Catalytic cracking catalyst for improving gasoline yield and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of small B/L acid ratio, small pore volume, low pore size, etc., and achieve high heavy oil conversion capacity, high Gasoline yield, effect of reducing liquefied gas and dry gas conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

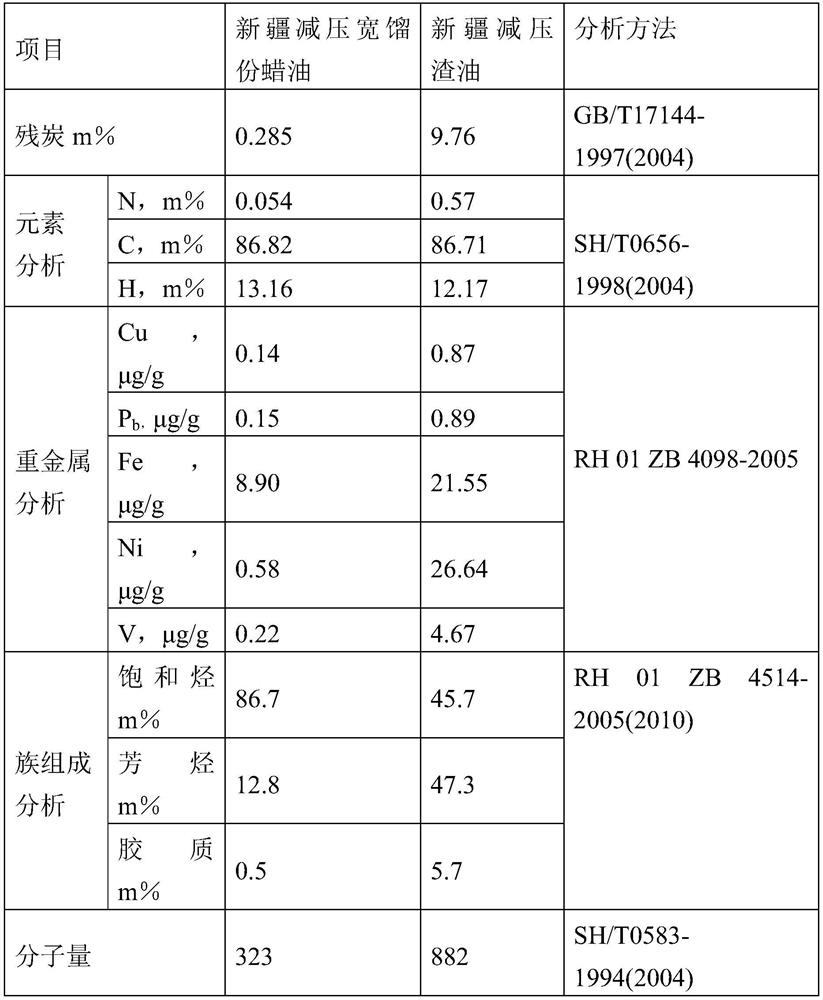

[0036] 1. Raw materials

[0037] NaY zeolite directing agent, produced by Lanzhou Petrochemical Company Catalyst Factory;

[0038] Water glass, Si0 2 250g / L, produced by the Catalyst Factory of Lanzhou Petrochemical Company;

[0039] Kaolin, an industrial product of China Kaolinshi Company, with a solid content of 82.7%;

[0040] Pseudoboehmite, produced by Shanxi Aluminum Plant, with a solid content of 60.0%;

[0041] Aluminum sol, containing Al 2 o 3 23.7wt%, produced by the Catalyst Plant of Lanzhou Petrochemical Company;

[0042] RDSY molecular sieve, produced by Lanzhou Petrochemical Company Catalyst Factory, solid content 80.7%, Na 2 O content 1.2 wt%, RE 2 o 3 Content 2.1wt%;

[0043] REY molecular sieve, produced by Lanzhou Petrochemical Company Catalyst Factory, solid content 84.9%, Na 2 O content 1.1 wt%, RE 2 o 3 Content 13.4wt%;

[0044] Other reagents used purchased analytical reagents produced by Sinopharm Chemical Reagent Co., Ltd.

[0045] 2. Main...

Embodiment 1

[0055] Preparation of Medium and Large Porous Materials Containing Rare Earth

[0056] Take 26.8ml NaY zeolite directing agent and mix with 51.2ml 250g / l water glass evenly, add water to dilute to Si0 2 The concentration is 40g / L (as Si0 2 , the same below), after stirring evenly, neutralize with 6mol / L sulfuric acid solution at 60°C to form a gel for aging, the pH value of the gel is 8, after adding the acid, continue to age at a constant temperature for 1.5h under stirring conditions; after the aging is completed, add 6mol / L sulfuric acid to pH=4, then slowly add 9.9ml 90g / L aluminum chloride solution (A1 2 0 3After the addition, continue to stir for 2 hours; add 10wt% sodium hydroxide solution to adjust the pH value to 7, and age at a constant temperature for 1.5 hours under stirring at 90°C. After the obtained product is filtered and washed, the resulting solid precipitate is ion-exchanged according to ammonium nitrate: solid precipitate (dry basis): water = 1:0.5:8 to ...

Embodiment 2

[0063] Preparation of Medium and Large Porous Materials Containing Rare Earth

[0064] Take 22.23ml of NaY zeolite directing agent and 40.89ml of tetraethyl orthosilicate, mix evenly, add water to dilute to Si0 2 The concentration is 50g / L, after stirring evenly, neutralize with 5mol / L nitric acid solution at 80°C to form a gel for aging, the pH value of the gel is 9, after adding acid, continue aging at constant temperature for 1h under stirring conditions; after aging, add 5mol dropwise / L nitric acid until the pH value = 6, then slowly add 4.76ml 90g / L aluminum nitrate solution under stirring conditions, and continue stirring for 1.5h after the addition; add 10wt% potassium hydroxide solution to adjust the pH value = 9, and stir at 95°C Aging at constant temperature for 2h. After the resulting product is filtered and washed, the resulting solid precipitate is ion-exchanged to remove sodium ions according to ammonium nitrate:solid precipitate (dry basis):water=1:0.7:9, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com