Preparation method of copper nano-particle soldering paste and product thereof

A copper nanoparticle and solder paste technology, applied in the fields of nanotechnology and electronic manufacturing, can solve the problems of affecting the thermal stability and electrical conductivity of the bonding layer, poor resistance to ion migration, limiting application prospects, etc., so as to improve the overall performance of the product, Good antioxidant properties, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

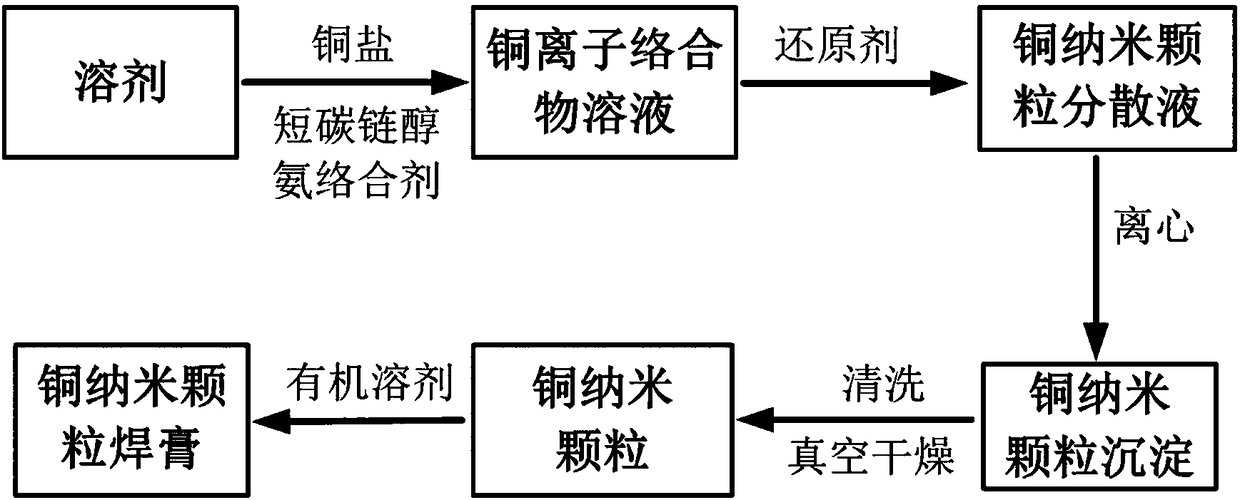

[0028] figure 1 It is the preparation flowchart of the copper nanoparticle solder paste constructed according to the preferred embodiment of the present invention, as figure 1 Shown, a kind of preparation method of oxidation-resistant copper nano particle solder paste, the method comprises the following steps:

[0029] (1) Dissolve the copper salt and the short carbon chain alcohol ammonia complexing agent in the solvent, then add the reducing agent, and continue stirring for 0.5 to 12 hours to obtain a copper nanoparticle dispersion; the copper salt is copper formate, copper acetate, chlorine Copper chloride, copper sulfate, copper nitrate or copper laurate, the short carbon chain alcohol ammonia complexing agent is 2-(methylamino)ethanol, 2-amino-1-butanol, 3-amino-1, 2-propanediol or 3- Amino-1-butanol, the solvent is ethylene glycol, ethylene glycol, glycerol, benzyl alcohol, 1,2-propanediol or pentylene glycol, isopropanol, the reducing agent is hydrazine hydrate, phenyl...

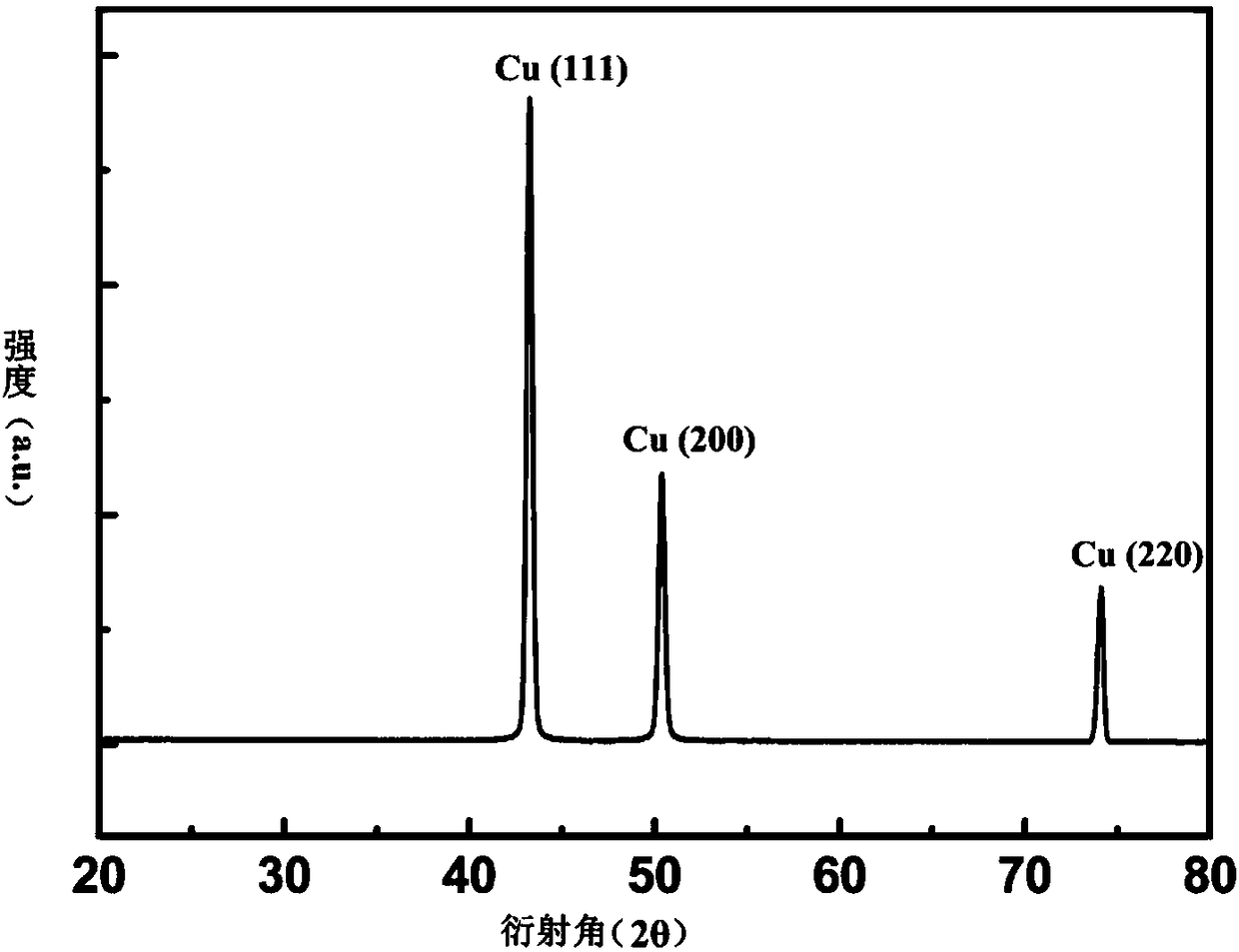

Embodiment 1

[0034](1) Dissolve copper acetate and 2-(methylamino)ethanol in ethylene glycol, then add hydrazine hydrate, and continue stirring for 6 hours to obtain a copper nanoparticle dispersion. Wherein the molar ratio of copper acetate to methylamine-2-ethanol is 1:10, and the molar ratio of copper acetate to hydrazine hydrate is 1:10.

[0035] (2) centrifuging the copper nanoparticle dispersion obtained in step 1, then washing with ethanol, and finally vacuum drying at 60° C. for 2 hours to obtain copper nanoparticles;

[0036] (3) Dispersing the copper nanoparticles obtained in step 2 into butanol for vacuum stirring treatment to obtain copper nanoparticle solder paste.

Embodiment 2

[0038] (1) Dissolve copper formate and 2-amino-1-butanol in ethylene glycol, then add hydrazine hydrate, and continue stirring for 12 hours to obtain a copper nanoparticle dispersion. Wherein the molar ratio of copper formate to 2-amino-1-butanol is 1:8, and the molar ratio of copper acetate to hydrazine hydrate is 1:15.

[0039] (2) centrifuging the copper nanoparticle dispersion obtained in step 1, then washing with methanol, and finally vacuum drying at 60° C. for 2 hours to obtain copper nanoparticles;

[0040] (3) Disperse the copper nanoparticles obtained in step 2 into methyl amyl alcohol and carry out vacuum stirring treatment to obtain copper nanoparticle solder paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com