Process for synthesizing core-shell structure compound molecular sieve and use thereof

A technology of composite molecular sieve and core-shell structure, which is applied in the synthesis field of core-shell structure composite molecular sieve, and can solve the problems of large particle diameter and inability to form core-shell structure composite molecular sieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Mix 5.0 g of phosphorus pentoxide with 15 ml of deionized water, and load it onto the surface of 10.0 g of HZSM-5 raw powder by dipping (self-made, with a silicon-aluminum ratio of 76), and treat it at 180 ° C for 48 hours. P-ZSM-5 with the phosphorus source immobilized on the surface of ZSM-5 was obtained. P-ZSM-5 was added to 3.5 g of pseudoboehmite (w(Al 2 O 3 )=68%), 6.2g silica sol (w(SiO 2 ) 40%)) and 10 g of deionized water, after stirring, add 1.46 g of triethylamine.

[0025] The above gel was put into an autoclave, formed at room temperature for 10 hours, firstly crystallized at 120 °C for 7 hours, and then crystallized at 170 °C for 48 hours. The solid obtained by filtration of the product was washed with water, and dried at 160° C. for 24 h to obtain sample C.

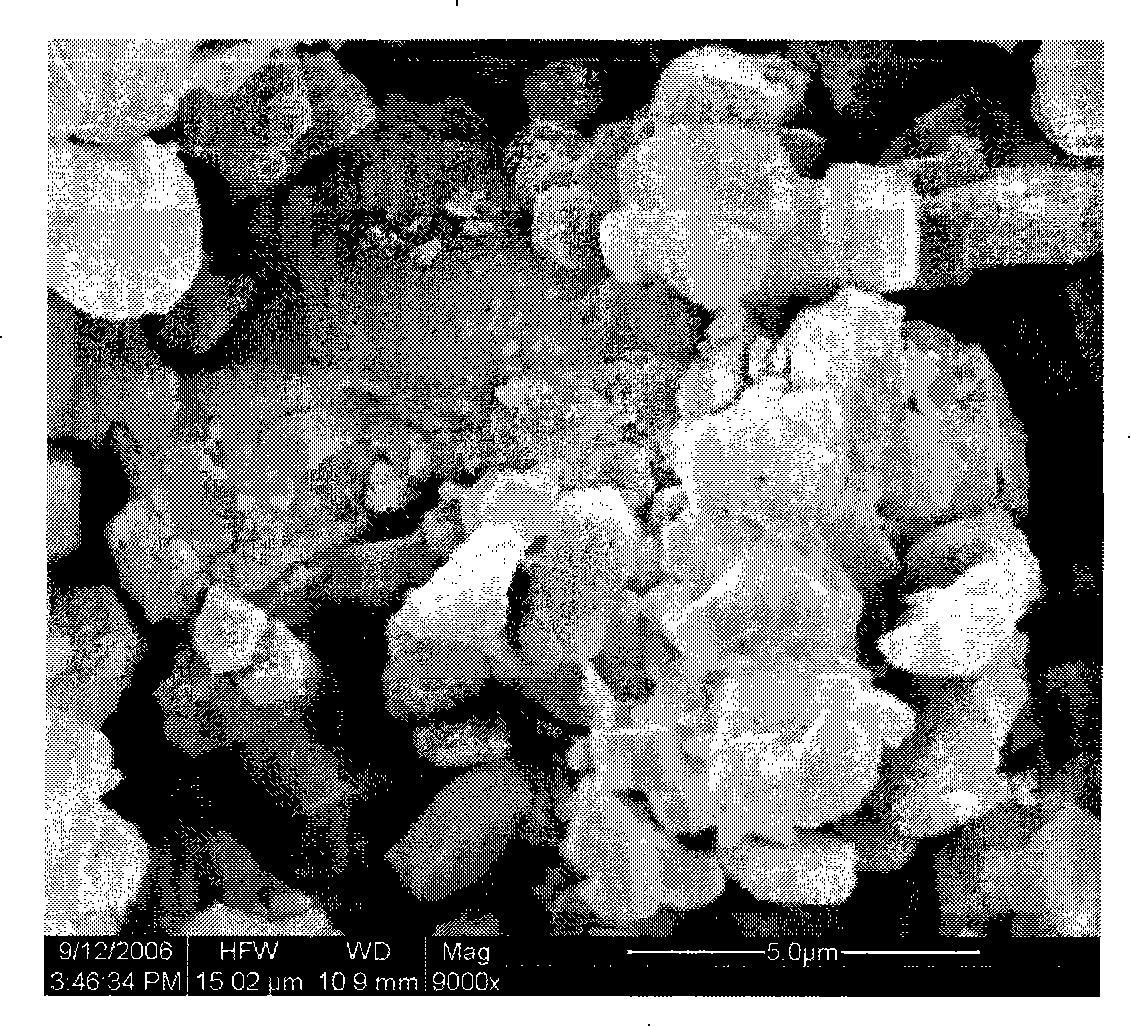

[0026] The X powder diffraction of sample C is shown in Figure 1, and the scanning electron microscope is shown in Figure 4.

Embodiment 2

[0029] Example 2: Mix 7.8g of ammonium hydrogen phosphate and ammonium dihydrogen phosphate mixture with 15ml of deionized water, and add to 25.5g of HZSM-5 powder by ion exchange (self-made, silicon-aluminum ratio is 76), 300 ℃ for 4 hours to prepare P-ZSM-5 with phosphorus source immobilized on the surface of ZSM-5. P-ZSM-5 was added to 5.9g pseudo-boehmite (w(Al 2 o 3 )=68%), 11.2g silica sol (w(SiO 2 )=40%)) and 10 g of deionized water, after stirring, 1.35 g of triethylamine was added.

[0030] The above gel was placed in an autoclave, aged at room temperature for 5 hours, then crystallized at a constant temperature of 120°C for 7 hours, and then crystallized at a constant temperature of 180°C for 48 hours. The product was washed by filtration and dried at 160°C for 24h. The X powder diffraction spectrum of the obtained sample has the characteristics of accompanying drawing 1.

Embodiment 3

[0031] Example 3: Load 11.5g of phosphorus powder on the surface of 34.2g of HZSM-5 raw powder (self-made, with a silicon-aluminum ratio of 76) by vapor deposition, and keep the temperature at 600°C for 2 hours to obtain a phosphorus source fixed on the surface of ZSM-5 The P-ZSM-5. P-ZSM-5 was added to 4.6g pseudo-boehmite (w(Al 2 o 3 )=68%), 5.3g of ethyl orthosilicate and 10g of deionized water mixture, after stirring, add 5.43g of triethylamine.

[0032] The above gel was put into an autoclave, and crystallized at a constant temperature of 80°C for 10h, and at a constant temperature of 200°C for 24h. The product was filtered and washed, and dried at 160°C for 24 hours to obtain sample D. The X powder diffraction spectrum of the obtained sample has the characteristics of accompanying drawing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com