Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Reduce secondary cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

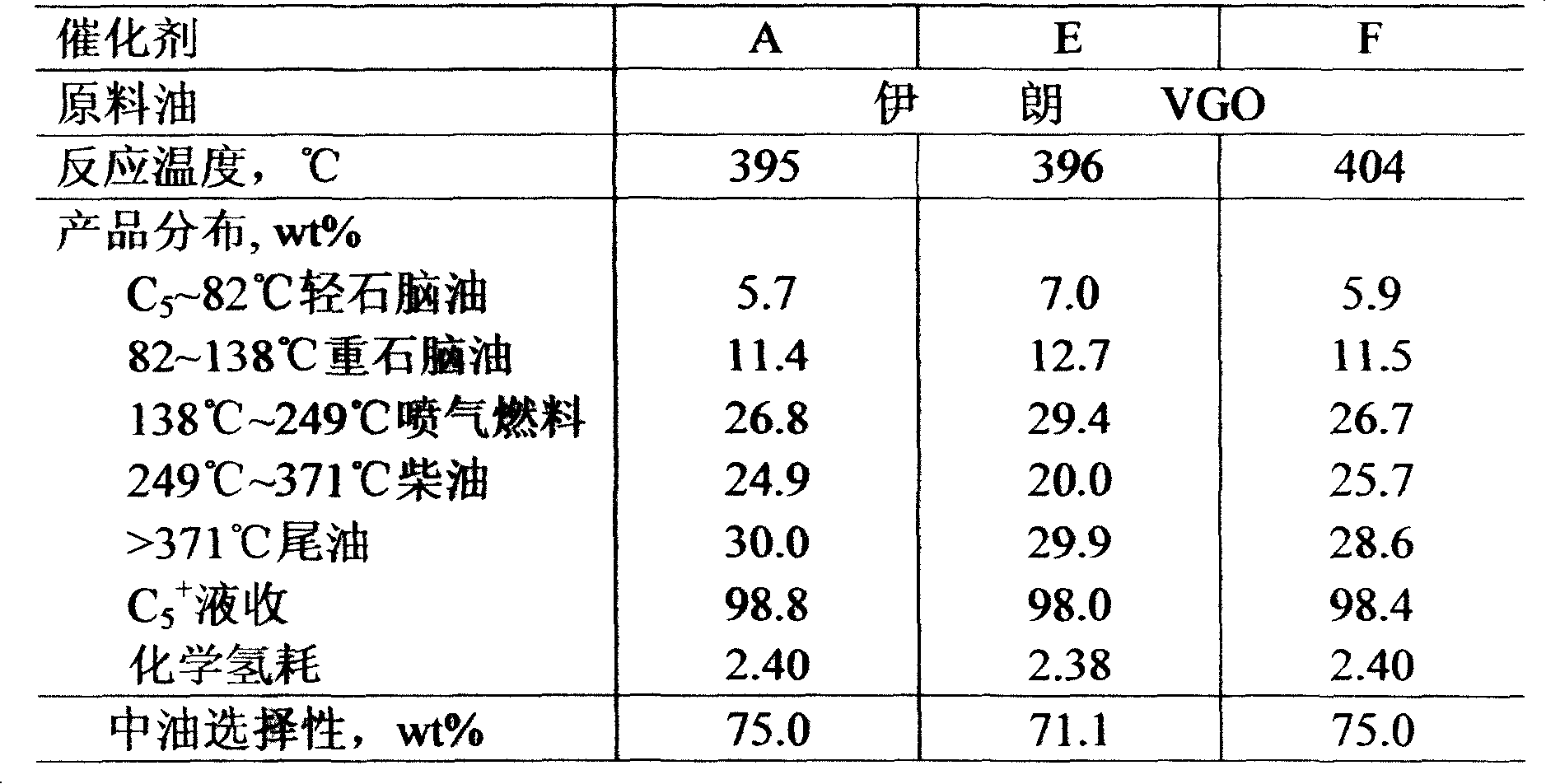

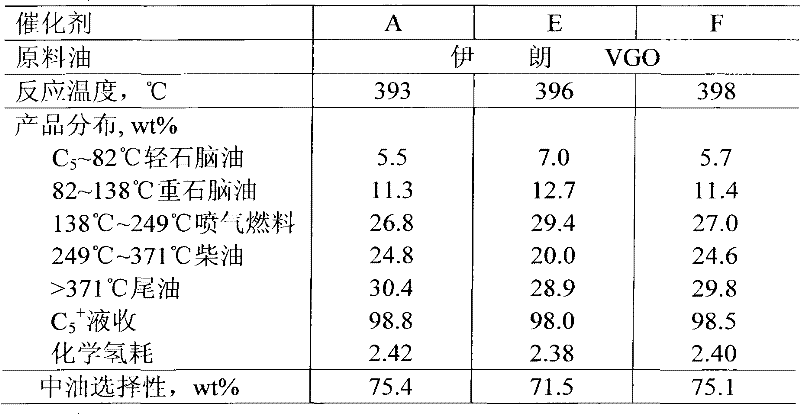

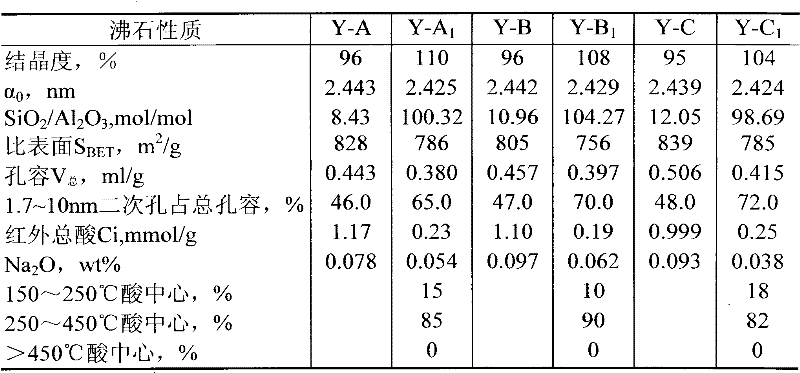

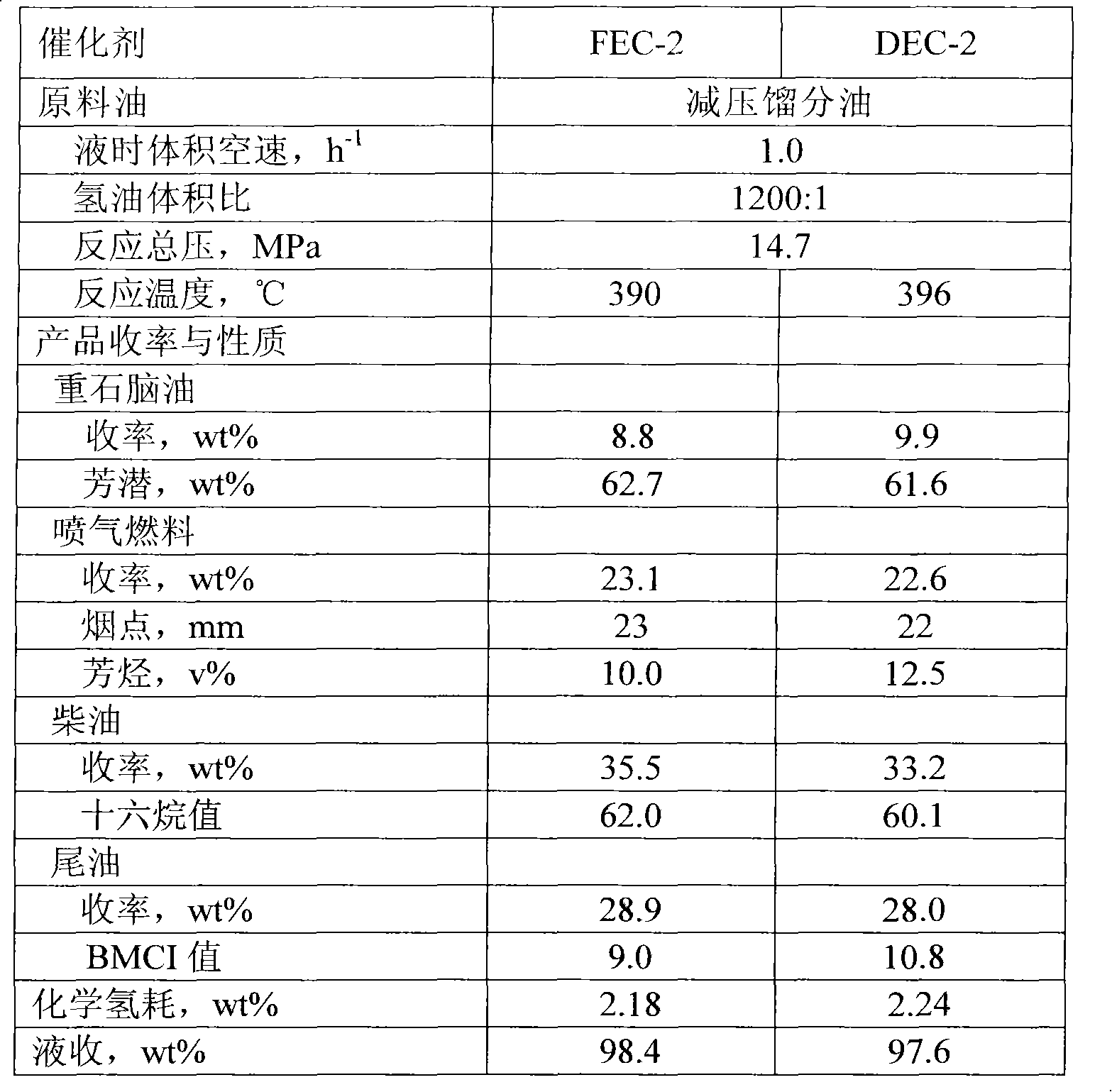

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

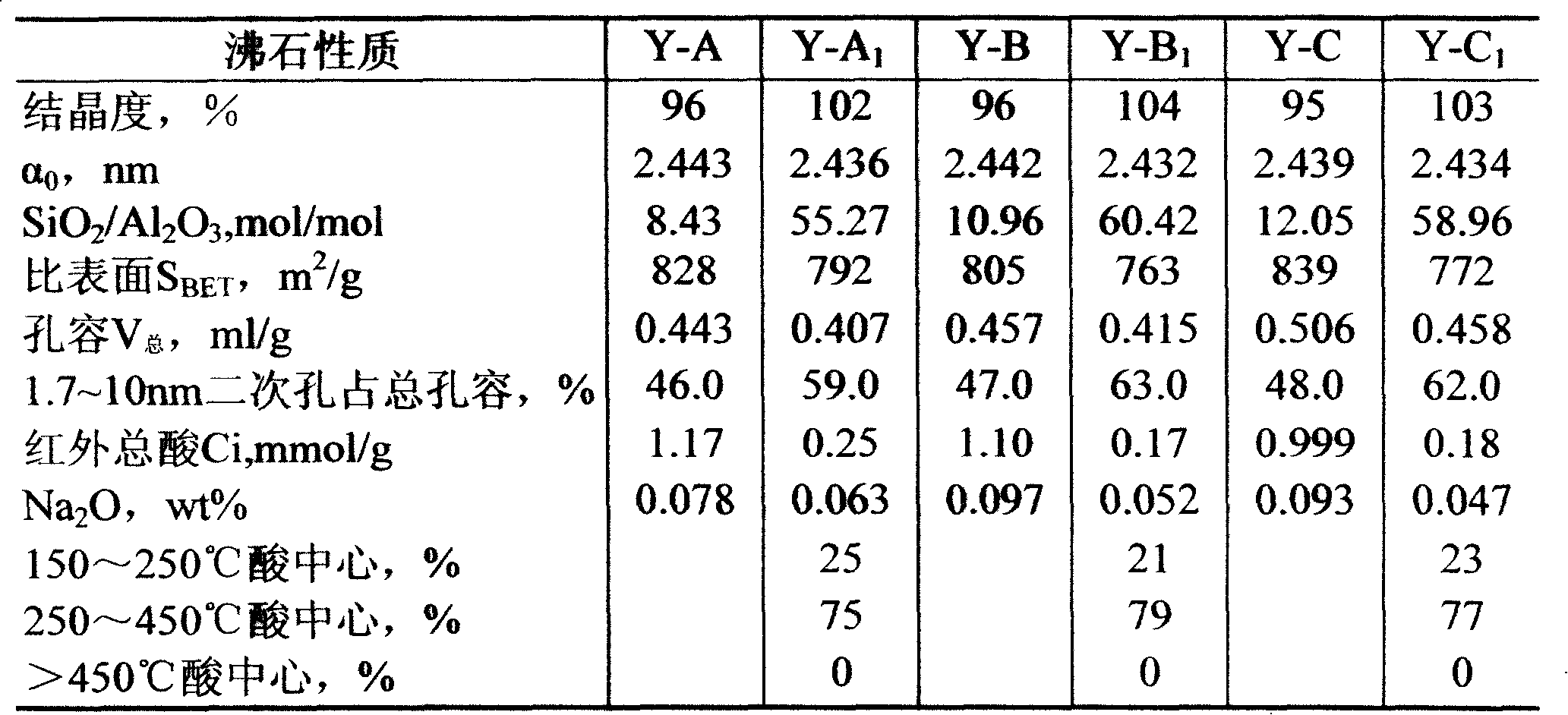

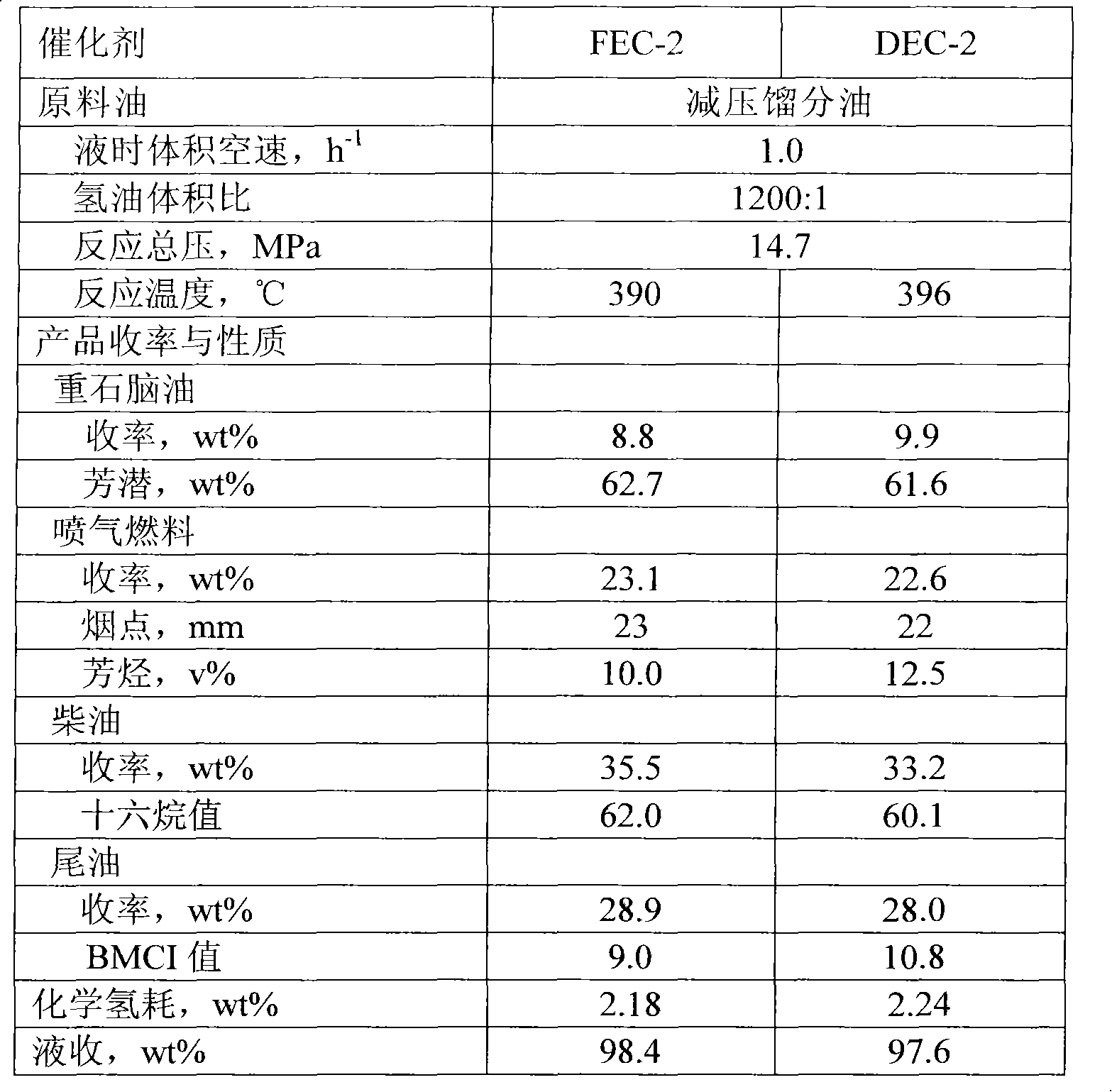

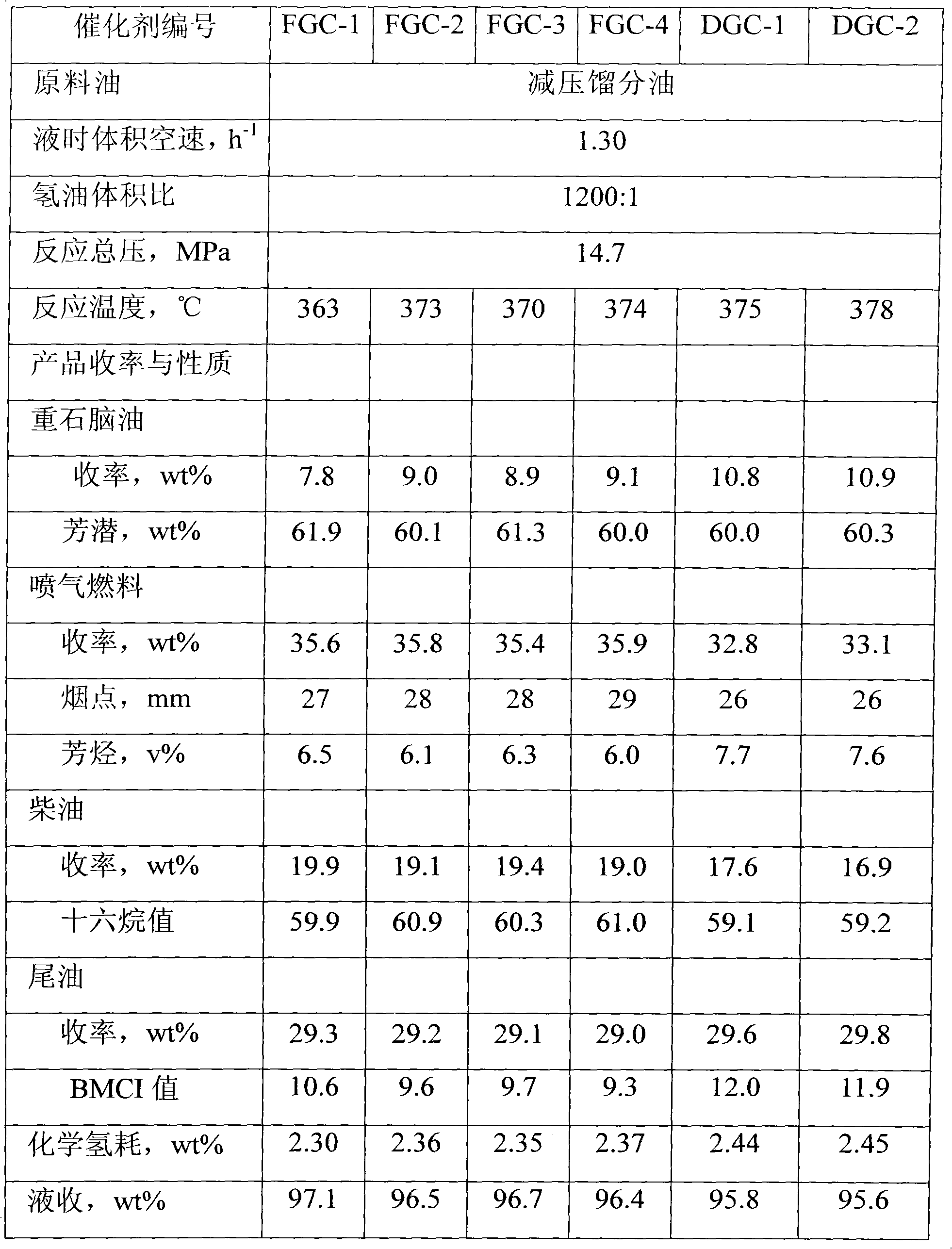

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

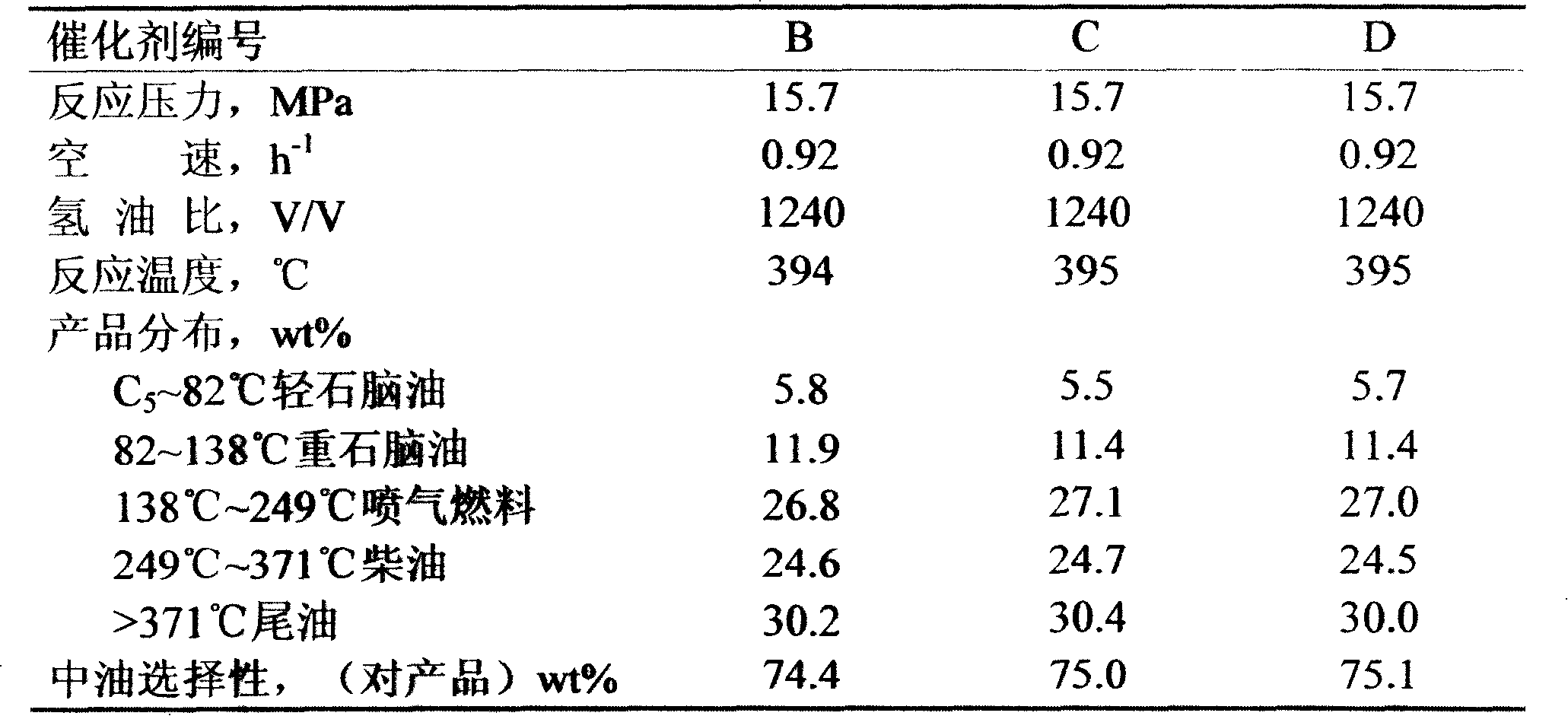

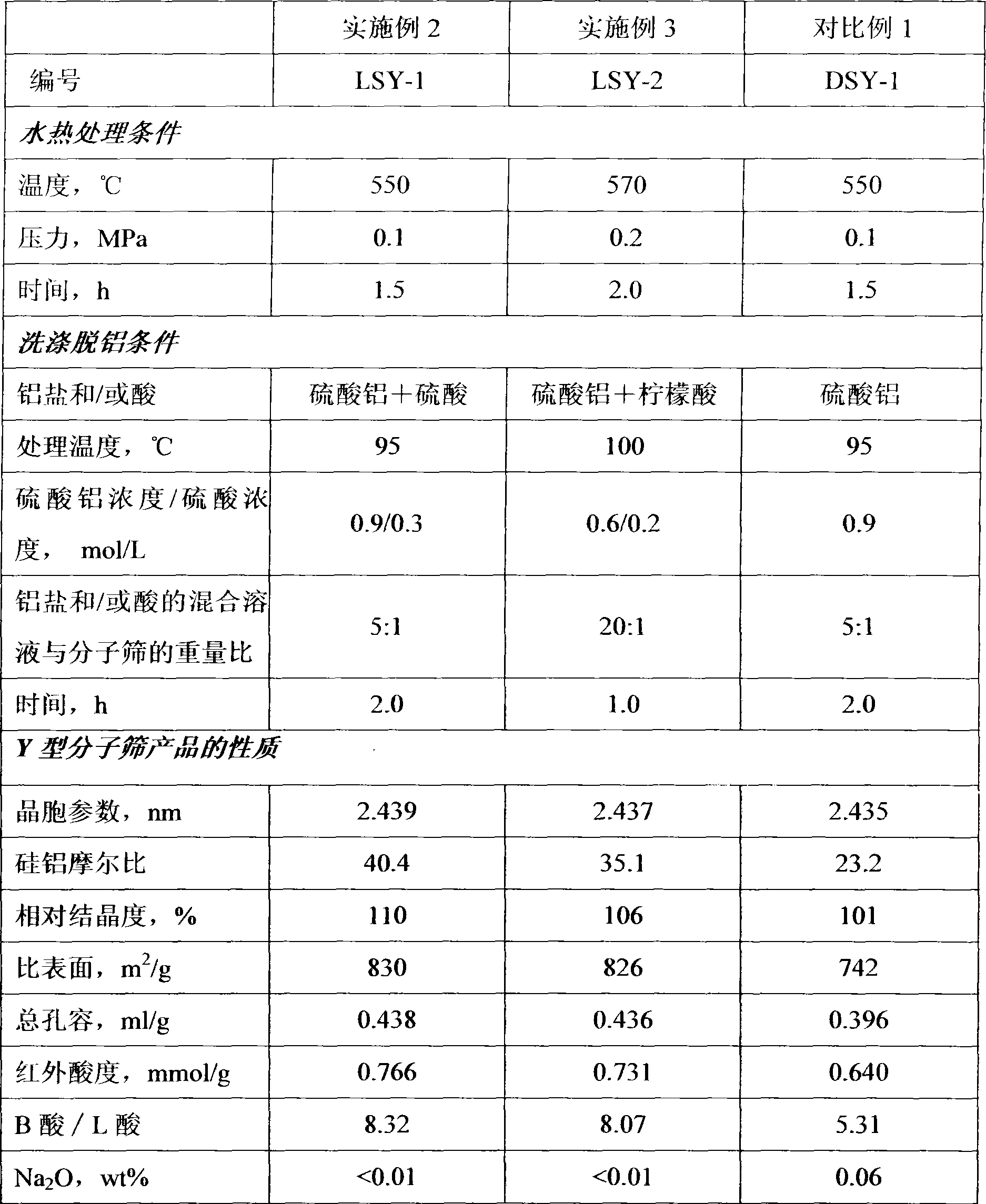

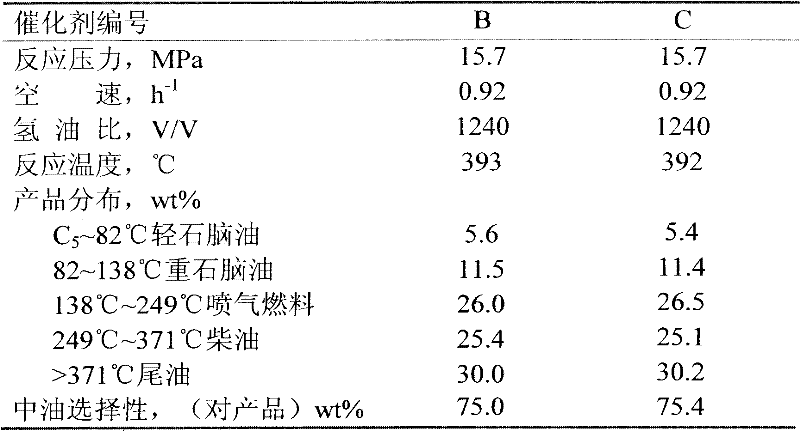

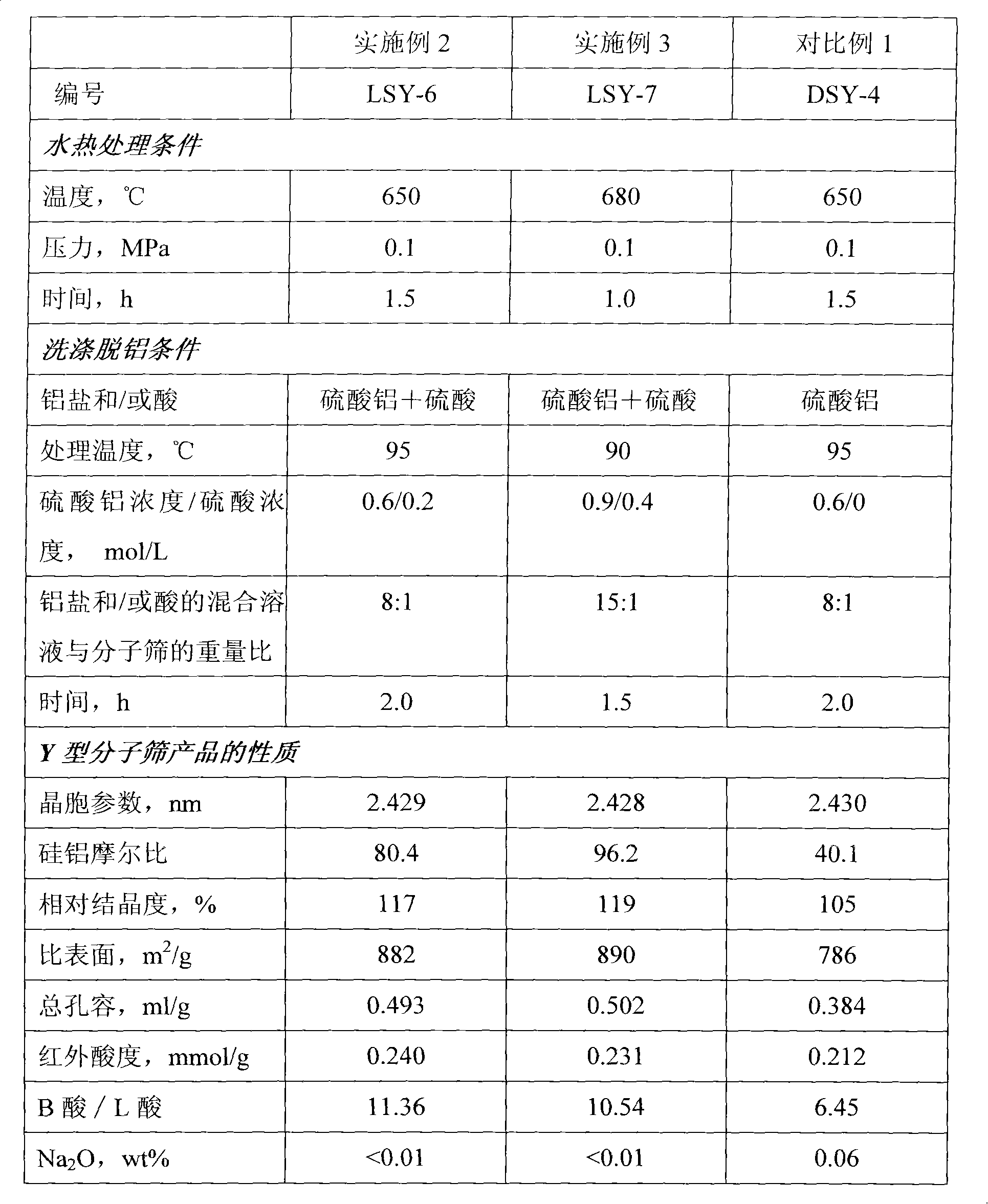

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

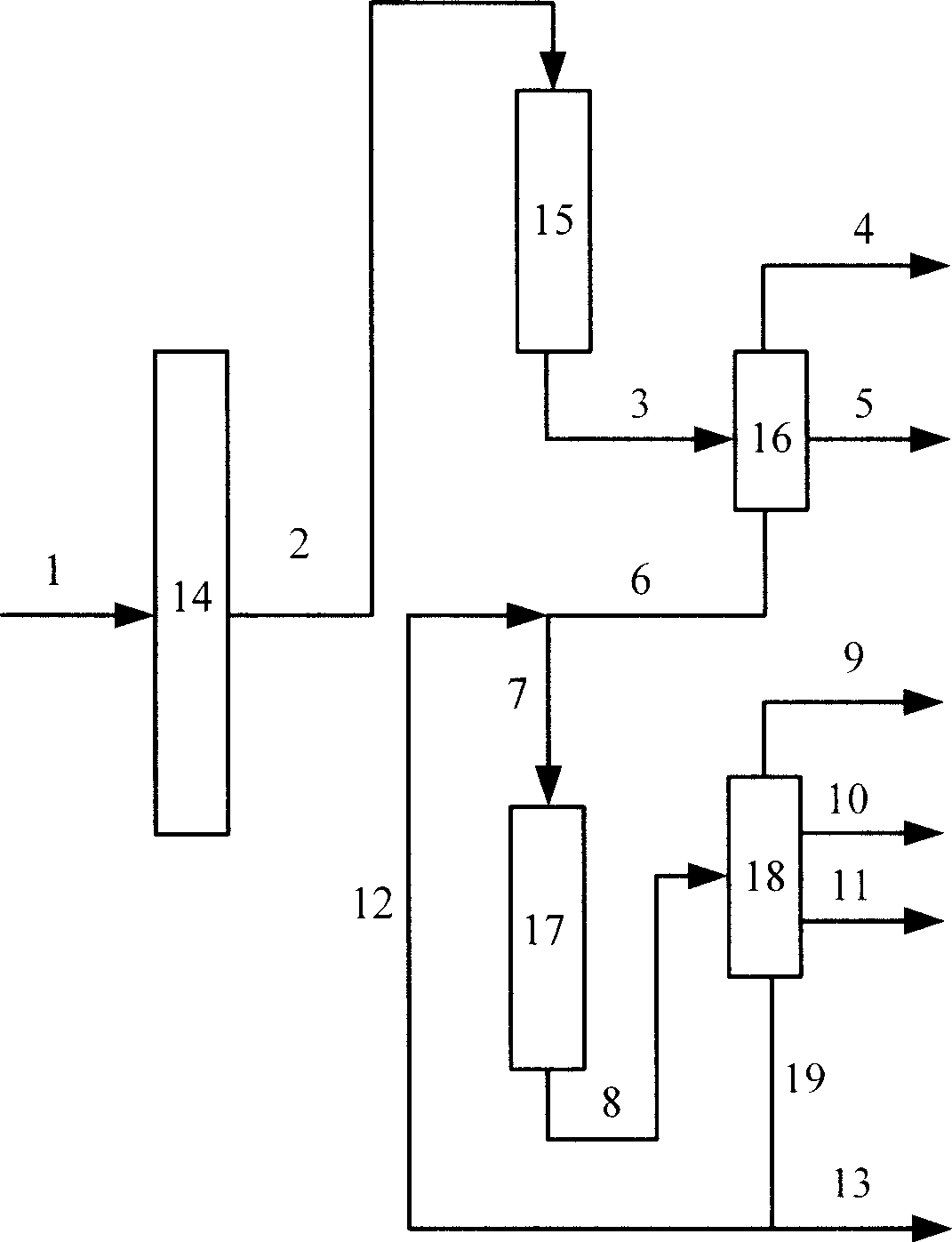

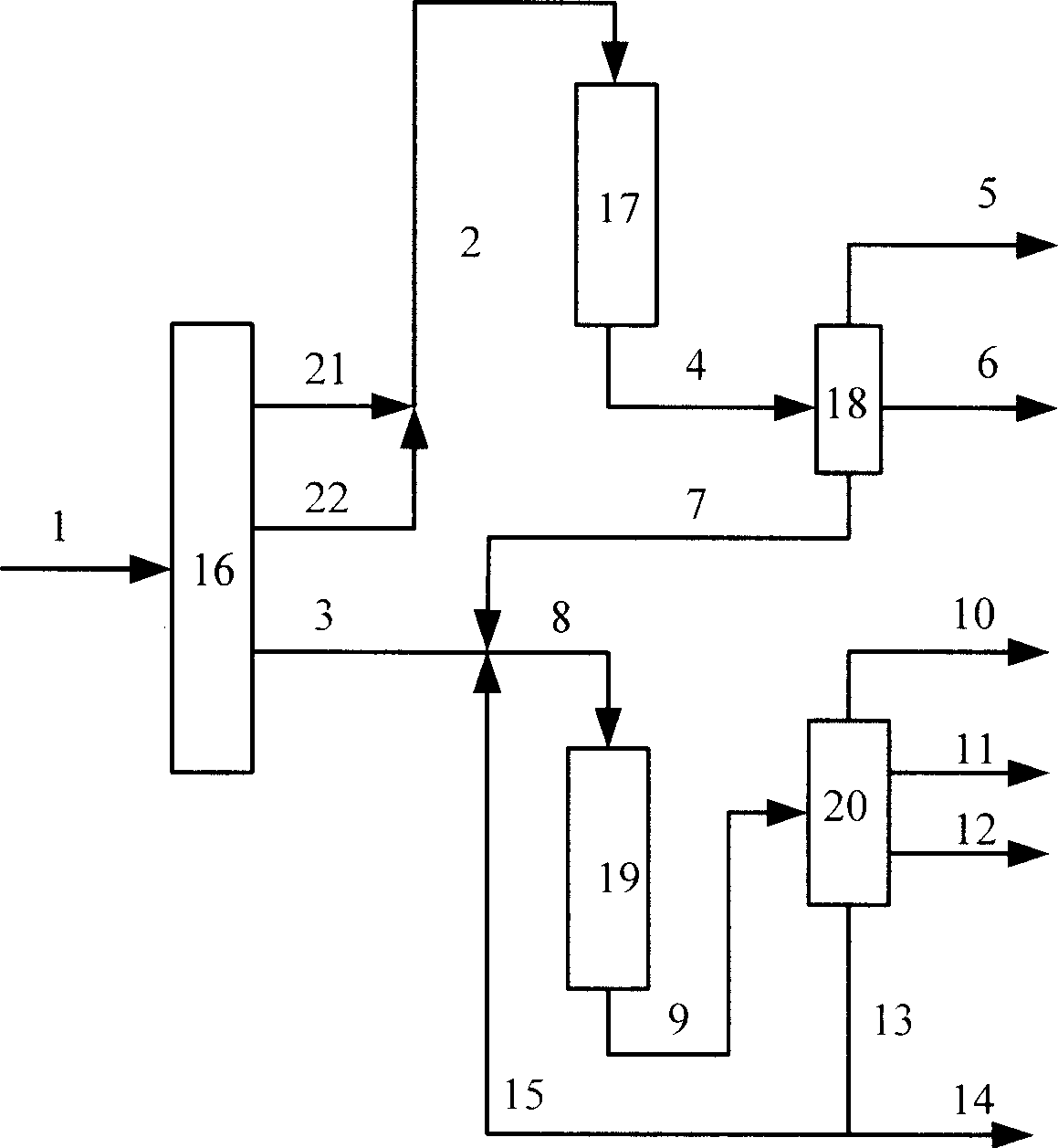

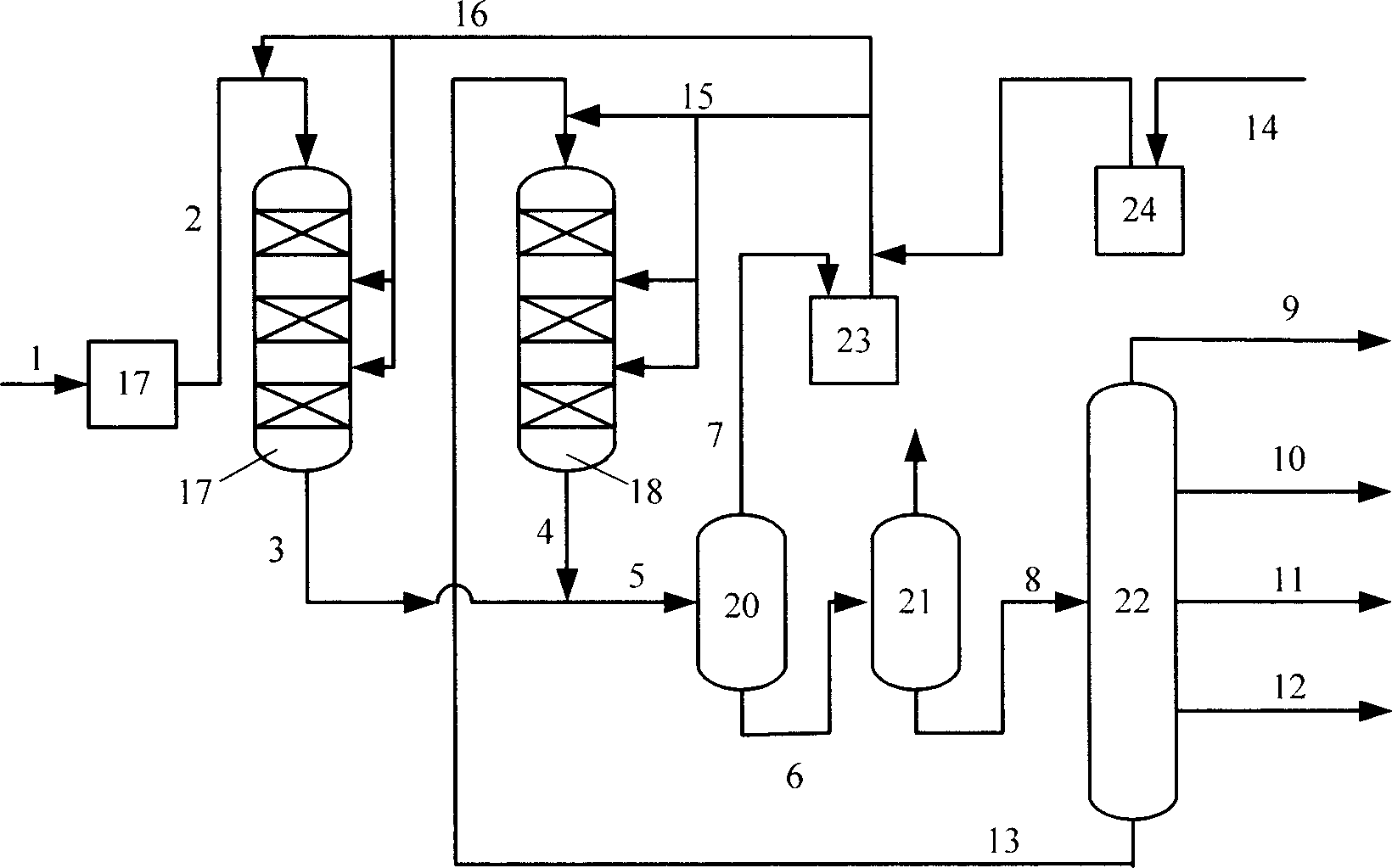

Production of intermediate fractional oil from Fischer-Tropsch synthetic oil

ActiveCN1854265ADifferent performanceLow priceTreatment with hydrotreatment processesHydrogenNaphtha

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation purifying combined process for Fischer-Tropsch synthetic substance

A kind of combined technology method to hydrogenate and improve quality of the product from Fishcher-Tropsch synthesis process, condensate and synthetic wax can be gained by natural isolation of the product from Fishcher-Tropsch synthesis process, and the condensate will contact with hydrogen and hydrofining catalyst, then the tail oil produced by the isolation of the hydrofining reactant liquor will contact with the synthetic wax, hydrogen, and hydrocracking and isocracking catalyst, the middle oil fraction product can be gained after the isolation of the hydrocracking reactant liquor at last. The yield of the diesel oil is more than 80% by the method, the cetane number will be more than 80, and sulfur, nitrogen and aromatic hydrocarbon can barely found in the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated Fischer-Tropsch synthetic oil hydrogenation purification

ActiveCN1854264AAvoid enteringImprove overall utilizationTreatment with hydrotreatment processesHydrogenNaphtha

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

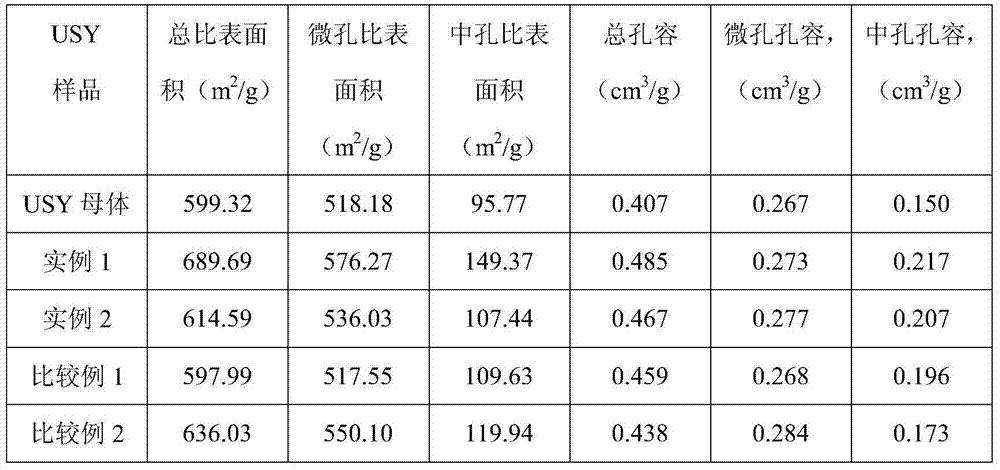

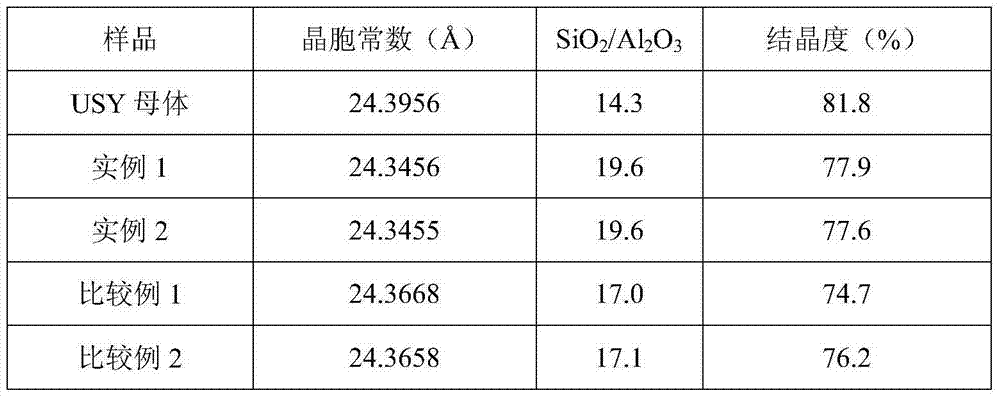

Combined modification method for mesopore USY molecular sieve

InactiveCN103936024AHigh crystallinityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

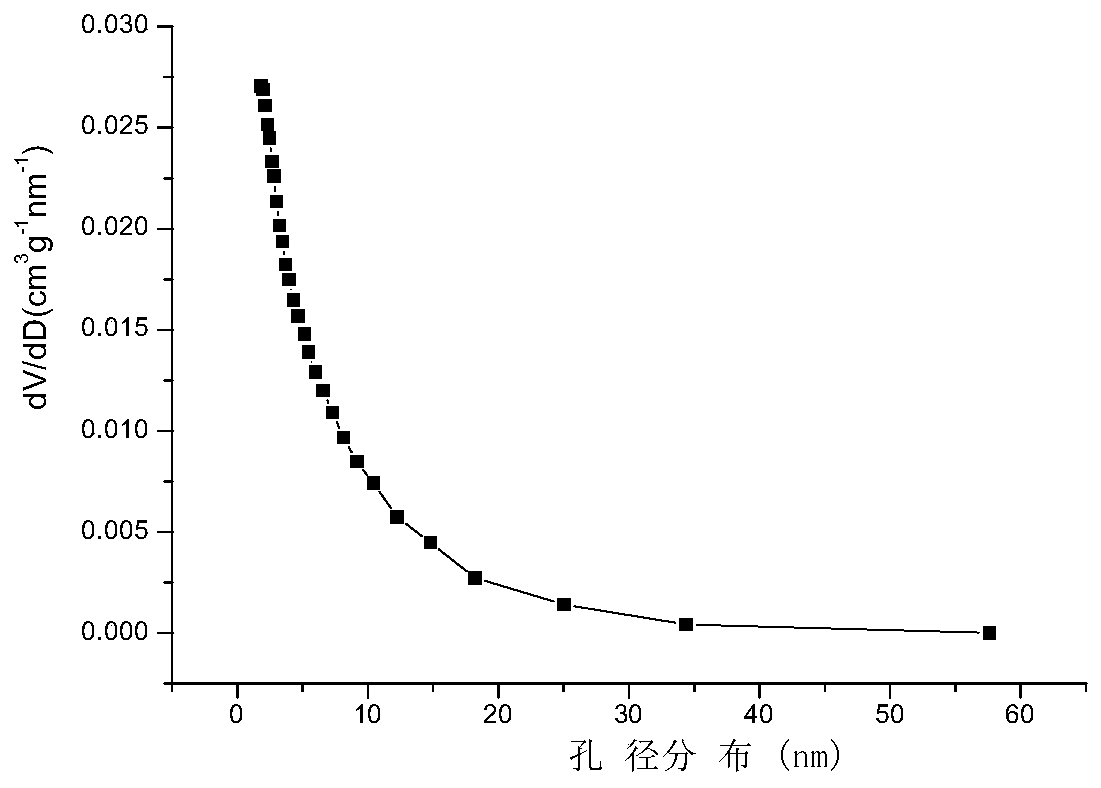

The invention relates to a modification method for a USY molecular sieve and in particular relates to a combined modification method for a mesopore USY molecular sieve. The combined modification method for the mesopore USY molecular sieve comprises that raw materials such as a USY material, an organic acid solution and an inorganic salt solution are measured in ratio, stirring in a closed reactor is carried out, temperature is increased to 90 DEG C, an organic acid-inorganic salt combined dealumination reaction is carried out for 8 hours; reactants are washed at room temperature, and suction filtration is carried out until the surface of USY is neutral; and drying is carried out at constant temperature of 110 DEG C for 16 hours, so that the USY molecular sieve product is obtained. The combined modification method for the mesopore USY molecular sieve has the advantages that a mixed aqueous solution of organic acid and inorganic salt is adopted for treating the USY type molecular sieve, so that high crystallinity of the molecular sieve can be maintained, silica-alumina ratio of the molecular sieve is increased, lattice constant is reduced, specific surface of the molecular sieve is increased, and acidity and acid distribution of the molecular sieve are improved; and more secondary holes are formed through dealumination, so that components with larger molecular diameter can easily enter into pore passages of the molecular sieve or get close to the surface of the molecular sieve, and conversion efficiency of hydrogen cracking can be improved.

Owner:PETROCHINA CO LTD +1

Heavy distillate oil hydrogenation catalyst and its preparation method

The invention discloses the heavy distillate oil hydrotreatment catalyst and preparing method. The method comprises the following: using the metal at the VIB and VIII as hydrogenation componemt, using the refractory oxide as carrier, the catalyst containing the 1%-20% modified ª‰ zeolite possessing the multi-stage pore path structure of 0.1-1.7nm,1.7-6.0nm and 10.0-90.0nm, The mole ratio of SiO2 and Al2O3 in the ª‰ zeolite being 80-120, and the particle mean size being 0.1-0.5ª–m. Due to choose the proper ª‰ zeolite, the catalyst possesses the characteristics of the high activity of desulfuration and denitrification, and is used for hydrotreating process of inferior distillate oil to produce FCC raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

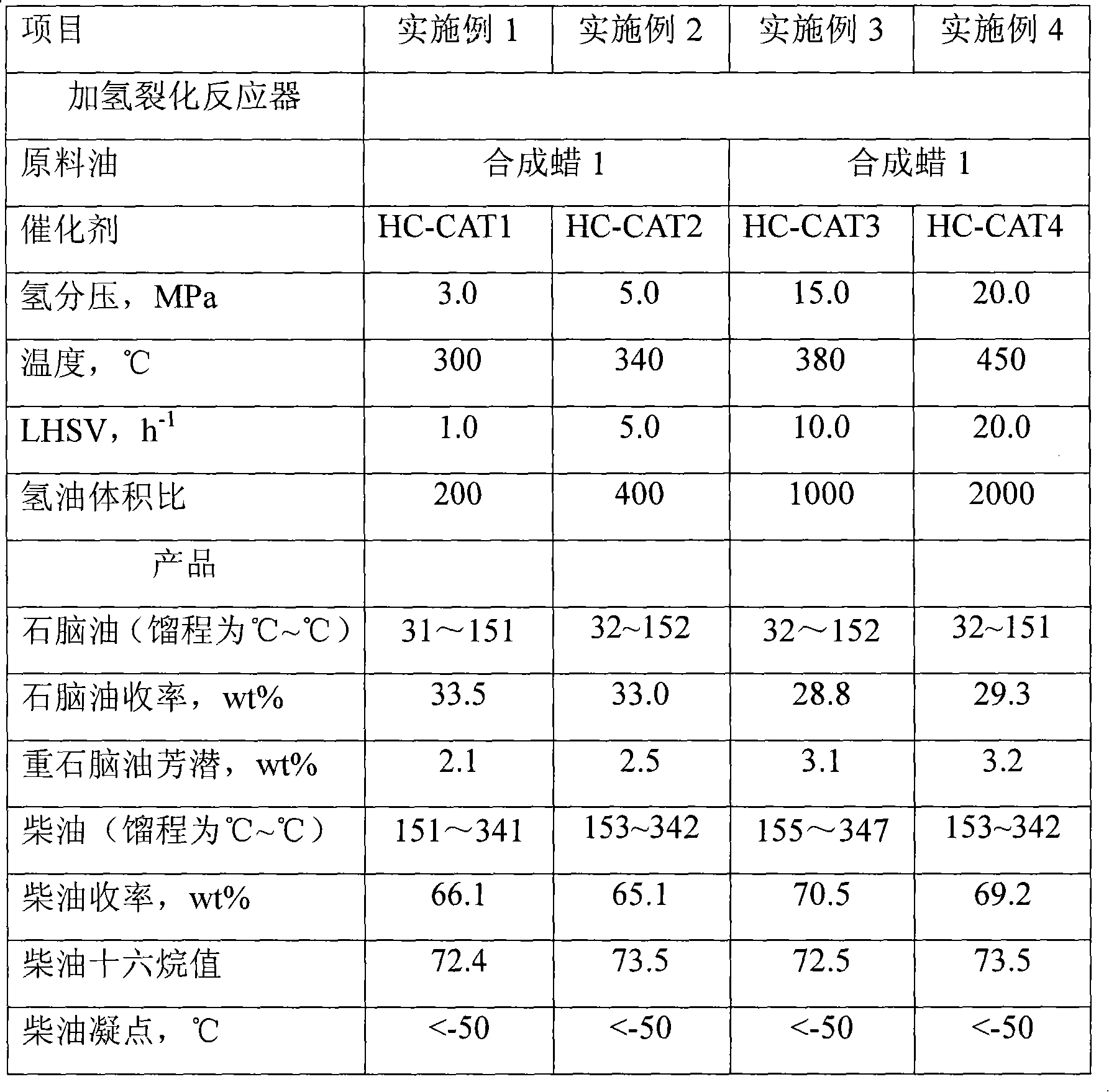

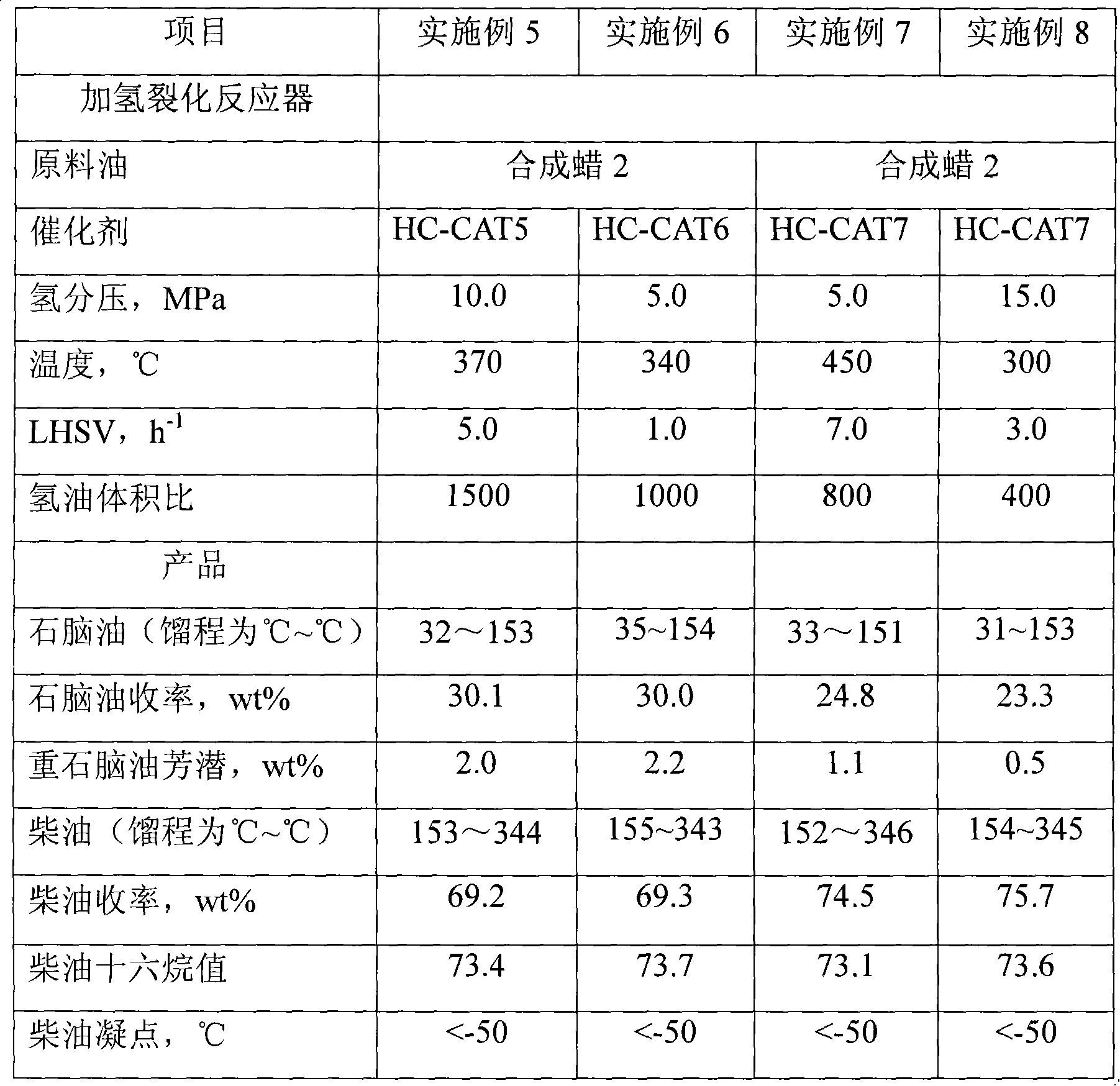

Method for producing diesel oil and chemical materials by f-t synthetic wax

InactiveCN101177619ALowering the freezing pointHigh activityHydrocarbon oil crackingGasoline stabilisationWaxNaphtha

The invention discloses a method for producing chemical raw material and diesel oil by Fischer-Tropsch synthetic wax and the method is that the Fischer-Tropsch synthetic wax and hydrogen gas contact with hydrogen cracking catalyst under hydrogen cracking condition and then the reaction products are treated by fractionation; diesel distillate obtained is the clean diesel with a low freezing point, while the naphtha cut obtained is high-quality raw material used for cracking of steam to ethane, and distillation range is higher than the hydrogen cracking of tail oil circulation of the diesel oil, wherein, the hydrogen cracking catalyst is the hydrogen cracking catalyst containing Beta zeolite and the weight content of the Beta zeolite in the catalyst is 0.5 percent to 60 percent; the Beta zeolite has properties that SiO2 / Al2O3 molar ratio is 20 to 150 and Na2O less than or equal to 0.2w percent. The method of the invention can prepare the Fischer-Tropsch synthetic wax into the clean diesel oil with a low freezing point and high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

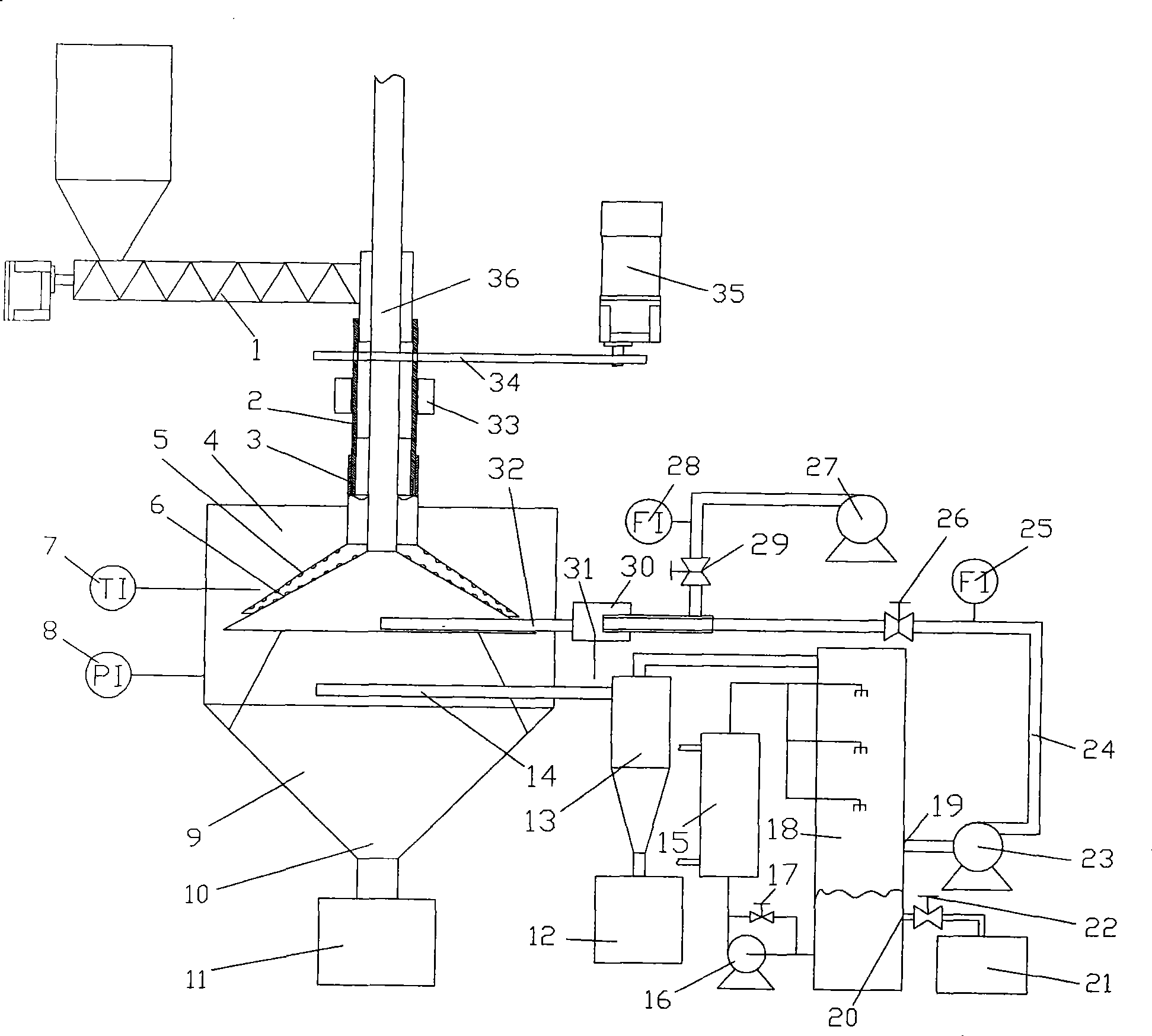

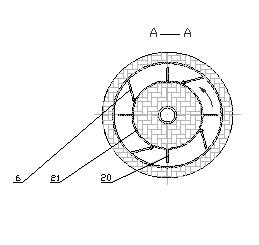

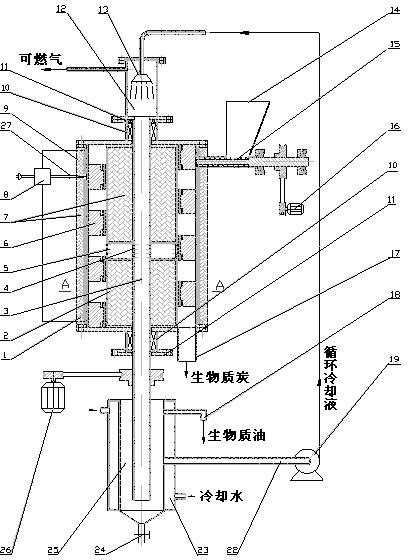

Internal combustion type heating rotating cone type biomass pyrolysis liquefaction device

ActiveCN101445737ARealize inverse motionImprove heat transfer effectBiofuelsSpecial form destructive distillationFlue gasFuel tank

The invention relates to an internal combustion type heating rotating cone type biomass pyrolysis liquefaction device. The device is characterized in that two concentric cones are arranged in a reactor, the outer cone is a rotating cone, and the inner cone is a fixed cone; a charging barrel is sectionally arranged into an upper section charging barrel and a lower section charging barrel, the upper part of the rotating cone is connected with the lower section charging barrel, and the upper section charging barrel is communicated with a spiral feeding mechanism; the upper part of the fixed cone is communicated with a flue gas pipeline; the end surface at the bottom part of the fixed cone is closed, and the lower part of the fixed cone is tangentially connected with a burning pipeline; a porous filter tube is arranged in the reactor, a reactor is led out form the other end of the porous filter tube, and the reactor is communicated with a cyclone dust collector positioned outside the reactor, the output end of the bottom part of the cyclone dust collector is connected with a carbon collecting box, and a gas outlet opening at the top part is connected with a condenser through a pyrolysis gas pipeline; an oil outlet opening on the condenser is communicated with an oil collecting tank, the air outlet opening of the condenser is accessed into a pyrolysis gas burner through a pyrolysis gas return pipeline. The invention realizes biomass self-heating type pyrolysis liquefaction, effectively improves the utilization ratio of the pyrolysis byproduct and reduces the total cost for biomass liquefaction.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Method for preparing coal tar by carrying out catalytic pyrolysis on pulverized coal and device thereof

ActiveCN101935539AReduce secondary crackingHigh yieldLiquid hydrocarbon mixture productionCatalytic pyrolysisProcess engineering

The invention discloses a method for preparing coal tar by carrying out catalytic pyrolysis on pulverized coal and a device thereof. The device thereof is characterized in that the upper outlet of a catalytic pyrolysis reactor is communicated with the inlet of a crude gas purification device, and the middle outlet thereof is communicated with the lower inlet of a heating riser tube and the middleinlet of a high-temperature carbocoal heat exchanger; a heating furnace is communicated with the inlet of the heating riser tube; the middle outlet of the heating riser tube is communicated with the carbocoal inlet of the catalytic pyrolysis reactor, and the upper outlet thereof is communicated with the smoke inlet of a high-temperature gas heat exchanger; the outlet of the crude gas purificationdevice is communicated with the gas input end of the high-temperature gas heat exchanger through a circulating gas blower, and the lower outlet thereof is communicated with the inlet of the high-temperature carbocoal heat exchanger through a gas blower; one output port of the high-temperature gas heat exchanger is communicated with the catalytic pyrolysis reactor, and the other output port thereof is communicated with the inlet of the heating riser tube through a smoke draught fan; and the outlet of the high-temperature carbocoal heat exchanger is communicated with the inlet pipeline of the catalytic pyrolysis reactor. The method comprises: circulating carbocoal powder heating, pulverized coal catalytic pyrolytic reaction, coal tar recovery and residual-heat utilization.

Owner:王树宽

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320BHigh ratio of silicon to aluminumIncrease acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

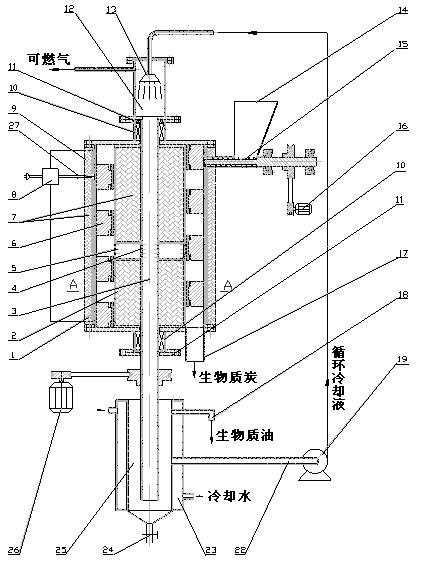

Revolving-scraper type biomass pyrolysis reactor

InactiveCN102329631ASave materialReduce secondary crackingBiofuelsLiquid hydrocarbon mixture productionProcess engineeringPyrolysis

The invention discloses a revolving-scraper type biomass pyrolysis reactor, which belongs to the field of biomass pyrolysis equipment. The revolving-scraper type biomass pyrolysis reactor comprises a heating cylinder, a revolving drum, a temperature control instrument, a dynamic seal, a bearing, a spray header, a hopper, a charging threaded rod, a charging motor, a circulating pump, a recirculated cooling liquid pipeline and an oil-water collecting cylinder, wherein the revolving drum is composed of a revolving shaft, a revolving-shaft through hole, a through hole of an external cylinder of the revolving drum, a revolving scraper, heat insulation cotton, a fixed wing and the external cylinder of the revolving drum. By using the reactor disclosed by the invention, the integration of a pyrolysis device, a cyclone separation device and a scrubbing-condensing device is truly realized; just through changing the preset temperature of the temperature control instrument and the revolving speeds of a revolving drum speed regulating motor and a charging speed regulating motor, the productivities of three products comprising biological oil, combustible gas and biomass carbon can be adjusted; and compared with the existing biomass pyrolysis reactor, the pyrolysis temperature is reduced by 100-150 DEG C.

Owner:NANJING UNIV

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348BHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

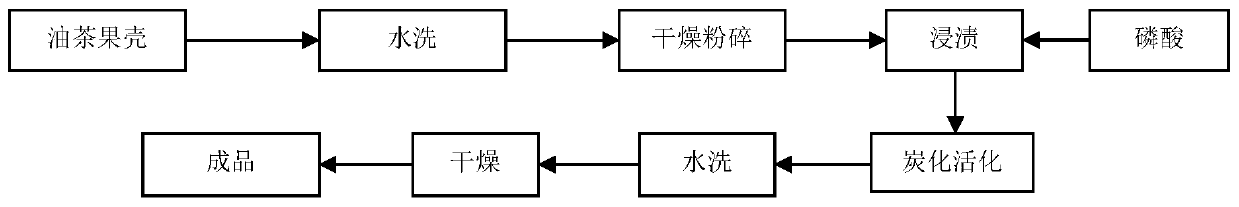

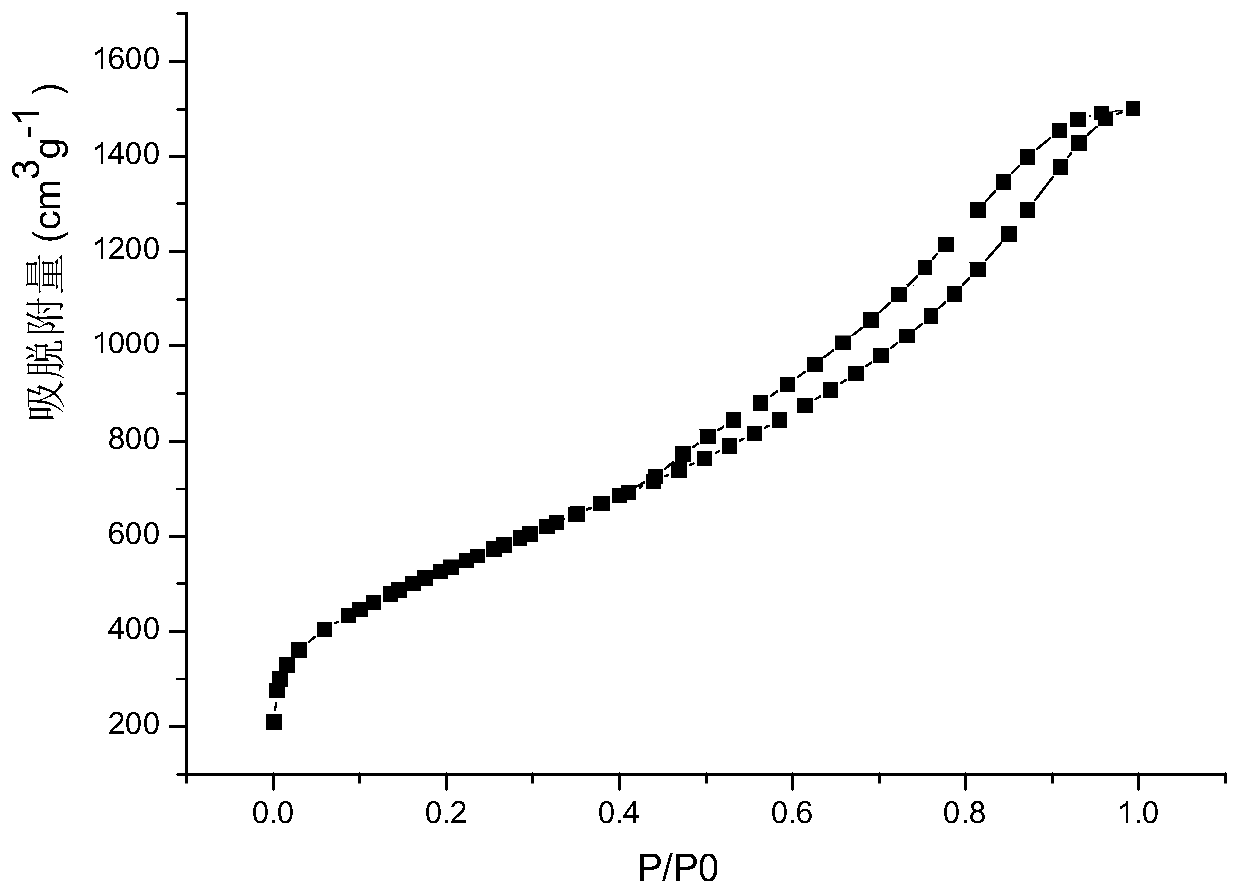

Preparation method and application of oil tea fruit shell activated carbon

PendingCN109734088ALarge specific surface areaHigh pore volumeCarbon compoundsOther chemical processesActivated carbonActivation method

The invention discloses a preparation method and an application of oil tea fruit shell activated carbon. According to the method, oil tea fruit shells serve as a raw material, the activated carbon isprepared under vacuum condition in a thermal cracking manner by a phosphoric acid activation method, carbonization and activation are simultaneously implemented, dosage of an activating agent is less,the specific surface area of a prepared product is large, total pore volume is high, a preparation process is green and clean, short in procedure and low in cost, the prepared oil tea fruit shell activated carbon is applied to adsorption and synthesis of dye rhodamine B, excellent adsorption effects are acquired, and large-scale production and application can be implemented.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for producing clean diesel oil from synthetic gas

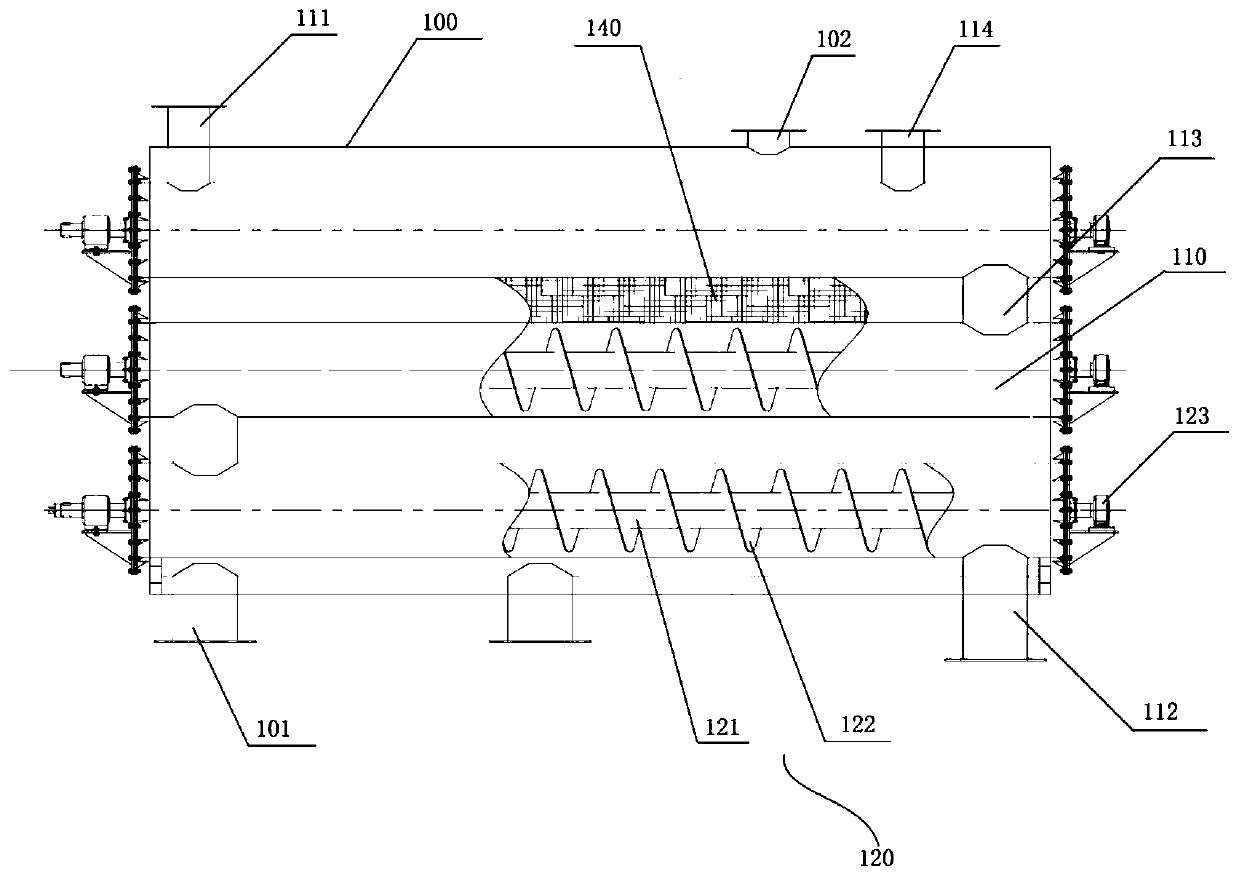

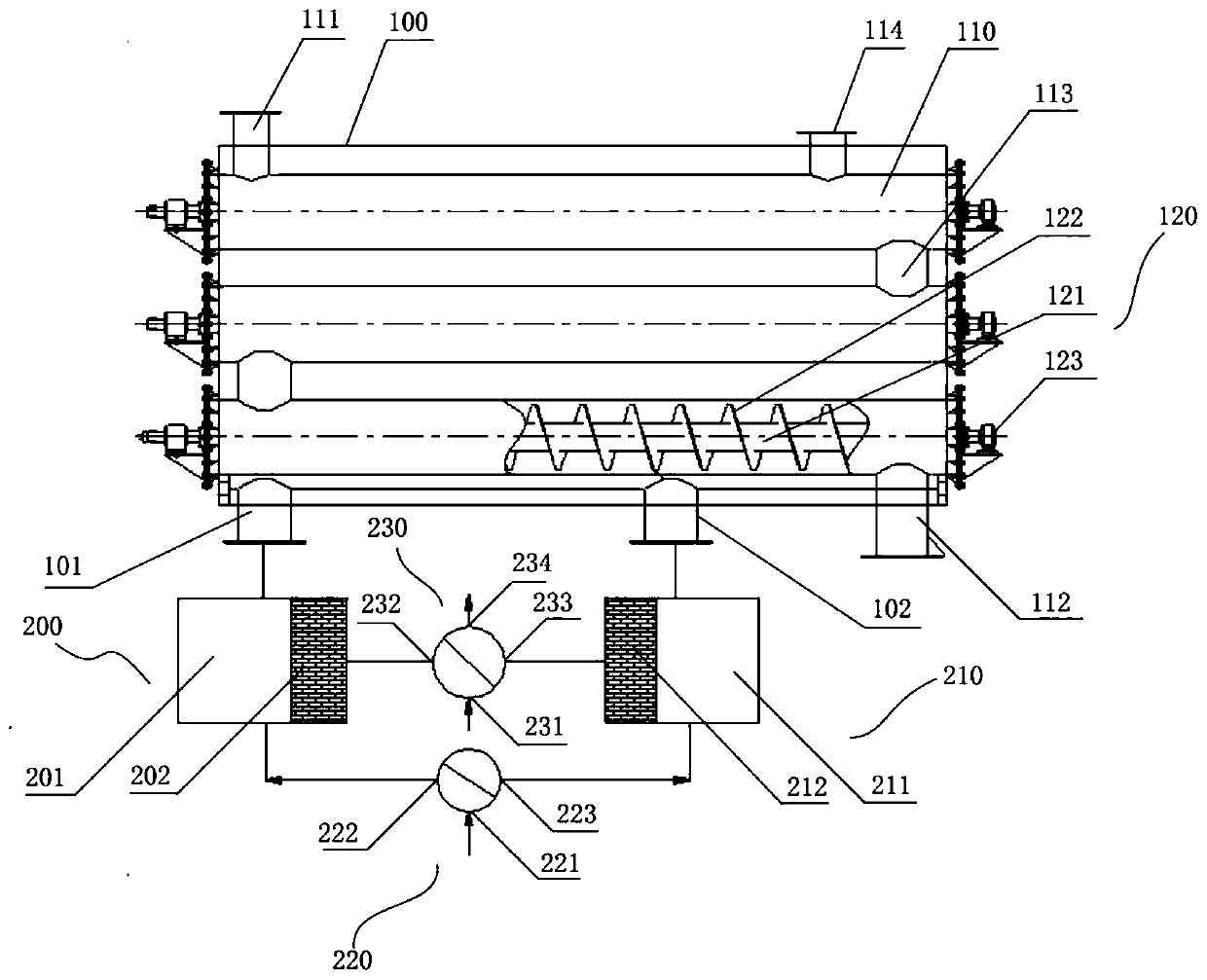

ActiveCN103965941ASolve axialSolve temperature problemsLiquid hydrocarbon mixture recoveryTreatment with hydrotreatment processesHydrogenSeparation system

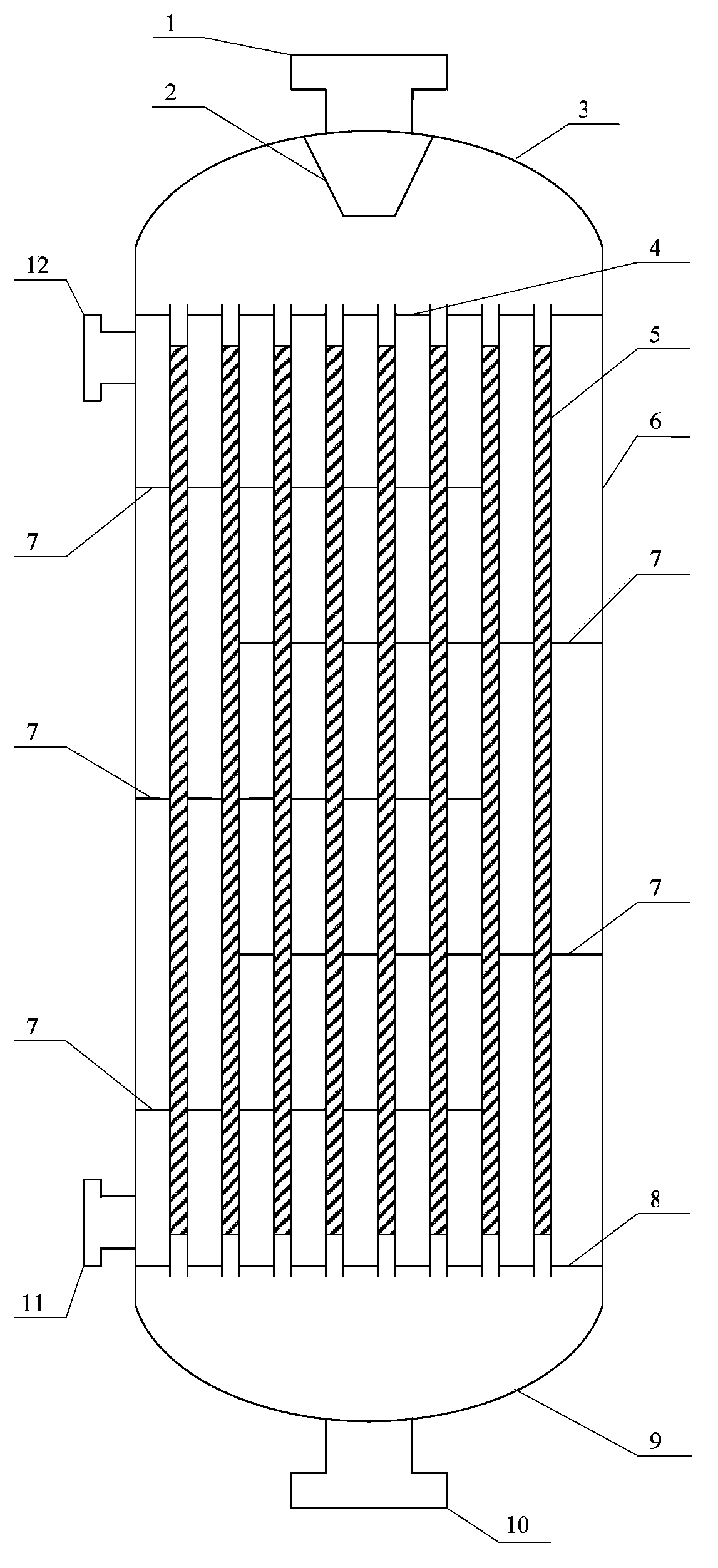

The invention provides a method for producing clean diesel oil from synthetic gas. The method comprises the following steps: allowing synthetic gas to enter a tubular fixed bed reactor and contact with a catalyst for a Fischer-Tropsch synthesis reaction, wherein the interior surface of a reaction tube is smooth, and the exterior surface of the reaction tube has a groove; separating heavy hydrocarbon and light hydrocarbon out from a synthetic product; mixing light hydrocarbon with hydrogen, allowing an obtained mixture to enter a hydrorefining reactor and contact with a catalyst for a hydrogenation saturation reaction and a hydrogenation deoxidation reaction; and allowing a hydrorefining reaction product to enter a separation system, mixing separated tail oil with heavy hydrocarbon, allowing an obtained mixture to enter a hydrogenation isocraking reactor and allowing a product to enter the separation system so as to obtain an intermediate distillate oil product. The method provided by the invention overcomes the problems of hardly controllable reaction heat and difficult heat transfer and hot spots of a reactor during the Fischer-Tropsch synthesis reaction and realizes economic and effective production of the clean diesel oil directed at the characteristic that hydrocarbons are produced in the process of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Forward-reverse combined construction method for foundation pit of non-permanent vertical support system

ActiveCN109944250ALow costEffective control of displacement and deformationExcavationsBasementSupporting system

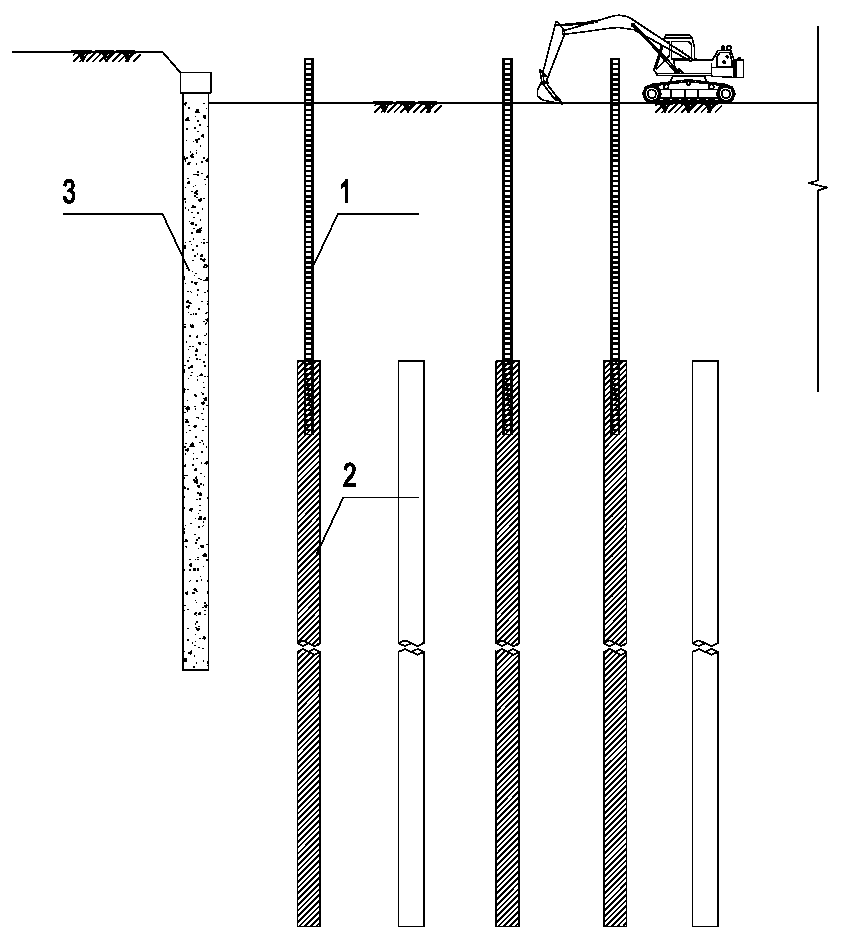

The invention provides a forward-reverse combined construction method for a foundation pit of non-permanent vertical support system, and belongs to the technical field of foundation pit support designand construction, and provides a construction method which has the advantages of a reverse construction method and a forward construction method at the same time. According to the method, a beam plate with a permanent structure is adopted as a horizontal support, and a temporary vertical support member is adopted to bear a vertical force during foundation pit construction. And earthwork is excavated according to the floor from top to bottom, a structural beam plate is poured, a permanent vertical member is poured from bottom to top after bottom plate construction is finished, and finally temporary steel upright posts are disassembled from top to bottom to finish earthwork excavation and structural construction of the whole basement. Namely, when the permanent structural beam plate is adopted to replace a support in the foundation pit, the temporary vertical support member is adopted to bear the vertical force during the construction of the foundation pit, and the excavation of the foundation pit and the construction of the basement structure of the whole basement are achieved through reasonable construction sequence and reliable node connection.

Owner:SHANGHAI CONSTRUCTION GROUP +1

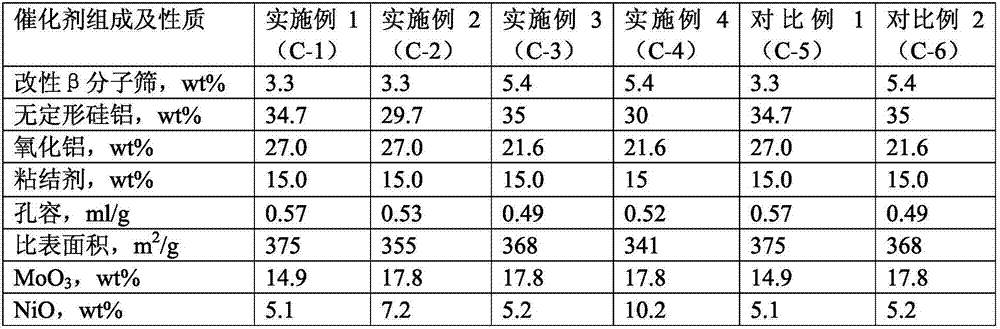

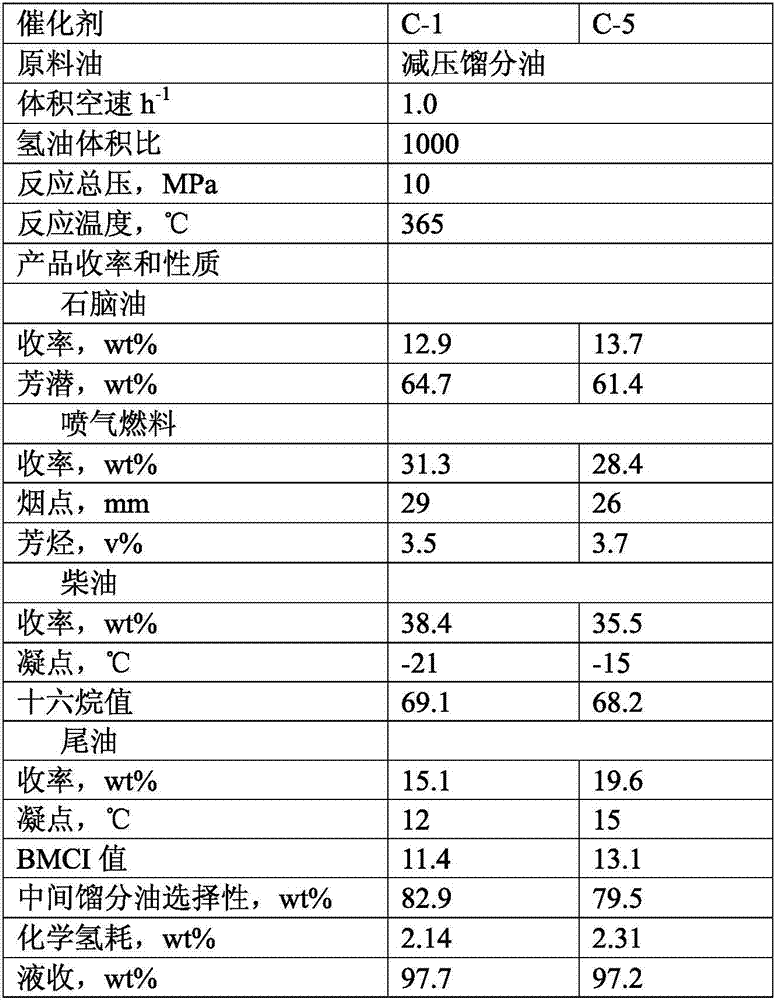

Optimized diesel hydrocracking catalyst and preparation method thereof

ActiveCN107051575AHomogeneous acid centerModerate acidityMolecular sieve catalystsHydrocarbon oil crackingDispersityAdhesive

The invention discloses an optimized diesel hydrocracking catalyst and a preparation method thereof. The optimized diesel hydrocracking catalyst is prepared from the following raw materials in percentage by weight: 1 to 25 percent of a modified molecular sieve, 10 to 65 percent of gamma-Al2O3, 15 to 70 percent of amorphous silica-alumina, 9 to 40 percent of an adhesive and 10 to 35 percent of active metal oxide. The catalyst has a specific surface area of 200 to 400m<2> / g and a total pore volume of 0.30 to 0.65cm<3> / g. The catalyst is obtained by adding the modified molecular sieve into an inorganic aluminum salt solution for preparing the gamma-Al2O3, performing precipitation, drying and calcination to obtain a composite material of the molecular sieve and the gamma-Al2O3, and performing mixing, rolling, forming, drying and activating on the other materials and the composite material according to the material proportion of the catalyst. The molecular sieve in a catalyst carrier of the catalyst is high in silica-alumina ratio, high in dispersity in the carrier and large in specific surface area, so that the carrier has more uniform acidic sites; alumina makes contact with the molecular sieve more closely, so that the condensation point of a diesel distillate can be obviously reduced and the cetane number of diesel can be increased on the premise of ensuring high yield of the diesel.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Sludge pyrolysis recycling system and pyrolysis method

ActiveCN110066083AImprove thermal efficiencyHeating evenlySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHeat carrierSludge

The embodiment of the invention provides a sludge pyrolysis recycling system, which adopts solid porcelain balls or quartz sand as a heat carrier to rapidly transfer heat to sludge according to the material and pyrolysis characteristics of the sludge, and comprises a specially designed spiral pyrolysis reactor capable of achieving forced mixing and rapid heat transfer of the sludge. According to the invention, the solid heat carrier and the sludge are mixed and directly heated, compared with an indirect heating mode, the heat efficiency is high and the heating is uniform; spiral blades and stirring blades which are reasonably arranged in the pyrolysis reactor can achieve full mixing and rapid heat transfer of the sludge and the heat carrier, the pyrolysis reaction speed is high, the systemtreatment capacity is strong, the coking problem caused by uneven stirring of the sludge is effectively solved, and the long-term stable operation of the system is achieved; the waste heat flue gas is recycled to pre-dry the sludge, so that the energy grading utilization is achieved, the energy consumption can be effectively reduced, and the energy utilization efficiency of the system is improved. The embodiment of the invention also provides a method for pyrolyzing the sludge by adopting the sludge pyrolysis recycling system.

Owner:嘉禾聚能(天津)科技有限公司

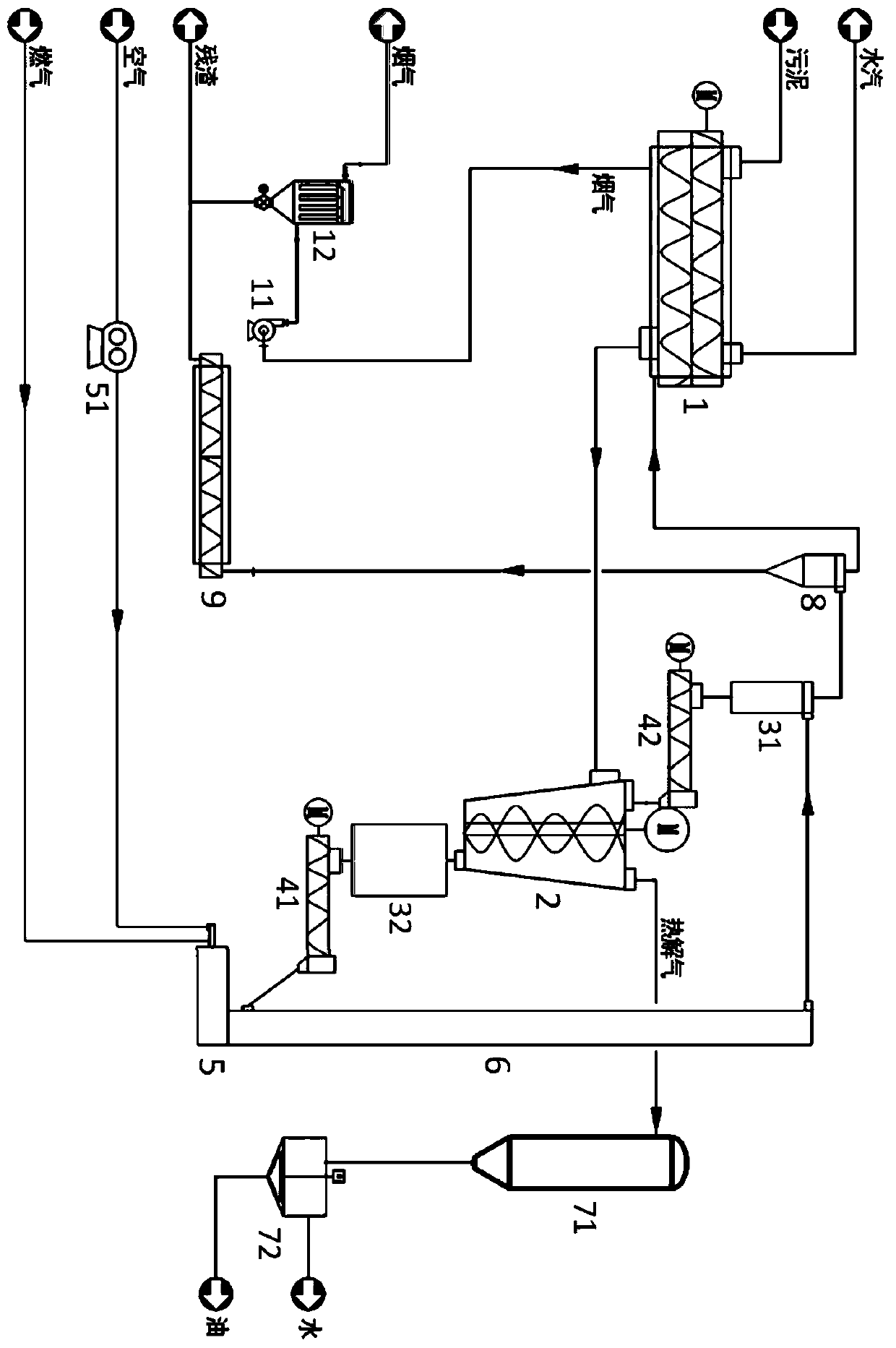

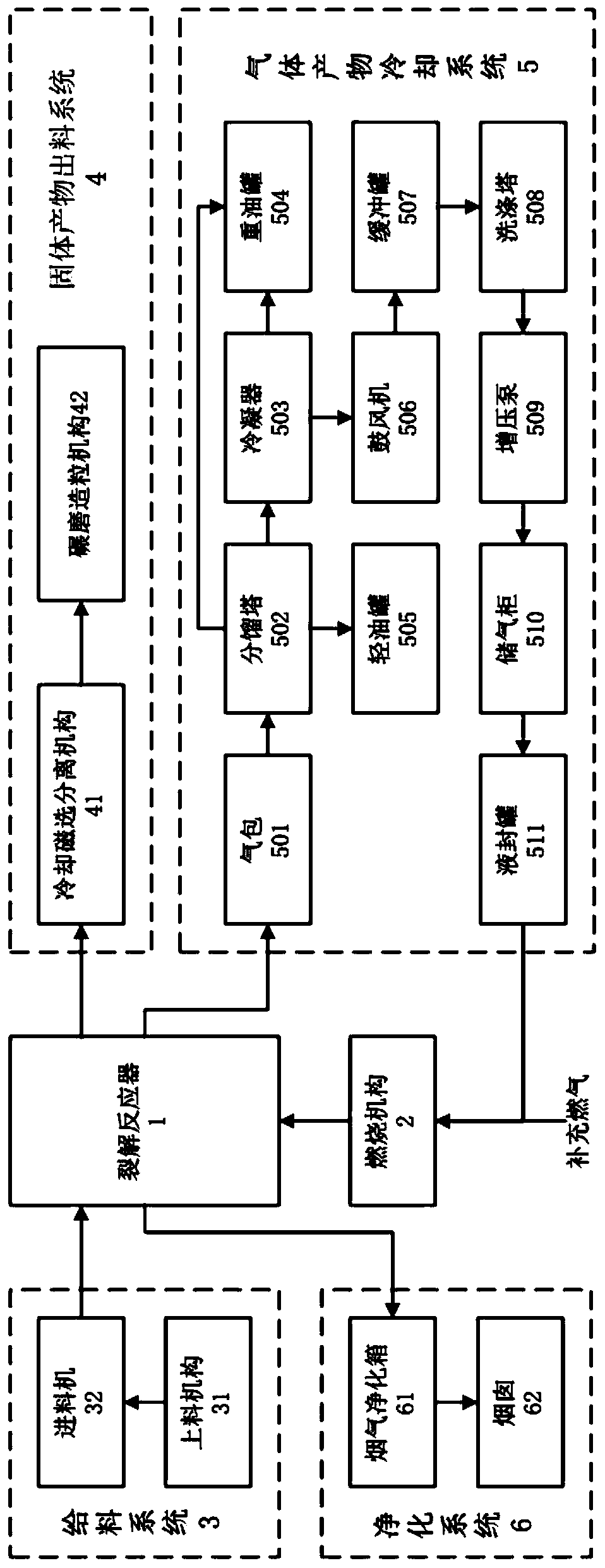

Novel rubber block pyrolysis oil production system

PendingCN110129085AStable combustionGuarantee self-sufficiencyLiquid hydrocarbon mixture productionEnvironmental resistanceCombustion

The invention discloses a novel rubber block pyrolysis oil production system, and relates to the technical field of environment-friendly equipment. The novel rubber block pyrolysis oil production system comprises a cracking reactor, a combustion mechanism, a material feeding system, a solid product discharging system, a gas product cooling system and a purification system, wherein the material feeding system is used for sending crushed rubber blocks into the cracking reactor, the cracking reactor is used for heating and cracking the rubber blocks, and the solid product discharging system is used for collecting and filtering carbon black generated in the cracking reactor, grinding the filtered carbon black, and performing granulation, drying and packaging; the gas product cooling system isused for collecting oil-gas products produced in the cracking reactor, and separating the oil-gas products so as to obtain an oil product and flammable non-condensable gas, the combustion mechanism isused for introducing and burning the flammable non-condensable gas, and sending the generated high-temperature flue gas into the cracking reactor so as to provide heat for cracking of the rubber blocks, and the purification system is used for purifying exhausted flue gas.

Owner:武汉兴泰荣达科技有限公司

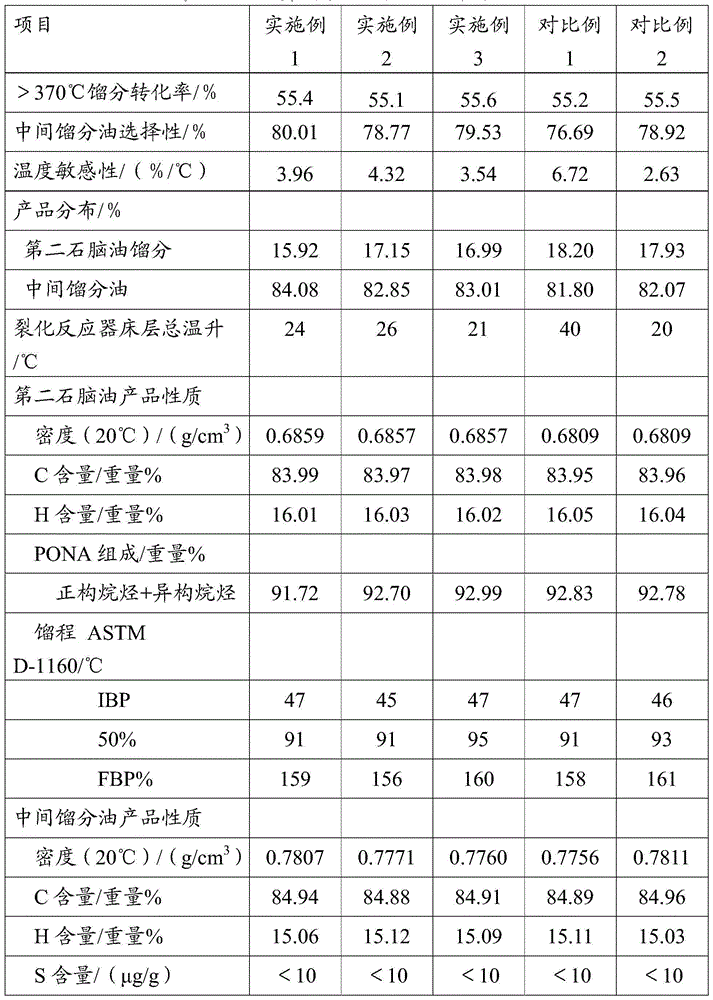

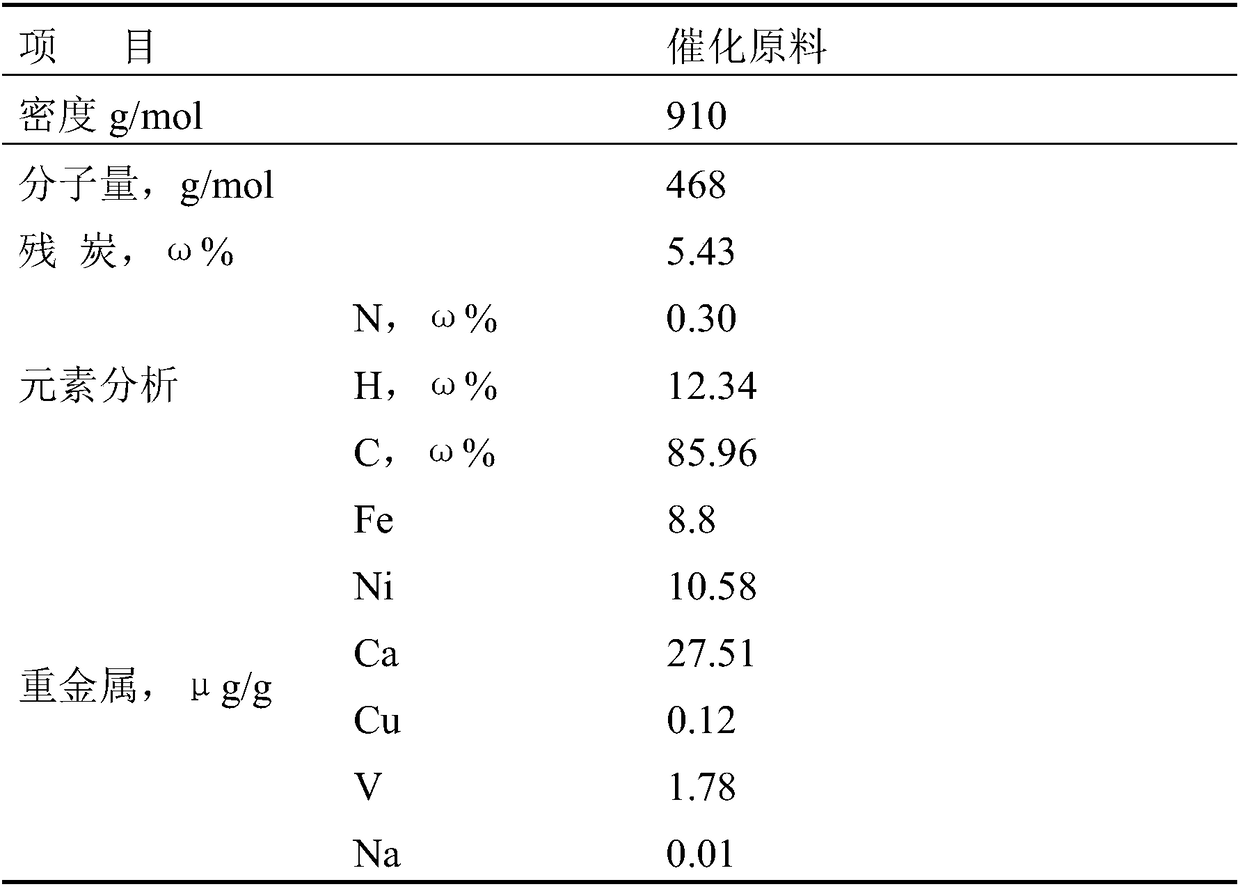

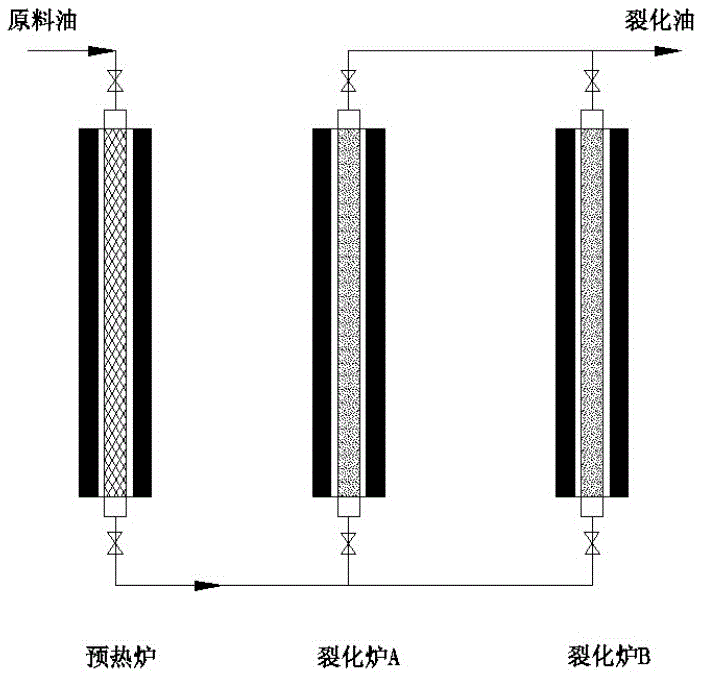

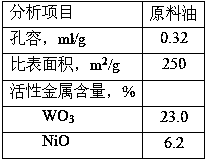

Method for producing middle distillate oil through hydrogenation of Fischer-Tropsch synthesis oil

ActiveCN106398762ADifferent performanceFlexible product planTreatment with hydrotreatment processesHydrogenNaphtha

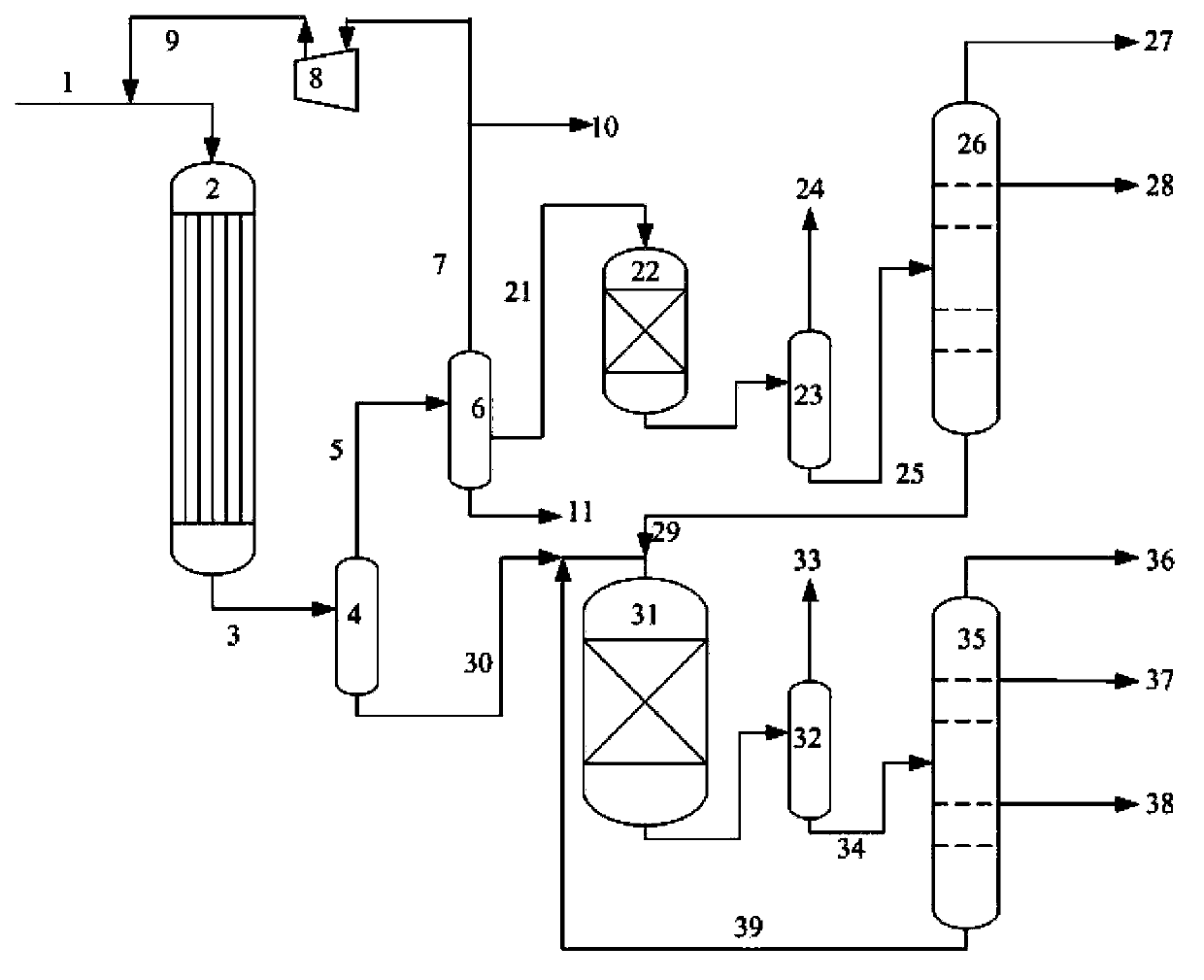

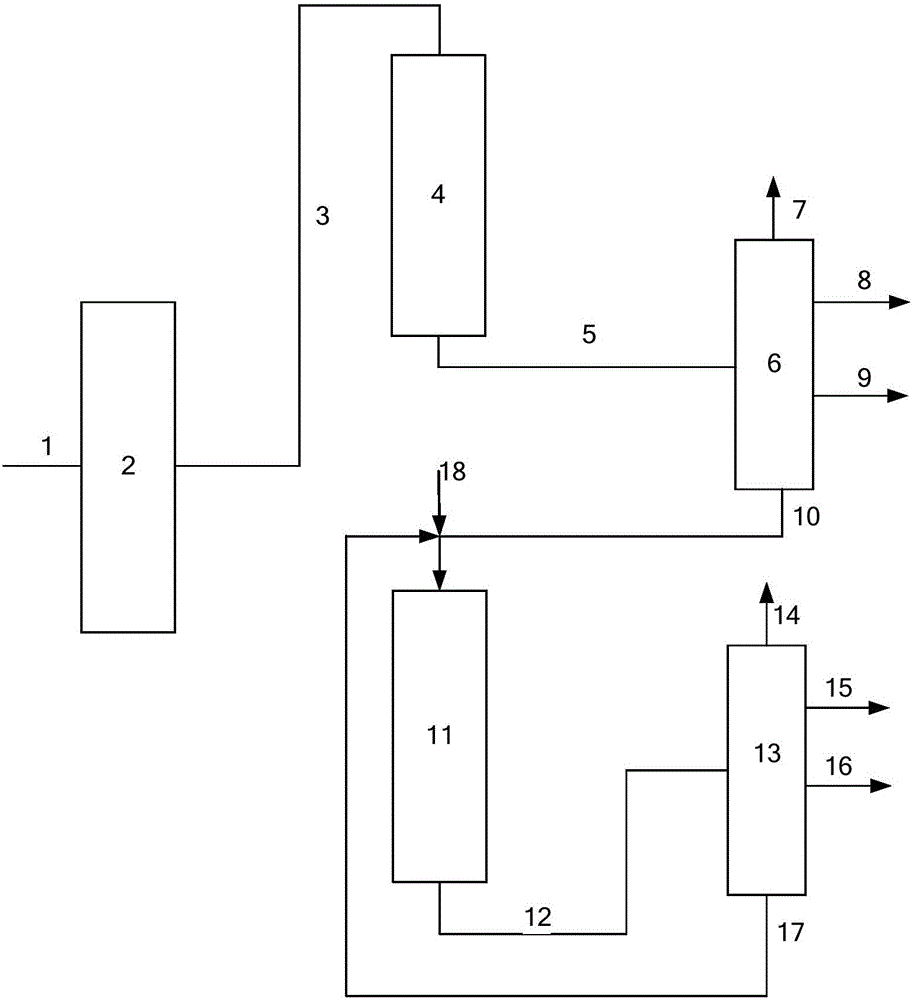

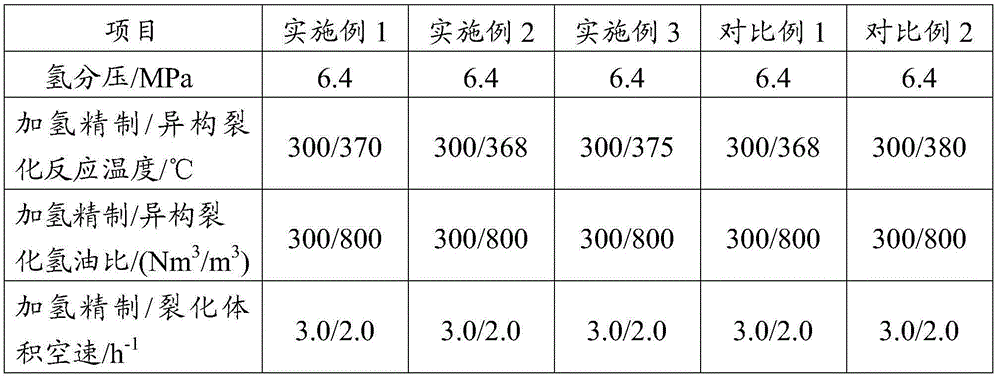

The invention relates to a method for producing middle distillate oil through hydrogenation of Fischer-Tropsch synthesis oil. According to the method, the whole distillate of Fischer-Tropsch synthesis oil and hydrogen gas are mixed, the obtained mixture enters a hydrorefining reactor and is subjected to a contact reaction with a hydrorefining catalyst, the obtained hydrorefining reaction effluent is sequentially subjected to separation and fractionation to obtain a first naphtha distillate, a light diesel oil distillate and a heavy oil distillate, the heavy oil distillate is mixed with at least a distillate oil and hydrogen gas, the obtained mixed material enters a hydroisomerization cracking reactor and is subjected to a contact reaction with a hydroisomerization cracking catalyst, and the obtained hydroisomerization cracking reaction effluent is sequentially subjected to separation and fractionation to obtain a second naphtha distillate, a middle distillate oil and a tail oil distillate. With the method of the present invention, the selectivity and the yield of the middle distillate oil are easily improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589BHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The present invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for catalytic cracking catalyst for cracking coker gas oil and increasing production of diesel

ActiveCN109304210AHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveMagnesium salt

The invention provides a preparation method for a catalytic cracking catalyst for cracking coker gas oil and increasing production of diesel. The preparation method comprises the following steps thata rare earth, phosphorus and magnesium modified Y-type molecular sieve is prepared, specifically, a NaY molecular sieve is subjected to ammonium salt and rare earth salt exchange and then is sequentially modified by phosphorus and magnesium, wherein the step is characterized in that phosphorus modification is carried out before magnesium modification; (2) the catalyst is formed, specifically, water, the molecular sieve, clay, pseudo-boehmite and a binder are mixed, pulped, spray-dried and roasted; and (3) modification is carried out, specifically, the water, magnesium salt and catalyst particles are uniformly mixed, the pH value is adjusted, and filtering and drying are carried out. The catalyst shows good heavy oil conversion capability and diesel selectivity in the process of cracking the coker gas oil.

Owner:PETROCHINA CO LTD

Method for preparing 10-undecylenic acid and heptanal by catalytic cracking

ActiveCN103819330BReduce aggregationReduced responsePreparation from carboxylic acid saltsMolecular sieve catalystsMethyl ricinoleateIsomerization

The invention relates to a process for producing polyundecancylamide resin through castor oil and particularly relates to a method for preparing 10-undecenoic acid and heptanal through the castor oil in the process. The method comprises the following steps: ester interchange is performed on the castor oil and methyl alcohol to generate ricinic acid methyl ester; catalytic cracking is performed on the ricinic acid methyl ester to generate10-undecenoic acid methyl ester and heptanal; pressure-reduction rectification separation is performed on the 10-undecenoic acid methyl ester and heptana; saponification and acidification are performed on the 10-undecenoic acid methyl ester and heptana, so that 10-undecylenic acid is obtained; the ricinic acid methyl ester is mixed with water (or water vapor) according to the mass ratio of 1:(0.5-2), the mixture is preheated to 200-400 DEG C, and then is loaded into a cracking still filled with a catalyst, and cracking is performed at the temperature of 400-500 DEG C, so that the 10-undecenoic acid and heptanal are generated. According to the invention, due to catalytic action, the cracking temperature is reduced greatly, so that side reactions such as polymerization and isomerization of the double bond, the secondary cracking of a product and coking are reduced, and the yield of the 10-undecenoic acid and heptanal is improved greatly.

Owner:江苏东鼎化学科技有限公司

A Catalytic Diesel Hydrogenation Conversion Process

ActiveCN107304373BIncrease secondary crackingLow yieldMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveHydrogenation reaction

The invention discloses a hydro-conversion technology for catalytic diesel oil. The technology comprises the following steps: firstly, putting a mixture of catalytic diesel oil and hydrogen into a hydrogenation reactor and performing hydrofining reaction, and then guiding into a cracking reactor and generating contact reaction with hydrocracking catalyst layers, wherein upper and lower catalyst layers are arranged in the hydrocracking reactor; the hydrocracking catalyst in the upper layer has the properties as follows: on the basis of the total weight of the catalyst, 10%-18% of MoO3, 2%-10% of Co, 40%-90% of modified Y-shaped molecular sieve, preferably 50-80%, and the balance of aluminum silicon carrier; the hydrocracking catalyst in the lower layer has the properties as follows: on the basis of the total weight of the catalyst, 15-30% of MoO3 or WO3, 2-15% of NiO, 10%-60% of modified Y-shaped molecular sieve, preferably 20-40%; the filling mass ratio of the hydrocracking catalysts in the upper layer and the lower layer is (1:5)-(5:1). The hydro-conversion technology disclosed by the invention can further increase the device liquid yield, can reduce the hydrogenation saturation of the generated gasoline component and can increase the octane value of the gasoline component under the condition of better meeting the requirement for the conversion rate of catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst for moderate oil and preparation thereof

ActiveCN101450319BHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAmorphous silicon

The invention discloses a high-activity and high and medium oil type hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieves, amorphous silicon aluminum and alumina, wherein the modified Y molecular sieves have high crystallinity, large silicon aluminum ratio and proper total acid amount and acid distribution, and are obtained by treating Y molecular sieves after hydro-thermal treatment by a mixed aqueous solution of aluminum salts and an acid. The hydrocracking catalyst has high activity and good intermediate distillate oil selectivity and product quality, and is particularly suitable for hydrocracking technology for producing intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation purifying combined process for Fischer-Tropsch synthetic substance

A kind of combined technology method to hydrogenate and improve quality of the product from Fishcher-Tropsch synthesis process, condensate and synthetic wax can be gained by natural isolation of the product from Fishcher-Tropsch synthesis process, and the condensate will contact with hydrogen and hydrofining catalyst, then the tail oil produced by the isolation of the hydrofining reactant liquor will contact with the synthetic wax, hydrogen, and hydrocracking and isocracking catalyst, the middle oil fraction product can be gained after the isolation of the hydrocracking reactant liquor at last. The yield of the diesel oil is more than 80% by the method, the cetane number will be more than 80, and sulfur, nitrogen and aromatic hydrocarbon can barely found in the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Improved diesel hydrocracking catalyst and preparing method thereof

ActiveCN106925342AIncrease dispersionUniform acidityMolecular sieve catalystsSal ammoniacMolecular sieve

The invention discloses an improved diesel hydrocracking catalyst and a preparing method thereof. Raw materials of the catalyst includes, by weight, 4-25% of molecular sieve, 10-65% of gamma-Al2O3, 15-70% of amorphous silica-alumina, 9-40% of binder and 7-35% of active metal oxide, the specific surface area of the catalyst is 220-450 m<2> / g, and the total pore volume is 0.30-0.73 cm<3> / g. Molecular sieve with an template agent not removed is added in the process of preparing a molecular sieve and aluminum oxide composite material, NH4+ generated through aluminum salt and ammonia water reaction exchanges with alkali Na+ for balancing negative charges of a molecular sieve skeleton in a mixed solution, the organic template agent and NH4+ in the molecular sieve are simultaneously removed in the calcinations process, ammonium exchange and template agent removal of the zeolite molecular sieve are completed in the process of preparing the composite material, the step of individually conducting template agent removal and ammonium exchange on the molecular sieve, the template agent has the effects of supporting and protecting the molecular sieve pore structure, and the catalyst can obviously reduce the condensation point of diesel fraction and increase the cetane number of diesel on the premise of ensuring the high diesel yield.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com