braking pedal position sensor are connected with an integrated control unit through wire harnesses respectively; the integrated control unit collects the signals of the braking pipeline pressure sensor and the braking pedal position sensor to determine a target braking torque, distributes friction braking torque and electromagnetic braking torque reasonably, realizes a wheel locking prevention function through torque regulation of a magnet brake, and achieves the vehicle locking prevention function by utilizing the magnet brake; and the magnet brake participates in shunting of vehicle braking energy in the whole braking process, so that the braking is rapider and more stable, the braking noise is lower, poisonous friction dust produced by friction braking can be greatly reduced, the safety and the thermal failure prevention performance of a braking system are improved, the service life of the braking system is prolonged, and the maintenance cost of the braking system is reduced.

Owner:TRW AUTOMOTIVE COMPONENTS SHANGHAI

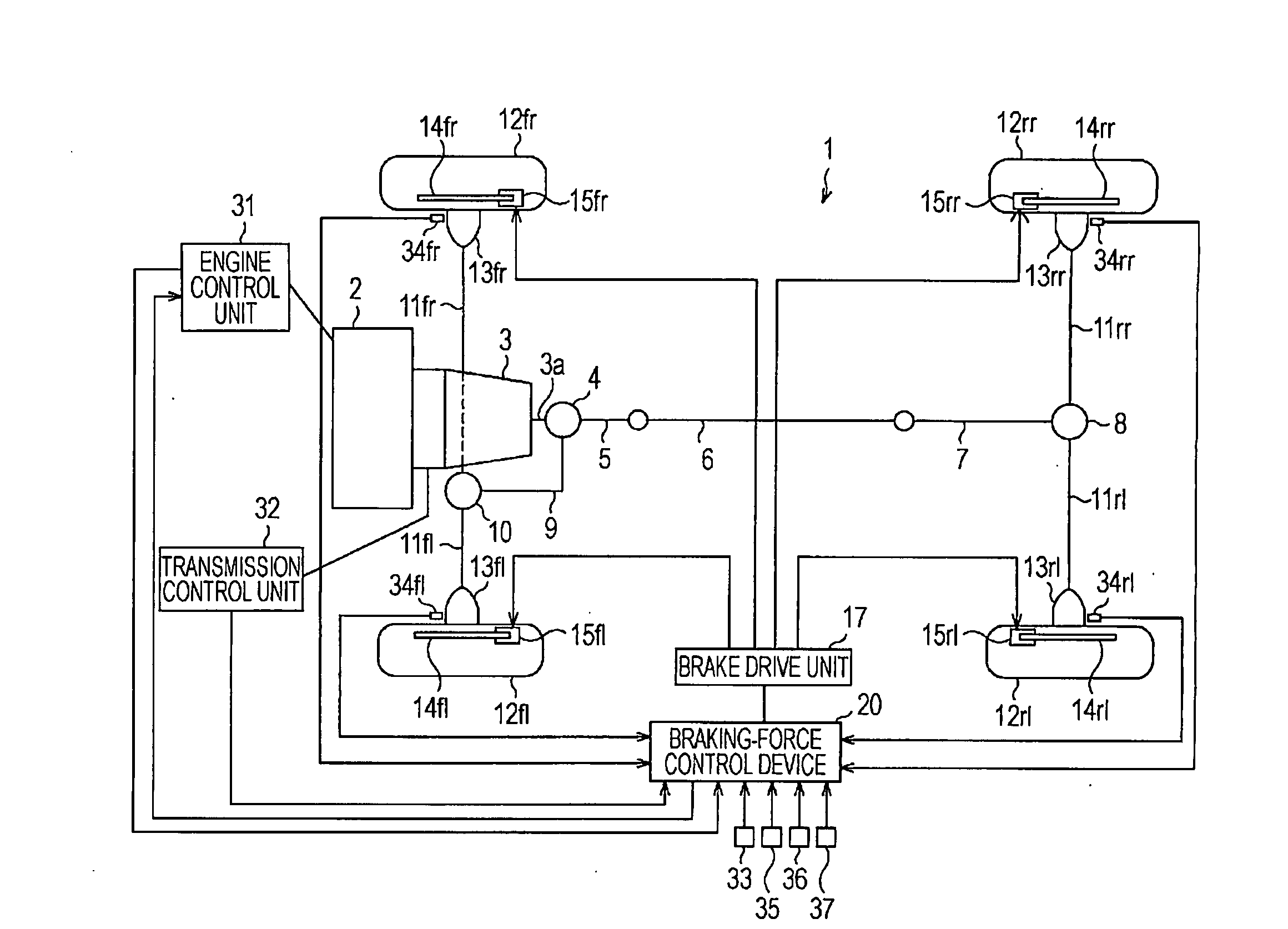

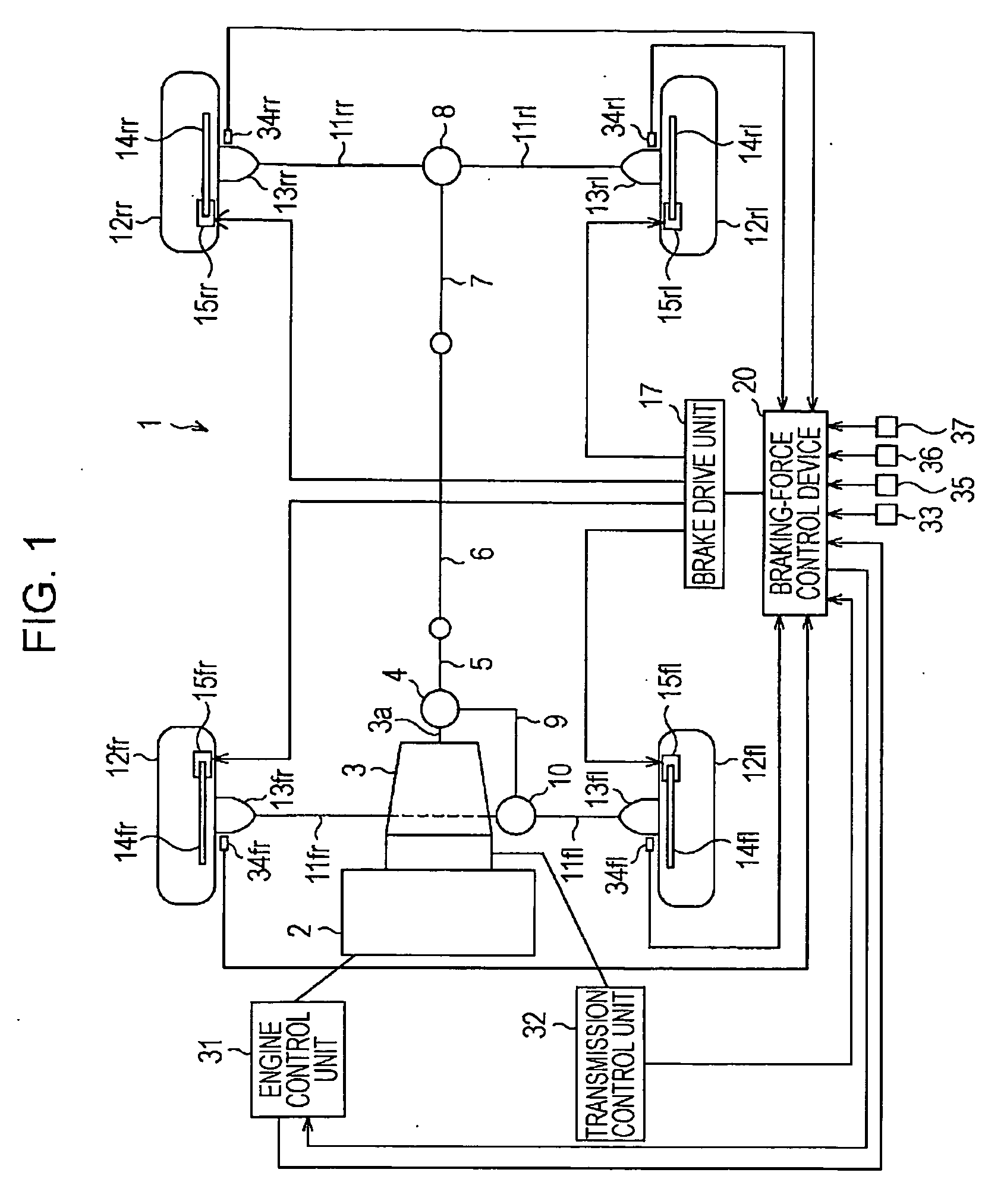

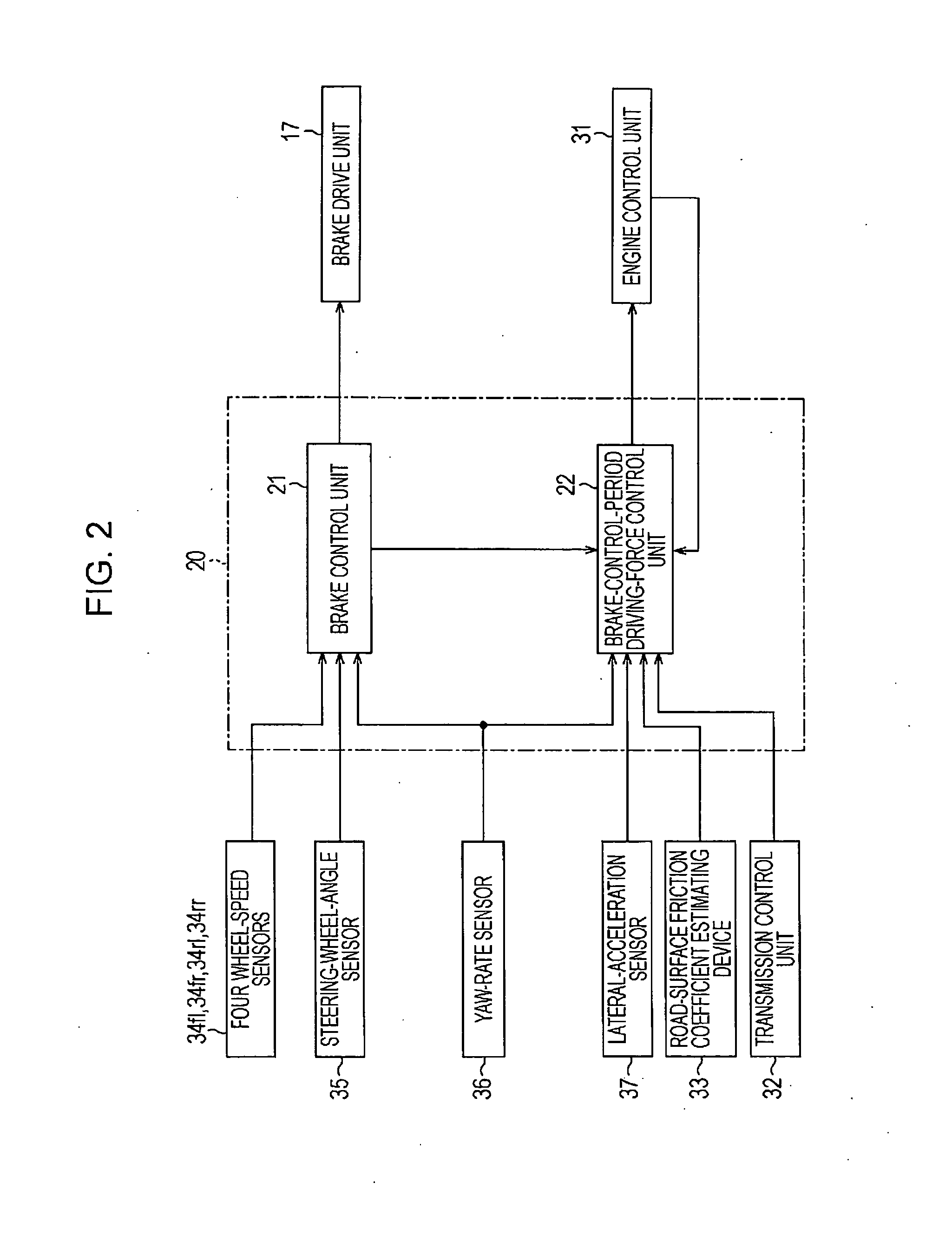

Vehicle braking-force control device

ActiveUS20080208427A1Improve vehicle stabilityAvoid adjustmentDigital data processing detailsAutomatic initiationsTweelTorque regulation

A braking-force control device has a brake control function for performing brake control on a front outside wheel when a vehicle is detected to be in an oversteer condition during a turning operation and for performing brake control on a rear inside wheel when the vehicle is detected to be in an understeer condition during a turning operation. For preventing the oversteer condition, a command for reducing the engine torque is output. On the other hand, for preventing the understeer condition, the engine torque is limited in accordance with a permissible engine torque value that is calculated on the basis of a road-surface friction coefficient, and ground loads and lateral tire forces of individual wheels. If it is detected that engine braking is in operation, the engine torque is adjusted to substantially zero.

Owner:SUBARU CORP

Torque-controlled rotational module

InactiveUS7461433B2Easy to displayAvoid scratchesTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesTorque regulationControl theory

A torque-controlled rotational module is described. The torque-controlled rotational module has a fixing base, a rotational member, a spring member, and a torque adjusting ring. The fixing base further has a fixing wall and a cable hole therein for a cable to pass therethrough. The module further utilizes wear-resisting members configured on both sides of the rotational member, between the torque adjusting ring and the fixing base, to protect the torque adjusting ring and the fixing base from wear and tear. The fixing wall further utilizes a fixing indentation to couple to arresting protrusions of the wear-resisting members to avoid rotation of the wear-resisting members. The fixing base further utilizes a knob coupled to a slot of the rotational member to limit a rotational angle of the rotational member.

Owner:QUANTA COMPUTER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com