Preparation method for Cu-based hydrogenation catalyst

A hydrogenation catalyst, copper-based technology, applied in the direction of organic chemistry, etc., can solve problems such as difficult to control the interface structure of copper and oxides, and achieve the effects of good product preparation uniformity, good universality, and high hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

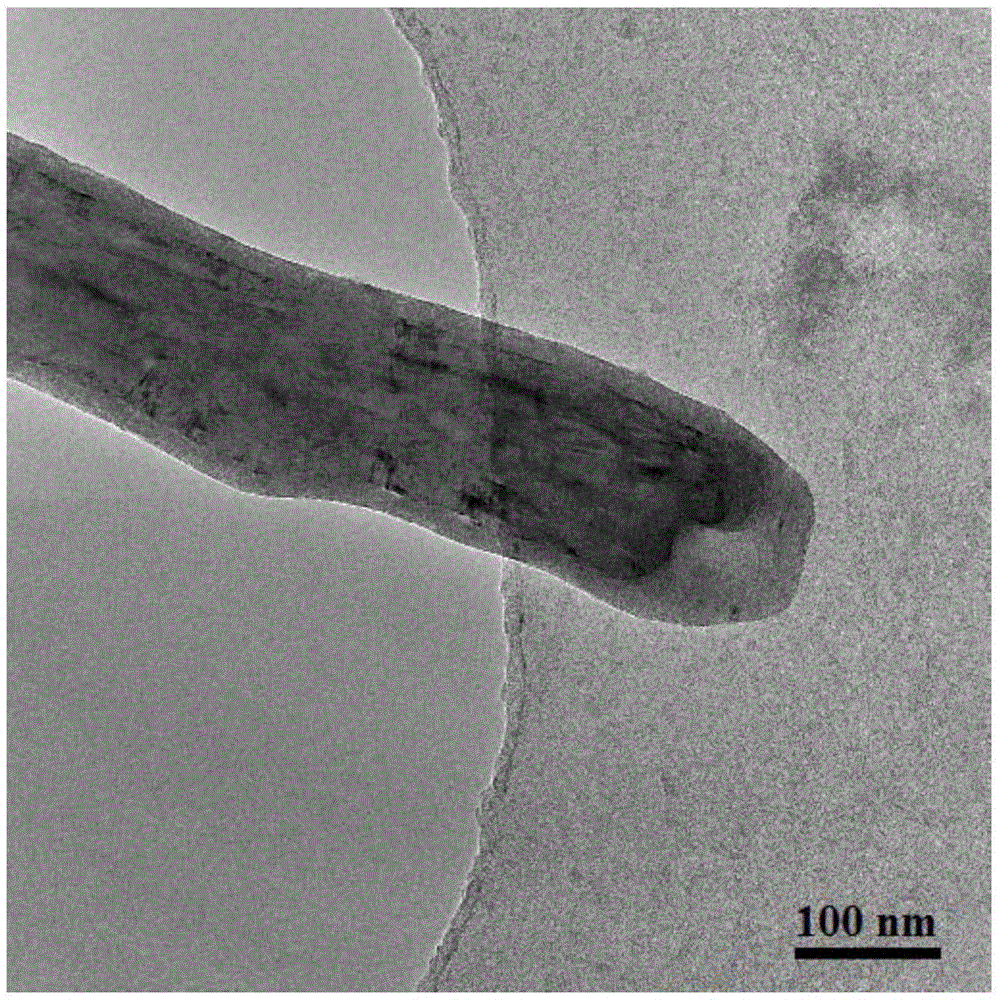

[0031] 1) Weigh 1.52g copper nitrate (Cu(NO 3 ) 2 .3H 2 O) and 1.5g of urea were dissolved in 10ml of water, 1.5g of multi-walled carbon nanotubes (CNTs) was added, and stirred at 150°C for 0.5h. Copper nitrate precursor (Cu / CNTs).

[0032] 2) The sample loaded with copper is mixed with ethanol to form a uniform suspension, the concentration of the sample is 0.1g / ml, coated on the surface of the glass sheet, evaporated to dryness and placed in the molecular layer deposition vacuum reaction chamber, the temperature of the chamber is 80°C, the cavity pressure is 50Pa, the cavity volume is 200ml, the carrier gas is nitrogen during the deposition process, and the flow rate is 1sccm-1000sccm, preferably 60sccm.

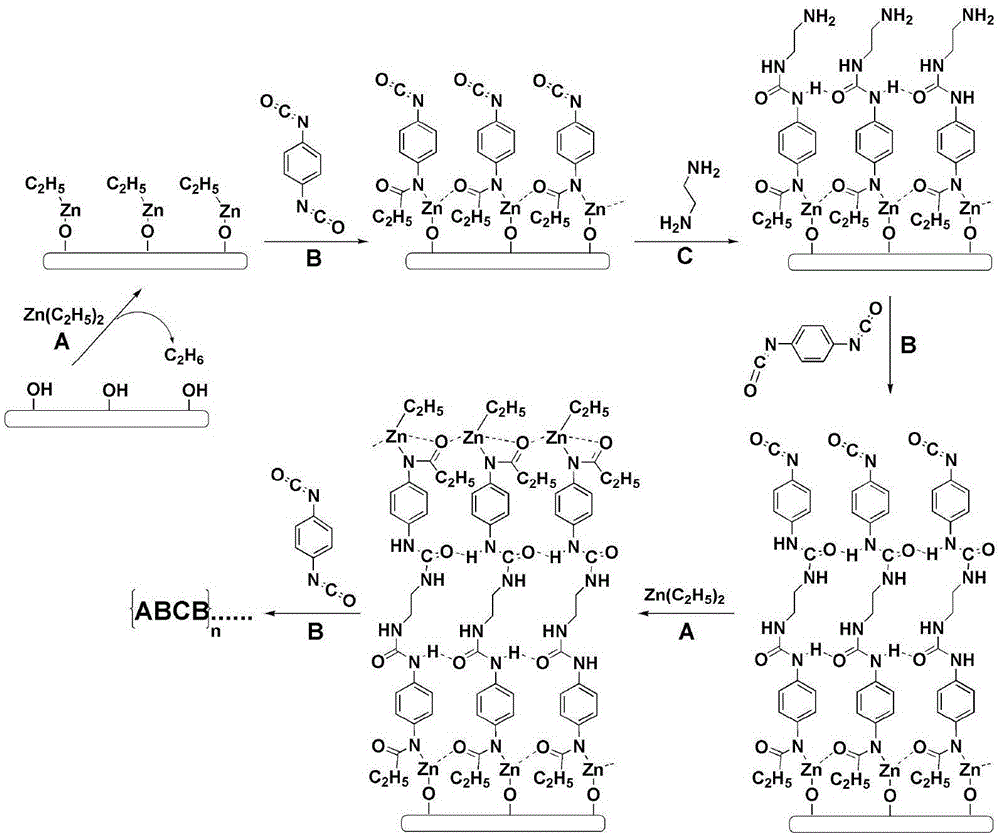

[0033] 3) Polyurea hybrid film deposited by molecular layer deposition technology:

[0034] (a) The first pulse of diethyl zinc vapor is chemically adsorbed on the surface of the Cu / CNTs sample, and the physically adsorbed part is removed by pumping;

[0035] (b) The ...

Embodiment 2

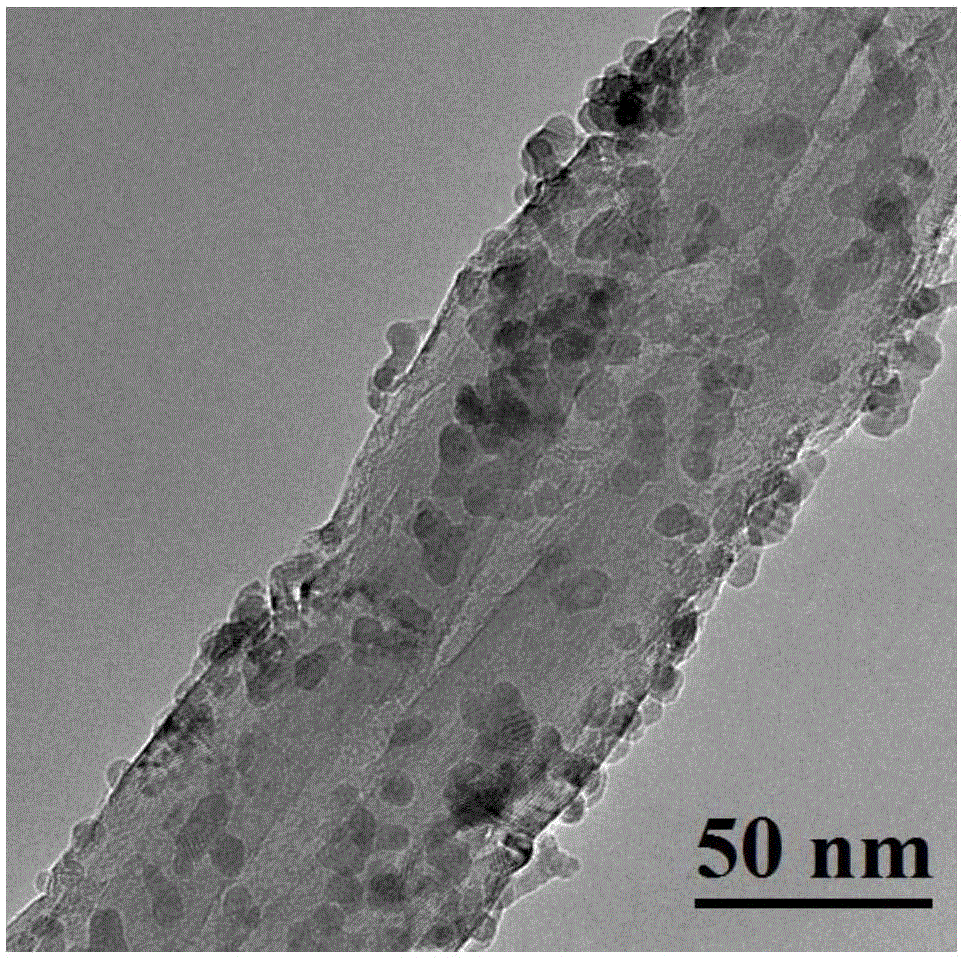

[0043] Adopt the same method of embodiment 1 to test, and the difference with embodiment 1 is that the number of deposition cycles increases by 120 cycles, and the yield of gamma-valerolactone in levulinic acid hydrogenation is improved to 74%, showing that Zn-poly The thickness of the urea hybrid film can change the number of Cu-ZnO binding sites, and its TOF is 11.2h -1 . This indicates that more Cu-ZnO interfaces can be obtained by increasing the thickness of molecular layer deposition, which improves the intrinsic activity of the catalyst. Example 3:

Embodiment 3

[0044] 1) Weigh 1.9g of copper acetate and dissolve it in 10ml of ethanol, add 7.9g of porous alumina, stir at room temperature for 12h, and dry at 60°C for 24h to prepare alumina-supported copper acetate precursor (Cu / Al 2 o 3 ).

[0045] 2) The sample loaded with copper is mixed with ethanol to form a uniform suspension, the concentration of the sample is 0.03g / ml, coated on the surface of the glass sheet, evaporated to dryness and placed in the molecular layer deposition vacuum reaction chamber, the temperature of the chamber is 90°C, the cavity pressure is 40Pa, the cavity volume is 200ml, the carrier gas is nitrogen during the deposition process, and the flow rate is 1sccm-1000sccm, preferably 50sccm.

[0046] 3) Polyurea hybrid film deposited by molecular layer deposition technology:

[0047] (a) The first pulse of dimethyl zinc vapor chemisorption on Cu / Al 2 o 3 On the surface of the sample, pump air to remove the physically adsorbed part;

[0048] (b) The second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com