Rubber for sports shoe soles and preparation method thereof

A technology for soles and rubber, applied in the field of materials, can solve the problems of elasticity, poor weather resistance, general anti-slip effect, poor softness, etc., and achieve low permeability, excellent wet skid resistance, and excellent wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

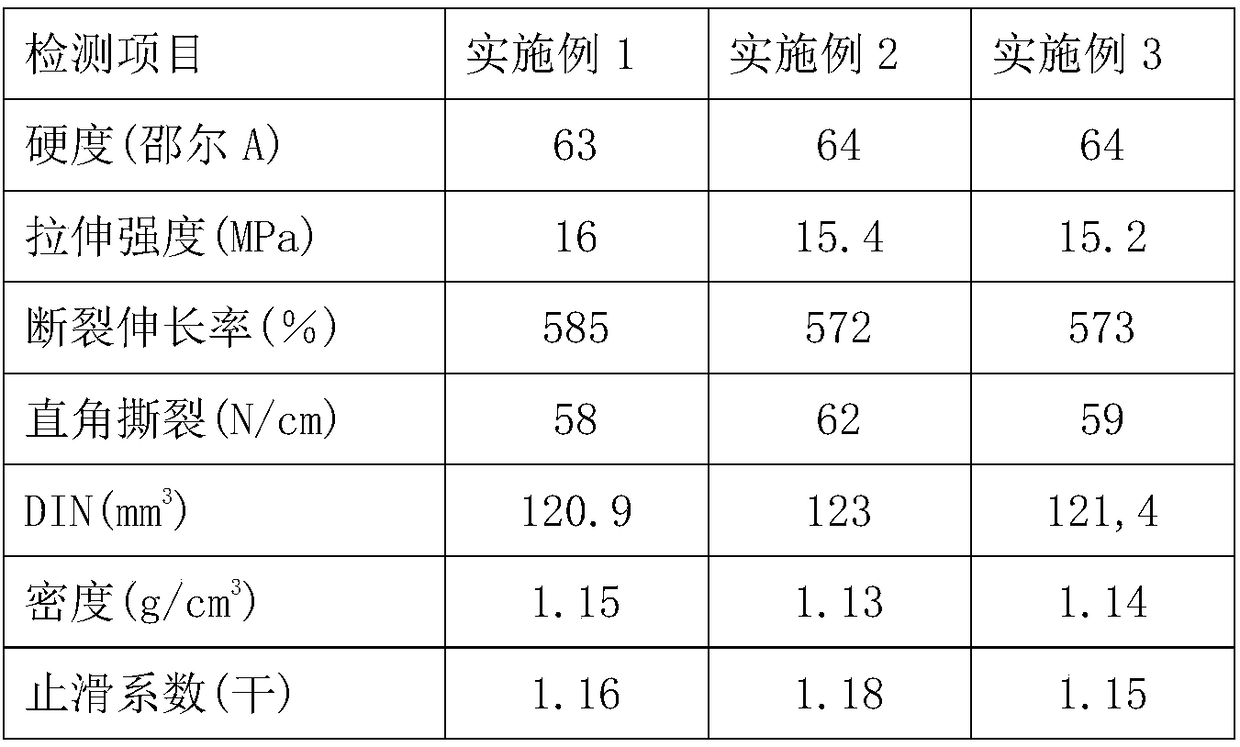

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of rubber for sports shoe sole simultaneously, comprises the following steps:

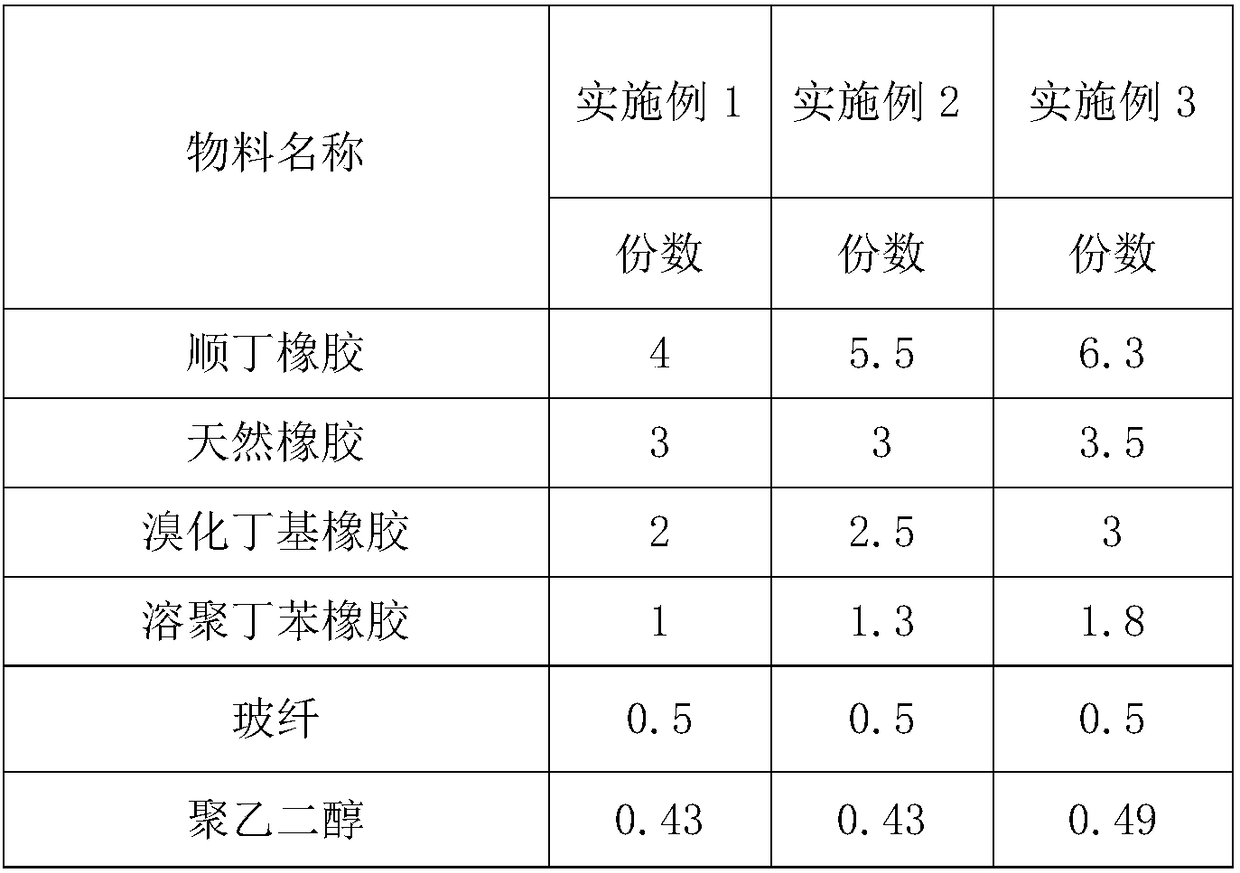

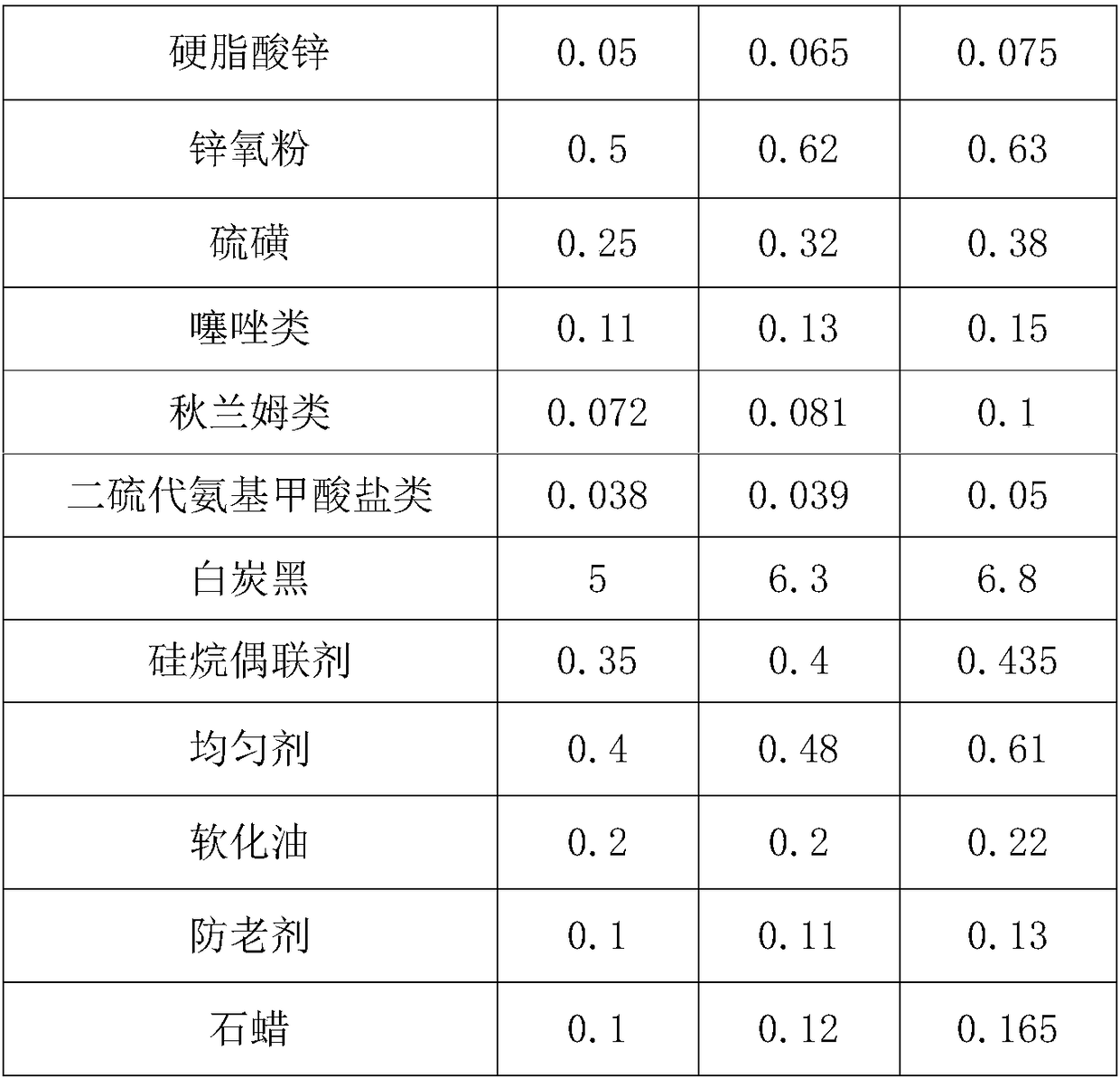

[0029] 1) Weigh the following components by mass: 30-70 parts of butadiene rubber, 20-40 parts of natural rubber, 15-30 parts of brominated butyl rubber, 10-20 parts of solution polystyrene butadiene rubber, 5-10 parts of glass fiber 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 2-5 parts of zinc oxide powder, 30-50 parts of white carbon black, 3-4.5 parts of silane coupling agent, 4-7 parts of leveling agent 2-5 parts of softening oil, 1-3 parts of anti-aging agent and 0.5-1 part of paraffin;

[0030] 2) Pour all the ingredients weighed in step 1) into the internal mixer for mixing, the mixing time is 7-9 minutes, and the temperature is 120-140°C;

[0031] 3) discharging, discharging, and cooling the mixture obtained in step 2);

[0032] 4) Weigh the following components by parts by mass: 2.5-4 parts of sulfur a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com