Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

413results about How to "Shorten vulcanization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Golf ball

InactiveUS7226367B2Improve productivityIncrease elasticityGolf ballsSolid ballsPtru catalystEngineering

A golf ball comprises a solid core consisting of a center core and an outer core, wherein at least one of cores is made of a rubber composition comprising 100 parts by weight of a base rubber including. 60 to 100% by weight of a polybutadiene containing at least 60% by weight of cis-1,4-bond, having a Mooney viscosity (ML1+4 (100° C.)) of at least 52, and synthesized using a rare-earth catalyst, 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, 5 to 80 parts by weight of an-inorganic filler, and an organic peroxide, and wherein the center core has a JIS-C hardness of 40 to 60 on its center and a JIS-C hardness of 55 to 75 on its surface and the difference therebetween is at least 10, the outer core is harder than the surface hardness of the center core, the cross-sectional hardness of 1 mm outside from the border between the center core and the outer core is from 65 to 85 on a JIS-C hardness, the surface of the outer core has a JIS-C hardness of 75 to 95.

Owner:BRIDGESTONE SPORTS

Composite foaming agent and preparation method and application thereof

The invention discloses a composite foaming agent, a preparation method thereof and application thereof. The composite foaming agent comprises azodicarbonamide, sodium bicarbonate and an auxiliary foaming agent in a weight ratio of (0.3-0.9):(0.2-0.6):(0.1-0.8). The auxiliary foaming agent is prepared by uniformly stirring attapulgite, zeolite and calcite, soaking the mixture in diluted hydrochloric acid of which the concentration is 0.5 to 6 weight percent, drying the mixture, crushing the dried mixture into powder, blending the powder and powdery white carbon black and uniformly stirring the mixture, wherein the weight ratio of the attapulgite to the zeolite to the calcite to the white carbon black is (0.3-0.8):(0.02-0.6):(0.1-0.8):(0.01-0.8). The composite foaming agent disclosed by the invention has relatively high liquidity and dispersibility, a low decomposition temperature and a long decomposition temperature period.

Owner:常州市英特玛柯橡塑科技有限公司

Multi-piece solid golf ball

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

InactiveCN103980320AGood oil solubilityReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSlurry reactorDecomposition

The invention provides an oil soluble molybdenum-based precursor of a catalyst, a preparation method and application thereof, relating to the technical field of heavy oil hydrocracking catalysts and solving the problems of low catalytic hydrogenation activity and high cost of the existing catalysts. The preparation method for the precursor comprises the steps of (1) mixing a molybdenum source with water, reacting for 30-240 minutes at 70-90DEG C, and adding inorganic acid; (2) adding polycarbon alcohol into P2S5 in 5-15 minutes at 50-80DEG C, and reacting for 1-3 hours at 70-100DEG C; (3) adding the product of step (2) into the product of step (1), adding resin, and reacting for 4-8 hours at 70-110DEG C; (4) separating oil phase from the product of step (3) so as to obtain the target product. The precursor can form MoS2 active components through self sulfurization and in situ decomposition, is used in slurry reactor hydrocracking of poor heavy oil with high content of metal, carbon residue and sulfur, and can lower the yield of coke and keep a device to run for a long period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Less harmful nontoxic rubber automobile seal strip

The invention provides a less-harmful nontoxic rubber vehicle sealing strip which has excellent processability and physical properties and belongs to an environment friendly sulfidizing system. Main raw materials are as follows: 200 plus or minus 10 portions of ethylene propylene diene methylene, and 150 plus or minus 10portions of carbon black; 20 plus or minus 2 portions of light super fine calcium carbonate and 30 plus or minus 3 portions of talc as fillers; 20 plus or minus 2 portions of high-flash paraffin oil or styrene / Alpha-methyl styrene / vinyl toluene terpolymer as a softener; 10 plus or minus 1 portions of aluminum hydroxide as a flame retardant; 5 plus or minus 0.5 portions of zinc oxide and 2 plus or minus 0.2 portions of stearic acid as active agents together; 4 plus or minus 0.4 portions of polyethylene glycol of a hydroxyl polar group as an additive; 5 plus or minus 0.5 portions of calcium oxide as a neutralizer; 4 plus or minus 0.4 portions of nitrogen-free sulfidation material which is mainly sulphur; and 0.3 plus or minus 0.03 portion of Alpha-tocopherol as an inhibitor. The less harmful nontoxic rubber vehicle sealing strip can not only reduce environmental pollution, but also maintain reasonable cost.

Owner:ANHUI CHENYANG RUBBER & PLASTRIC CO LTD

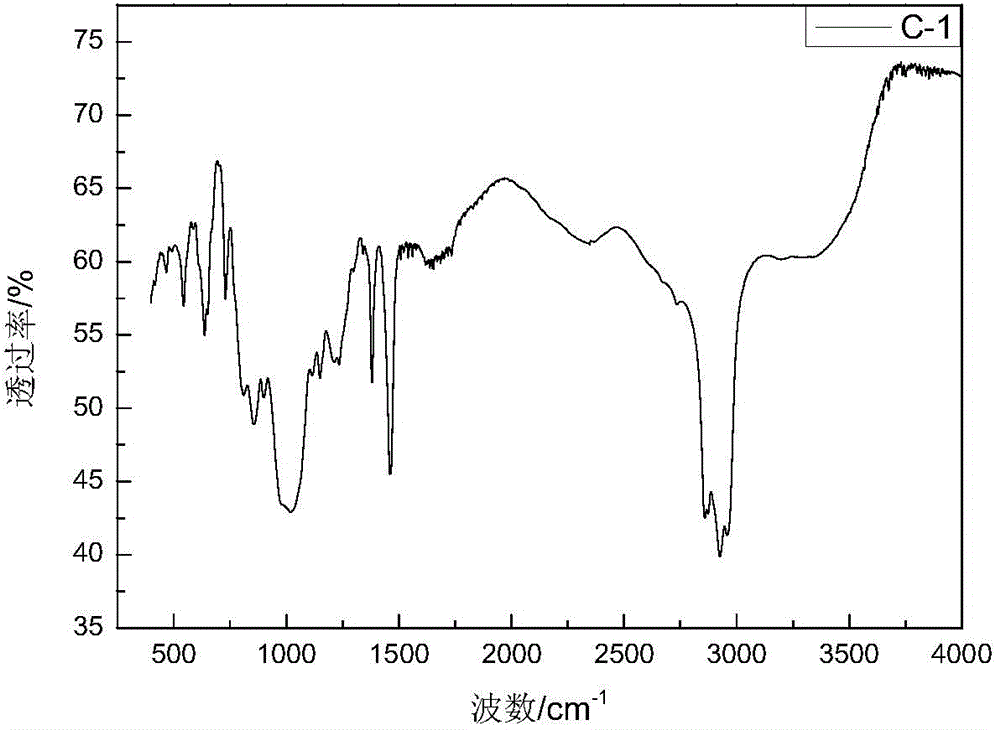

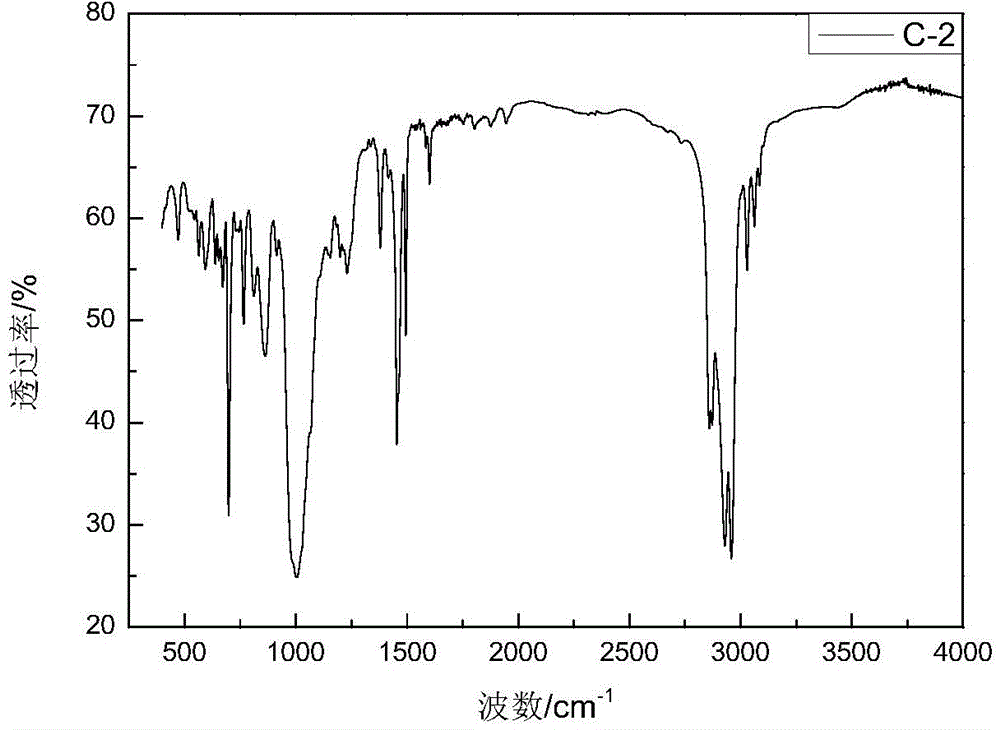

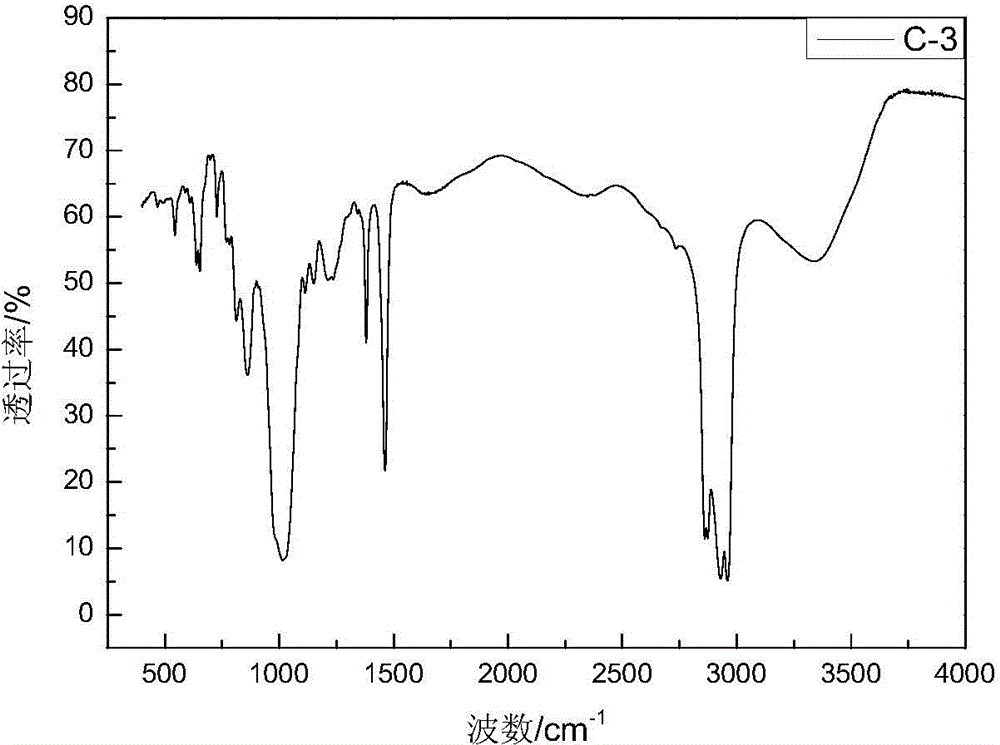

Automobile rubber sealing strip and preparation method thereof

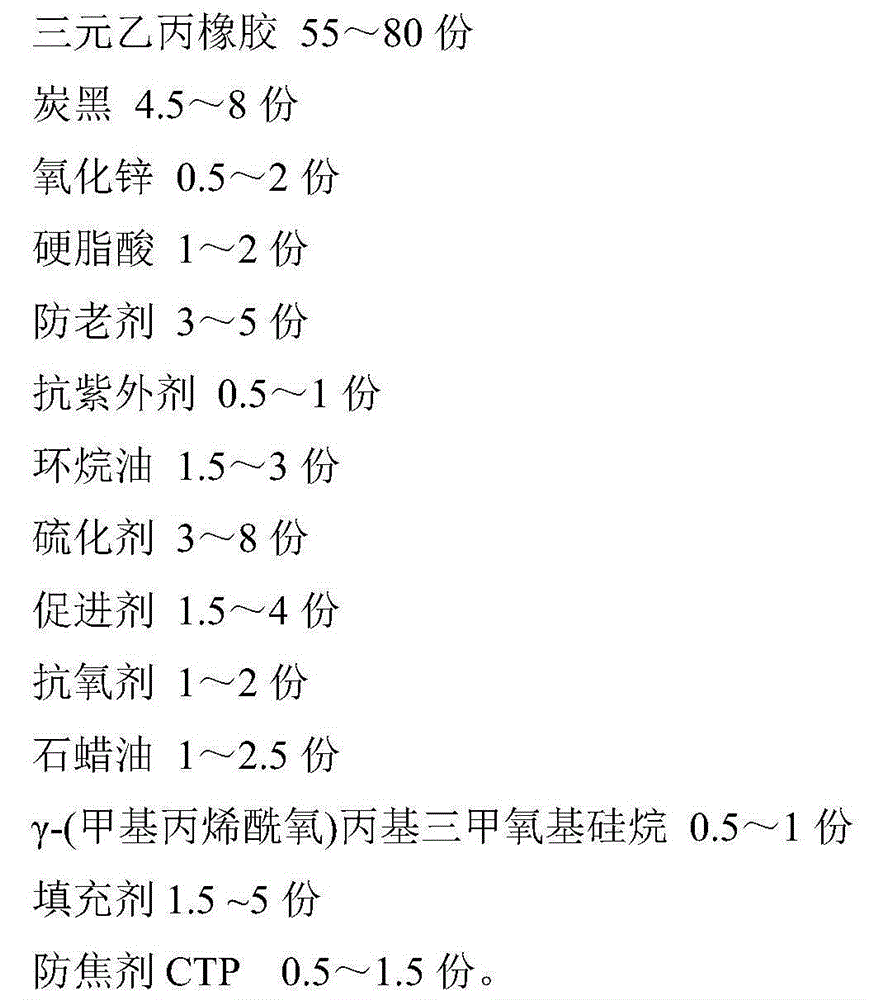

The invention discloses an automobile rubber sealing strip and a preparation method thereof. The automobile rubber sealing strip comprises the following components in parts by weight: 55-80 parts of ethylene propylene diene monomer rubber, 4.5-8 parts of carbon black, 0.5-2 parts of zinc oxide, 1-2 parts of stearic acid, 3-5 parts of anti-aging agent, 0.5-1 part of ultraviolet-resistant agent, 1.5-3 parts of naphthenic oil, 3-8 parts of vulcanizing agent, 1.5-4 parts of accelerator, 1-2 parts of antioxidant, 1-2.5 parts of paraffin oil, 0.5-1 part of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-5 parts of filler and 0.5-1.5 parts of anti-scorching agent CTP. The automobile rubber sealing strip enhances the high temperature resistance, low temperature resistance, stability to light, ozone. oxygen and the like and other comprehensive properties of the product and improves the interface compatibility on the premise of keeping the original mechanical properties. The preparation method has the advantages of simple technique, short vulcanization time, lower energy consumption and lower production cost.

Owner:SUZHOU GOODTIME TECH DEV

Polysiloxane-containing rubber composition for tire

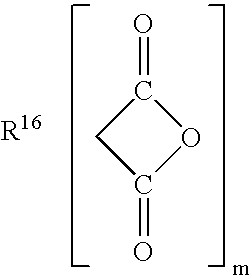

InactiveUS6103811AEasy to processLow viscosityGroup 4/14 element organic compoundsSpecial tyresSilylenePolymer science

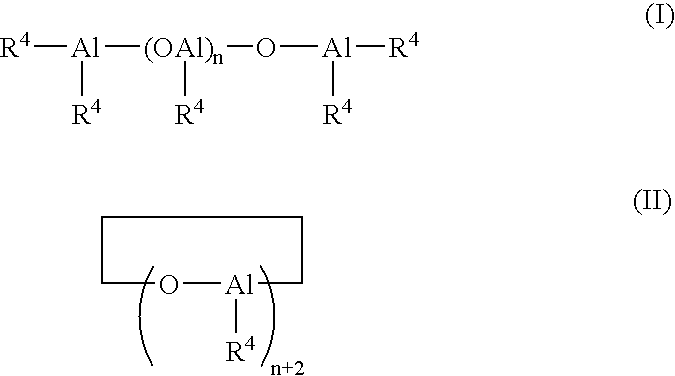

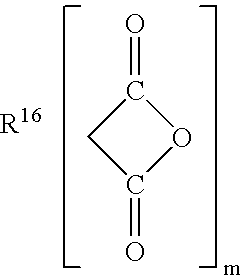

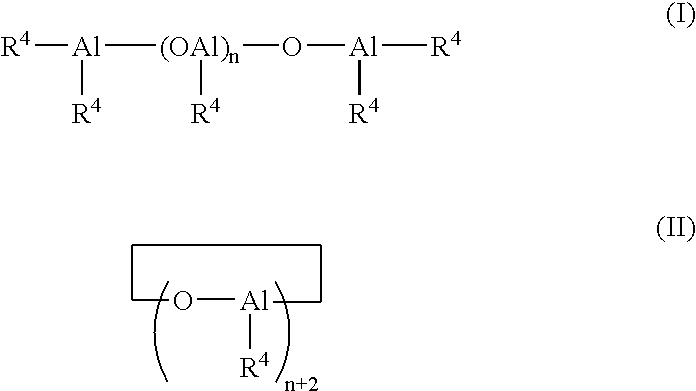

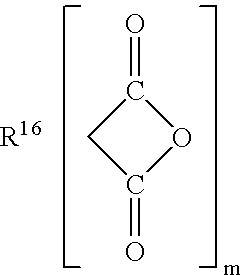

PCT No. PCT / JP97 / 03212 Sec. 371 Date May 8, 1998 Sec. 102(e) Date May 8, 1998 PCT Filed Sep. 11, 1997 PCT Pub. No. WO98 / 11161 PCT Pub. Date Mar. 19, 1998A rubber composition for a tire comprising: 100 parts by weight of a starting rubber; 10 to 150 parts by weight of a carbon black; 0.1 to 20 parts by weight of a sulfur; and 40 parts by weight or less of a polysiloxane having the following alkoxysilyl group (I) or acyloxysilyl group (II) and having an average degree of polymerization of 3 to 10,000: 3BOND Si-OR1(I) 3BOND Si-OCOR2(II) wherein R1 is a substituted or unsubstituted monovalent hydrocarbon group or an organic group containing an ether bond and having 1 to 18 carbon atoms and R2 is hydrogen or a hydrocarbon group having 1 to 21 carbon atoms.

Owner:YOKOHAMA RUBBER CO LTD

Wear-resisting sole material and preparation method thereof

The invention relates to a formula of a rubber sole material and an improvement of the preparation method of the rubber sole material. The wear-resisting sole material comprises the following components by weight percent: 50-60% of natural rubber 3L, 3-5% of accelerator, 40-45% of filler, 1-1.5% of hardener and 1.5-2% of vulcanizing agent, wherein the hardener is high styrene; and the acceleratoris the mixture of inorganic accelerator, polyethylene glycol, stearic acid, antioxidant and tackifier and the accelerator also contains organic accelerator which is perferably selected from accelerator D, accelerator M and accelerator DM. The sole material of the invention is prepared from good natural rubber by adding the accelerator with various functions; and the sole prepared from the material has light weight, good wear resistance, water resistance and good heat retention property and is suitable to be used as the sole of the shoe with high wear strength such as tennis shoe and outdoor sneaker.

Owner:CHINADIVE WATERSPORTS INC

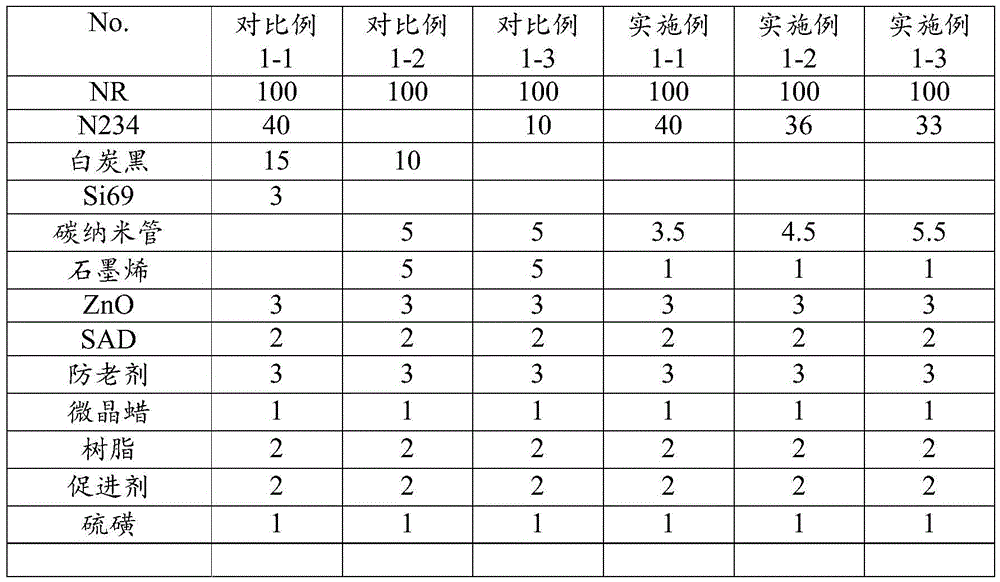

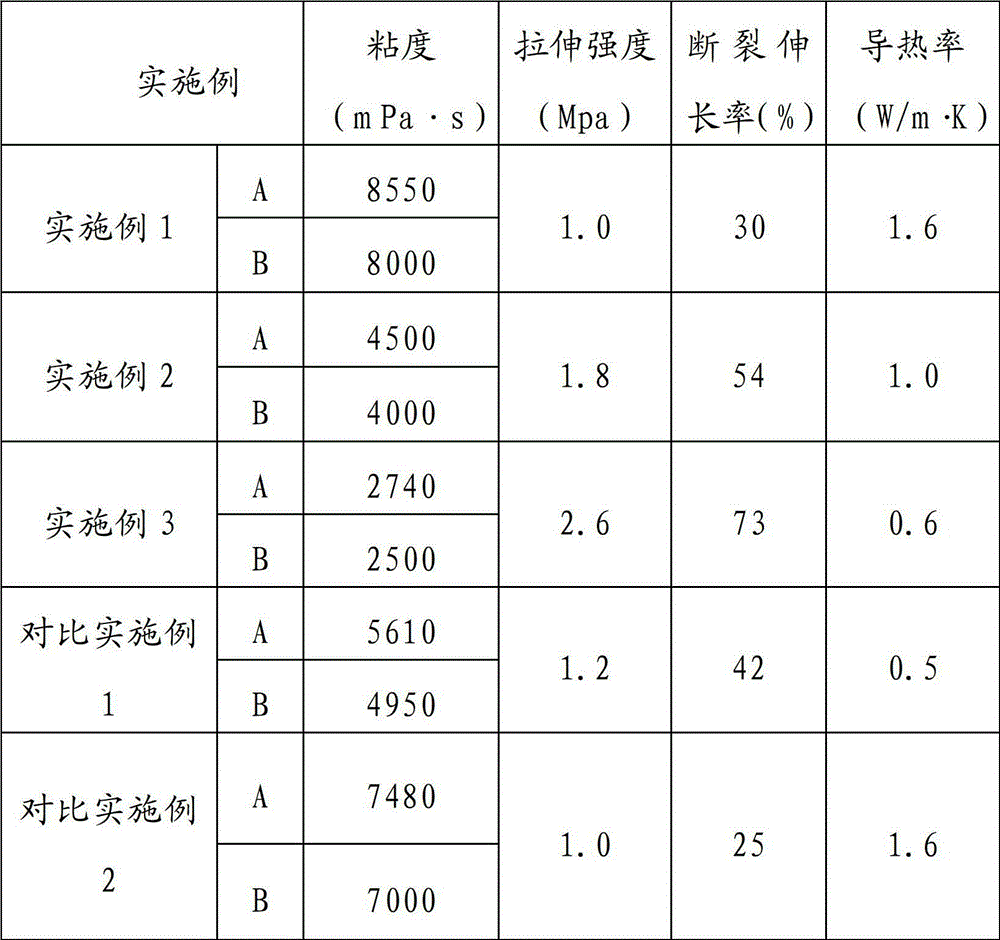

High-heat-conductive rubber composition, preparation method thereof and tyre

InactiveCN105419004AIncreased durabilityHigh thermal conductivitySpecial tyresPolymer scienceCarbon nanotube

The application discloses a high-heat-conductive rubber composition, a preparation method thereof and a tyre. The high-heat-conductive rubber composition includes, by weight, 100 parts of rubber, 20-75 parts of carbon black, 0-25 parts of white carbon black, 0.1-10 parts of carbon nano tubes, and 0.1-10 parts of graphene. The tyre, on the basis of original processing performance and conventional physical performance maintained, is improved in heat-conductivity of total materials and is reduced in vulcanizing time, and meanwhile is improved in durability when being used for long time under high load.

Owner:ZHANGJIAGANG OTSUKA CHEM

Heat-conduction electronic potting adhesive and preparation method thereof

InactiveCN102942895AMeet potting requirementsEffective protectionNon-macromolecular adhesive additivesAdhesiveUltimate tensile strength

The invention relates to the field of a potting adhesive and particularly relates to a low-viscosity heat-conduction electronic potting adhesive applicable to each electronic element and a preparation method thereof. The heat-conduction electronic potting adhesive is formed by a component A and a component B in a weight ratio from 100: 90 to 100: 110; the component A comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 0.80-2.00% of color matching agent, 0.40-1.00% of silane coupling agent, 16.20-43.80% of liquid silicon oil and 3.00-14.50% of silane cross-linking agent; and the component B comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 18.00-57.80% of liquid silicon oil, 0.20-1.00% of silane coupling agent, 1.00-1.96% of color matching agent and 0.04-1.00% of catalyst. The low-viscosity heat-conduction electronic potting adhesive has lower viscosity, excellent mobility, good heat-conduction performance and high inflaming retarding grade; the potting requirement of a seam less than 0.02 mm can be met and the construction is convenient; and after the heat-conduction electronic potting adhesive is cured, the strength is good, and the dustproof, moisture-proof and vibration-proof performances are good, the electronic element can be effectively protected and the service life of the electronic element is prolonged.

Owner:YANTAI DARBOND TECH

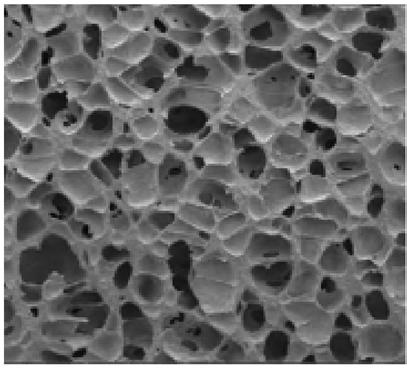

Mico-crosslinking thermoplastic elastomer and preparation method thereof

ActiveCN104356582AKeep for recyclingLower vulcanization temperatureFoaming agentThermoplastic elastomer

The invention relates to the technical field of high-molecular materials, and provides a mico-crosslinking thermoplastic elastomer and a preparation method thereof. The mico-crosslinking thermoplastic elastomer comprises the following components: a styrene type thermoplastic elastomer, synthetic rubber, white mineral oil, a foaming agent, a crosslinking agent, an antioxidant, a light stabilizer, zinc oxide, zinc stearate, abrasion-resistant agent and nano calcium carbonate. The preparation method comprises the following steps: placing the component materials into an internal mixer, and carrying out internal mixing for 10-15 minutes; controlling discharge temperature at 130-135 DEG C; then pressing into a uniform flaky shape by virtue of a double-roller open mill for discharge; finally cutting a material into a specified dimension, placing into a large-flake vulcanizing machine, carrying out vulcanizing forming, and controlling vulcanizing temperature at 170-175 DEG C and vulcanizing time at 180-350 seconds so as to obtain the mico-crosslinking thermoplastic elastomer. The mico-crosslinking thermoplastic elastomer disclosed by the invention has the characteristics of low density, high abrasion resistance, uniformity in froth, good low temperature flexibility, dimensional stability and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Ultralight graphene rubber foaming colloidal particles for shoe soles and preparation method thereof

InactiveCN109627512AImprove thermal stabilityImprove wear resistanceSolesRubber materialPolymer science

The invention relates to ultralight graphene rubber foaming colloidal particles for shoe soles. The colloidal particles are prepared from, by weight, 60-65 parts of natural rubber, 8-12 parts of isoprene rubber, 8-12 parts of butadiene rubber, 6-8 parts of butadiene styrene rubber, 0.8-1.0 part of modified graphene, 0.08-0.12 part of poly N-vinyl acetamide, 0.8-1.0 part of silicone oil, 3.0-3.5 parts of inorganic nanoparticles, 1.2-1.5 parts of activated zinc oxide, 0.8-1.0 part of zinc stearate, 1.0-1.2 part of stearic acid, 0.8-1.0 part of a cross-linking agent, 2.0-3.0 parts of a flow assistant and 1.5-1.8 parts of a foaming agent. By adopting the ultralight graphene rubber foaming colloidal particles, the modified graphene is uniformly dispersed in all rubber materials, the rubber foaming colloidal particles have good heat stability, good abrasive resistance performance and good stretching intensity, the permanent compression deformation performance and the heat resistance shrinkage performance are improved, and 50% or above weight can be reduced.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Production method for sealing gasket

InactiveCN103057238AIncrease elasticityImprove plasticityLaminationLamination apparatusFiberVulcanization

The invention discloses a production method for a sealing gasket, which is characterized by comprising the following steps of: 1, according to a prescription, stirring graphite powder, rubber, reinforced fibres and an antiager in a stirrer, uniformly mixing, and then discharging; 2, adding an accelerant in the mixture after discharging, uniformly mixing, then placing the mixture in a mould, and tabletting at normal temperature; 3, adding a metal layer between two tablets to form a composite tablet, and performing rolling vulcanization on the composite tablet in a vulcanization machine having a vulcanization temperature which is controlled to be 165-200 DEG C, so as to obtain a semi-finished product; and 4, stamping the semi-finished product after vulcanization into the needed sealing gasket, namely, the finished product. Compared with the prior art, the production method disclosed by the invention has the advantages that the production process is simple, and the operation is safe and convenient; natural rubber is high in elasticity, so that the produced sealing gasket is good in elasticity and plasticity, and resistant to corrosion and wear; and the sealing gasket is not easy to age via the rolling vulcanization.

Owner:DAISHAN WEIER SEALING MEMBER CO LTD

Radiation sulfidization processing method for rubber

The present invention relates to the application of high energy radiation technology for vulcanizing rubber, and is especially rubber radiation vulcanizing process. Raw rubber material, compounding material, stuffing and vulcanizing agent are first mixed in a double roll blending mill or a Banbury mixer to un-vulcanized rubber shapes. The un-vulcanized rubber shapes are then radiation vulcanized to form radiation vulcanized rubber, or radiation vulcanized before or after being heated and vulcanized chemically to form mixed vulcanized rubber. The present invention can provide rubber product with excellent ozone tolerance, high chap tolerance, high heat resistance and good mechanical performance, and has the advantages of saving in energy, saving in material, short vulcanizing period and high vulcanizing quality.

Owner:QINGDAO UNIV OF SCI & TECH

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

Golf ball

InactiveUS6943208B2Easy extrusionIncrease elasticityFibre treatmentOrganic dyesProcedure AgentsPolymer science

A golf ball is characterized by comprising a molded and vulcanized product of a rubber composition as a constituent component, the rubber composition comprising 100 pbw of a base rubber composed primarily of a polybutadiene containing at least 60 wt % of cis-1,4-bond, having a Mooney viscosity (ML1+4, 100° C.) of at least 30, and synthesized using a rare-earth catalyst, 15-50 pbw of an unsaturated carboxylic acid and / or a metal salt thereof, at least 2 pbw of a processing aid having a highest melting point of up to 115° C., and at least two organic peroxides including an organic peroxide having the shortest half-life at 155° C. designated (a) and another organic peroxide having the longest half-life at 155° C. designated (b), a ratio of half-lives (bt / at) being at least 7 wherein at is the half-life of (a) and bt is the half-life of (b), a total content of the organic peroxides being 0.1-0.9 pbw per 100 pbw of the base rubber.

Owner:BRIDGESTONE SPORTS

Method for circularly and rapidly pre-vulcanizing sulfur tolerant shift catalyst and carrying out segmental pre-vulcanizing by utilizing sulfur tolerant shift catalyst

ActiveCN103657741AThe vulcanization method is simpleHeating up fastCatalyst activation/preparationSocial benefitsVulcanization

The invention relates to a segmental pre-vulcanizing method of a sulfur tolerant shift catalyst in a multi-segment conversion process, particularly relates to a method for rapidly pre-vulcanizing cobalt-molybdenum-series sulfur tolerant shift catalysts and belongs to the technical field of pretreatment of the sulfur tolerant shift catalyst. According to the method, aiming at the situations of the temperature raising and the slow vulcanizing speed caused due to insufficient vulcanizing conditions, a segmental vulcanizing method is utilized, namely the rapid pre-vulcanizing of a first-segment furnace is reinforced to raise the temperature of a subsequent second-segment furnace; first-segment vulcanizing conditions are reinforced to guarantee the vulcanization of the catalyst so as to realize the rapid, efficient and complete vulcanization, meanwhile, the temperature of a subsequent second-segment bed is raised by high-temperature vulcanized gas in a rapid vulcanizing process, and the subsequent working segments are similarly processed, so that the vulcanizing and temperature raising time is greatly shortened, and the vulcanizing cost is lowered; by utilizing a circular vulcanizing manner, the emptying quantity is few, the overtemperature is avoided, the vulcanizing process is convenient and safe, the pollution is light, and the method has remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

High-dispersity white carbon black and preparation method thereof

ActiveCN107697921ADoes not affect the BET specific surface areaGood dispersionSilicon compoundsDispersityAlcohol

The invention provides high-dispersity white carbon black and a preparation method thereof. The preparation method comprises the following steps: (1) heating water, adding water glass, then adding ethyl alcohol, and mixing the water, the water glass and the ethyl alcohol to obtain a reaction base solution, wherein the temperature in the whole process does not change, the concentration of the waterglass is 0.01 to 1.00 mol / L, and the mass percentage of the ethyl alcohol is 0.1 to 5 weight percent; (2) simultaneously adding acid and water glass into the reaction base solution for mixing for reaction, thereby obtaining white carbon black suspension, wherein the reaction temperature is kept constant and is equal to that of the reaction base solution, and the concentration of the water glass is kept constant and is equal to that of the reaction base solution; (3) stopping adding the water glass into the white carbon black suspension, and independently adding acid to adjust the pH of a reaction system to 3.0 to 5.0, thereby obtaining acidified white carbon black suspension; (4) carrying out solid-liquid separation on the acidified white carbon black suspension to obtain a filter cake, thereby obtaining the white carbon black. The white carbon black provided by the invention is extremely high in dispersivity, and shows a good rubber reinforcing effect.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Preparation method for novel rubber strip for sealing of automobile doors and windows and product

The invention relates to a preparation method for a novel rubber strip for sealing of automobile doors and windows and a product. The preparation method employs ethylene propylene diene monomers as basic materials with cooperation of certain amounts of carbon black, calcium carbonate, paraffin oil, zinc oxide, stearic acid, polyvinyl alcohol, high-molecular wax, compound antioxidants, dispersants, compound accelerants, vulcanizing agents, fire retardants and the like. The above materials are subjected to mixing, open milling and vulcanization technologies to obtain the rubber strip. The preparation method has advantages of simple formula, simple production technology, short vulcanizing time, high production efficiency, relatively low production cost, easy industrialization enforcement and the like. The rubber product for sealing is advantaged by good sealing performance, uniform structure, resistance to corrosion, resistance to high and low temperature, flame resistance, environment protection and comfort.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

Preparation method of hydrophobic white carbon black

The invention provides a preparation method of hydrophobic white carbon black. The preparation method includes following steps: 1), allowing hydrolysis reaction: mixing silane coupling agent-vinyltriethoxysilane, organic solvent and water for hydrolysis reaction to obtain silane coupling agent hydrolysate, wherein the organic solvent comprises n-heptane and alcohol; 2), allowing modifying reaction: using an atomizer to atomize the silane coupling agent hydrolysate obtained in the step 1), mixing with white black carbon, drying an obtained mixture, and heating for modifying reaction to obtain the hydrophobic white carbon black. The preparation method is simple in preparation process, little in equipment investment, short in production period, high in labor production efficiency and easy forindustrialization and has high technical economic efficiency; the hydrophobic white carbon black is good in mechanical performance and high in hydrophobicity and can well improve processability of rubber when being applied to butadiene styrene rubber, vulcanizing time is shortened, mechanical performance of vulcanized rubber is improved, and wear resistance of rubber is enhanced.

Owner:WUXI HENGCHENG SILICON IND CO LTD

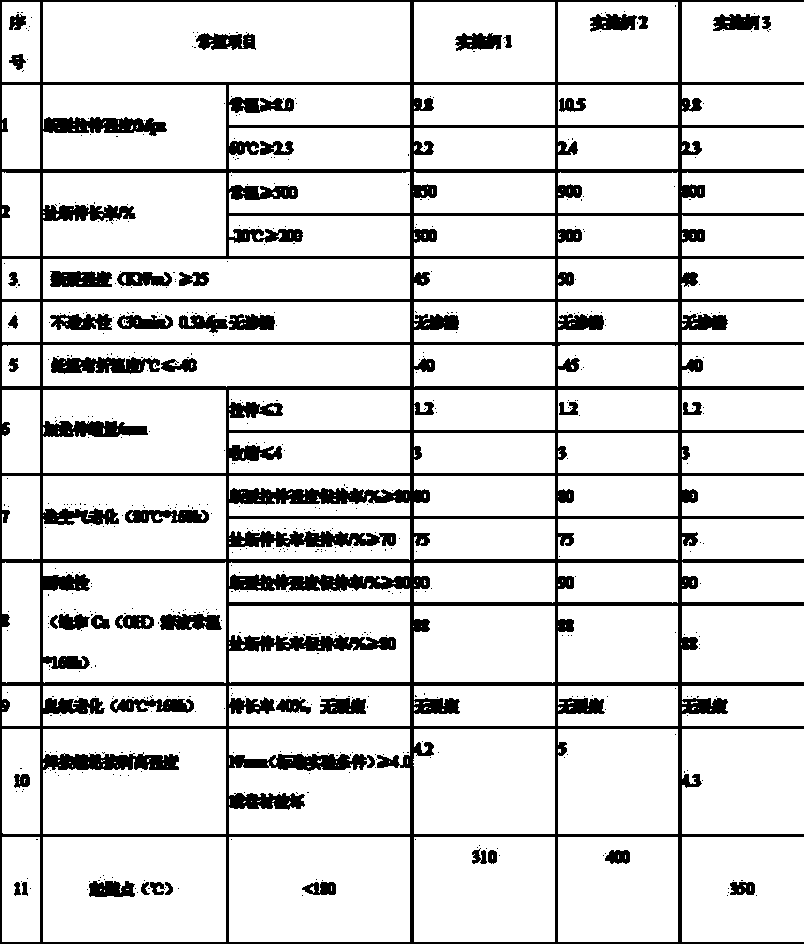

Ethylene-propylene-diene monomer rubber waterproof roll and production method thereof

The invention discloses an ethylene-propylene-diene monomer rubber waterproof roll. The ethylene-propylene-diene monomer rubber waterproof roll is prepared from the following raw materials in parts by weight: ethylene-propylene-diene monomer rubber, DOP (Dioctyl-Phthalate) thermal welding agent, carbon black, light calcium carbonate, stearic acid, zinc oxide, rubber accelerator, sulfur, processing oil, fire-retardant plasticizer, chlorinated polyethylene (CPE), white carbon black and rubber accelerator tetramethyl thiuram disulfide (TMTD). A production method of the ethylene-propylene-diene monomer rubber waterproof roll comprises the steps of banburying, filtering, compounding, thermal cracking, calendering, rolling, vulcanization and packaging. The ethylene-propylene-diene monomer rubber waterproof roll produced by the method has good ageing resistance, small possibility of cracking and good waterproof effect and has an inflaming retarding function, the initiation temperature exceeds 300 DEG C, and the ethylene-propylene-diene monomer rubber waterproof roll has no water-permeating phenomenon through permeable experiments.

Owner:WEIFANG ZHENGTAI WATERPROOF MATERIAL

Process for producing ageing-resistant tire bladder sizing material

InactiveCN104017280AImprove thermal stabilityImprove antioxidant capacityMicrocrystalline waxProcess engineering

The invention discloses a process for producing an ageing-resistant tire bladder sizing material. The process comprises the steps of (1) respectively weighing chlorinated butyl rubber and chloroprene rubber, adding the rubber into an internal mixer, mixing for 1-1.5 minutes, then adding butyl rubber, performing primary mixing, adding zinc oxide, microcrystalline wax and carbon black after 2-3 minutes, mixing for 3-5 minutes, adding castor oil, mixing, discharging the rubber after 3-4 minutes, and performing open mixing; (2) filtering the primary mixed rubber in a rubber filter; (3) adding the filtered mother rubber into the internal mixer, performing secondary mixing, adding a vulcanizing agent after mixing for 1-2 minutes, and discharging the rubber after 1-2 minutes; (4) extruding the secondary mixed rubber into a shape required by a die pressing vulcanizing machine or an injection vulcanizing machine by adopting a cold feed extruder. The process disclosed by the invention is improved from the formula and the production process, so that the production efficiency of bladders is greatly improved, the problems of surface cracking, seam allowance cracking and short service life of a finished product under severe use conditions are solved, the qualification rate of the bladder product is greatly improved, and the service life of the bladder product is greatly prolonged.

Owner:东营金泰轮胎胶囊有限公司

Antiskid wear-resistant sole material and preparation method thereof

The invention discloses an antiskid wear-resistant sole material which comprises 15-20% of natural 3L rubber, 10-20% of butyl rubber, 10-15% of styrene butadiene rubber, 5-10% of short fiber, 10-15% of carbon black, 10-15% of white carbon black (SiO2), 1-2% of stearic acid (SA), 2-3% of paraffin oil, 2-3% of bis-silane tetrasulfide (Si-69), 3-6% of sulfur (S), 1-2% of an active agent, 0.5-0.7% of an antioxidant, 3-5% of zinc oxide (ZnO), 0.3-0.5% of magnesium oxide, 1-2% of an accelerant and 1-3% of a filler. According to the antiskid wear-resistant sole material disclosed by the invention, the antiskid coefficient of the sole is improved, the loss index of the obtained material is low, and the abrasion property and tear resistance are strong. The antiskid wear-resistant sole material has relatively good wear resistance and puncture resistance, improves the comfort and safety of the mountain climbing fitness exercise, prolongs the service life of shoes to a certain degree, and has a broad market application prospect.

Owner:朱伟萍

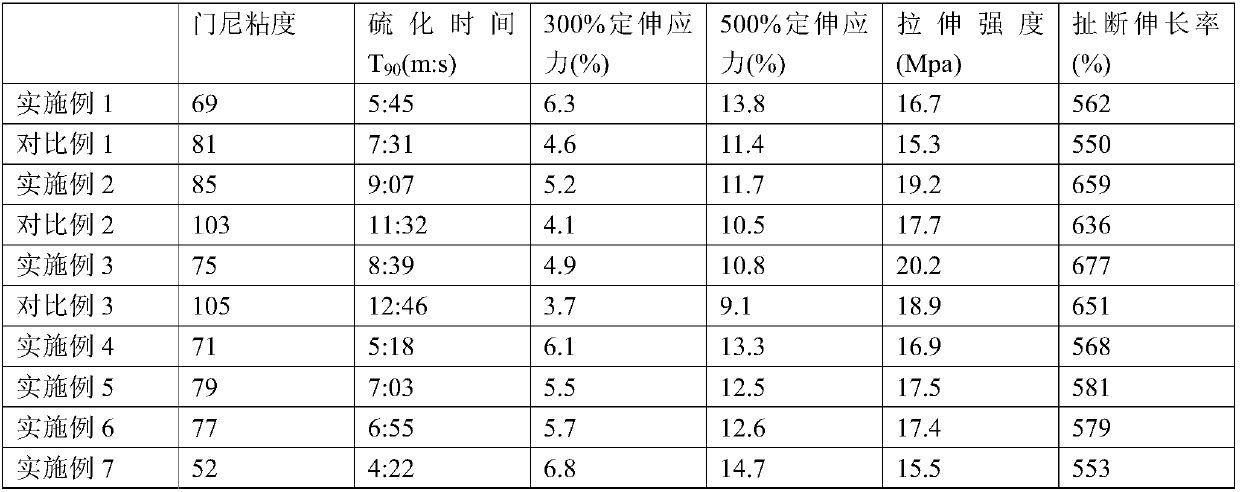

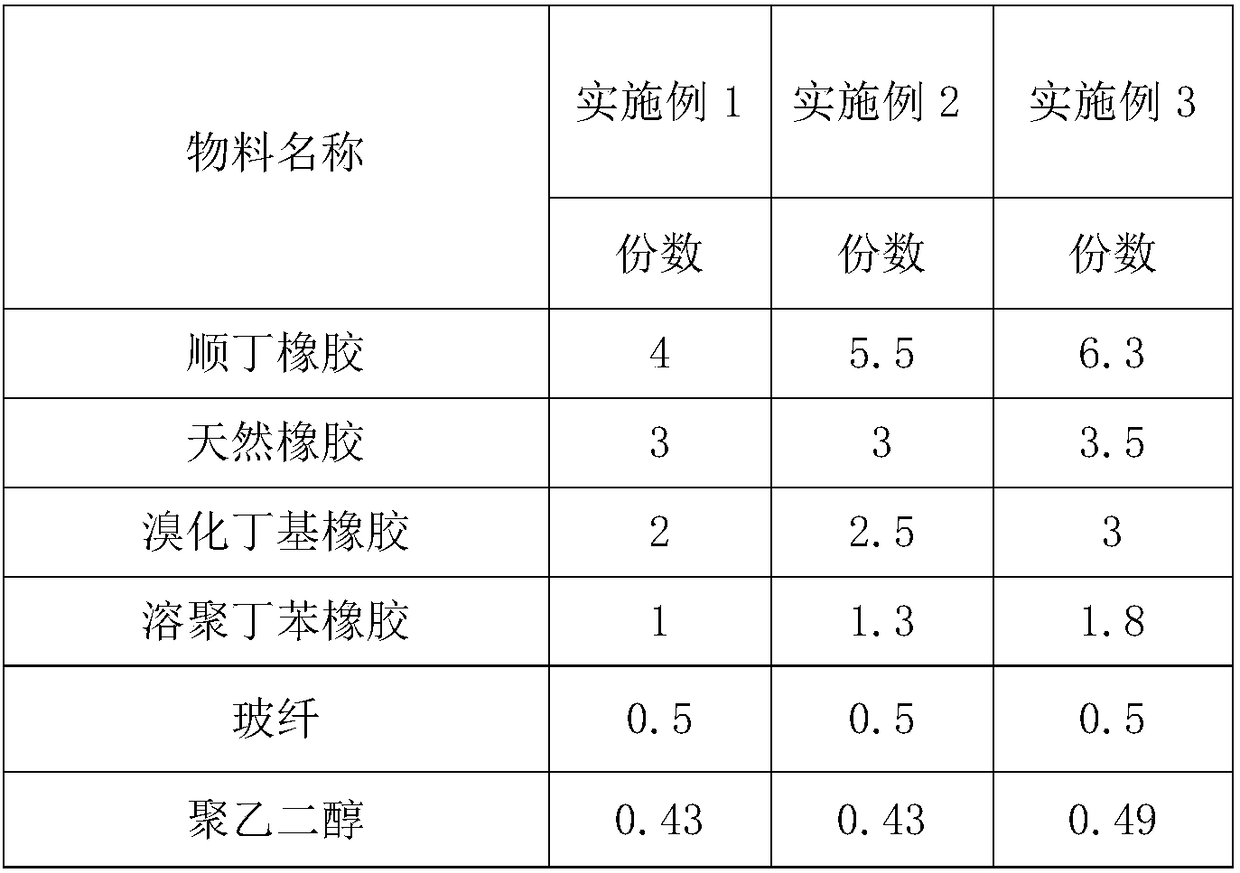

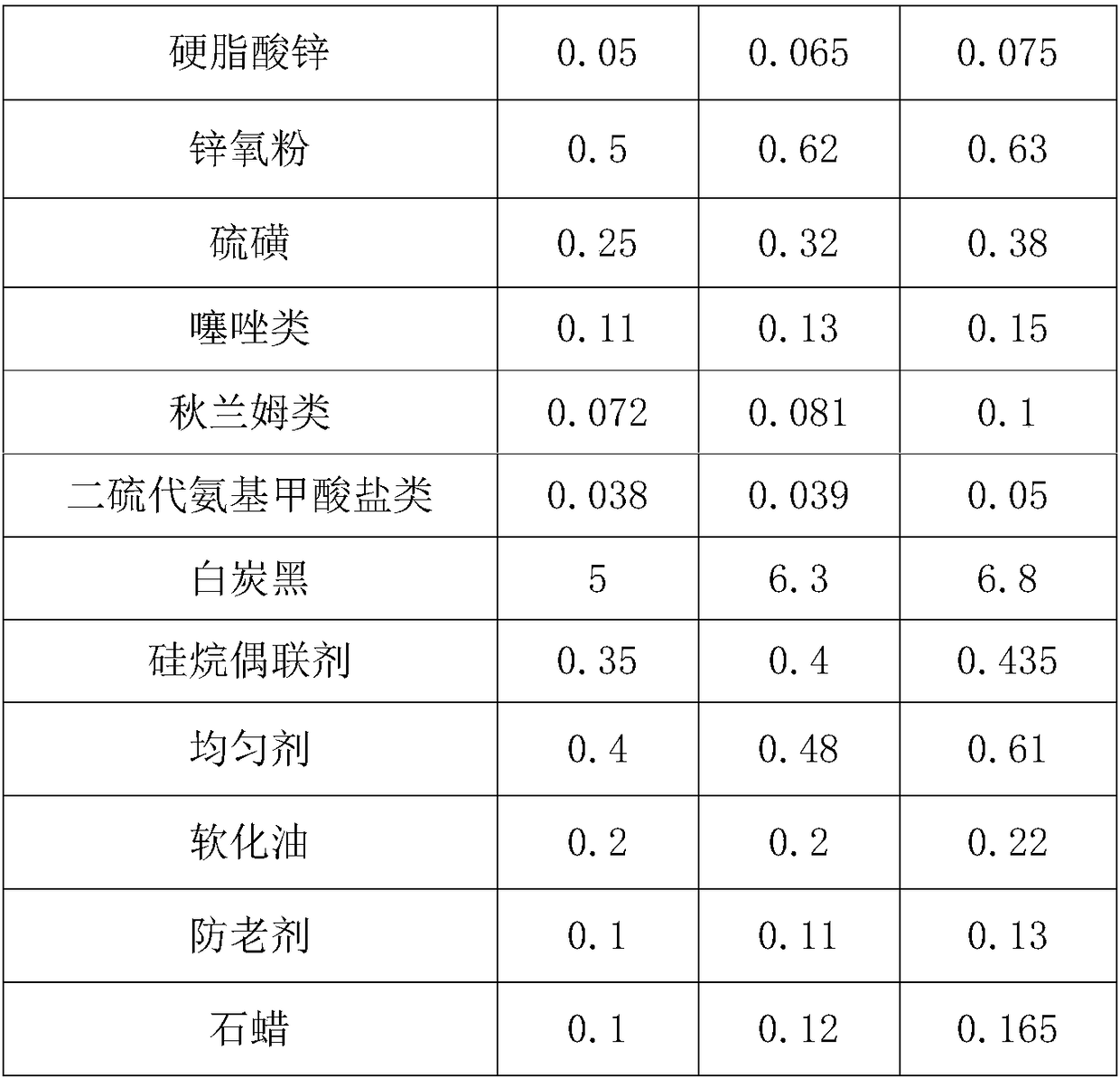

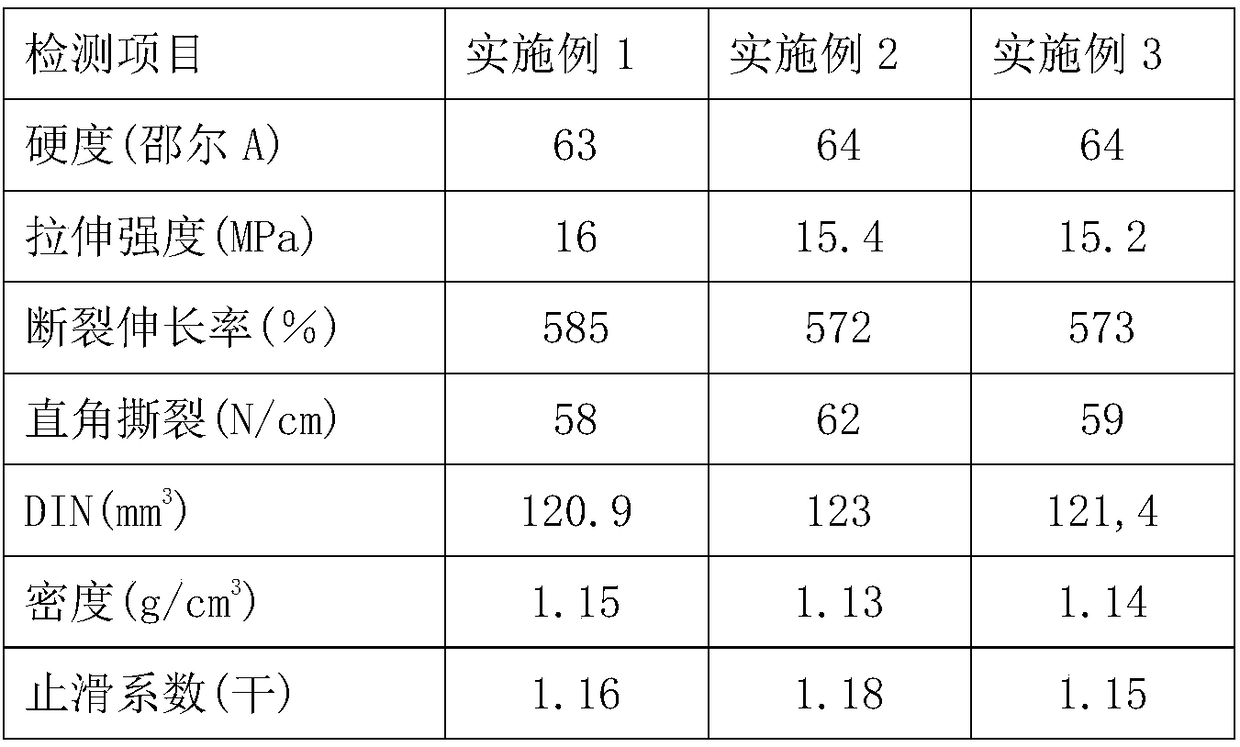

Rubber for sports shoe soles and preparation method thereof

InactiveCN108192163AImprove physical strengthGood vibration damping performanceSolesChemistryButadiene-styrene rubber

The invention discloses rubber for sports shoe soles. The rubber for the sports shoe soles comprises the following components in parts by mass: 30-70 parts of butadiene rubber, 20-40 parts of naturalrubber, 15-30 parts of brominated butyl rubber, 10-20 parts of solution-polymerized styrene-butadiene rubber, 5-10 parts of glass fiber, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate,2-5 parts of zinc oxide powder, 2.5-4 parts of a vulcanizing agent, 1.5-2.5 parts of an accelerator, 30-50 parts of white carbon black, 3-4.5 parts of a silane coupling agent, 4-7 parts of a homogenizing agent, 2-5 parts of softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the rubber for the sports shoe soles. Rubbershoe soles for sports shoes, prepared according to the technical scheme adopted by the invention, have many properties such as super wear resistance, good folding resistance and anti-slip performance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

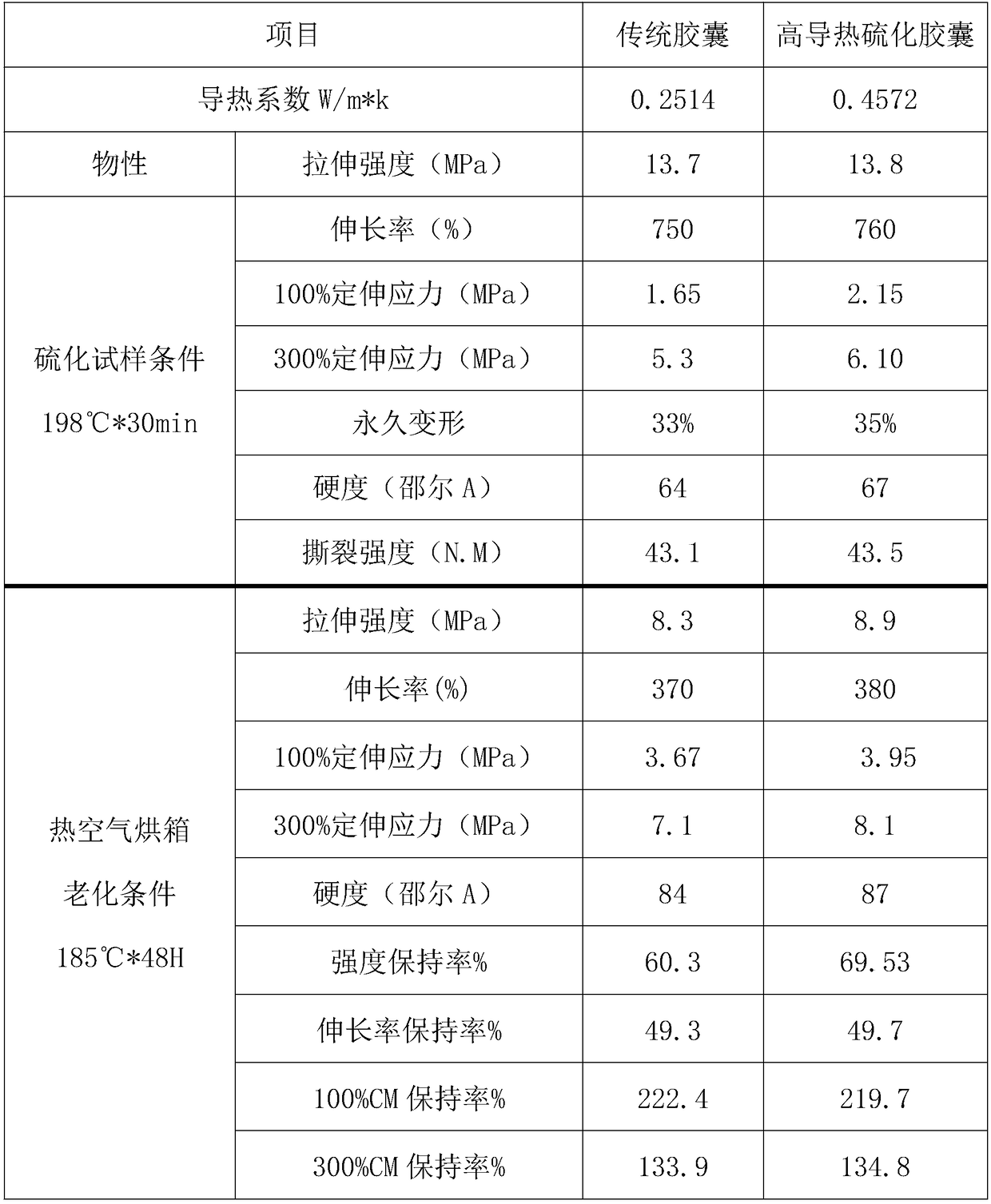

Processing method of heat conducting capsules

InactiveCN101280178AFast heat conductionShorten vulcanization timeHeat-exchange elementsCarbon blackZinc

The invention relates to the machining method of a heat conduction tire bladder. The technical proposal of the invention includes the steps of mixing the materials, milling, extruding and forming, adhesive drying, vulcanization, edging and examination; wherein, the composition of the raw materials and the weight ratio are adjusted to: 50-67 portions of butyl rubber, 2-4 portions of chloroprene rubber, 2-4 portions of zinc dioxide, 1-2 portions of static agent, 8-15 portions of carbon black, 15-25 portions of acetylene carbon black, 1-3 portions of thermal conduction agent, 2-3 portions of castor oil and 4-5 portions of WS resin. The machining method of the heat conduction tire bladder has the advantages of (1) indicated in the thermal conduction experiment and compared with the common capsule, the thermal conduction speed is increased by 4 DEG C; (2) indicated in the client application experiment, the service life is increased by 15% generally due to the fast thermal conduction speed and the shortened vulcanization time; (3) the tire vulcanization time is shortened; the production efficiency of tires is improved; the cost is reduced by 5% for the tire manufacturer; (4) because the thermal conduction is fast, the preheating speed is increased when the new tire bladder is in use, the quality of the tire is ensured to be more stable.

Owner:东营金泰轮胎胶囊有限公司

Low hydroxyl content white carbon black and preparation method thereof

The invention relates to a low hydroxyl content white carbon black and a preparation method of the low hydroxyl content white carbon black. The preparation method comprises the following steps: 1) preparing a reaction base solution with the pH of 7.0-10.5 at the temperature of 65-99 DEG C; 2) adding concentrated sulfuric acid and a sodium silicate solution to conduct a precipitation reaction, wherein the temperature of the precipitation reaction and the temperature of the reaction base solution are the same, keeping the pH of a system to 7.0-10.5 constant; 3) regulating the pH and post-processing to obtain the white carbon black. The white carbon black is low in hydroxyl content, the density of hydroxyl is less than 3 / nm<2>, the white carbon black is excellent in dispersity, the white carbon black is taken as a reinforcing agent to prepare a rubber, the excellent reinforcing effect is shown, the vulcanizing rate is increased, the vulcanizing time of the rubber material is shortened, and the processing performances and the mechanical property of a rubber compound are improved.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

Novel high-pressure-resistant sealing system for automobile engine and manufacture method thereof

InactiveCN102558717ADimensionally stableReduce pollutionOther chemical processesChemical industryAdhesiveReciprocating motion

The invention relates to a novel high-pressure-resistant sealing system for an automobile engine and a manufacture method thereof. The manufacture method includes: step 1, improving definite elongation of rubber, adjusting proportion of raw materials of the rubber, adjusting a reinforcement system and improving definite elongation of the rubber so as to improve pressure resistance of the rubber by specifically increasing 3-4 parts by weight of white carbon black and reducing1-2 parts by weight of carbon black; and step 2, improving hardness of the rubber and increasing abrasion resistance of the rubber by increasing 30-40 parts by weight of wollastonite. The novel high-pressure-resistant sealing system has the advantages of being stable in size, oil resistant and anti-aging in engine oil, being low in friction factor, slow in temperature rise in unit time and abrasion resistant in valve guide rod reciprocating motion, enabling medium and high pressure resistance of a turbine to be increased, being capable of using environment-friendly adhesive for bonding, reducing pollution on environment, shortening vulcanizing time of an oil seal, saving energy, ensuring sealing reliability, prolonging service life of the oil seal and the like.

Owner:HUNAN MASTER SEALING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com