Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Easy thickness control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

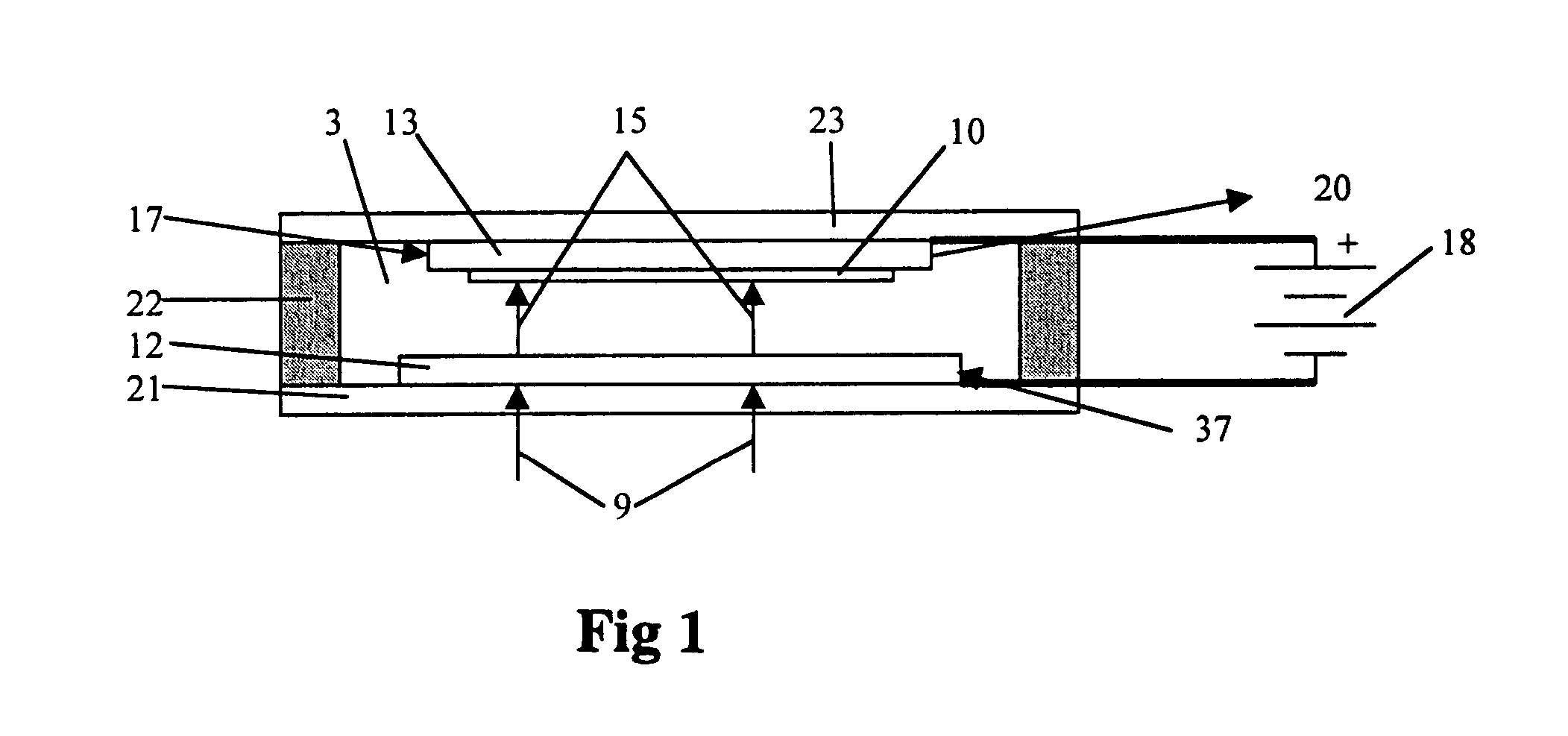

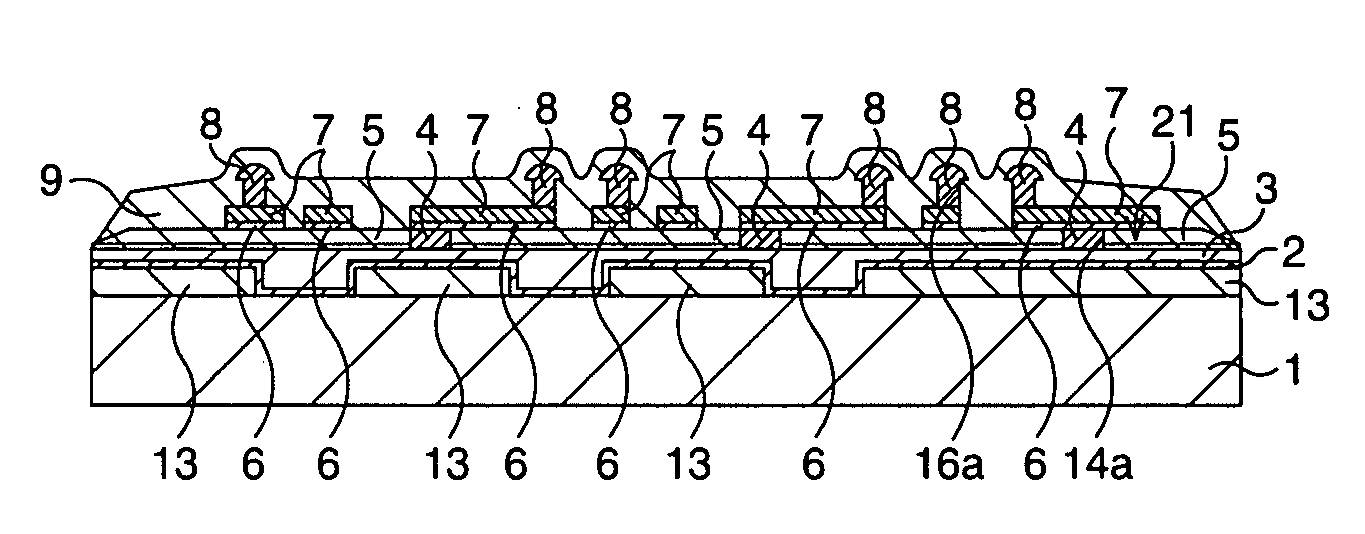

Substrate processing apparatus

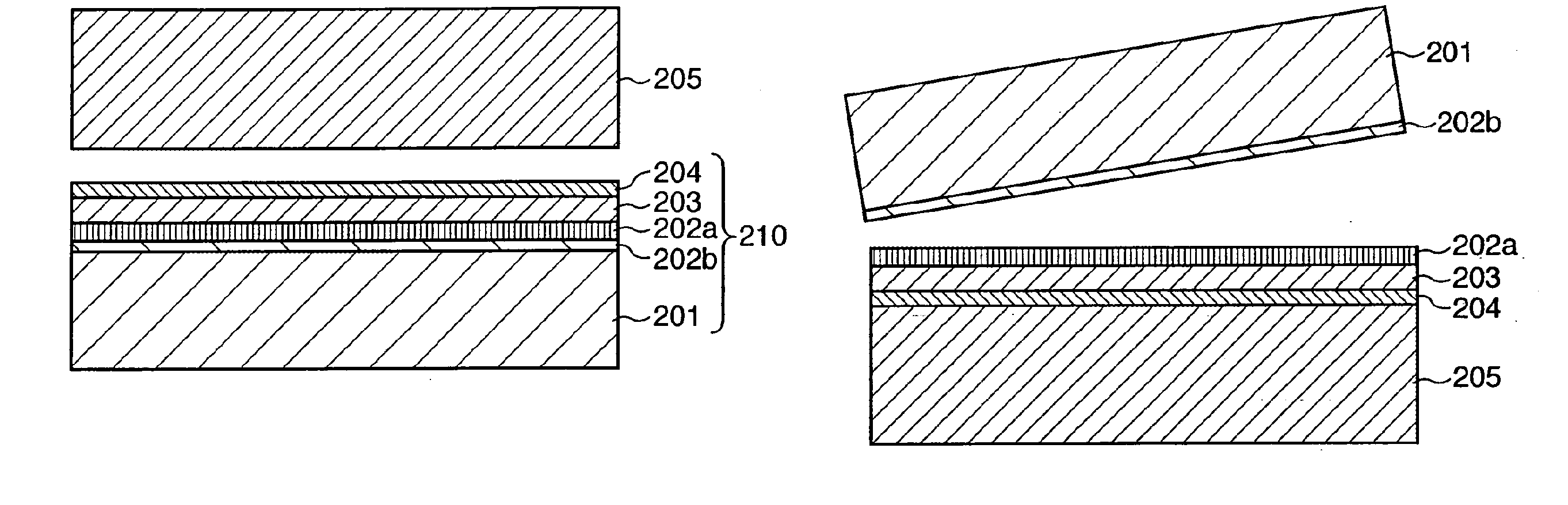

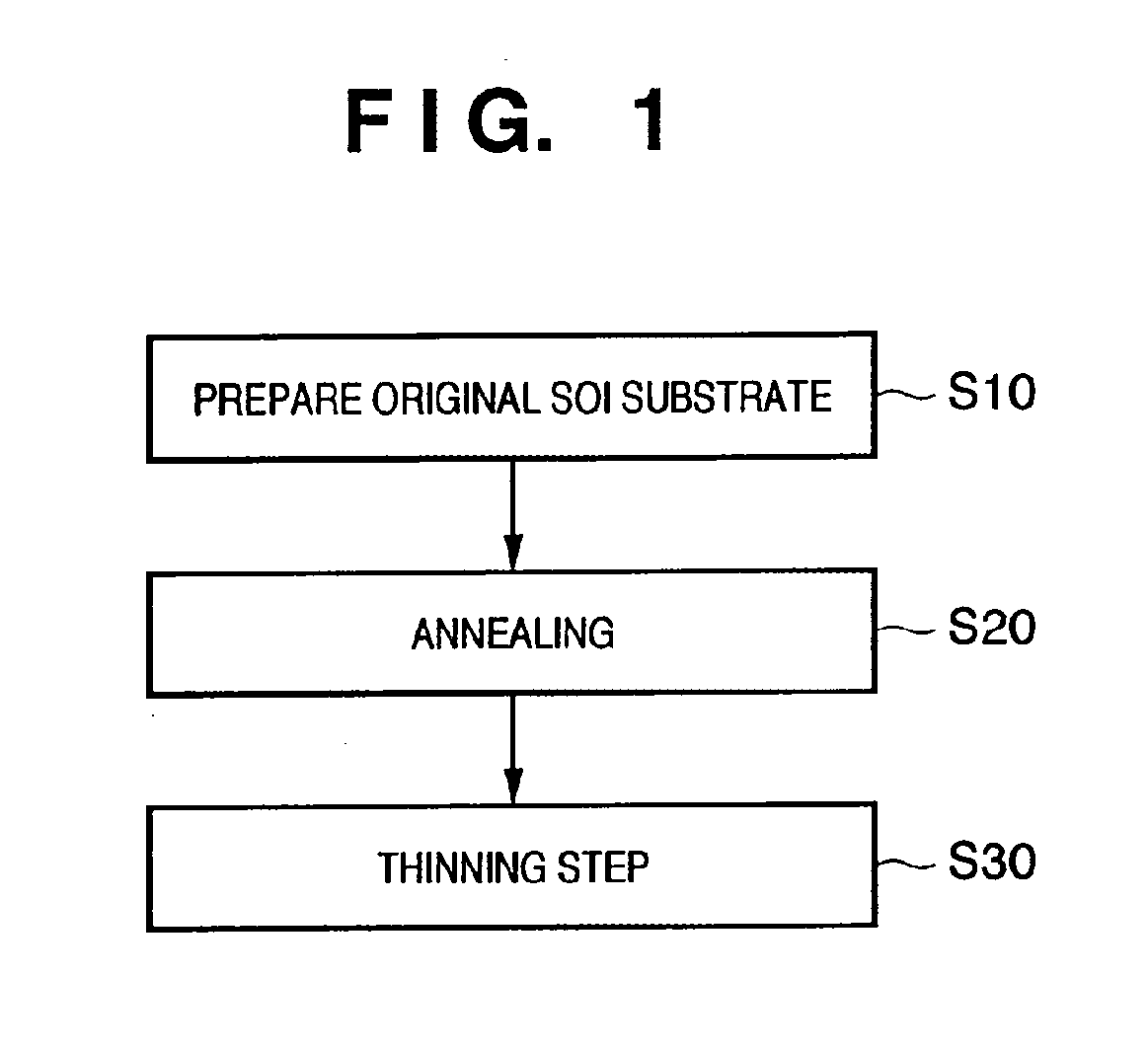

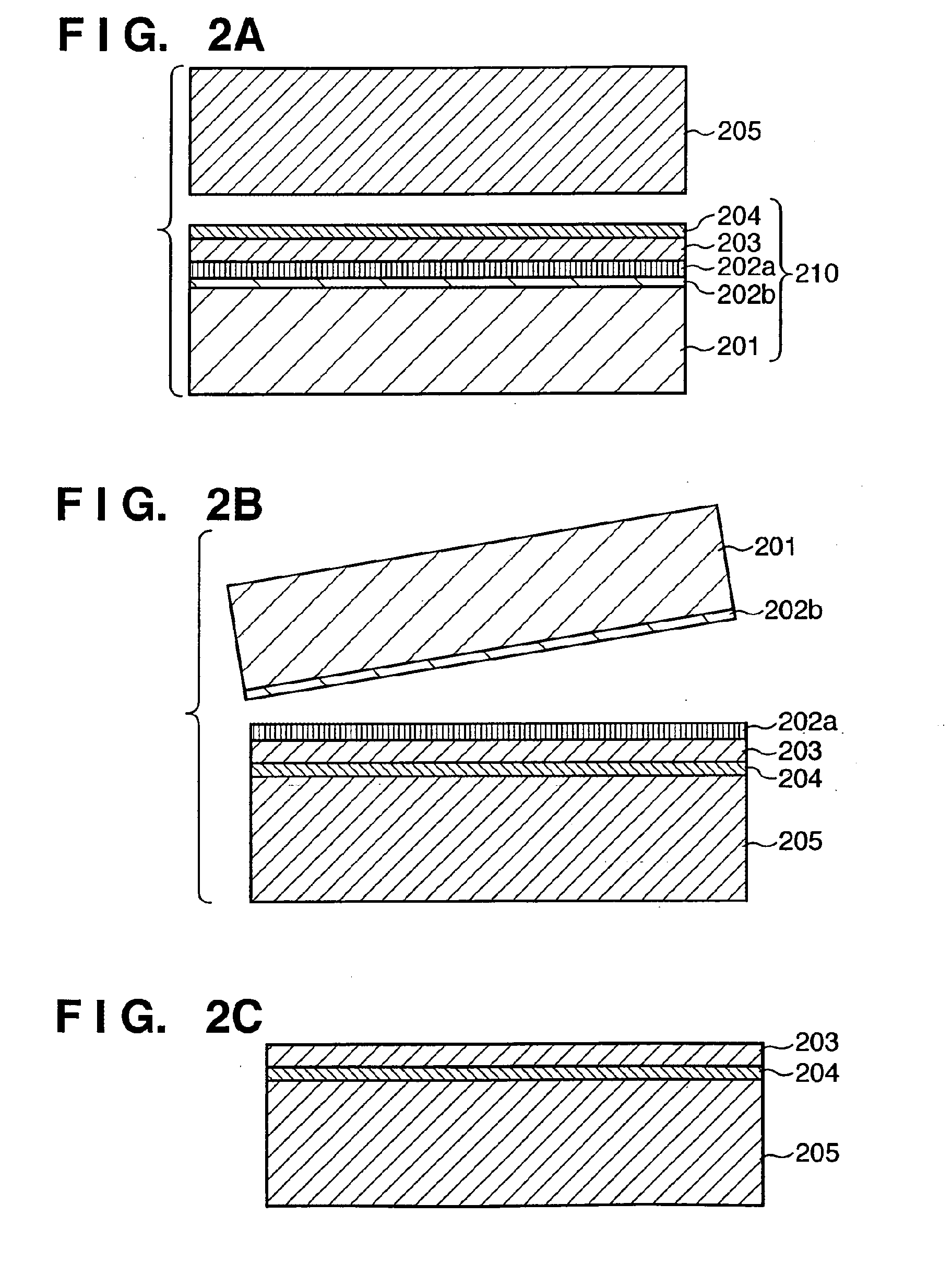

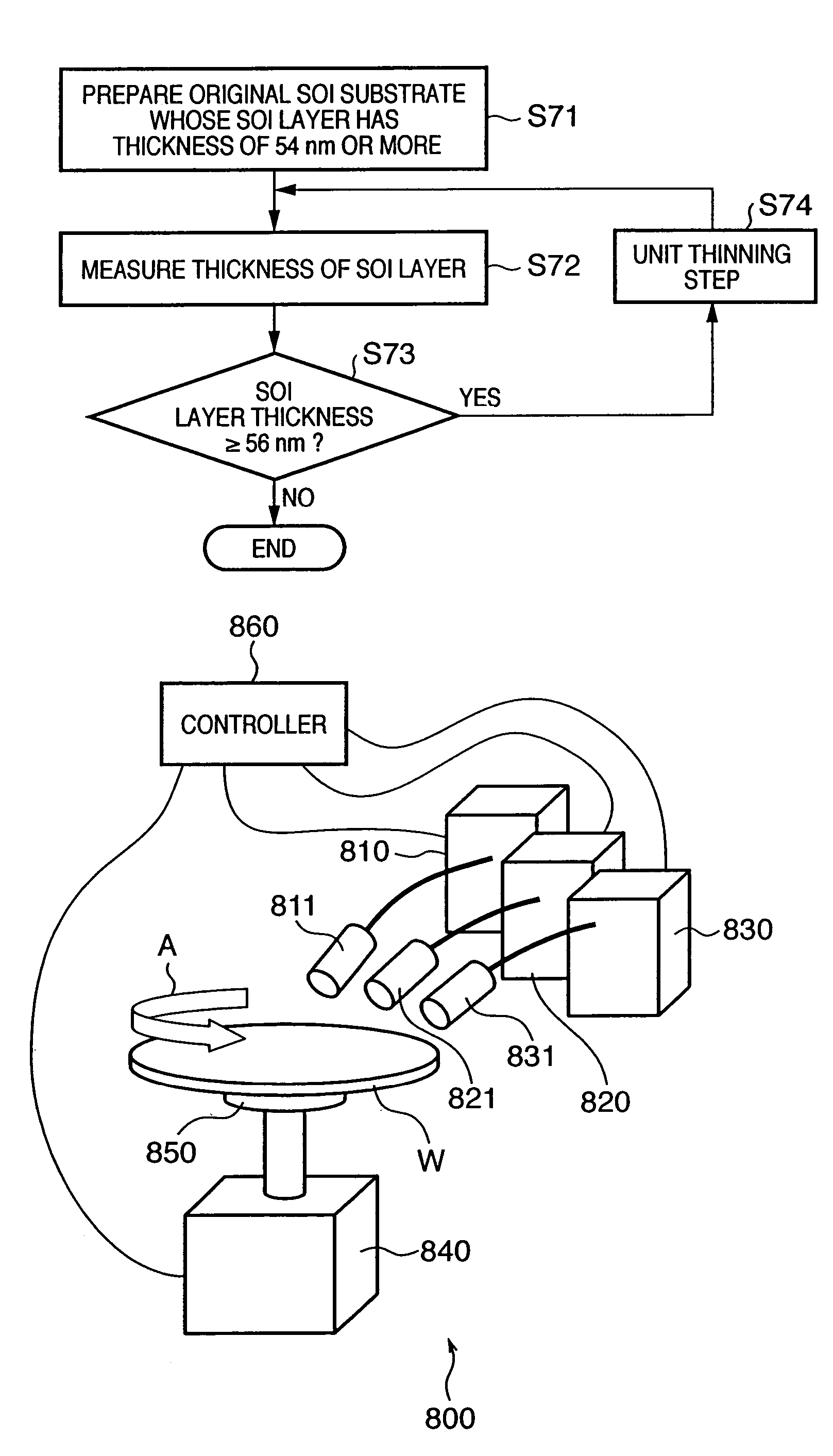

InactiveUS20070190746A1Easy thickness controlIncrease flexibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical solutionSoi substrate

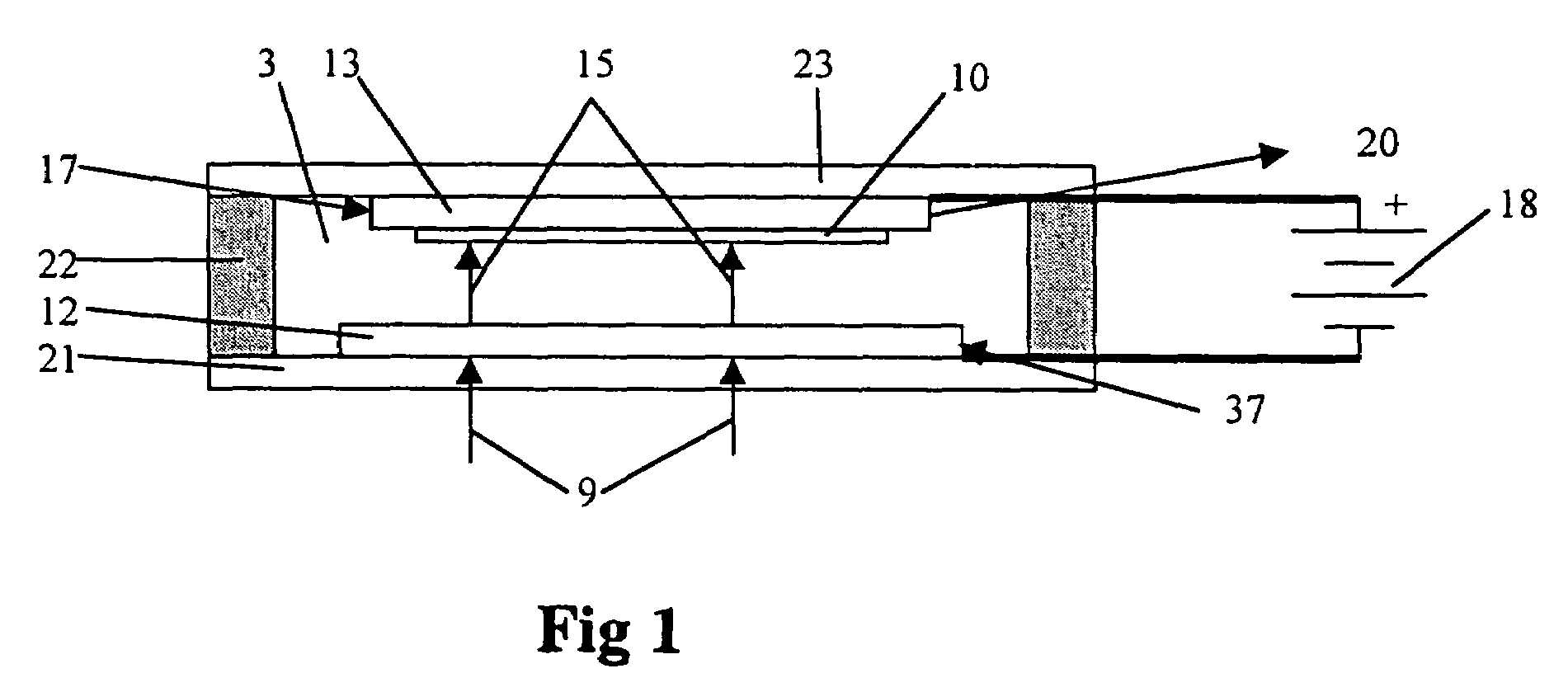

An SOI substrate which has a thick SOI layer is first prepared. Then, the SOI layer is thinned to a target film thickness using as a unit a predetermined thickness not more than that of one lattice. This thinning is performed by repeating a unit thinning step which includes an oxidation step of oxidizing the surface of the SOI layer by the predetermined thickness not more than that of one lattice and a removal step of selectively removing silicon oxide formed by the oxidation. The SOI layer of the SOI substrate is chemically etched by supplying a chemical solution to the SOI layer, and the film thickness of the etched SOI layer is measured. When the measured film thickness of the SOI layer has a predetermined value, a process of chemically etching the SOI layer ends.

Owner:CANON KK

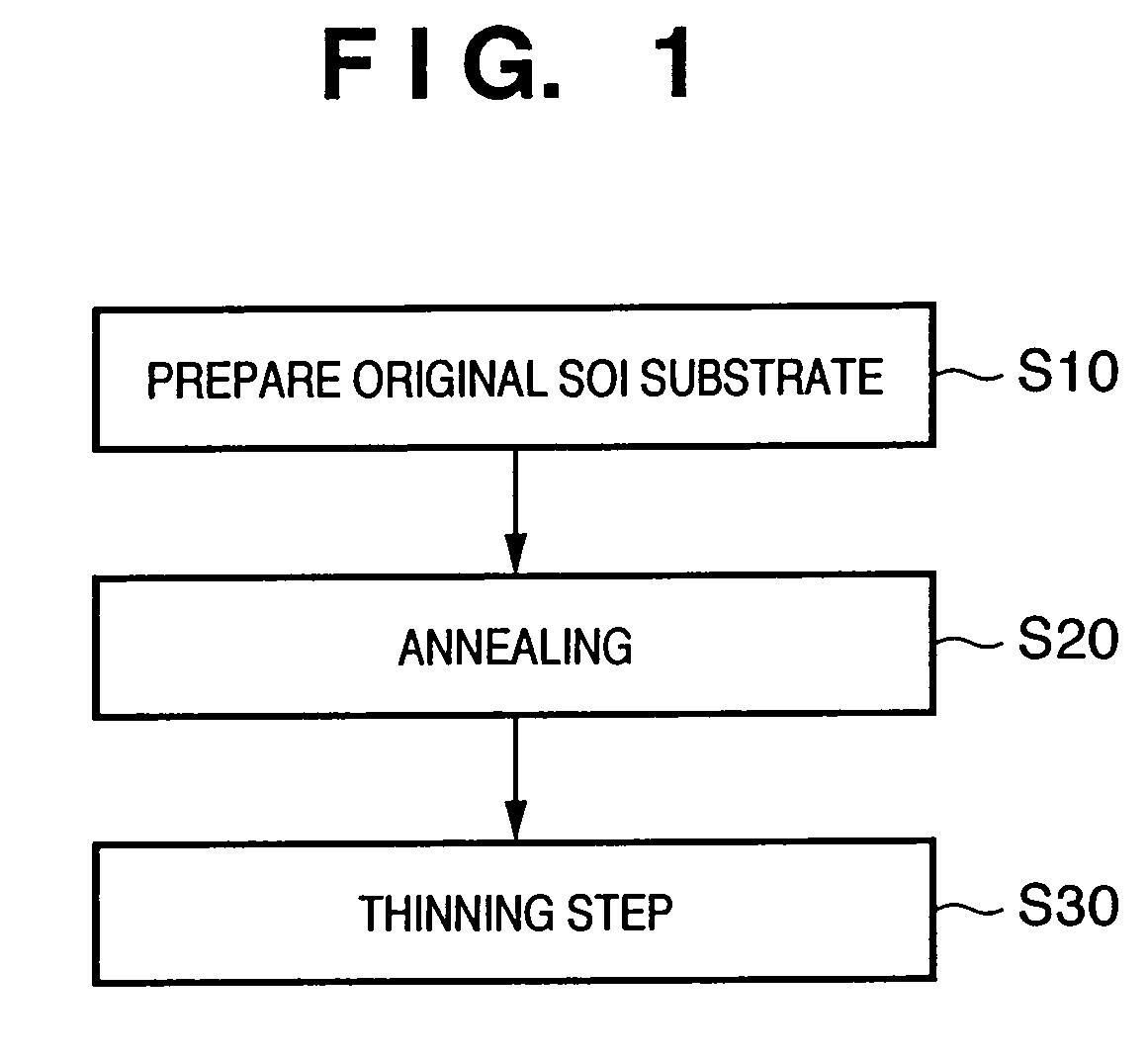

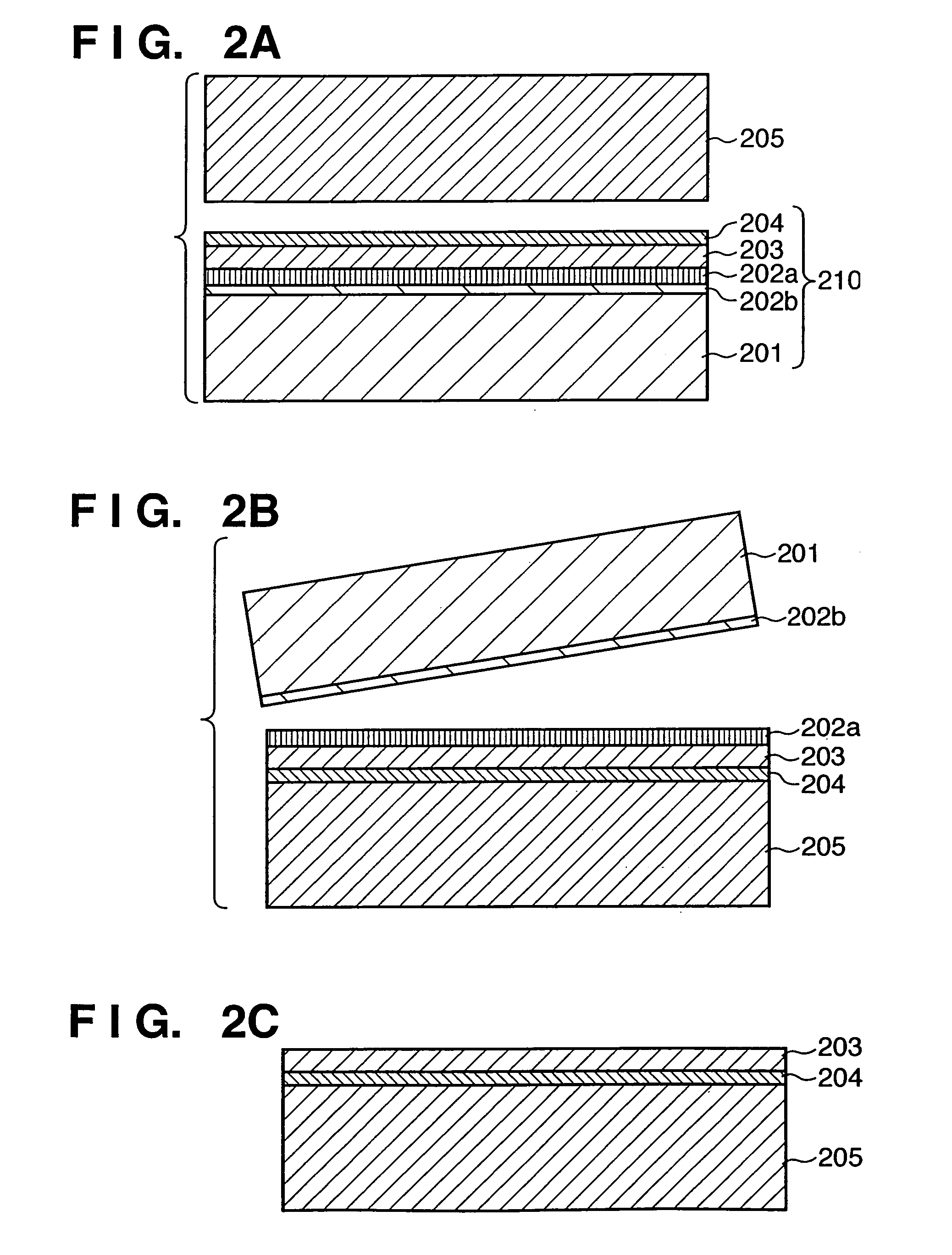

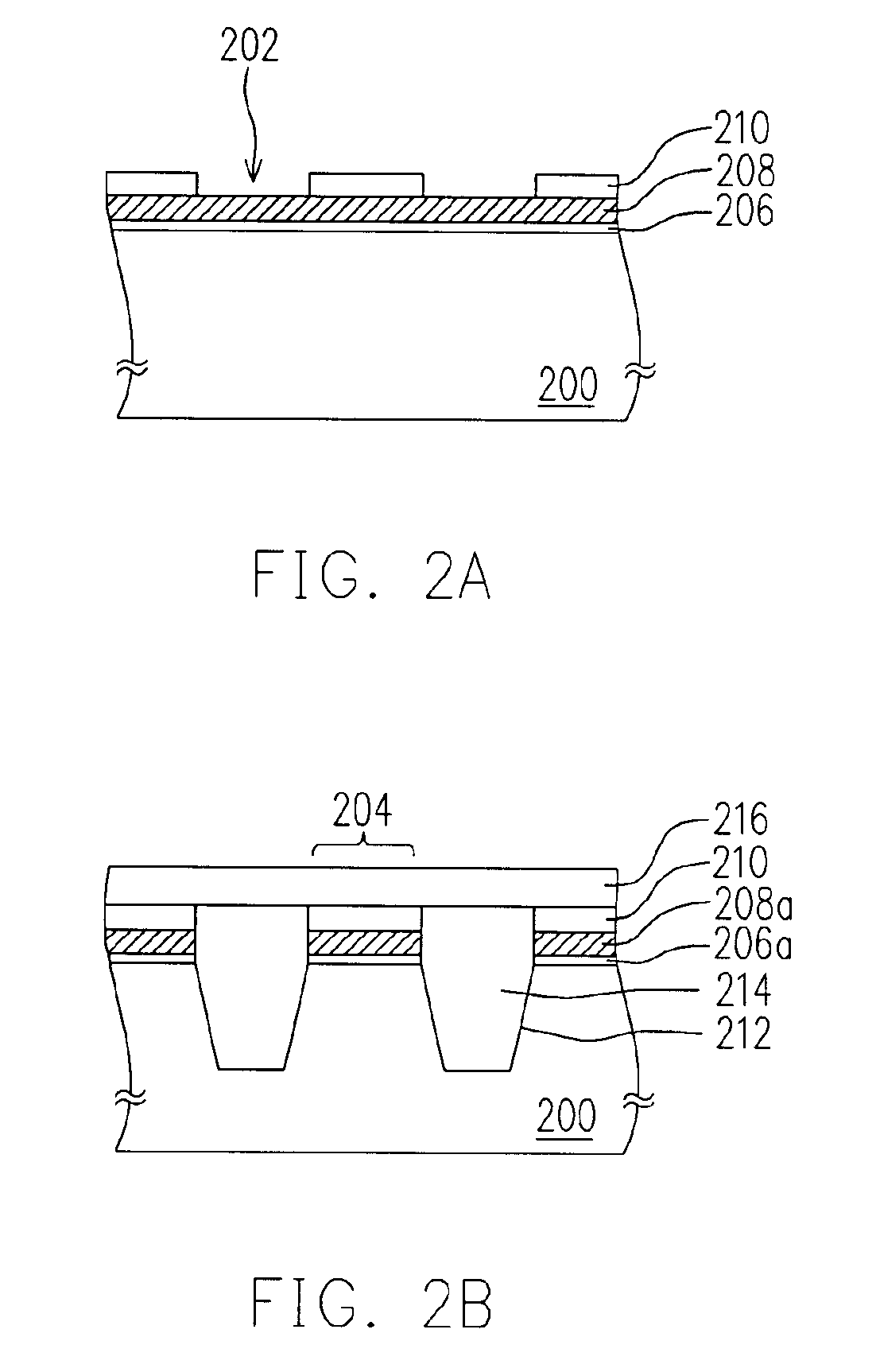

Substrate manufacturing method and substrate processing apparatus

InactiveUS7256104B2Easy thickness controlIncrease flexibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical solutionSoi substrate

An SOI substrate which has a thick SOI layer is first prepared. Then, the SOI layer is thinned to a target film thickness using as a unit a predetermined thickness not more than that of one lattice. This thinning is performed by repeating a unit thinning step which includes an oxidation step of oxidizing the surface of the SOI layer by the predetermined thickness not more than that of one lattice and a removal step of selectively removing silicon oxide formed by the oxidation. The SOI layer of the SOI substrate is chemically etched by supplying a chemical solution to the SOI layer, and the film thickness of the etched SOI layer is measured. When the measured film thickness of the SOI layer has a predetermined value, a process of chemically etching the SOI layer ends.

Owner:CANON KK

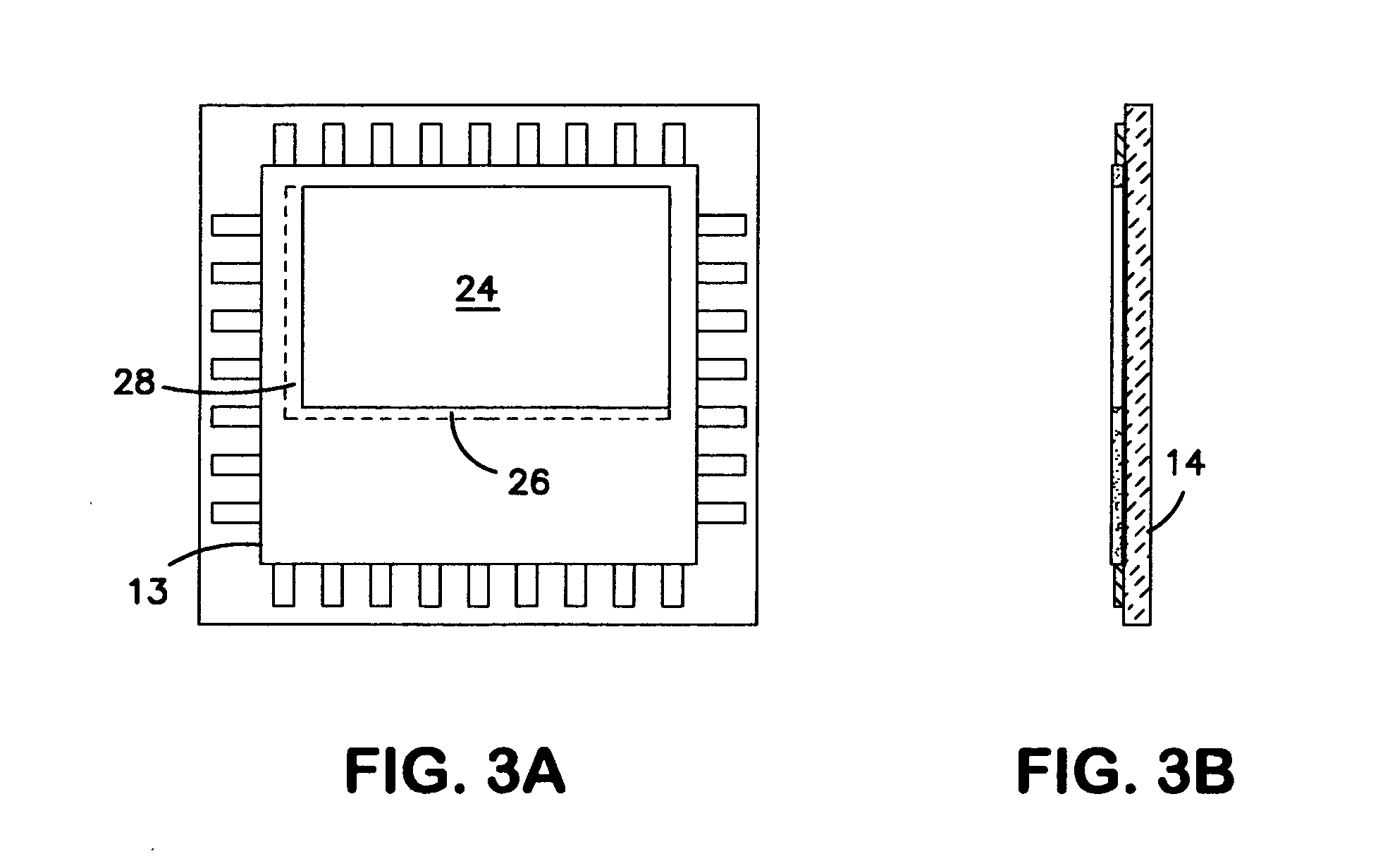

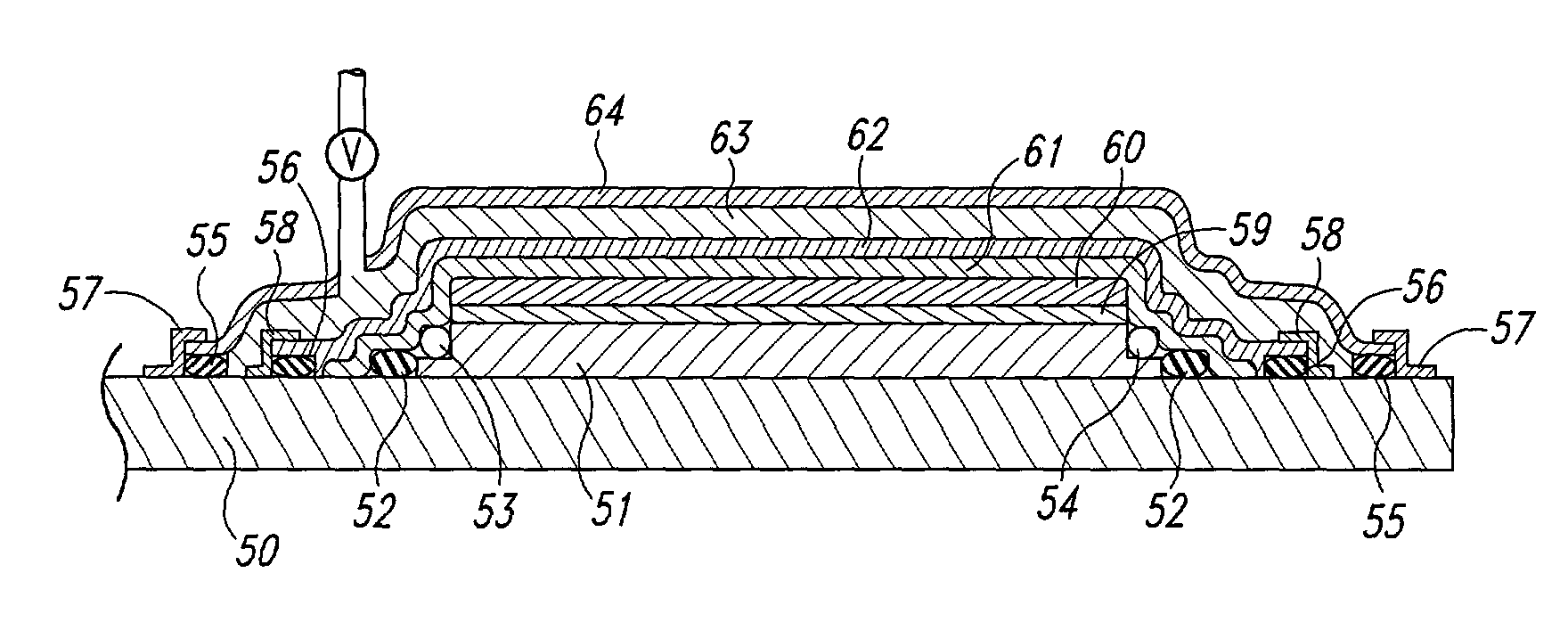

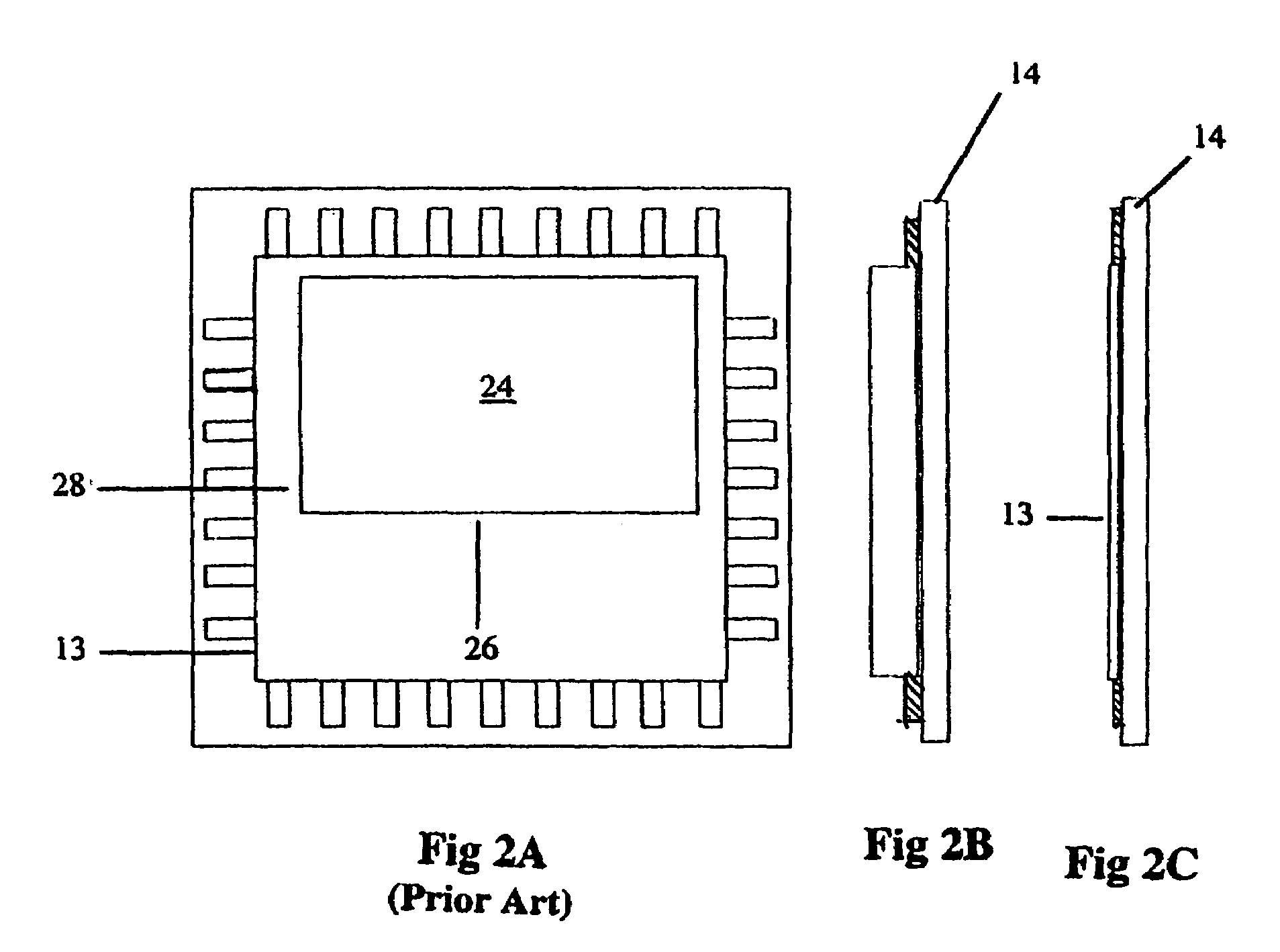

Backside imaging through a doped layer

ActiveUS20060138322A1Improve imaging effectImprove device yieldSolid-state devicesMaterial analysis by optical meansCMOSImage resolution

Backthinning in an area selective manner is applied to CMOS imaging sensors 12 for use in electron bombarded active pixel array devices. A further arrangement results in an array of collimators 51 aligned with pixels 42 or groups of pixels of an active pixel array providing improved image contrast of such image sensor. Provision of a thin P-doped layer 52 on the illuminated rear surface provides both a diffusion barrier resulting in improved resolution and a functional shield for reference pixels. A gradient in concentration of P-doped layer 52 optimizes electron collection at the pixel array.

Owner:EOTECH LLC

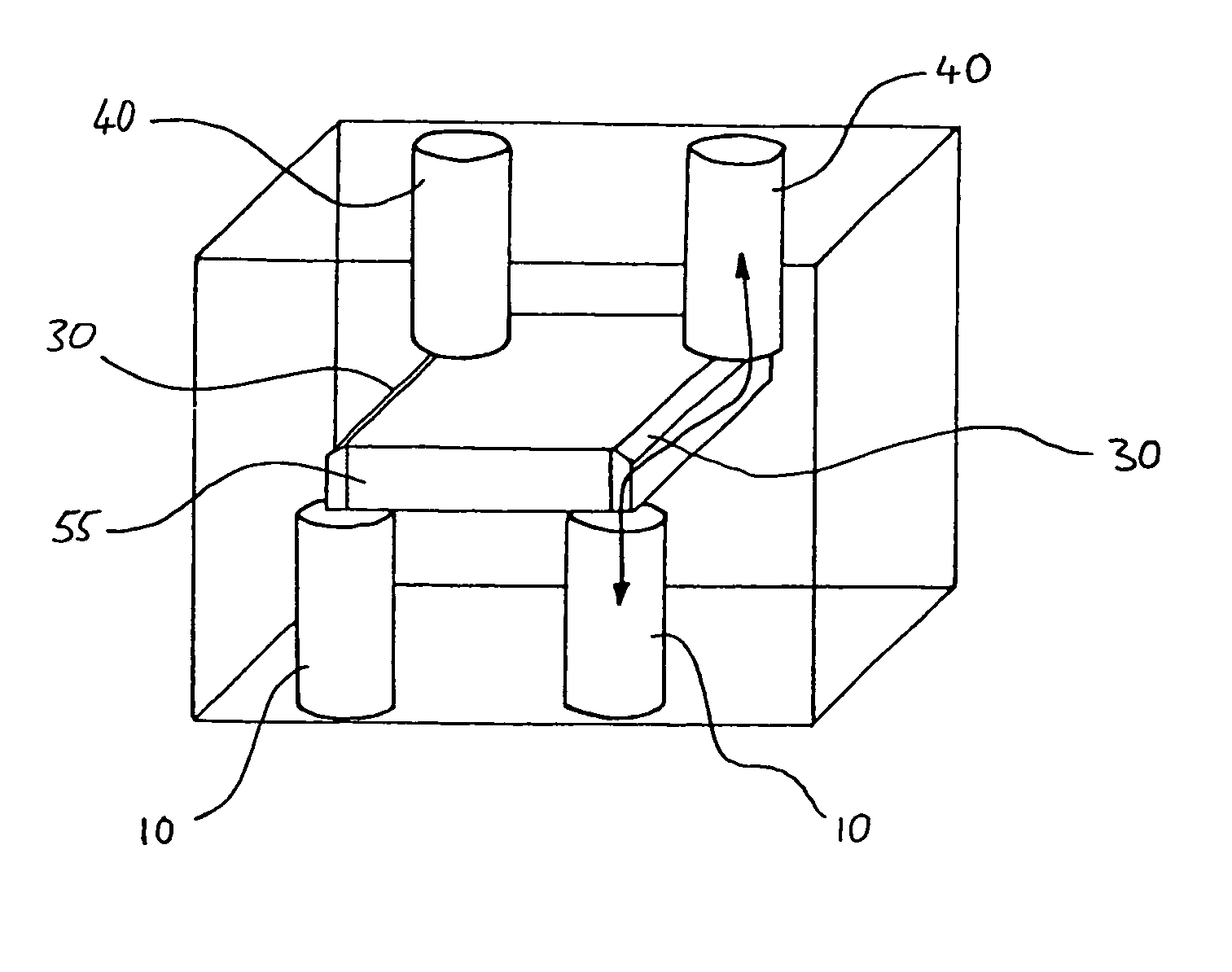

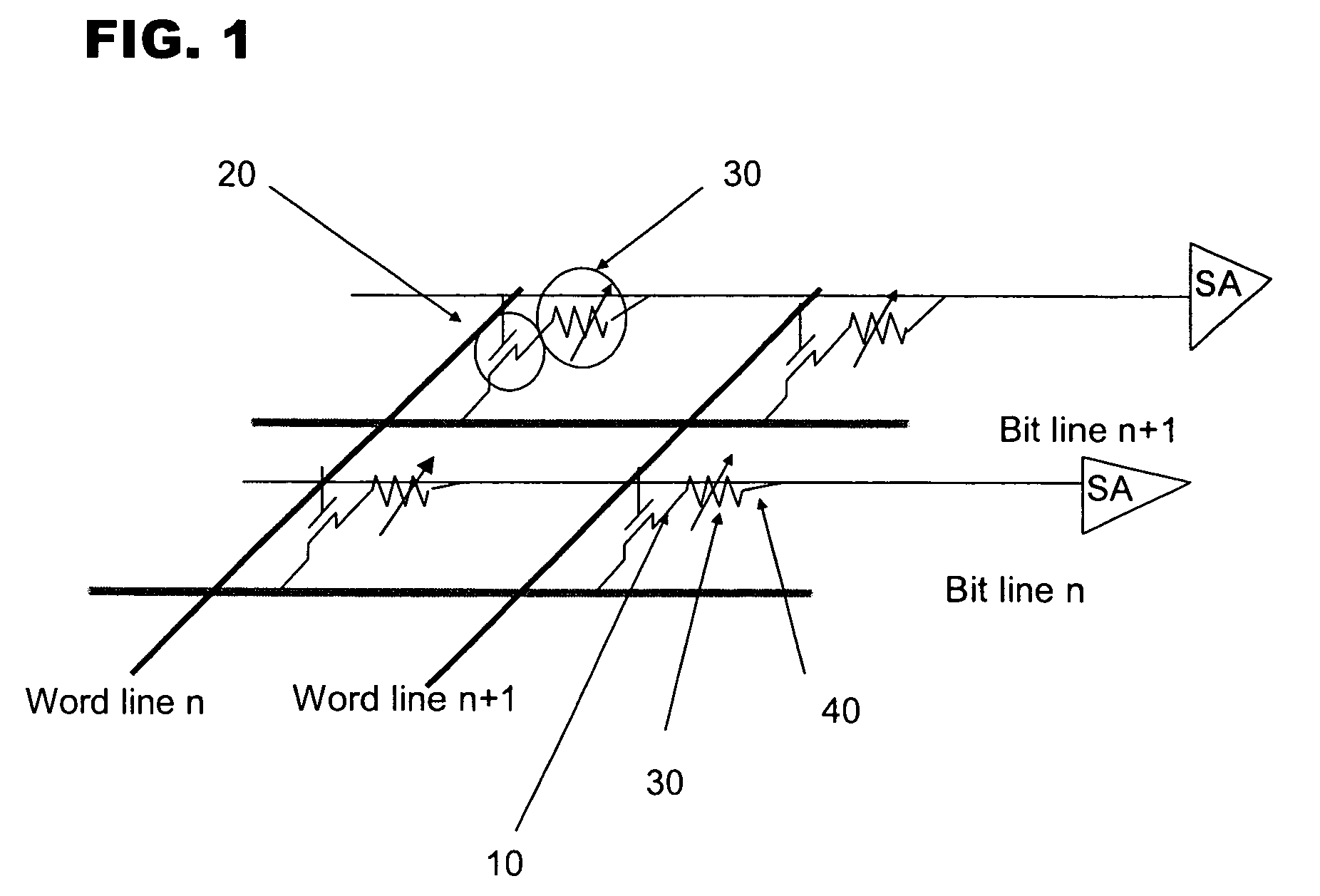

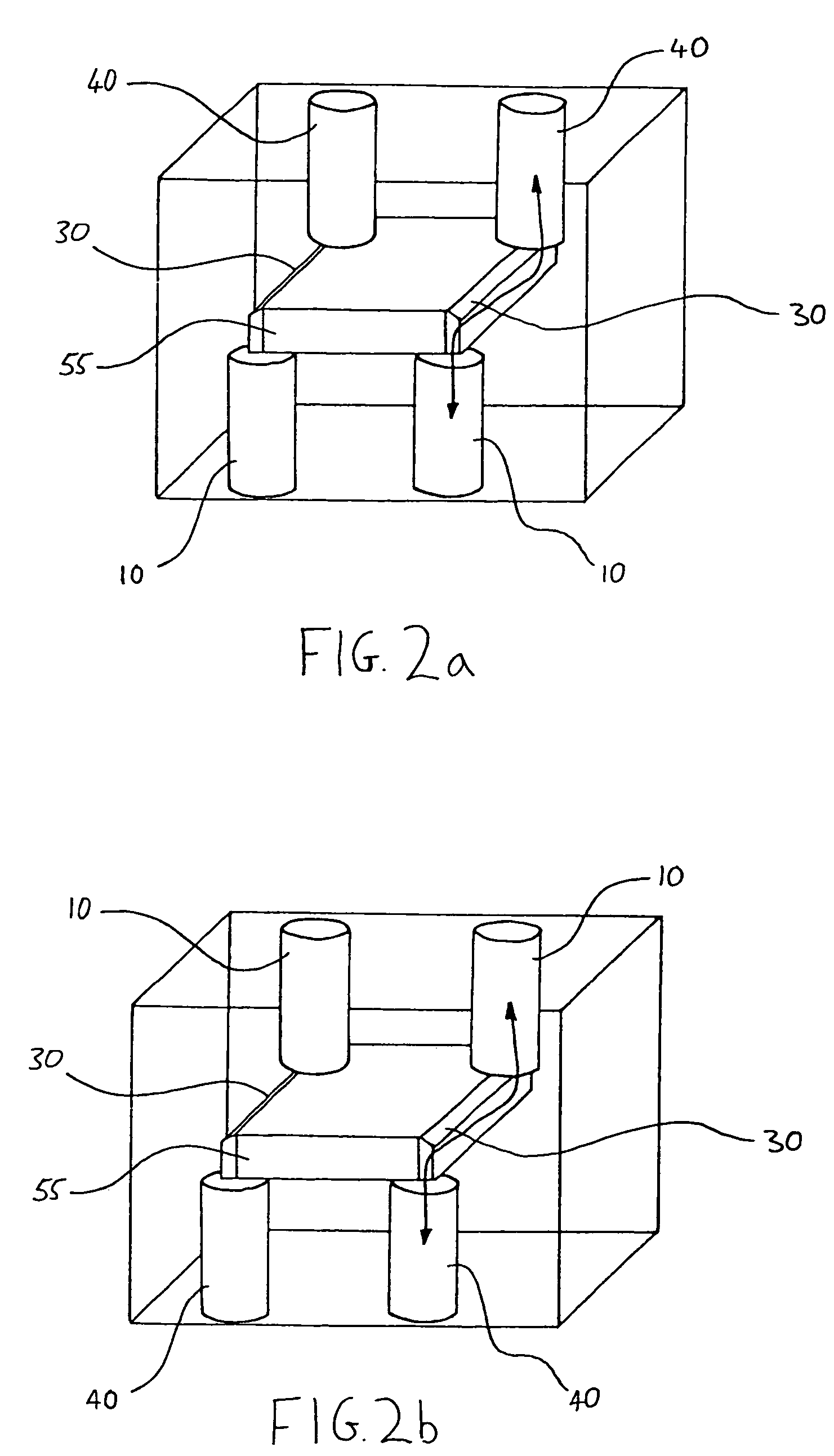

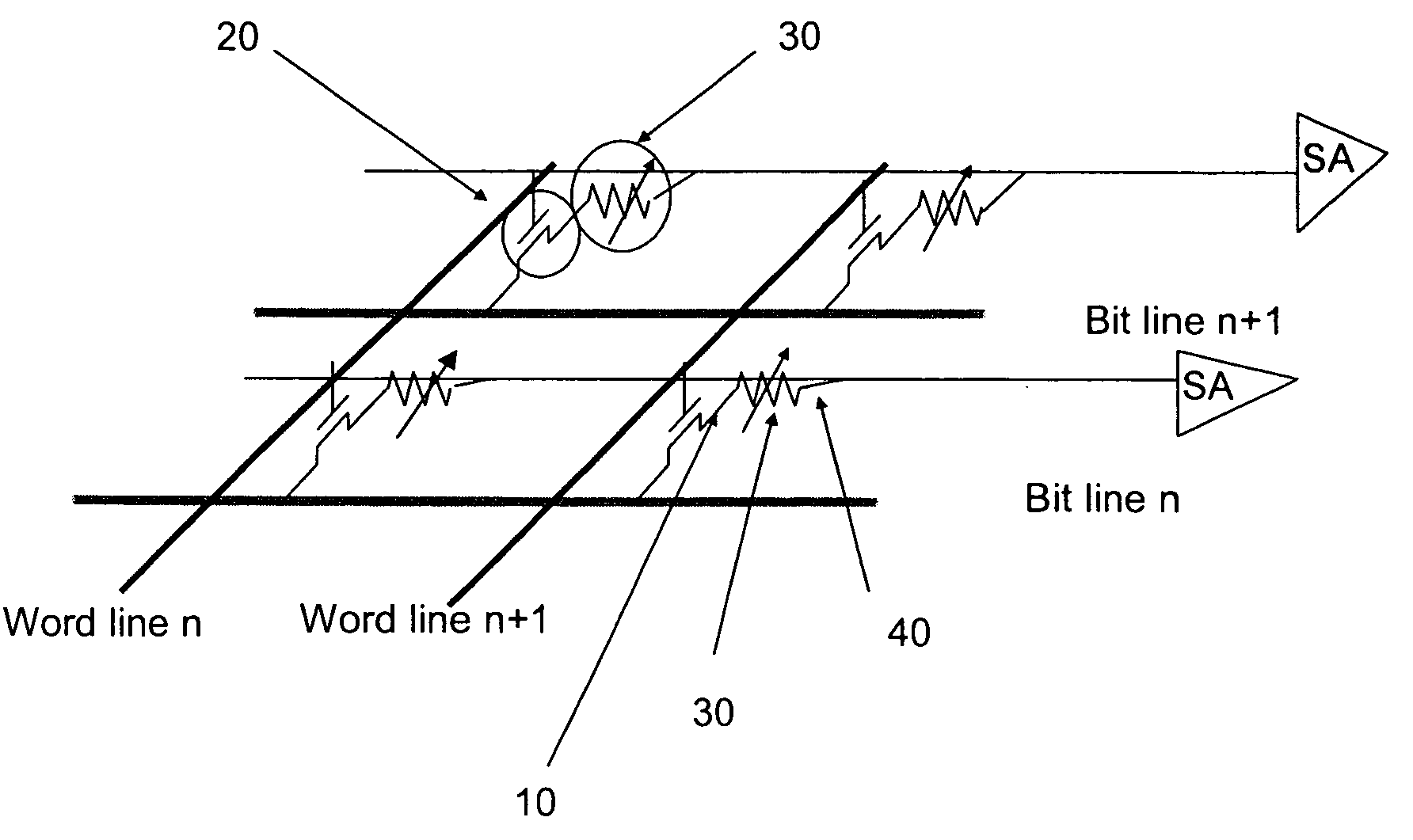

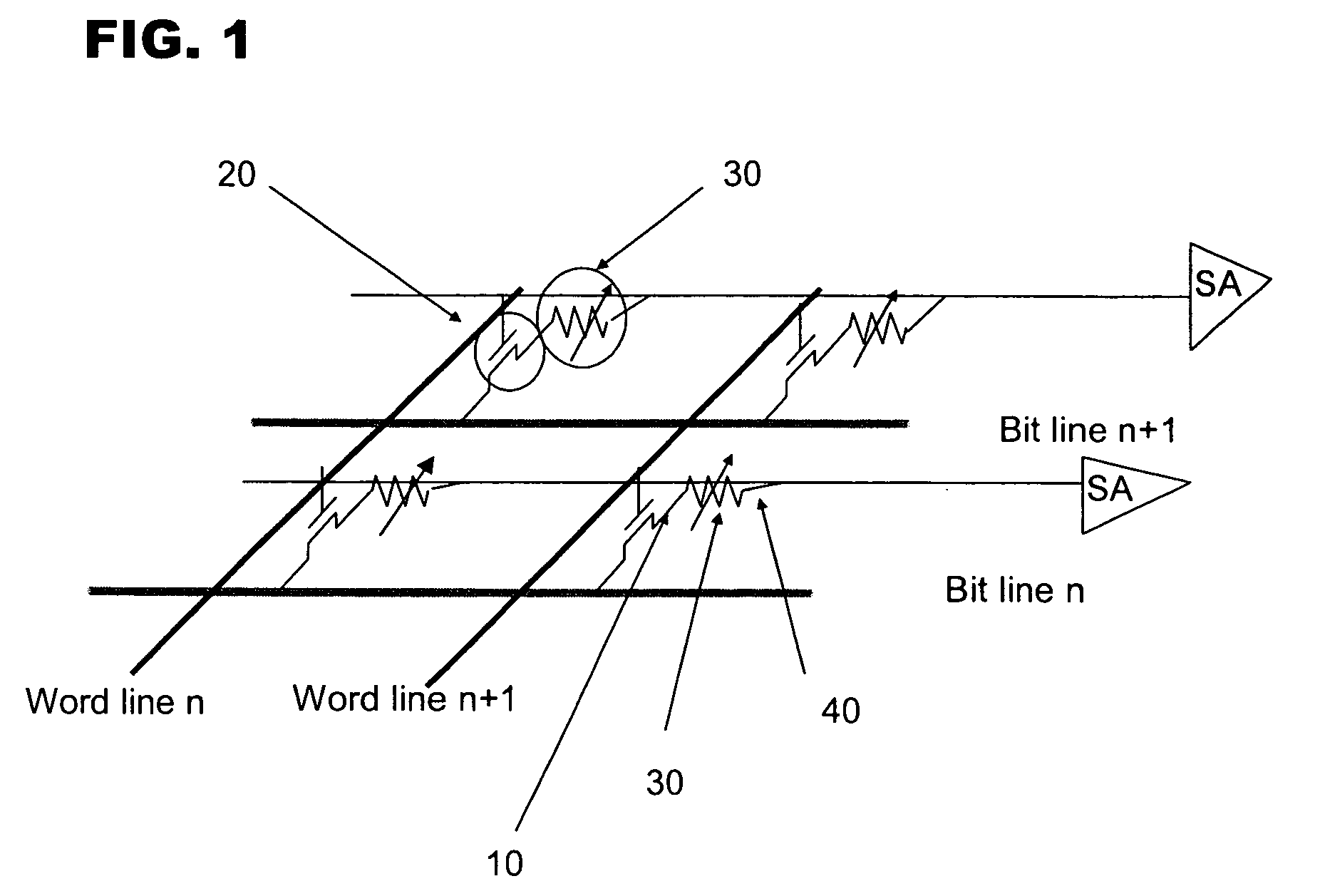

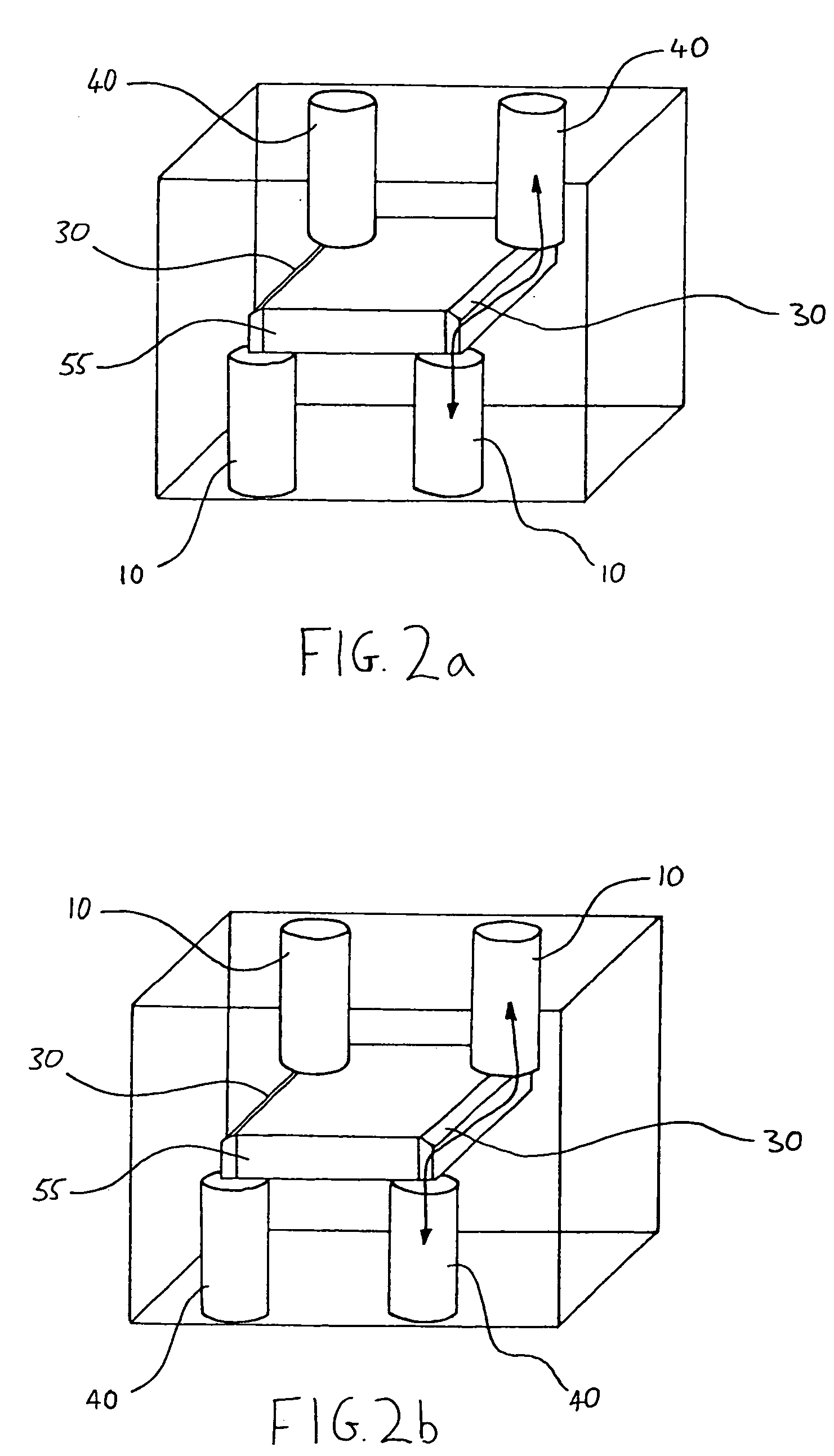

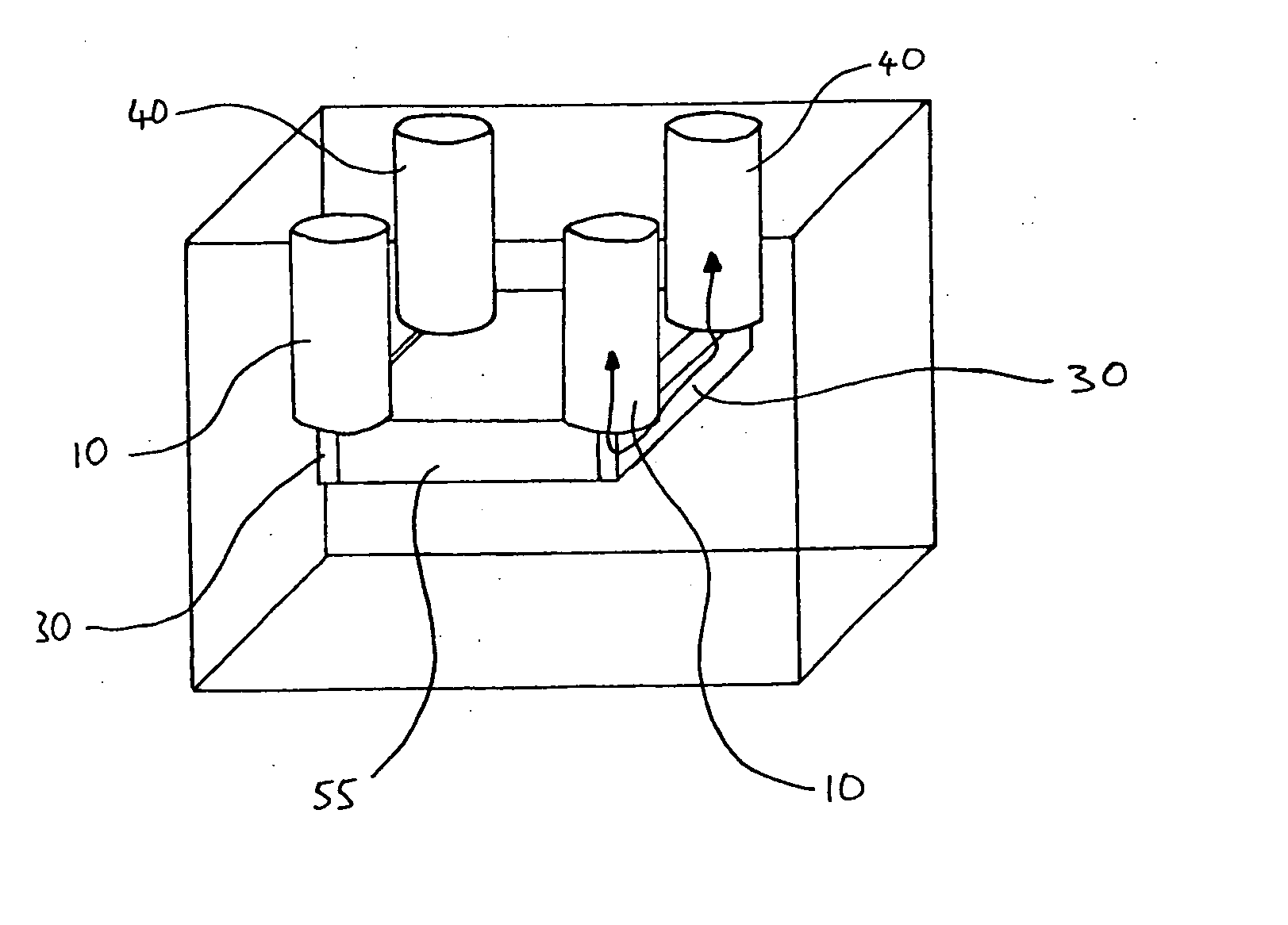

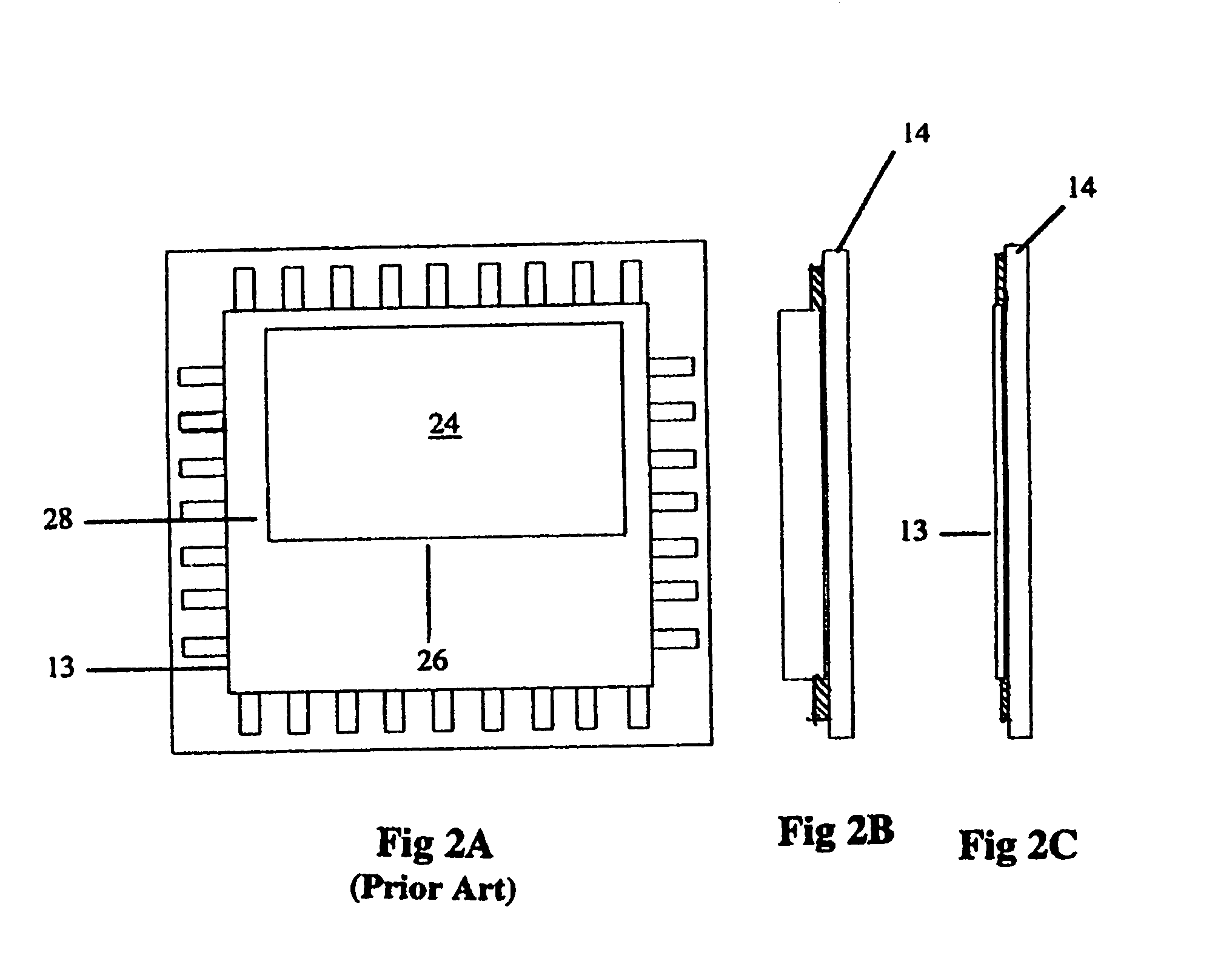

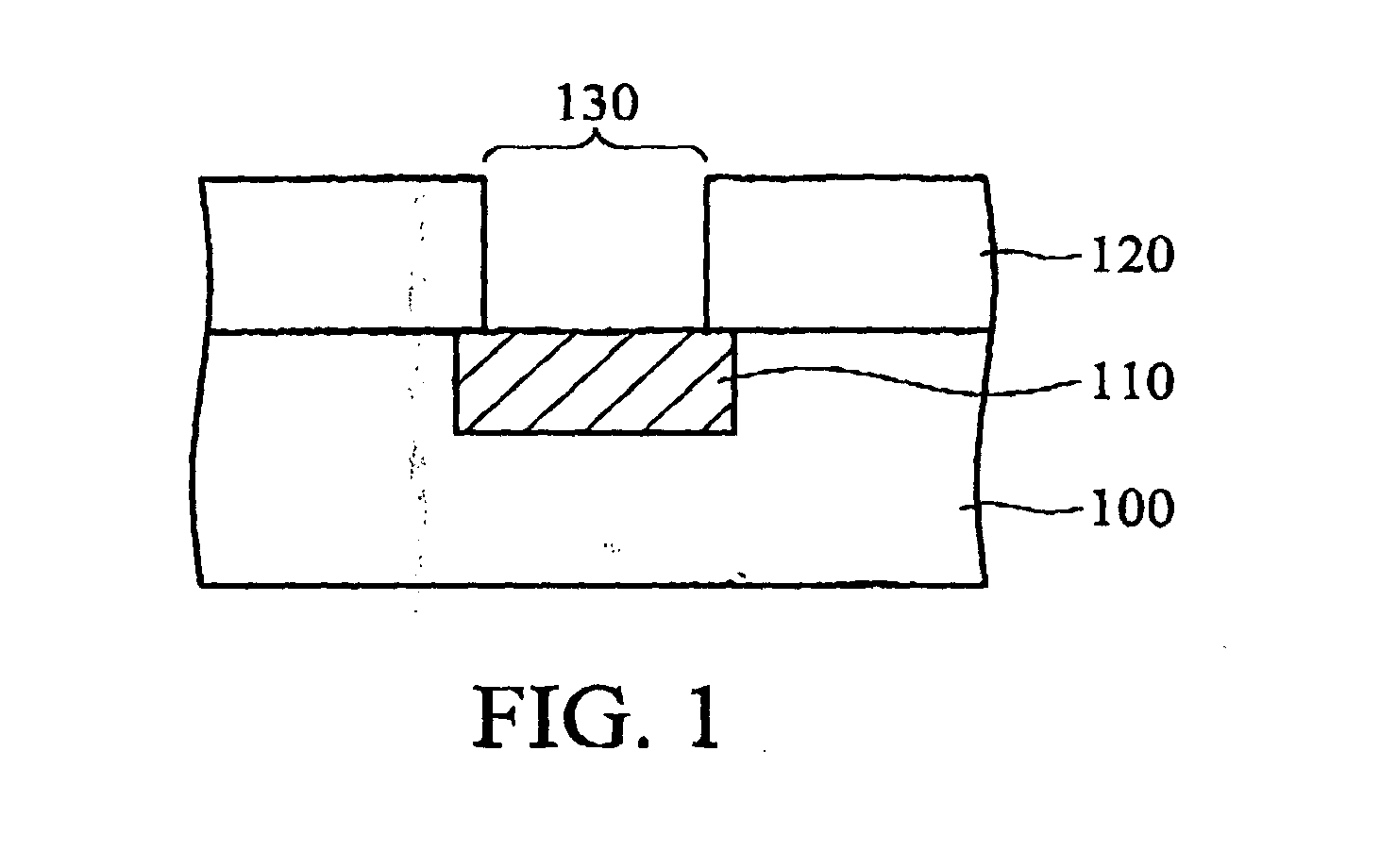

Horizontal chalcogenide element defined by a pad for use in solid-state memories

ActiveUS7038230B2Decreased current/power requirementRemove restrictionsSolid-state devicesRead-only memoriesPhase-change memorySemiconductor

A process for fabricating phase-change elements having ultra small cross-sectional areas for use in phase change memory cells specifically and in semiconductor devices generally in which pads are implemented to create horizontally aligned phase change elements is disclosed. The elements thus defined may be used within chalcogenide memory cells or other semiconductor devices.

Owner:MACRONIX INT CO LTD

Horizontal chalcogenide element defined by a pad for use in solid-state memories

ActiveUS20050145984A1Decreased current/power requirementRemove restrictionsSolid-state devicesRead-only memoriesPhase-change memoryDevice material

A process for fabricating phase-change elements having ultra small cross-sectional areas for use in phase change memory cells specifically and in semiconductor devices generally in which pads are implemented to create horizontally aligned phase change elements is disclosed. The elements thus defined may be used within chalcogenide memory cells or other semiconductor devices.

Owner:MACRONIX INT CO LTD

Horizontal chalcogenide element defined by a pad for use in solid-state memories

InactiveUS20060157681A1Decreased current/power requirementRemove restrictionsSolid-state devicesRead-only memoriesPhase-change memoryDevice material

A process for fabricating phase-change elements having ultra small cross-sectional areas for use in phase change memory cells specifically and in semiconductor devices generally in which pads are implemented to create horizontally aligned phase change elements is disclosed. The elements thus defined may be used within chalcogenide memory cells or other semiconductor devices.

Owner:MACRONIX INT CO LTD

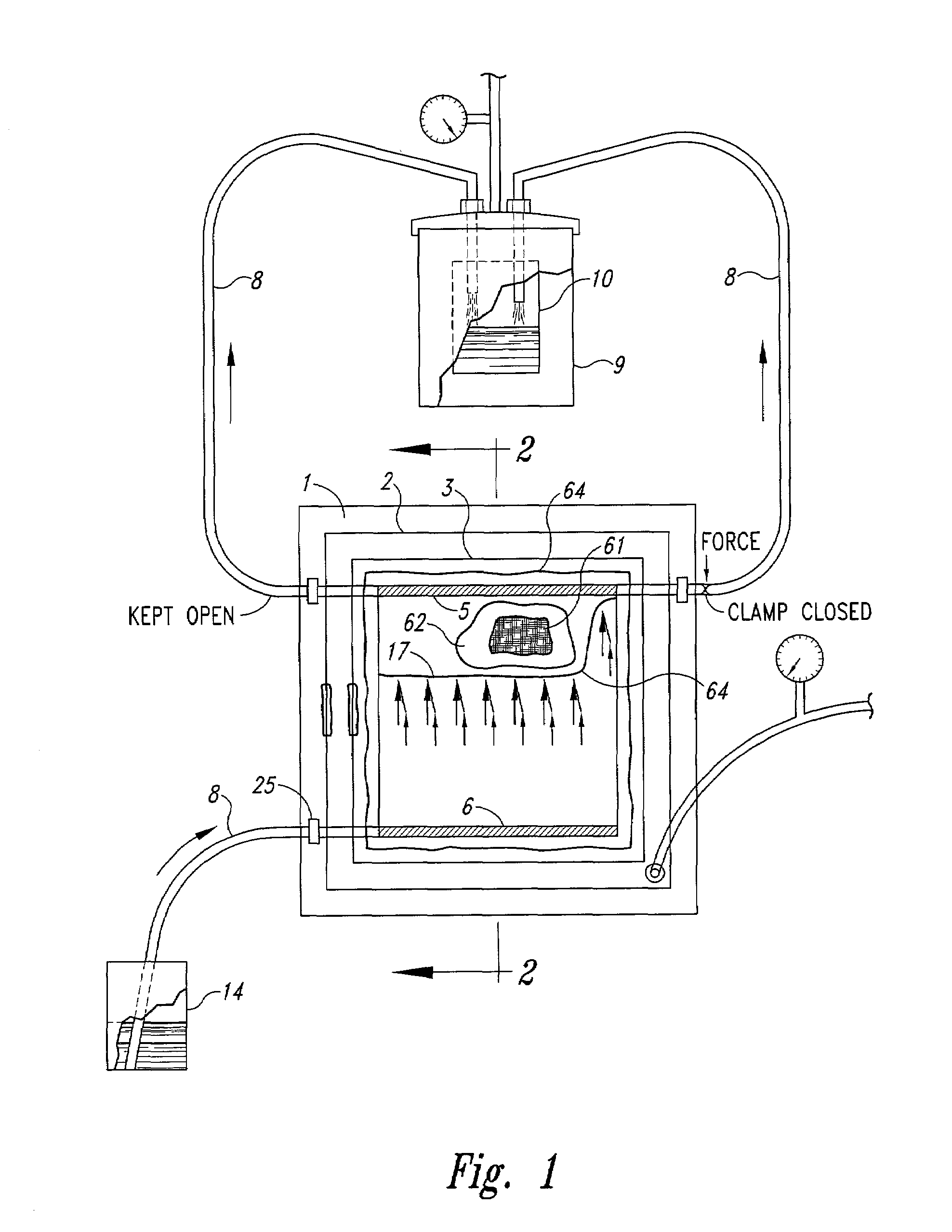

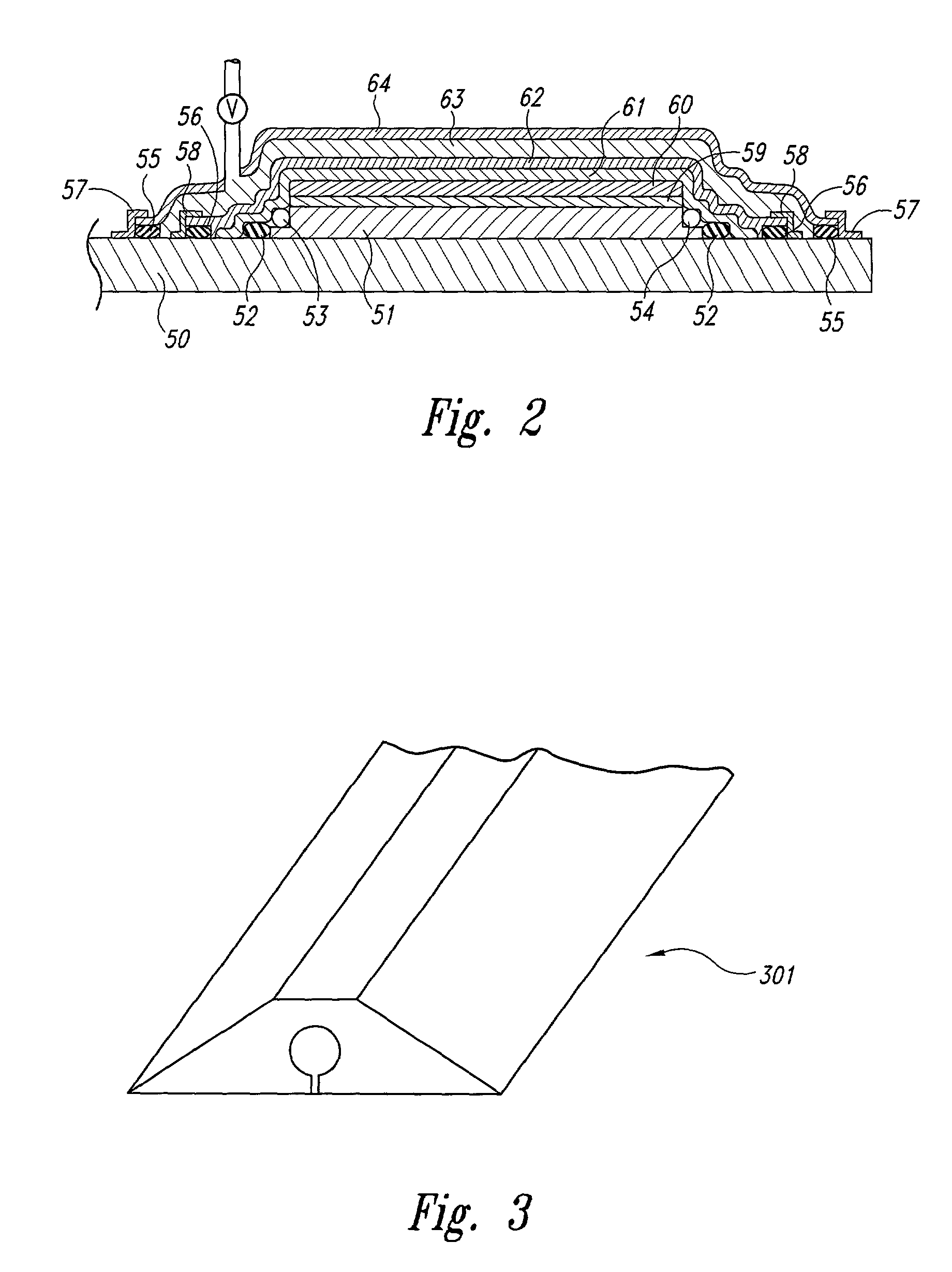

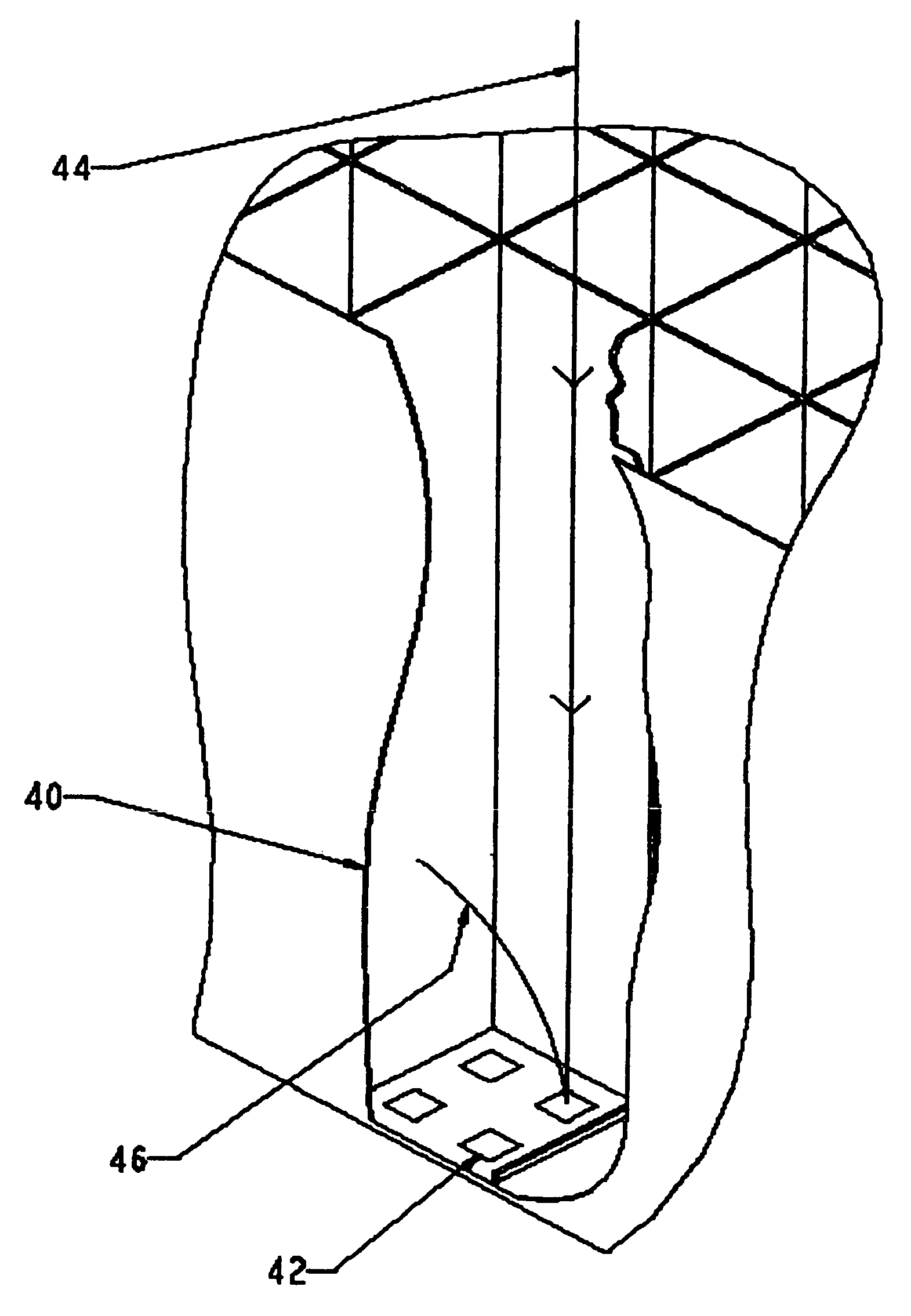

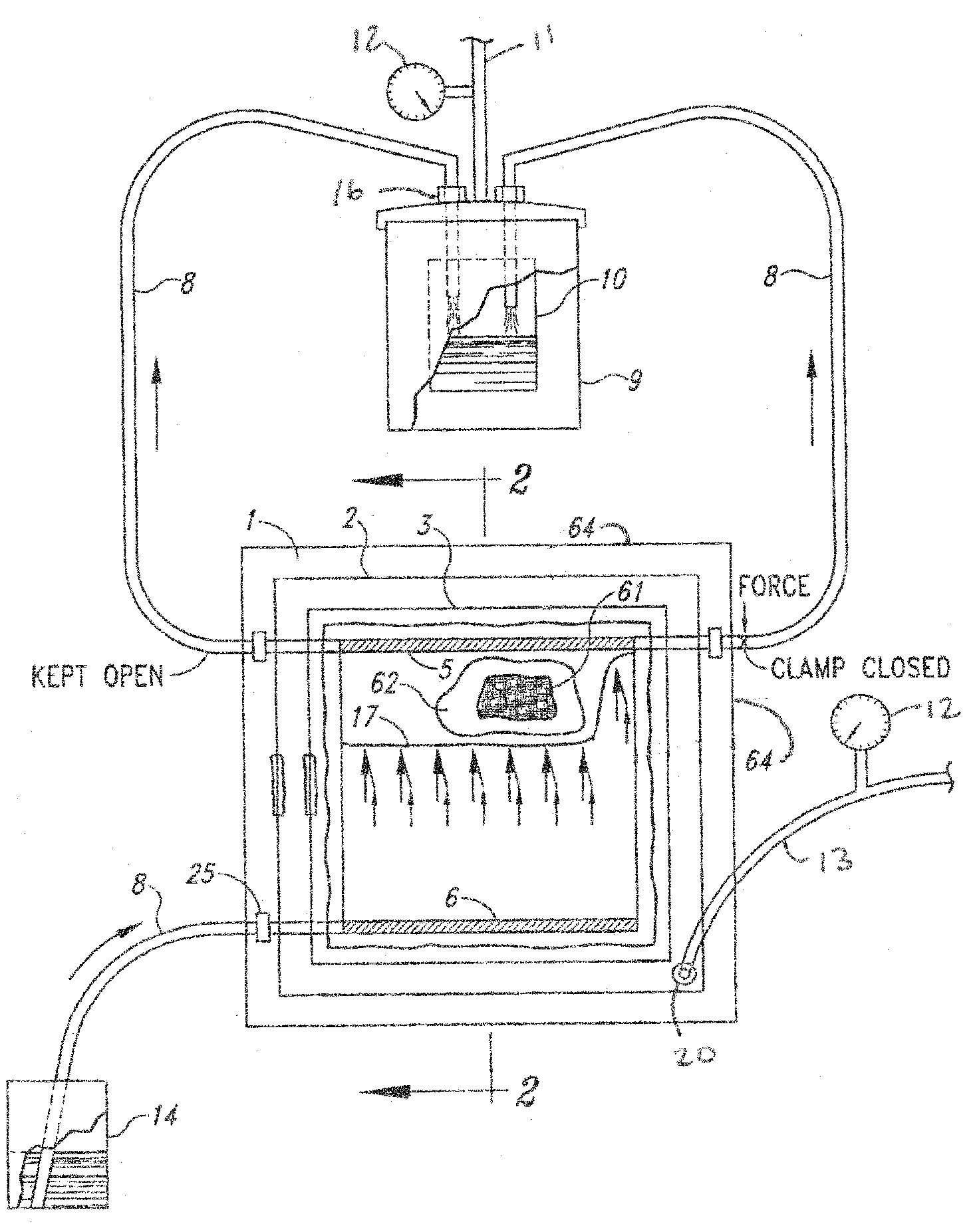

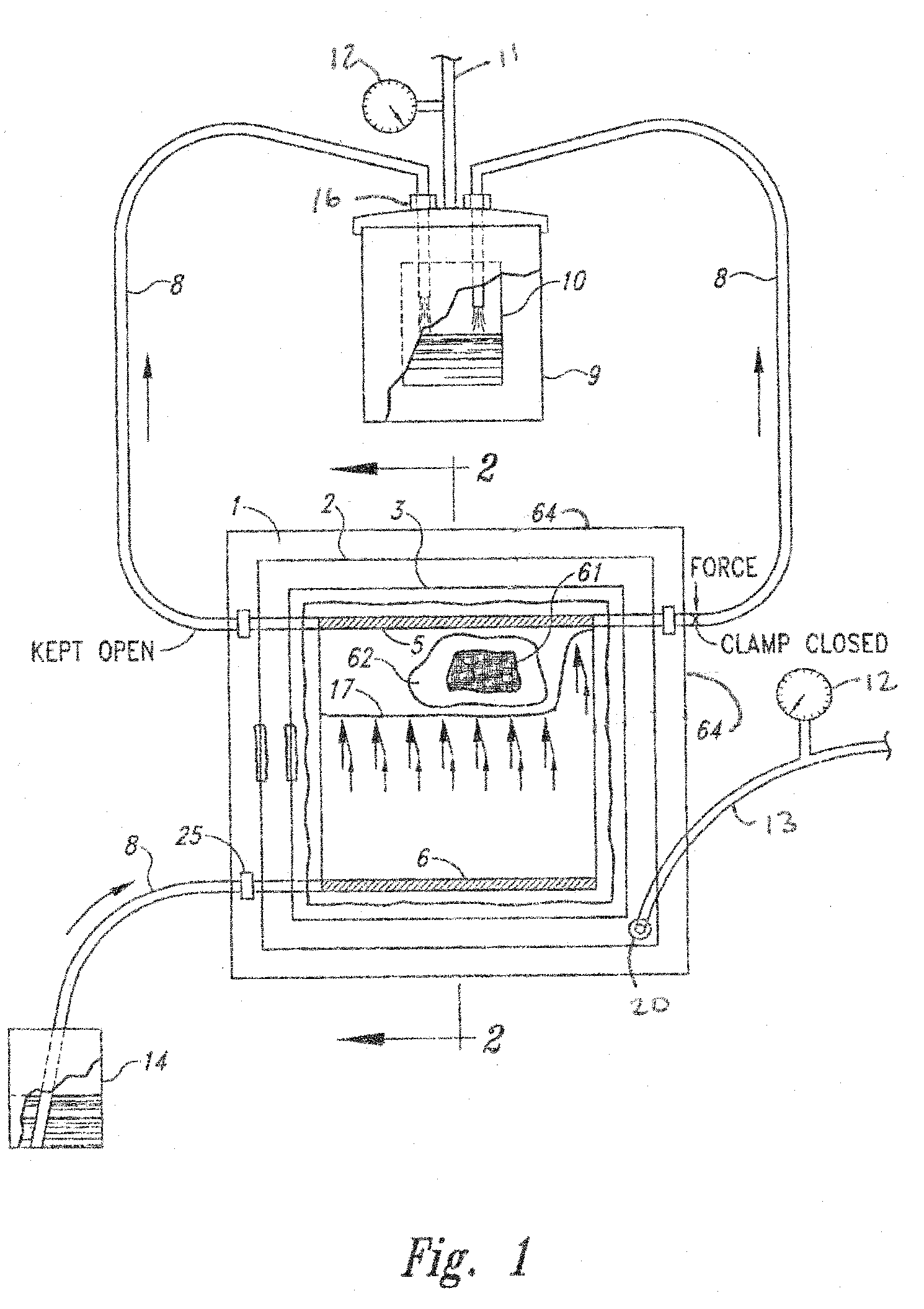

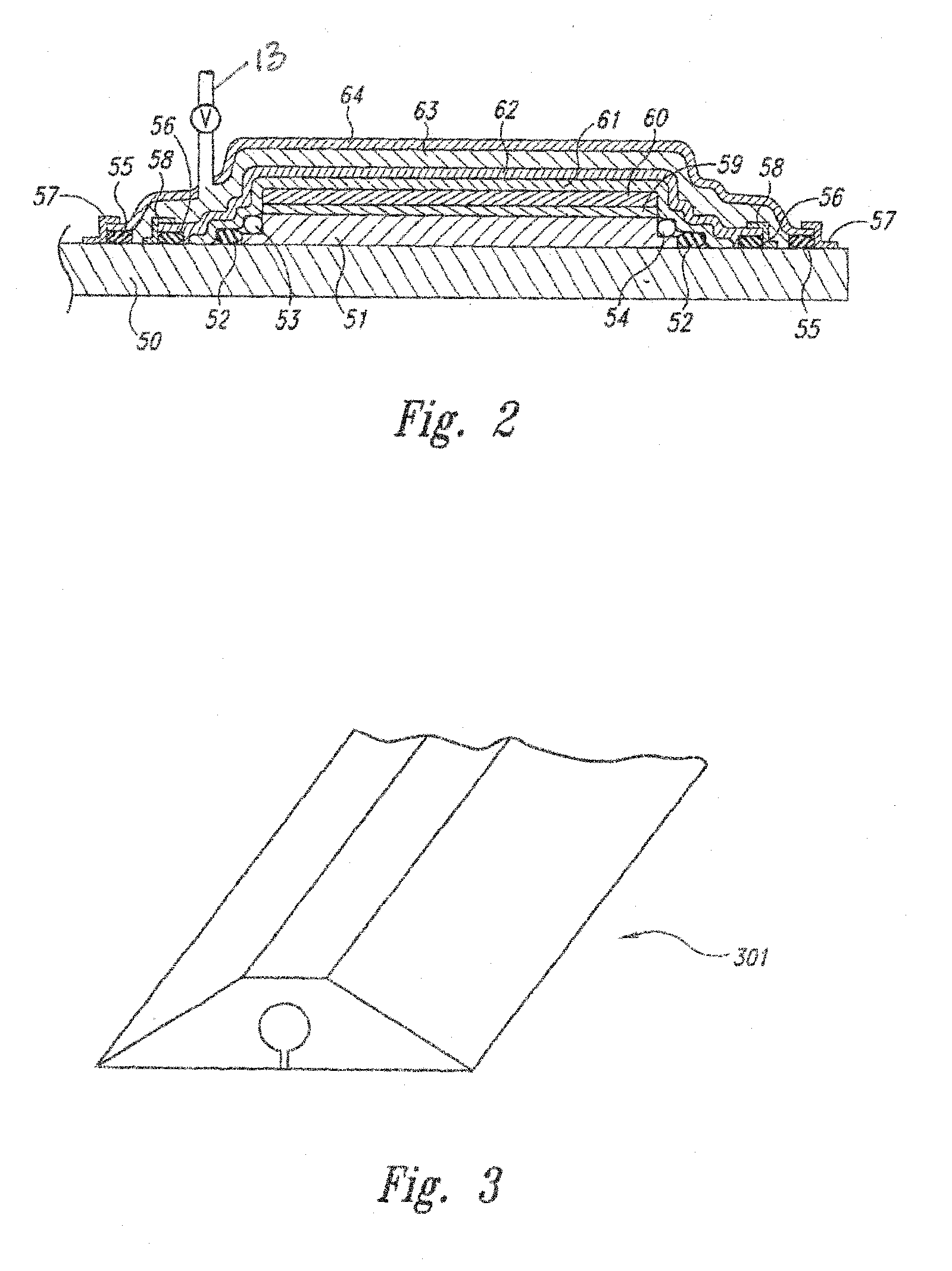

Double bag vacuum infusion process

InactiveUS7413694B2Reduce porosityMinimal surface porositySynthetic resin layered productsLaminationMedia controlsFiber

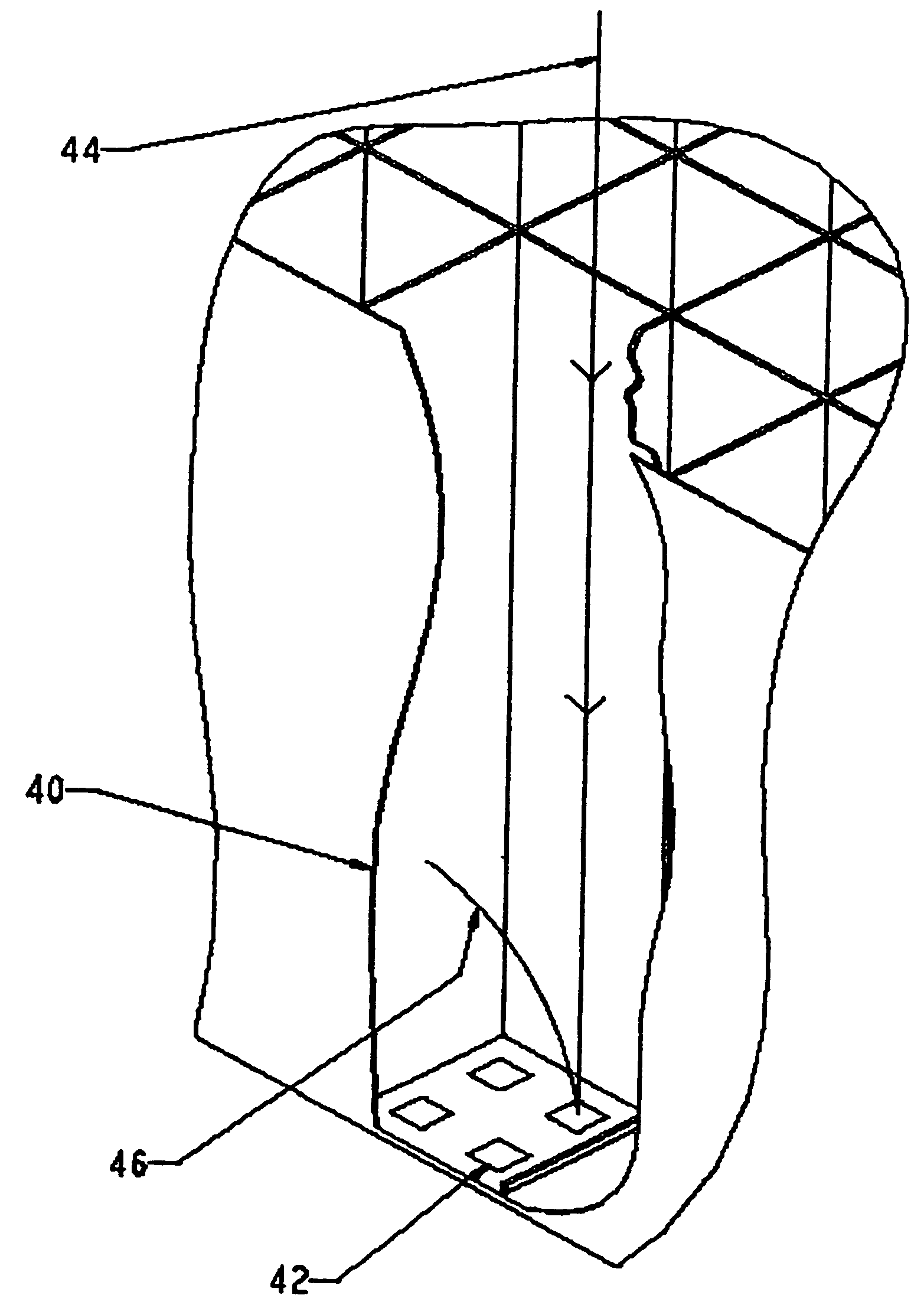

The double bag vacuum infusion process of the present invention provides a low cost method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement, and autoclave curing. Double bagging provides vacuum integrity, controls bag relaxation while flow media controls the flow front to allow high quality aerospace-grade products.

Owner:THE BOEING CO

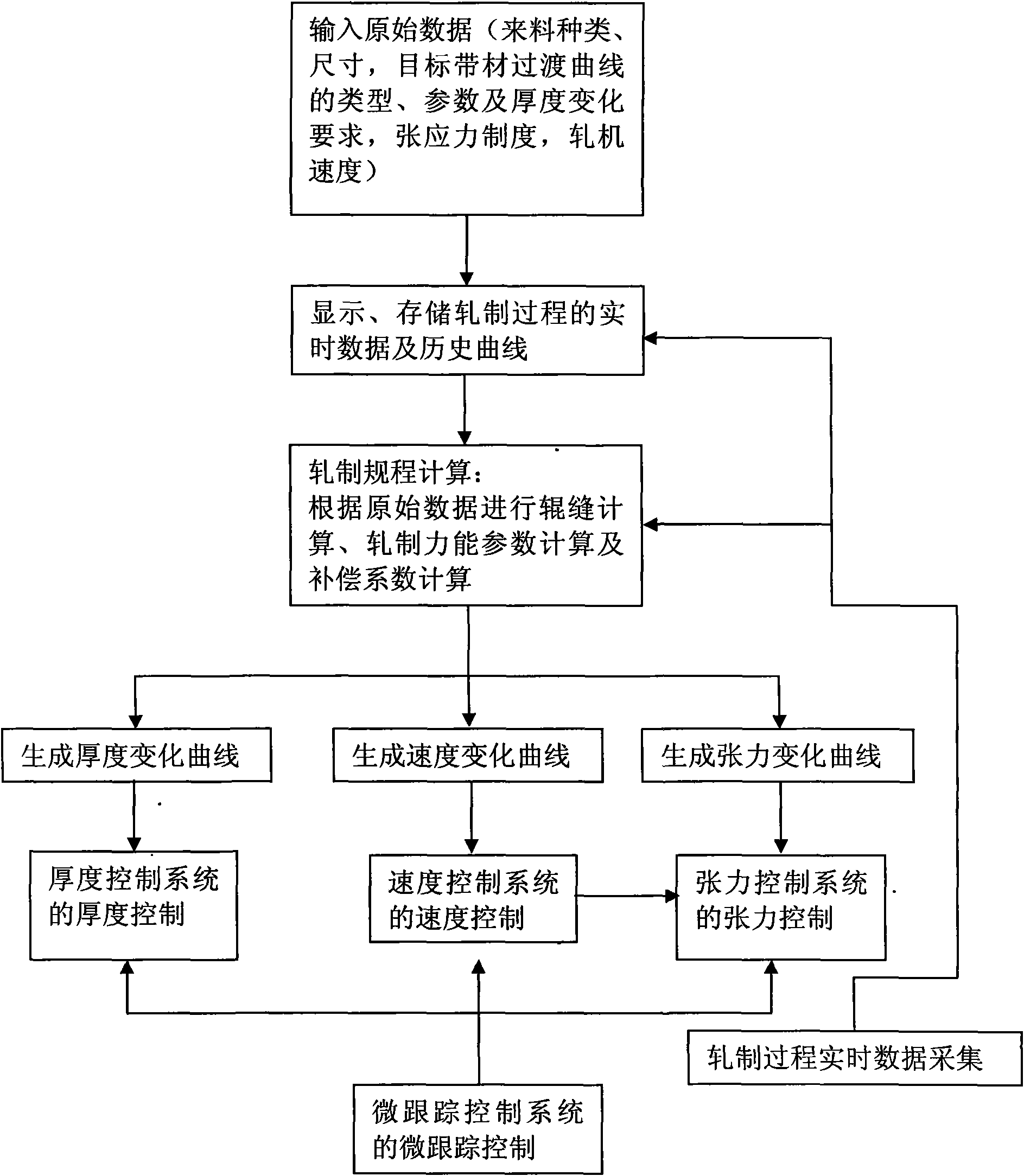

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

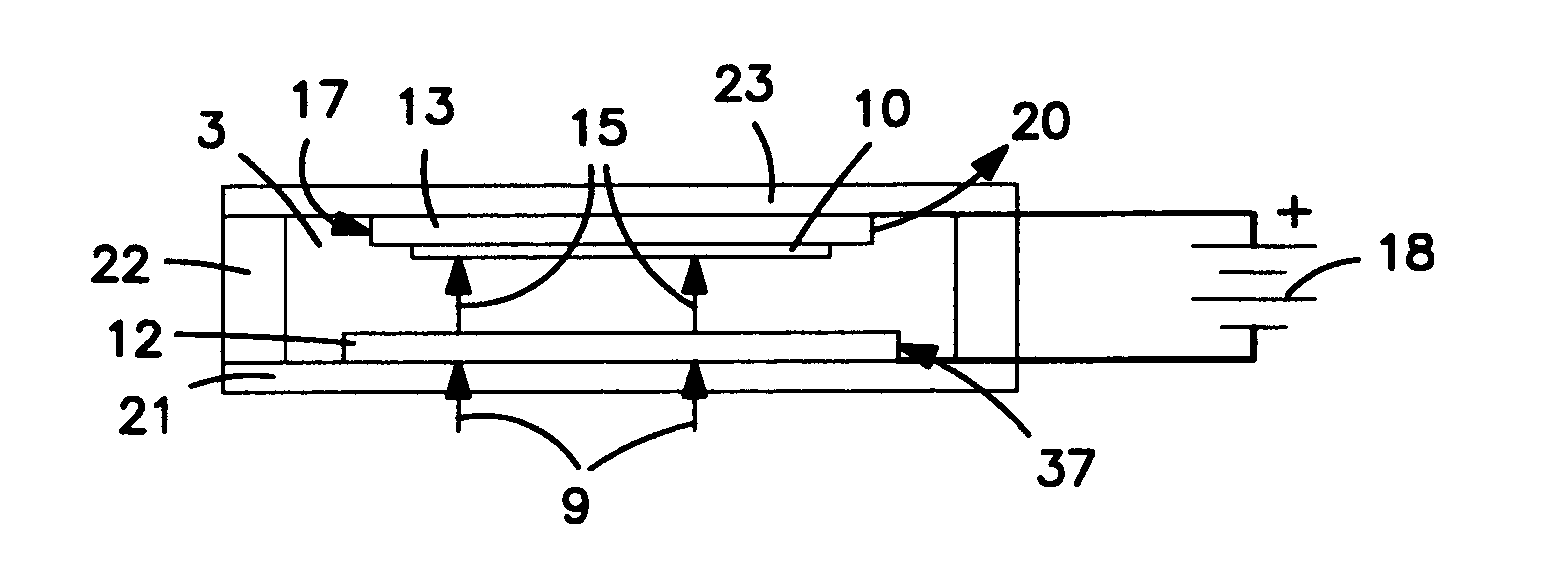

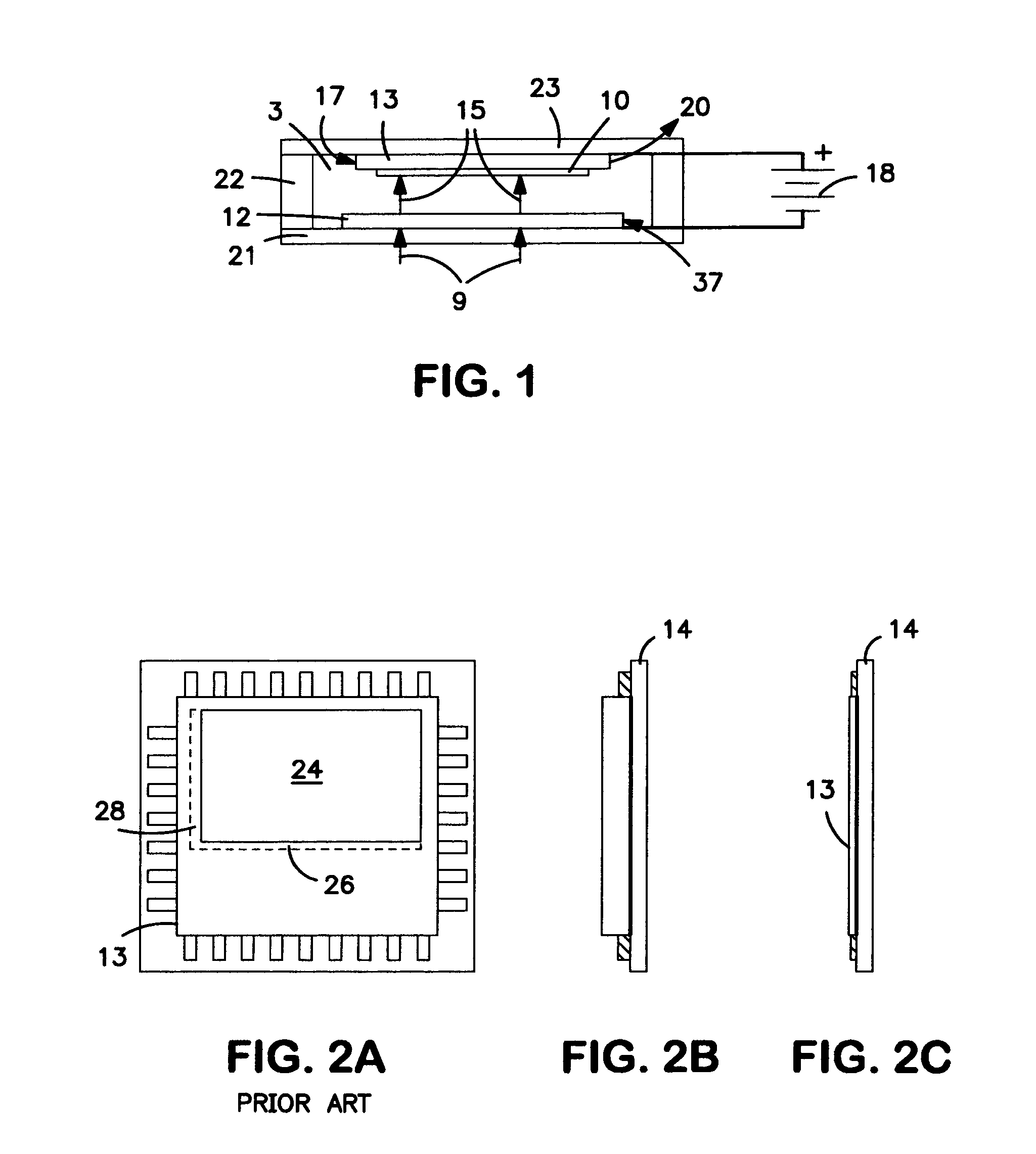

Backside thinning of image array devices

InactiveUS7005637B2Improve imaging effectImprove device yieldSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionImage contrast

Backthinning in an area selective manner is applied to imaging sensors 12 for use in electron bombarded devices. A further arrangement results in an array of collimators 51 aligned with pixels 42 or groups of pixels providing improved image contrast of such image sensor. Provision of a thin P-doped layer 52 on the illuminated rear surface provides both a diffusion barrier resulting in improved resolution and a functional shield for reference pixels. A gradient in concentration of P-doped layer 52 optimizes electron collection at the pixel array.

Owner:EOTECH LLC

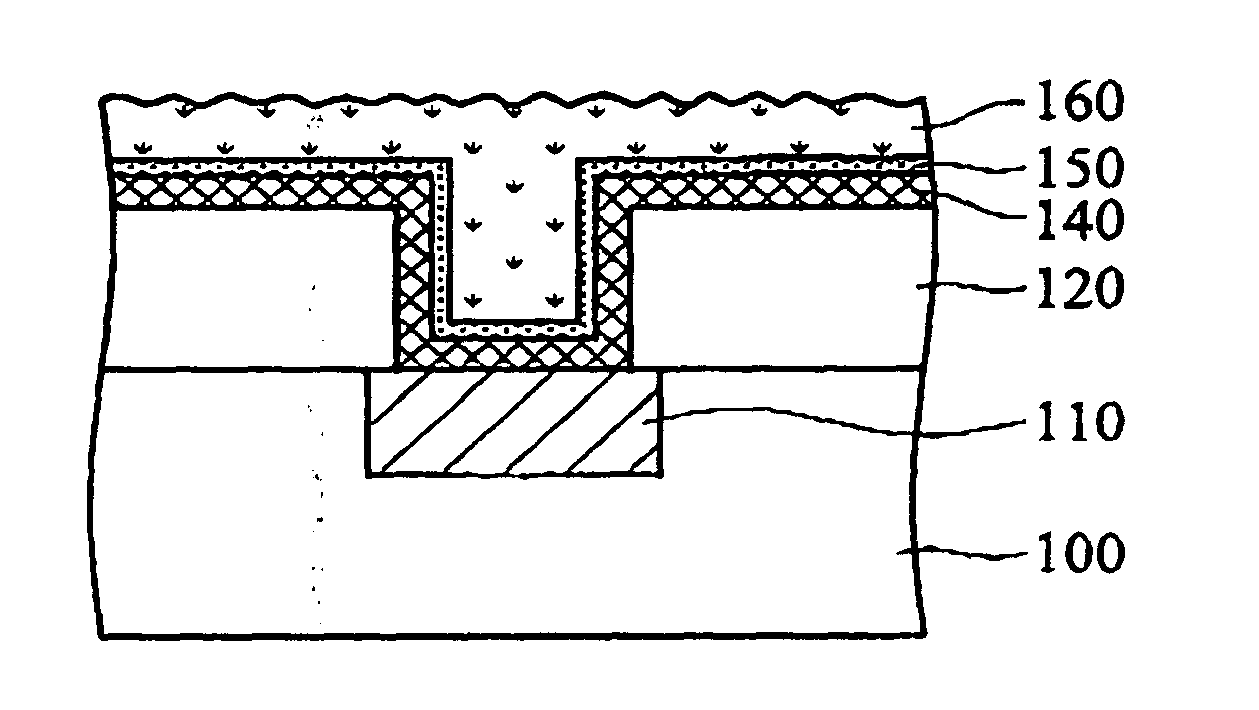

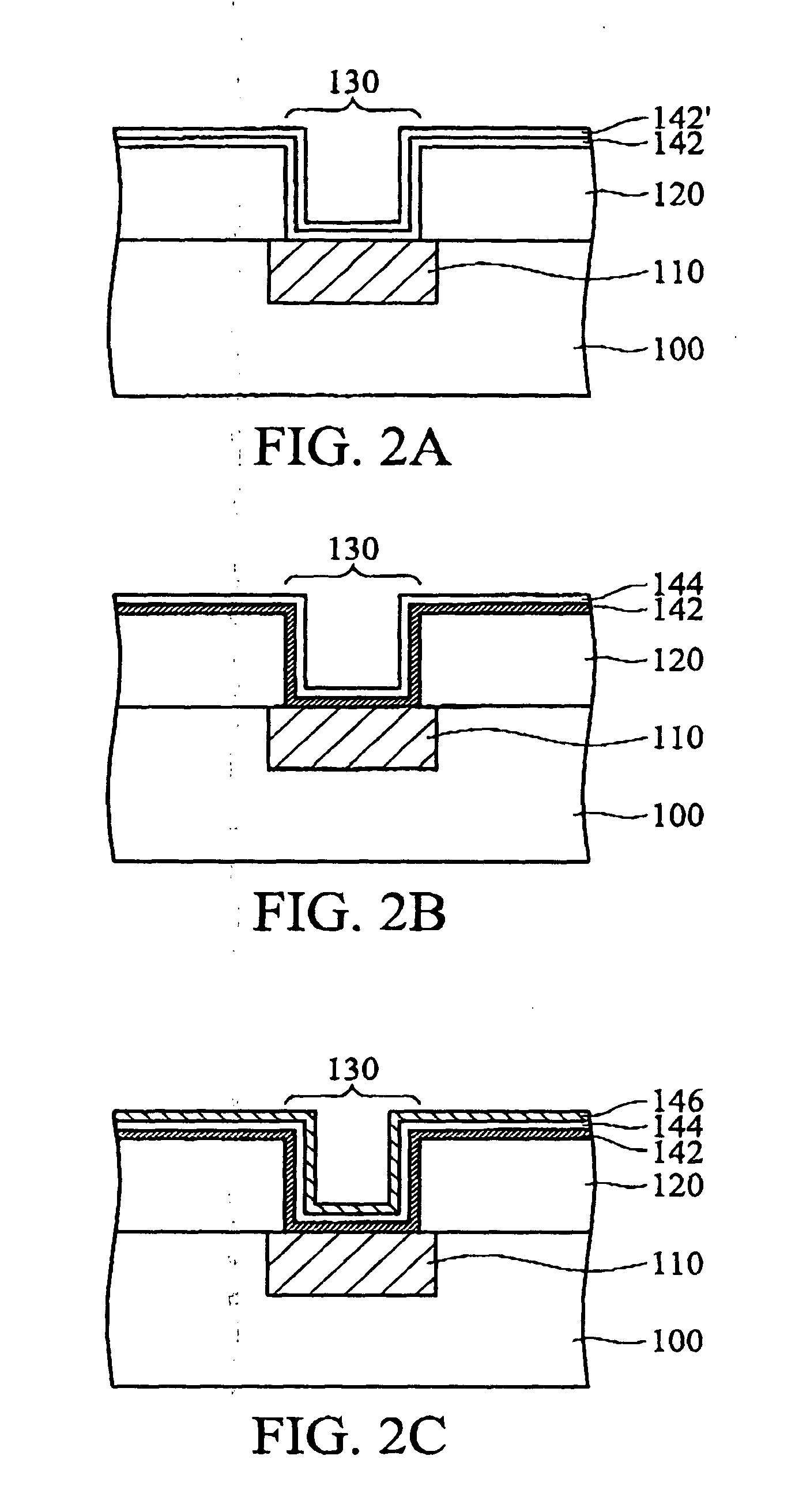

Interconnect with composite barrier layers and method for fabricating the same

ActiveUS20050054191A1Improve adhesionGood step coverageSemiconductor/solid-state device manufacturingDielectricTantalum nitride

Composite ALD-formed diffusion barrier layers. In a preferred embodiment, a composite conductive layer is composed of a diffusion barrier layer and / or a low-resistivity metal layer formed by atomic layer deposition (ALD) lining a damascene opening in dielectrics, serving as diffusion blocking and / or adhesion improvement. The preferred composite diffusion barrier layers are dual titanium nitride layers or dual tantalum nitride layers, triply laminar of tantalum, tantalum nitride and tantalum-rich nitride, or tantalum, tantalum nitride and tantalum, formed sequentially on the opening by way of ALD.

Owner:TAIWAN SEMICON MFG CO LTD

Double bag vacuum infusion process and system for low cost, advanced composite fabrication

Boeing is actively engaged in the production of lightweight composite airframes for both military and commercial applications. The double bag vacuum infusion process of the present invention provides a low cost, method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement and autoclave curing.

Owner:THE BOEING CO

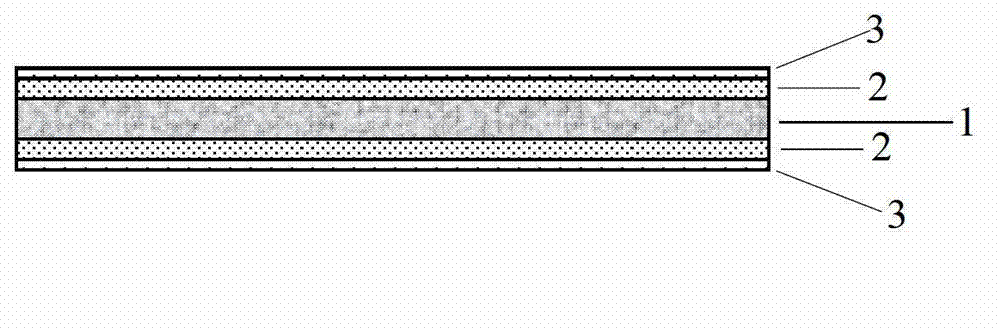

Composite battery membrane and preparation method thereof

InactiveCN103094517ASimple production processEasy thickness controlSynthetic resin layered productsLaminationTemperature resistanceMembrane configuration

The invention discloses a composite battery membrane and a preparation method thereof. The composite battery membrane comprises a porous base membrane, a porous inorganic layer compounded on at least one surface of the porous base membrane, and a porous closing layer compounded on the surface of the porous inorganic layer, wherein the porous inorganic layer is clamped between the porous closing layer and the porous base membrane. The composite battery membrane provided by the invention has the properties of low-temperature closing and high-temperature resistance; and the 'dusting' problem of the membrane added with inorganic particles can be effectively solved. Compared with the prior art, the composite battery membrane provided by the invention has a simple and convenient production process, is convenient and flexible in thickness control, and good in machining property.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

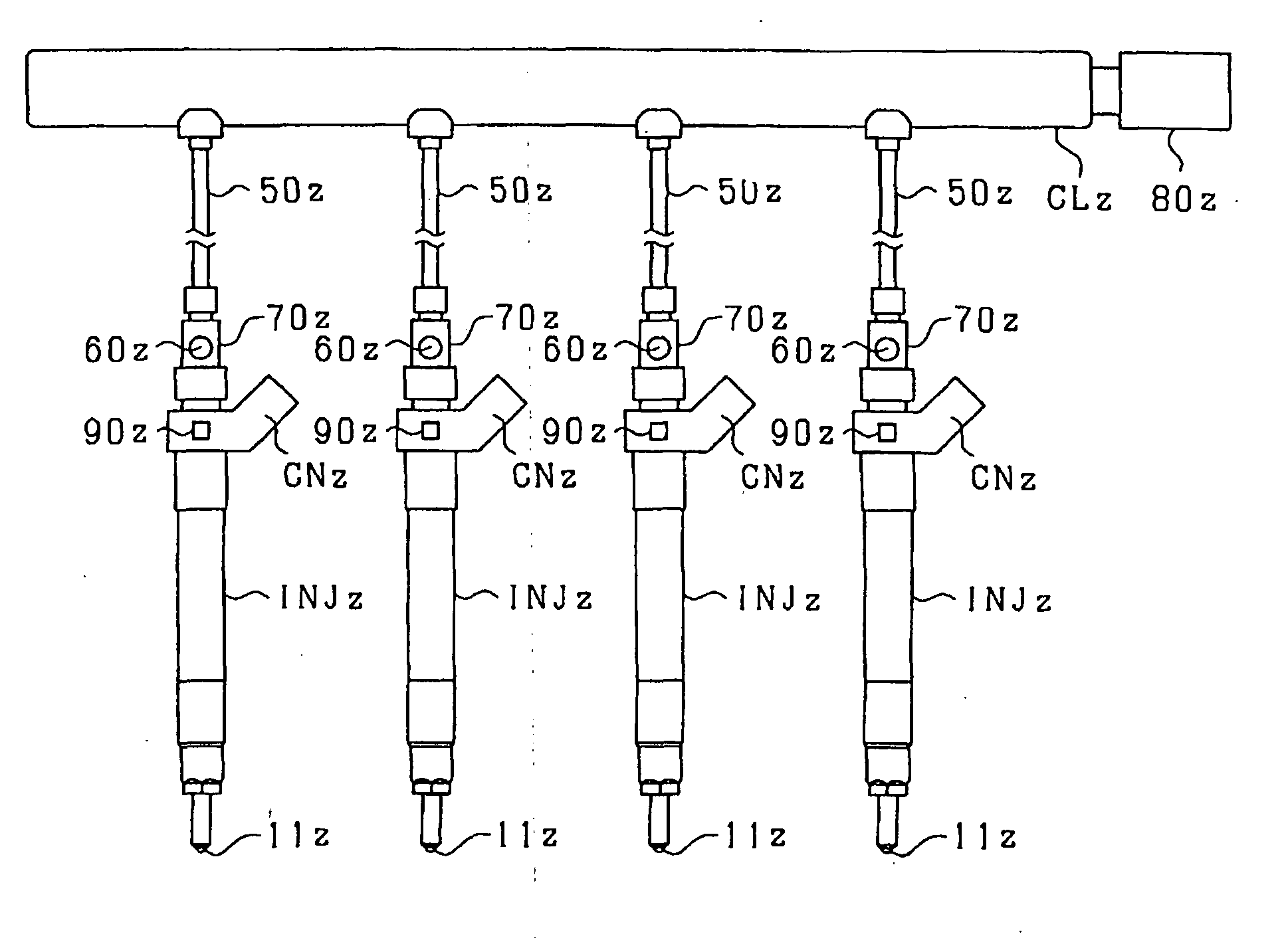

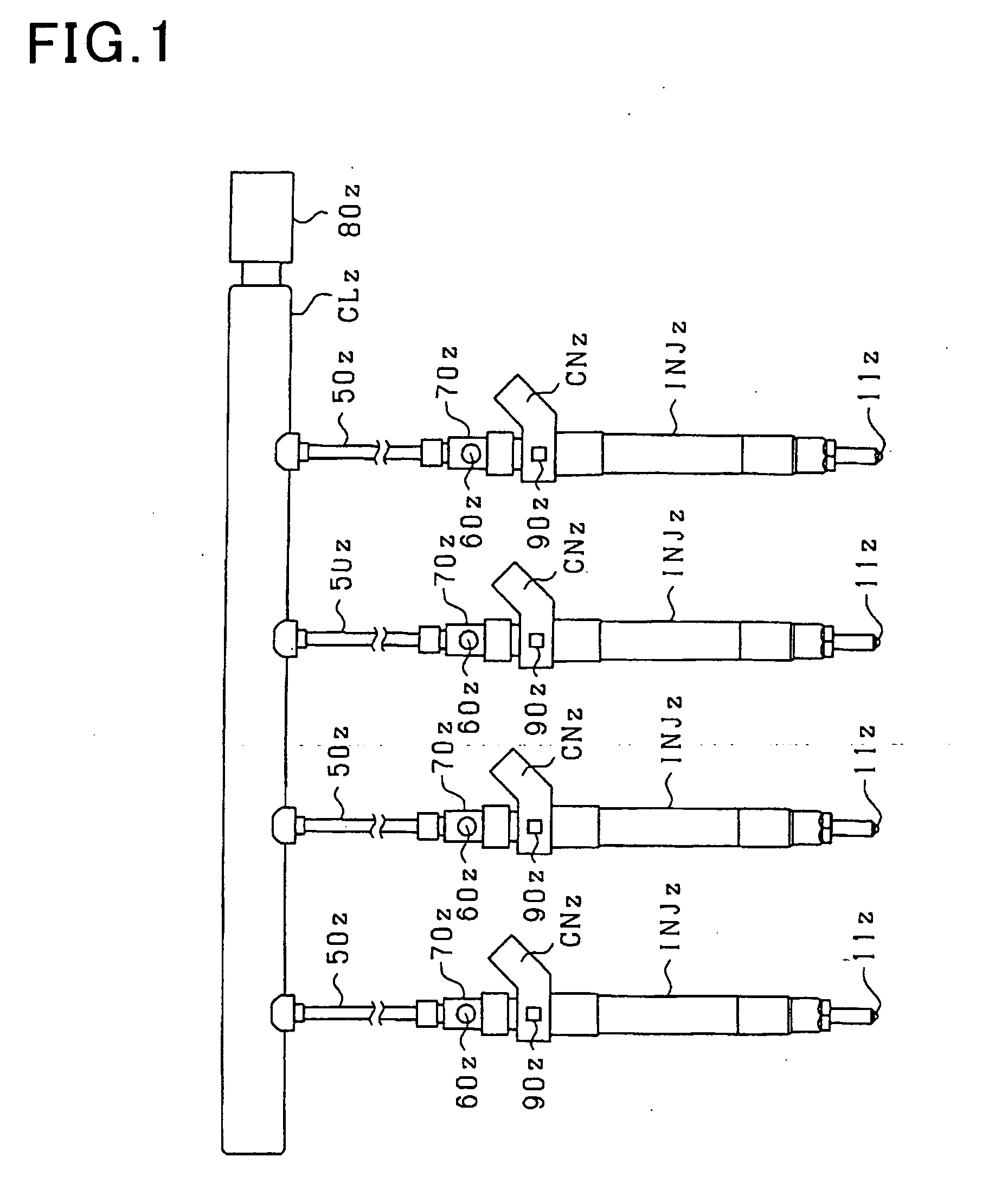

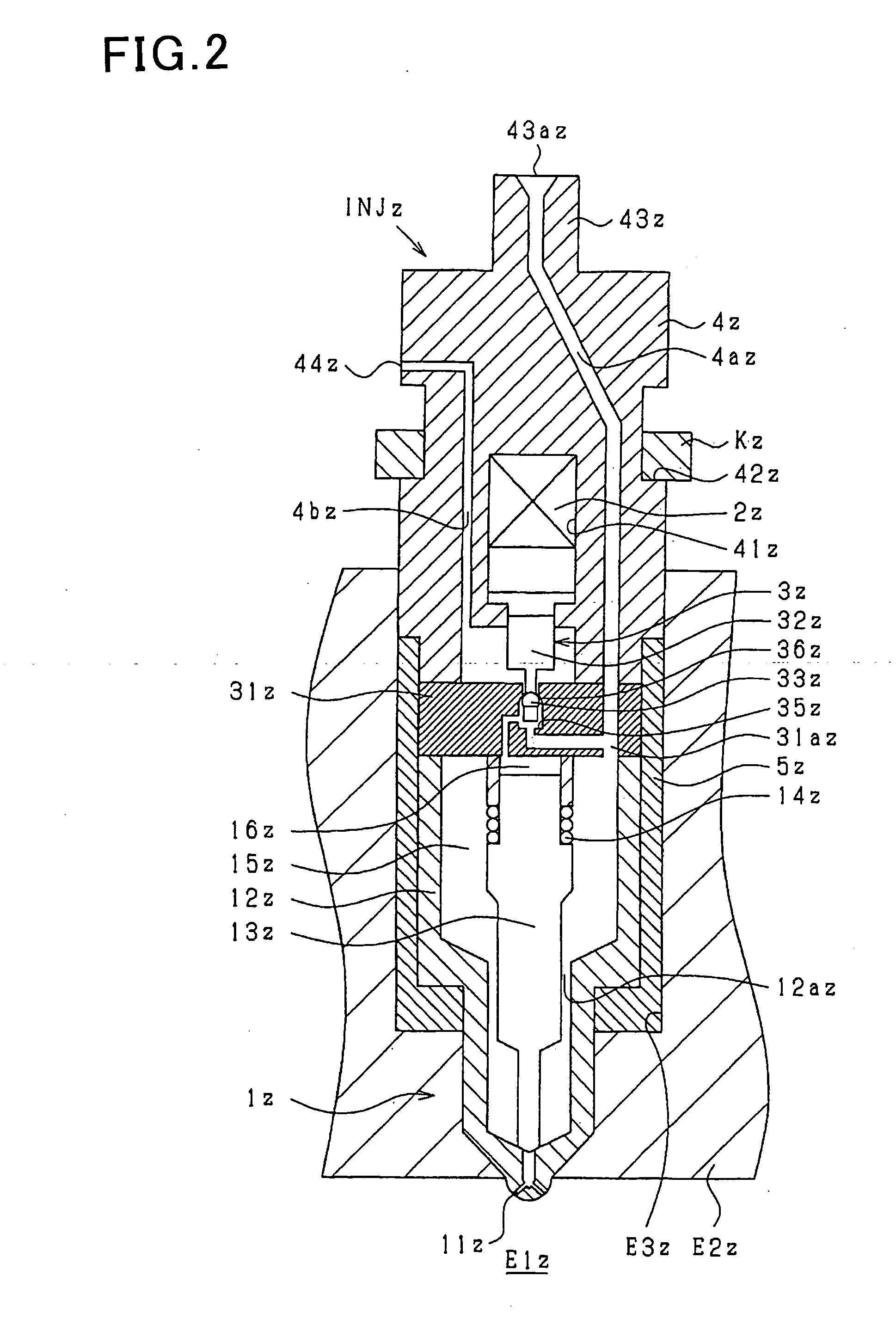

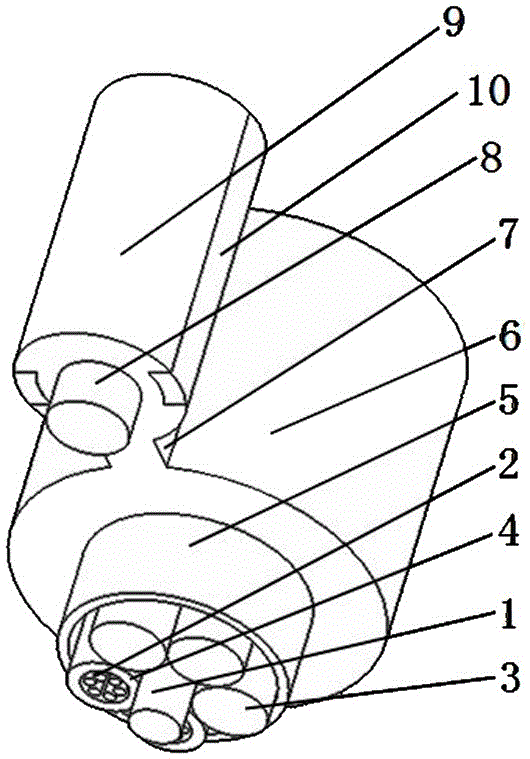

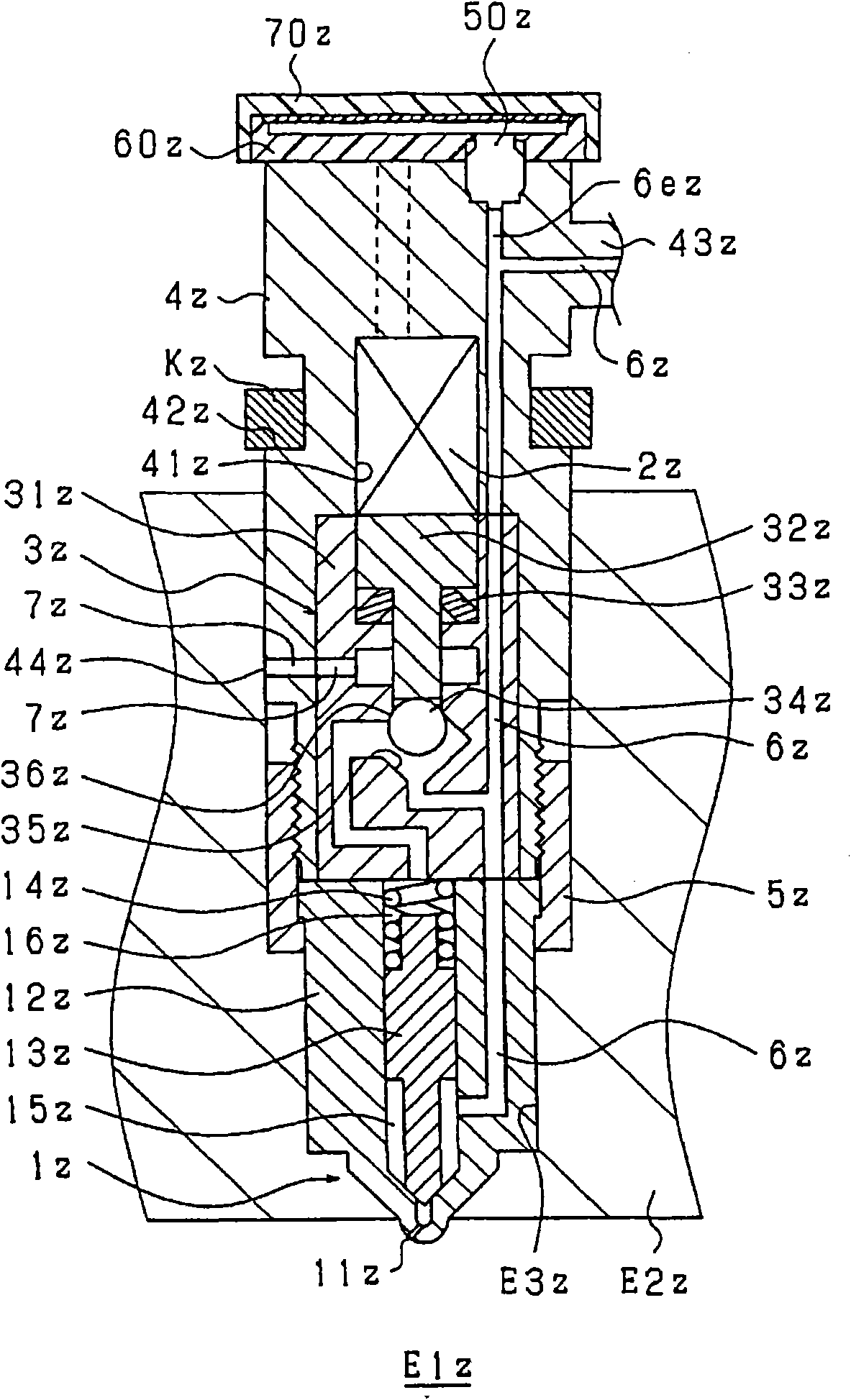

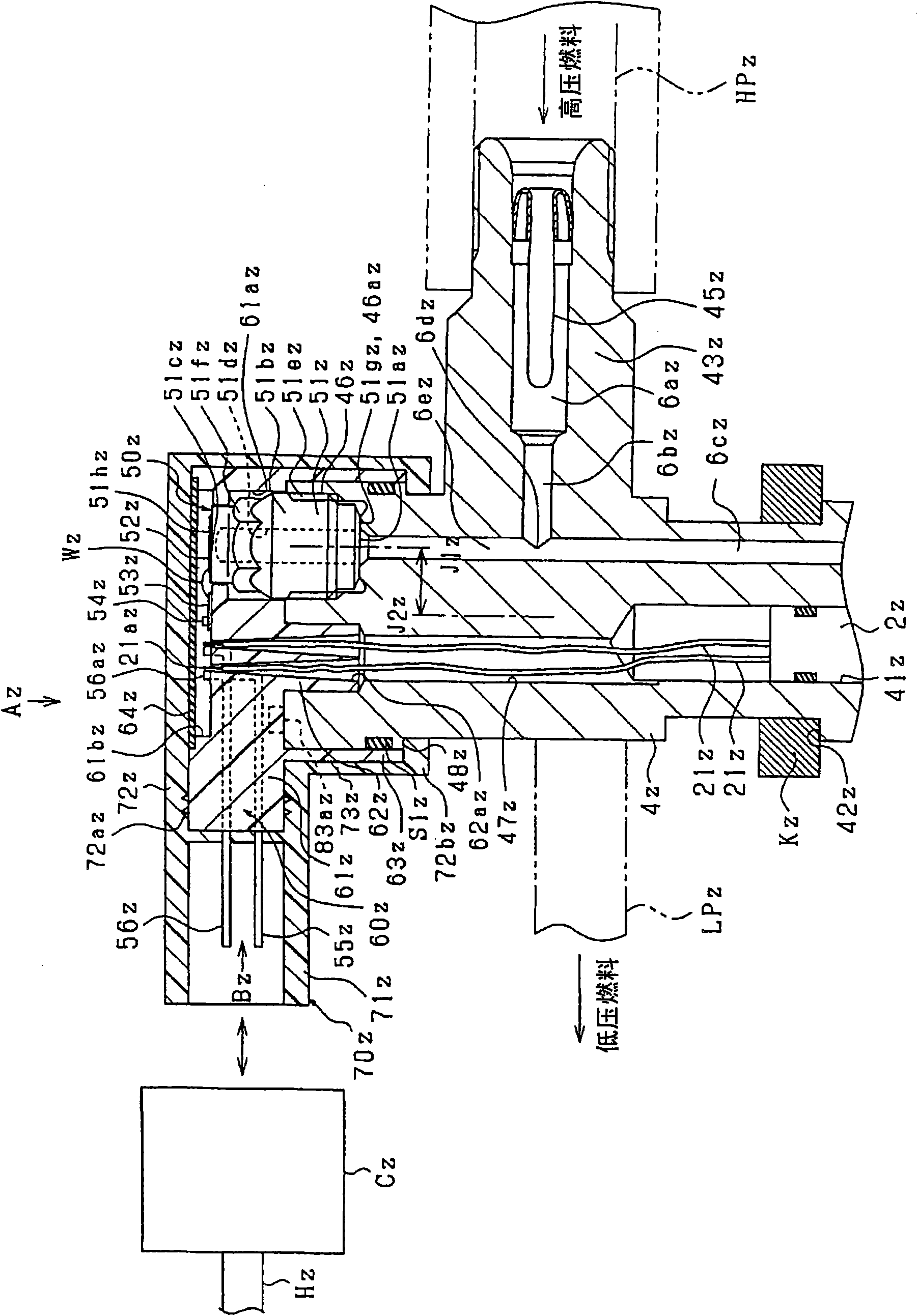

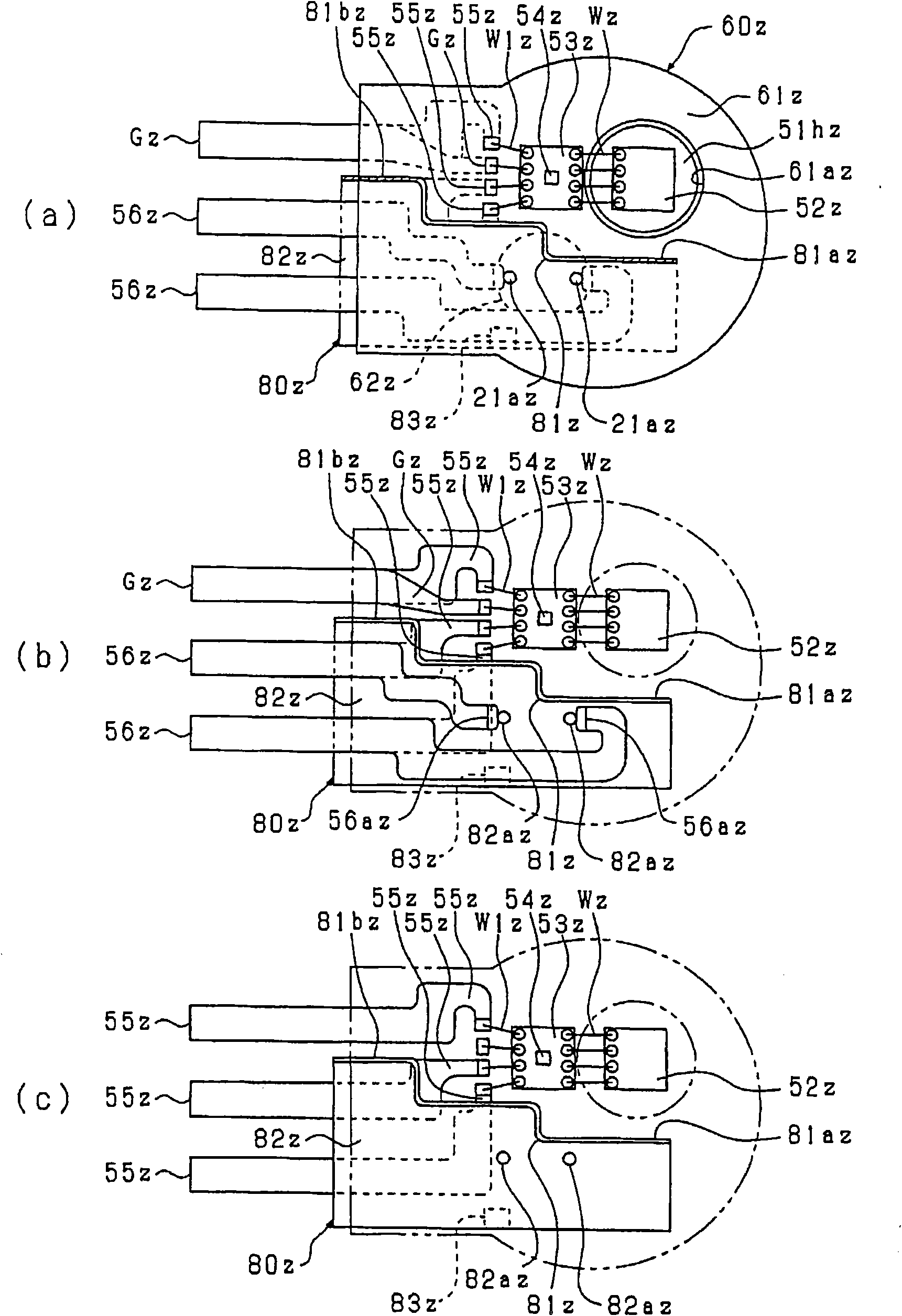

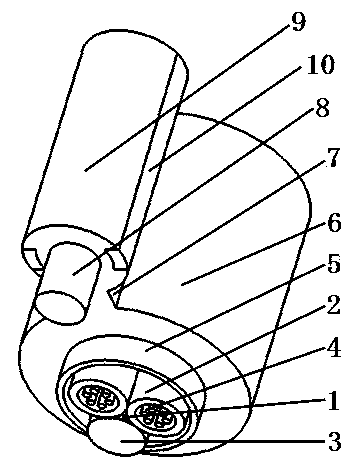

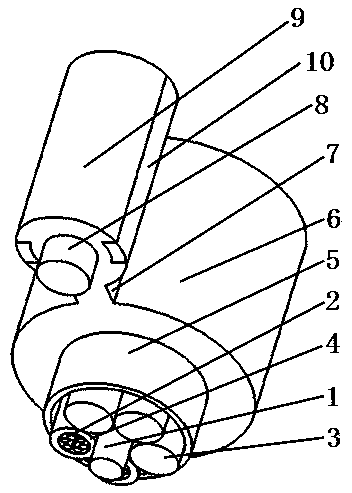

Fuel pressure measuring device, fuel pressure measuring system, and fuel injection device

ActiveUS20110006130A1Facilitate easeGuaranteed accuracyElectrical controlLiquid transferring devicesCommon railInternal combustion engine

It is used with a fuel injection system for an internal combustion engine which supplies fuel to an injector (fuel injection valve) from a common rail (accumulator) through a high-pressure pipe to spray the fuel from a spray hole formed in the injector. A thin-walled portion 70bz is formed in a path member (e.g., an injector body 4z, the high-pressure pipe, or a connector 70z connecting the injector and the high-pressure pipe) and defined by a locally thin wall of the path member. A strain gauge 60z (strain sensor) is affixed to the thin-walled portion 70bz to measure strain of the thin-walled portion 70bz arising from the pressure of fuel in a high-pressure fuel path 70az.

Owner:DENSO CORP

Interconnect with composite barrier layers and method for fabricating the same

InactiveUS6958291B2Improve adhesionGood step coverageSemiconductor/solid-state device manufacturingDielectricTantalum nitride

Composite ALD-formed diffusion barrier layers. In a preferred embodiment, a composite conductive layer is composed of a diffusion barrier layer and / or a low-resistivity metal layer formed by atomic layer deposition (ALD) lining a damascene opening in dielectrics, serving as diffusion blocking and / or adhesion improvement. The preferred composite diffusion barrier layers are dual titanium nitride layers or dual tantalum nitride layers, triply laminar of tantalum, tantalum nitride and tantalum-rich nitride, or tantalum, tantalum nitride and tantalum, formed sequentially on the opening by way of ALD.

Owner:TAIWAN SEMICON MFG CO LTD

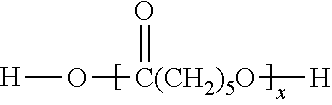

Transparent synthetic resin laminate having photochromism

InactiveUS6986946B2StructuredIncrease speedSpectales/gogglesSynthetic resin layered productsSynthetic resinOrganic compound

A transparent synthetic resin laminate with photochromism property consisting essentially of two transparent synthetic resin layers and a photochromic layer formed by curing a mixture of a two liquid polyurethane of a polyurethane prepolymer and a curing agent and a photochromic organic compound which is interposed between said two transparent synthetic resin layers.

Owner:MITSUBISHI GAS CHEM CO INC

Backside thinning of image array devices

InactiveUS7042060B2Poor resolutionMaximize fill factorSolid-state devicesDiodeImage resolutionImage contrast

Backthinning in an area selective manner is applied to imaging sensors 12 for use in electron bombarded devices. A further arrangement results in an array of collimators 51 aligned with pixels 42 or groups of pixels providing improved image contrast of such image sensor. Provision of a thin P-doped layer 52 on the illuminated rear surface provides both a diffusion barrier resulting in improved resolution and a functional shield for reference pixels. A gradient in concentration of P-doped layer 52 optimizes electron collection at the pixel array.

Owner:EOTECH LLC

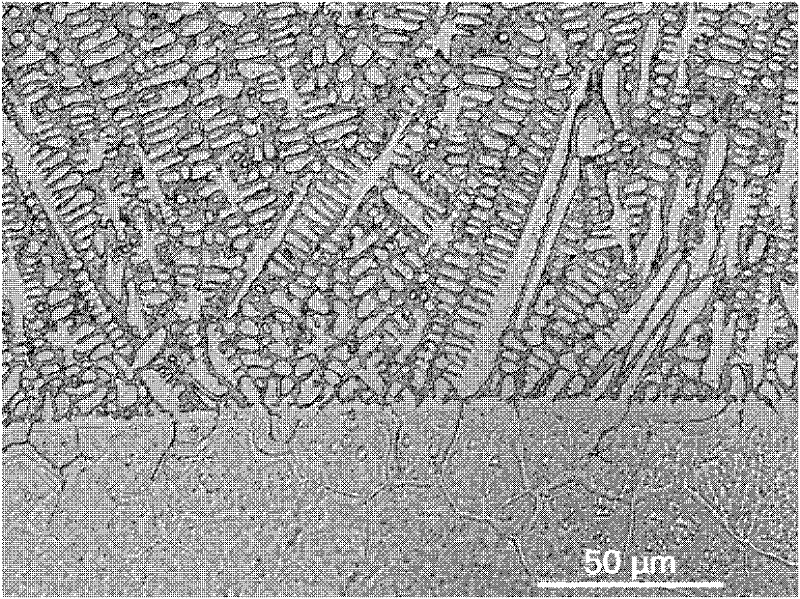

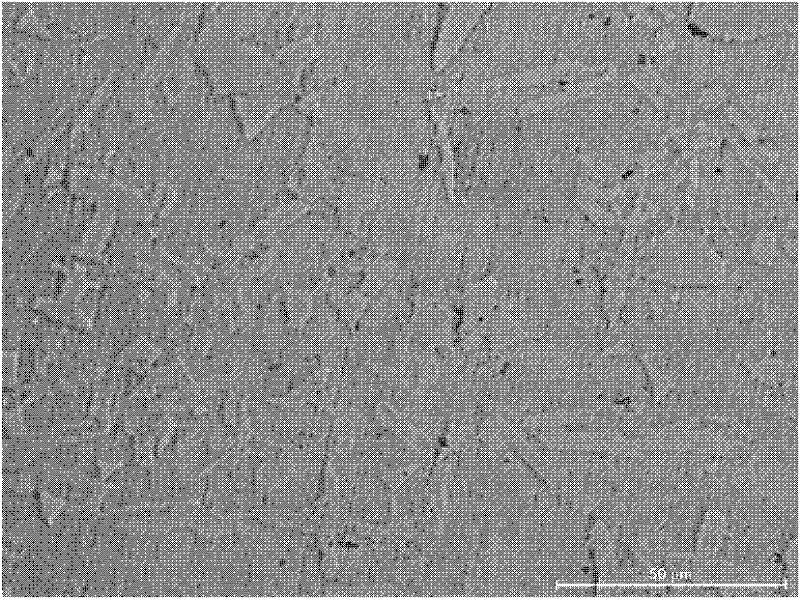

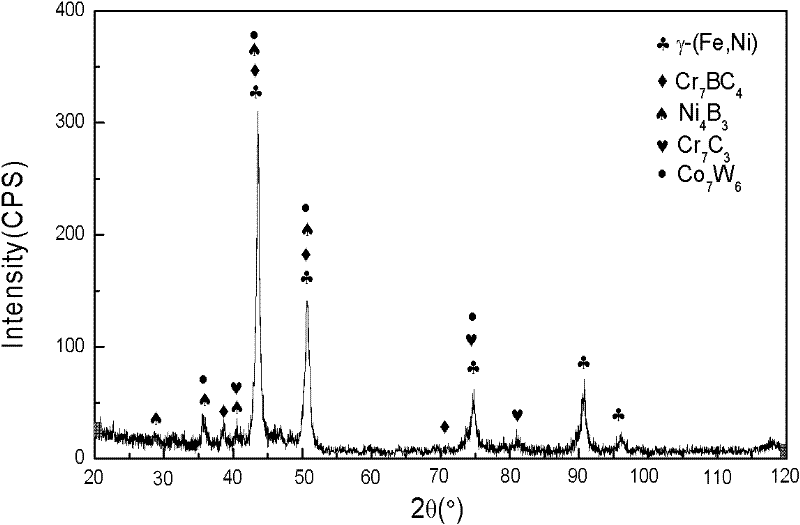

Tungsten carbide reinforced composite material strengthened layer of mould steel basal body and preparation process thereof

InactiveCN102212771AEasy thickness controlImprove surface qualityMolten spray coatingMaterials preparationChemical composition

The invention relates to a tungsten carbide reinforced composite material strengthened layer of a mould steel basal body and a preparation process thereof, belonging to the technical fields of surface material preparation and surface processing. A surface strengthened layer comprises the following chemical components in percentage by weight: 1.85-2.45% of C, 2.90-3.85% of Si, 12.45-15.25% of Cr, 3.10-3.65% of B, 7.55-8.50% of W, 2.20-2.85% of Co, 4.50-5.50% of Fe, and the balance of Ni. Main strengthened phases in a spray welding layer comprise WC, Cr7C3, Ni4B3 and Co7W6. The process for preparing the surface strengthened layer through plasma spray welding comprises the following steps of: cleaning the surface of an H13 steel basal body; preparing the spray welding layer with required thickness by using mixed gas of argon and hydrogen; and controlling the overlapping amount between every two spray welding layer, wherein the obtained composite material surface layer can achieve the functions of repairing defects or strengthening the basal body; and the service life of a mould is recovered and prolonged.

Owner:CHINA FIRST AUTOMOBILE

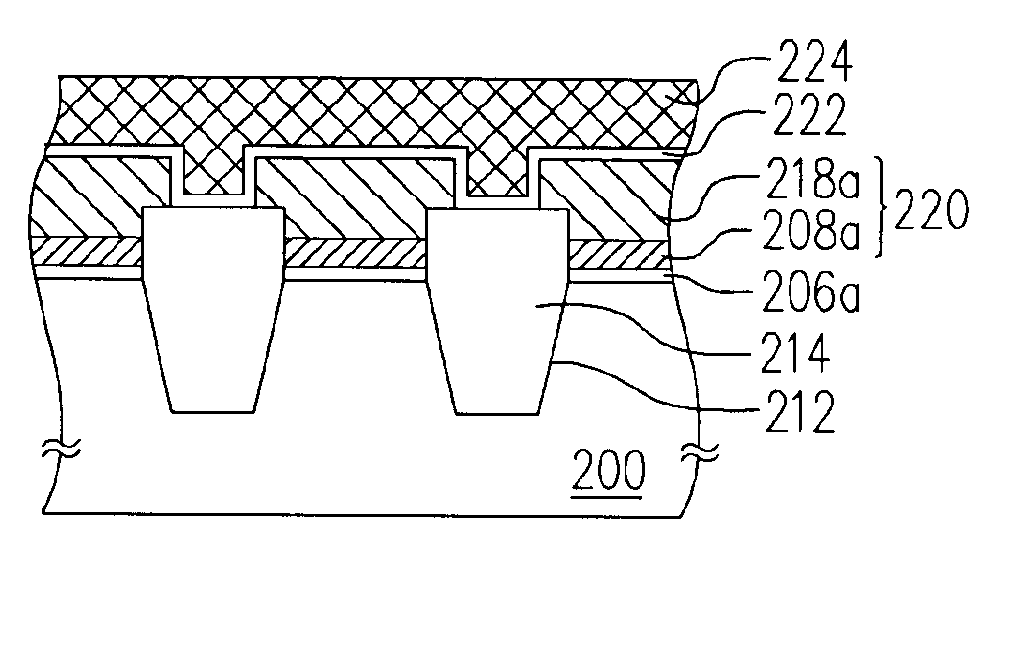

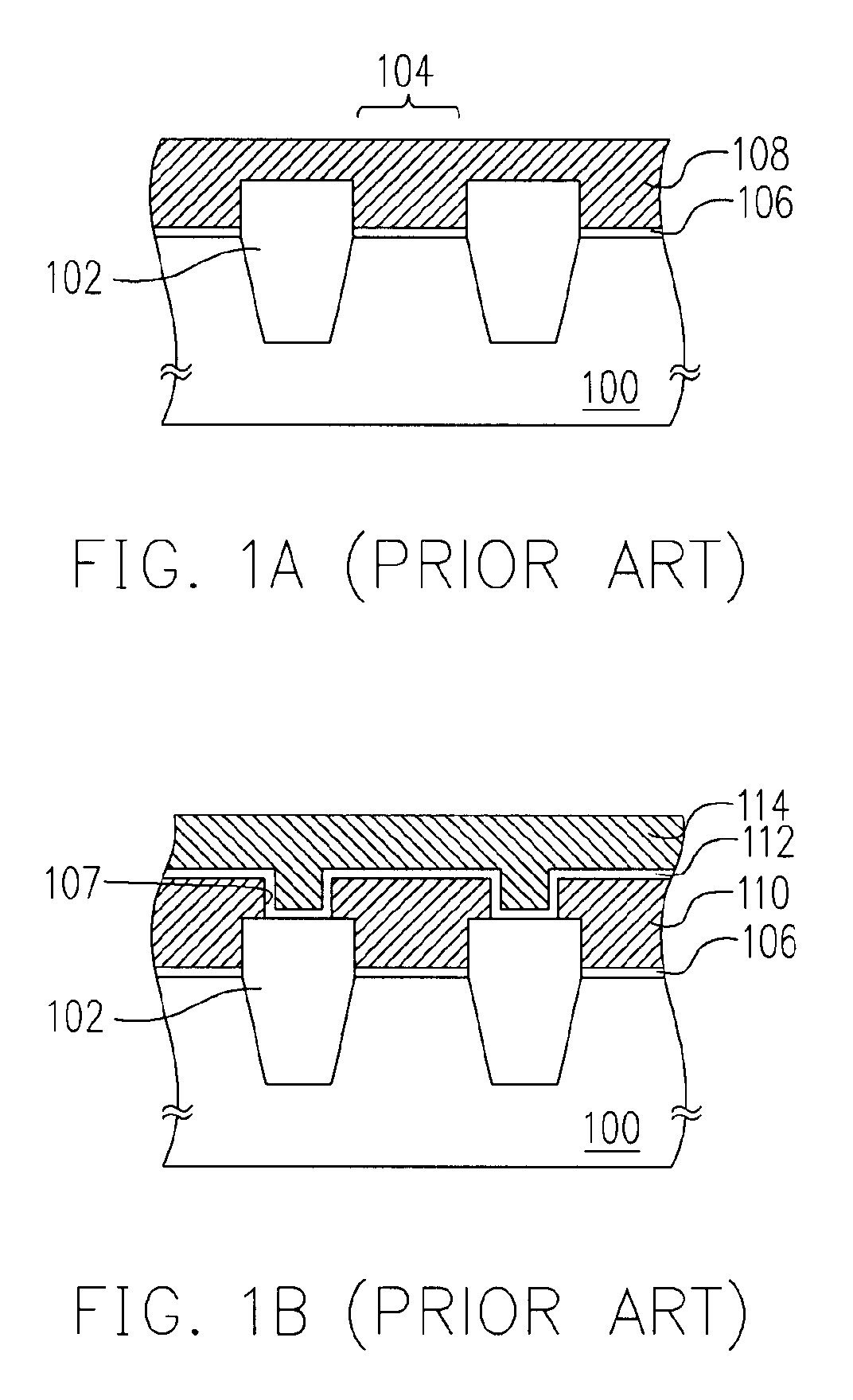

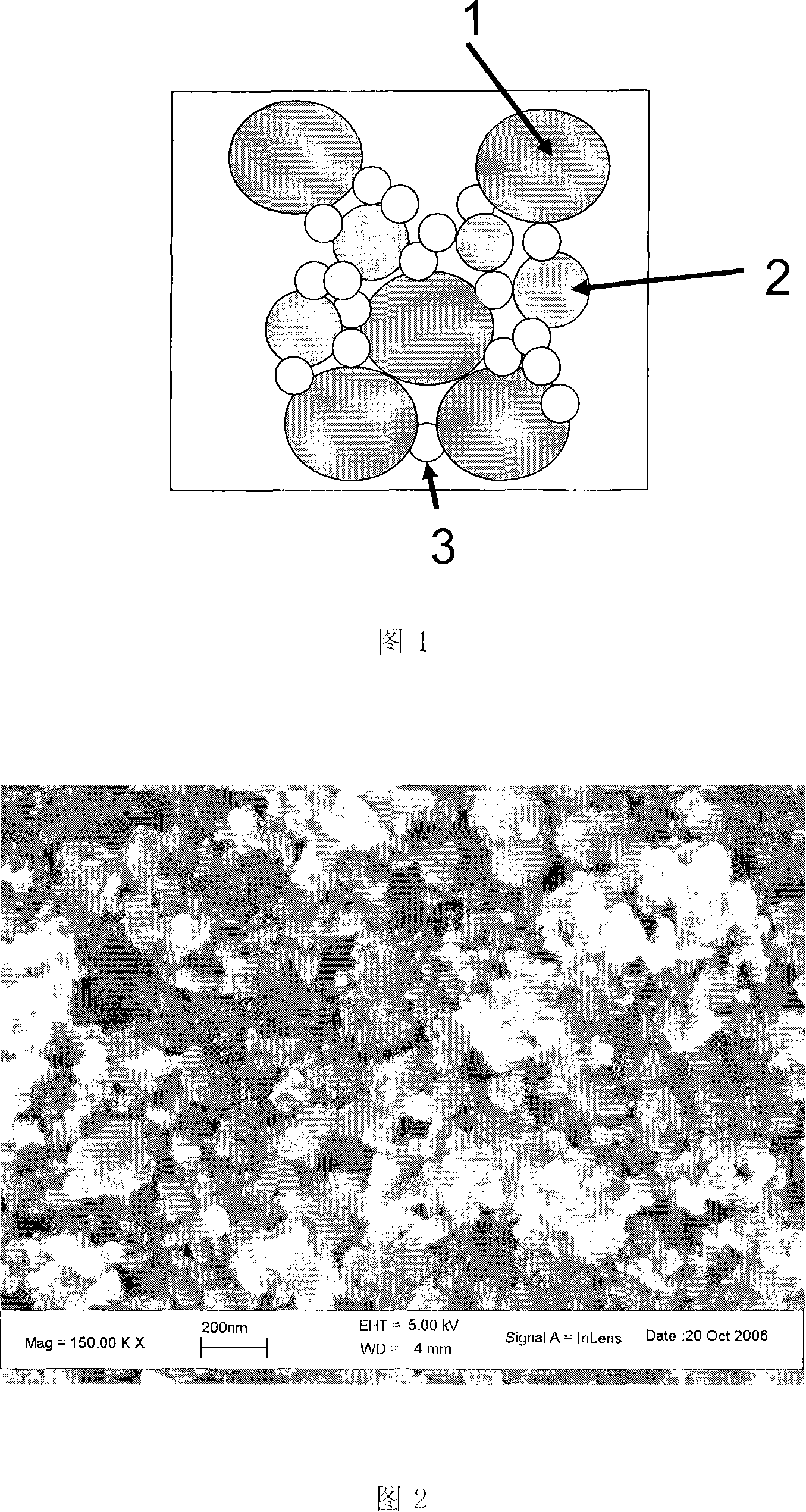

Method of fabricating a flash memory

ActiveUS6893918B1Improve gate coupling ratioImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricEngineering

A method of fabricating a flash memory is provided. A substrate having several device isolation structures for defining an active region is provided. A tunneling dielectric layer and a patterned mask layer are sequentially formed over the active region of the substrate. A sacrificial layer is formed on the substrates. Thereafter, the sacrificial layer is patterned to retain a part of sacrificial layer on the device isolation structures. The patterned mask layer is removed, and a conductive layer that exposed the top section of the sacrificial layers is formed over the substrate. After removing the sacrificial layer, an inter-gate dielectric layer is formed over the substrate. A control gate is formed over the inter-gate dielectric layer. Finally, a source region and a drain region are formed in the substrate on each side of the control gate.

Owner:POWERCHIP SEMICON MFG CORP

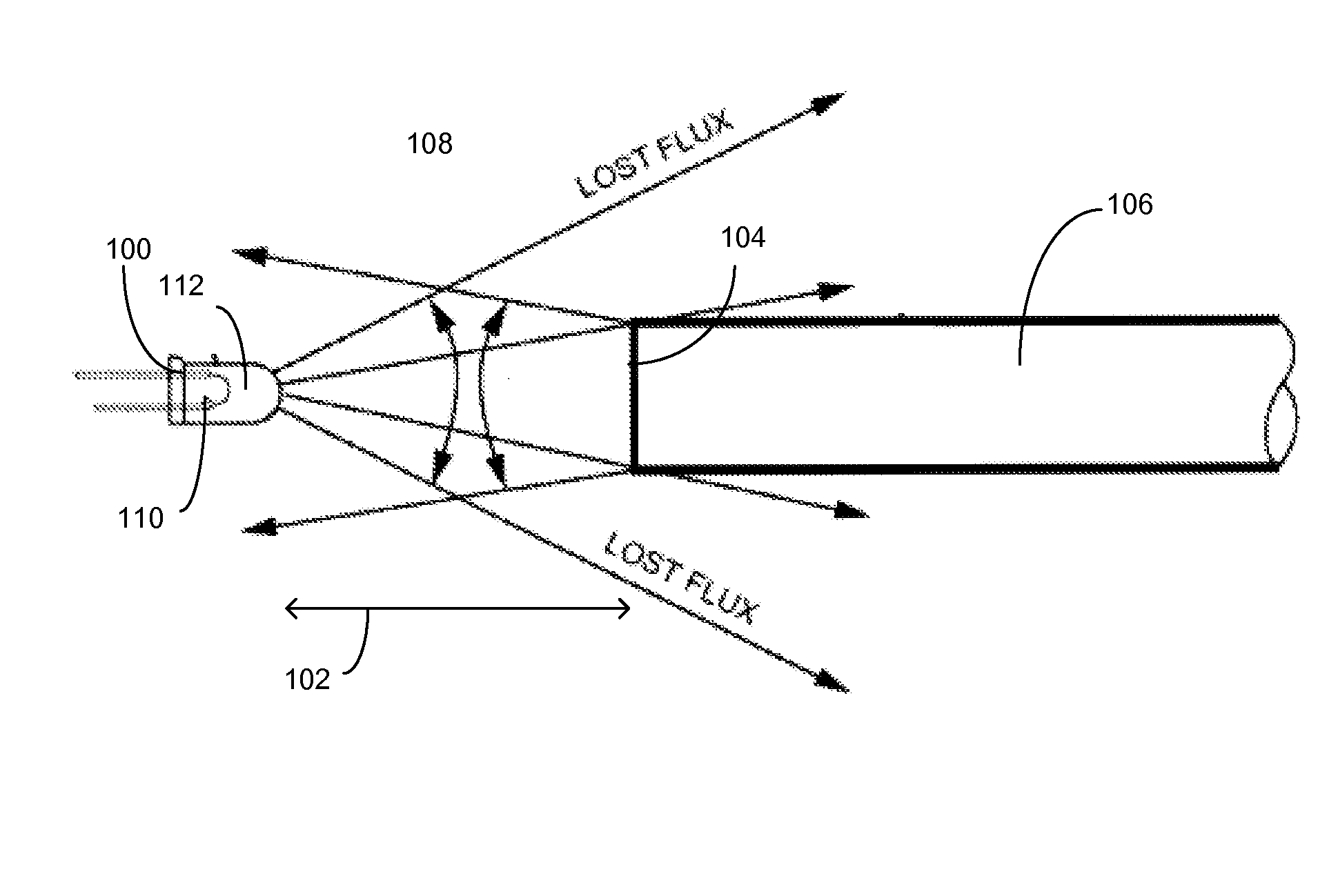

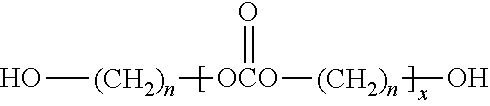

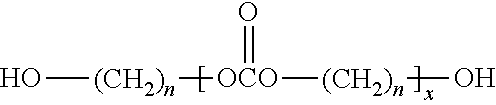

Light guide and associated light assemblies

ActiveUS20150043241A1Easy thickness controlLow hazeMechanical apparatusElectric discharge tubesLight guideRefractive index

A light guide has a transmission of greater than 90 percent, a refractive index greater than 1.4, and less than 10 haze percent. The light guide also includes an organosiloxane block copolymer having a weight average molecular weight of at least 20,000 g / mole. The organosiloxane block copolymer includes 40 to 90 mole percent disiloxy units of the formula [R12SiO2 / 2] arranged in linear blocks each having an average of from 10 to 400 disiloxy units [R12SiO2 / 2] per linear block, 10 to 60 mole percent trisiloxy units of the formula [R2SiO3 / 2] arranged in non-linear blocks each having a weight average molecular weight of at least 500 g / mol, and 0.5 to 25 mole percent silanol groups [≡SiOH]. R1 is independently a C1 to C30 hydrocarbyl and R2 is independently a C1 to C20 hydrocarbyl. Moreover, at least 30% of the non-linear blocks are crosslinked with another non-linear block and aggregated in nano-domains.

Owner:DOW SILICONES CORP

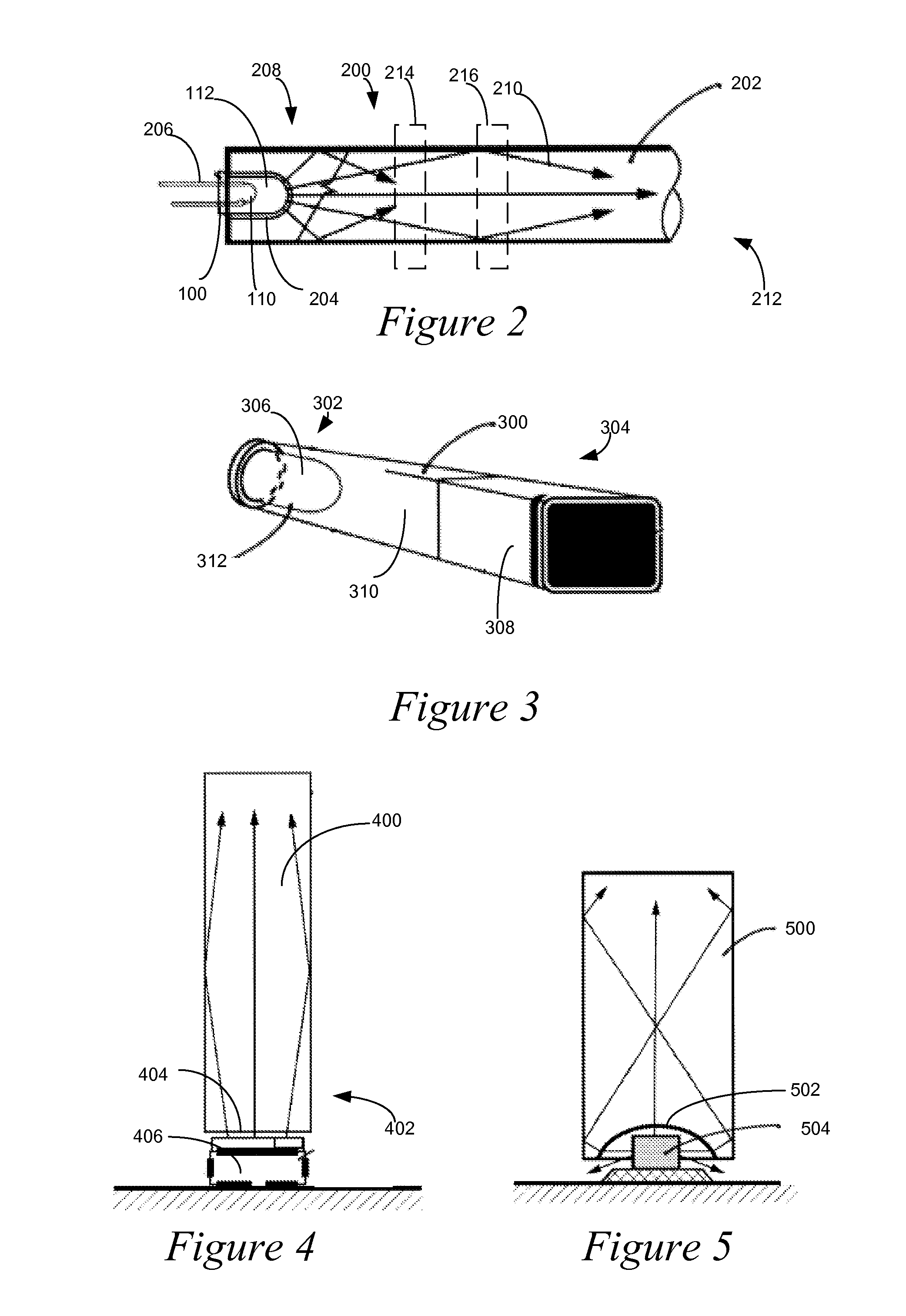

Nanocrystalline film and its low temperature preparing method

ActiveCN101143357AHigh strengthEasy thickness controlPolycrystalline material growthFinal product manufactureReaction temperatureSlurry

The present invention relates to a nano-crystal thin film and a low temperature preparation method. The thin film is provided with graded structure and uses nano-crystal titania particles of different sizes as raw materials to add specific chemical bonds or function masses to the surfaces of the nano-crystal particles through a method of surface modification. The materials are mixed in inorganic or organic solution to be prepared into carcass slurries before graded, which are made into films on a flexible conductive basement or any other basement through a simple film making method. Under a low reaction temperature, the particles in the thin films are well connected through chemical sintering, and the nano-crystal particles are connected through good chemical bonds. The whole thin film is provided with high mechanical strength. Flexible dye sensitization solar energy batteries, which are assembled from the thin films, are provided with the high photoelectric conversion efficiency. The thin film and the low temperature preparation method is predicated to be provided with a wide application prospect in photoelectric transformation and photo-catalyst fields.

Owner:TSINGHUA UNIV

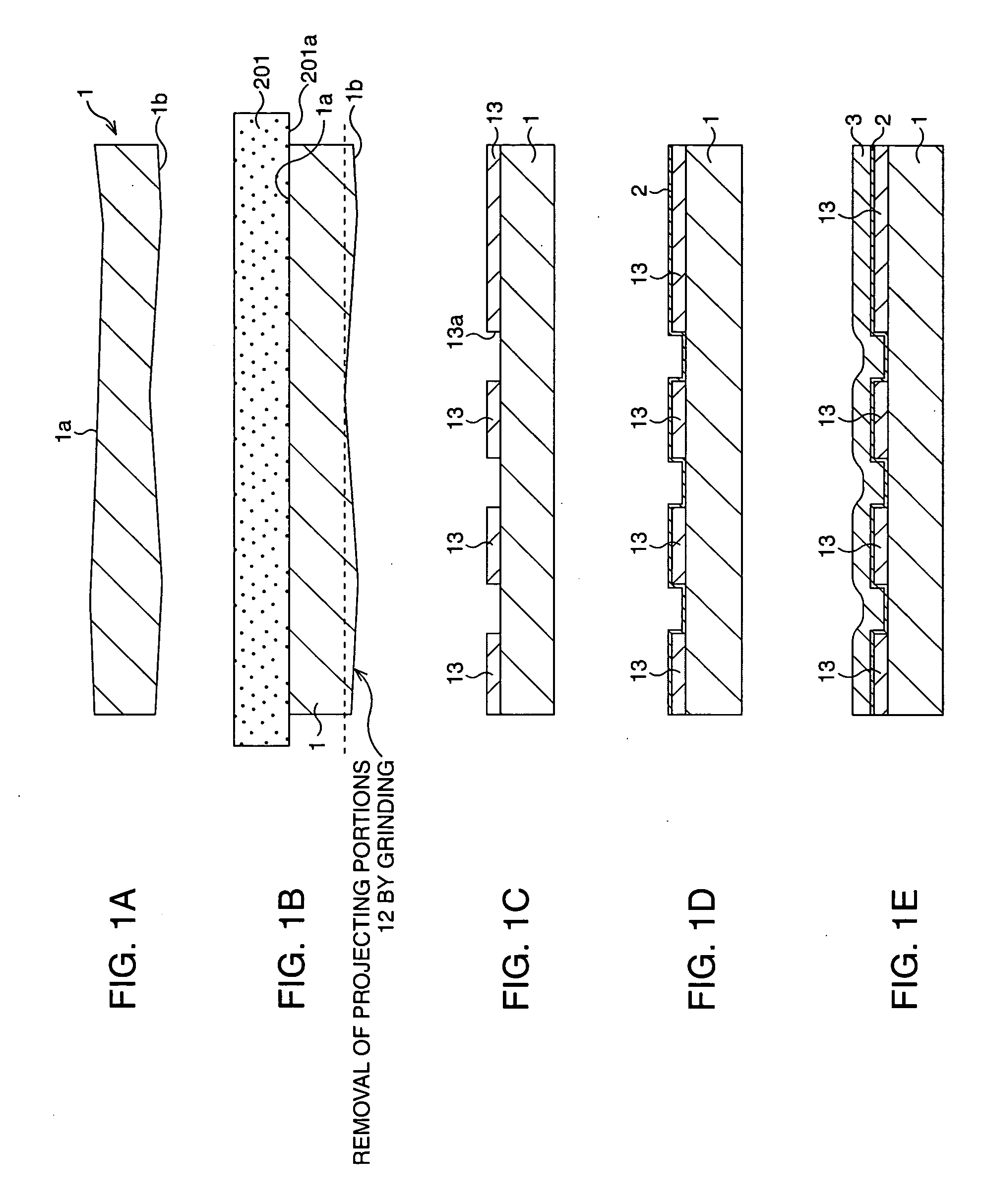

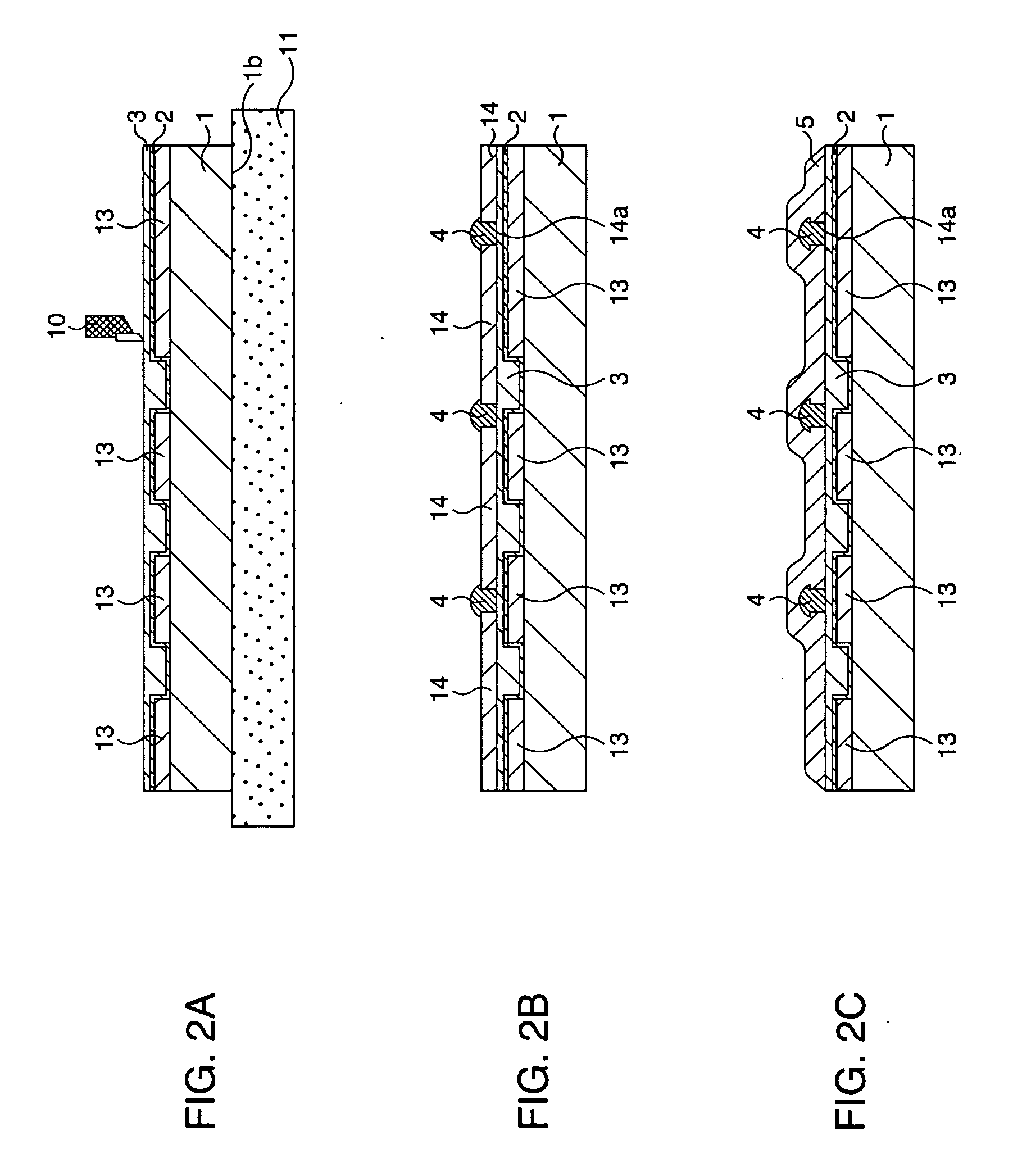

Semiconductor device, wiring substrate forming method, and substrate processing apparatus

InactiveUS20050170640A1Easy thickness controlHigh-speed planarization is realized easily and inexpensivelySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A substrate support (201) having a flat supporting surface (201a) is prepared, and a semiconductor substrate (1) is fixed to the substrate supporting surface (201) by attaching a wiring forming surface (1a) to the supporting surface (201a) by suction, for example, by vacuum suction. On this occasion, the wiring forming surface (1a) is forcibly flattened by being attached to the supporting surface (201a) by suction, and therefore the wiring forming surface (1a) becomes a reference plane for planarization of a back surface (1b). In this state, planarization processing is performed by mechanically grinding the back surface (1b) to grind away projecting portions (12) of the back surface (1b). Hence, variations in the thickness of the substrate (especially, semiconductor substrate) are made uniform, and high-speed planarization is realized easily and inexpensively without disadvantages such as dishing and without any limitation on a wiring design.

Owner:FUJITSU LTD

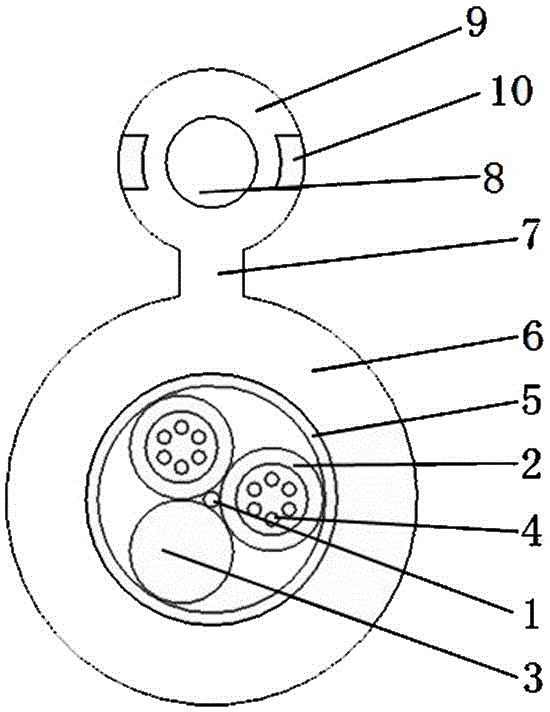

Self-supporting aerial optical cable capable of being identified through night vision

The invention relates to the technical field of cables and in particular relates to a self-supporting aerial optical cable capable of being identified through night vision. The self-supporting aerial optical cable comprises a cable core, an outer sheath, a reinforcing element, a suspension wire sheath and a rib, wherein the cable core is coated by the outer sheath; the reinforcing element is made of a single steel wire or glass fiber reinforced plastics and is coated by the suspension wire sheath; the rib is used for connecting the suspension wire sheath with the outer sheath; the cable core is formed by a central reinforcer, a plurality of loose tubes and a protective layer, wherein the loose tubes are arranged outside the central reinforcer and are coated by the protective layer; at least an optical fiber is arranged in each loose tube; two marking strips are symmetrically arranged on the suspension wire sheath; the suspension wire sheath, the outer sheath and the rib, which are made of the same materials, are formed integrally; and the marking strips are made of special materials. The self-supporting aerial optical cable has the main beneficial effects that the thickness of the suspension wire sheath is more convenient to control; the suspension wire sheath is smoother and round; the product production speed is higher and the percent of pass of the product is higher; the dead weight of the optical cable is lighter and the suitable span is longer; and the colors of the marking strips are more stable.

Owner:SUZHOU HIGH & SPECIALITY INFORMATION TECH CO LTD

Photochromic Polyurethane Laminate

ActiveUS20140272426A1Improve propertiesEnhanced network structurePhotosensitive materialsSynthetic resin layered productsPolyurethane laminatePhotochromism

Photochromic polyurethane laminates and methods for the formation of same wherein a photochromic polyurethane layer of the laminate is interposed between two primer coated transparent resin sheets.

Owner:HOYA OPTICAL LABS OF AMERICA INC

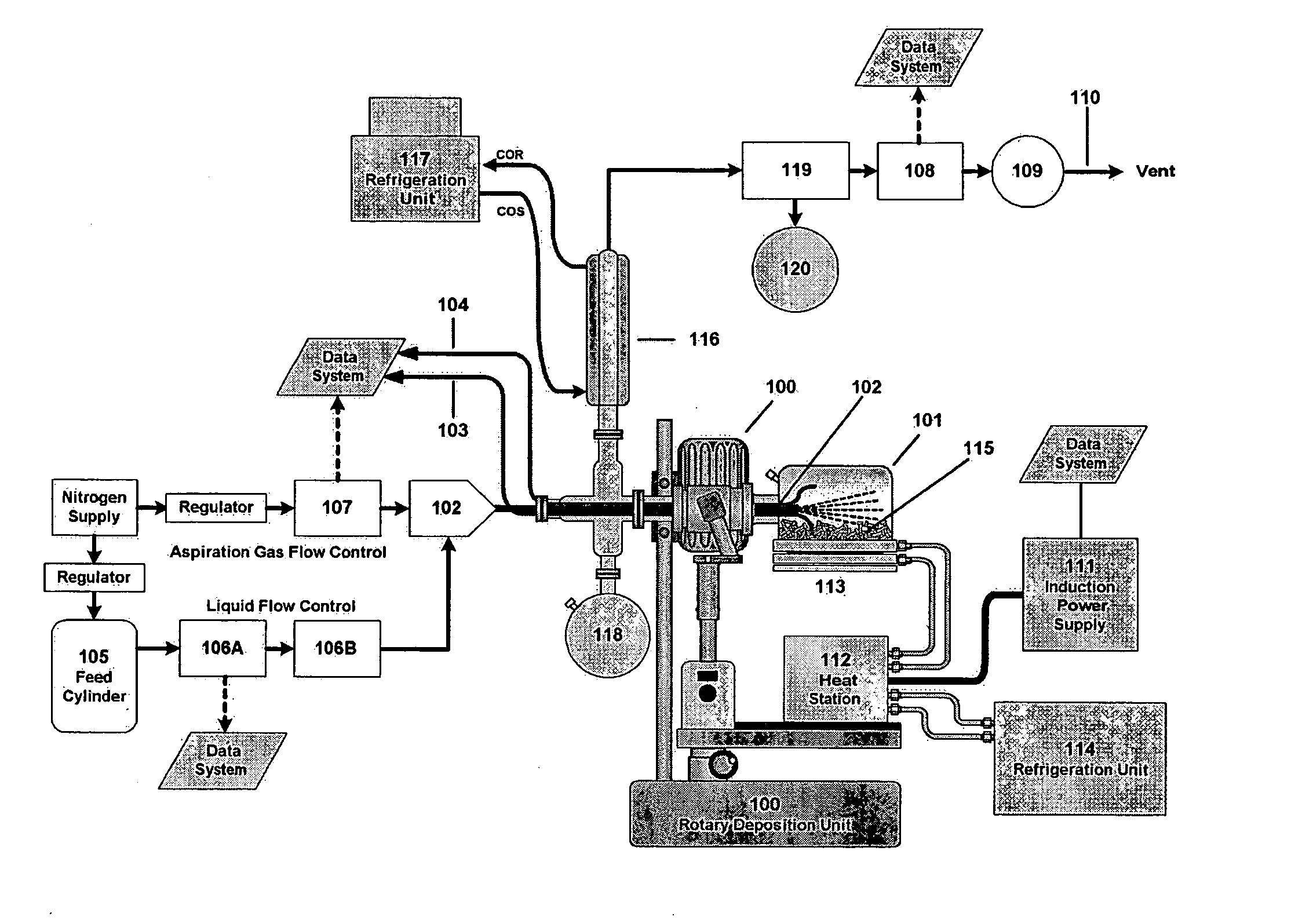

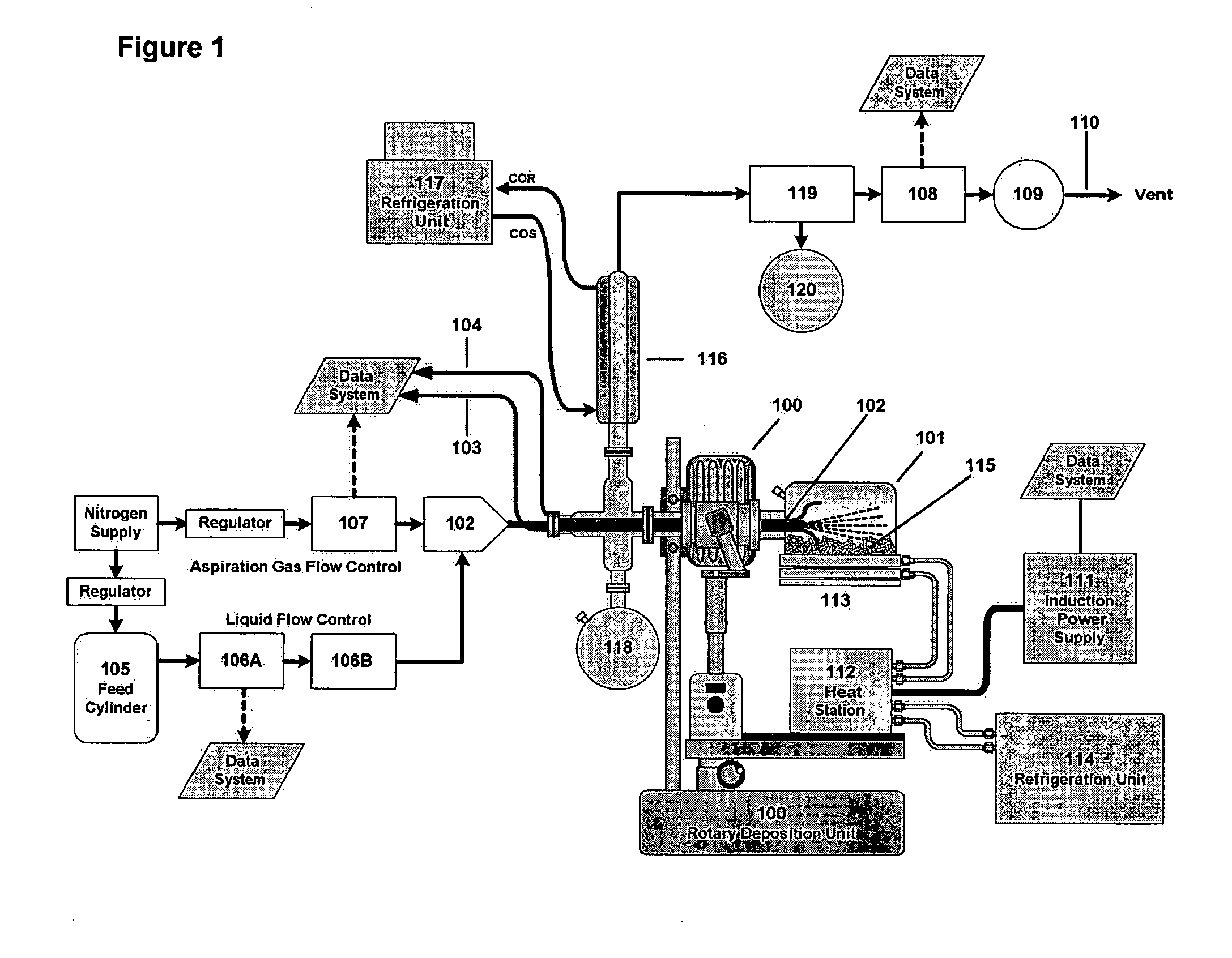

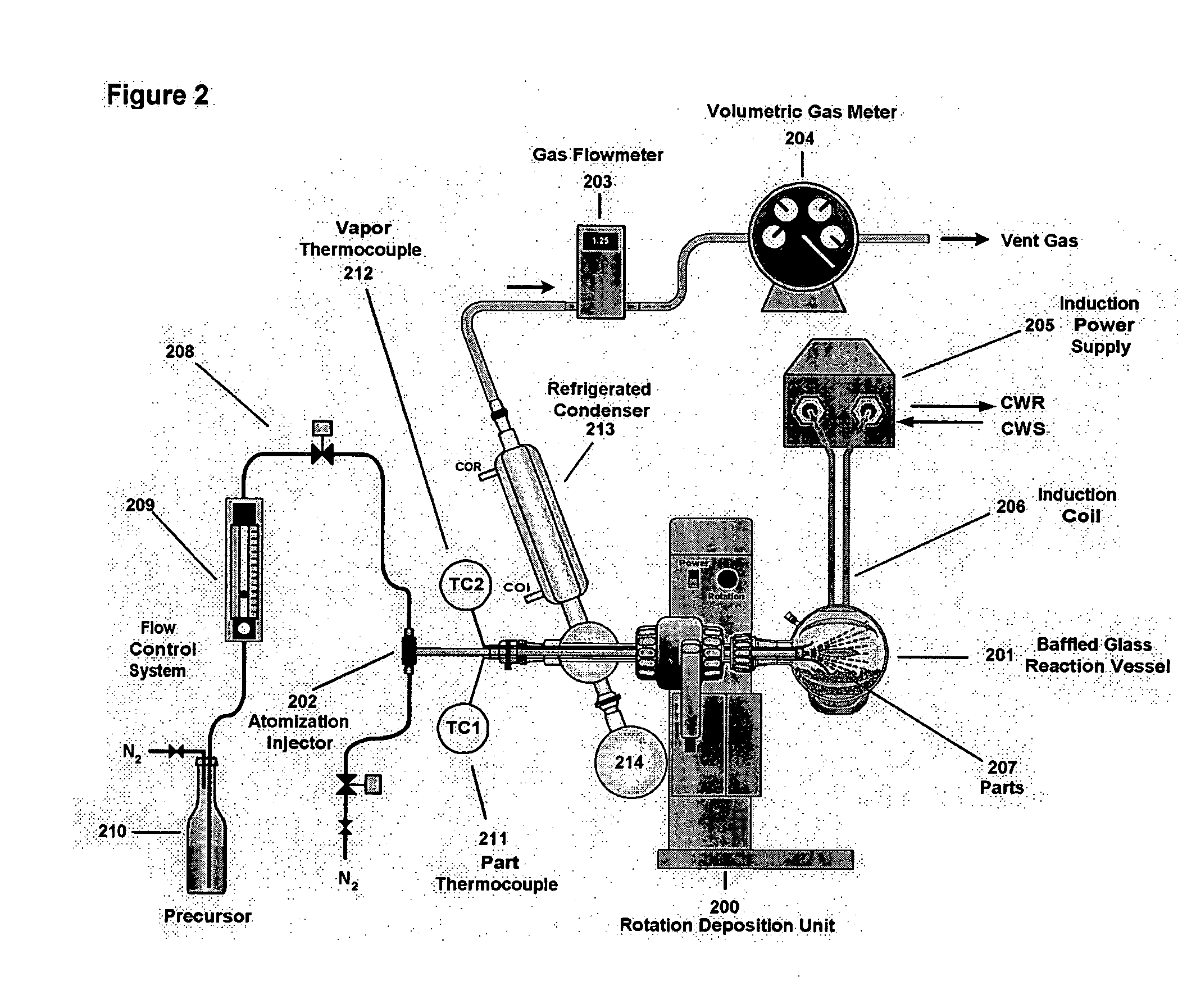

Metallization of substrate(s) by a liquid/vapor deposition process

InactiveUS20050064211A1Improve deposition qualityReduce productionDielectric heatingInduction heatingTemperature controlGas phase

A process for depositing a substantially pure, conformal metal layer on one or more substrates through the decomposition of a metal-containing precursor. During this deposition process, the substrate(s) is maintained at a temperature greater than the decomposition temperature of the precursor while the surrounding atmosphere is maintained at a temperature lower than the decomposition temperature of the precursor. The precursor is dispersed within a transport medium, e.g., a vapor phase. The concentration of the metal-containing precursor(s) in the vapor phase, which also contains liquid therein, can be at a level to provide conditions at or near saturation for the metal precursor(s). In ensuring the aforementioned temperature control between the transport media and substrate, and in maintaining saturation conditions for the transport media, the quality of the deposited metal thin film is markedly improved and the production of by-product metal dust is greatly reduced or substantially eliminated.

Owner:AKZO NOBEL NV

Flat solar heat absorption coated plate production method and vertical coating apparatus

ActiveCN102206806AFlexible processImprove absorption rateVacuum evaporation coatingSputtering coatingSputteringLow emissivity

The invention provides a flat solar heat absorption coated plate production method. A large area sheet metal is used as a substrate; two sides of each sheet rack can be equipped with metal substrates; a speed reducer outside a vacuum chamber drags a transmission mechanism to drive sheet racks travel straight, and the sheet racks continuously enter into magnetic-control sputtering targets and corresponding sputtering cavities of a continuous coating chamber one by one with a uniform velocity, wherein each sputtering cavity is equipped with magnetic-control sputtering targets on two sides thereof, so that the metal substrates on two sides of a sheet rack can be deposited with films, such as an infrared light reflecting layer / a heat absorption function layer / an antireflection layer, in asolar heat absorption functional film The invention also provides a vertical coating apparatus for the flat solar heat absorption coated plate production. The apparatus includes sheet racks, a front vacuum lock chamber, a front hold chamber, a front buffer area, a continuous coating chamber, a back buffer area, a back hold chamber and a back lock chamber, so as to double the production efficiencyof a horizontal coating apparatus. The heat absorption coated plate of the invention has advantages of a high absorptivity and a low emissivity. In addition, high production efficiency and low costs can be realized through the present invention.

Owner:SICHUAN GOLDSTONE-ORIENT NEW MATERIAL TECH CO LTD

Fuel injection valve and fuel injection device

ActiveCN101821494AEasy to handleReduce sizeElectrical controlMachines/enginesEngineeringHigh pressure

Owner:DENSO CORP +1

Self-supporting optical cable with marking strips

ActiveCN103777295ALight weightIncrease weightFibre mechanical structuresStructural engineeringProtection layer

The invention relates to the technical field of cables, in particular to a self-supporting optical cable with marking strips. The self-supporting optical cable with the marking strips is formed by a cable core, an outer protecting sleeve wrapping the cable core, a strengthening element, a suspension wire protecting layer wrapping the strengthening element and a rib enabling the suspension wire protecting layer and the outer protecting sleeve to be connected. The cable core is formed by a central strengthening piece located in the center, a plurality of loose sleeve pipes located outside the central strengthening piece and a protecting layer. Optical fibers are arranged in the loose sleeve pipes. The self-supporting optical cable with the marking strips is characterized in that the strengthening element is made of a steel wire or glass fiber strengthening plastic, the two marking strips are symmetrically arranged on the suspension wire protecting layer, and the suspension wire protecting layer, the outer protecting sleeve and the rib are formed integrally and are made of identical materials. The invention further discloses the components and proportions of the marking strips. The self-supporting optical cable with the marking strips has the advantages that the thickness of the suspension wire protecting layer is more convenient to control, more smooth and round, products can be produced faster and are higher in qualified rate, the optical fibers are lower in self-weight and longer in adaptive span, and the color of the marking strips is more stable.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD +1

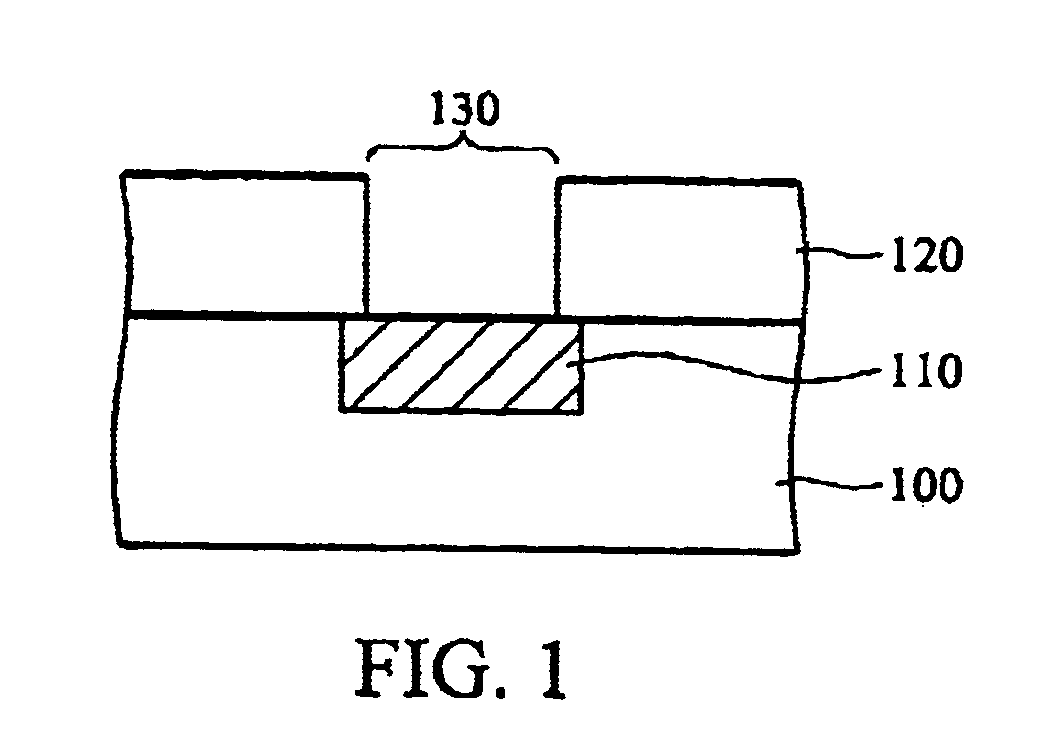

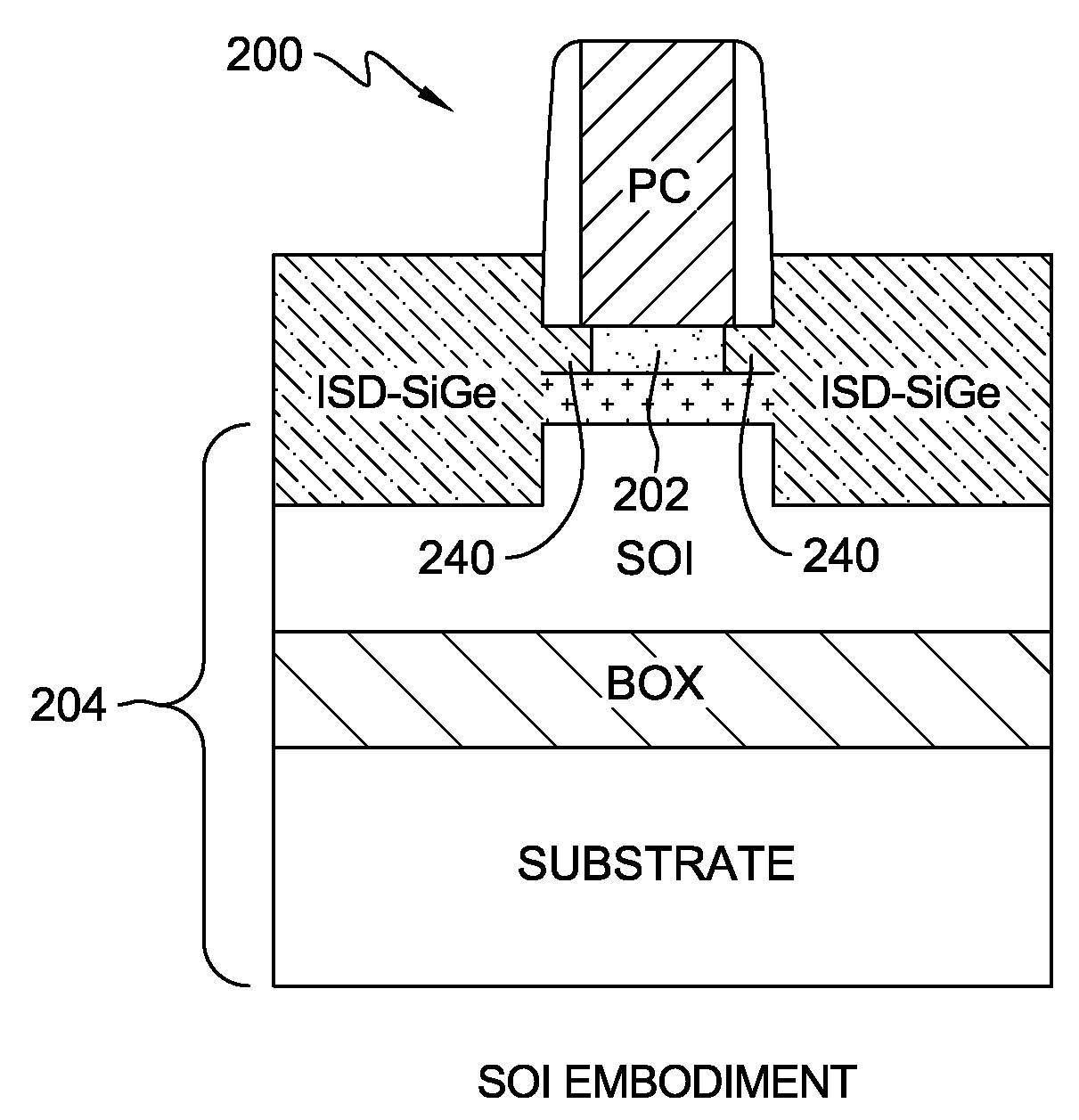

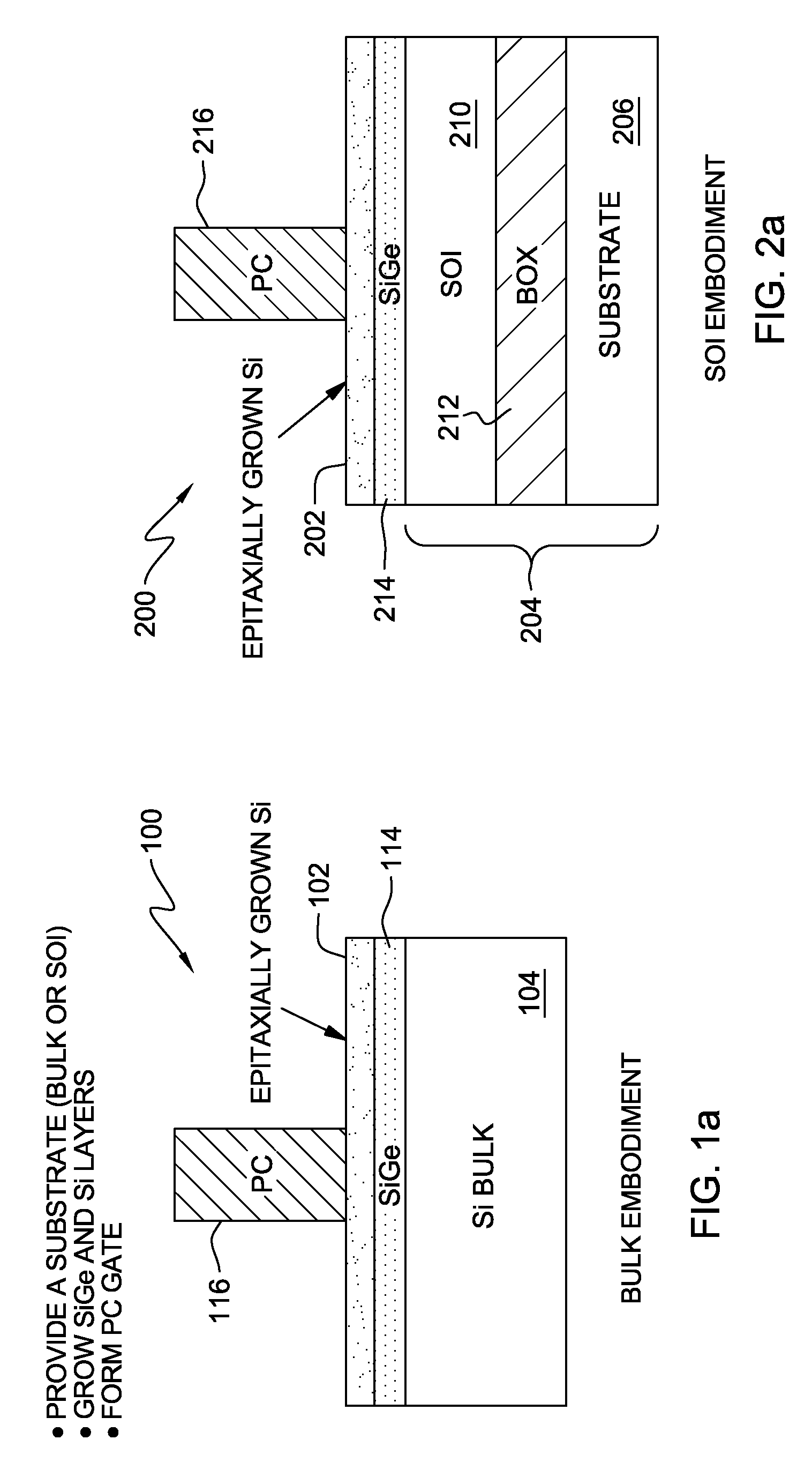

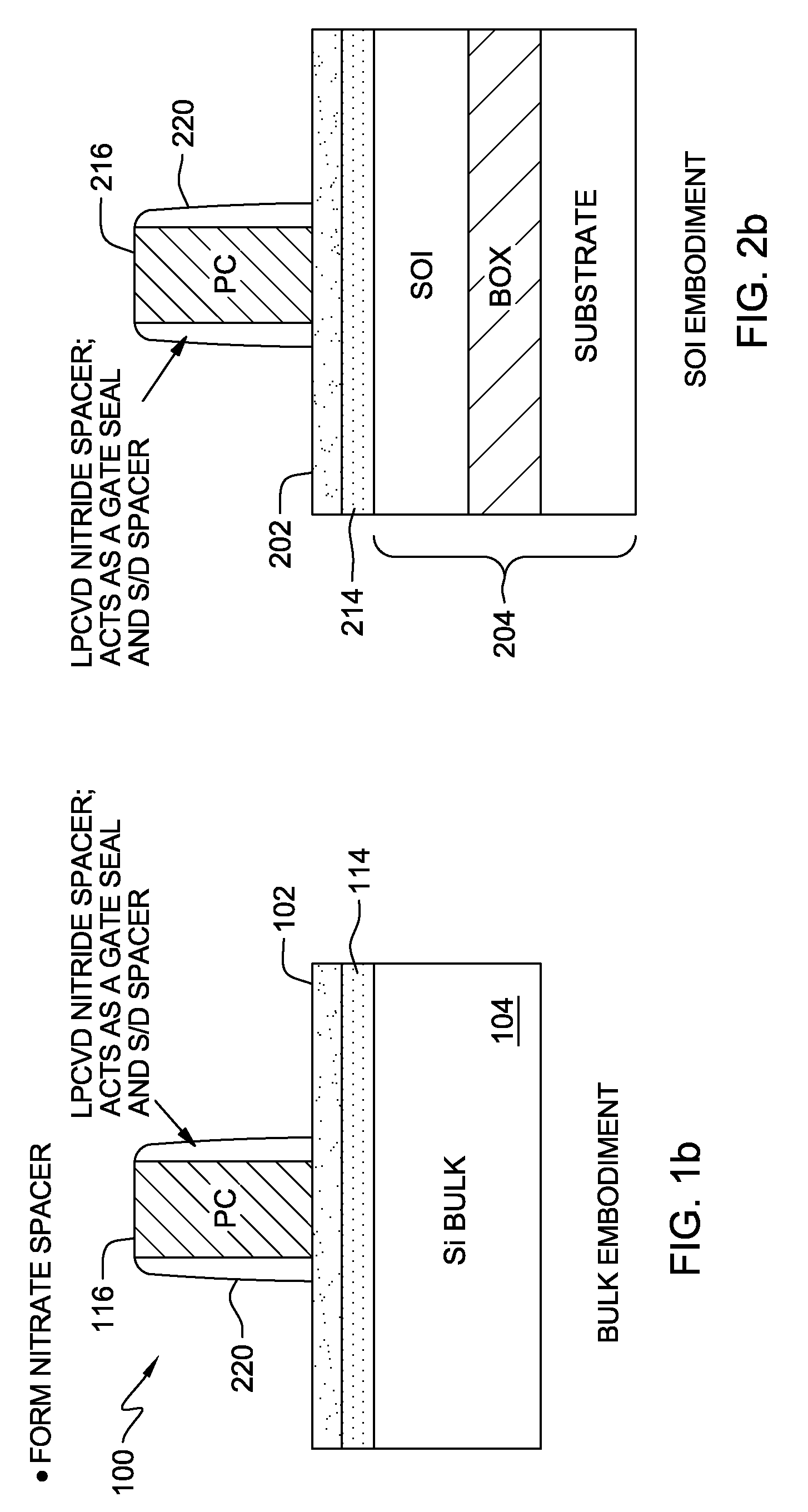

Implant free extremely thin semiconductor devices

ActiveUS8304301B2Easy thickness controlSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packageSemiconductor device

A semiconductor device and a method of fabricating a semiconductor device are disclosed. In one embodiment, the method comprises providing a semiconductor substrate, epitaxially growing a Ge layer on the substrate, and epitaxially growing a semiconductor layer on the Ge layer, where the semiconductor layer has a thickness of 10 nm or less. This method further comprises removing at least a portion of the Ge layer to form a void beneath the Si layer, and filling the void at least partially with a dielectric material. In this way, the semiconductor layer becomes an extremely thin semiconductor-on-insulator layer. In one embodiment, after the void is filled with the dielectric material, in-situ doped source and drain regions are grown on the semiconductor layer. In one embodiment, the method further comprises annealing said source and drain regions to form doped extension regions in the semiconductor layer. Epitaxially growing the extremely thin semiconductor layer on the Ge layer ensures good thickness control across the wafer. This process could be used for SOI or bulk wafers.

Owner:TAIWAN SEMICON MFG CO LTD

Method of manufacturing a bulk acoustic wave device

ActiveUS20110315654A1Easy thickness controlAccurate thicknessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveActive layer

A method of manufacturing a Bulk Acoustic Wave device by providing an active layer formed of an electro-mechanical transducer material, providing a first electrode on the active layer, defining a first electrode portion of the device, whereby a remaining portion of the device is defined around the first electrode, providing a stop-layer on the first electrode, depositing a first dielectric layer on the resultant structure, and planarizing the first dielectric layer until the stop-layer on the first electrode is exposed.

Owner:VLSI TECH LLC

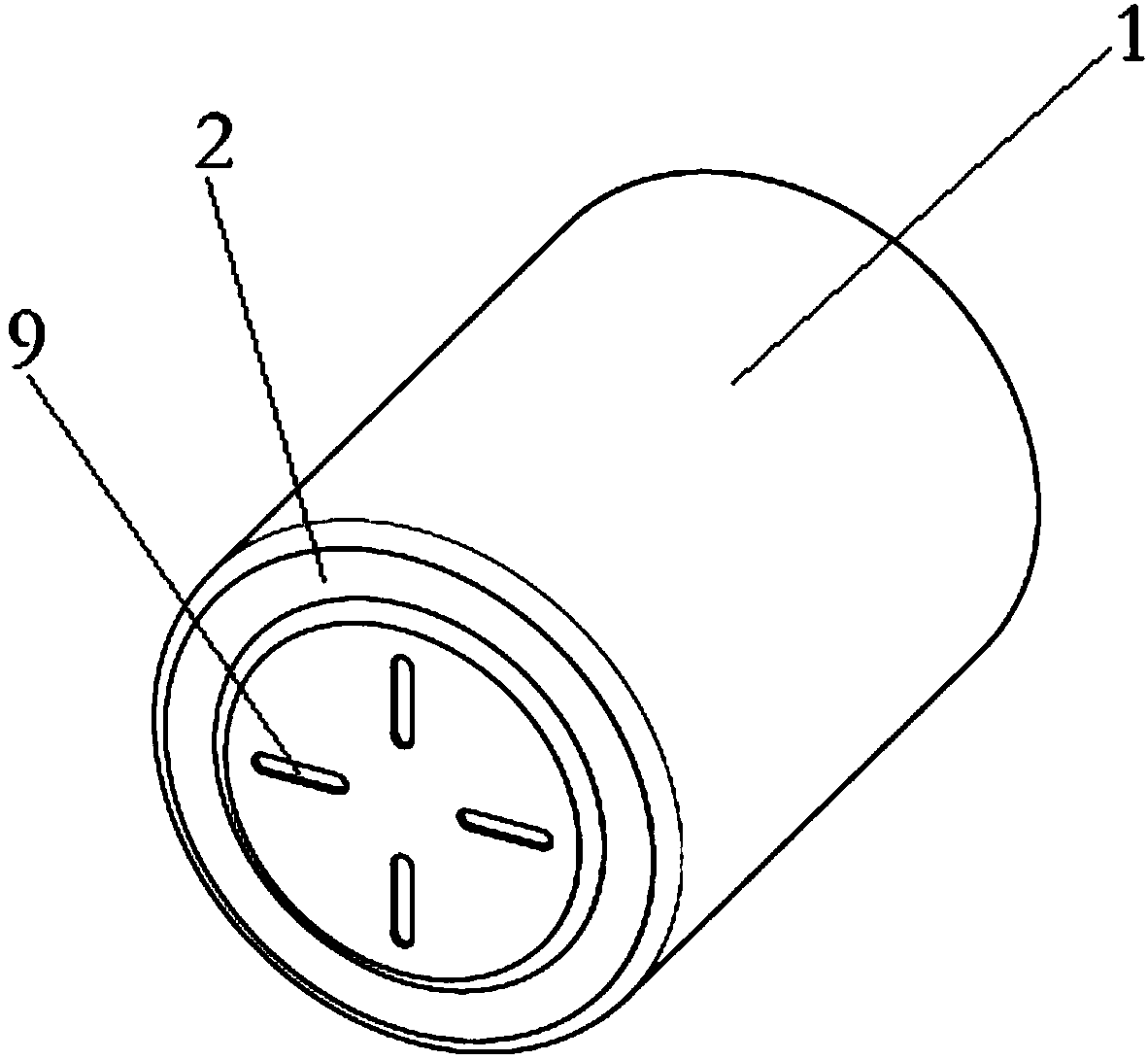

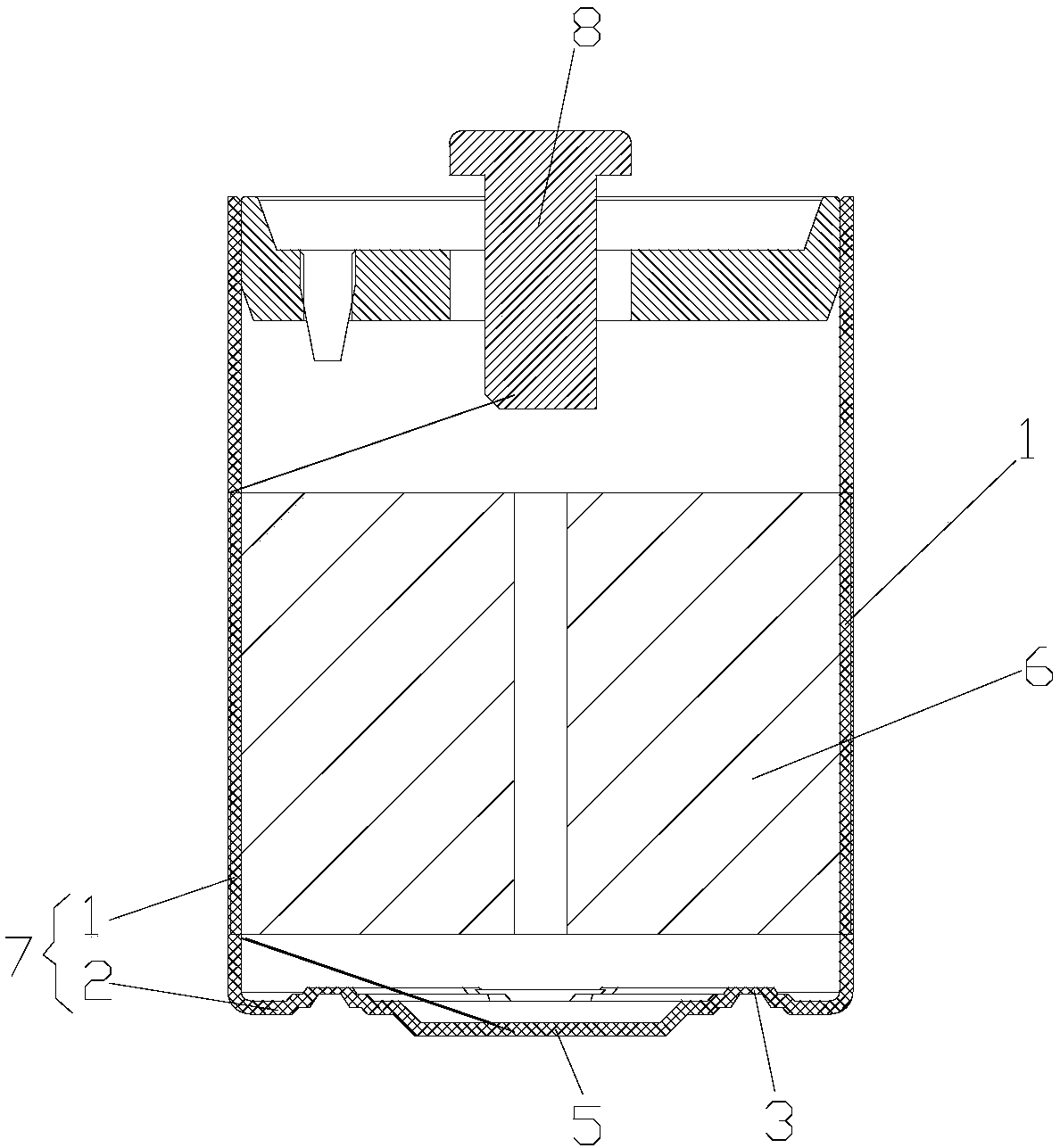

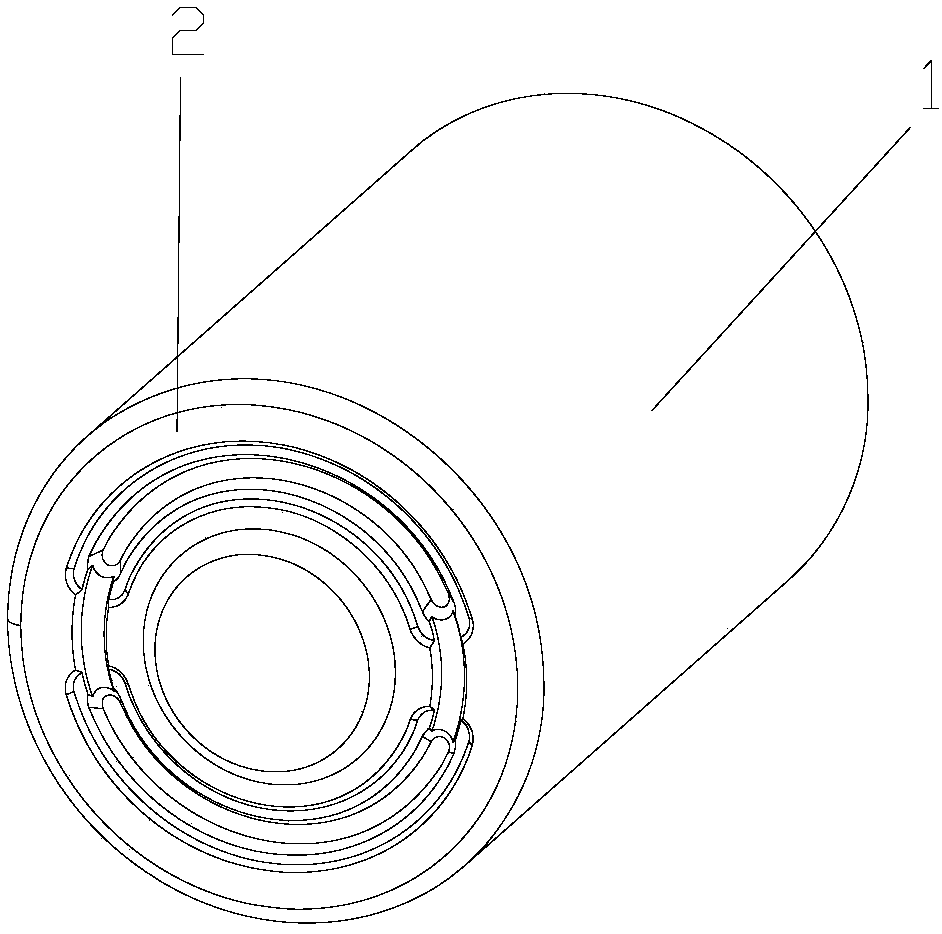

Lithium ion battery and case thereof

PendingCN108565492AEasy to processReduce the probability of ruptureFinal product manufactureSmall-sized cells cases/jacketsAtmospheric pressureLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and relates to a lithium ion battery and a case thereof. The lithium ion battery comprises the case, an upper cover and a roll core, wherein the upper cover covers the case; the roller core is positioned inside the case; a positive electrode of the roll core is connected with an electrode post through a guide foil strip; the electrode post is positioned in the center of the upper cover and is used for guiding out the positive electrode of the lithium ion battery; the case comprises a cylindrical case body and a case bottompositioned at the bottom of the cylindrical case body; a negative electrode of the roll core is connected with a center lug boss through a guide foil strip; the center lug boss is positioned in the center of the case bottom and is used for guiding out a negative electrode of the lithium ion battery; one section or a plurality of sections of arc-shaped safety valves are arranged on the base; the arc-shaped safety valve is an arc-shaped groove with the gradually reduced thickness in the circumference direction; the radius of the arc-shaped groove is 1 / 2 to 3 / 4 of the radius of the case bottom. Through the arrangement of the arc-shaped safety valve with the gradually reduced thickness on the case base, product service life reduction caused by occurrence of advanced opening of the safety valvecan be effectively avoided; meanwhile, the potential safety hazards caused when the safety valve is not opened at too high inside air pressure in the lithium ion battery can be avoided.

Owner:无锡凯帕德瑞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com