Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195results about How to "High ratio of silicon to aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

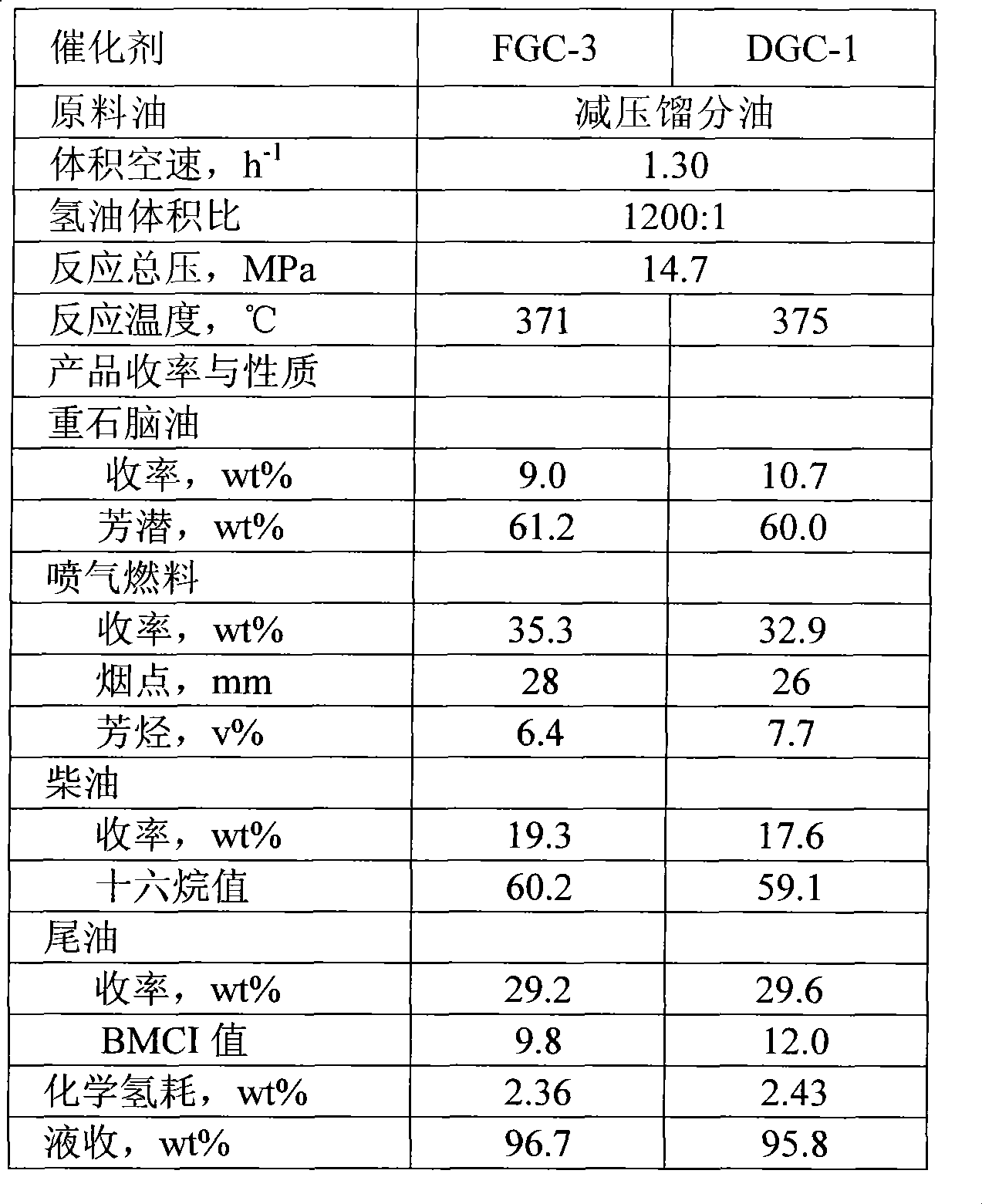

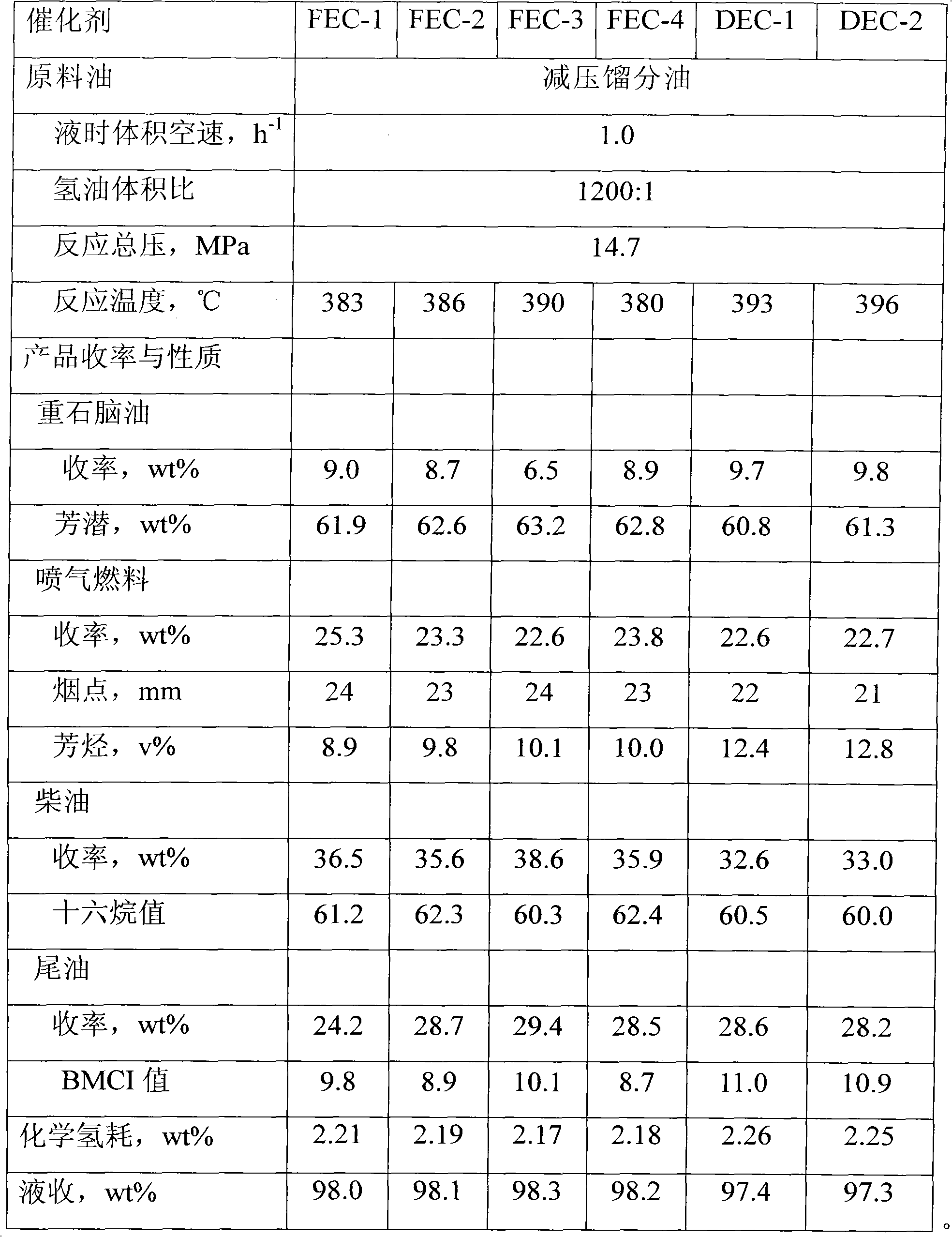

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

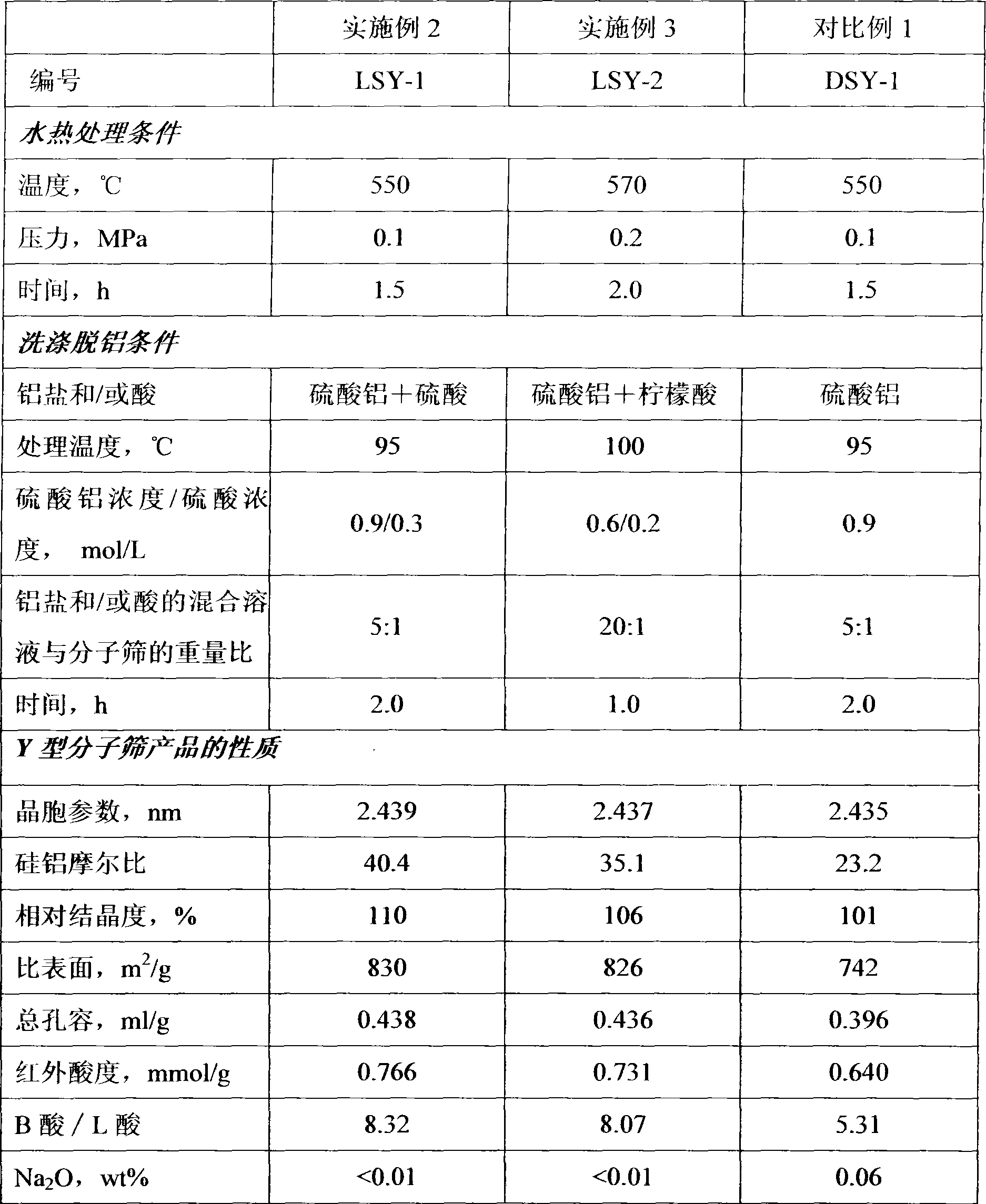

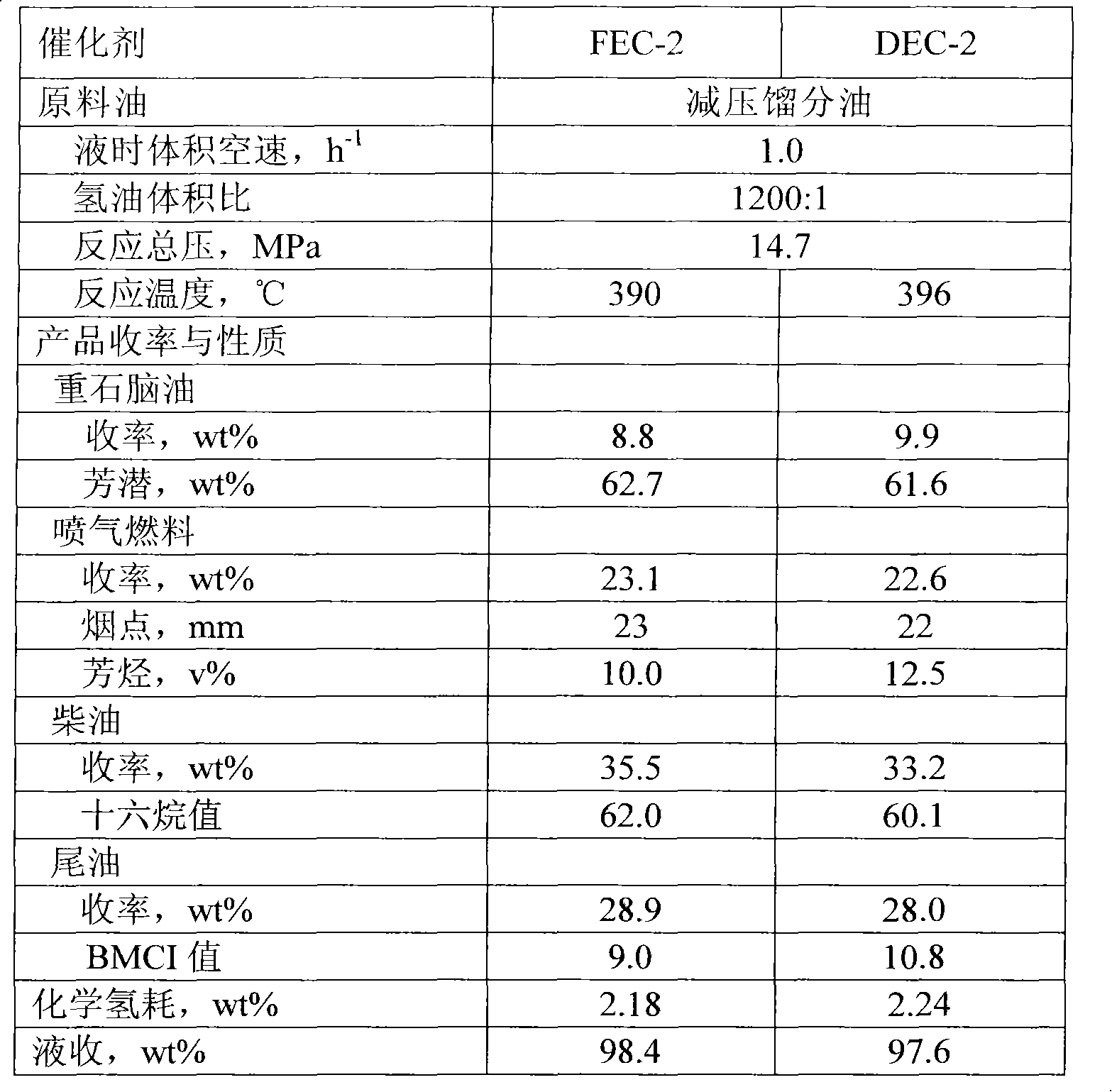

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

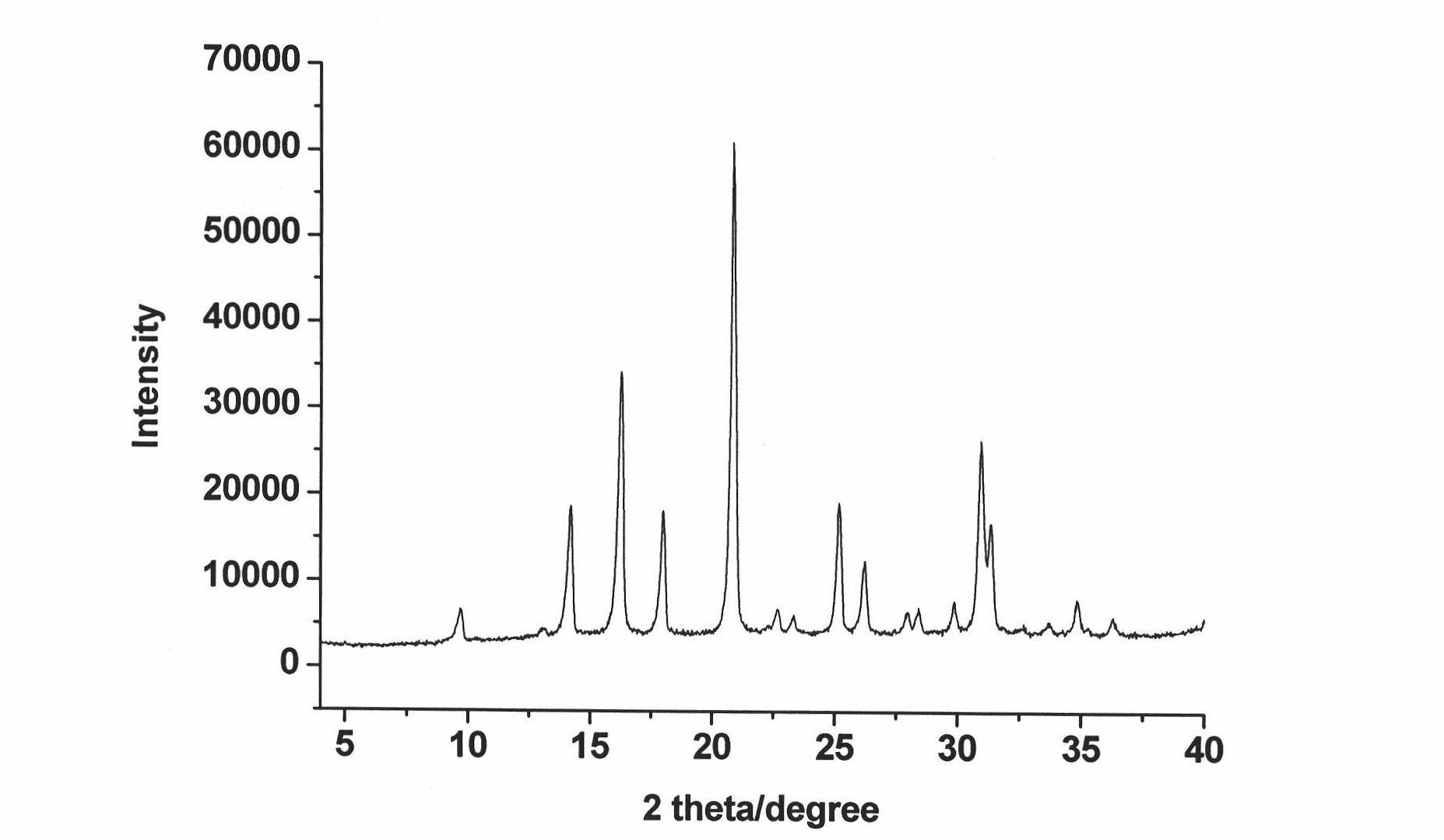

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

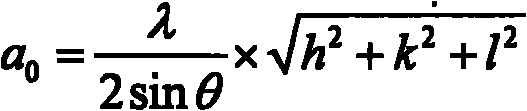

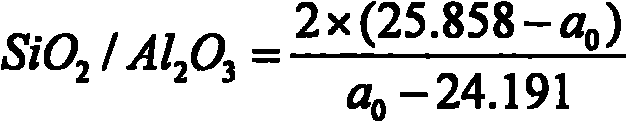

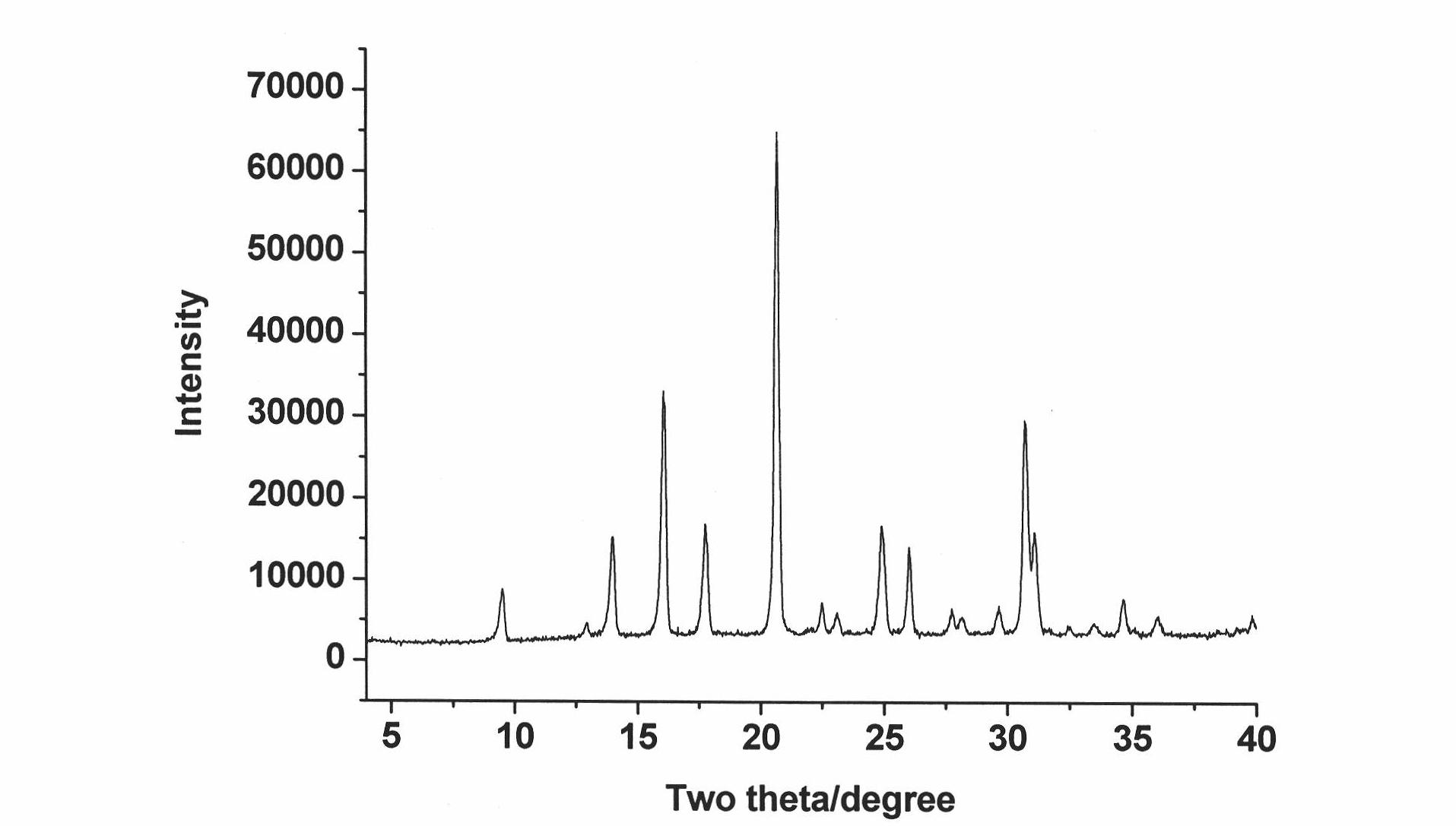

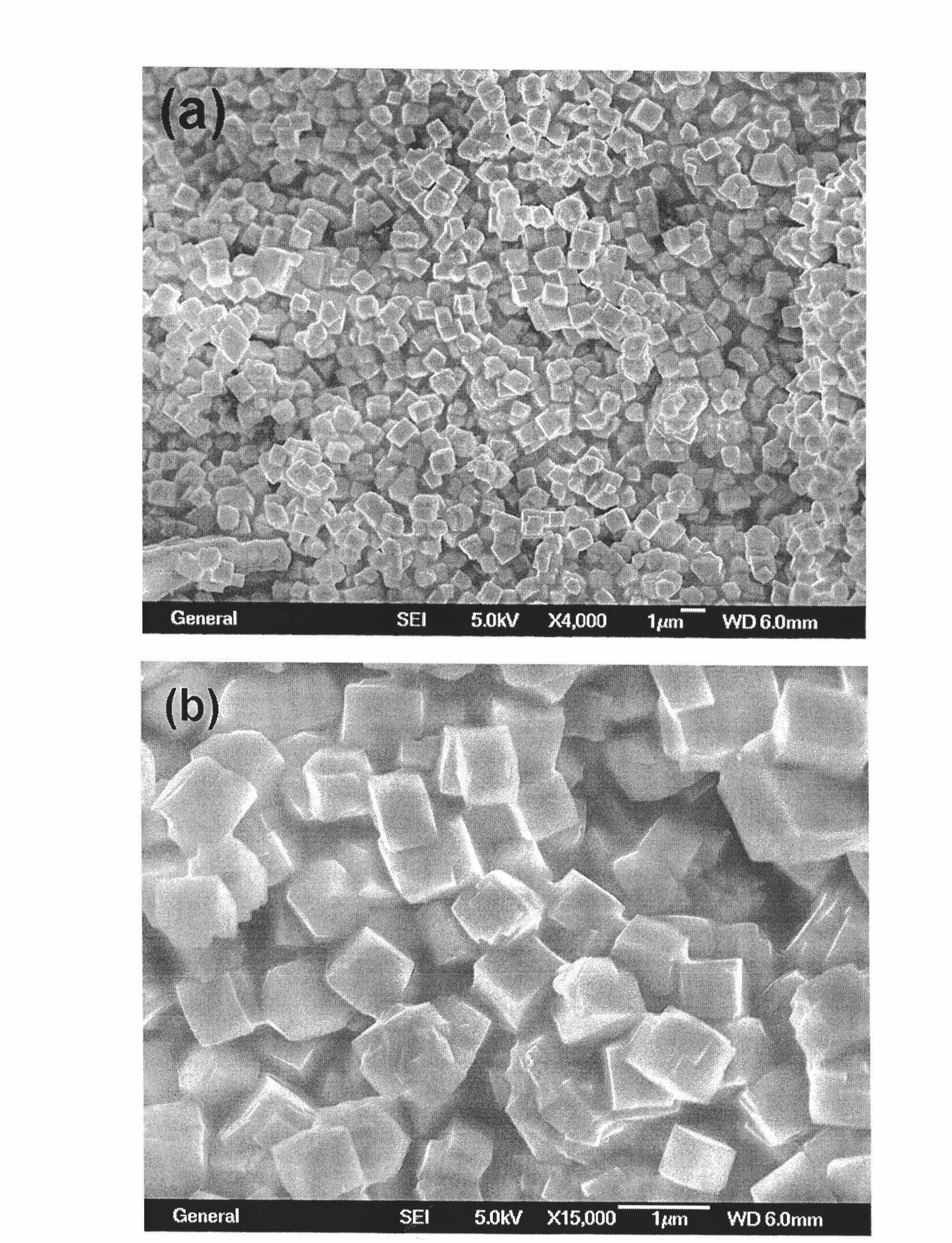

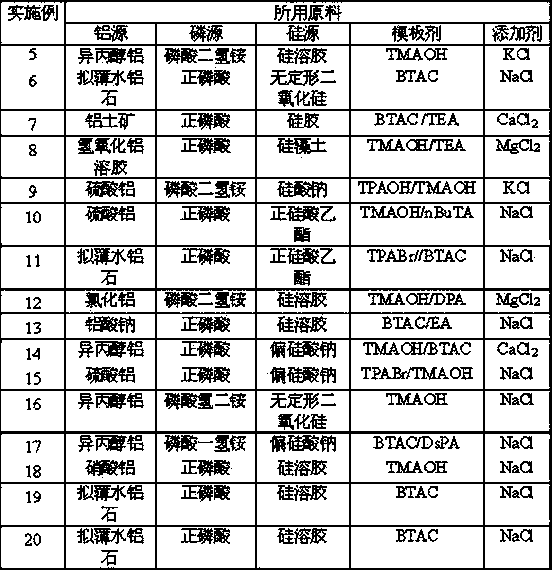

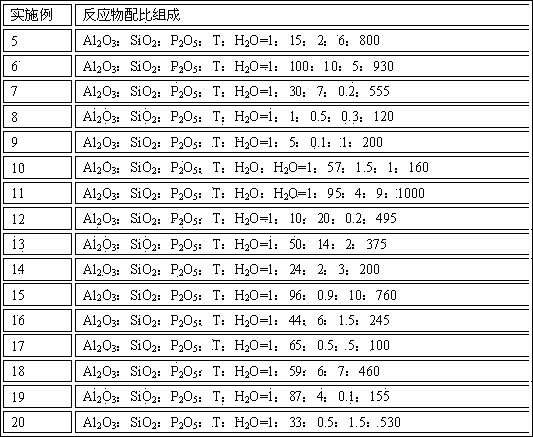

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y molecular sieve modification method

ActiveCN1803612ASmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveDistilled oil

The invention relates to a modifying method for Y molecular sieve, which comprises: using industrial NaY molecular sieve as material for ammonium exchange, baking deeply; then, adding surfactant during dealumination with acid. This invention obtains HY molecular sieve with high SiO2 / Al2O3(9~15) and crystallinity, improves secondary pores and acid structure compared with the industrial NaY, and fits to be carrier for hydrotreating catalyst for heavy distilled oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrogenation dearomatization catalyst and preparation method thereof

ActiveCN104588073AHigh activityFacilitates selective loop openingMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveNaphtha

The invention discloses a hydrogenation dearomatization catalyst and a preparation method thereof. The catalyst comprises a main active component Pt, an auxiliary component Pd and a carrier prepared from a small-grain Y type molecular sieve, alumina and amorphous silicon aluminum. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of great dealumination depth, good crystallinity retentivity and well-developed secondary pores is used as an acid component and cooperates with the amorphous silicon aluminum, the main active component and the auxiliary component, so the hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of heavy aromatic-containing naphthenic high-viscosity white oil and solvent naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

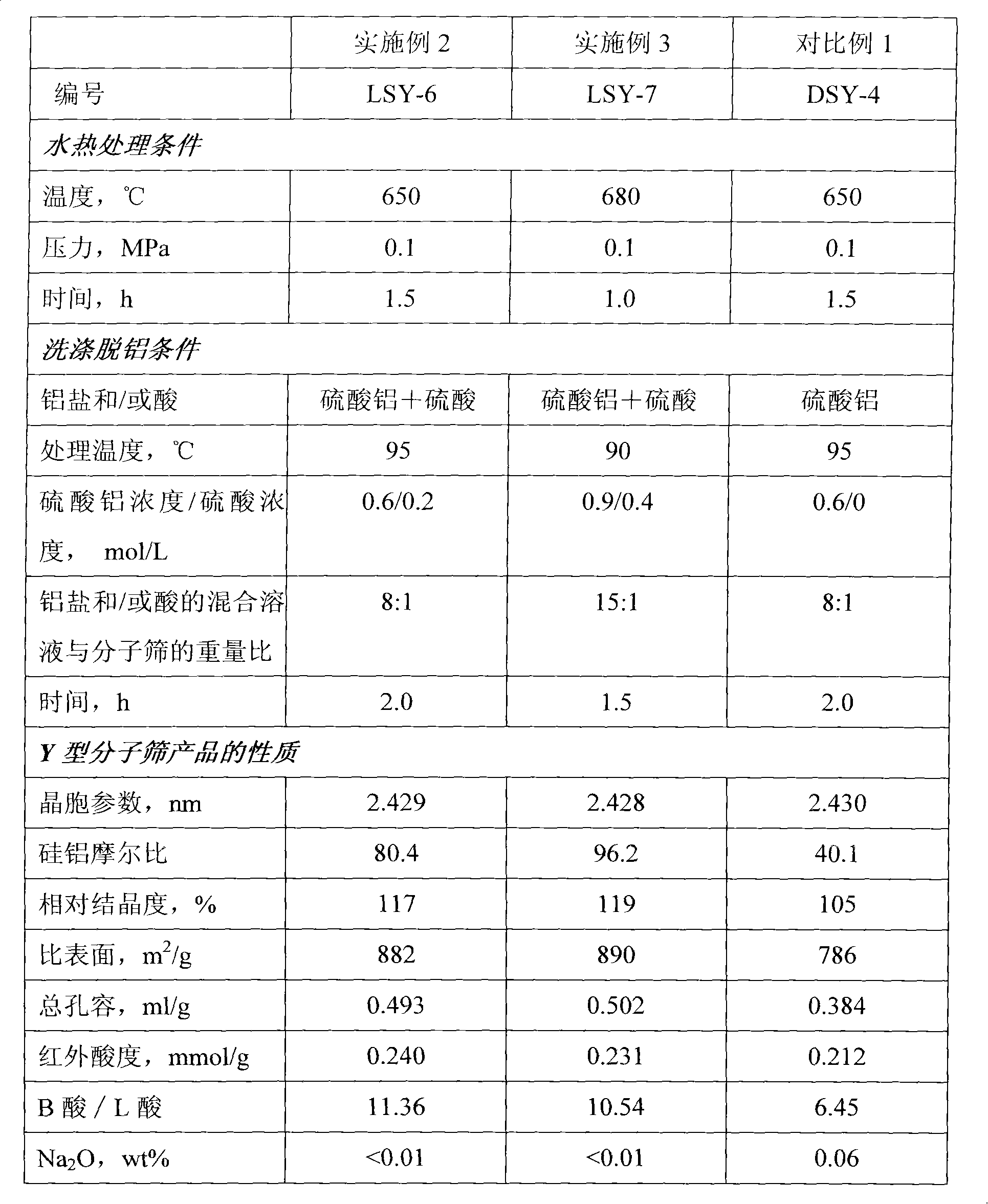

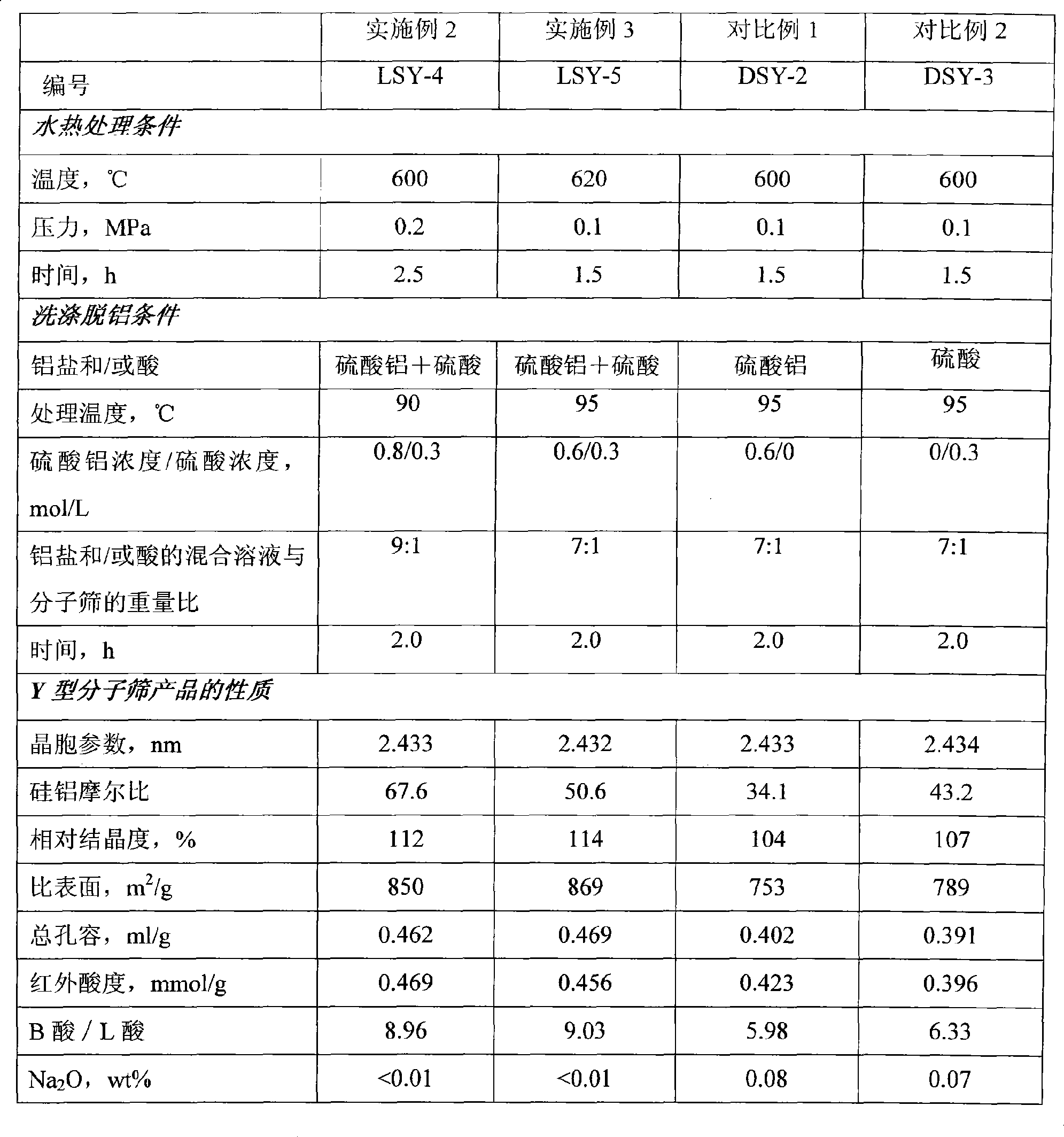

ActiveCN101380588AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveChemistry

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y molecular sieve, amorphous aluminium silicon and alumina, wherein, the preparation method of the Y molecular sieve is as follows: the Y molecular sieve which is treated by mixed water solution of aluminum salt and acid in a heating way is adopted. The performance of the modified Y molecular sieve is as follows: specific surface is 800m<2> / g to 900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the ratio of the acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The hydrocracking catalyst prepared by the carrier has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

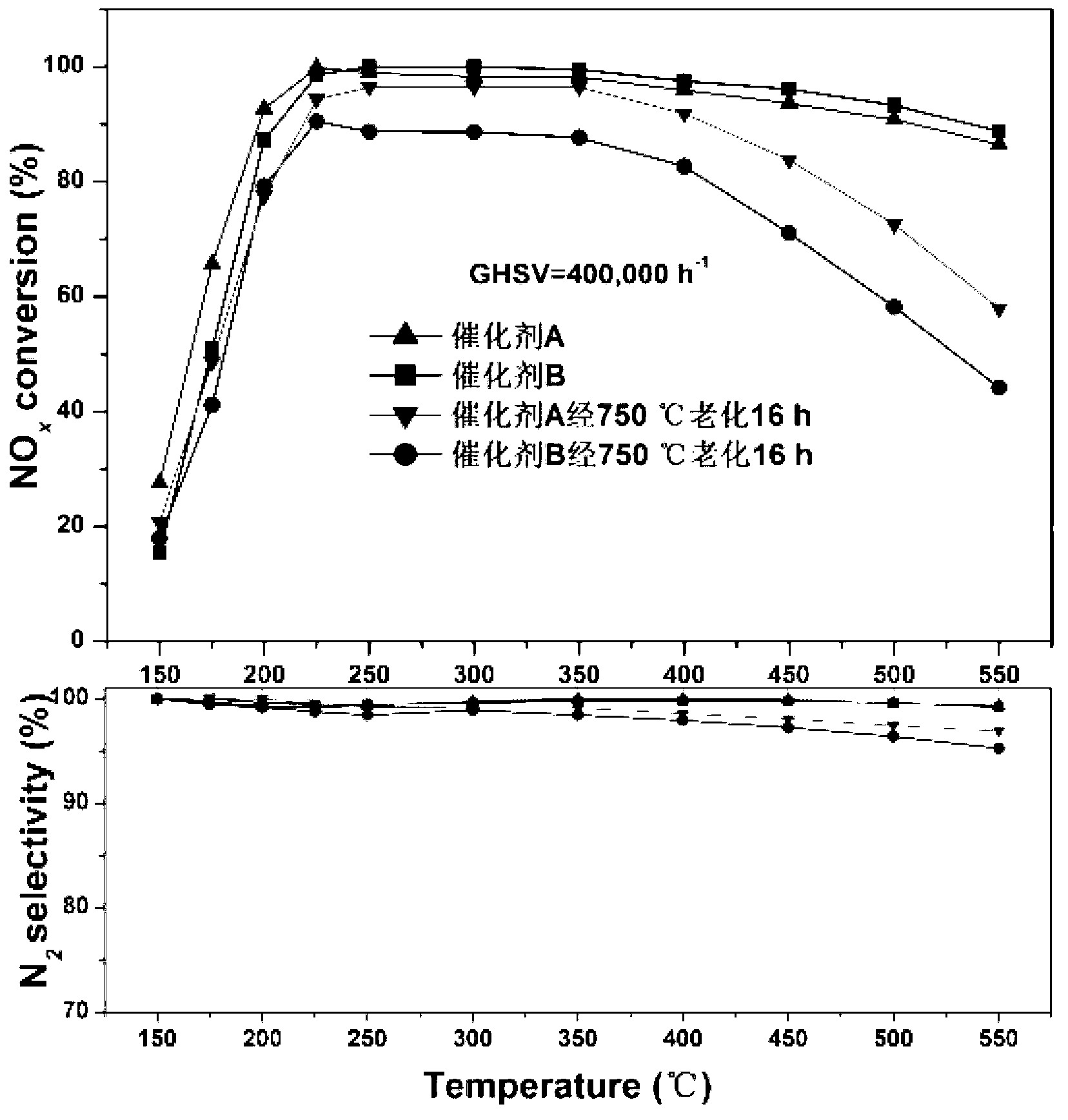

Cu-SSZ-13 catalyst, and preparation method and application thereof

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

Method for preparing NaY molecular sieve with high aluminum-silicon ratio

ActiveCN102198950AShorten crystallization timeHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The invention relates to a method for preparing a NaY molecular sieve with a high aluminum-silicon ratio, which comprises the following steps of: mixing a silicon source, an aluminum source and deionized water, uniformly mixing two guide agents in different molar ratios, water glass, acidic aluminum salt and sodium aluminate solution in a molar ratio of gel materials to prepare two gels, and crystallizing respectively, wherein the molar ratio of the gel materials is (1.0-6.5)Na2O:Al2O3:(5.0-18)SiO2:(100-280)H2O, and Al2O3 in the guide agents accounts for 0.01 to 15 percent of the total weightof Al2O3; uniformly mixing the two gels in a mass ratio of 1:(0.1-10) to prepare a mixed gel; and crystallizing the prepared mixed gel at the temperature of between 80 and 120 DEG C for 2 to 50 hoursto prepare the NaY molecular sieve. Compared with the prior art, the method has the advantages that: the NaY molecular sieve with the high aluminum-silicon ratio can be prepared in shorter time underthe condition of the same feeding molar ratio.

Owner:PETROCHINA CO LTD +1

High-silicon amorphous silica aluminum and preparation method thereof

ActiveCN101491774AHigh ratio of silicon to aluminumLarge specific surface area and pore volumeCatalyst carriersLarge poreCoprecipitation

The invention discloses high-silicon amorphous silica alumina and a preparation method thereof. The amorphous silica alumina product has the properties of a specific surface area of 400 to 650m / g, a pore volume of 1.0 to 2.0cm / g, a silicon oxide content of 20 to 80wt percent, a infrared acid content of 0.3 to 0.8 mmol / g and evenly distributed acidic centers. Moreover, the amorphous silica alumina is prepared by a method comprising first coprecipitation of silicon oxide and alumina and then modification of organic silicon. Compared with the prior art, the amorphous silica alumina has larger pore volume and specific surface area, evenly distributed acidic centers and excellent service performance; moreover, the preparation method is simple, free from special environmental protection problem and low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

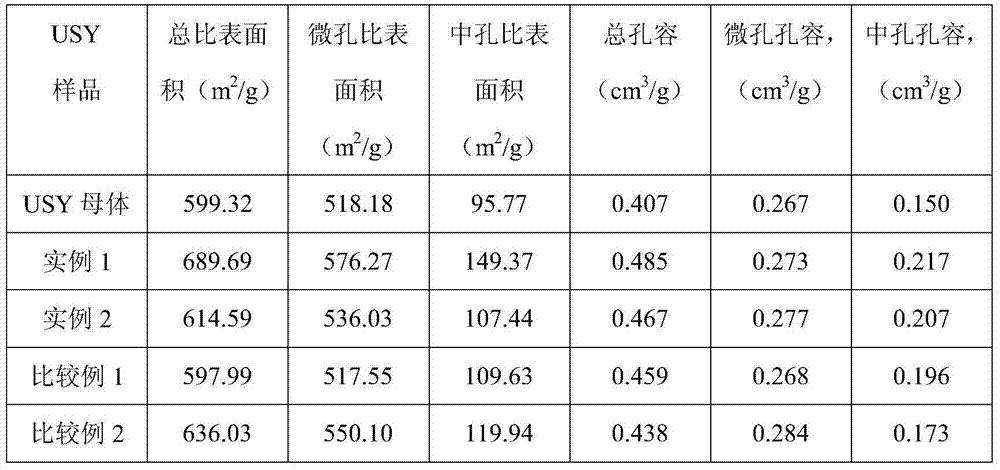

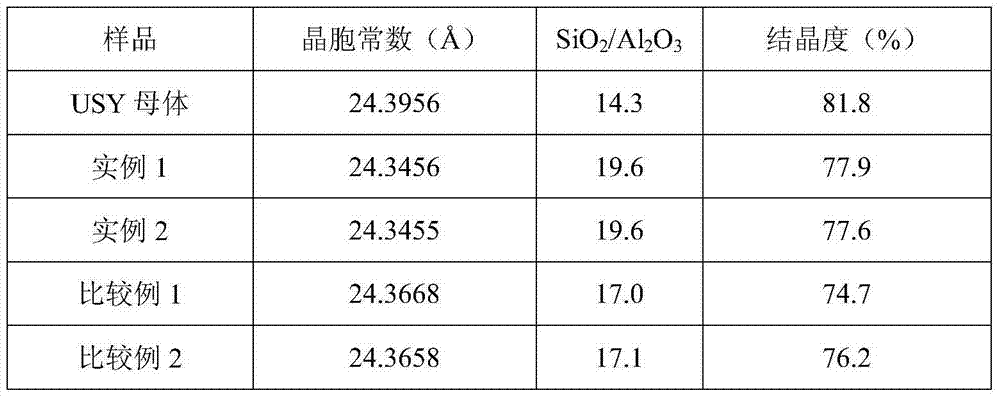

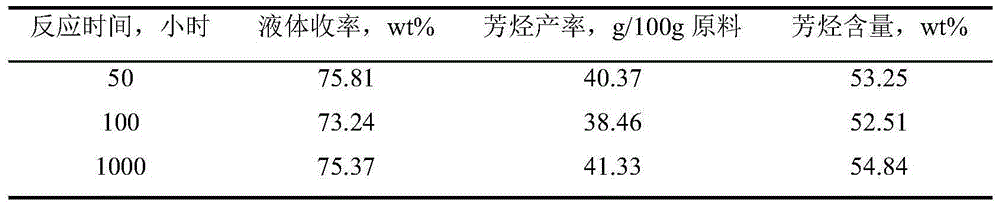

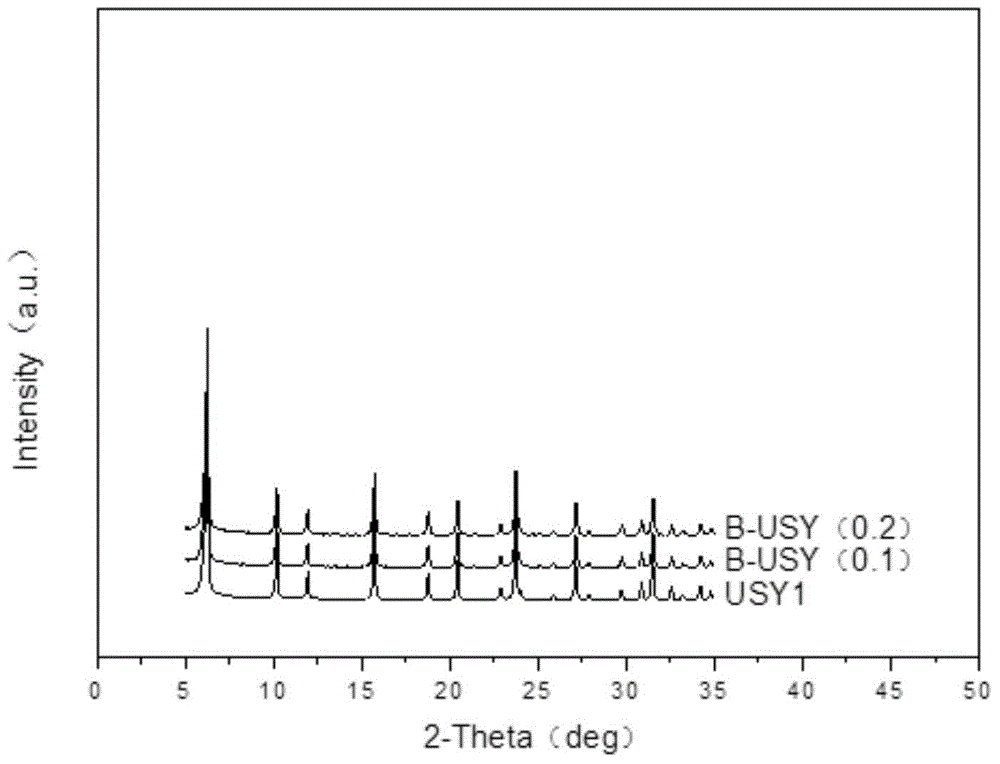

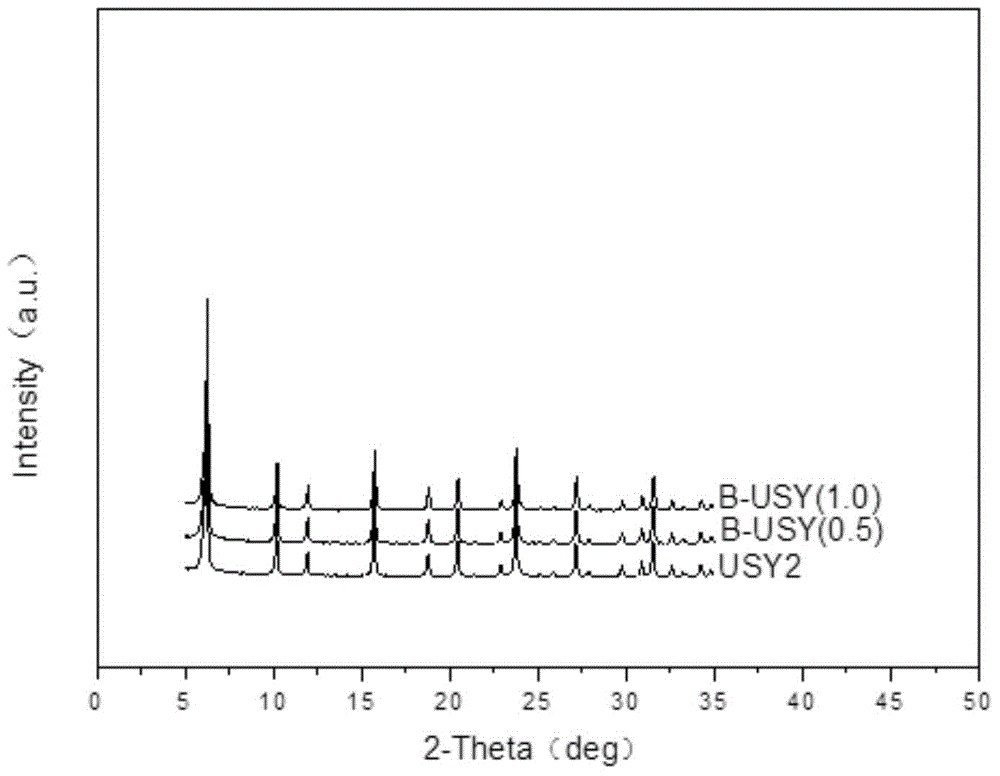

USY molecular sieve modification method

InactiveCN104096586AHigh ratio of silicon to aluminumHigh crystallinityMolecular sieve catalystsMolecular sieveReaction temperature

The invention relates to a USY molecular sieve modification method. The USY molecular sieve modification method comprises the following steps of adding a citric acid solution having a concentration of 0.10-0.35mol / L into a USY molecular sieve according to a solid-liquid quality ratio of 1: 5 for modification with stirring at a reaction temperature of 500-1200 DEG C, after a temperature is increased to a preset temperature of 600-900 DEG C, adding an ammonium fluosilicate solution having a concentration of 0.05-0.20mol / L into the reaction product at a rate of 0.1-3.5ml / min according to a volume ratio of citric acid to the ammonium fluosilicate solution of 0.5-3.0, after material addition, carrying out a reaction process at a temperature of 50-120 DEG C for 1-6h, carrying out washing by deionized water until a pH value is 7, and carrying out constant-temperature drying at a temperature of 110 DEG C. The USY molecular sieve obtained by the USY molecular sieve modification method has substantially improved specific surface, secondary pore volume and moderate strong acid level and can be used for a hydrocracking catalyst for maximizing middle distillates as desired products.

Owner:PETROCHINA CO LTD

Preparation method of NaY molecular sieve

ActiveCN1621349AHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The process of synthesizing NaY molecular sieve includes the following steps: synthesizing guide agent; mixing the guide agent, water glass, acid aluminum salt and sodium aluminate to obtain gel; crystallizing the gel; and filtering, washing and drying. The preparation process features the step of crystallizing the gel, and the step includes first crystallization at 80-120 deg.c for 0.1-70 hr and subsequent addition of one kind of silicon-containing matter in the amount of molar ratio between SiO2 and the Al2O3 in the gel in 0.1-10 before further crystallization for 1-50 hr. The said preparation process has shortened crystallization time and increased Si / Al ratio in the NaY molecular sieve product.

Owner:CHINA PETROLEUM & CHEM CORP +1

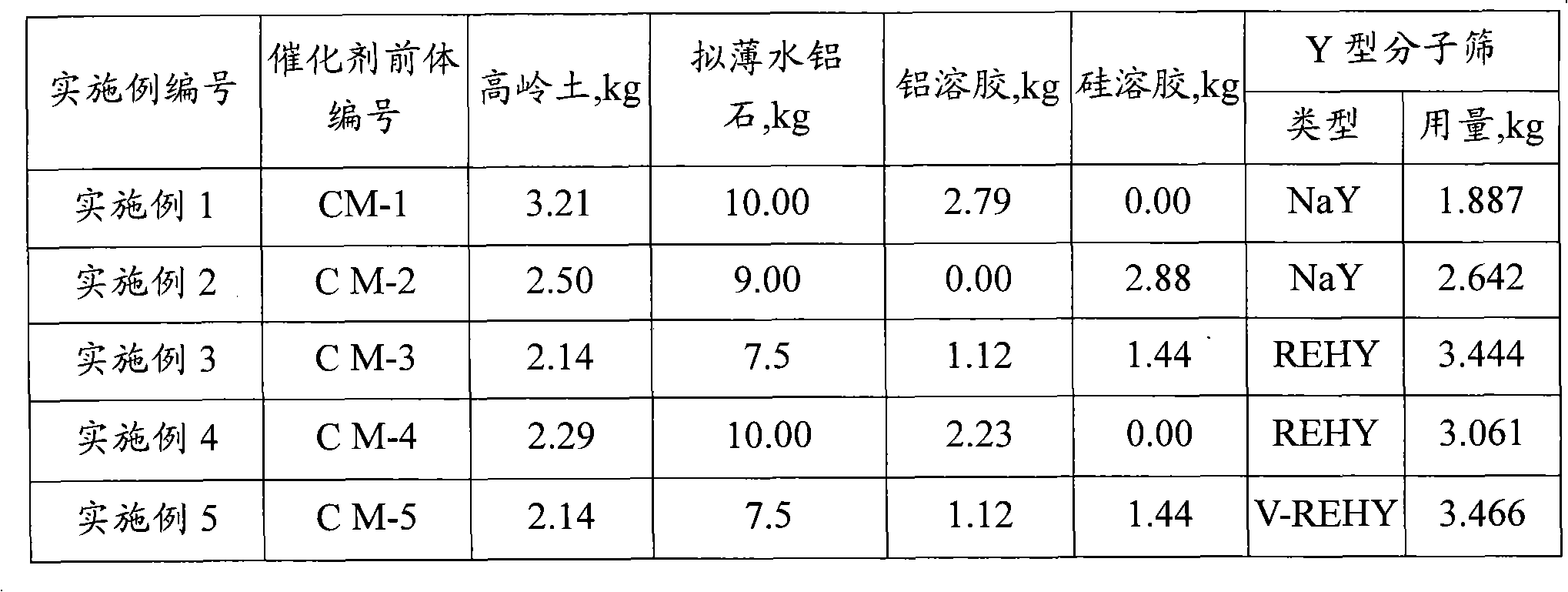

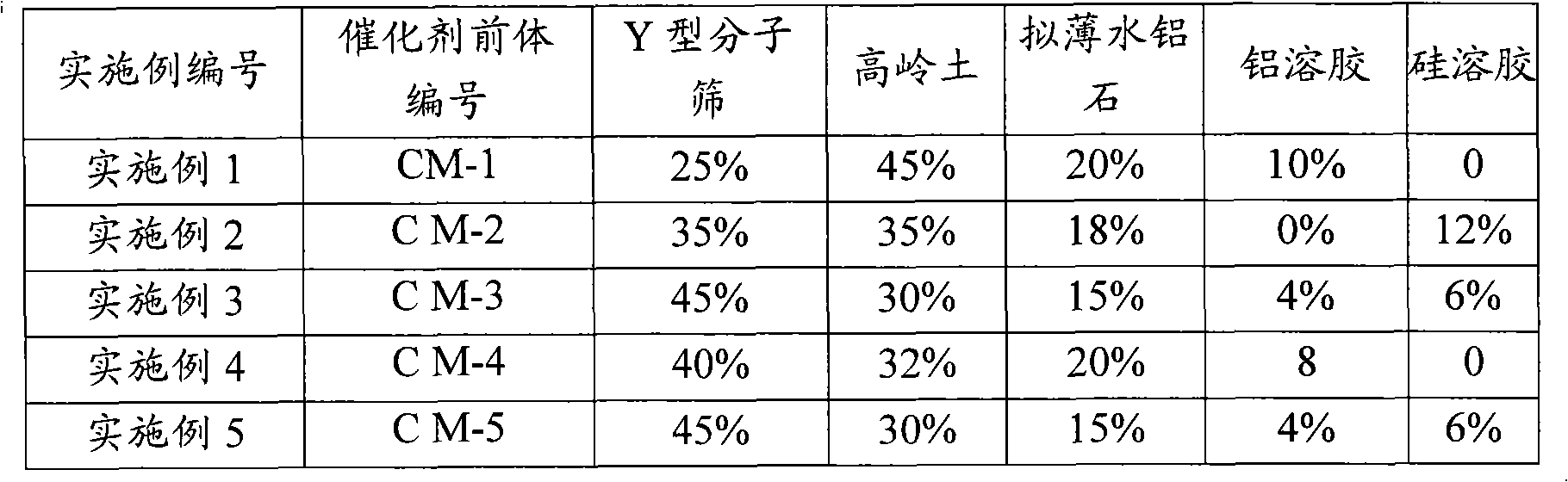

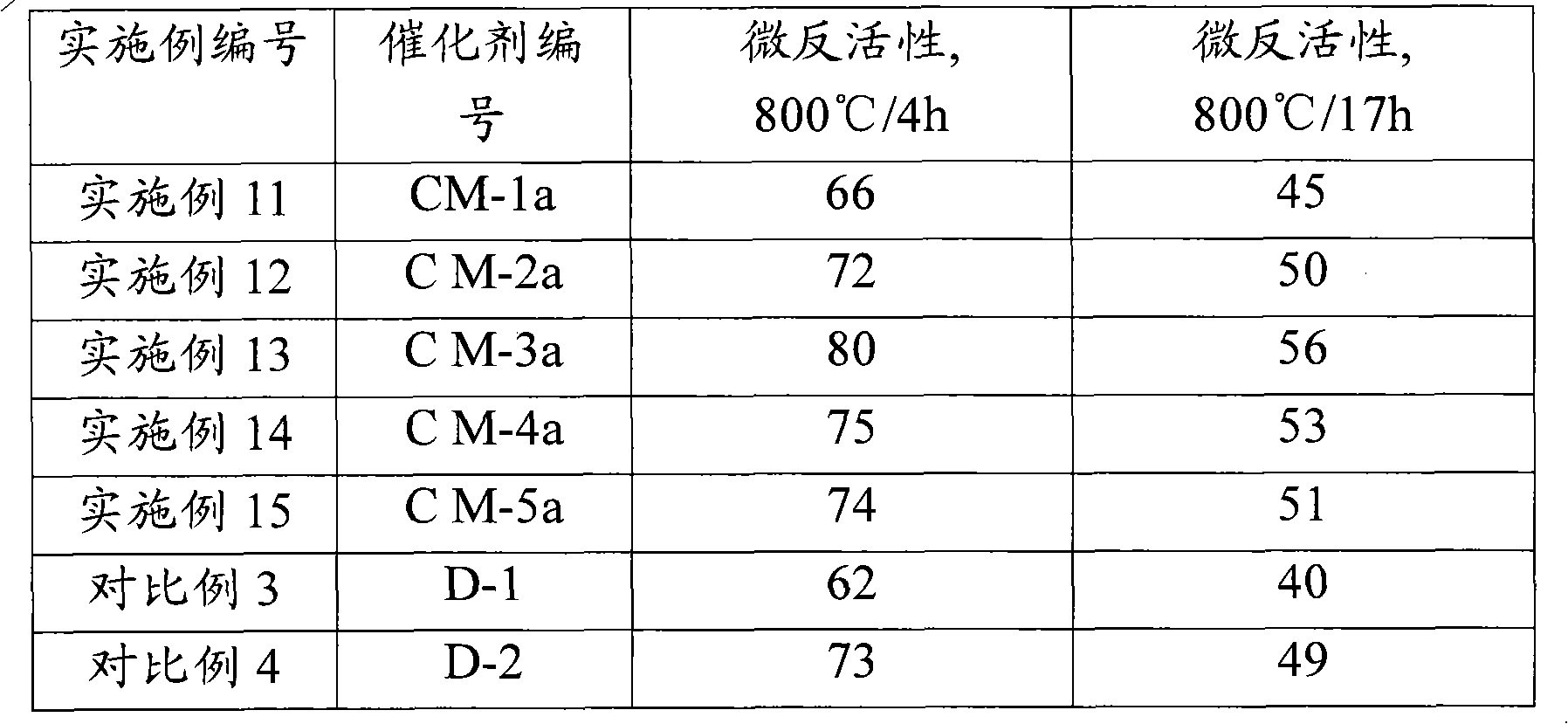

Cracking catalyst and preparation method thereof

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

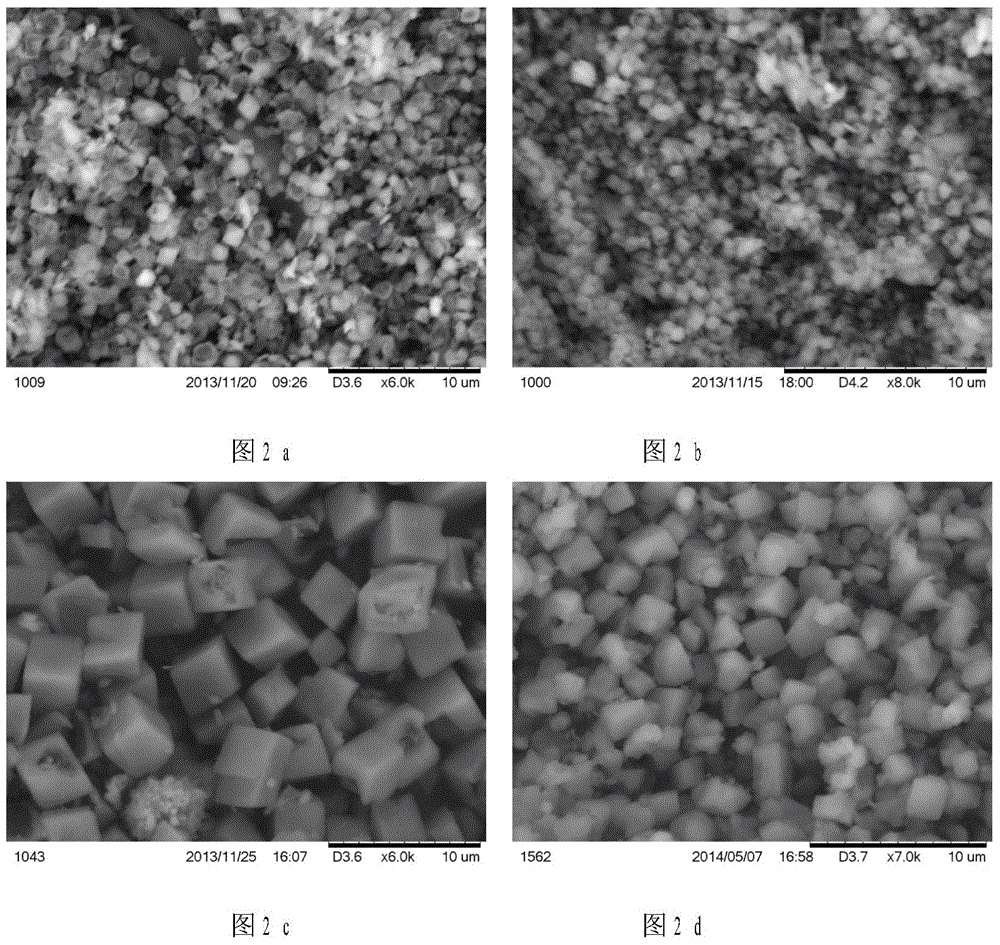

Combined modification method for mesopore USY molecular sieve

InactiveCN103936024AHigh crystallinityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

The invention relates to a modification method for a USY molecular sieve and in particular relates to a combined modification method for a mesopore USY molecular sieve. The combined modification method for the mesopore USY molecular sieve comprises that raw materials such as a USY material, an organic acid solution and an inorganic salt solution are measured in ratio, stirring in a closed reactor is carried out, temperature is increased to 90 DEG C, an organic acid-inorganic salt combined dealumination reaction is carried out for 8 hours; reactants are washed at room temperature, and suction filtration is carried out until the surface of USY is neutral; and drying is carried out at constant temperature of 110 DEG C for 16 hours, so that the USY molecular sieve product is obtained. The combined modification method for the mesopore USY molecular sieve has the advantages that a mixed aqueous solution of organic acid and inorganic salt is adopted for treating the USY type molecular sieve, so that high crystallinity of the molecular sieve can be maintained, silica-alumina ratio of the molecular sieve is increased, lattice constant is reduced, specific surface of the molecular sieve is increased, and acidity and acid distribution of the molecular sieve are improved; and more secondary holes are formed through dealumination, so that components with larger molecular diameter can easily enter into pore passages of the molecular sieve or get close to the surface of the molecular sieve, and conversion efficiency of hydrogen cracking can be improved.

Owner:PETROCHINA CO LTD +1

Method for synthesizing chabazite-type molecular sieve with high silica-alumina ratio by using seed crystal and composite inorganic base and application thereof

ActiveCN104129800AReduce water usageHigh solid contentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePotassium hydroxide

A method synthesizing a chabazite-type molecular sieve with high silica-alumina ratio by using seed crystal and composite inorganic base is as below: evenly mixing an alkaline silica sol and a template; slowly adding potassium hydroxide; adding sodium hydroxide; continuing to stir; then slowly adding an aqueous solution of aluminum sulfate; adding a chabazite crystal phase molecular sieve as the seed crystal; distilling to remove excessive water; sealing, insulating and stirring; conducting high speed shearing to obtain a uniform gel; and conducting crystallization, roasting and ammonium exchange to obtain a product. The invention has the advantages of high silica-alumina ratio, high specific surface area, high MTO diolefin selectivity and pollution-free preparation process.

Owner:天津众智科技有限公司

Method for preparing high silica alumina ratio NaY molecular sieve

ActiveCN101254929AImprove structural stabilityHigh catalytic activityFaujasite aluminosilicate zeoliteMolecular sieveAlkalinity

A preparation method of the NaY molecular sieve with high silica-alumina ratio includes: preparing the high alkalinity silica-alumina gel (3.0-6.0)Na2O:Al2O3:(7-20)SiO2:(100-600)H2O and the low alkalinity silica-alumina gel (0.5-3.0)Na2O:Al2O3:(7-20)SiO2:(100-600)H2O obtained by evenly mixing conventional directing agent, silicon source, aluminum source and water, heating up the high alkalinity silica-alumina gel to 90-110 DEG C, crystallizing for 0.5-20 hours, adding the low alkalinity silica-alumina gel, filtering, washing, drying and obtaining the NaY molecular sieve. The modified NaY molecular sieve is applicable to the catalyst preparation of catalytic cracking, hydrogen cracking and isomerization.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for synthesizing silicon substrate molecular sieve by using copper amine complex as template agent

ActiveCN101973562AHigh ratio of silicon to aluminumLarge specific surface areaCrystalline aluminosilicate zeolitesMolecular sieveHigh silica

The invention relates to a preparation method of a molecular sieve, aiming at providing a method for synthesizing a silicon substrate molecular sieve by using a copper amine complex as a template agent. The method comprises the steps of dissolving sodium metaaluminate in deionized water, adding cupric salt, dropping organic amine in the solution after stirring, stirring completely, adding sodium hydroxide solid and stirring, then adding a silica solution in the solution, stirring for 2 to 3 hours, placing in a reaction kettle, crystallizing for 3 to 20 days at 140-180 DEG C, completely washing the reaction output with deionized water after reaction, drying for 12 hours above at 80 DEG C, exchanging through ammonium nitrate and calcining for four hours at 500 DEG C, removing the template agent to obtain the final product. Compared with the CHA molecular sieve synthesized without templates, the CHA molecular sieve has higher silica alumina ratio, stability and specific surface area and has higher reaction activity in the MTO catalytic reaction. The synthesizing method has simple template agent and lower cost, and the method for removing the template is simple and easy.

Owner:中科鸿景(宁波)环保科技有限公司

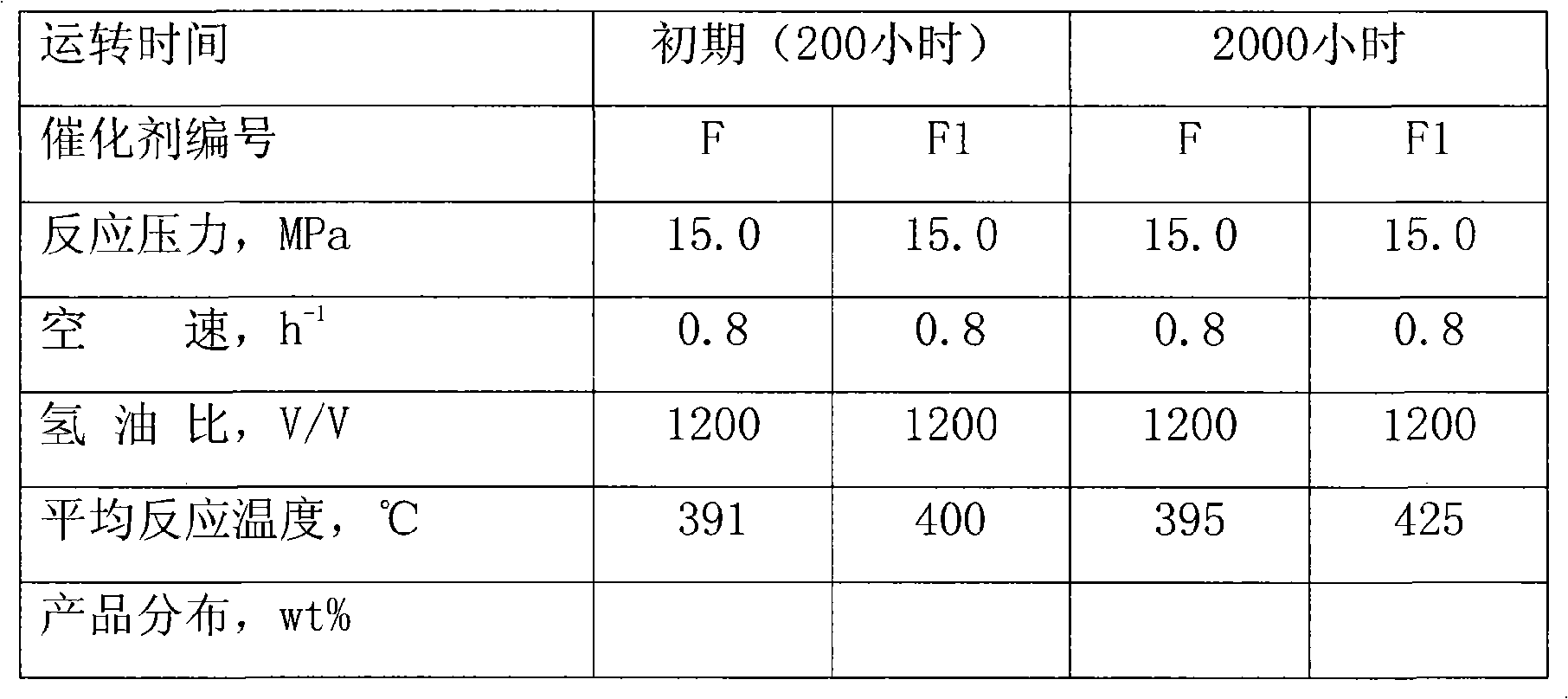

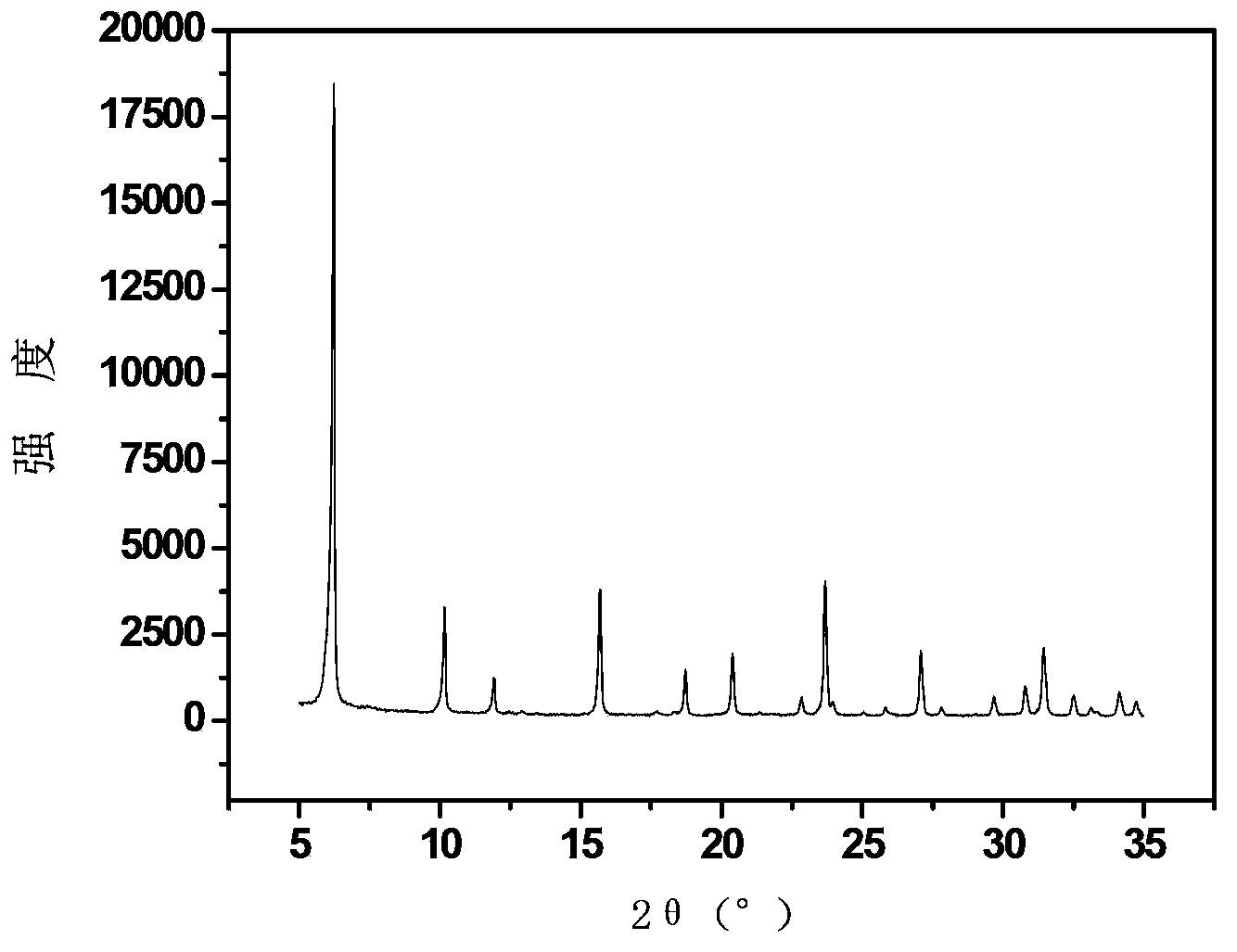

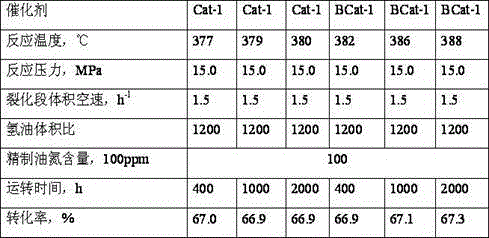

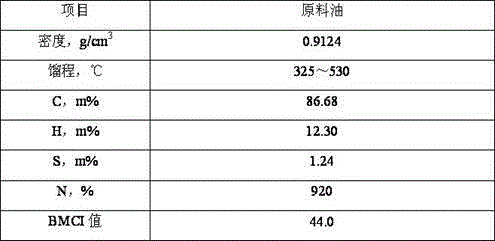

Process for producing high-performance catalyst for hydrocracking

ActiveCN101402048AImprove nitrogen toleranceExtended service lifeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceRare earth

The invention relates to a method for preparing a high-performance hydrocracking catalyst, which comprises the following steps: preparing amorphous aluminium-silicon into a paste material of which the pH value is between 3.0 and 5.5, evenly mixing Y zeolite solid powder of modified rare earth with the paste material of the amorphous aluminium-silicon, and then drying and dehydrating the mixture to prepare a moldable paste so as to prepare a catalyst carrier through molding, drying, and calcining, and finally obtaining the final hydrocracking catalyst by loading hydrogenation metal components through an impregnation method. The hydrocracking catalyst prepared by the method has the advantages of high activity and middle oil selectivity, and strong nitrogen resisting performance and water resistance, thus the hydrocracking catalyst can be used in the process of an unrefined single-stage hydrocracking, which not only can be used for processing heavy oil fraction of oil, but also can be used for processing heavy raw materials of other sources, such as the heavy distillate of coal liquefaction oil.

Owner:胜帮科技股份有限公司

Synthetic method for NaY zeolite with high silica-alumina ratio

ActiveCN104118885AHigh crystallinityMild preparation temperatureFaujasite aluminosilicate zeoliteHigh silicaSilicon

The invention provides a synthetic method for NaY zeolite with a high silica-alumina ratio. The method comprises the main steps: according to the proportioning requirement of a directing agent to uniformly mix a silicon source, an aluminium source and water, and ageing at 15 DEG C-60 DEG C for 0.5-120 h, so as to prepare the directing agent; according to the proportioning requirement of a gel reaction mixture to adding the directing agent and an alkaline solution into a silicone source at 10 DEG C-90 DEG C, stirring for 1 h-80 h, and stirring uniformly to obtain the gel reaction mixture; performing crystallization on the gel reaction mixture at 80-120 DEG C for 10-50 h, and then filtering, washing and drying to prepare NaY zeolite. The method does not employ a template, the preparation of the directing agent is mild in temperature, NaY zeolite with high crystallization degree and the high silica-alumina ratio is synthesized at a relatively short crystallization time. Also the method is capable of replacing conventional production technology without changing current apparatuses for industrial production, and has great important meaning on improving performances of catalytic cracking catalysts.

Owner:PETROCHINA CO LTD +1

Method for synthesizing Y-zeolite composite material

ActiveCN1709794AReduce processing costsHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteSodium silicateSodium hydroxide

The invention discloses one Y zeolite compound material's synthesizing method, its characteristic lay in this method includes the kleit roasts under 500 - 900 íµ temperatures the dehydration transforms the leaning kleit, the smashing, then made the particle size which is smaller than 230 microns powder, then joined the sodium silicate, the guide medicinal preparation, the sodium hydroxide and the water, the crystallization, filtered, the collection mother liquor, and then collect the mother liquor direct sales commission, which played partial or the complete sodium silicate and the sodium hydroxide role.

Owner:CHINA PETROLEUM & CHEM CORP +1

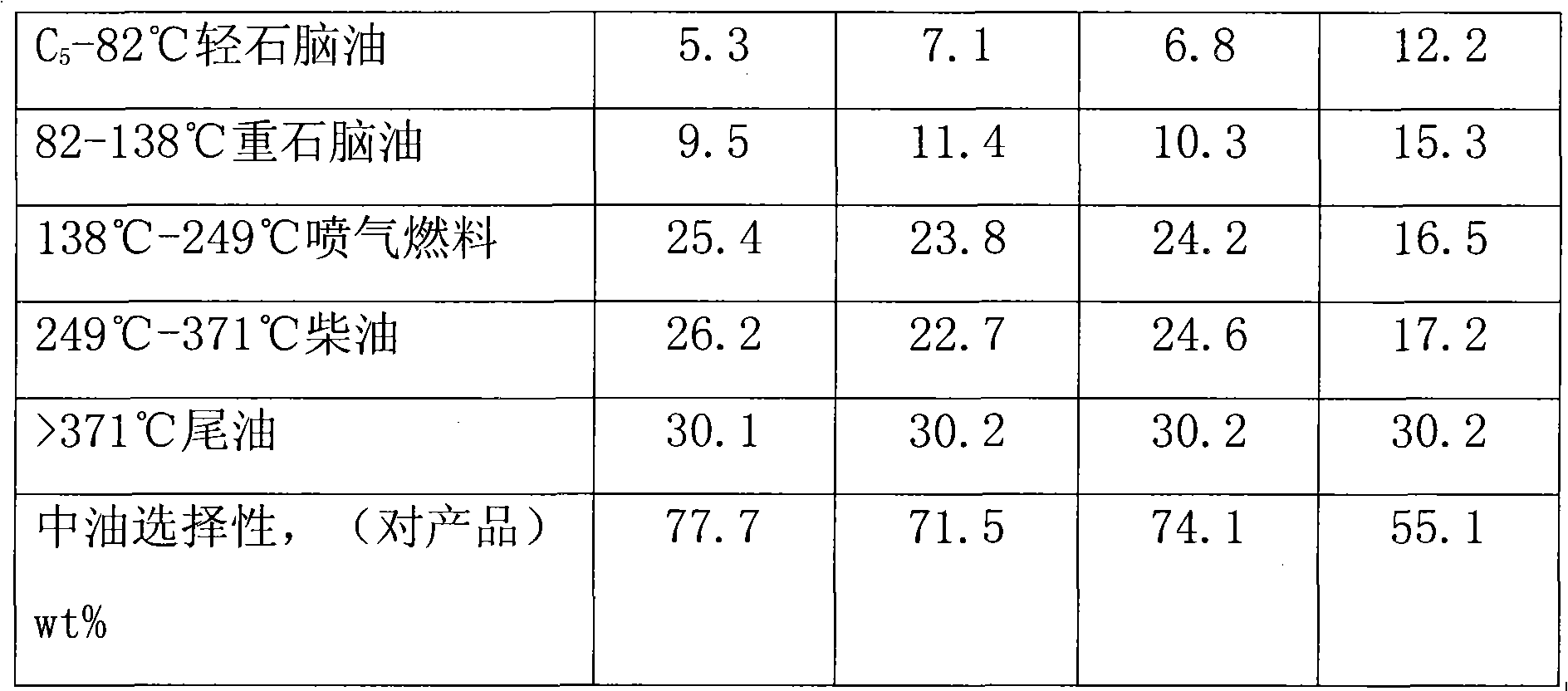

Hydro-cracking catalyst and preparation method thereof

ActiveCN102049283AIncrease removalHigh ratio of silicon to aluminumMolecular sieve catalystsCatalyst activation/preparationMolecular sieveChemistry

The invention discloses a hydro-cracking catalyst and a preparation method thereof. The catalyst comprises hydrogenated active metal ingredients and carriers containing small grain Y molecular sieves, amorphous silica-alumina and alumina, wherein the small grain Y molecular sieves are obtained by treating hydrothermally treated Y molecular sieves by using mixed aqueous solution of aluminum salt and acid. The Y molecular sieves have small grains, high crystallization degree, high silica-alumina ratio and proper total acid amount and acid distribution; the Y molecular sieves and the amorphous silica-alumina are used as acid components of the catalyst together; and the prepared catalyst can treat heavier and / or poor-quality raw materials, and has the characteristics of high catalytic activity, good selectivity of intermediate fraction oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of NaY molecular sieve

ActiveCN1621348AHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveSynthesis methods

The process of synthesizing NaY molecular sieve includes the following steps: synthesizing guide agent; mixing the guide agent, water glass, acid aluminum salt and sodium aluminate to obtain gel; crystallizing the gel; and filtering, washing and drying. The preparation process features the step of crystallizing the gel, and the step includes first crystallization at 80-120 deg.c for 0.1-70 hr and subsequent addition of one kind of acid matter in the amount of molar ratio to Al2O3 in the gel in 0.01-3 before further crystallization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN100364890CUniform particle sizeHigh ratio of silicon to aluminumMolecular sieve catalystsPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

High silica/ aluminum ratio octagonal zeolite synthesizing method

ActiveCN1951812AHigh molar ratio of silicon to aluminumHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteHigh silicaSilicon

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing organic solvent adsorbing material

ActiveCN101850239AThorough and even reactionSi-Al Ratio UniformOther chemical processesAluminium silicatesMolecular sieveHoneycomb

The invention discloses a method for preparing an organic solvent adsorbing material. The method comprises the following steps of: manufacturing molecular sieve paper; thermally pressing the molecular sieve paper into corrugated molecular sieve paper; preparing the molecular sieve paper into a honeycomb; performing a chemical reaction on the molecular sieve honeycomb and a mixed gas of nitrogen and SiCl4 gas or water vapor in an airtight container; exhausting residual reaction gas; repeatedly cleaning the molecular sieve honeycomb to remove a solid reaction product on the molecular sieve honeycomb and washing the molecular sieve honeycomb with acid; and continuing to perform a chemical reaction on the molecular sieve honeycomb and the mixed gas of nitrogen and SiCl4 gas or water vapor in the airtight container. The adsorbing material prepared by the method has a high and uniform ratio of silicate to aluminum, so the adsorbing material has excellent organic solvent adsorbing performance and can be widely used for adsorbing and separating an organic solvent from the air or adsorbing and separating the organic solvent in water which contains the organic solvent.

Owner:马军

Silicoaluminophosphate molecular sieve with high silica-alumina ratio and CHA structure, and synthetic method thereof

ActiveCN104108726AHigh catalytic activityReduce coking rateMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveAluminium

The invention discloses a silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure, and a synthetic method thereof. The problems of low silica-alumina ratio, poor activity on a methanol-to-low carbon olefin reaction, and fast coking rate of silicoaluminophosphate molecular sieve with the CHA structure are mainly solved. The atom ratio of silicon / aluminum of the silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure is 10-25. The silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure well solves the problems, and can be used in the methanol-to-low carbon olefin industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification treatment method of Y-type zeolite

ActiveCN104628010AReduce drynessHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteWater vaporStrong acids

The invention relates to a modification treatment method of a Y-type zeolite. The method comprises the following steps: carrying out ammonium exchange and direct burning on industrially-produced common NaY zeolite, repeating the ammonium exchange and direct burning for at least three times, then subjecting the NaY zeolite to a water steam treatment at a high temperature, and finally processing the NaY zeolite by a critic acid solution. The silicon / aluminum ratio of processed Y-type zeolite is in a range of 9 to 11, and the specific surface area of the processed Y-type zeolite is in a range of 550 to 650 m2 / g. Furthermore, the zeolite stability is improved, the sodium content is decreased, at the same time the amorphous aluminum out of the skeleton is removed, secondary mesopores (3-20 nm) are generated in the Y-type zeolite, strong acid centers are generated at the meantime, no environmental pollutant is generated during the treatment process, the efficiency is high, the modification treatment method is environment-friendly, the whole process is carried out on the basis of conventional modification treatments, and the provided method is suitable for massive preparation of Y-type zeolite with a high silicon / aluminum ratio through modification on NaY zeolite.

Owner:PETROCHINA CO LTD

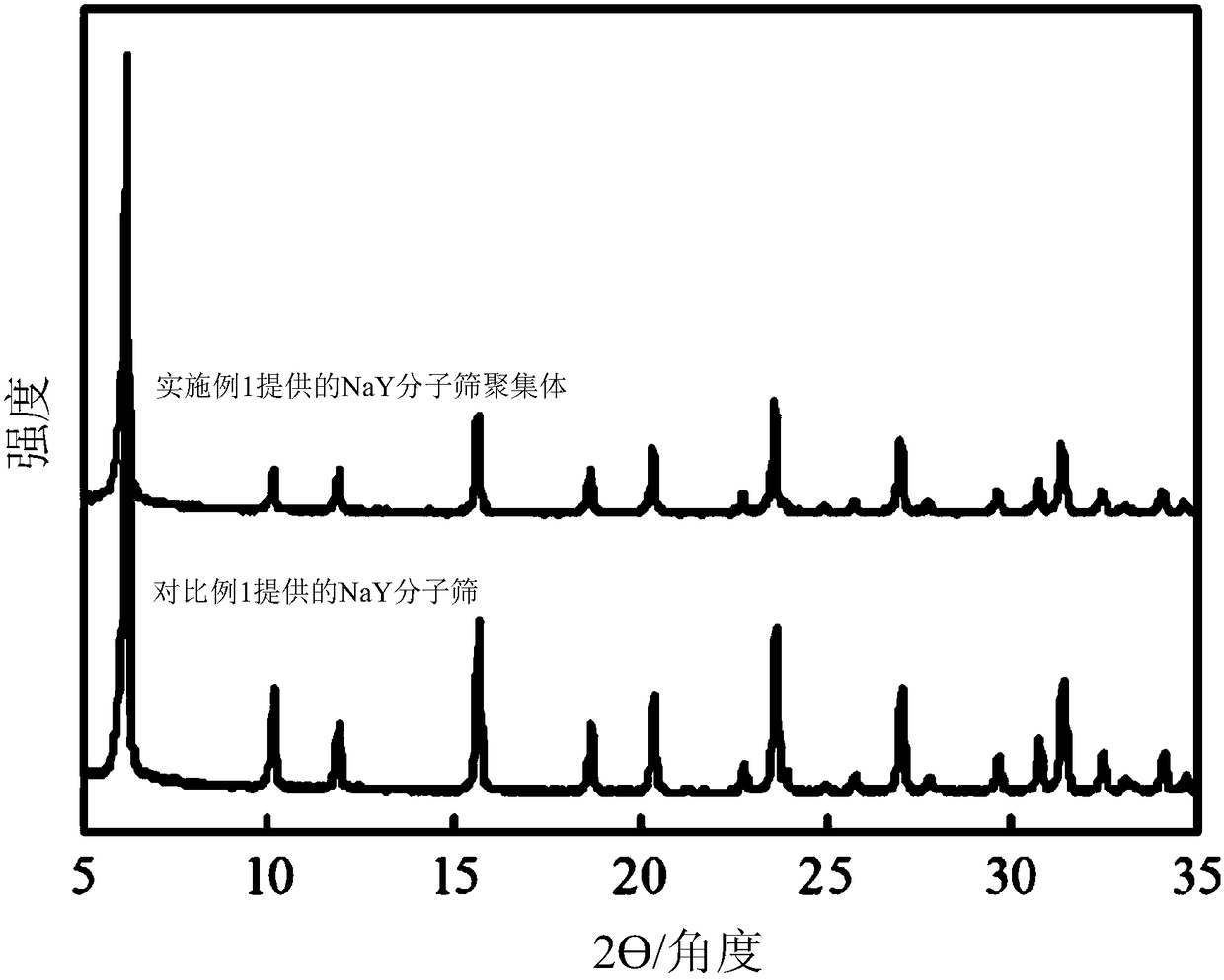

NaY molecular sieve aggregate with nano-micro structure and preparation method thereof

ActiveCN108862309AImprove uniformitySeparation Engineering Challenges SolvedFaujasite aluminosilicate zeoliteMolecular sieveMicro structure

The invention provides a NaY molecular sieve aggregate with a nano-micro structure and a preparation method thereof. The method comprises the following steps of synthesizing a guide agent; preparing reaction gel by using the guide agent; performing crystallization on the reaction gel to obtain the NaY molecular sieve aggregate with the nano-micro structure, wherein organosilicon quaternary ammonium salt is introduced in the process of synthesizing the guide agent and / or preparing the reaction gel. The technical scheme provided by the invention has the advantages that the process is simple; thecost is low; the finally obtained product has a series of advantages of complete crystal phase, high silicon-aluminum ratio, high specific area, rich mesoporous-microporous structure, controllable crystal particle dimension and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

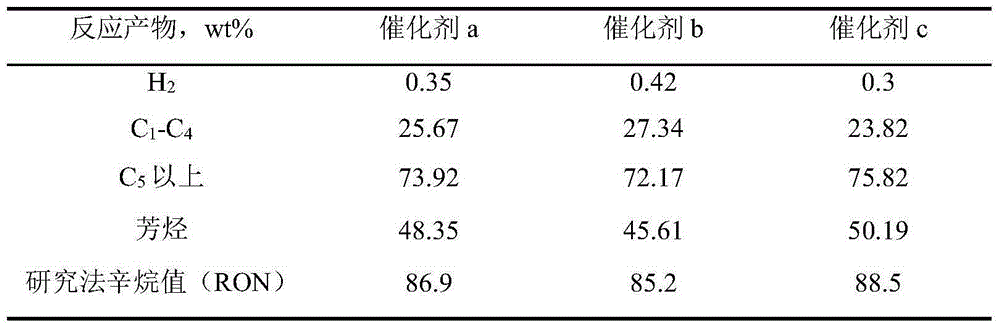

Catalyst for straight-run naphtha aromatization and preparation method thereof

InactiveCN106552663ARegular skeleton structureFast responseMolecular sieve catalystsHigher alkanesNaphtha

The invention discloses a catalyst for straight-run naphtha aromatization and a preparation method thereof. The catalyst for straight-run naphtha aromatization is prepared by modifying a nano ZSM-5 molecular sieve, preparing a carrier and preparing the catalyst. The catalyst is suitable for treating raw materials with high alkane content. And the catalyst has high catalytic activity and high arene selectivity. So the catalyst can be applied to more mild process conditions and can be applied to production of high-octane gasoline blending components and chemical raw materials like benzene, toluene, xylene, etc.

Owner:PETROCHINA CO LTD

Method for preparing hydrocracking catalyst

ActiveCN105618117AHigh ratio of silicon to aluminumHigh reactivityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a method for preparing a hydrocracking catalyst. The method comprises the following steps of uniformly mixing modified Y molecular sieves, amorphous silica-alumina and / or alumina according to a certain proportioning ratio, adding dilute nitric acid into the mixture so as to carry out pulping, then, carrying out strip-extruding forming, drying and roasting so as to obtain a silica-alumina carrier containing the modified Y molecular sieves, then, dipping the silica-alumina carrier by active ingredients, and carrying out drying and roasting, so as to obtain the hydrocracking catalyst, wherein the bulk-phase silica-alumina ratio of the modified Y molecular sieves is 9 to 50, the surface layer SiO2 / Al2O3 silica-alumina ratio is 30 to 120, and the surface layer silica-alumina ratio is higher than the bulk-phase silica-alumina ratio; and the modified Y molecular sieves have the specific surface area of 650m<2> / g to 900m<2> / g and the pore volume of 0.30ml / g to 0.50ml / g. The hydrocracking catalyst prepared by the method has good reaction activity and nitrogen resistance and has a broad application prospect in hydrocracking reaction processes of diesel oil multiproduction, chemical raw material multiproduction, diesel oil hydro-conversion catalysis and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y-type zeolite with intracrystalline hierarchical pores and preparation method and application thereof

ActiveCN105366690AHigh catalytic activityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteActive componentThermal treatment

The invention provides a Y-type zeolite with intracrystalline hierarchical pores and a preparation method and application thereof. The method comprises: mixing the NaY zeolite containing boron, ammonium salt and water to obtain a mixture, performing stirring, filtering and washing to obtain an ammonium-type Y zeolite containing boron; performing a high-temperature hydro-thermal treatment of the ammonium-type Y zeolite containing boron to obtain the Y-type zeolite with intracrystalline hierarchical pores. The Y-type zeolite with intracrystalline hierarchical pores is full of hierarchical pores structure, and the preparation method of the zeolite is simple in operation. The invention also provides the application of the Y-type zeolite with intracrystalline hierarchical pores in using as an active component of a catalytic cracking catalyst and a catalytic hydrogenation catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com