Ethylene-propylene-diene monomer rubber waterproof roll and production method thereof

A technology of EPDM rubber and waterproof membrane, which is applied in the field of architectural waterproof coatings, and can solve problems such as unsuitability, easy burning of the waterproof layer, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

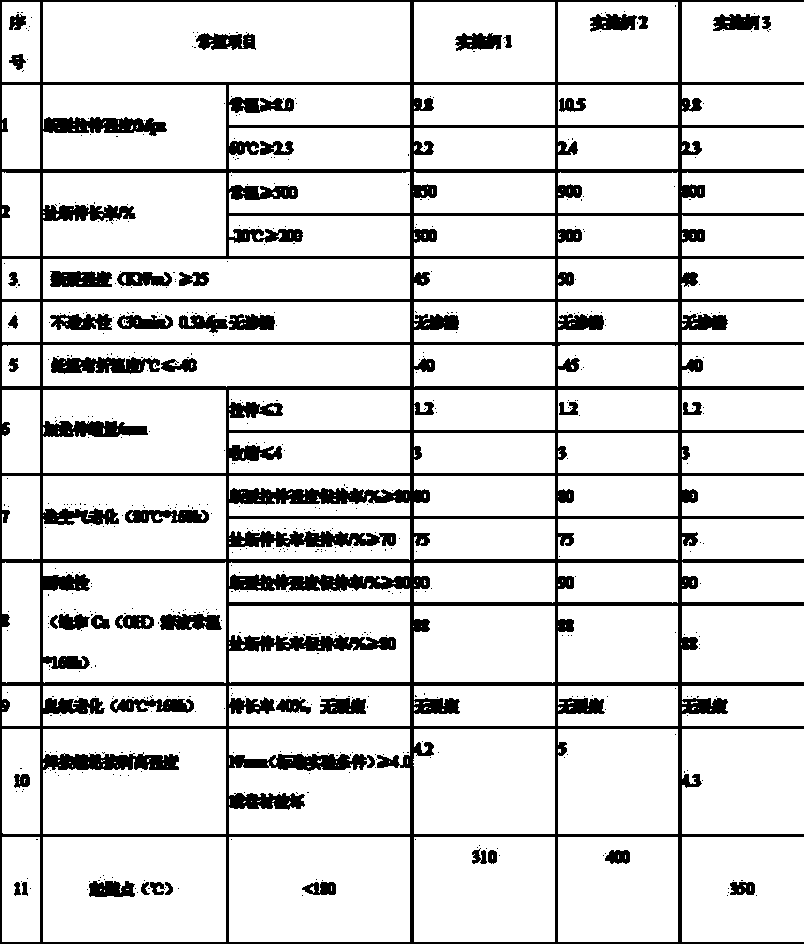

Examples

Embodiment 1

[0037] The EPDM rubber is a copolymerized body of three monomers of ethylene, propylene and diene.

[0038] The flame retardant plasticizer is tricresyl phosphate.

[0039] The processing oil is machine oil.

[0040] A kind of production method of above-mentioned EPDM waterproof coiled material, comprises the steps:

[0041] a. Mixing: 35 parts of EPDM rubber, 2 parts of DOP thermal welding agent, 12 parts of carbon black, 22 parts of light calcium, 7 parts of stearic acid, 1 part of rubber accelerator DM, 1 part of sulfur, and processing oil 30 parts, 8 parts of flame retardant plasticizer, 10 parts of chlorinated polyethylene CPE, 6 parts of white carbon black, 1.5 parts of rubber accelerator TMTD are added to the internal mixer for internal mixing, and the density is controlled by adjusting the steam valve and the circulating water valve. For the mixing temperature and mixing time, the temperature is controlled at about 135-140°C, and the mixing time is 8 minutes.

[004...

Embodiment 2

[0050] The EPDM rubber is a copolymerized body of three monomers of ethylene, propylene and diene.

[0051] The flame retardant plasticizer is tricresyl phosphate.

[0052] The processing oil is engine oil.

[0053] A kind of production method of above-mentioned EPDM waterproof coiled material, comprises the steps:

[0054]a. Mixing: 38 parts of EPDM rubber, 3 parts of DOP thermal welding agent, 15 parts of carbon black, 28 parts of light calcium, 9 parts of stearic acid, 3 parts of rubber accelerator DM, 2 parts of sulfur, and processing oil 40 parts, 10 parts of flame retardant plasticizer, 15 parts of chlorinated polyethylene CPE, 8 parts of white carbon black, 2 parts of rubber accelerator TMTD are added to the internal mixer for internal mixing, and the density is controlled by adjusting the steam valve and the circulating water valve. For the mixing temperature and mixing time, the temperature is controlled at about 135-140°C, and the mixing time is 8 minutes.

[0055...

Embodiment 3

[0063] The EPDM rubber is a copolymerized body of three monomers of ethylene, propylene and diene.

[0064] The flame retardant plasticizer is tricresyl phosphate.

[0065] The processing oil is engine oil.

[0066] A kind of production method of above-mentioned EPDM waterproof coiled material, comprises the steps:

[0067] a. Mixing: 40 parts of EPDM rubber, 5 parts of DOP thermal welding agent, 20 parts of carbon black, 30 parts of light calcium, 13 parts of stearic acid, 5 parts of rubber accelerator DM, 5 parts of sulfur, and processing oil 50 parts, 15 parts of flame retardant plasticizer, 20 parts of chlorinated polyethylene CPE, 10 parts of white carbon black, 5 parts of rubber accelerator TMTD are added to the internal mixer for internal mixing, and the density is controlled by adjusting the steam valve and circulating water valve. For the mixing temperature and mixing time, the temperature is controlled at about 135-140°C, and the mixing time is 8 minutes.

[0068]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com