Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High conversion capacity of heavy oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrated alumina with structure of similar to thin diaspore of containing additive

ActiveCN1915486AHigh conversion capacity of heavy oilHigh yieldCatalyst activation/preparationAlkaline earth metalHydrated alumina

A hydrated alumina containing additive (0.5-40 Wt %) and with alpha-AlO (OH) structure for preparing the catalyst used for catalytic cracking reaction. Said additive is chosen from RE metal, La-family metal, Si, Ga, B and P. Its preparing process includes such steps as mixing alpha-AlO (OH) with H2O and acid while stirring, ageing, and mixing with additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

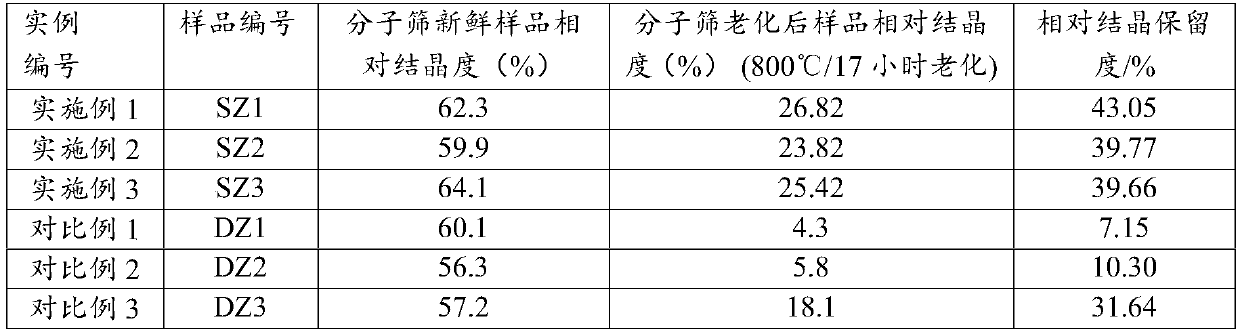

ActiveCN1916116AHigh conversion capacity of heavy oilHigh yieldCatalytic crackingPseudoboehmiteMolecular sieve

This invention discloses a cracking catalyst, which comprises an appropriate amount of molecular sieve, and aluminum oxide containing 0.5-40 wt. % of additive. The cracking catalyst is prepared by: (1) mixing pseudoboehmite, water and acid by stirring to obtain mixed slurry; (2) aging the mixed slurry at room temperature to 90 deg.C for 0-24 h; (3) mixing the product of step 2 with the additive; (4) mixing the product of step 3 with the molecular sieve, drying and torrefying. The weight ratio of the acid to aluminum oxide in pseudoboehmite is 0.01-0.5. The cracking catalyst has better heavy oil reforming performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

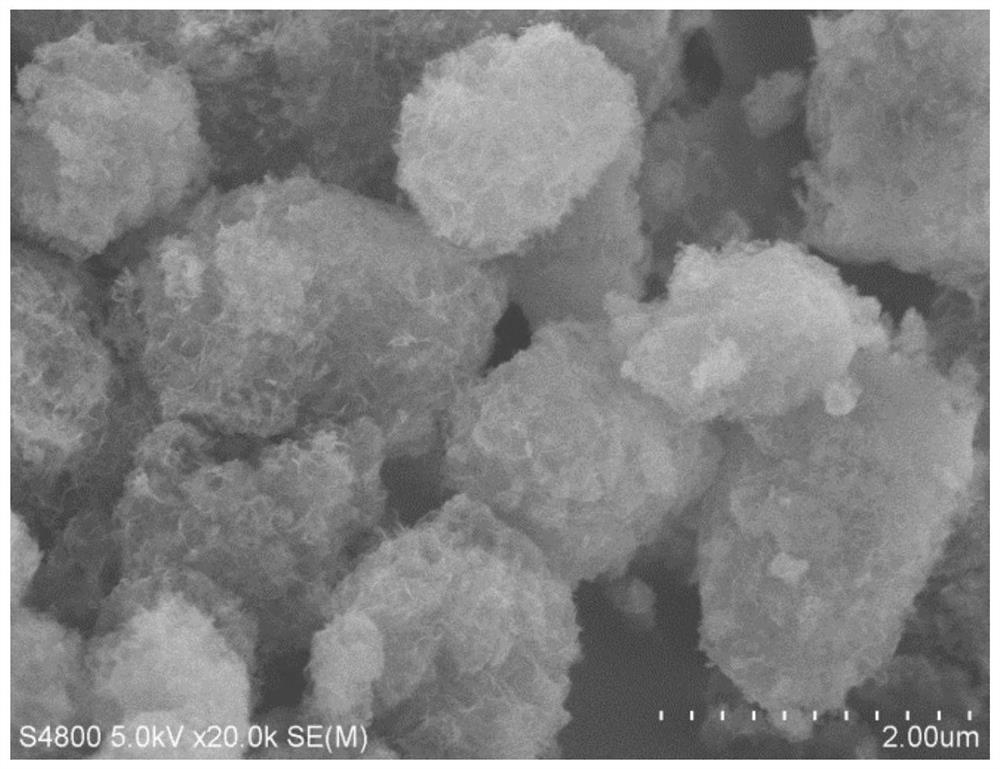

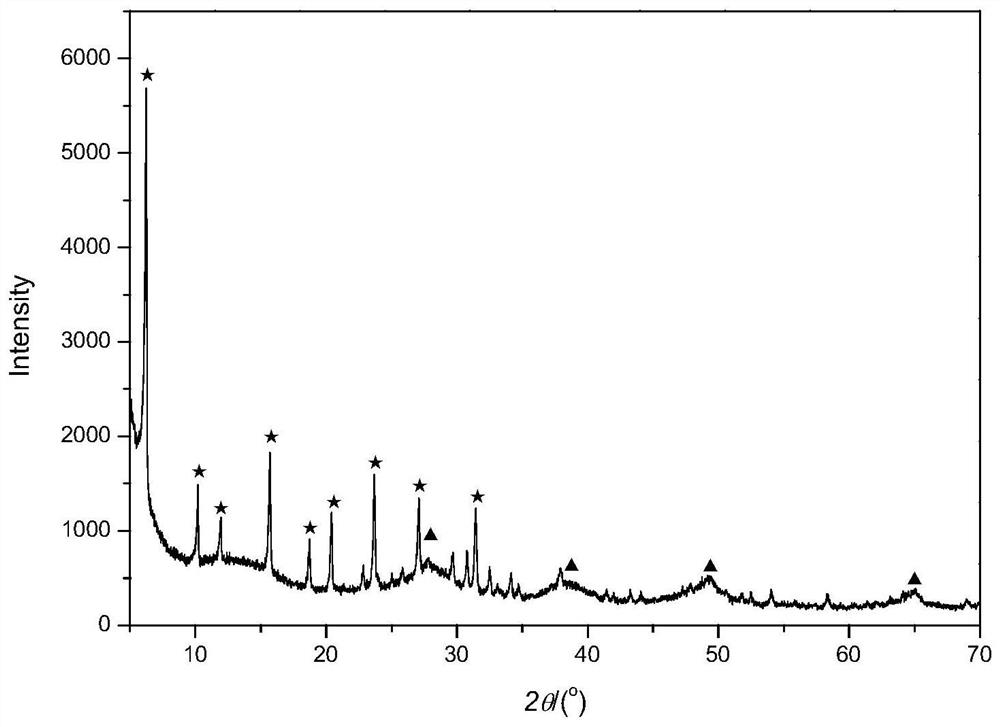

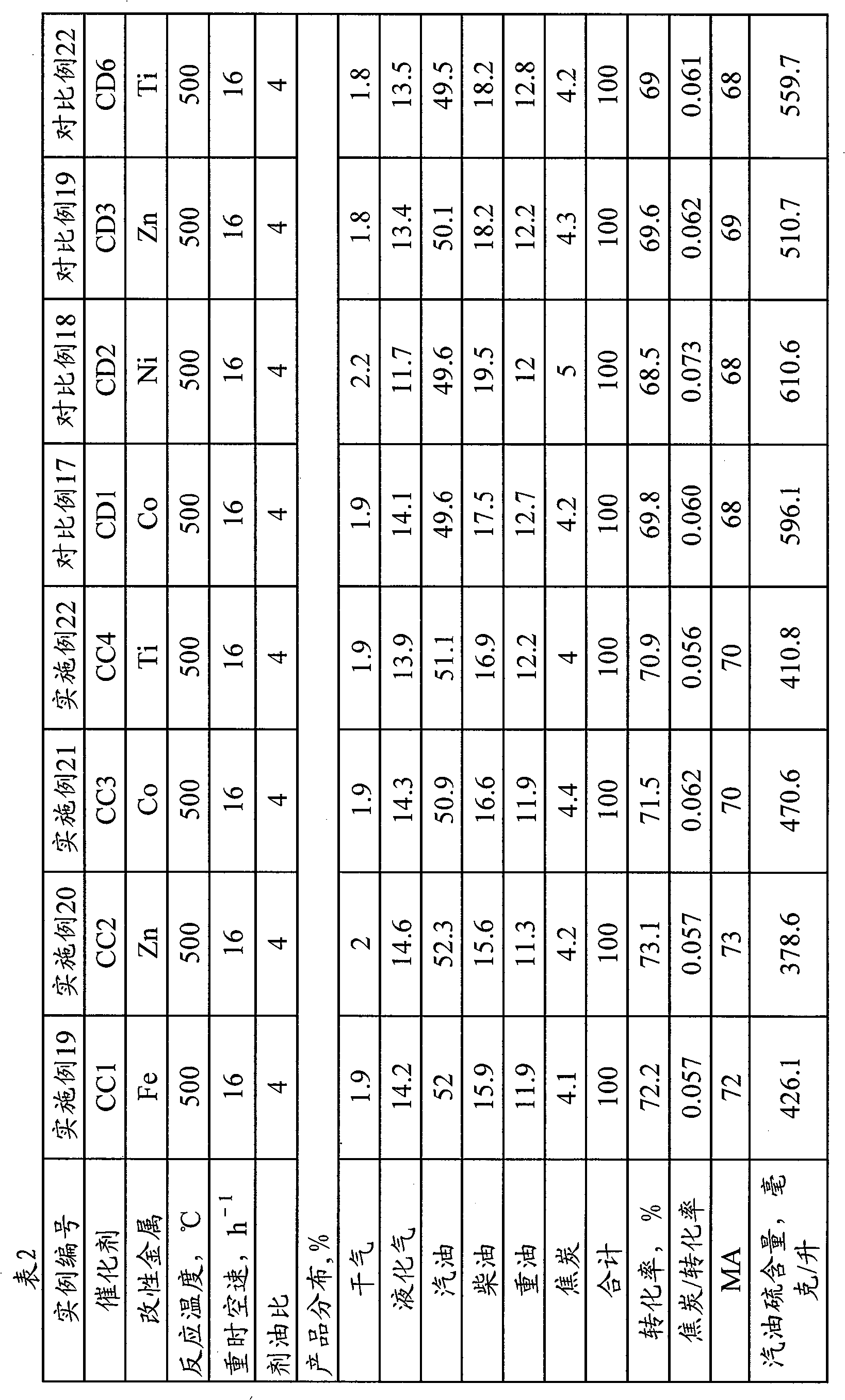

Hydrated alumina containing metallic element and method for preparing the same

ActiveCN101116818ALarge average pore sizeHigh conversion capacity of heavy oilCatalytic crackingCatalyst activation/preparationHydrated aluminaGasoline

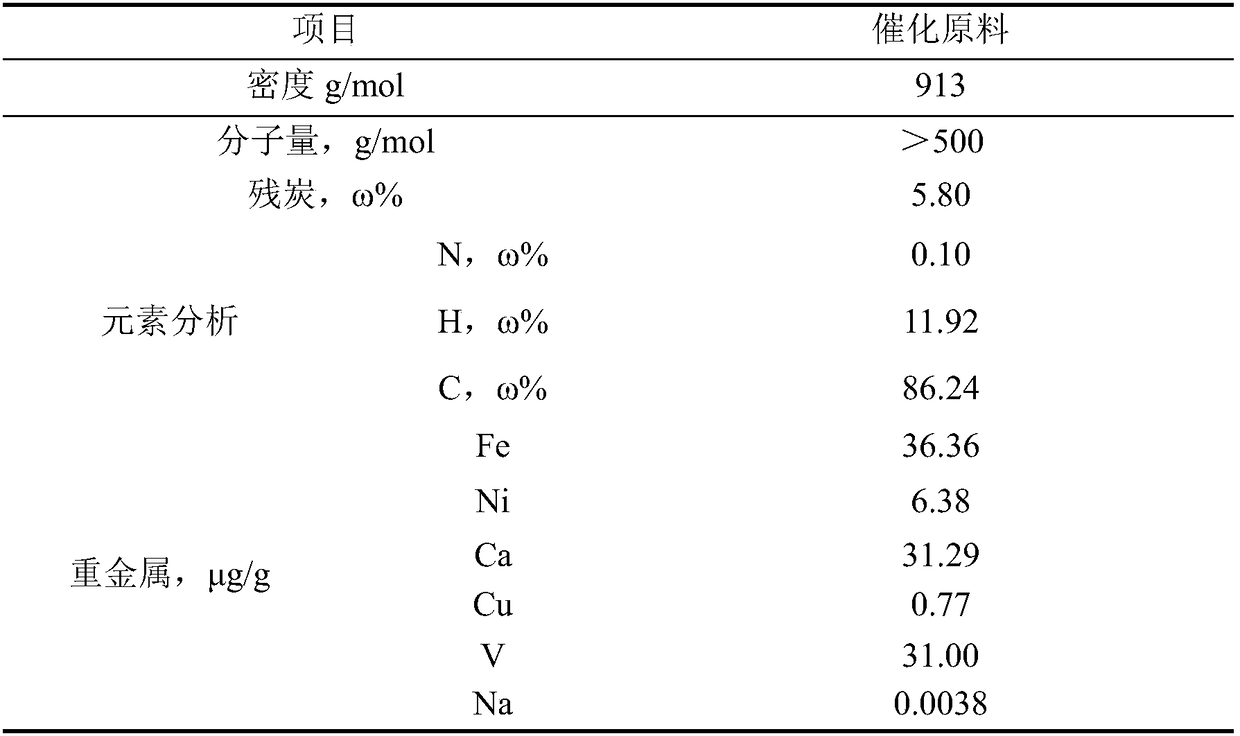

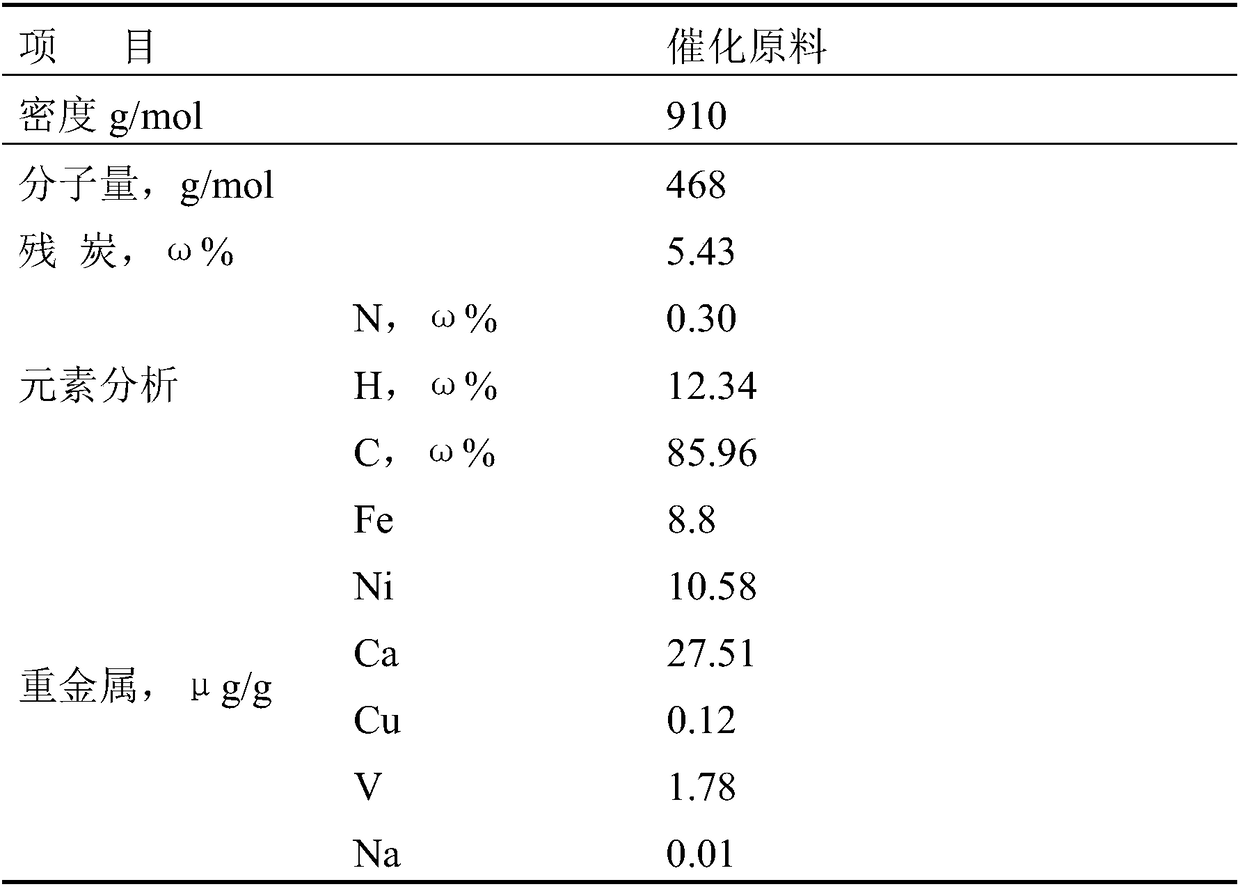

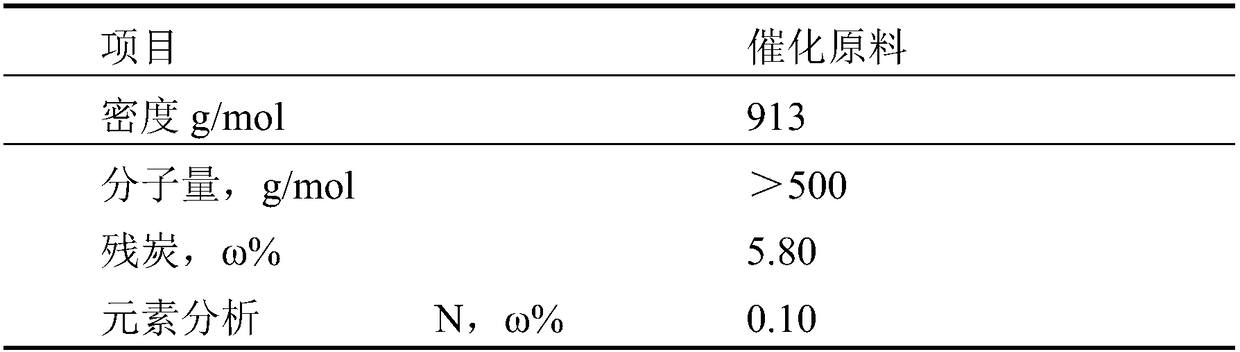

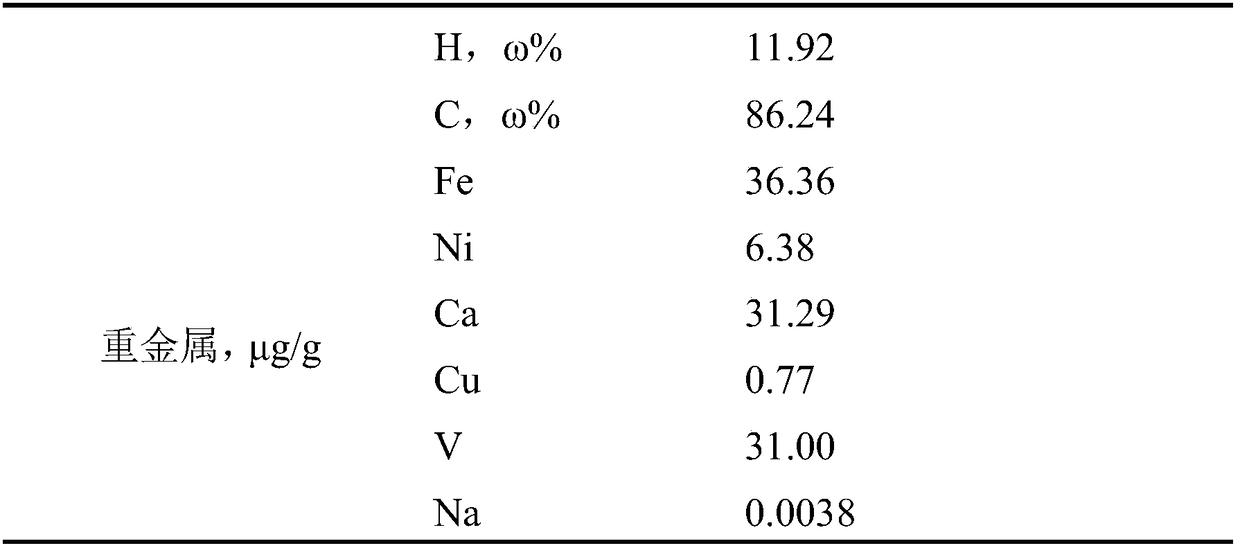

A hydrated alumina containing metal elements and the preparation method is provided. The alumina after being roasted contains 50-99 percent by weight of alumina and one species or a plurality of species of metal oxide selected from Cu, Fe, V, Cr, Mn, Zr, Zn, Co, Ti and Mo, wherein firstly, the content of the Cu, Fe, V, Cr, Mn and Zr is 0.5-50 percent; secondly, the content of the Zn, Co, Ti and Mo is 10- 50 percent. The catalyst adopting the hydrated alumina preparation provided by the present invention has higher heavy oil conversion capability and lower gasoline sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

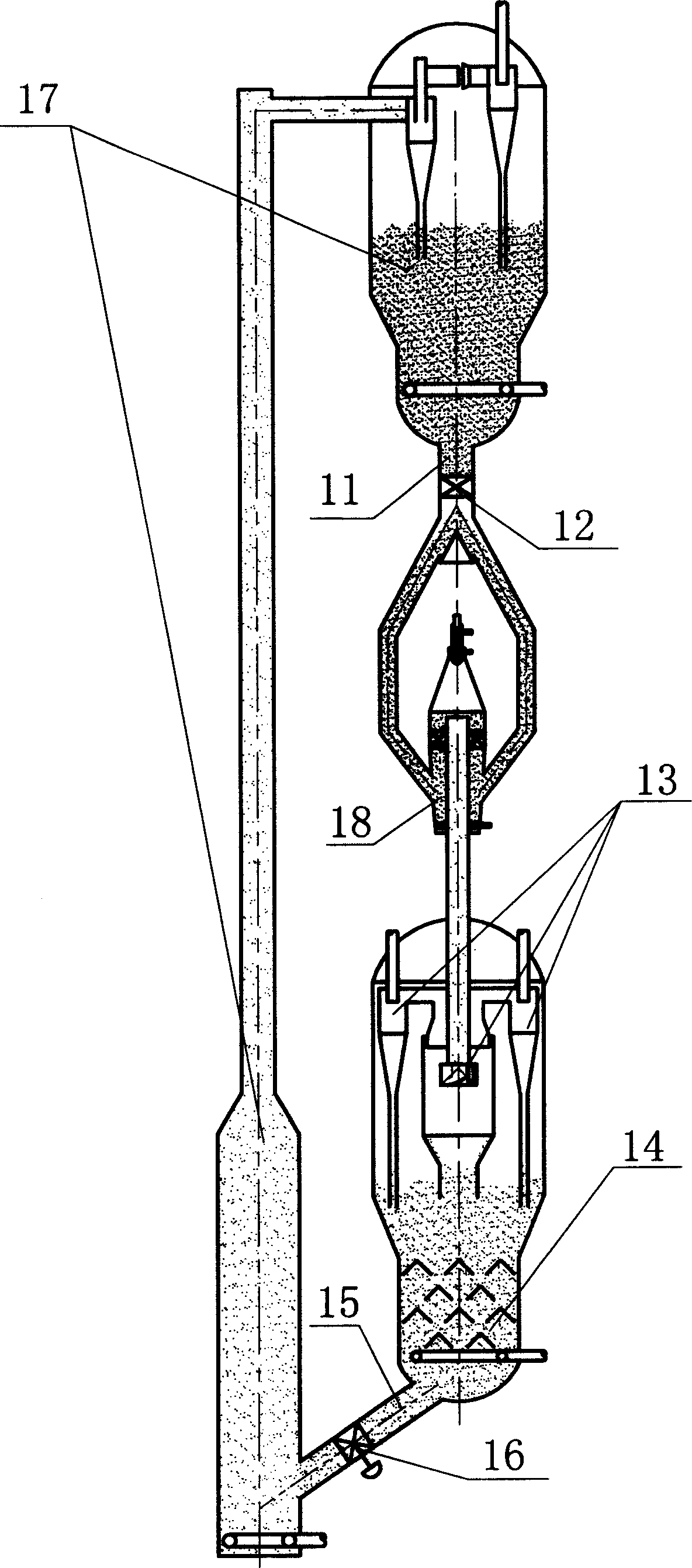

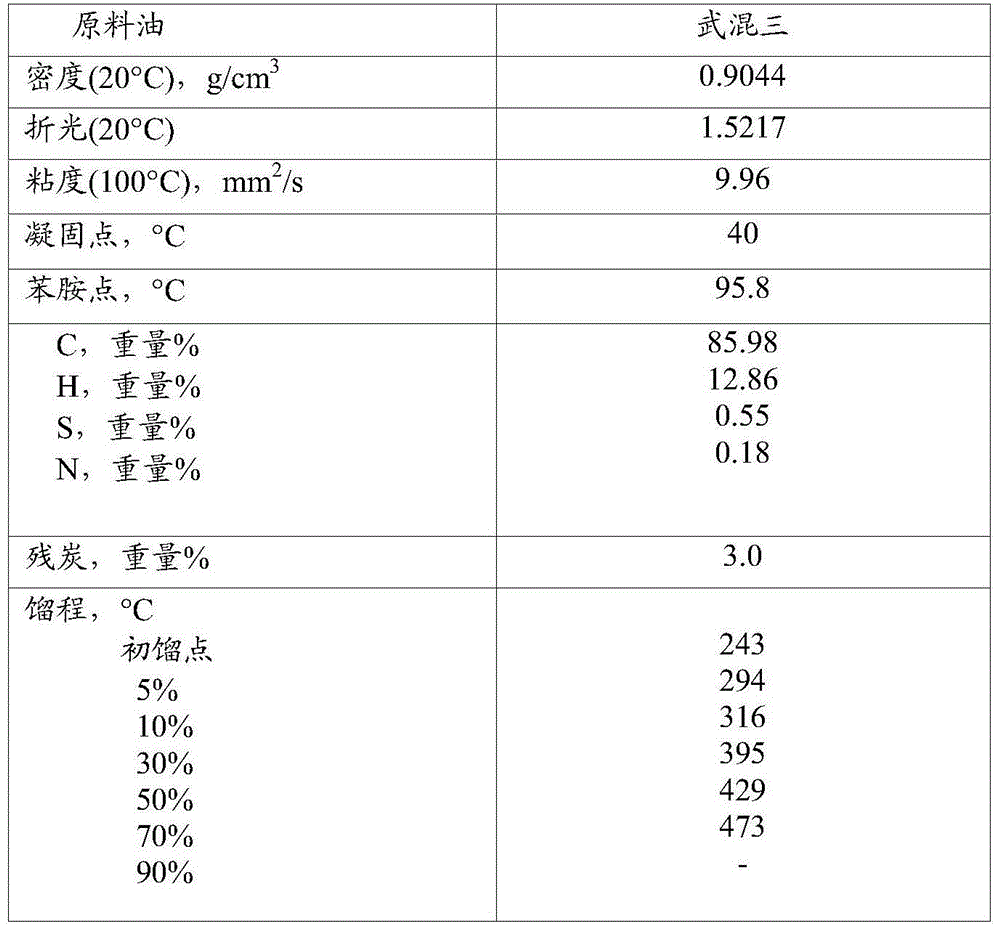

Descending naphtholite catalytic cracking method

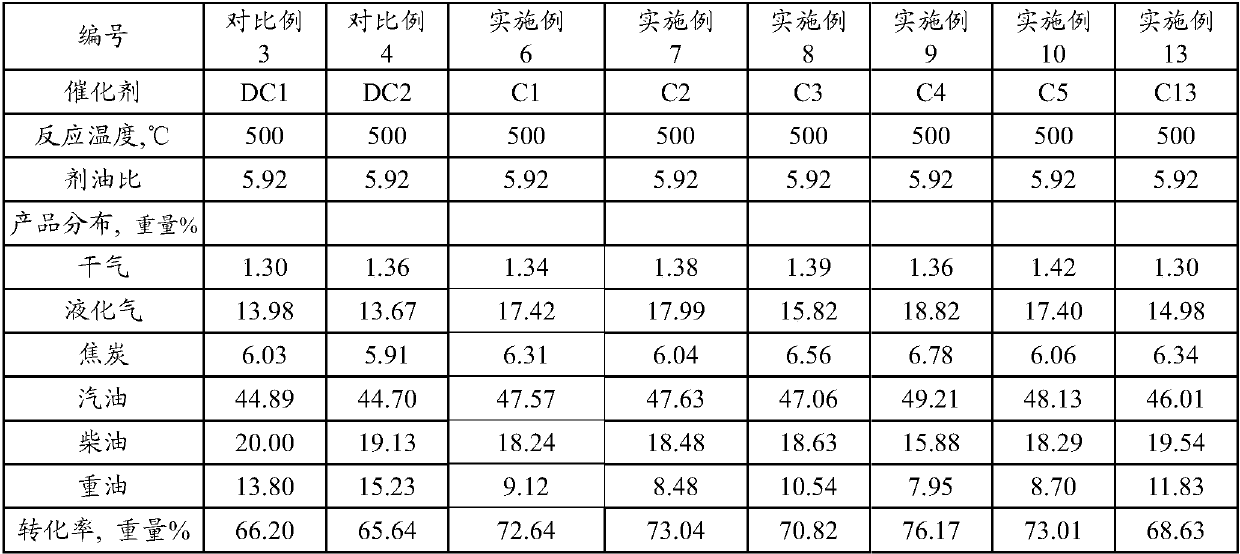

A down-flow catalytic cracking process for hydrocarbon oil includes such steps as spraying the raw hydrocarbon oil in an reactor by nozzle, atomizing in atomizing chamber, contacting with catalyst, reacting in reaction pipe, quick separating of oil mixture, introducing the oil gas to the followed separation system, and stripping and regenerating the used catalyst for cyclic use. It can increase the conversion power of heavy oil and improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

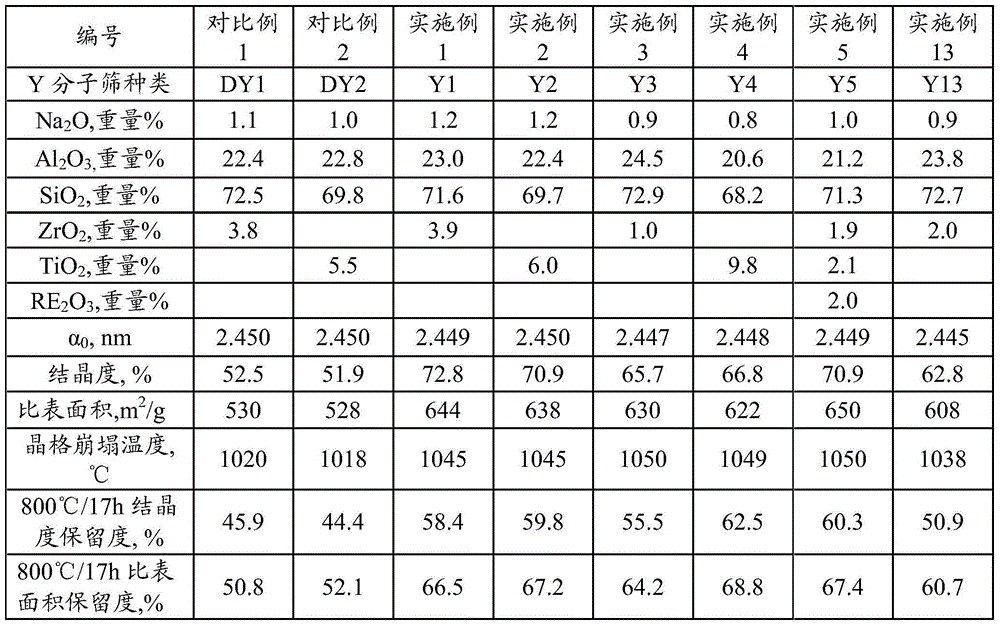

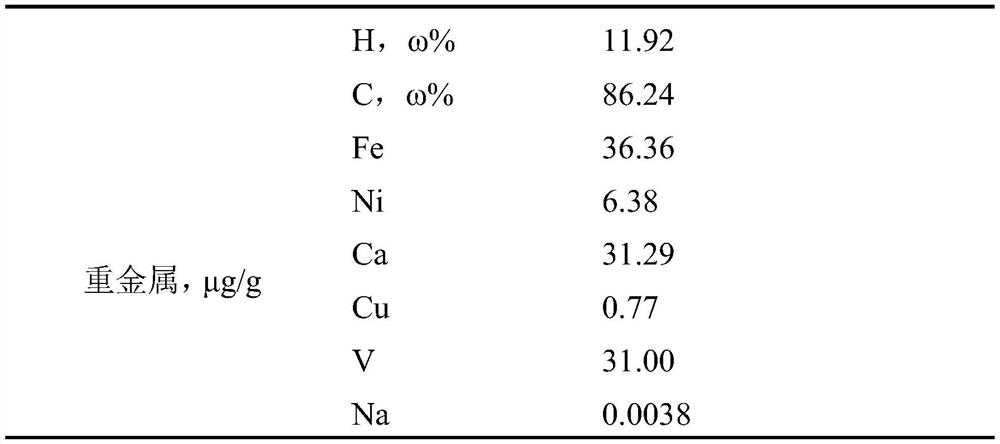

ActiveCN105618107AHigh conversion capacity of heavy oilImprove cracking capacityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveGasoline

A catalytic cracking catalyst and its preparation method are disclosed. With total weight of the catalyst as the reference, the catalyst contains, by weight, 10-60% of titanium and / or zirconium modified Y molecular sieve, 10-60% of clay and 5-50% of a binder. The titanium and / or zirconium modified Y molecular sieve contains 1.0-15.0 wt% of titanium and / or zirconium metal oxide. The preparation method of the catalyst comprises the following steps: preparing the titanium and / or zirconium modified Y molecular sieve, preparing catalyst slurry and spray-drying. The step of preparing the titanium and / or zirconium modified Y molecular sieve comprises the following steps: (1) dispersing a compound containing titanium and / or zirconium in water, and adjusting pH value of the mixture to 3-10; (2) mixing the molecular sieve and the mixture obtained in the Step (1), and stirring; optionally filtering and / or drying; and (3) roasting at 300-700 DEG C. The catalyst has high heavy oil conversion ability and gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN109304212AReduce sodiumHigh activityCatalytic crackingMolecular sieve catalystsPseudoboehmiteMolecular sieve

The invention provides a catalytic cracking catalyst and a preparation method thereof, the catalyst is prepared from 15-60 wt% of molecular sieve, 15-60 wt% of clay, 10-30 wt% of pseudoboehmite, 5-20wt% of adhesive, 0.1-5 wt% of phosphorus-containing compound (calculated by P), 0.1-3 wt% of magnesium-containing compound (calculated by Mg), and may also contain 0-5 wt% of rare earth oxide. The preparation method comprises the following steps: (1) catalyst forming: mixing and pulping molecular sieve, clay, pseudoboehmite, phosphorus-containing compound and adhesive; then adding magnesium-containing compound to mix and pulp, heating and stirring, spraying and forming, and roasting to obtain the formed catalyst; (2) catalyst modification: mixing and pulping the formed catalyst, ammonium salt,phosphorus-containing compound and water, adjusting pH, heating and reacting, and filtering and drying to obtain the catalytic cracking catalyst of the invention. The catalytic cracking catalyst provided by the invention has the characteristics of low coke yield and high total liquid collection (liquefied gas, gasoline and diesel).

Owner:PETROCHINA CO LTD

Preparation method for catalytic cracking catalyst for cracking coker gas oil and increasing production of diesel

ActiveCN109304210AHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveMagnesium salt

The invention provides a preparation method for a catalytic cracking catalyst for cracking coker gas oil and increasing production of diesel. The preparation method comprises the following steps thata rare earth, phosphorus and magnesium modified Y-type molecular sieve is prepared, specifically, a NaY molecular sieve is subjected to ammonium salt and rare earth salt exchange and then is sequentially modified by phosphorus and magnesium, wherein the step is characterized in that phosphorus modification is carried out before magnesium modification; (2) the catalyst is formed, specifically, water, the molecular sieve, clay, pseudo-boehmite and a binder are mixed, pulped, spray-dried and roasted; and (3) modification is carried out, specifically, the water, magnesium salt and catalyst particles are uniformly mixed, the pH value is adjusted, and filtering and drying are carried out. The catalyst shows good heavy oil conversion capability and diesel selectivity in the process of cracking the coker gas oil.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst for cracking coker gas oil and increasing production of liquefied gas and preparation method thereof

ActiveCN109304222AHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsWater vaporRare earth

The invention provides a catalytic cracking catalyst for cracking coker gas oil and increasing production of liquefied gas and a preparation method thereof. The catalyst is prepared from 10-50 wt% a Ymolecular sieve, 2-50 wt% of an MFI structure molecular sieve, 15-60 wt% of clay, 8-30 wt% of pseudo-boehmite and 3-20 wt% of a binder. The preparation method comprises the following steps that (1) arare earth, phosphorus and magnesium modified Y type molecular sieve is prepared, specifically, a NaY molecular sieve is subjected to ammonium salt and rare earth salt exchange and then is sequentially modified by phosphorus and magnesium, wherein the step is characterized in that phosphorus modification is carried out before magnesium modification; (2) the catalyst is formed, specifically, water, the Y type molecular sieve, the MFI structure molecular sieve, the clay, the pseudo-boehmite and the binder are mixed and are subjected to spray drying; and (3) the catalyst is modified, specifically, catalyst solid particles are roasted by water vapor, the pH value is adjusted by using an acidic substance, and then filtering and drying are carried out. The catalyst has the characteristics of being high in coker gas oil cracking capacity and high in liquefied gas yield.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst capable of increasing yield of gasoline and preparation method thereof

ActiveCN109304209AHigh catalytic activityIncrease chance of contactCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

The invention provides a catalytic cracking catalyst capable of increasing the yield of gasoline and a preparation method thereof. The catalyst is prepared from 15-70 wt% of a molecular sieve, 15-60 wt% of clay, 8-30 wt% of pseudo-boehmite, 3-20 wt% of a binder, 0.01-2 wt% of phosphorus in terms of phosphorus and 0.01-3 wt% of magnesium in terms of magnesium. The preparation method comprises the following steps that (1) a phosphorus and magnesium modified Y type molecular sieve is prepared, specifically, the Y-type molecular sieve and a phosphorus-containing compound are mixed and pulped for reaction, and then a magnesium-containing compound is added for heating reaction; (2) a modified matrix material is prepared, specifically, the clay, the pseudo-boehmite, the binder and water are mixedand pulped, and the phosphorus-containing compound is added for uniform stirring; and (3) the phosphorus and magnesium modified Y type molecular sieve and the modified matrix material are mixed and pulped, and spray drying, washing, filtering and drying are carried out in sequence. The catalyst prepared through the method has strong heavy oil conversion capability and good coke and gasoline selectivity, the preparation process is simple, and industrial production is easy to realize.

Owner:PETROCHINA CO LTD

Multifunctional catalysis composition

ActiveCN104741138AImprove gasification effectReduce churnPhysical/chemical process catalystsCatalytic crackingActive componentPetroleum

The invention discloses a multifunctional catalysis composition, which comprises the following raw materials in percentage by weight: 1%-80% of a mesopore active phosphorus-silicon-aluminum material, 1%-60% of a gasified active component, 0%-70% of clay and 2%-98% of heat-resistant inorganic oxide, wherein the mesopore active phosphorus-silicon-aluminum material has a phase structure of pseudo-boehmite, an anhydrous chemical expression based on the weight of oxides is (0-0.2)Na2O.(50-86)Al2O3.(12-50)SiO2.(0.5-10)P2O5, the specific surface area is 200-600m<2> / g, the pore volume is 0.5-1.8mL / g, and the mean pore size is 8-18nm. The catalysis composition can be applied to cracking gasification of heavy petroleum hydrocarbon, and is good in cracking property and low in gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN110653001AHigh hydrothermal stabilityHigh conversion activity of heavy oilCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

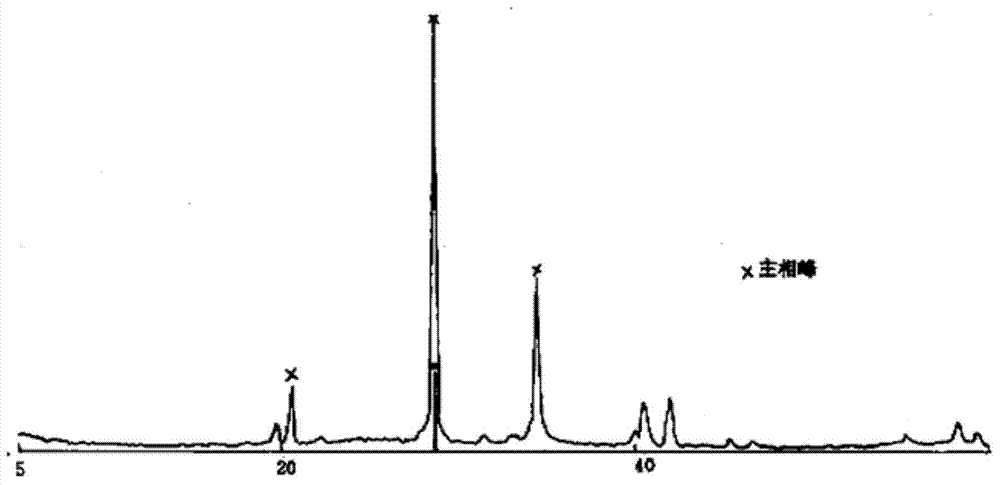

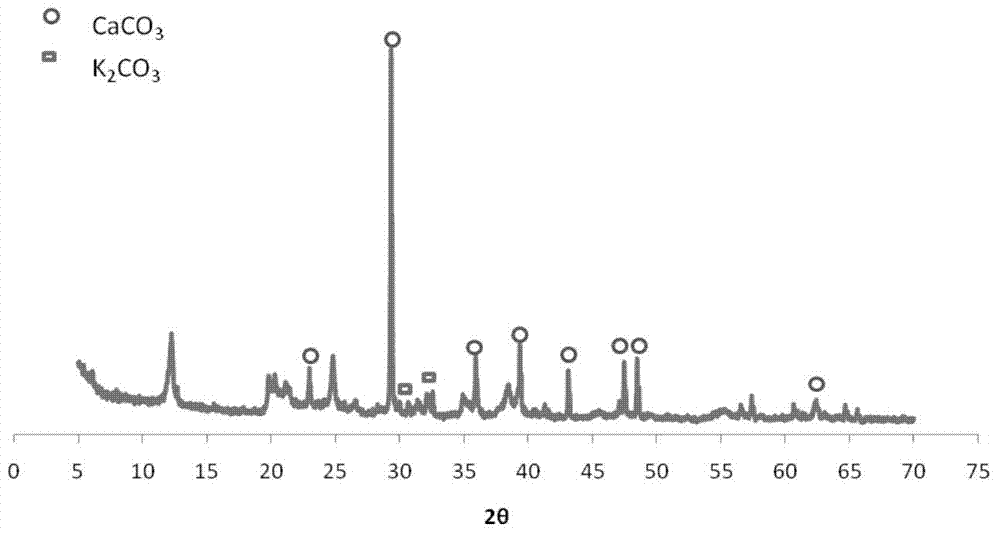

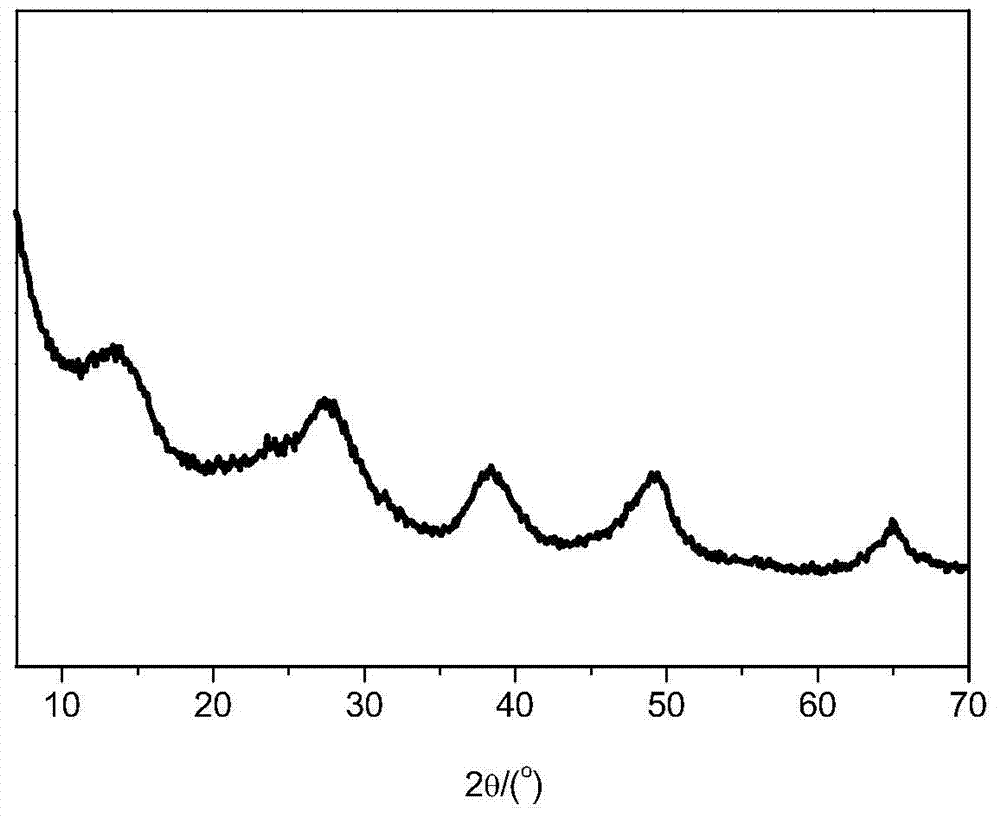

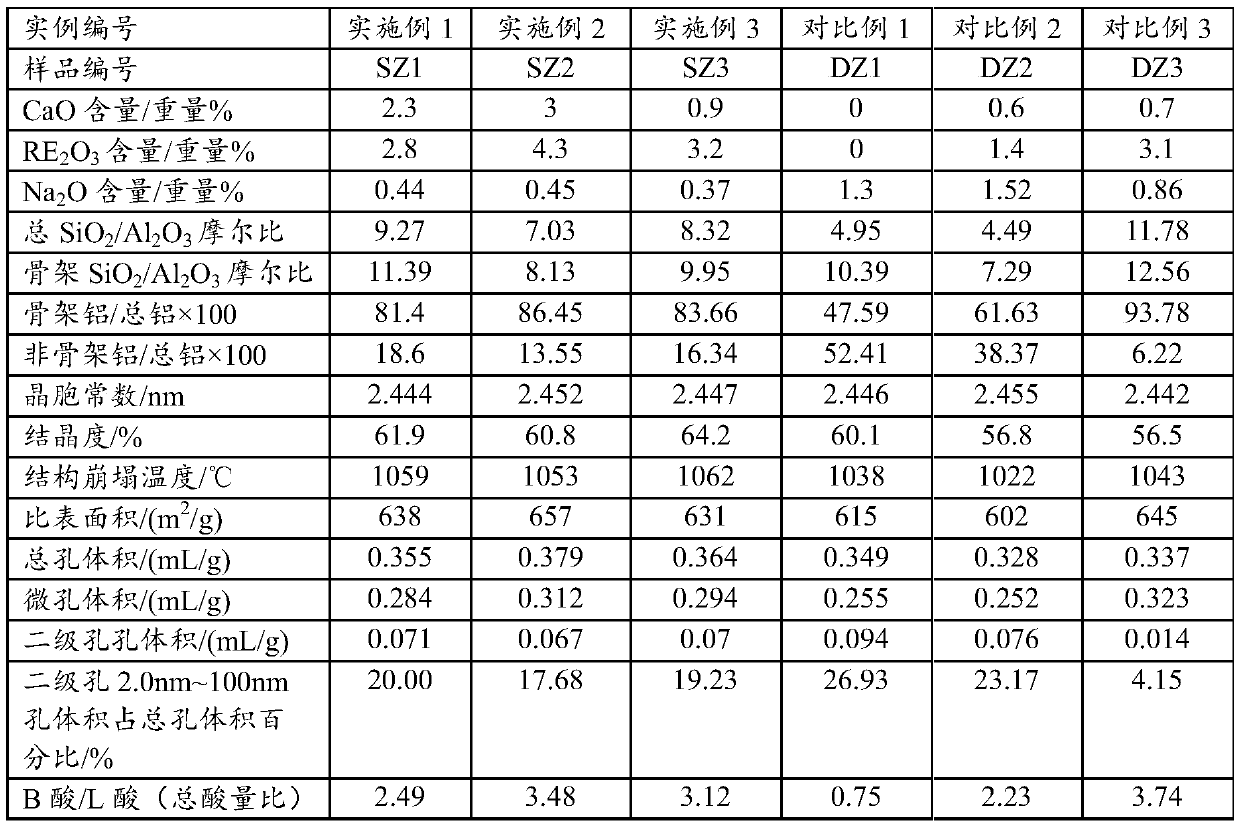

The catalytic cracking catalyst comprises a modified Y-type molecular sieve, an alumina binder and clay; according to the modified Y-type molecular sieve, the CaO content of the modified Y-type molecular sieve is 0.3-4% by weight, the RE2O3 content is 2 to 7 wt%, the content of sodium oxide is 0.1 wt%-0.5 wt%, the total pore volume is 0.33 mL / g to 0.39 mL / g, the pore volume of secondary pores withthe pore diameter of 2nm-100nm of the modified Y-type molecular sieve accounts for 10%-25% of the total pore volume, the lattice constant is 2.440 to 2.455nm, the content of non-framework aluminum inthe modified Y-type molecular sieve is not higher than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of the amount of acid B to the amount of acid L is not lower than 2.30. The catalytic cracking catalyst has the advantages of higher heavy oil conversion activity, lower coke selectivity, higher gasoline yield, higher isomeric C4 yield and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for synthesizing core-shell structure compound molecular sieve and use thereof

ActiveCN101279288BSmall particle diameterReduce in quantityMolecular sieve catalystsBulk chemical productionSynthesis methodsFuel oil

The present invention relates to a synthesizing method for a core-shell structure compound molecular sieve. The method mainly adopts a location growing method to fix a loaded phosphor aluminum or silicon aluminum molecular sieve on the surface of a ZSM-5 molecular sieve to compose the raw materials and then prepare a gel in a primarily wet state and crystallize under a constant temperature, thus synthesizing the core-shell structure compound molecular sieve. The method overcomes the defects of the prior technology, thus reducing the independent growing number of the composed phosphor aluminumor silicon aluminum molecular sieves, further improving the distribution of the phosphor aluminum or silicon aluminum molecular sieve of the shell on the surfaced of the ZSM-5 and reducing the grain diameter of the compound molecular sieve. When the core-shell structure compound molecular sieve prepared by the method is used for heavy oil catalytic cracking, the heavy oil converting rate and the low carbon olefin yield are all higher than the molecular sieve synthesized by the prior technology. Compared with the catalyst which only adopts the ZSM-5 molecular sieve as the active component, theheavy oil converting rate is improved by 2 to 3 percent; the ethylene yield is increased by 1 to 1.5 percent and the liquid gas yield is enhanced by 1.5 to 3.5 percent.

Owner:PETROCHINA CO LTD +1

Preparation method of catalytic cracking catalyst

ActiveCN103252258AHigh conversion capacity of heavy oilImprove total liquid recoveryCatalytic crackingMolecular sieve catalystsMolecular sieveSlurry

The invention provides a preparation method of a catalytic cracking catalyst. The method comprises mixing polydimethyl diallyl ammonium chloride with matrix slurry and molecular sieve slurry, homogenizing, molding, drying, and roasting to remove the polydimethyl diallyl ammonium chloride to obtain the catalyst, wherein an adding amount of the polydimethyl diallyl ammonium chloride is 0.4-4.5 % of a total mass of dry basis of a catalyst feeding amount, that is, the matrix and the molecular sieve. On basis of mass of the catalyst, the catalyst is 10 parts, the matrix is 90-50 parts and the molecular sieve is 10-50 parts. The method improves a heavy oil conversion capability and a total liquid yield of the catalytic cracking catalyst.

Owner:PETROCHINA CO LTD

Hydrated alumina with structure of similar to thin diaspore of containing additive

ActiveCN1915486BHigh conversion capacity of heavy oilHigh yieldCatalyst activation/preparationAlkaline earth metalHydrated alumina

A hydrated alumina containing additive (0.5-40 Wt %) and with alpha-AlO (OH) structure for preparing the catalyst used for catalytic cracking reaction. Said additive is chosen from RE metal, La-familymetal, Si, Ga, B and P. Its preparing process includes such steps as mixing alpha-AlO (OH) with H2O and acid while stirring, ageing, and mixing with additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst for cracking coker wax oil and preparation method thereof

ActiveCN109304207BHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a cracking coking wax oil catalytic cracking catalyst and a preparation method thereof. The catalyst contains 15-70wt% molecular sieve, 15-60wt% clay, 8-30wt% pseudo-boehmite, 3-20wt% binder, and its preparation method comprises the following steps: rare earth, phosphorus, magnesium composite modification Y type The preparation of the molecular sieve is characterized in that the phosphorus modification of the molecular sieve is before the magnesium modification; then the Y-type molecular sieve containing rare earth, phosphorus and magnesium modification, clay, pseudo-boehmite and binder are mixed and beaten, and then spray-dried in sequence , washing, filtering and drying steps to prepare the catalyst of the present invention. The catalyst provided by the invention can reduce the adsorption capacity of nitrogen compounds and aromatics in the coker gas oil and the acid center of the catalyst, and reduce the negative impact of the coker gas oil on the catalytic cracking reaction. When the conversion rate increases and the heavy oil decreases, the catalyst provided by the invention The catalyst has excellent coke selectivity.

Owner:PETROCHINA CO LTD

A kind of method for preparing compound molecular sieve

InactiveCN109437230BFull basic scientific valueIncreased secondary pore contentFaujasite aluminosilicate zeolitePentasil aluminosilicate zeoliteMolecular sieveDry basis

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of catalytic cracking catalyst for cracking coker gas oil to produce gasoline

ActiveCN109304206BHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a method for preparing a catalytic cracking catalyst for cracking coking wax oil and producing gasoline. The preparation method includes the following steps: (1) Preparation of Y-type molecular sieve modified by rare earth, phosphorus and magnesium: NaY molecular sieve is exchanged with ammonium salt and rare earth salt , and then carry out phosphorus and magnesium modification successively, which is characterized in that phosphorus modification is preceded by magnesium modification; (2) catalyst molding: mixing water, molecular sieve, clay, pseudo-boehmite and binder, beating, Spray drying and roasting; (3) Acid modification: mixing water and catalyst particles to make a slurry, adjusting the pH value, and filtering and drying. The catalyst prepared by the invention has good coker wax oil conversion ability and gasoline selectivity.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst for improving gasoline yield and preparation method thereof

ActiveCN108745409BHigh yieldHigh conversion capacity of heavy oilCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a catalytic cracking catalyst for increasing gasoline yield and a preparation method thereof. The catalytic cracking catalyst for increasing gasoline yield has 80-50 parts of substrate, preferably 75-60 parts based on 100 parts of catalyst mass composition. 1 to 20 parts, preferably 2 to 12 parts, of medium and macroporous silicon-aluminum materials containing rare earths; 20 to 50 parts, preferably 25 to 40 parts, of molecular sieves, wherein the molecular sieves include two types of Y-type molecular sieves, respectively, the rare earth content is 8 ‑18% REY and 1‑3% RDSY, the ratio of REY to RDSY is 1:3‑2:1. The catalyst of the invention has higher heavy oil conversion capacity and gasoline yield.

Owner:PETROCHINA CO LTD

A kind of prolific gasoline catalytic cracking catalyst and preparation method thereof

ActiveCN109304209BIncrease the areaHigh pore volumeCatalytic crackingMolecular sieve catalystsPseudoboehmiteMolecular sieve

The invention provides a prolific gasoline catalytic cracking catalyst and a preparation method thereof. The catalyst comprises 15-70wt% molecular sieve, 15-60wt% clay, 8-30wt% pseudo-boehmite, 3-20wt% binder, and 0.01-2wt% phosphorus in terms of phosphorus, and 0.01-3wt% magnesium in terms of magnesium. The preparation method is as follows: (1) Preparation of Y-type molecular sieve modified by phosphorus and magnesium: mixing Y-type molecular sieve and phosphorus-containing compound for beating reaction, and then adding magnesium-containing compound to raise the temperature for reaction. (2) Preparation of modified matrix material: mix clay, pseudo-boehmite, binder and water for beating, add phosphorus-containing compound and stir evenly. (3) mixing and beating the above-mentioned phosphorus and magnesium modified Y-type molecular sieves and modified matrix materials, followed by successive steps of spray drying, washing, filtering and drying. The catalyst prepared by the invention has strong heavy oil conversion ability, good coke and gasoline selectivity, simple preparation process and easy industrial production.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst and preparation method thereof

ActiveCN105618107BHigh conversion capacity of heavy oilImprove cracking capacityMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceFiltration

A catalytic cracking catalyst and a preparation method thereof, based on the total weight of the catalyst, the catalyst contains 10-60% by weight of titanium and / or zirconium modified Y molecular sieve, 10-60% by weight of clay and 5-50% by weight of Binder; the titanium and / zirconium modified Y molecular sieve contains 1.0% to 15.0% by weight of titanium and / zirconium metal oxides. The catalyst preparation method includes the steps of preparing titanium and / or zirconium modified Y molecular sieve, preparing catalyst slurry and spray drying, wherein the titanium and / or zirconium modified Y molecular sieve includes the following steps: (1) adding titanium and / or The zirconium compound is dispersed in water, and the pH value of the mixture is adjusted to 3 to 10; (2) the molecular sieve is mixed with the mixture obtained in step (1), and stirred; optionally filtered and / or dried; (3) calcined at 300 to 700° C. . The catalyst has high heavy oil conversion capacity and gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalytic cracking catalyst for cracking coker wax oil to produce diesel oil

ActiveCN109304210BHigh conversion capacity of heavy oilImprove activity stabilityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a method for preparing a catalytic cracking catalyst for cracking coking wax oil to produce diesel oil. The preparation method comprises the following steps: (1) Preparation of Y-type molecular sieve modified by rare earth, phosphorus and magnesium: NaY molecular sieve is exchanged with ammonium salt and rare earth salt, and then modified by phosphorus and magnesium in sequence, which is characterized in that phosphorus modification is carried out first , after magnesium modification; (2) Catalyst forming: mixing water, molecular sieve, clay, pseudo-boehmite and binder, beating, spray drying, roasting; (3) modification: mixing water, magnesium salt and catalyst The granules were mixed evenly, the pH was adjusted, and dried by filtration. The catalyst of the invention exhibits good heavy oil conversion capability and diesel selectivity in the process of cracking coker gas oil.

Owner:PETROCHINA CO LTD

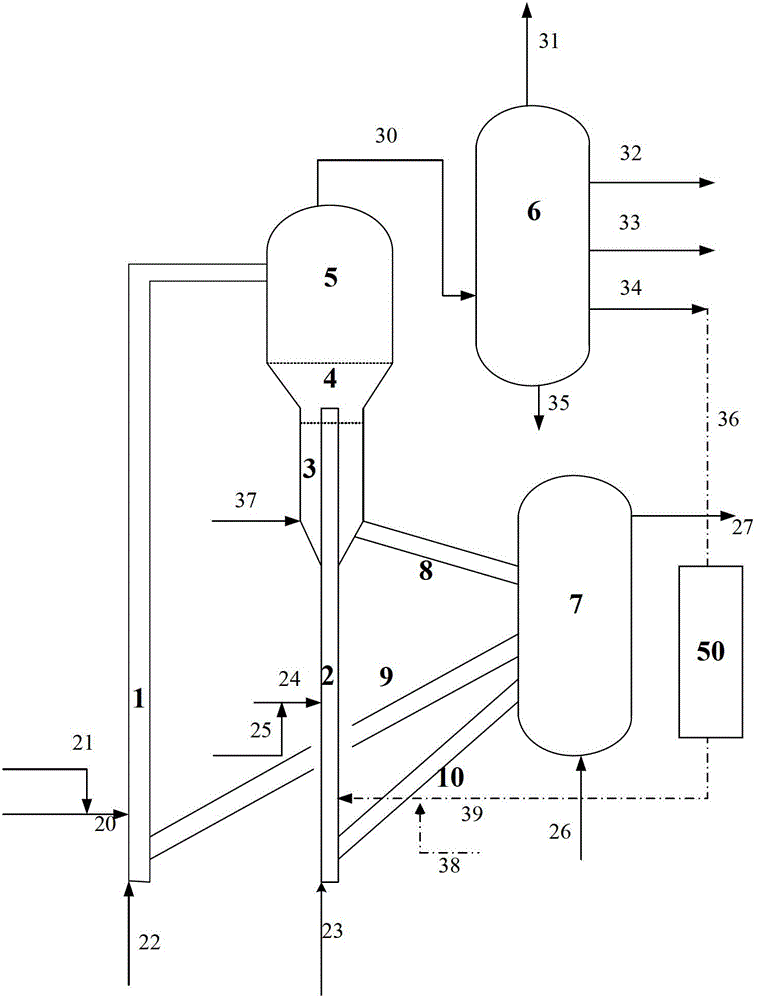

Hydrocarbon catalytic conversion method for increasing propylene yield

ActiveCN103131463BHigh selectivityReduce yieldChemical recyclingBulk chemical productionFuel oilCarbon deposit

A hydrocarbon catalytic conversion method for increasing propylene yield comprises the following steps: contacting a hydrocarbon raw material with a catalyst in a catalytic cracking reaction zone, contacting the obtained butylene-enriched C-4 fraction and / or olefin-enriched gasoline fraction with a catalyst with micropore modification in an oligomerization / cracking reaction zone to perform an oligomerization cracking reaction, separating to obtain a product rich in propylene, performing steam stripping and regeneration of the carbon deposited catalyst, dividing the carbon deposited catalyst into two parts, delivering one part to the catalytic cracking reaction zone for recycle, delivering the other part to a catalyst micropore modification zone, contacting and reacting with a modifier, and then delivering to the oligomerization / cracking reaction zone for recycle. According to the invention, with the method of micropore modification of the catalyst, the catalytic cracking catalyst containing dual active components of macroporous zeolites and medium pore zeolites is provided with not only high heavy oil conversion capability and high propylene selectivity for catalytic cracking of heavy hydrocarbon raw materials, but also high propylene selectivity for catalytic conversion of butylene and high-alkene gasoline, and thus the purpose of increasing propylene yield is reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

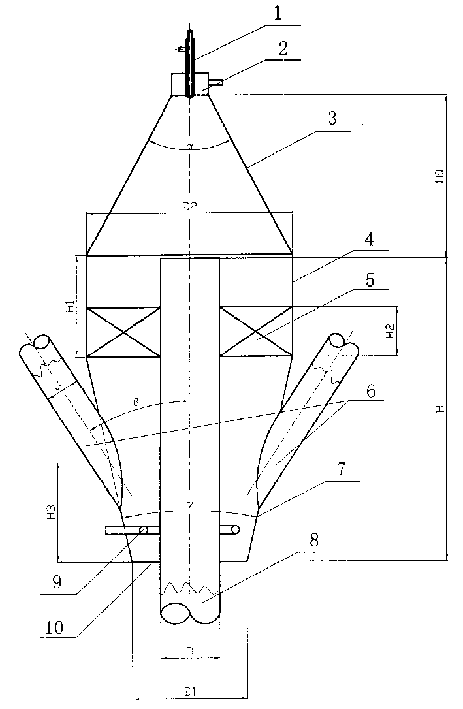

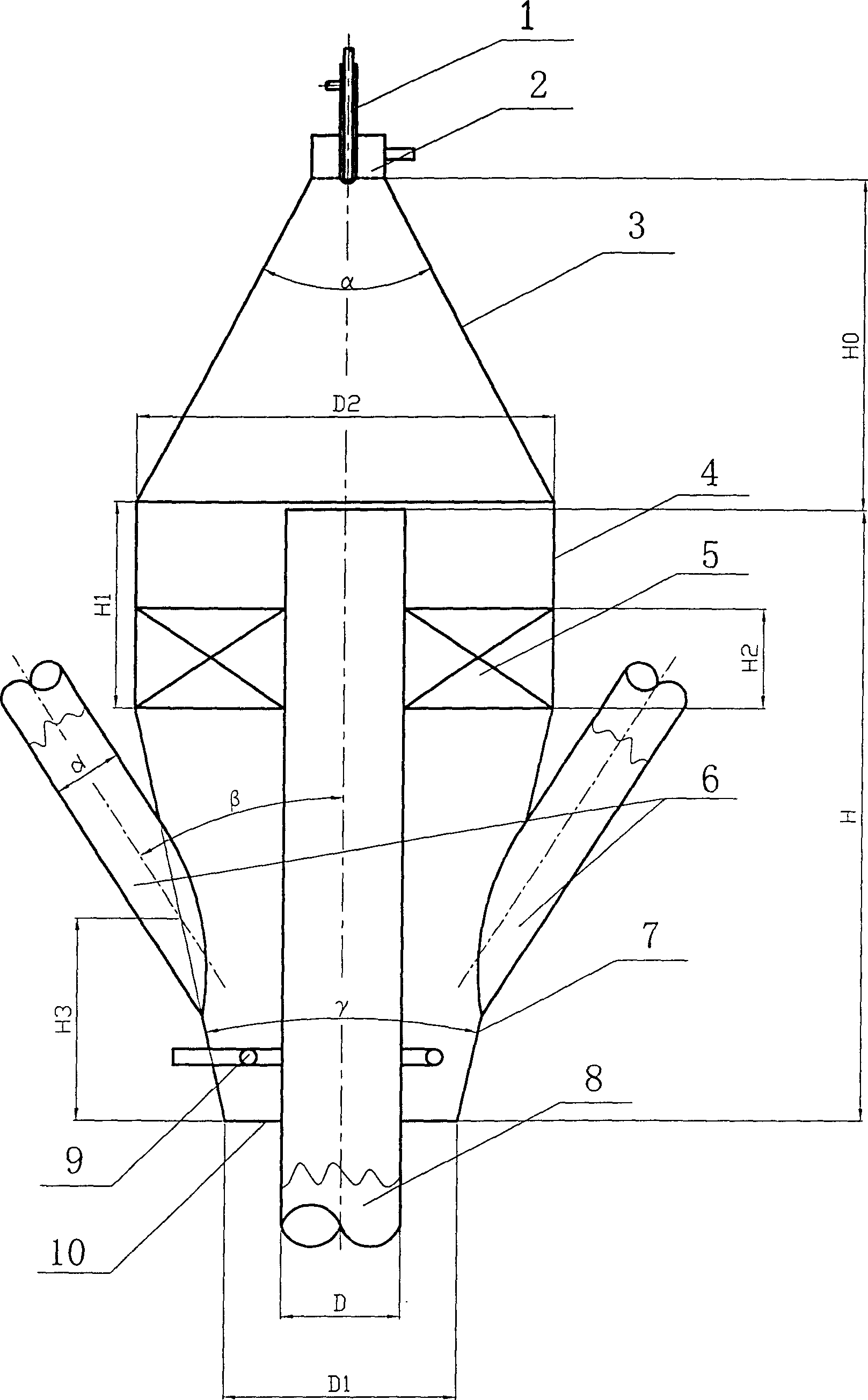

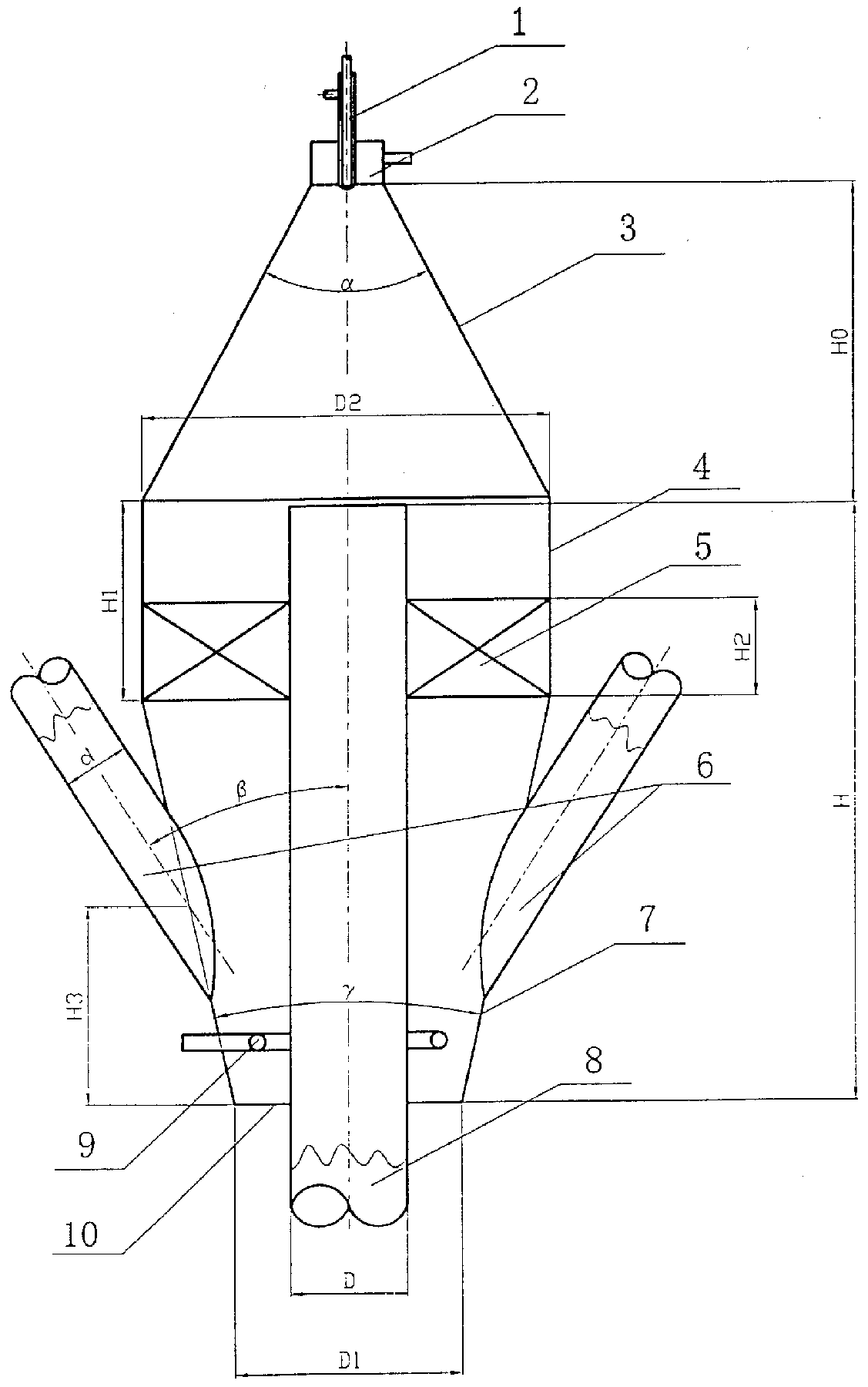

Descending hydrocarbon oil catalytic cracking reactor

A down-flow catalytic cracking reactor for hydrocarbon oil is composed of raw material nozzle, top cover, external cylindrical casing, catalyst delivering tube, prelifted medium distributor, down-flow reaction tube and bottom plate. It can obviously improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

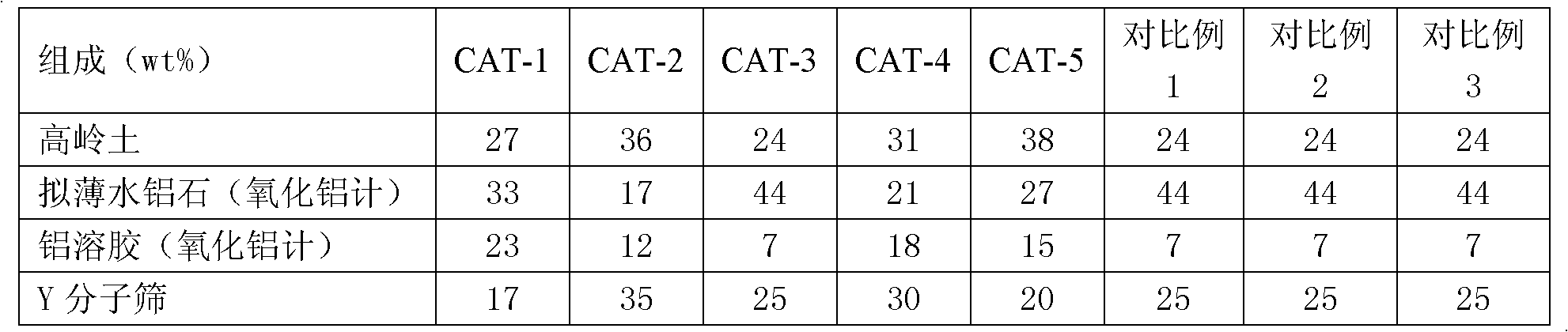

ActiveCN100569915CHigh conversion capacity of heavy oilHigh yieldCatalytic crackingMolecular sievePseudoboehmite

A catalytic cracking catalyst, containing an effective amount of molecular sieves and a kind of alumina containing additives, based on the alumina containing additives, the alumina containing additives contains 60-99.5% by weight of alumina, 0.5- 40% by weight of the additive, the catalyst is prepared by a process comprising the steps of: (1) mixing pseudo-boehmite with sufficient water and an acid sufficient to slurry it, wherein the amount of acid is such that the acid and The weight ratio of alumina in pseudo-boehmite is 0.01-0.5; (2) aging the mixed slurry in step (1) at room temperature-90°C for 0-24 hours; (3) aging the mixed slurry in step (2) The product is mixed with additives; (4) the product of step (3) is mixed with molecular sieves, dried and calcined. The catalytic cracking catalyst provided by the invention has higher heavy oil conversion performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic cracking method combined with hydrotreating to produce propylene

ActiveCN103627434BHigh yieldReduce yieldTreatment with hydrotreatment processesChemical recyclingFluidized bedFuel oil

A hydrotreatment combined catalytic cracking method for producing propylene comprises the following steps: carrying out a cracking reaction by allowing heavy raw materials to contact with a catalyst containing shape selective zeolite having an average aperture of below 0.7nm in first riser reactor, carrying out hydrotreatment of recycle cracked heavy oil in a fluidized bed reactor, carrying out a contact cracking reaction of the obtained hydrogenated recycle cracked heavy oil and the catalyst containing shape selective zeolite having an average aperture of below 0.7nm in a second riser reactor, and carrying out a contact reaction of the above obtained material and lightweight hydrocarbon oil. The method is used for the catalytic cracking of heavy oil, and realizes a high heavy oil conversion rate, a high propylene yield, a low dry gas yield and a low coke yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst capable of increasing yield of gasoline and preparation method thereof

ActiveCN108745409AHigh yieldHigh conversion capacity of heavy oilCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

The invention provides a catalytic cracking catalyst capable of increasing the yield of gasoline and a preparation method thereof. The catalytic cracking catalyst for increasing the yield of the gasoline is prepared from 50 to 80 parts of a matrix and 20 to 50 parts of a molecular sieve, wherein the content of the matrix is preferably 60 to 75 parts, and the content of a rare earth-containing medium and large porous silicon aluminum material in the matrix is 1 to 20 parts and is preferably 2 to 12 parts; the content of the molecular sieve is preferably 25 to 40 parts, the molecular sieve comprises two Y-shaped molecular sieves which are respectively an REY molecular sieve of which the rare earth content is 8 to 18 percent and an RDSY molecular sieve of which the rare earth content is 1 to3 percent, and a ratio of the REY molecular sieve to the RDSY molecular sieve is 1:3 to 2:1. The catalytic cracking catalyst provided by the invention has higher heavy oil conversion ability and higher gasoline yield.

Owner:PETROCHINA CO LTD

A kind of catalytic conversion method for producing propylene

ActiveCN104557395BHigh selectivityHigh yieldTreatment with plural serial stages onlyHydrocarbon from oxygen organic compoundsActive componentFuel oil

A catalytic conversion method for production of propylene, a petroleum hydrocarbon raw material and methanol are respectively contacted with a catalytic cracking catalyst in a petroleum hydrocarbon catalytic cracking reaction zone and a micropore modified catalytic cracking catalyst in a methanol catalytic conversion reaction zone to react, and separation is then carried out to obtain a propylene-rich product. a coked catalyst undergoes steam stripping and regeneration and then is divided into two parts: one part is directly sent into the catalytic cracking reaction zone to be recycled; and the other part is firstly sent into a catalyst micropore modification zone to be contacted with and react with a modifier, and then the other part is sent into the methanol catalytic conversion reaction zone to be recycled. By micropore modification of a catalyst, the catalytic cracking catalyst containing double active components macroporous zeolite and mesoporous zeolite has high heavy oil conversion ability and high propylene selectivity for catalytic cracking of a petroleum hydrocarbon raw material and also has high propylene selectivity for methanol catalytic conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

A multifunctional catalytic composition

ActiveCN104741138BImprove gasification effectReduce churnCatalytic crackingPhysical/chemical process catalystsActive componentCompound (substance)

The invention discloses a multifunctional catalysis composition, which comprises the following raw materials in percentage by weight: 1%-80% of a mesopore active phosphorus-silicon-aluminum material, 1%-60% of a gasified active component, 0%-70% of clay and 2%-98% of heat-resistant inorganic oxide, wherein the mesopore active phosphorus-silicon-aluminum material has a phase structure of pseudo-boehmite, an anhydrous chemical expression based on the weight of oxides is (0-0.2)Na2O.(50-86)Al2O3.(12-50)SiO2.(0.5-10)P2O5, the specific surface area is 200-600m<2> / g, the pore volume is 0.5-1.8mL / g, and the mean pore size is 8-18nm. The catalysis composition can be applied to cracking gasification of heavy petroleum hydrocarbon, and is good in cracking property and low in gasification temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic material containing rare earth and magnesium and preparation method thereof

PendingCN111744536AHigh conversion capacity of heavy oilCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

A catalytic material containing rare earth and magnesium is characterized in that the catalytic material simultaneously has a microporous crystal structure of a Y-type molecular sieve and a gamma-Al2O3 mesoporous structure layer, and comprises 2-14 wt% of rare earth oxide and 1-6 wt% of magnesium oxide. According to the catalytic material, a microporous structure and a mesoporous structure are organically combined, and through combination with proper modification treatment of rare earth and magnesium, the heavy oil conversion capacity of the catalytic material is effectively promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrated alumina containing metallic element and method for preparing the same

ActiveCN101116818BLarge average pore sizeHigh conversion capacity of heavy oilCatalytic crackingCatalyst activation/preparationHydrated aluminaGasoline

A hydrated alumina containing metal elements and the preparation method is provided. The alumina after being roasted contains 50-99 percent by weight of alumina and one species or a plurality of species of metal oxide selected from Cu, Fe, V, Cr, Mn, Zr, Zn, Co, Ti and Mo, wherein firstly, the content of the Cu, Fe, V, Cr, Mn and Zr is 0.5-50 percent; secondly, the content of the Zn, Co, Ti and Mo is 10- 50 percent. The catalyst adopting the hydrated alumina preparation provided by the present invention has higher heavy oil conversion capability and lower gasoline sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com