Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

402results about How to "Lower decomposition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

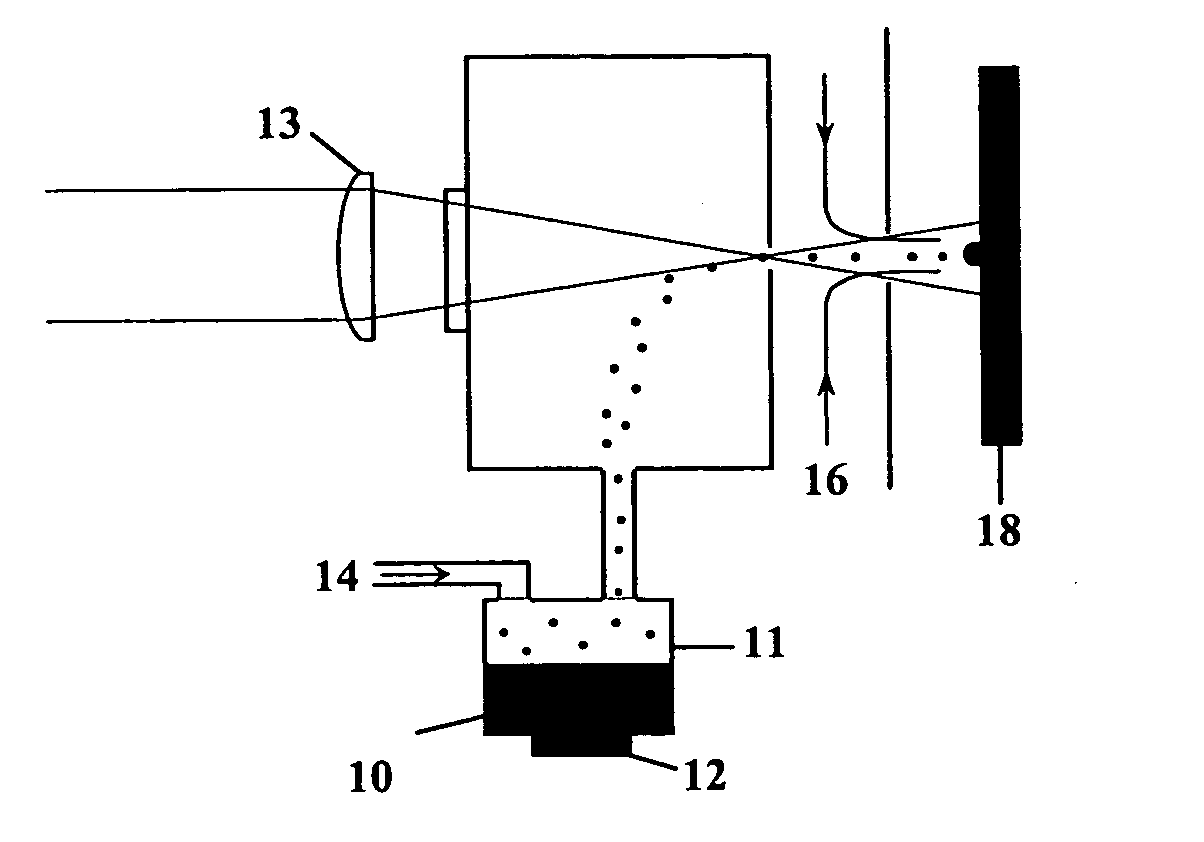

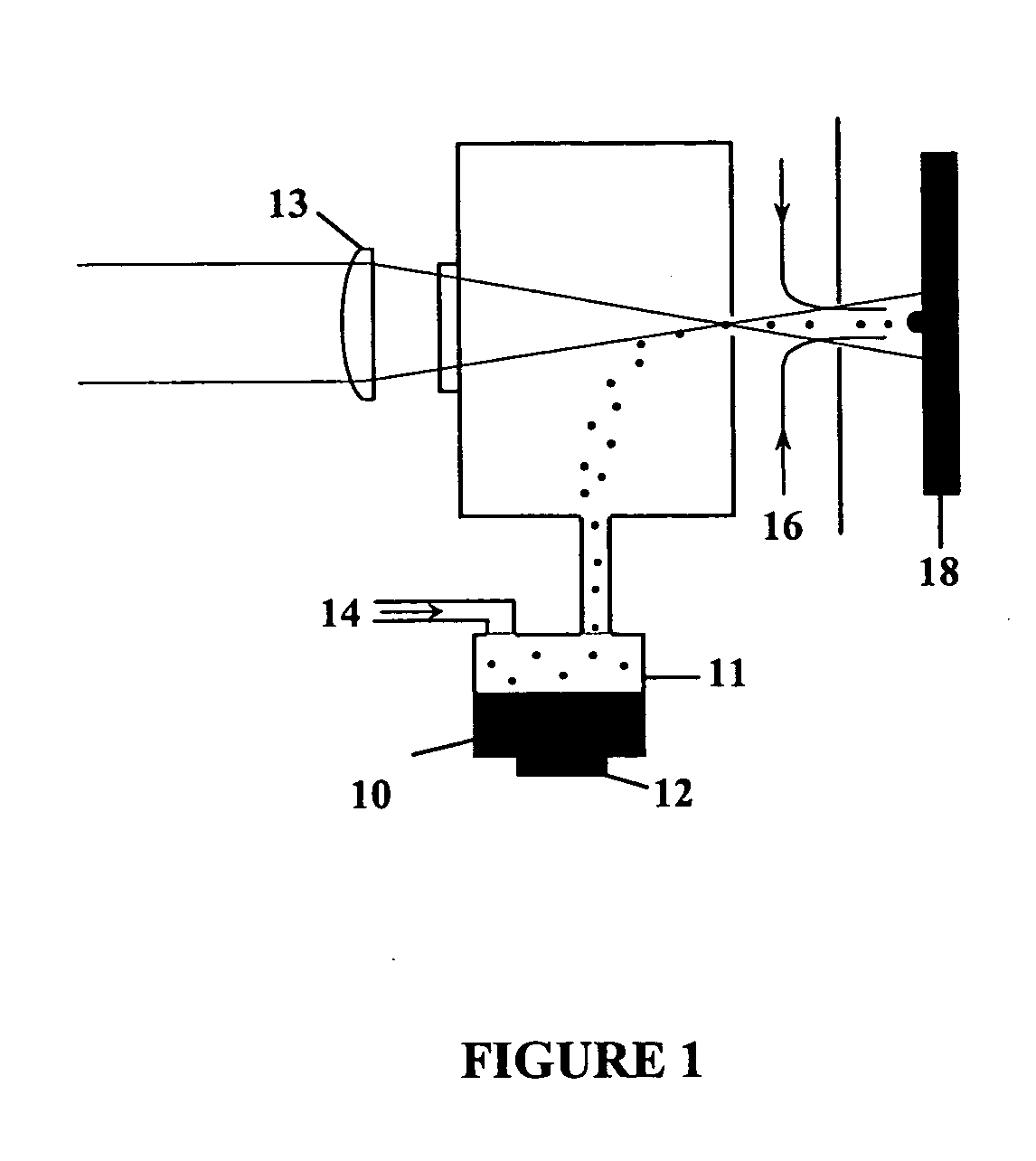

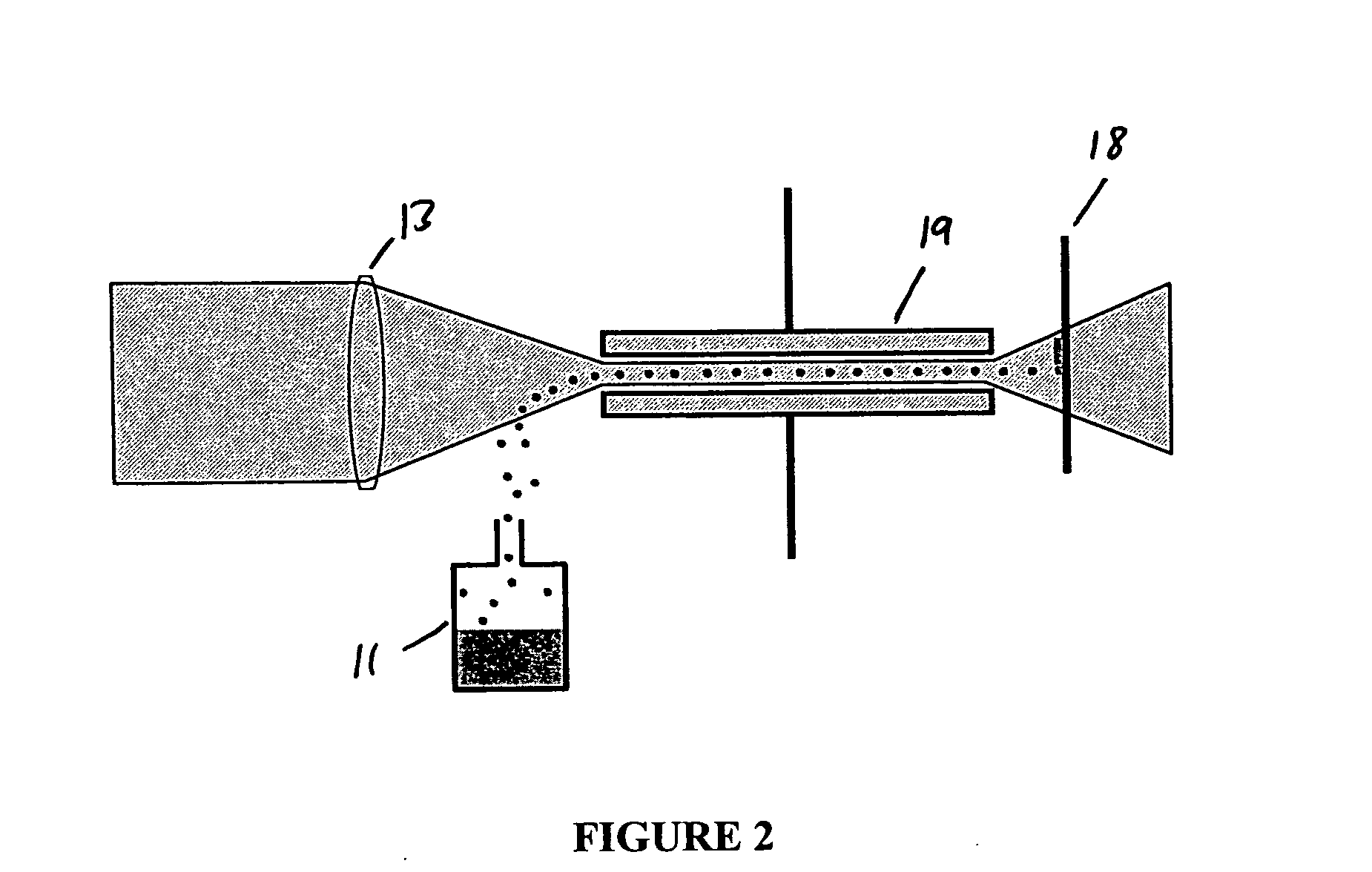

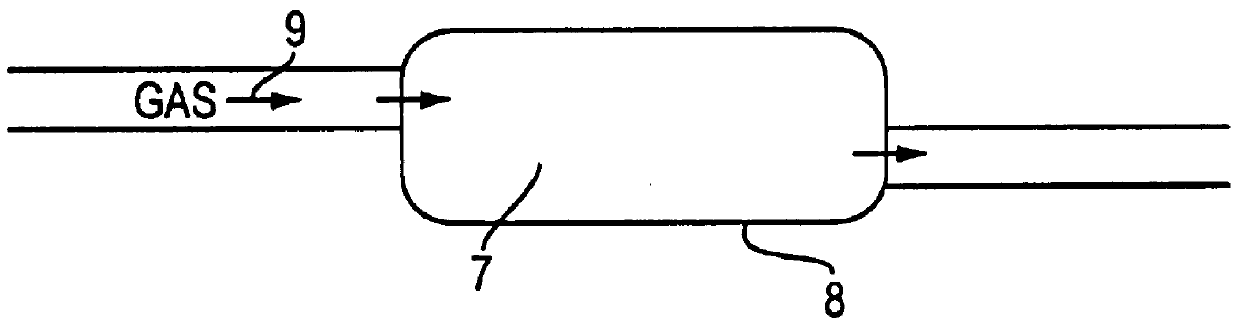

Maskless direct write of copper using an annular aerosol jet

InactiveUS20050156991A1Prevent crystallizationLower decomposition temperatureSolid-state devicesLiquid/solution decomposition chemical coatingLaser processingSource material

Methods and apparatus for the deposition of a source material (10) are disclosed. An atomizer (12) renders a supply of source material (10) into many discrete particles. A force applicator (14) propels the particles in continuous, parallel streams of discrete particles. A collimator (16) controls the direction of flight of the particles in the stream prior to their deposition on a substrate (18). In an alternative embodiment of the invention, the viscosity of the particles may be controlled to enable complex depositions of non-conformal or three-dimensional surfaces. The invention also includes a wide variety of substrate treatments which may occur before, during or after deposition. In yet another embodiment of the invention, a virtual or cascade impactor may be employed to remove selected particles from the deposition stream. Also a method and apparatus for maskless deposition of copper lines on a target, specifically relating to localized solution-based deposition of copper using an annular aerosol jet and subsequent material processing using conventional thermal techniques or laser processing.

Owner:OPTOMEC DESIGN CO

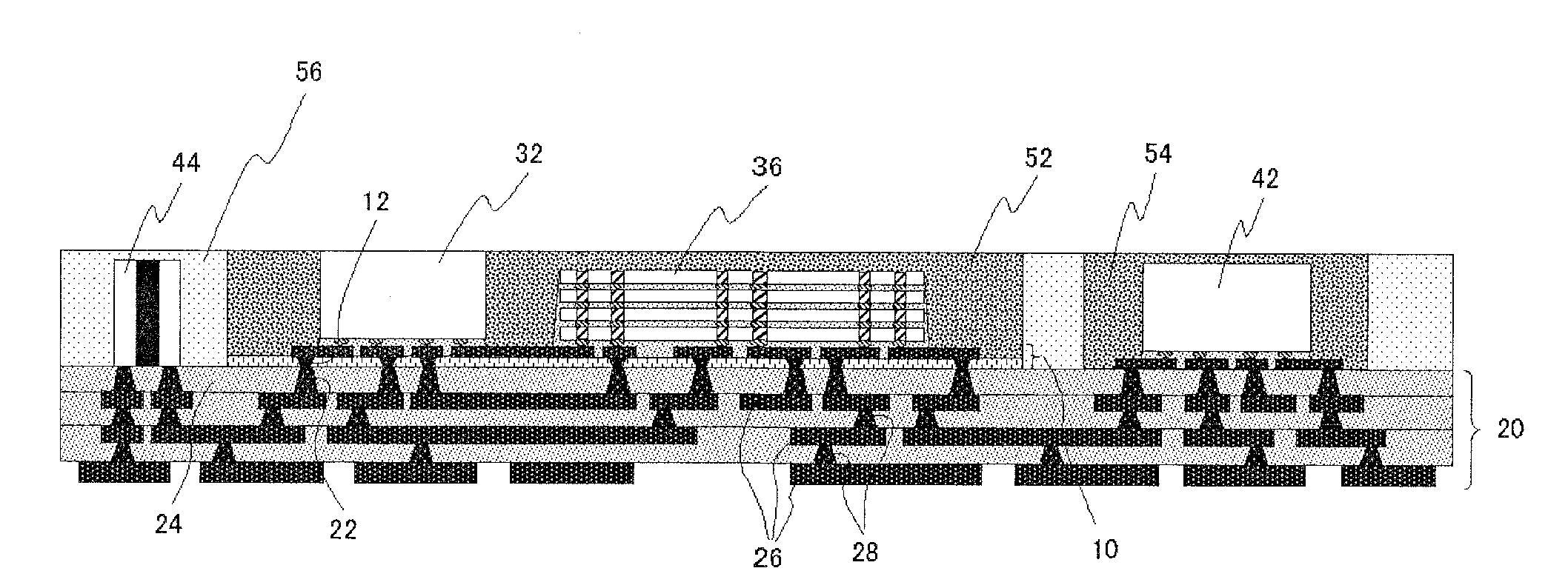

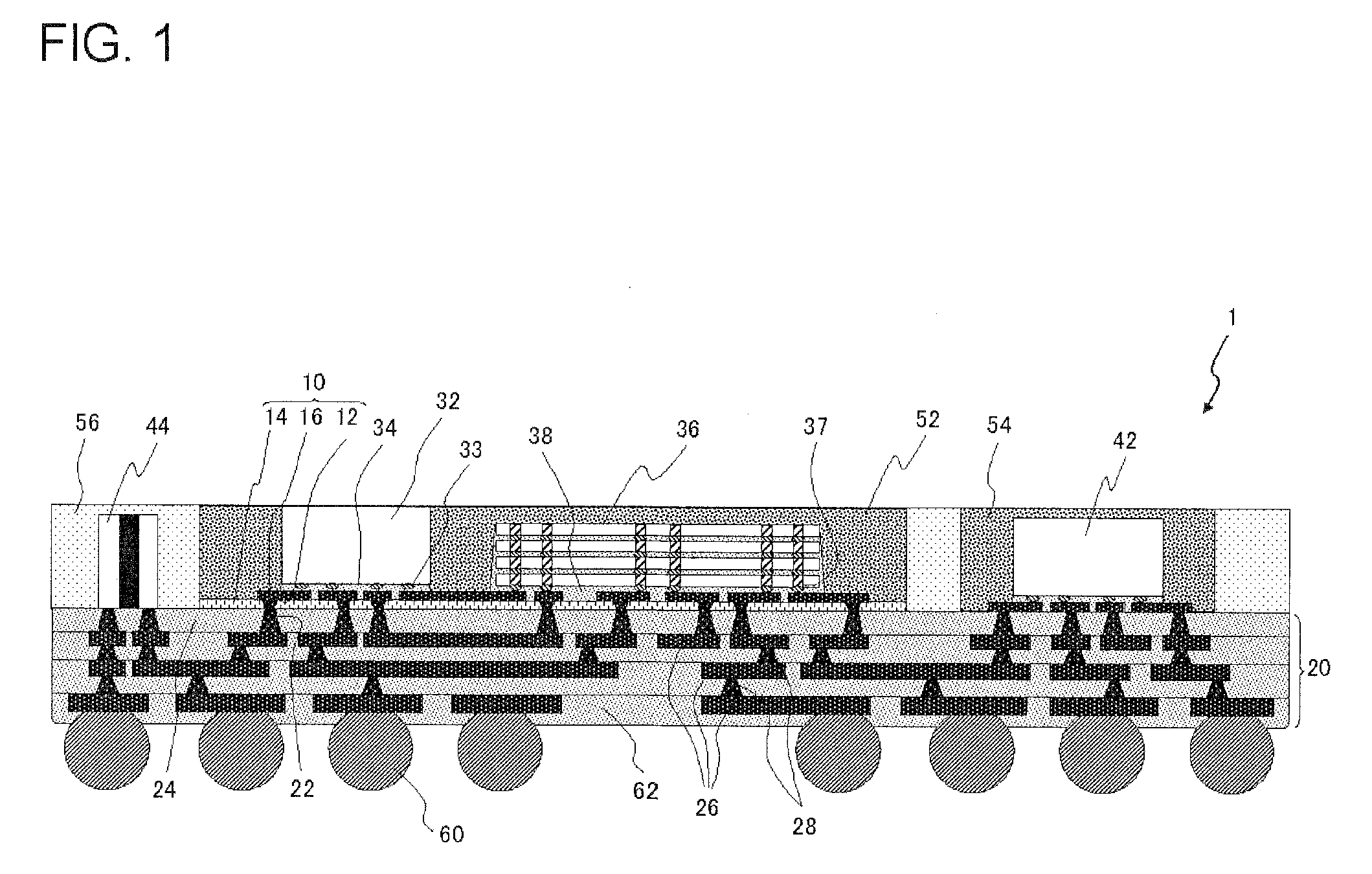

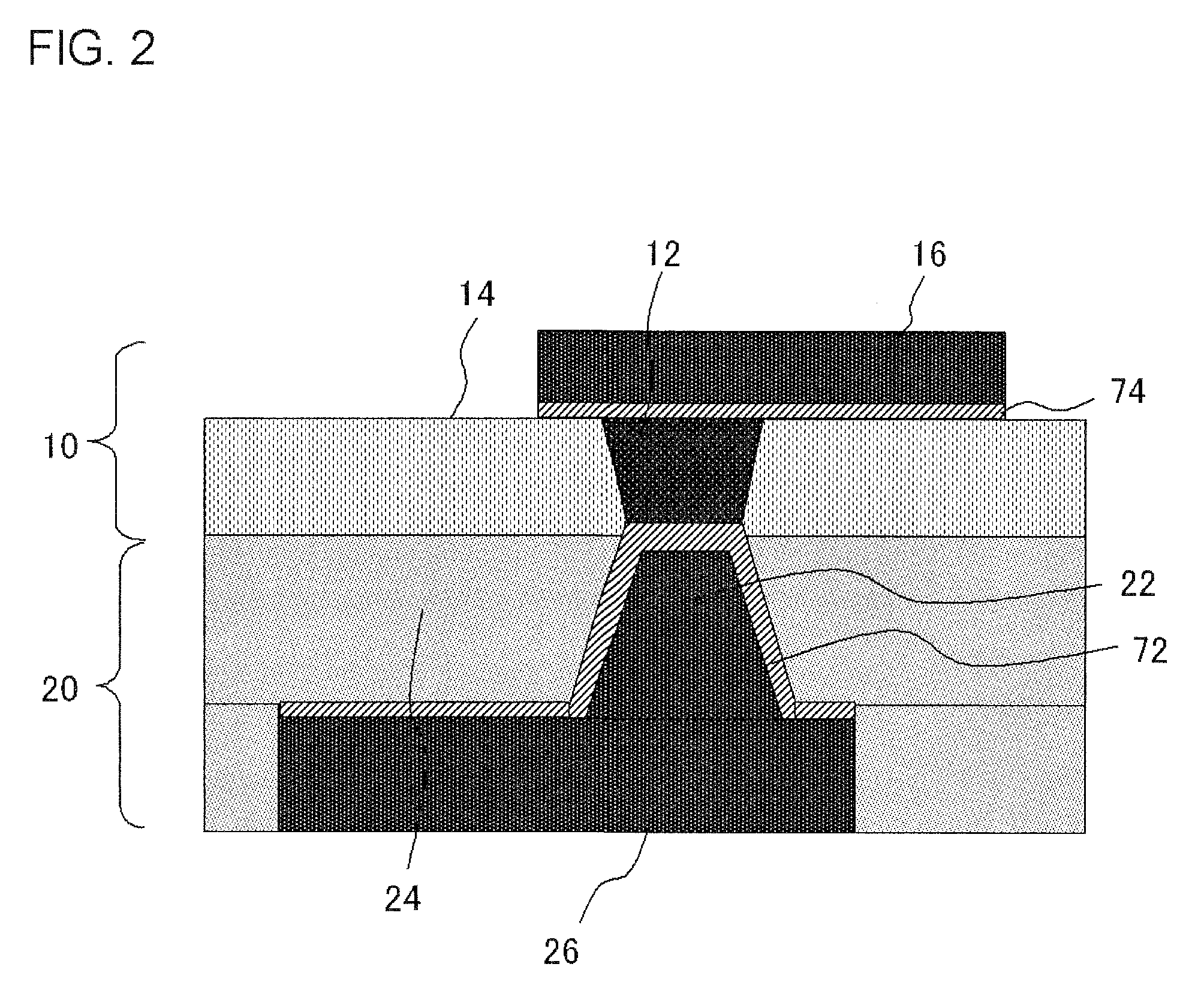

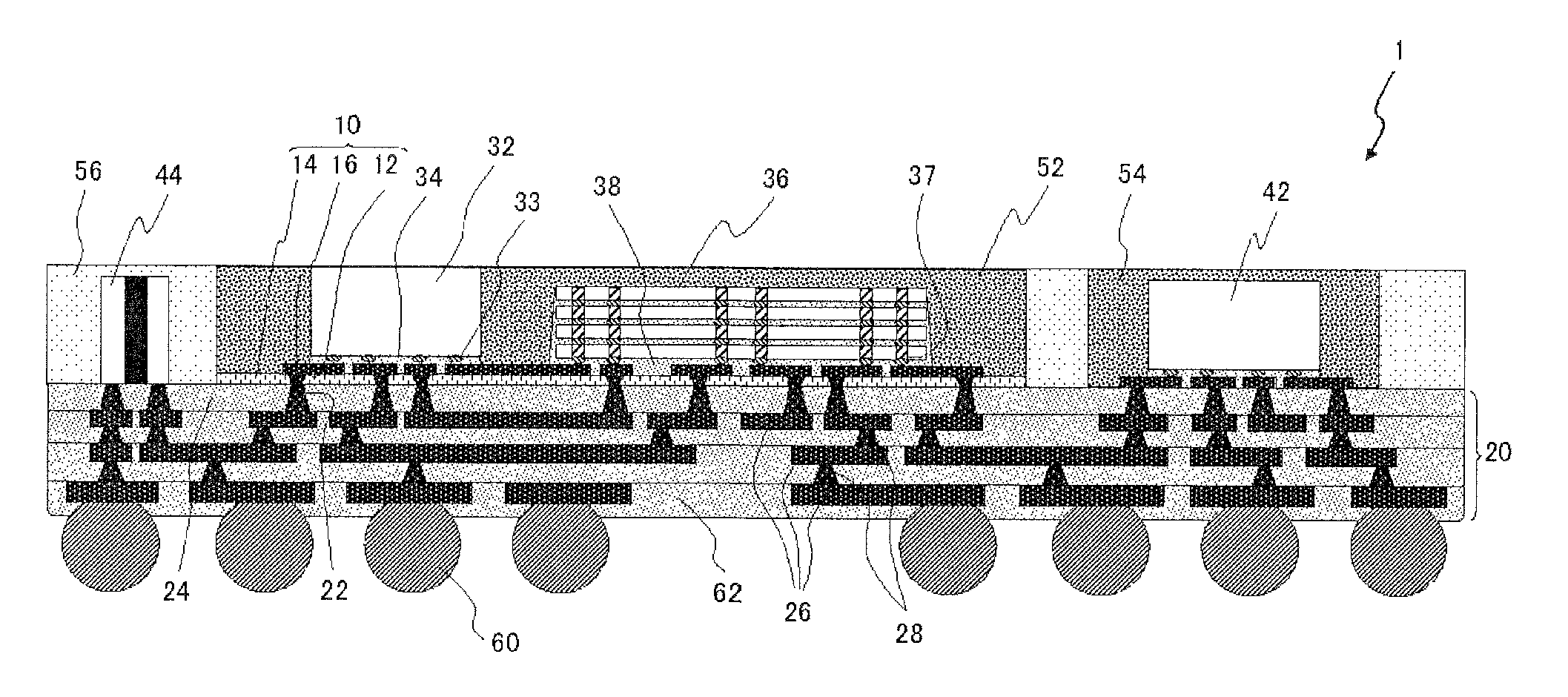

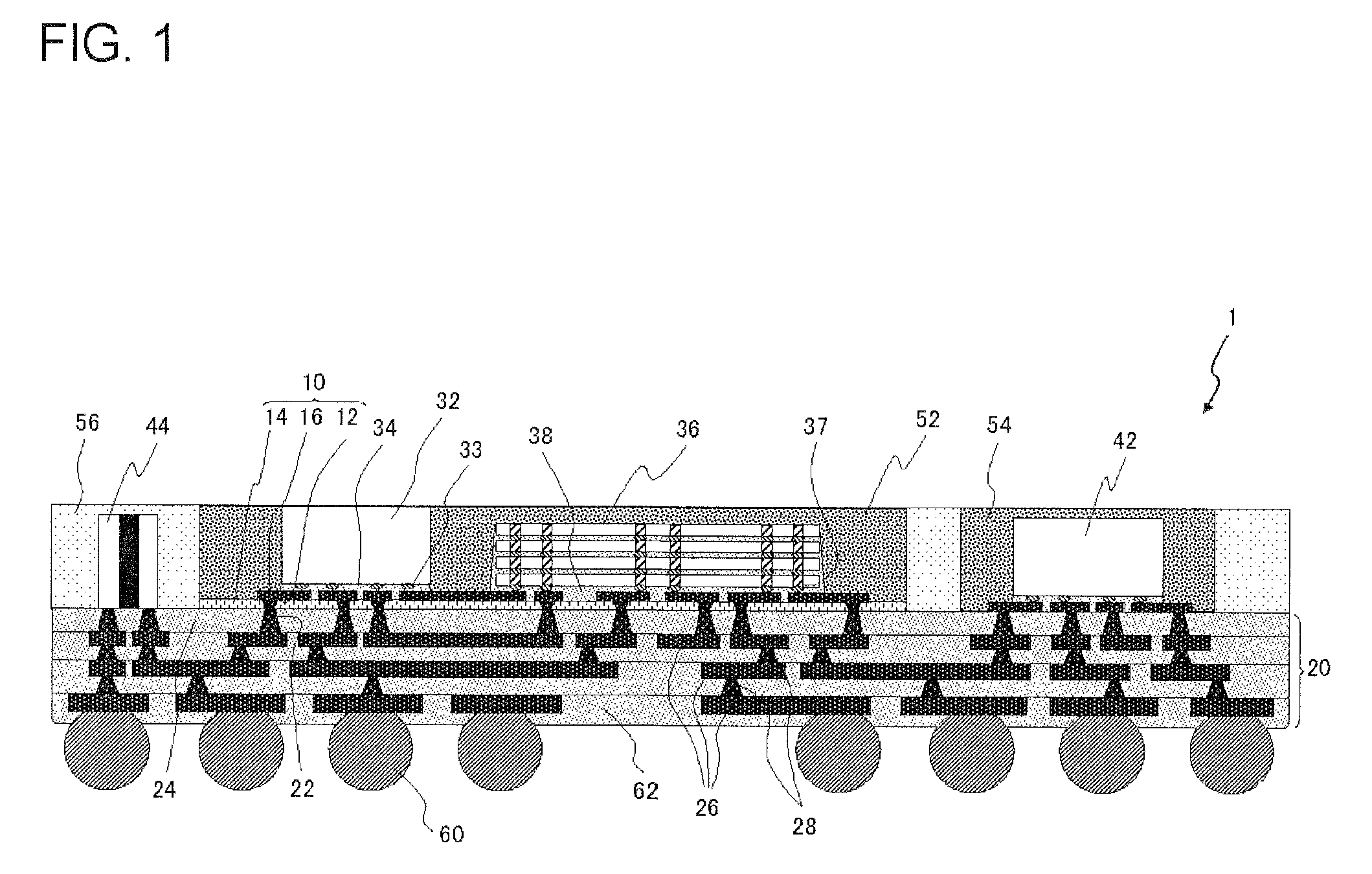

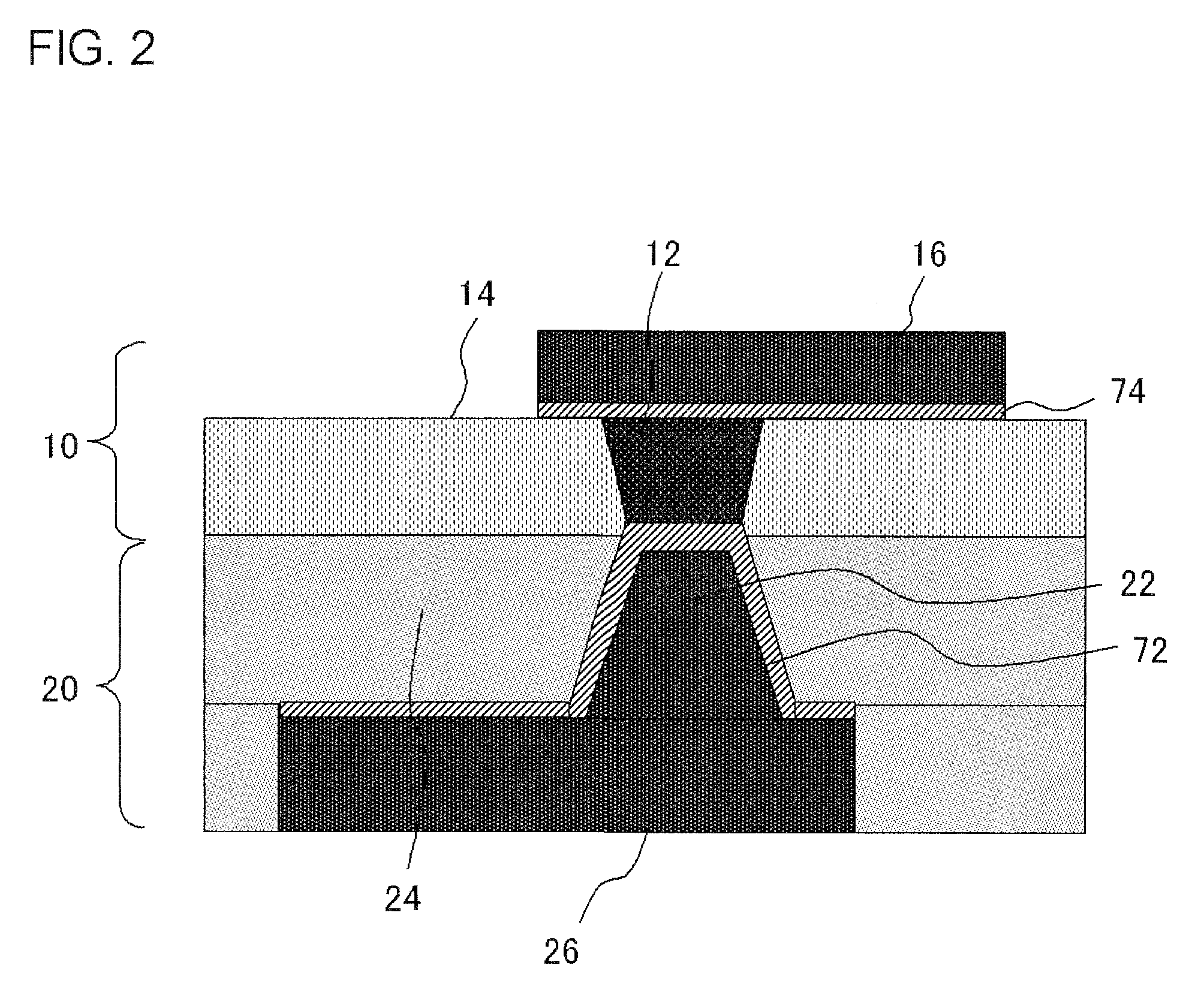

Electronic device and method of manufacturing the same

ActiveUS20080079163A1Low costLower decomposition temperatureSemiconductor/solid-state device detailsLaminating printed circuit boardsSolder ballElectronic equipment

In a conventional electronic device and a method of manufacturing the same, reduction in cost of the electronic device is hindered because resin used in an interconnect layer on the solder ball side is limited. The electronic device includes an interconnect layer (a first interconnect layer) and an interconnect layer (a second interconnect layer). The second interconnect layer is formed on the undersurface of the first interconnect layer. The second interconnect layer is larger in area seen from the top than the first interconnect layer and is extended to the outside from the first interconnect layer.

Owner:RENESAS ELECTRONICS CORP

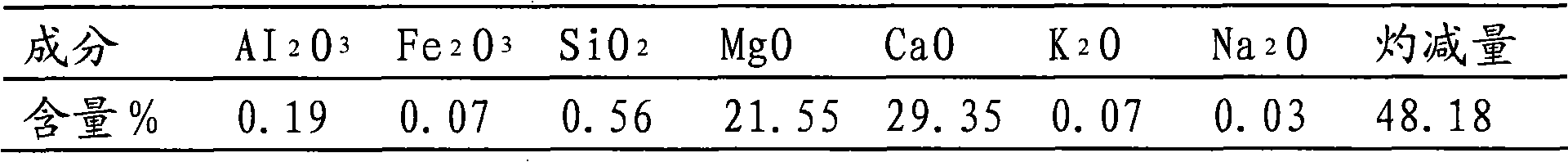

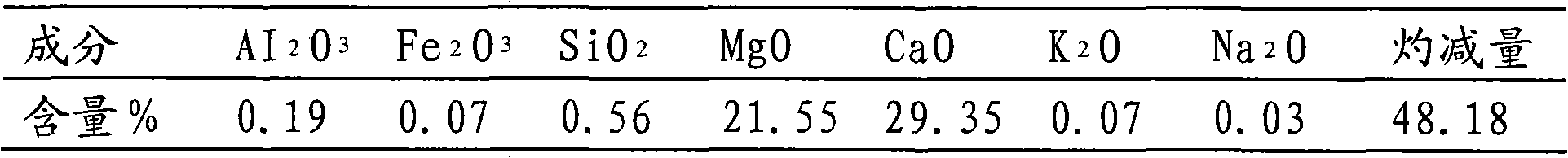

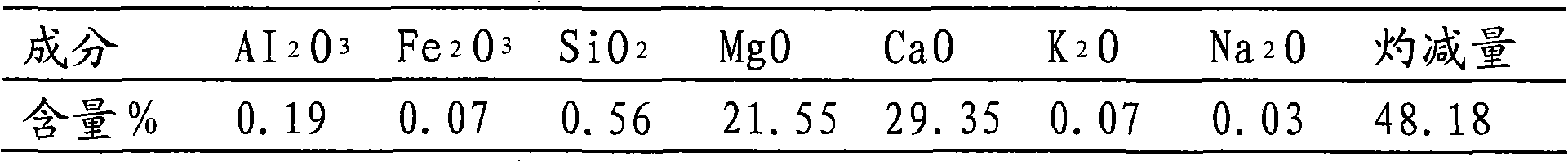

Composite foaming agent and preparation method and application thereof

The invention discloses a composite foaming agent, a preparation method thereof and application thereof. The composite foaming agent comprises azodicarbonamide, sodium bicarbonate and an auxiliary foaming agent in a weight ratio of (0.3-0.9):(0.2-0.6):(0.1-0.8). The auxiliary foaming agent is prepared by uniformly stirring attapulgite, zeolite and calcite, soaking the mixture in diluted hydrochloric acid of which the concentration is 0.5 to 6 weight percent, drying the mixture, crushing the dried mixture into powder, blending the powder and powdery white carbon black and uniformly stirring the mixture, wherein the weight ratio of the attapulgite to the zeolite to the calcite to the white carbon black is (0.3-0.8):(0.02-0.6):(0.1-0.8):(0.01-0.8). The composite foaming agent disclosed by the invention has relatively high liquidity and dispersibility, a low decomposition temperature and a long decomposition temperature period.

Owner:常州市英特玛柯橡塑科技有限公司

Carbon nanotube/polypropylene composite materials and process for preparing same

InactiveCN1654528ANo thermal decompositionImprove heat resistancePolypropylene compositesCarbon nanotube

The present invention provides one kind of composite antistatic carbon nanotube / polypropylene material and its preparation process. The composite antistatic carbon nanotube / polypropylene material has carbon nanotube as main antistatic modifying material and polypropylene as main modified target. The composite antistatic carbon nanotube / polypropylene material has both excellent antistatic performance and excellent mechanical performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

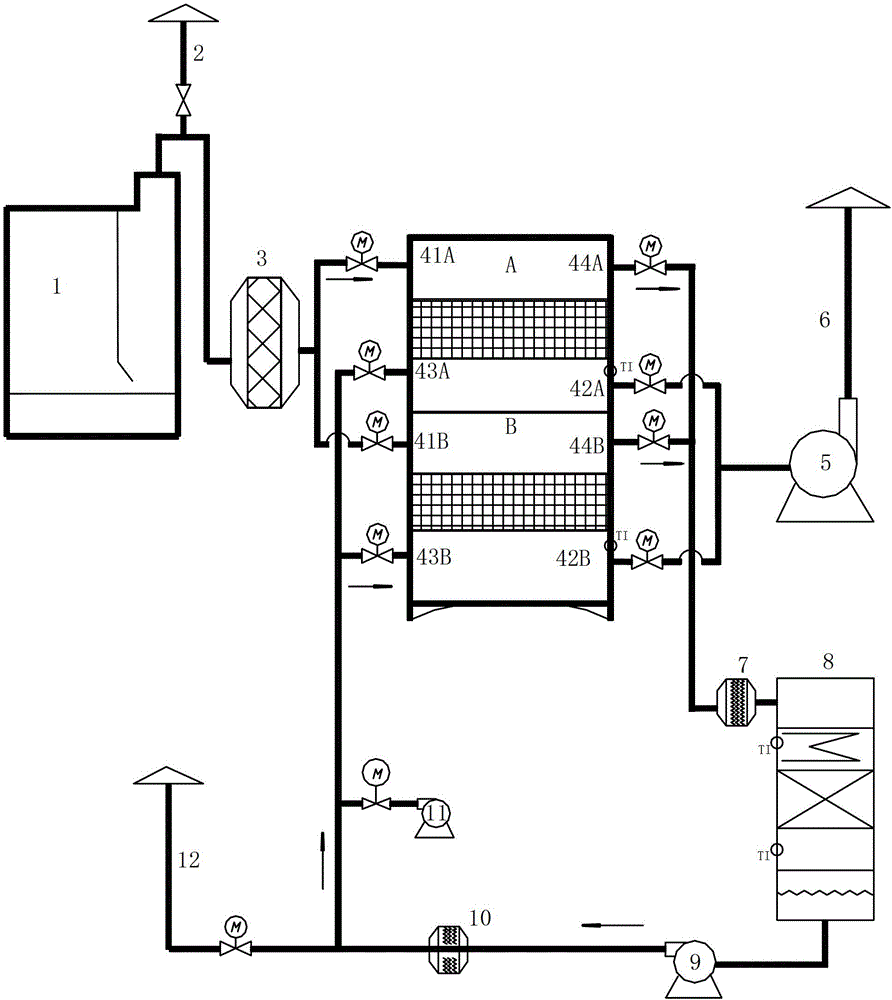

Organic waste gas multifunctional integral processing device

InactiveCN102941000AExtended service lifeLow running costDispersed particle separationIncinerator apparatusActivated carbonProgrammable logic controller

The invention discloses an organic waste gas multifunctional integral processing device, which comprises a programmable logic controller (PLC) control system, a dust filter device, active carbon adsorption beds A and B which are connected in parallel and a catalytic combustion bed. When organic waste gas is adsorbed, the organic waste gas firstly enters into the dust filter device to remove suspended solid; then enters into the active adsorption beds to remove organic substances; finally the purified waste gas is pumped through an adsorption exhaust fan and discharged on standard through an adsorption high-altitude discharge branch. When active carbon is desorbed and regenerated, the hot gas generated by the catalytic combustion bed is pressurized through a desorption fan, and then enters into the active absorption beds to reversely desorb and regenerate the saturated active carbon; the desorbed waste gas enters into the catalytic combustion bed; organics are burned to generate water and carbon dioxide; the hot gas generated at the same time is used for desorbing the active carbon. The processing device is controlled by the PLC, thereby realizing automatic switch between the two absorption beds, so that adsorption and desorption are carried out at the same time. The invention combines two technologies of adsorption and catalytic combustion organically and has complementary advantages.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

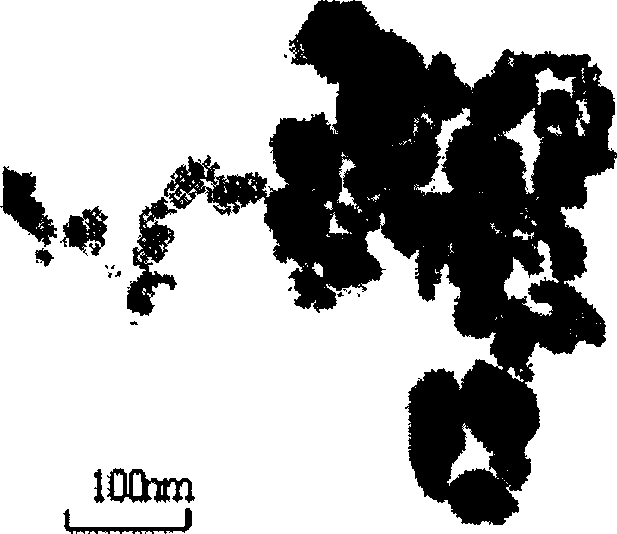

Process for preparing vanadium dioxide nano powder

A process for preparing VO2 nanoparticles includes such steps as proportionally adding V2O5 and oxalic acid to reactor, adding water, stirring at 40-70 deg.C while reaction, evaporating to obtain solid vanadium oxalate, vacuum heating to 350-500 deg.C, holding the temp for 20-40 min for thermodecomposing, and cooling. It is possible to add MoO3 or N5H37W6O24 for preparing the doped product.

Owner:SICHUAN UNIV

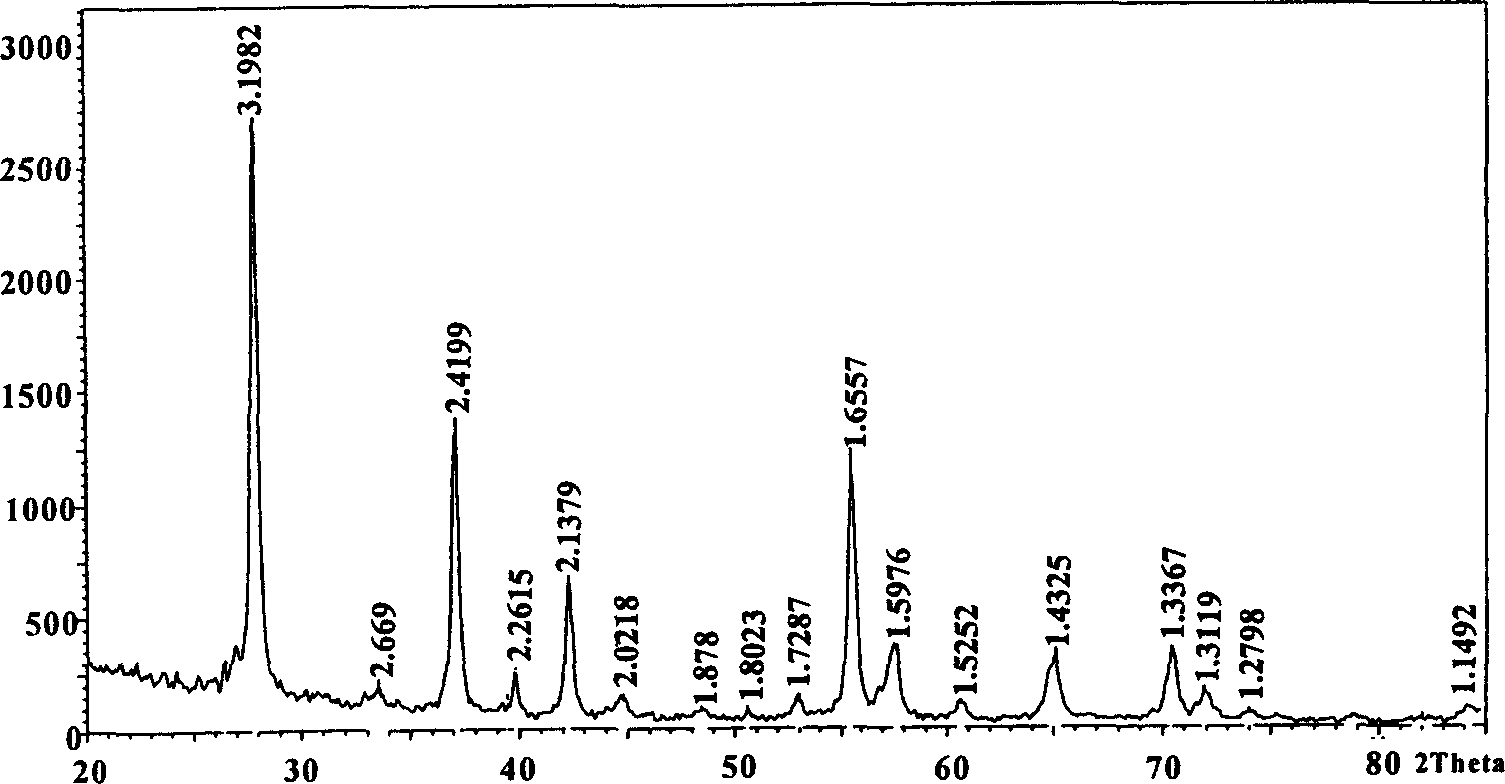

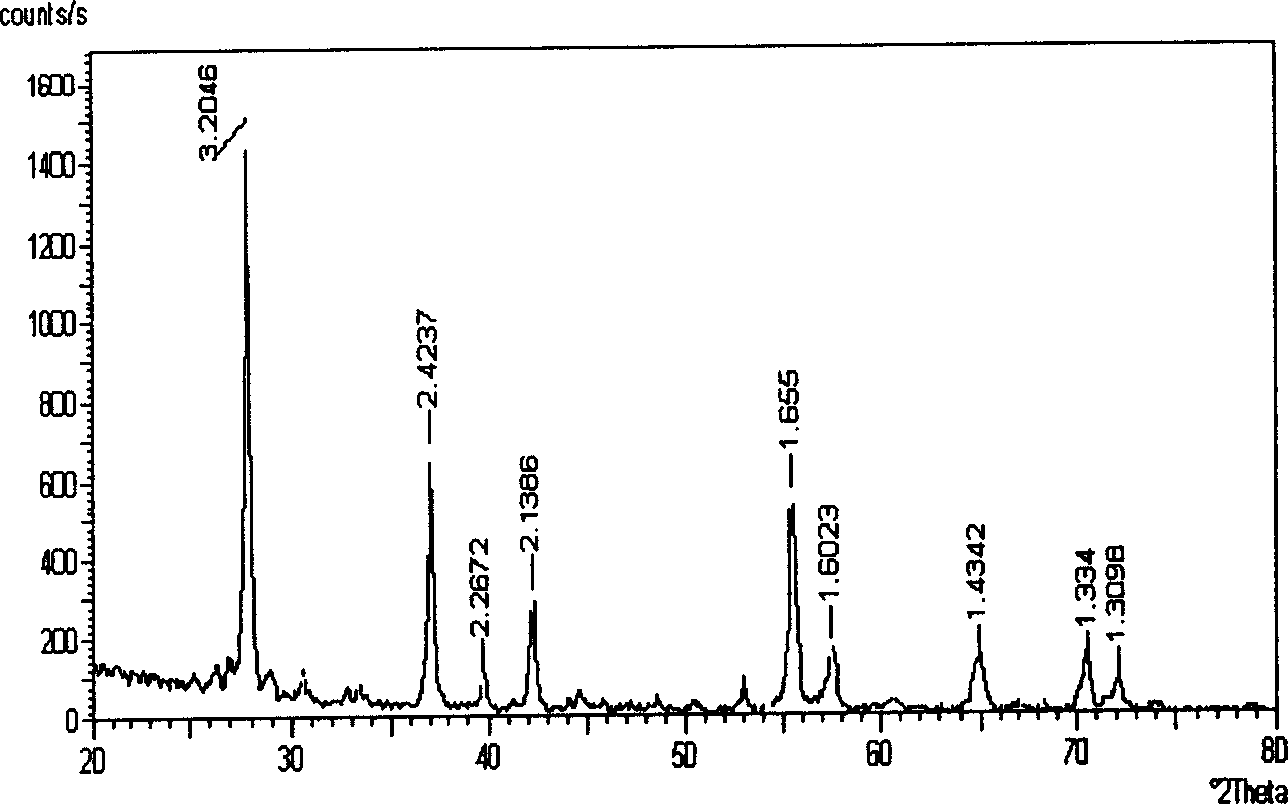

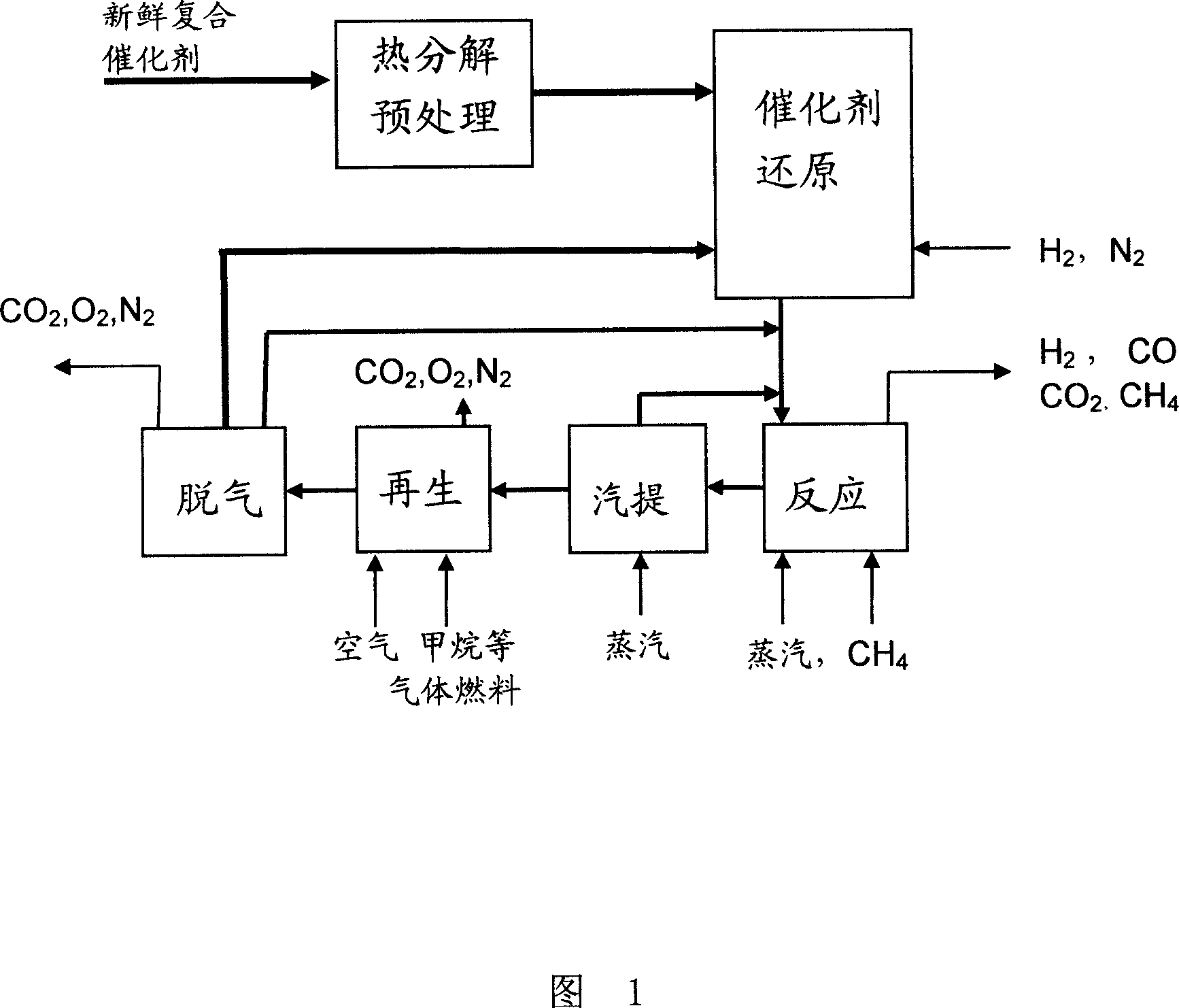

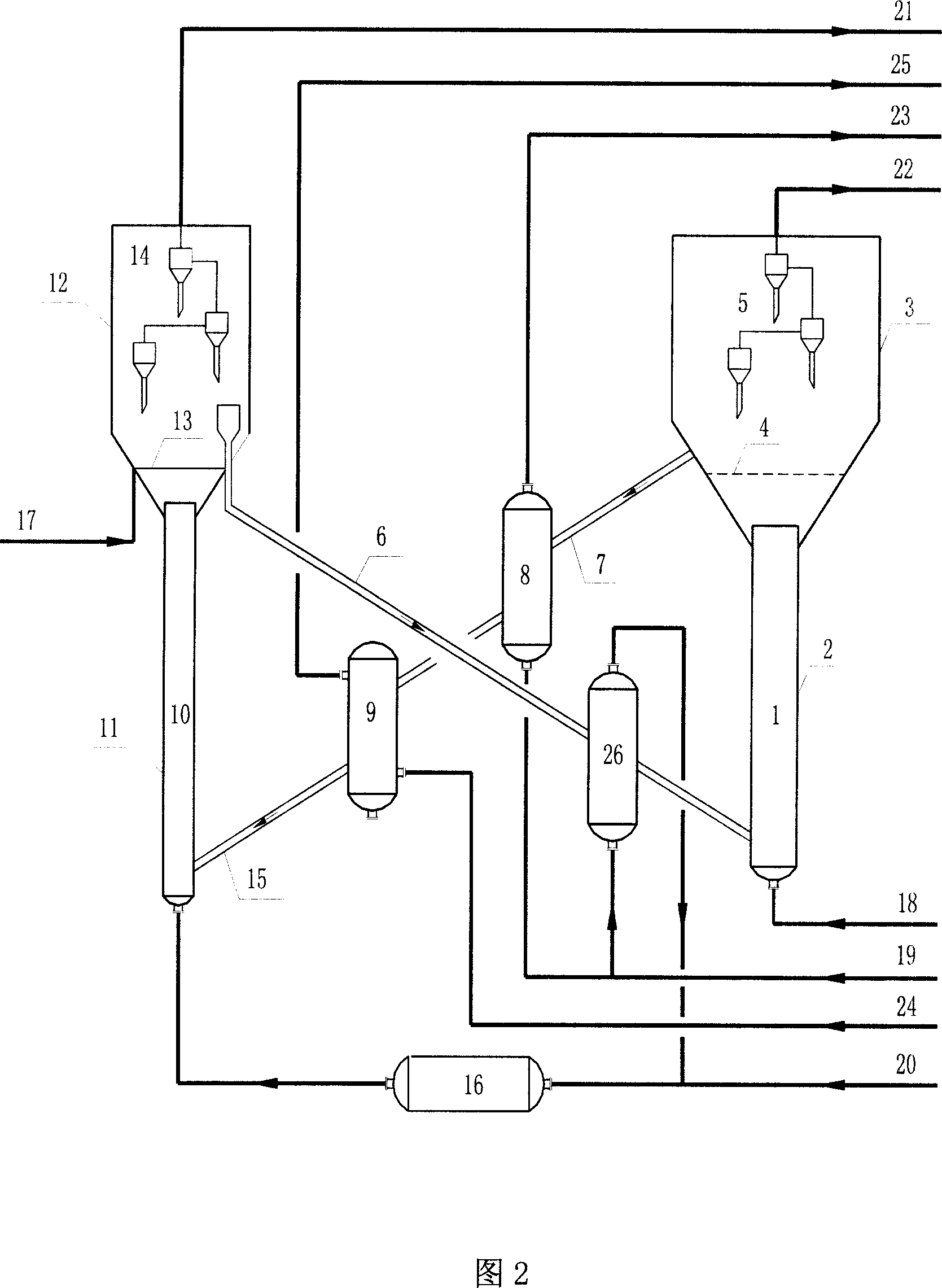

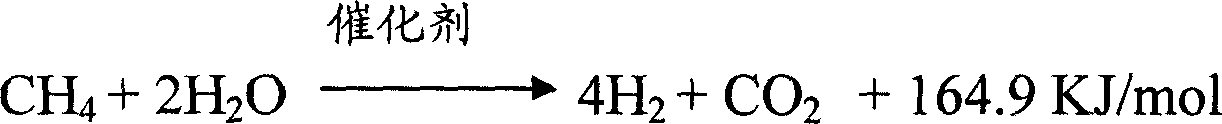

Adsorption forced methane steam reforming hydrogen manufacturing process and apparatus using circulating fluidized bed

The invention discloses a hydrogen preparing process of strengthening methane steam reforming by cyclic fluidized bed adsorption, comprising: transporting 5-200 micron composite catalyst grains into a regenerator for pretreating; degasifying the pretreated composite catalyst and tranfering it to a fluidized bed reactor for reducing; charing methane and steam into the fluidized bed reactor in the water-carbon ratio of 2-10, and making the fluidized composite catalyst perform reforming hydrogen preparing reaction with methane and steam at the same time, and finally transferring the composite catalyst into regnerator to be regenerated and recycled, where the reacting time is 1s-5min, the reacting gas speed is 0.3-1.0m / s, and the ratio of composite catalyst to methane is 10 : 1-0.002 : 1 in g / ml. And it also discloses a device of implementing the above process. And the process can implement stable and continuous operation of fluidized bed reactor, and has advantages of high mass and heat transfer efficiencies.

Owner:CHINA PETROLEUM & CHEM CORP +1

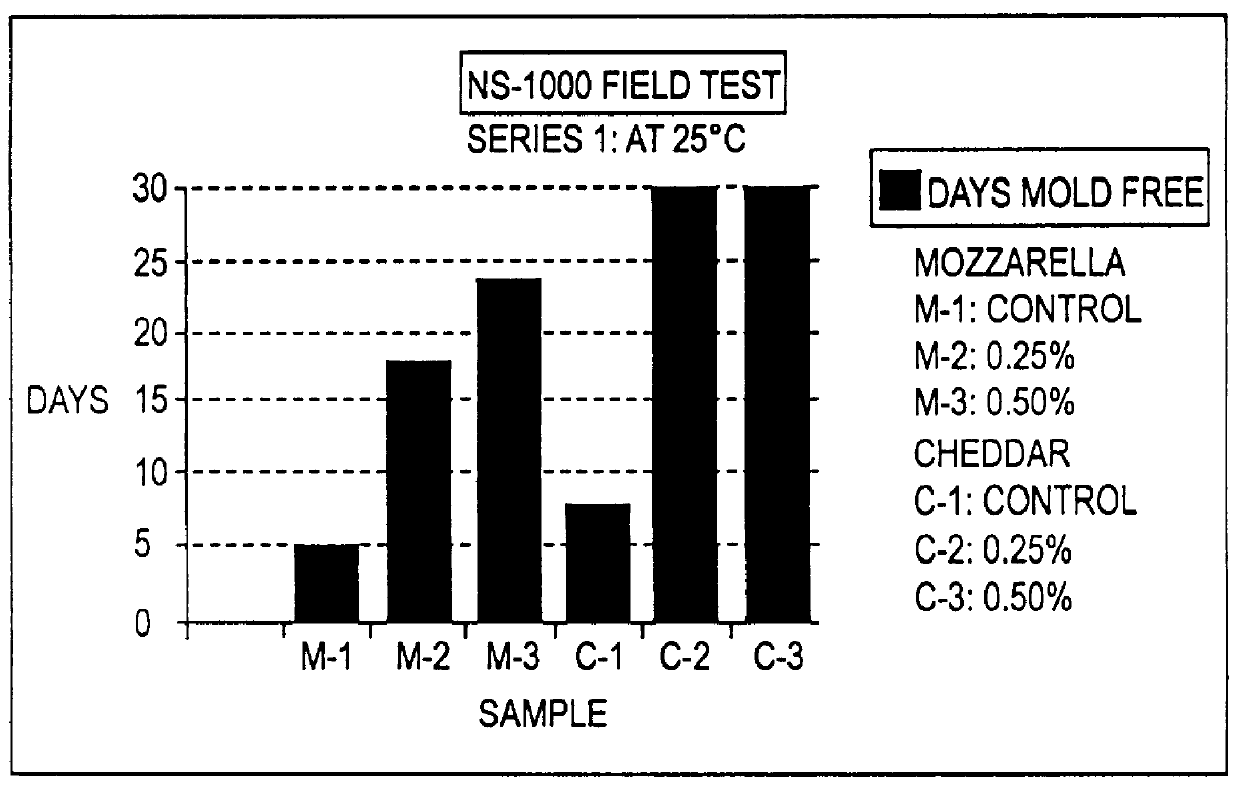

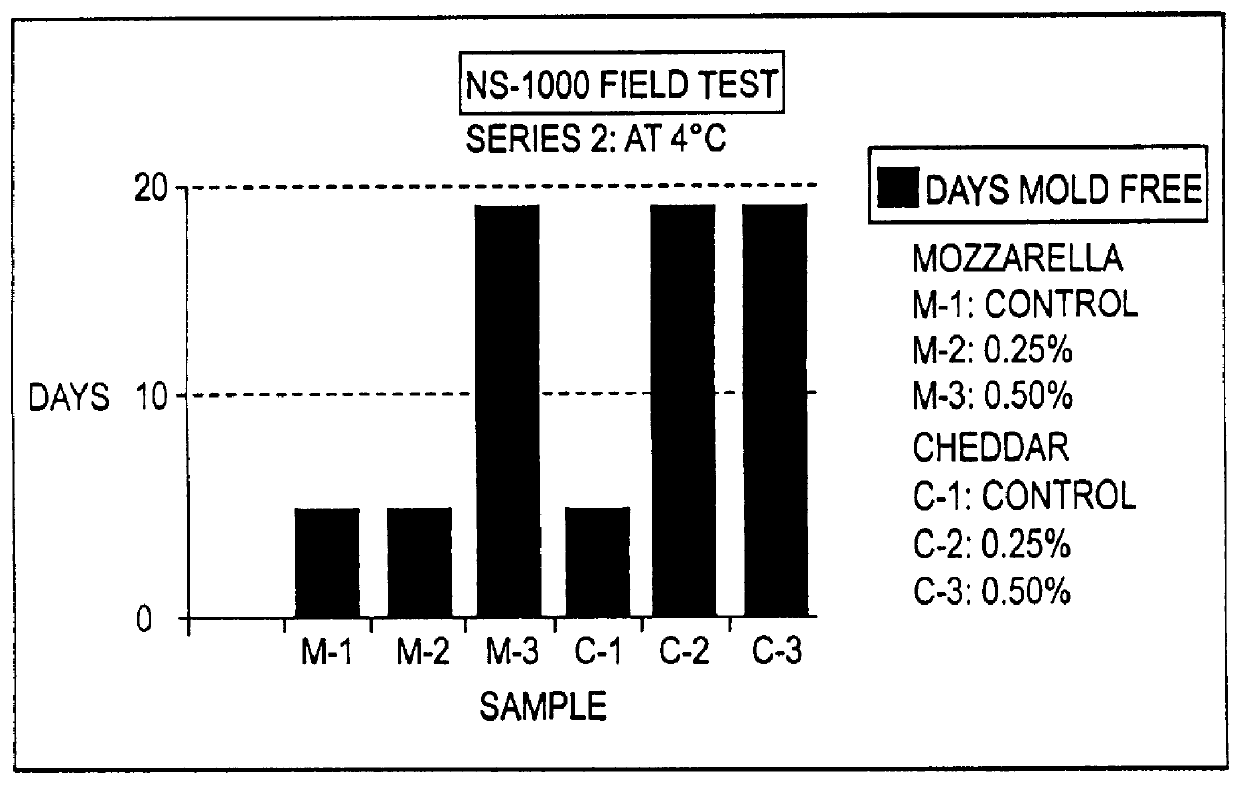

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

Doped cobalt carbonate, doped tricobalt tetroxide and preparation methods thereof

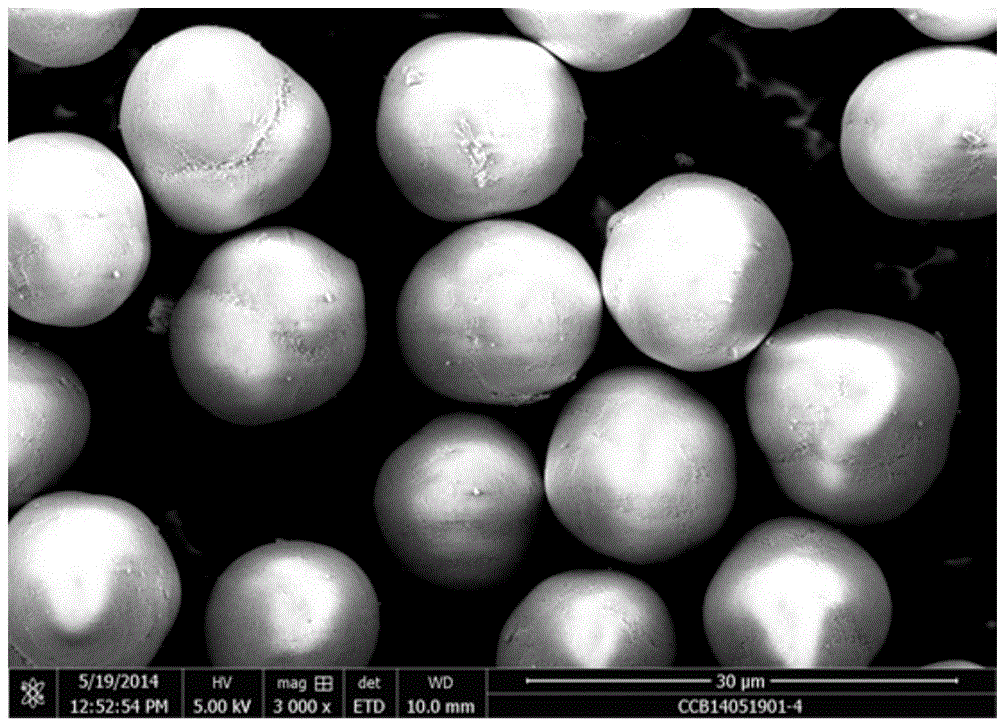

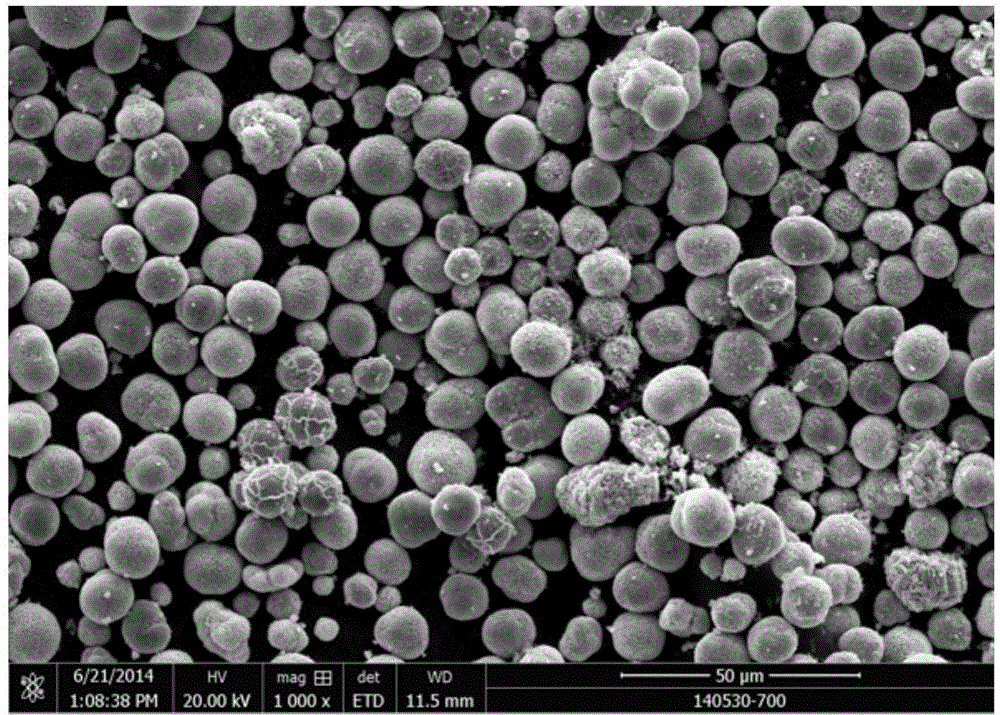

ActiveCN105731551AUniform particle sizeCoated evenlyCobalt oxides/hydroxidesCobalt carbonatesChemistryCobalt(II,III) oxide

The present invention provides a doped cobalt carbonate preparation method. The preparation method comprises the following steps: cobalt carbonate is prepared; the cobalt carbonate is added into a metal alkoxide solution to be mixed to obtain the cobalt carbonate wrapped by the metal alkoxide; and the wrapped cobalt carbonate is dried to obtain a doped cobalt carbonate. The present invention also provides the doped cobalt carbonate prepared by the doped cobalt carbonate preparation method, a doped tricobalt tetroxide preparation method, and a doped tricobalt tetroxide prepared by the doped tricobalt tetroxide preparation method. The doped cobalt carbonate preparation method and the doped tricobalt tetroxide preparation method can prepare the doped cobalt carbonate and the doped tricobalt tetroxide which are uniform in particle sizes, evenly coated, and large in particle sizes, respectively.

Owner:JINGMEN GEM NEW MATERIAL +1

Hydrofining catalyst and preparation method thereof

InactiveCN101590417AImprove physical and chemical propertiesImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsTitaniumBoron

The invention provides a hydrofining catalyst and a preparation method thereof. The catalyst comprises an aluminum oxide carrier which is modified by an assistant and VIII group and VIB group metal oxides which are loaded on the carrier, wherein, the assistant is at least one of boron, phosphorus, silicon and titanium compounds. The catalyst is prepared by an immersion method which is characterized in that an organic stabilizer is added into immersion fluid; the number of metal active centers of the catalyst is increased with the addition of the organic stabilizer; the physicochemical properties of the catalyst is improved by the way the aluminium oxide is modified by the assistant; therefore, the hydrofining catalyst prepared by the method in the invention has high desulfuration and denitrification activity, and is applicable to the hydrotreating process of various distillate oil, in particular to poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Phase-change energy-storage polyurethane foam and preparation method thereof

The invention discloses a phase-change polyurethane foam and a preparation method thereof. The foam is prepared by subjecting a polyurethane foam raw material to processes of reacting, foaming, and curing; wherein the polyurethane foam raw material comprises polyether, polymethylene polyphenyl isocyanate, silicone oil, and methyl chloride; the reactions are carrier out after the mixing of a phase-change energy-storage microcapsule and the polyurethane foam raw material, the phase-change energy-storage microcapsule is composed of a capsule wall made of polyurethane-polysiloxane and a capsule core made of an organic phase-change material, and polycarbodiimide is taken as the cross-linking agent. The phase-change energy-storage microcapsule integrates the advantages of organic materials and inorganic materials together, namely has the organic materials' advantages of flexibility and elasticity, also has the inorganic materials' advantages of excellent mechanical performance and fire-retardant performance, and overcomes the shortage of easy separation between the conventional microcapsule and the foam substrate.

Owner:CHINA PETROLEUM & CHEM CORP +1

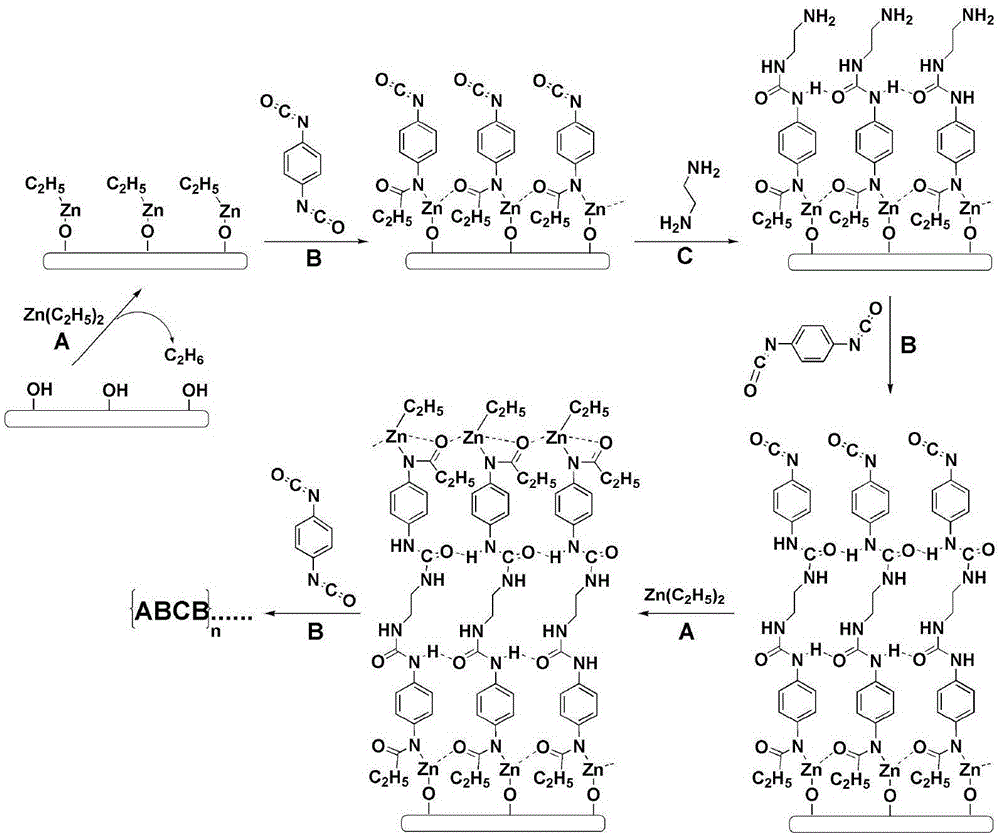

Preparation method for Cu-based hydrogenation catalyst

InactiveCN105148923AImprove hydrogenation performanceEnhanced interactionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReducing atmosphereGlass sheet

A preparation method for a Cu-based hydrogenation catalyst comprises the following steps: dissolving soluble copper salt into water, then adding a carrier into the solution, and uniformly loading a copper precursor on the surface of the carrier to obtain a precursor sample; mixing the precursor sample and ethanol to form a suspending liquid, coating the suspending liquid on the surface of a glass sheet, impulsing polyisocyanate into an MLD reaction cavity, then impulsing an M precursor to be subjected to monomolecular layer reaction on the sample surface in sequence to obtain a hybrid membrane coated copper precursor compound; conducting heat treatment on the compound in air to obtain a nanometer CuO-MOx compound, and then conducting reduction in the reducing atmosphere to obtain the Cu-MOx interface catalyst. The preparation method has the advantage that the Cu-MOx interface structure can be regulated and controlled.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

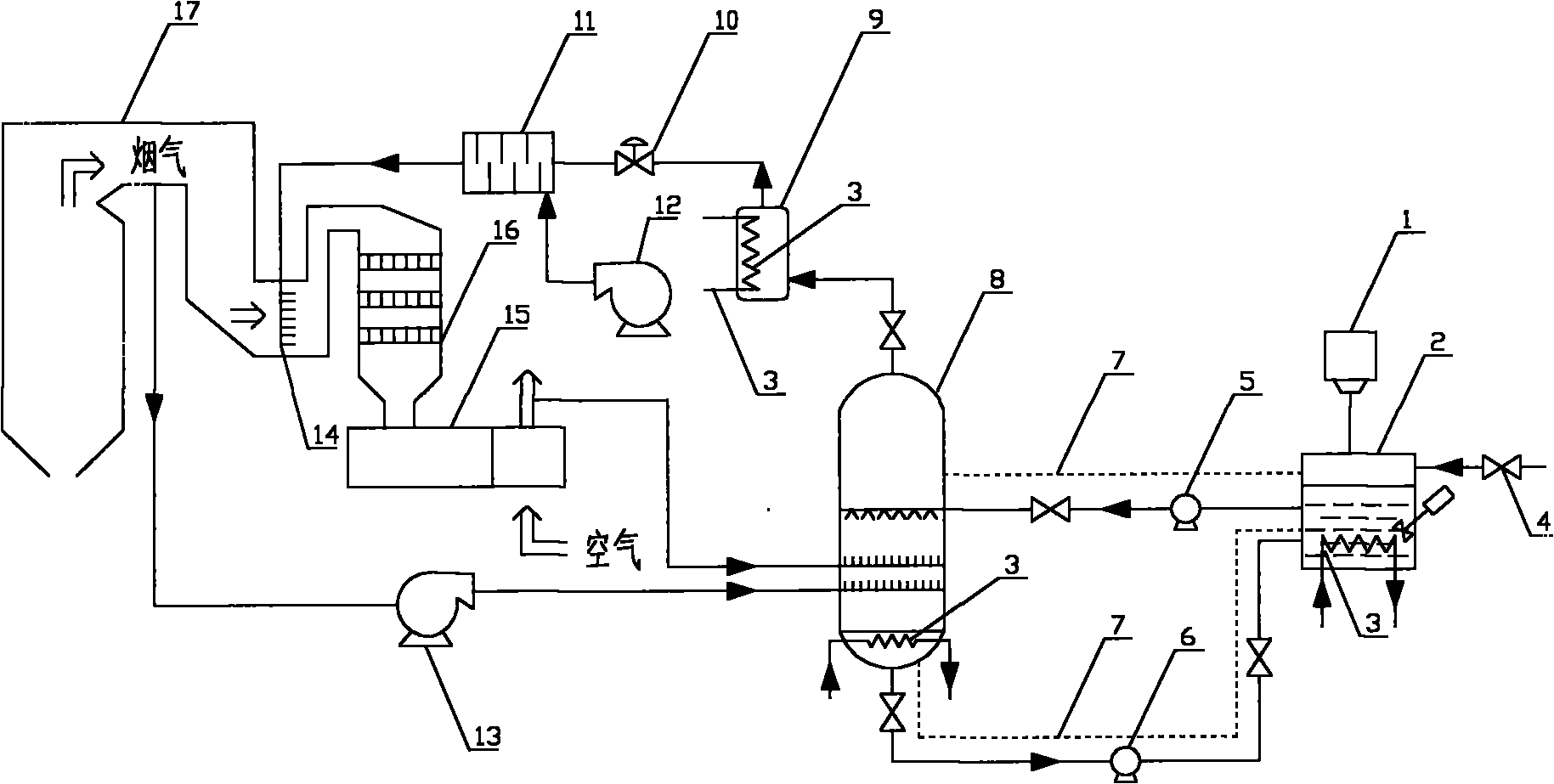

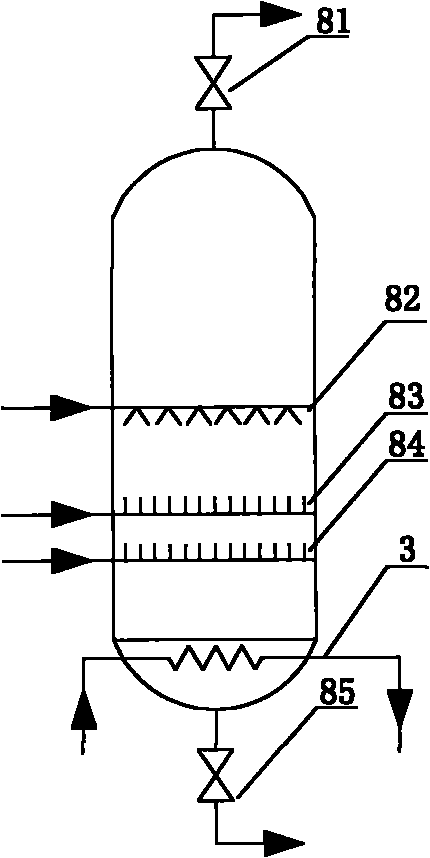

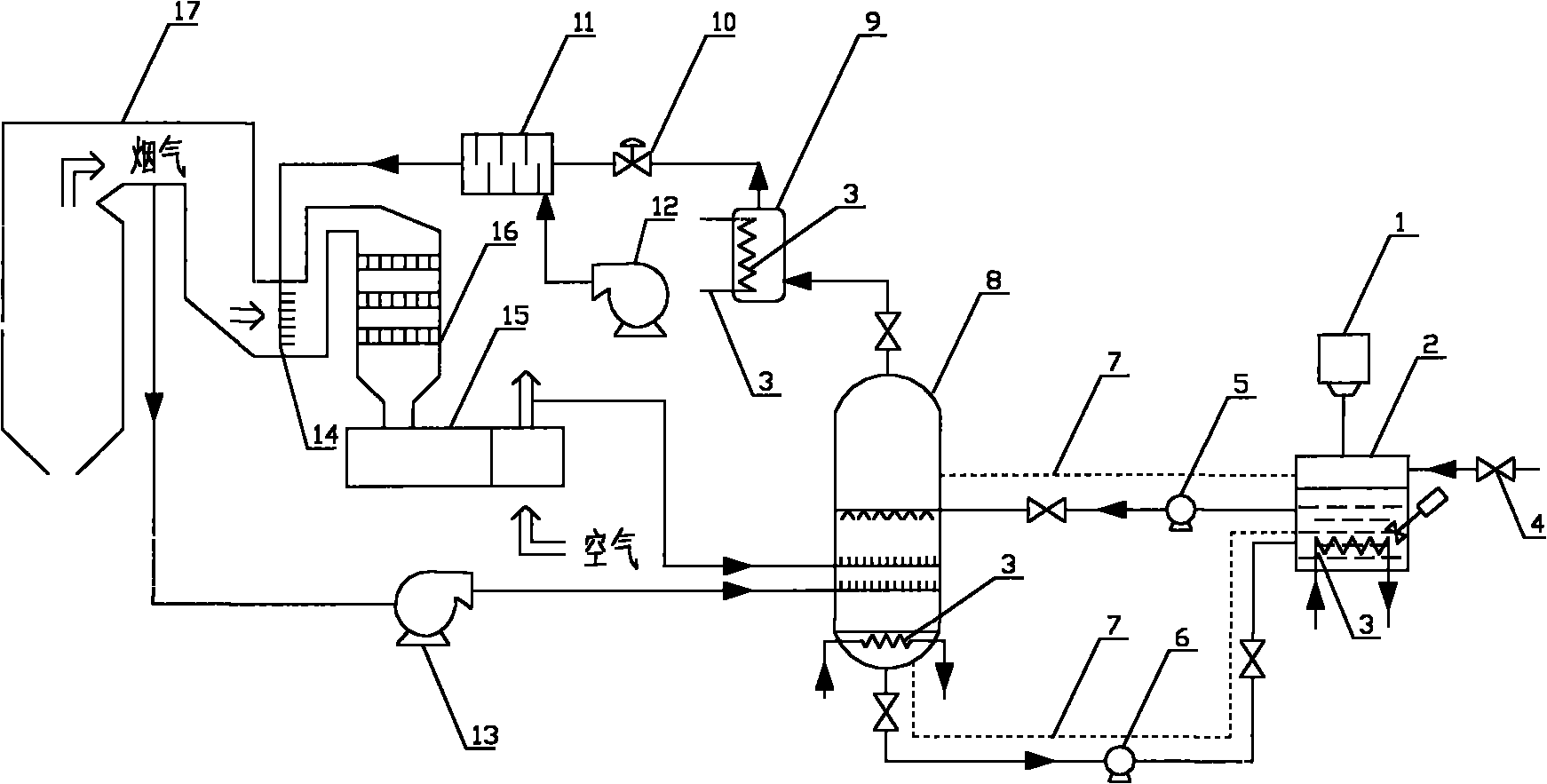

Process and system for preparing ammonia from ammonium bicarbonate by using wet process for flue gas denitration

ActiveCN101829486AAvoid safety hazardsTransport and storage safetyDispersed particle separationSodium bicarbonateGrating

The invention discloses a process and a system for preparing ammonia from ammonium bicarbonate by using a wet process for flue gas denitration, belonging to the technical field of flue gas denitration in a thermal power plant. In the process, an ammonium bicarbonate solution at 90 DEG C is boosted and then enters an atomizing nozzle of a pyrolyzing furnace for backflow ejection, fogdrop of the ammonium bicarbonate decompose out ammonia gas under the heating action of high-temperature flue gas flowing from bottom to top, and the residual ammonium bicarbonate solution converges at the bottom of the pyrolyzing furnace and then returns to a dissolution pool through a circulating pump for recycling; and the ammonia gas flows to a buffer tank together with air, enters an ammonia gas-air mixer and then enters an SCR (Selective Catalyst Reduction) reactor through an ammonia-spraying grating after being diluted to certain concentration, and in the presence of a catalyst, the ammonia gas reduces NOX into N2. The ammonium bicarbonate is a reducing agent which is convenient and safe to transport and store, has better economy than urea and avoids the potential safety hazard of the reducing agents of liquid ammonia, ammonia water and the like in the aspects of transportation and storage. By adopting the ammonium bicarbonate as the reducing agent to pyrolyze for preparing the ammonia with the wet process, the whole system has the advantages of easy dosage control of the ammonium bicarbonate, stable ammonia gas generation, simplicity and high efficiency.

Owner:ZHEJIANG GUANGHAN ENVIRONMENTAL PROTECTION TECH

Composite mixed vanadium dioxide nano powder material and its preparation process

InactiveCN1693211AImprove transmittanceLower phase transition temperatureVanadium oxidesVanadium dioxideOxalate

A process for preparing the doped composite VO2 nanoparticles with low phase-change temp (25-30 deg.C) and improved physical propoerties includes such steps as preparing the metal element and non-metal element doped solid vanadium oxalate as precursor from V2O5 and oxalic acid, and vacuum thermodecomposing. Its molecular formula is V1-xMxO2-yZy, where x=0-0.08, y=0-0.1, M is metal element and Z is non-metal element.

Owner:SICHUAN UNIV

Method for preparing metal magnesium by using dolomite as raw material

The invention discloses a method for preparing metal magnesium by using dolomite as a raw material, and aims to solve the problems of low reducing efficiency, high energy consumption, long production period and serious pollution existing in the conventional method for preparing the metal magnesium. The method comprises the steps: crushing of dolomites, vacuum low-temperature light calcining and recycling of carbon dioxide, cooling and heat recovery, ball-milling of mixed materials, briquetting of mixed materials, vacuum high-temperature hot reduction, separation of magnesium blocks, and utilization of slag, wherein in the vacuum low-temperature light calcining, the crushed dolomites undergo light calcining in a continuous type vacuum calcining furnace for 1 to 3 hours at the calcining temperature of between 500 and 1,000 DEG C and under the furnace pressure of 10,000 to 60,000Pa, MgCO3 and CaCO3 in the dolomites are decomposed in sequence, the reaction expression is: CaMg(CO3)2=CaCO3+MgO+CO2(gas) and CaCO3=CaO+CO2(gas), and the mixture of carbon dioxide and magnesium oxide and calcium oxide is obtained; and the carbon dioxide which flows in the furnace and heats the dolomites is recycled.

Owner:JILIN UNIV

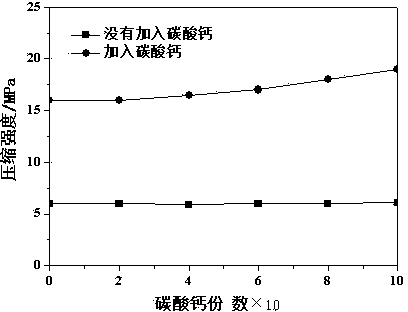

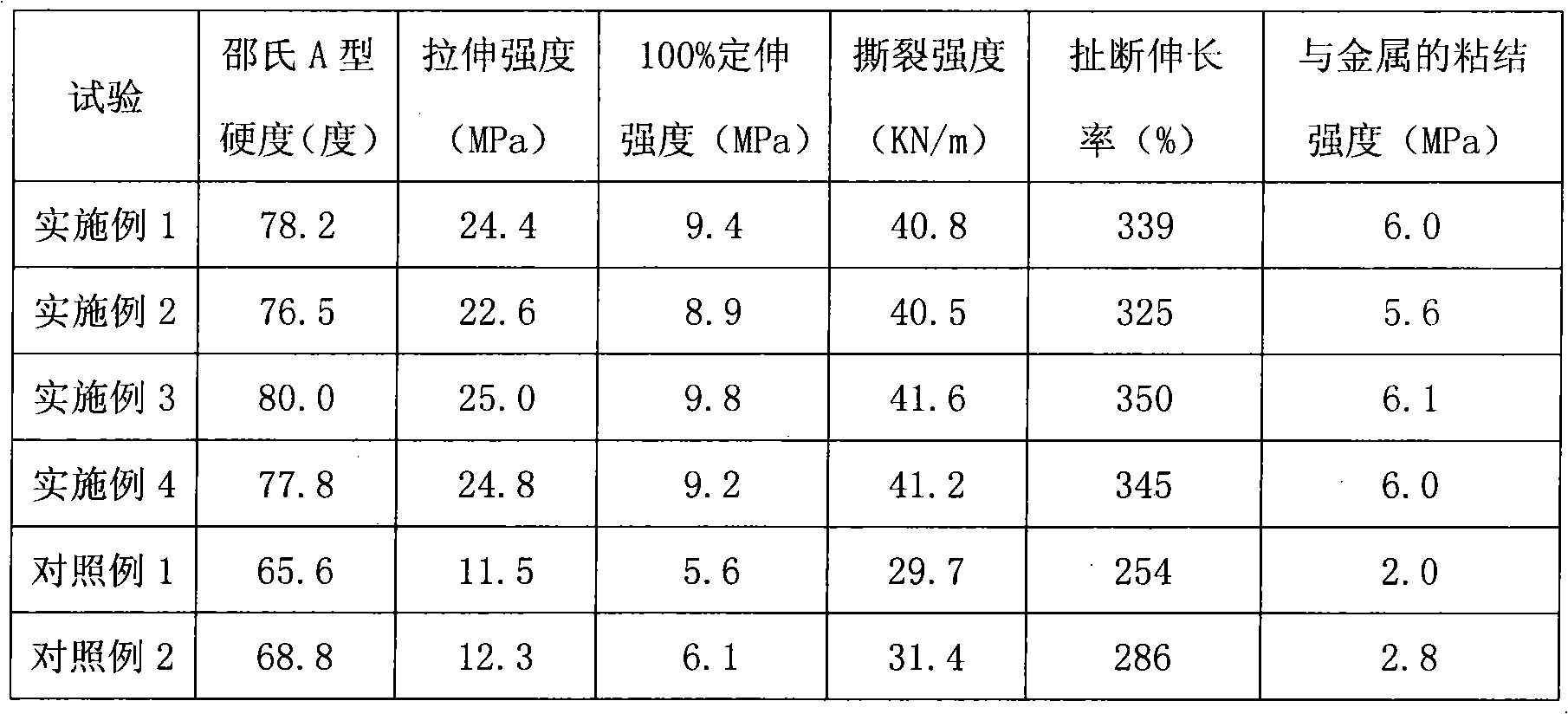

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

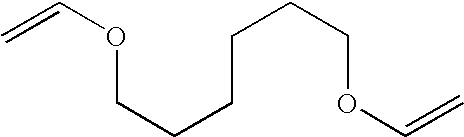

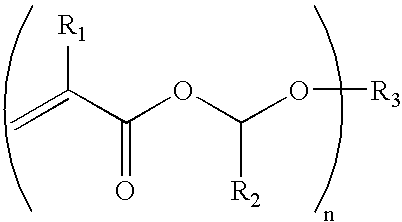

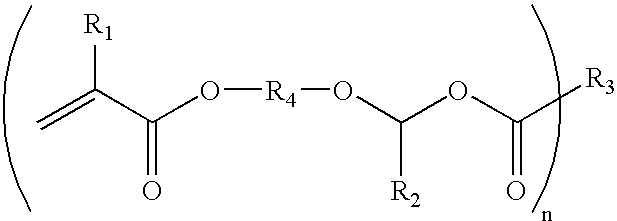

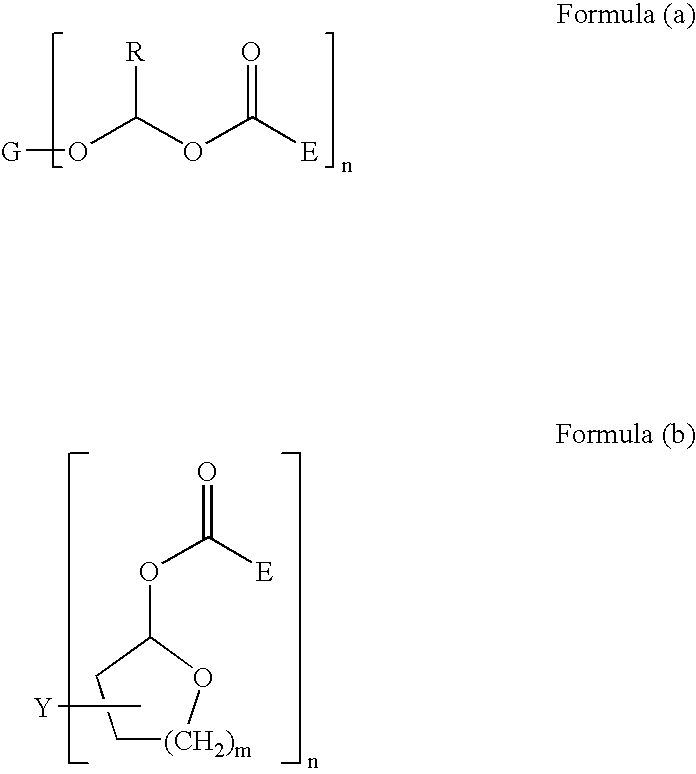

Multi-functional alpha-alkoxyalkyl acrylate and methacrylate ester compositions and reworkable polymers formed therefrom

InactiveUS20050101689A1Easy and less-expensive to prepareEasy to degradeOptical articlesCoatingsMethacrylatePolymer science

Adhesive compositions are disclosed which include acrylates, their polymers, and free radical initiators. The compositions include a multi-functional alpha-alkoxyalkyl(meth)acrylate compound and a free radical initiator. The multi-functional alpha-alkoxyalkyl(meth)acrylate compound is the reaction product of: (a) a (meth)acrylic acid or a (meth)acrylate ester having a free carboxylic acid group; and (b) a compound including two or more 1-alkenyl ether groups and free of acetal and ketal groups, or a compound free of acetal and ketal groups and including one or more 1-alkenyl ether groups and a (meth)acrylate group. The compositions are easier and less expensive to prepare than conventional acrylate compositions and degrade when contacted with an acid medium or when heated. The compositions are useful in a wide range of applications and are compatible with conventional adhesive additives.

Owner:HENKEL IP & HOLDING GMBH

Thermally reworkable epoxy resins and compositions based thereon

InactiveUS6916890B1Low production costEasy to cleanOrganic compound preparationCarboxylic acid esters preparationEpoxyEther

The present invention discloses reworkable epoxy compositions suitable for encapsulation of and underfill for electronic components including (a) the epoxidized reaction product of a multifunctional 1-alkenyl ether or 1-cycloalkenyl ether and an alkenyl carboxylic acid, the epoxidized reaction product having two or more thermally labile alpha-alkoxy ester linkages; and (b) a curing agent for the epoxy component. The epoxy composition, when cured, provides a composition which is thermally reworkable, the weak α-alkoxy ester linkages providing for the reworkable aspect of the invention.

Owner:HENKEL CORP

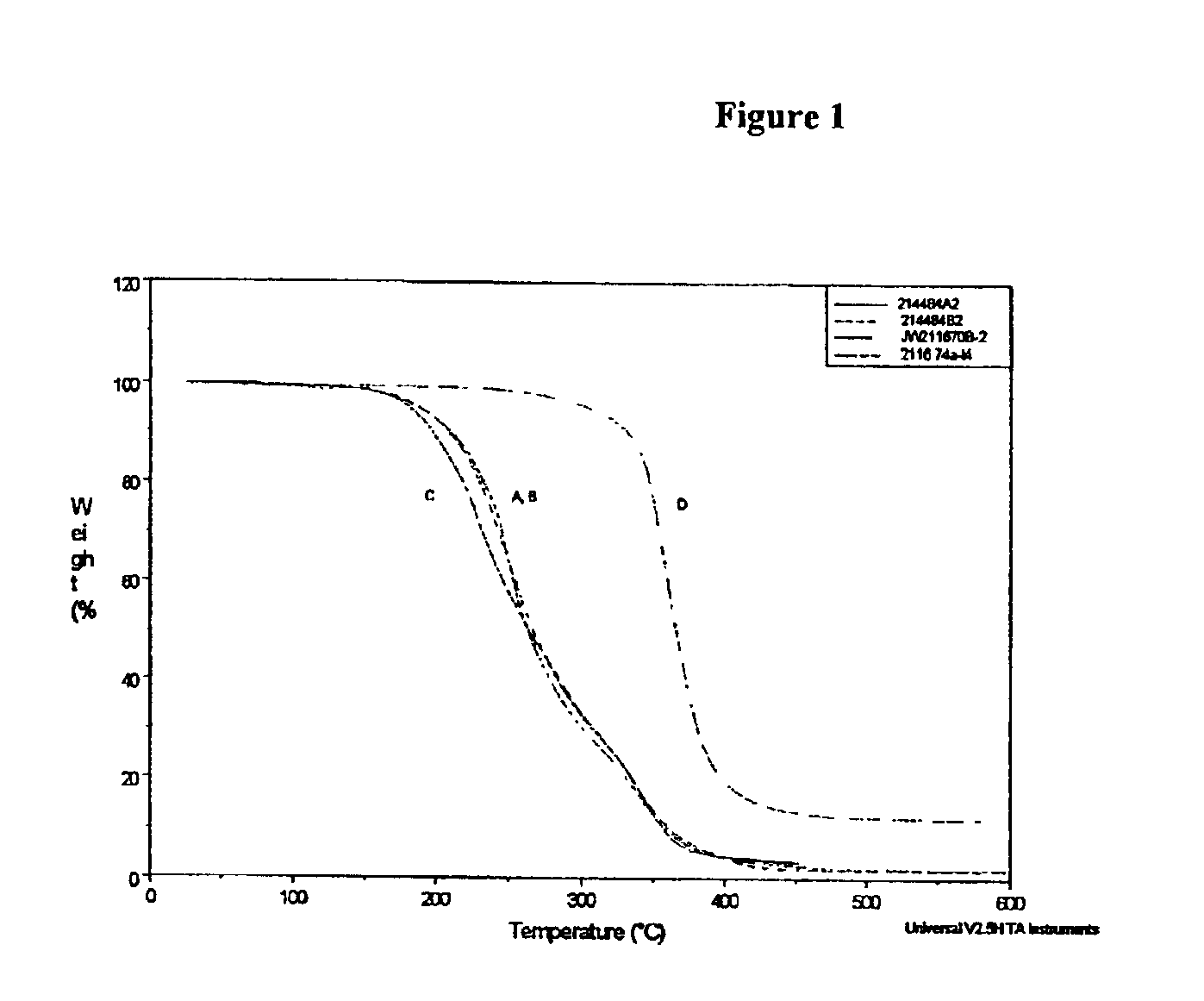

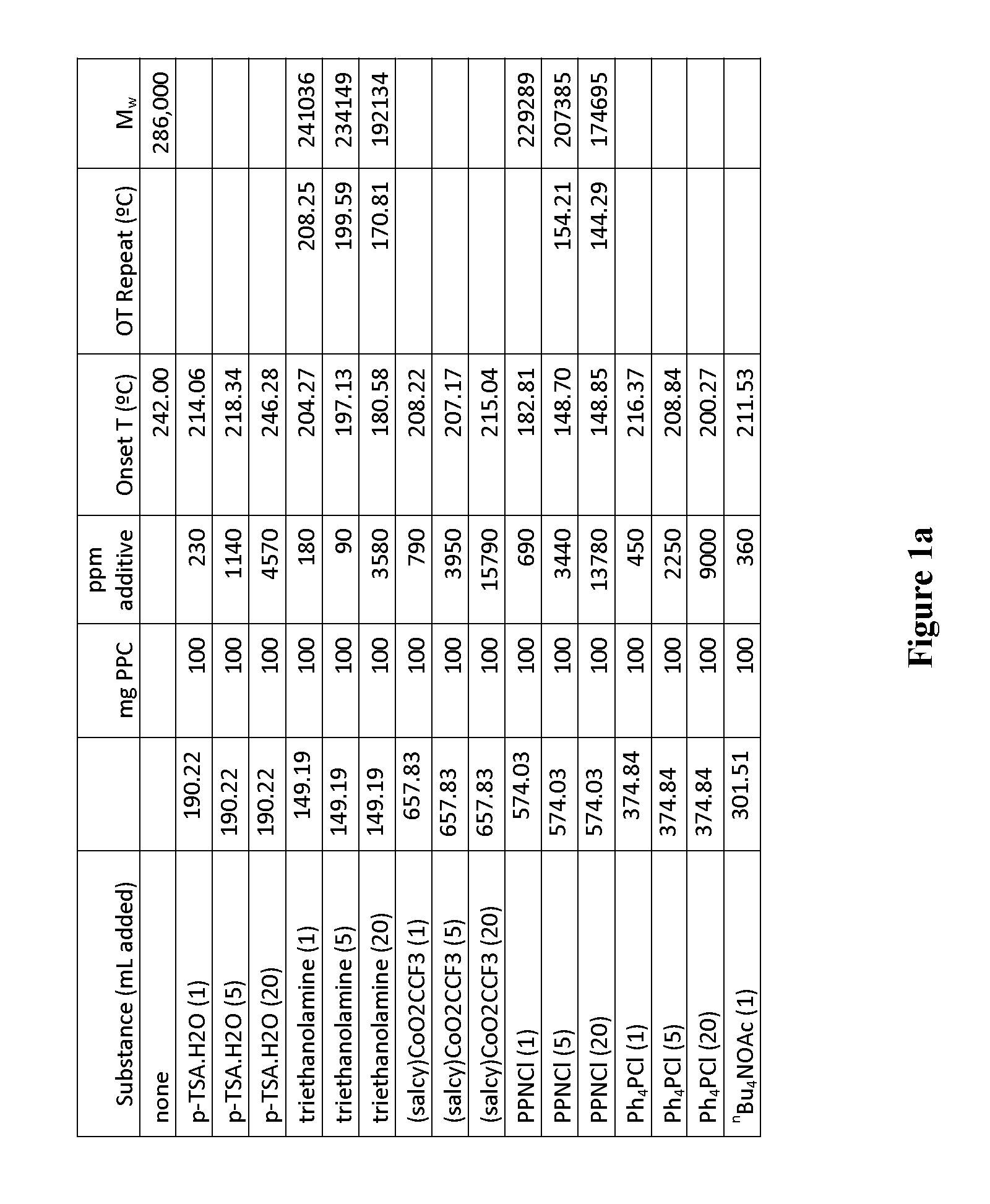

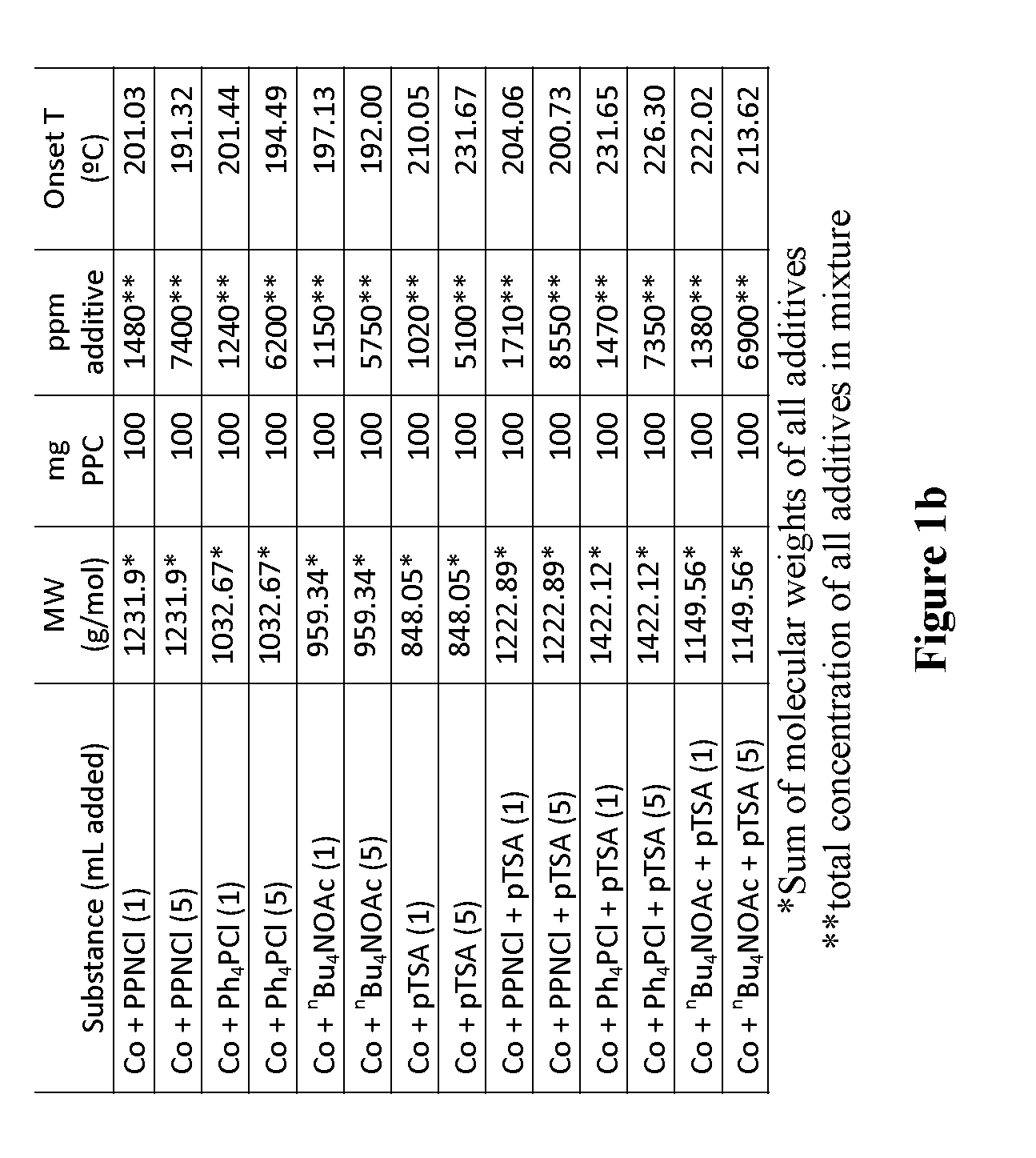

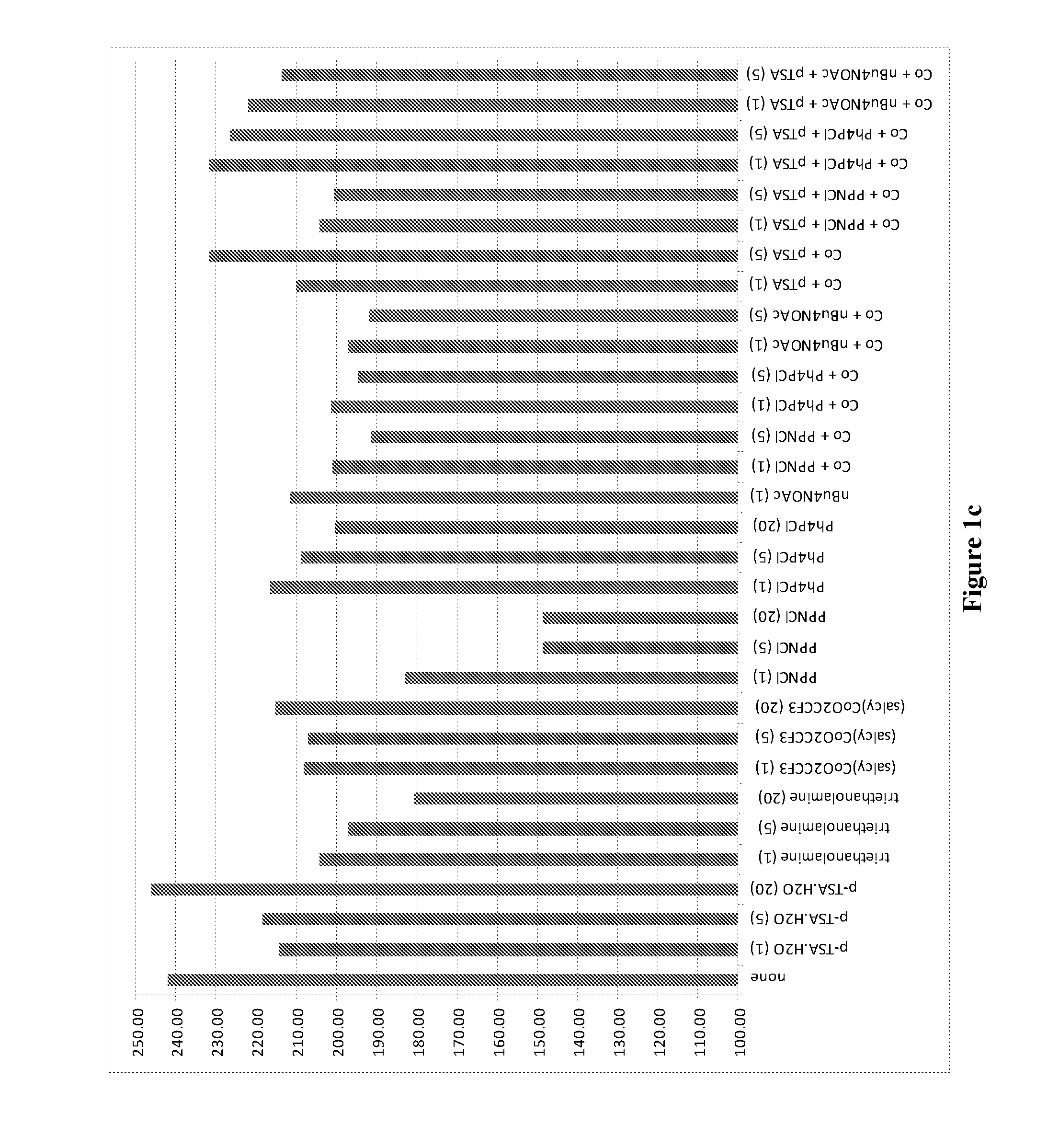

Tunable polymer compositions

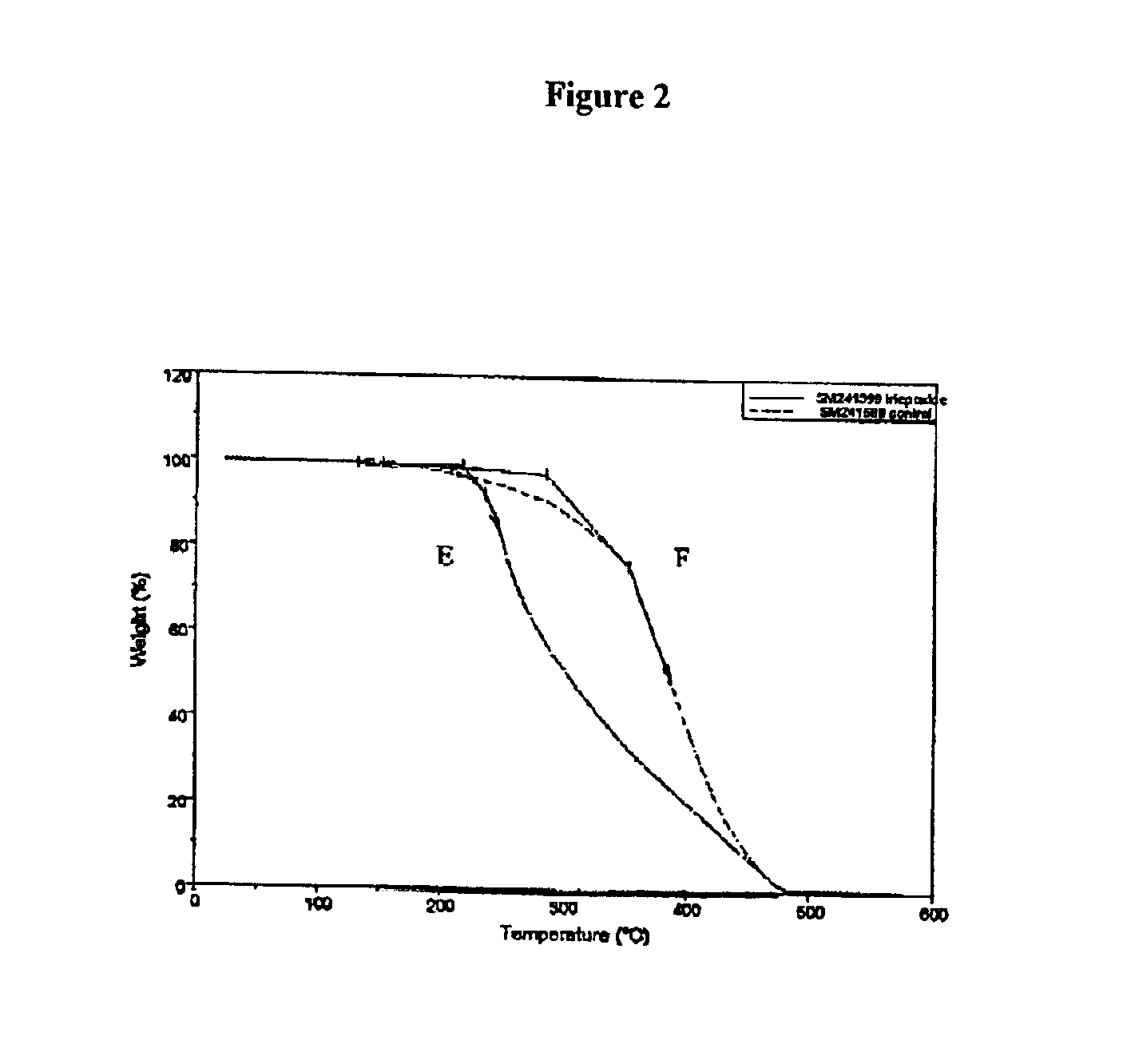

ActiveUS20110257296A1Lower decomposition temperatureConductive materialOrganic conductorsPolymer scienceDecomposition

The present invention provides polymer compositions having a tunable decomposition temperature. Suitable additives are disclosed for lowering the decomposition temperature of polymer compositions. The invention further provides methods of preparing such polymer compositions with tunable decomposition temperatures.

Owner:NOVOMER INC

Electronic device and method of manufacturing the same

ActiveUS8354340B2Low costLower decomposition temperatureSemiconductor/solid-state device detailsLaminating printed circuit boardsSolder ballEngineering

In a conventional electronic device and a method of manufacturing the same, reduction in cost of the electronic device is hindered because resin used in an interconnect layer on the solder ball side is limited. The electronic device includes an interconnect layer (a first interconnect layer) and an interconnect layer (a second interconnect layer). The second interconnect layer is formed on the undersurface of the first interconnect layer. The second interconnect layer is larger in area seen from the top than the first interconnect layer and is extended to the outside from the first interconnect layer.

Owner:RENESAS ELECTRONICS CORP

Catalyst used for decomposing N2O and preparation method and application thereof

InactiveCN101745394AHigh activityImprove stabilityNitrous oxide captureDispersed particle separationNitrateDecomposition

The invention relates to a catalyst used for decomposing N2O and a preparation method and application thereof, which are characterized in that an active component is a composite oxide which contains copper oxide and zinc oxide and has a spinelle structure or a perovskite-like structure, and the composite oxide is loaded on a gamma-Al2O3 carrier, and auxiliary metallic oxides can also be added; the nitrate or the acetate of the composite oxide is dissolved in water; the gamma-Al2O3 carrier is dipped, is evaporated to remove water and then is dried to obtain a precursor; and then the precursor is baked to obtain the catalyst. The catalyst is used for decomposing N2O and has high activity and high stability; the catalyst is used for the direct decomposition of N2O; the decomposing temperature of N2O is low, and the complete decomposition temperature is lower than or equal to 615 DEG C; after an intensified experiment is carried out for 100 hours, the catalyst still keeps the advantage and effect of high activity.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

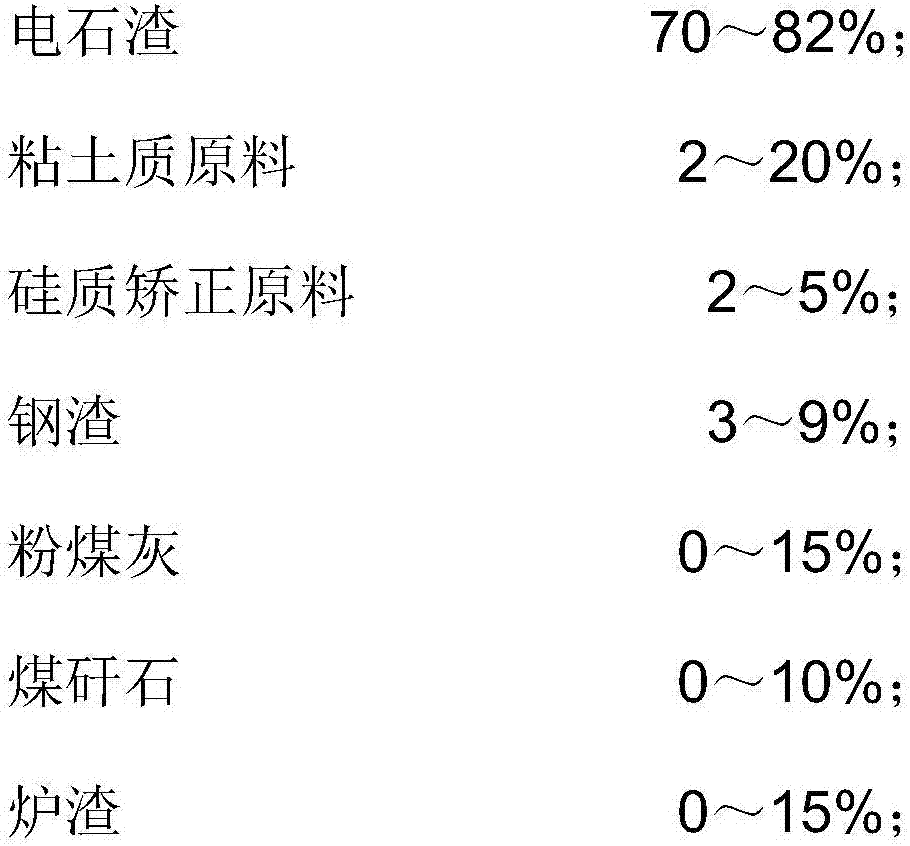

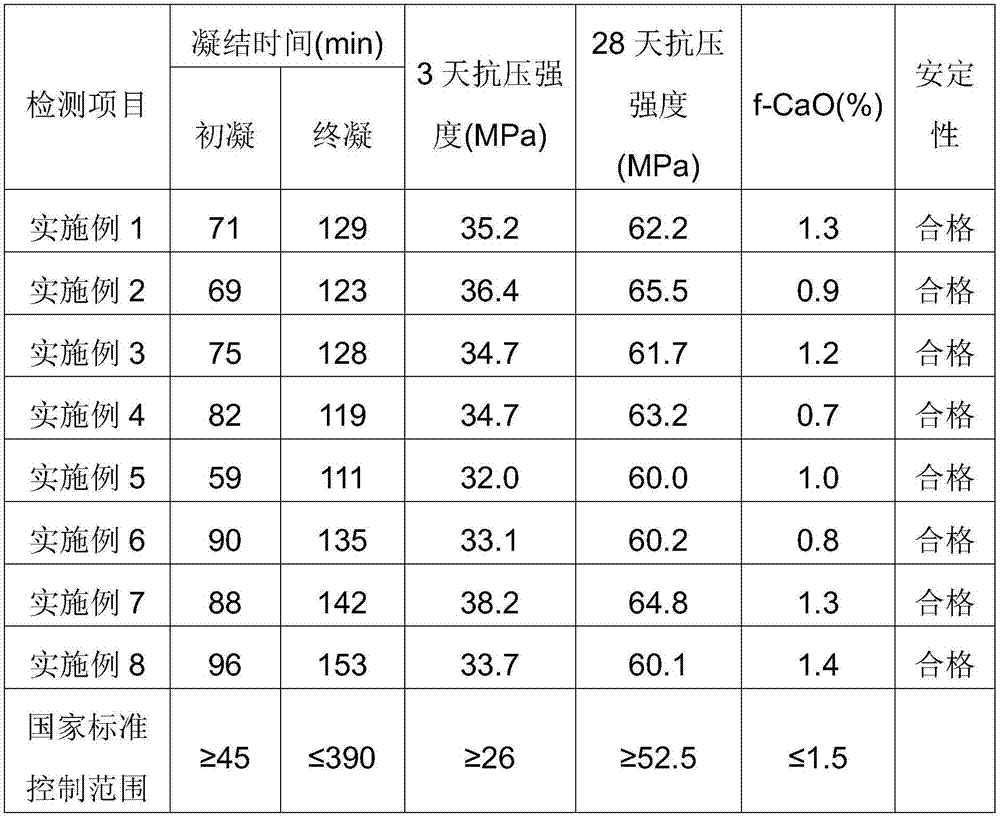

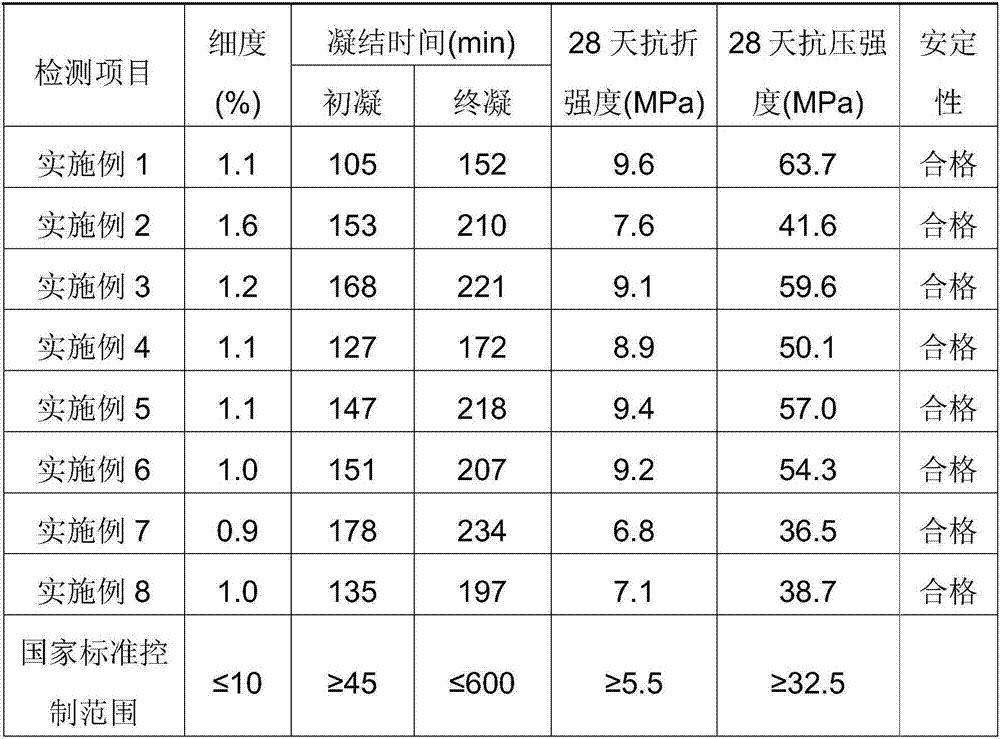

High-doped industrial waste residue cement and preparation method thereof

InactiveCN107200486AMeet preparation standardsLower decomposition temperatureCement productionGypsumSlag

The invention discloses high-doped industrial waste residue cement and a preparation method thereof. The high-doped industrial waste residue cement is prepared from raw materials: 70 to 82 percent of carbide slag, 2 to 20 percent of argillaceous raw materials, 2 to 5 percent of siliceous straightening raw material, 3 to 9 percent of steel slag, 0 to 15 percent of coal ash, 0 to 10 percent of coal gangue and 0 to 15 percent of furnace slag; and auxiliary materials: 0 to 50 percent of mixed materials and 0.8 to 7 percent of desulphurized gypsum. The carbide slag is used for completely substituting limestone, and by matching various industrial residues, the preparation standard of high-doped industrial waste residue cement can be satisfied; the production cost and the energy consumption are relatively low, and the resource waste and environmental pollution caused by the industrial residues can be avoided; and the produced clinker is high in strength, stable in quality and easy to popularize and use.

Owner:SHAANXI BEIYUAN CHEM GROUP

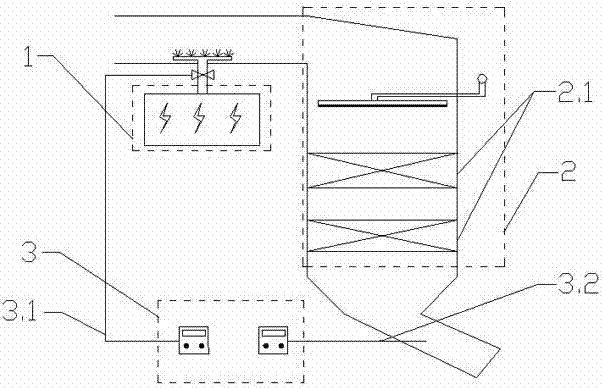

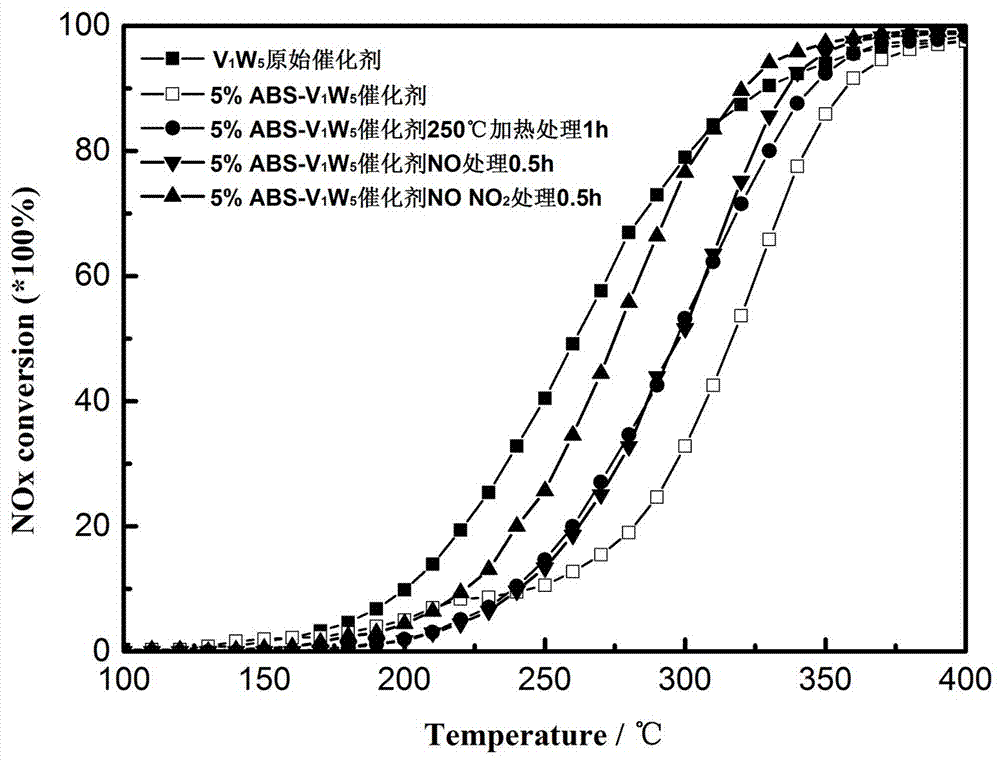

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

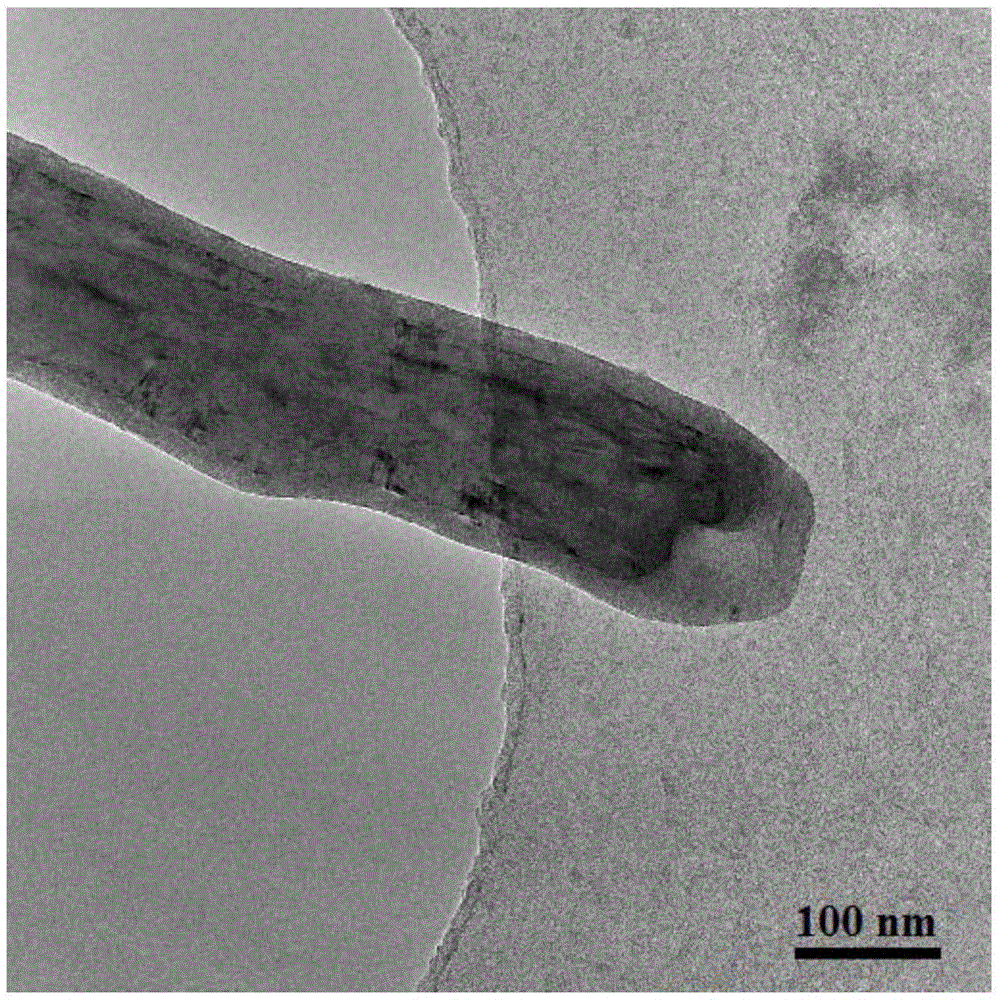

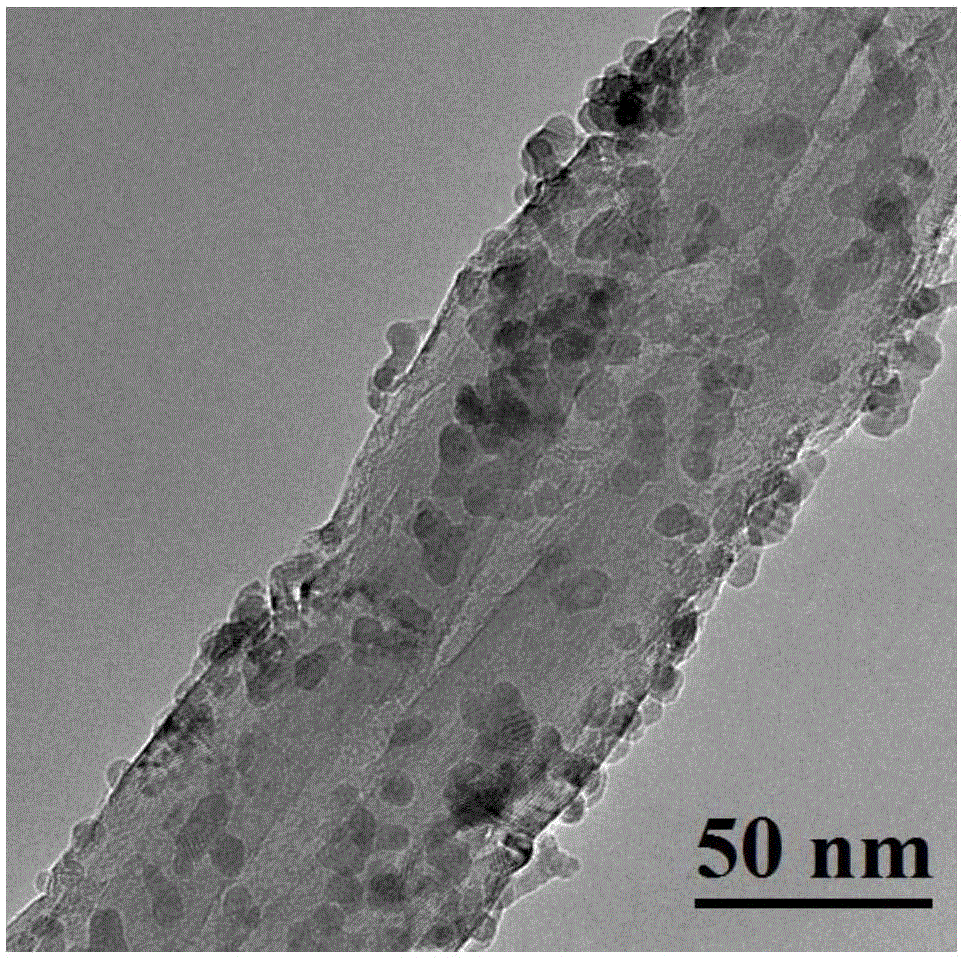

Synthesis process of nanometer silver sulfide/copper sulfide in controlled shape

InactiveCN1887719ALower decomposition temperatureHigh yieldCopper sulfidesSilve compoundsReaction temperatureAmmonium bromide

The synthesis process of nanometer silver sulfide / copper sulfide in controlled shape relates to shape controlling synthesis technology of silver sulfide / copper sulfide in nanometer structure. The present invention aims at lowering the synthesis temperature of silver sulfide / copper sulfide, and raising the yield and structure controllability. The technological scheme is that under magnetic stirring, silver nitrate or copper chloride solution of 6-15 mmol / L concentration is drop-by-drop added into sodium thiosulfate solution of 9-52.5 mmol / L concentration, cetyl trimethyl ammonium bromide in 2.0-3.5 mmol is then added into the solution, the solution is stirred strongly at 30-60 deg.c for 30 min, acid is added to regulate pH to 1-5, and through further heating at the same temperature for 1-8 hr and natural cooling, the product is obtained.

Owner:HARBIN NORMAL UNIVERSITY

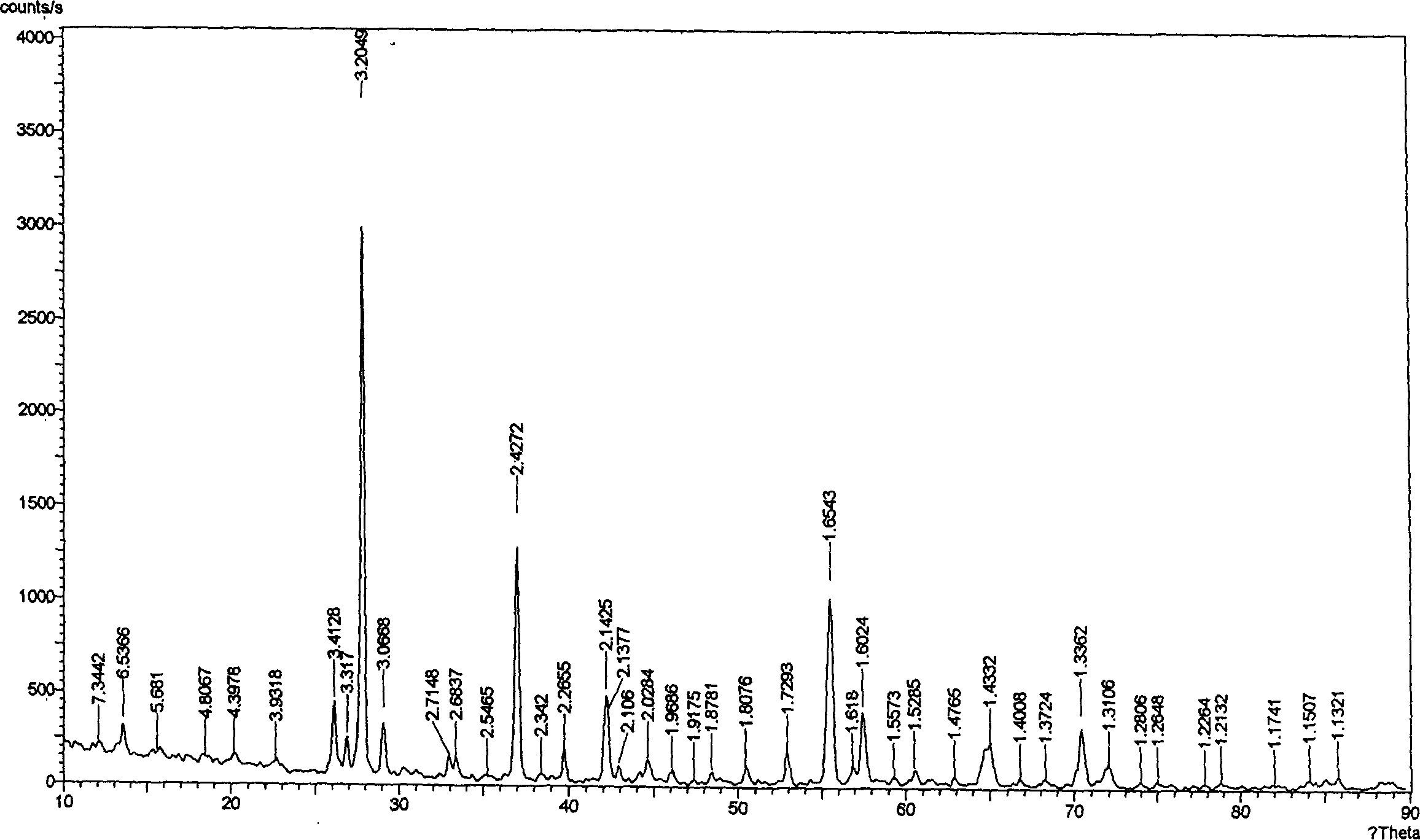

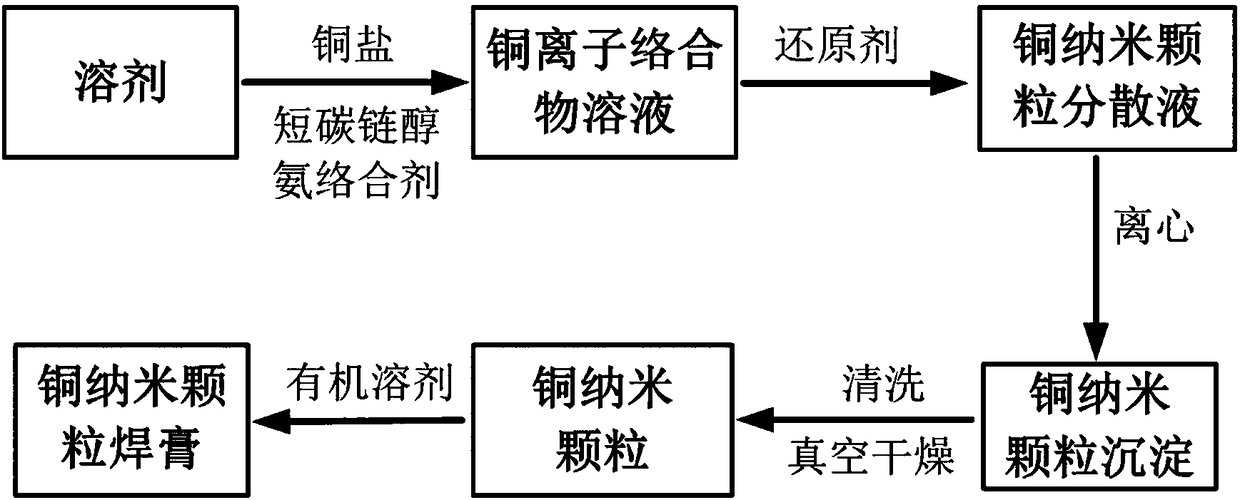

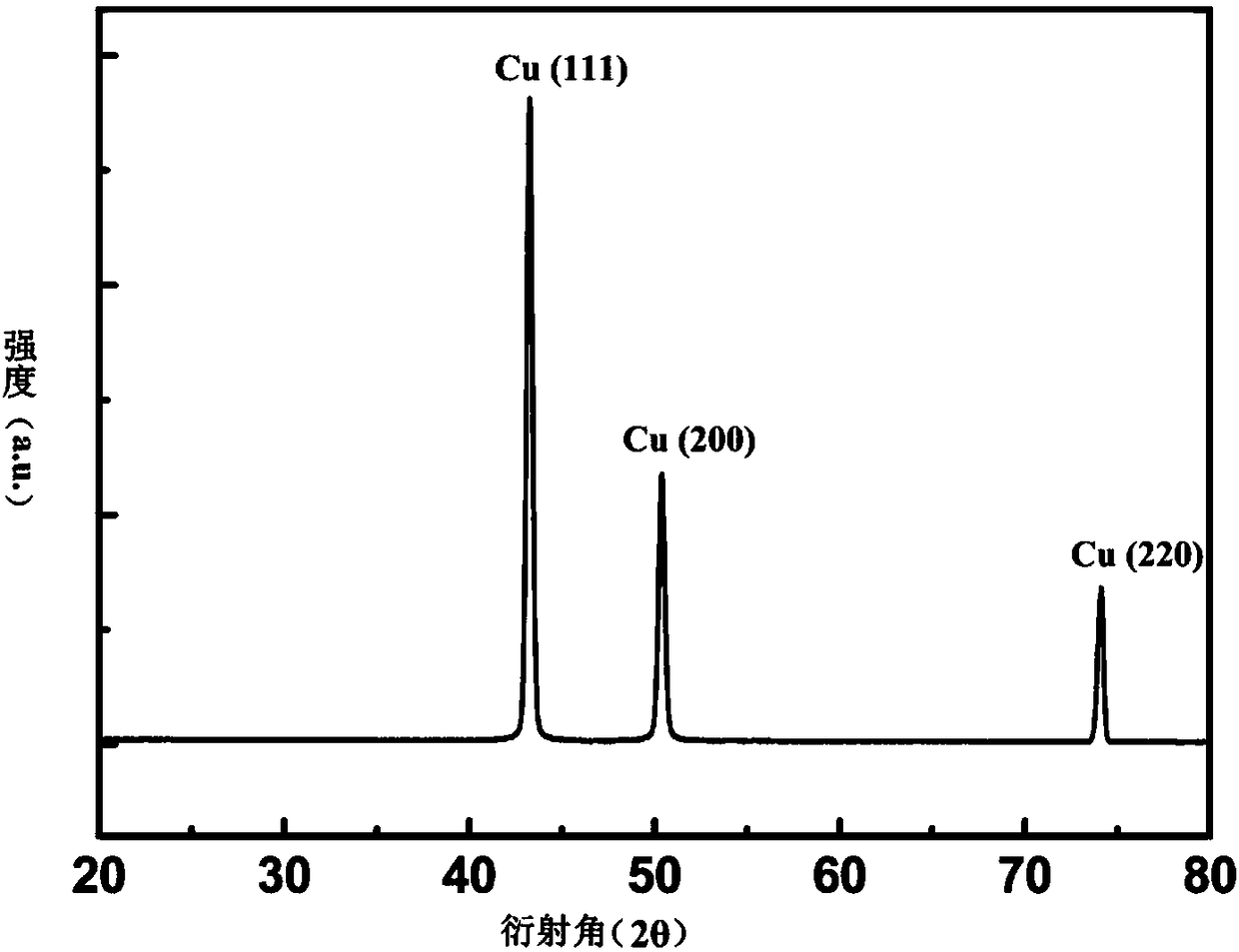

Preparation method of copper nano-particle soldering paste and product thereof

ActiveCN108098191AUniform particle size distributionThe characteristic diffraction peaks are obviousNanotechnologyWelding/cutting media/materialsCarbon chainSolvent

The invention belongs to the field of nanotechnology and electronic manufacturing, and discloses a preparation method of a copper nano-particle soldering paste and a product thereof. The method comprises the following steps that (a), a copper salt and short carbon chain (C3-C5) alcohol ammonia complexing agent is dissolved in a solvent to form a solution, a reducing agent is added into the solution to stir and react sufficiently, and copper nano-particle dispersion liquid is obtained after reaction; and (b), the copper nano-particle dispersion liquid is centrifuged to obtain the copper nano-particles, washing and vacuum drying treatment are carried out, the obtained dried copper nano-particles are dissolved in the copper nano-particle soldering paste in an organic solvent, and vacuum stirring is carried out so as to obtain the required copper nano-particle soldering paste. The invention further discloses the product using the method. According to the method, the prepared copper nano-particle soldering paste is low in cost and good in oxidation resistance, and the particle size distribution of the copper nano-particles in the soldering paste is uniform, and meanwhile, the preparation method is easy to control, low in cost, and simple in process.

Owner:HUAZHONG UNIV OF SCI & TECH

Efficient catalyst for decomposition of N2O and preparation method and application thereof

ActiveCN105363451AEconomicalHigh catalytic activityNitrous oxide captureDispersed particle separationDecompositionAdipic acid

The present invention provides an efficient catalyst for decomposition of N2O and a preparation method and application thereof. The catalyst comprises an active center and a carrier; the active center includes quantum dot oxide and spinel-type structural compound, and the carrier is a Al2O3 carrier; and the catalyst has a molecular formula L IIxO / M II1-xNIII2O4 / Al2O3, wherein: L II and M II are divalent metal cations, N III is a trivalent metal cation, and x equals to 0.01-1.0. The efficient catalyst for decomposition of N2O has high activity, good stability and low N2O decomposition temperature, is conducive to the purification of industrial waste gas from adipic acid plant; and the catalyst for decomposing N2O can significantly reduce the N2O concentration in industrial emission, reduce air pollution and protect the environment.

Owner:CHINA TIANCHEN ENG +1

High efficiency coal additive

The high efficiency coal additive consists of desulfurizer, leavening agent, combustion adjuvant, smoke suppressor and corrosion inhibitor mixed together. The desulfurizer contains CaO, NH4HCO3, ZnO and SiO2; the leavening agent contains NaHCO3, KAl(SO4)2 .12H2O and acidified coal gangue; the combustion adjuvant contains Fe2O3, MgO, KCl, KMnO4 and NaNO3; the corrosion inhibitor is humic acid and NaNO3; and the smoke suppressor is also KMnO4. The high efficiency coal additive is mixed directly with coal for boiler, furnace, kiln, oven, etc. Detection shows that the high efficiency coal additive can result in desulfurizing rate of 85 %, save coal rate by14.77 %, raise heat efficiency by 9.19 %, lower carbon content of coal slag by 14.86 %,and reduce smoke, scale and corrosion by 90 %.

Owner:郴州市宇洁环保建材有限公司

High-flux ceramic flat sheet membrane and preparation method thereof

The invention relates to a high-flux ceramic flat sheet membrane and a preparation method thereof. The high-flux ceramic flat sheet membrane comprises a ceramic flat sheet membrane supporting body and a separation membrane layer wrapping the outer surface of the ceramic flat sheet membrane supporting body. The ceramic flat sheet membrane support body is prepared from the following raw materials in parts by mass: 40-57 parts of diatomite, 30-40 parts of alpha-alumina powder, 4-12 parts of a pore forming agent, 20-40 parts of a support body binding agent, 8-12 parts of a lubricant, 9-13 parts of a plasticizer and 12-18 parts of chopped fibers. The separation membrane layer is prepared from the following raw materials in parts by mass: 40-43 parts of ceramic powder particles, 4-6 parts of ethanol, 19-40 parts of a separation membrane layer binding agent and 9-12 parts of polyethylene glycol. The high-flux ceramic flat sheet membrane product is low in sintering temperature, low in production cost, high in product porosity, small in filtering resistance and high in water flux.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com