Electric drill with driving mode switching

A driving mode and electric drill technology, which is applied in the manufacture of tools and portable mobile devices, etc., can solve the problems of many parts in the transmission link of mode switching, large running resistance, and cumulative error affecting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

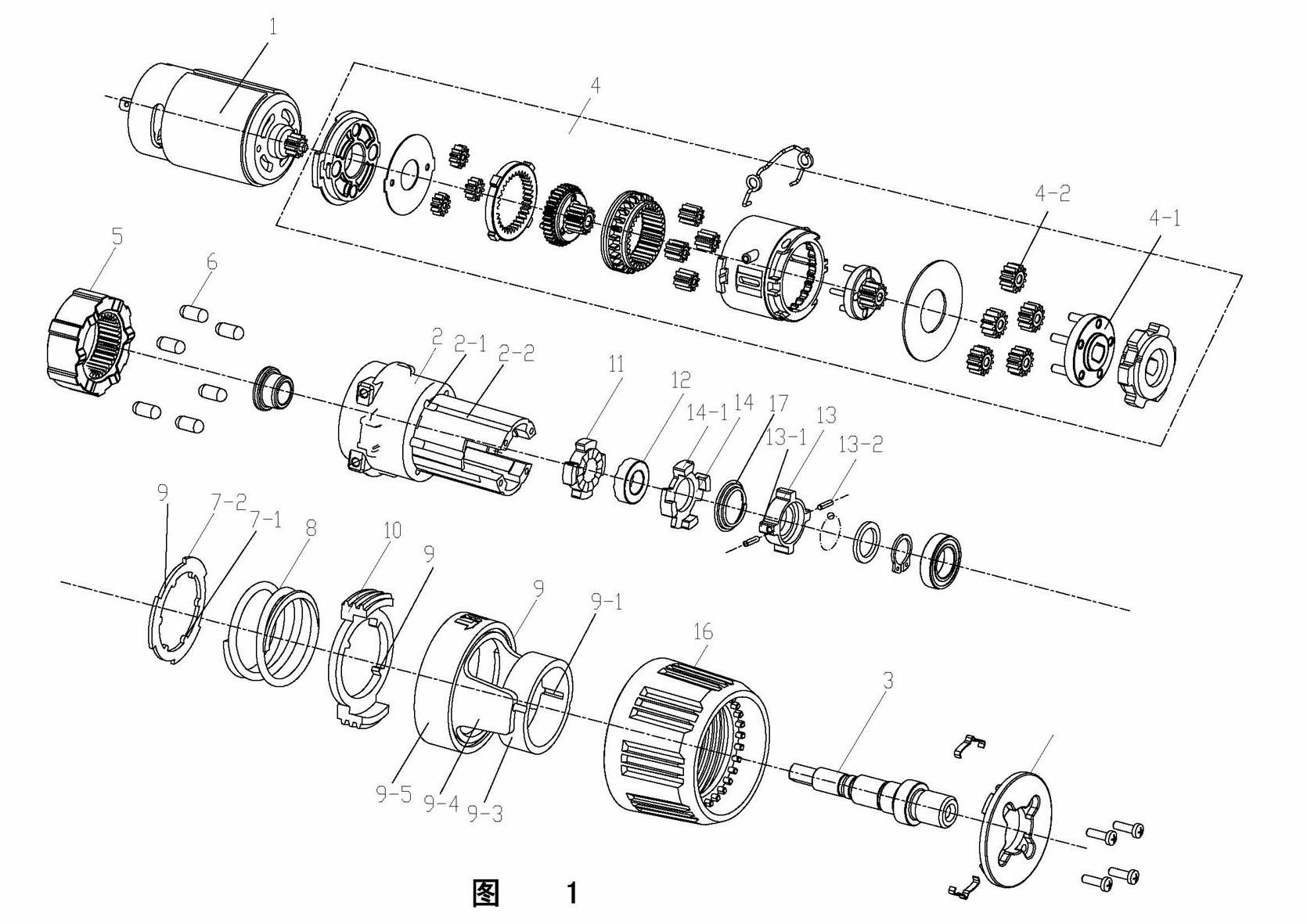

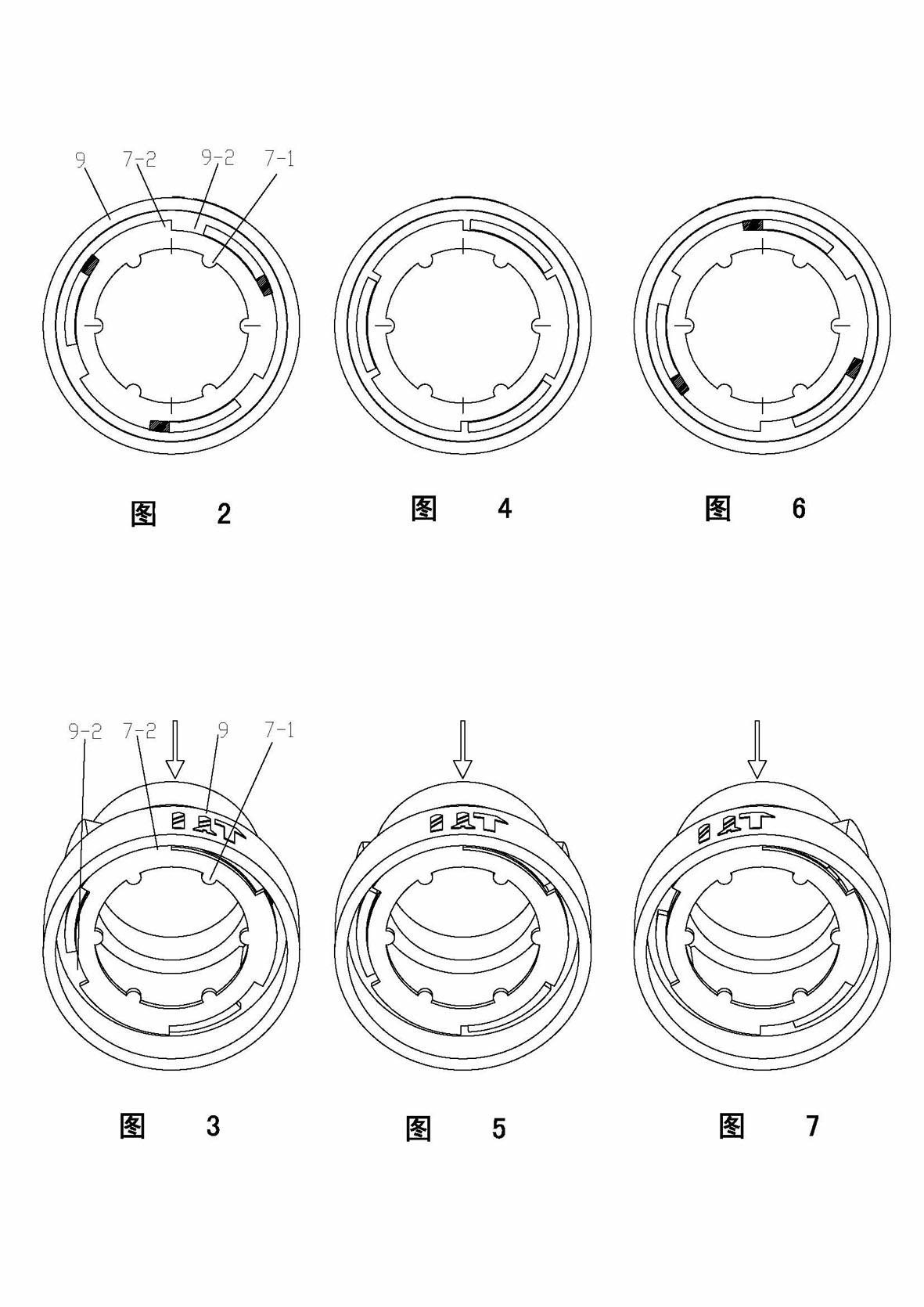

[0018] This embodiment has an electric drill with driving mode switching such as figure 1As shown, it includes a motor 1 placed inside the casing, a rotatable function switching cup 9 and a torque regulating cup 16 set outside the casing. The motor 1 is connected to the output shaft 3 through the two-stage planetary gear reduction mechanism 4 installed in the gearbox 2, and the output shaft 3 is engaged with the second stage of the inner ring gear 5 through the special-shaped hole in the center of the planetary gear train ring 4-1. The shaft centers of the planetary gears 4-2 form a synchronous rotation relationship, and the static impact ring 11 with end teeth and the fixed block 14 with evenly spaced end bosses 14-1 are fixedly installed in the gearbox 2. The function switching cup 9 is composed of a gear ring 9-5 and a ring constraint ring 9-3 connected by two side wing plates 9-4 extending towards the output shaft direction. The inner hole of the gear ring 9-5 has a 7 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com