Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259results about How to "High speed printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image forming method and inkjet recording apparatus

InactiveUS20060238592A1Increased speed in liquid removalImproved liquid removal efficiencyMeasurement apparatus componentsDuplicating/marking methodsWater basedOligomer

The image forming method comprises: a treatment liquid deposition step of depositing, on a recording medium, a treatment liquid which reacts with a water-based emulsion-type ink comprising a water-based ink solvent, a pigment-based coloring material and at least one constituent material of a radiation-curable monomer, a radiation-curable oligomer, and a mixture material of the radiation-curable monomer and the radiation-curable oligomer; an ink ejection step of ejecting the water-based emulsion-type ink by means of an inkjet head toward the recording medium on which the treatment liquid has been deposited in the treatment liquid deposition step; a radiation irradiation step, in a state where the water-based emulsion-type ink has reacted with the treatment liquid on the recording medium after the ink ejection step and an aggregate of the pigment-based coloring material and the at least one constituent material is separated in phase from a liquid component including the water-based ink solvent, of irradiating radiation onto at least the aggregate on the recording medium, to cure the aggregate; and a liquid removal step of removing at least a portion of the liquid component from the recording medium, after the radiation irradiation step.

Owner:FUJIFILM CORP

Ink set and method and apparatus for recording image

InactiveUS20070054981A1Improve scratch resistanceImprove waterproof performanceInksCoatingsOrganic solventWater soluble

An ink set comprising an ink containing at least an organic pigment, a water-soluble organic solvent and water and a treating liquid which is applied to a recording medium before applying the ink to the recording medium and produces an agglomerate upon contact with the ink, the ink containing a low molecular weight dispersant having a molecular weight of 2000 or lower and polymer fine particles.

Owner:FUJIFILM CORP

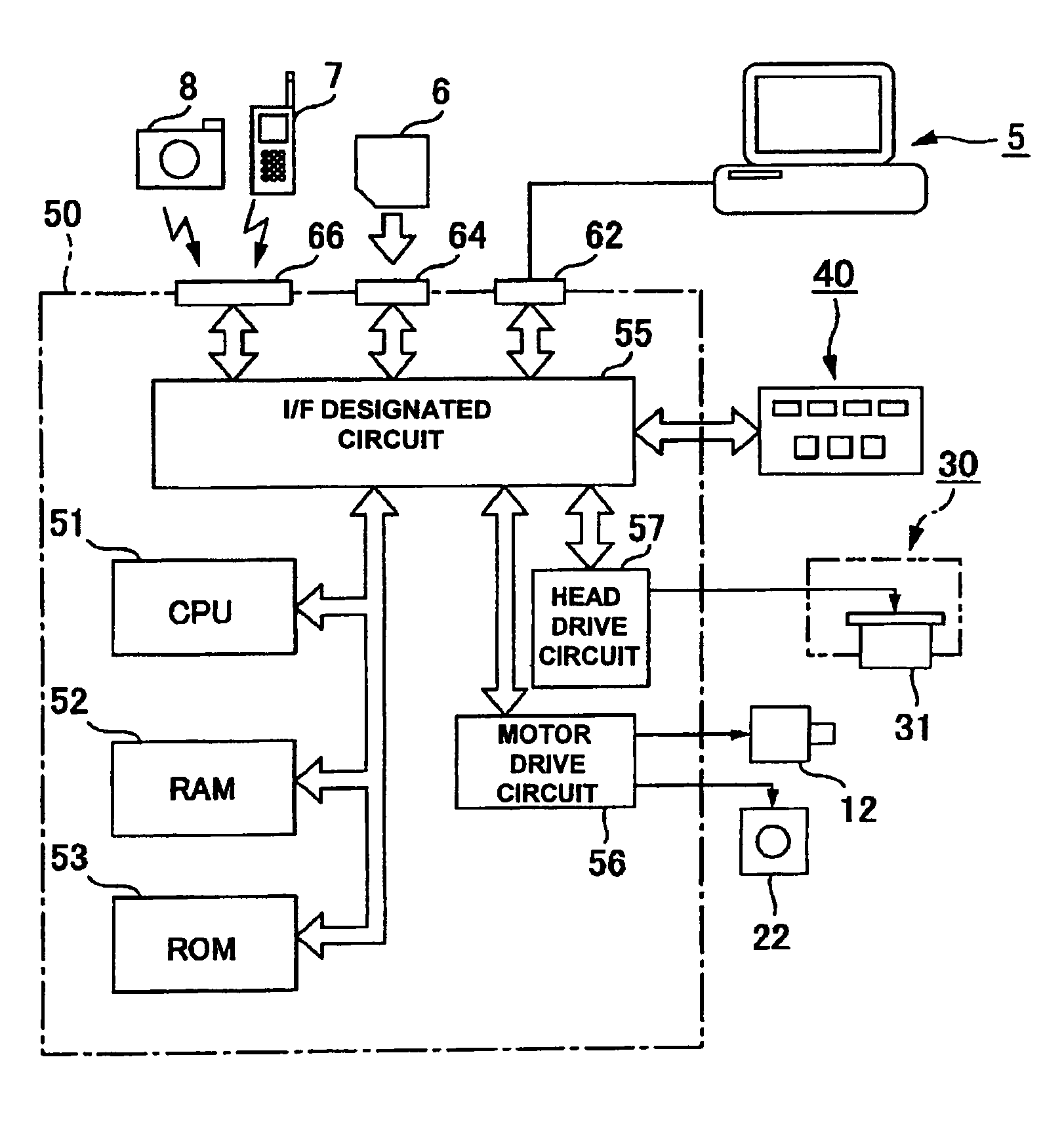

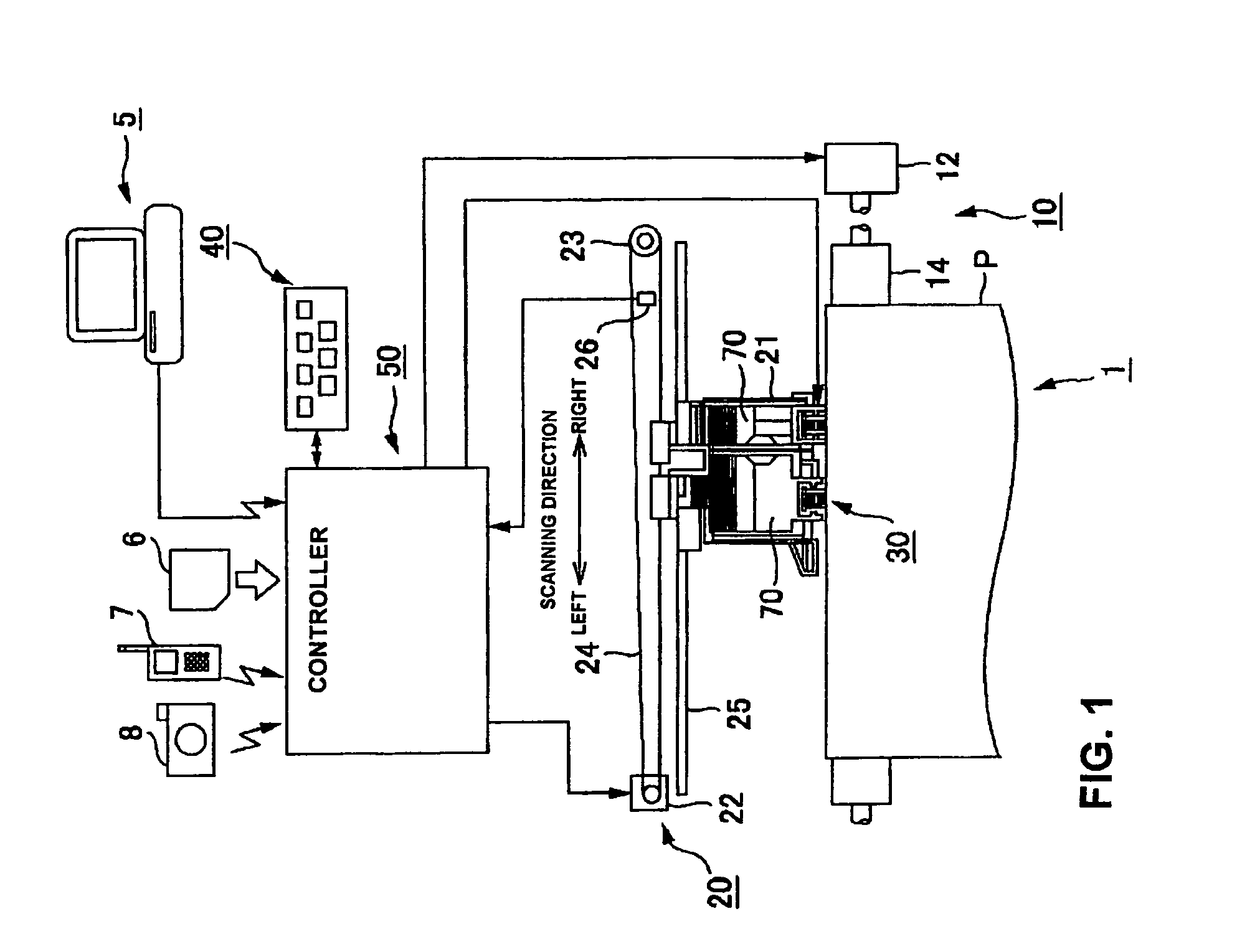

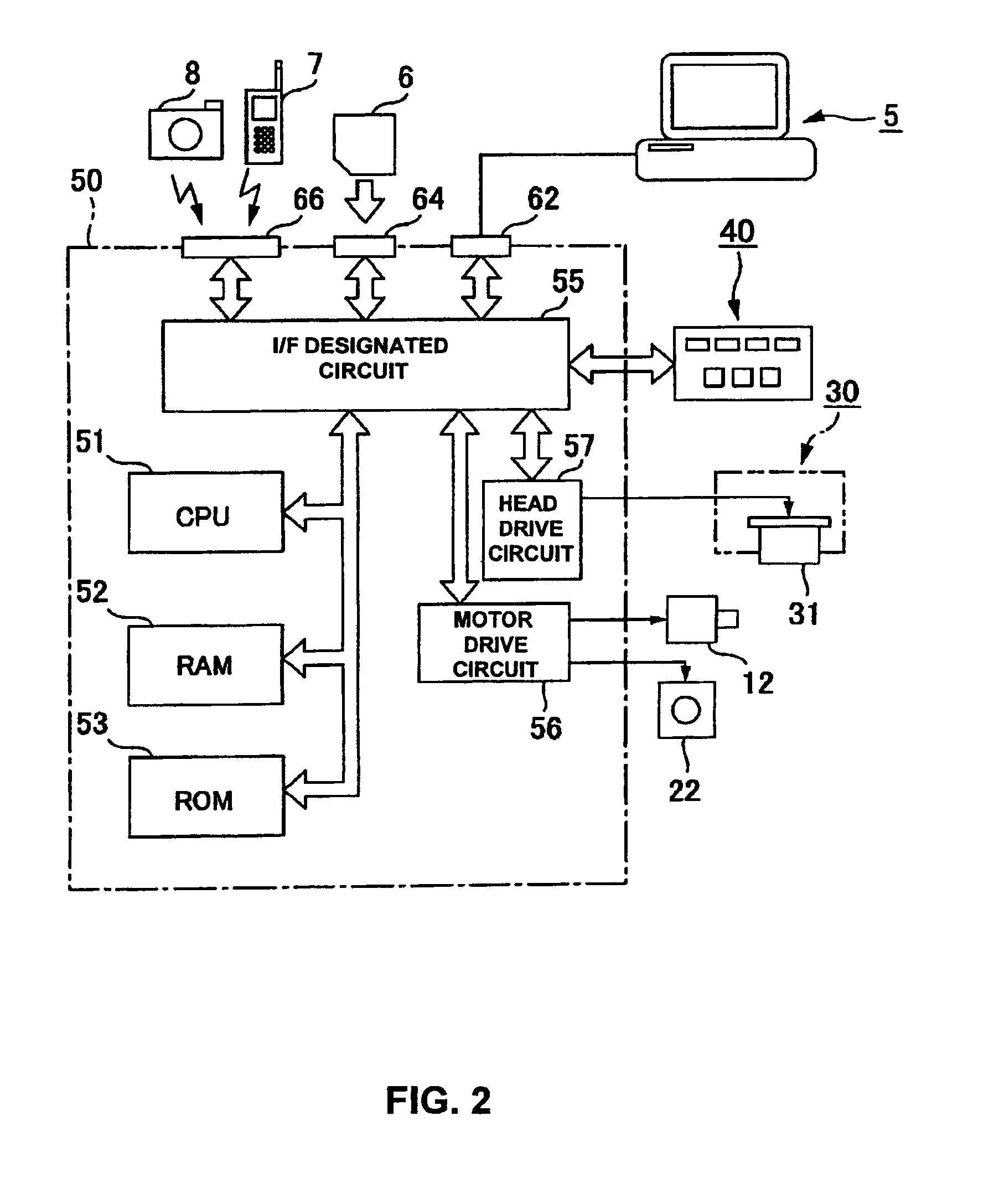

Printing apparatus and printing method for performing pre-communication with an external device

InactiveUS7014374B2High speed printingDigitally marking record carriersCharacter printing data arrangement from carrierComputer sciencePeripheral

Owner:SEIKO EPSON CORP

Inkjet ink, ink cartridge, inkjet recording apparatus, inkjet recording method and image forming apparatus

ActiveUS20110164086A1Improve image qualityLess loadMeasurement apparatus componentsDuplicating/marking methodsOrganic solventImaging quality

The present invention provides an inkjet ink which is excellent in image quality and high-speed printing on plain paper, in storage stability and in ejection stability and gives less load on a maintenance device for an inkjet recording apparatus; and an ink cartridge, an inkjet recording apparatus, and an inkjet recording method, using the inkjet ink. An inkjet ink containing a water dispersion of pigment-containing water-insoluble vinyl polymer particles; a water-soluble organic solvent; and water, wherein an ink residue from the inkjet ink has a viscosity of 3,000 mPa·s or less, the ink residue is obtained by leaving the inkjet ink to stand at a temperature of 25° C. and a humidity of 15% until substantially no mass change occurs, and wherein the inkjet ink, pH of which is adjusted to 7 with an acid, has a viscosity of 500 mPa·s or more.

Owner:RICOH KK

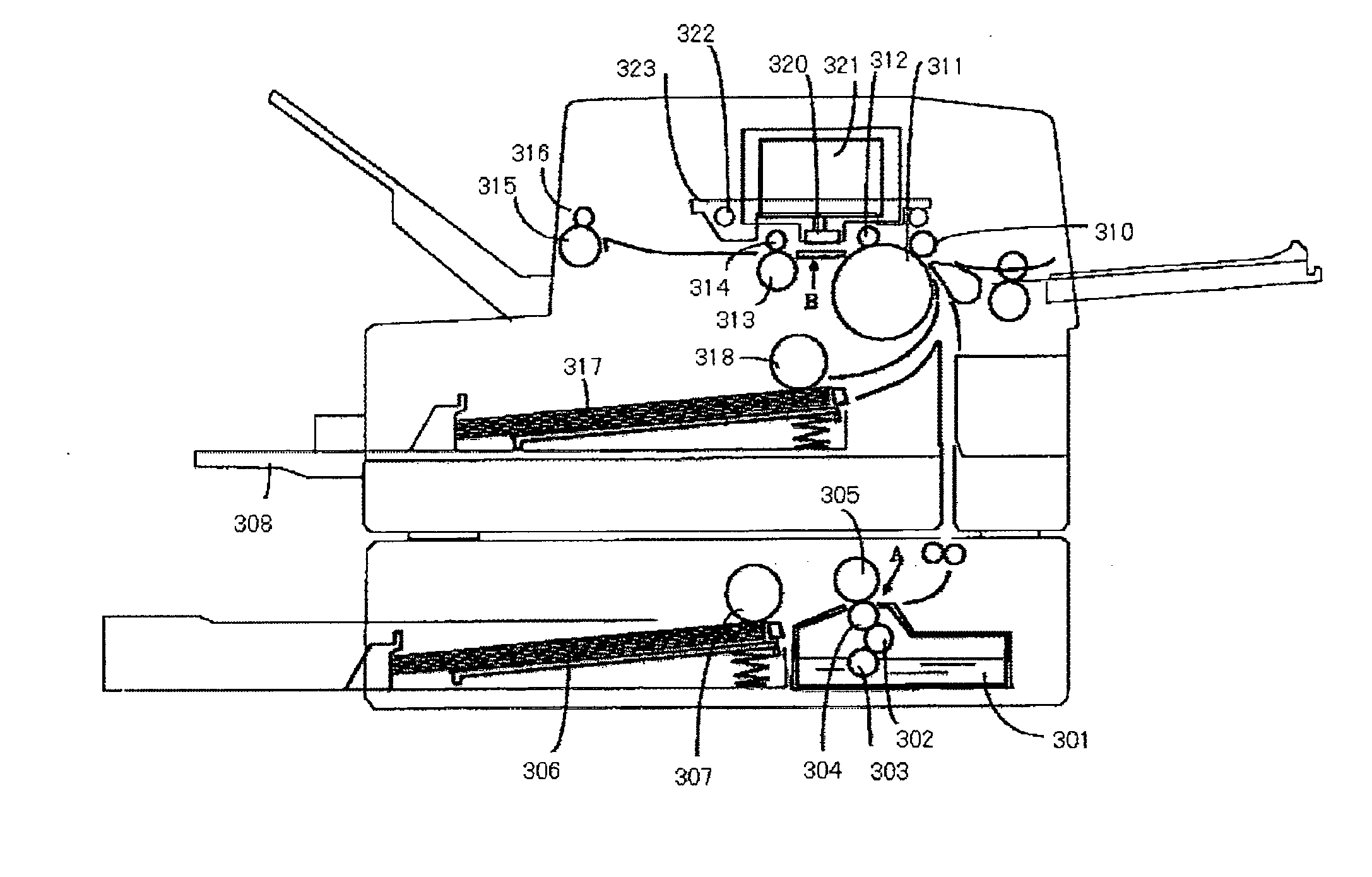

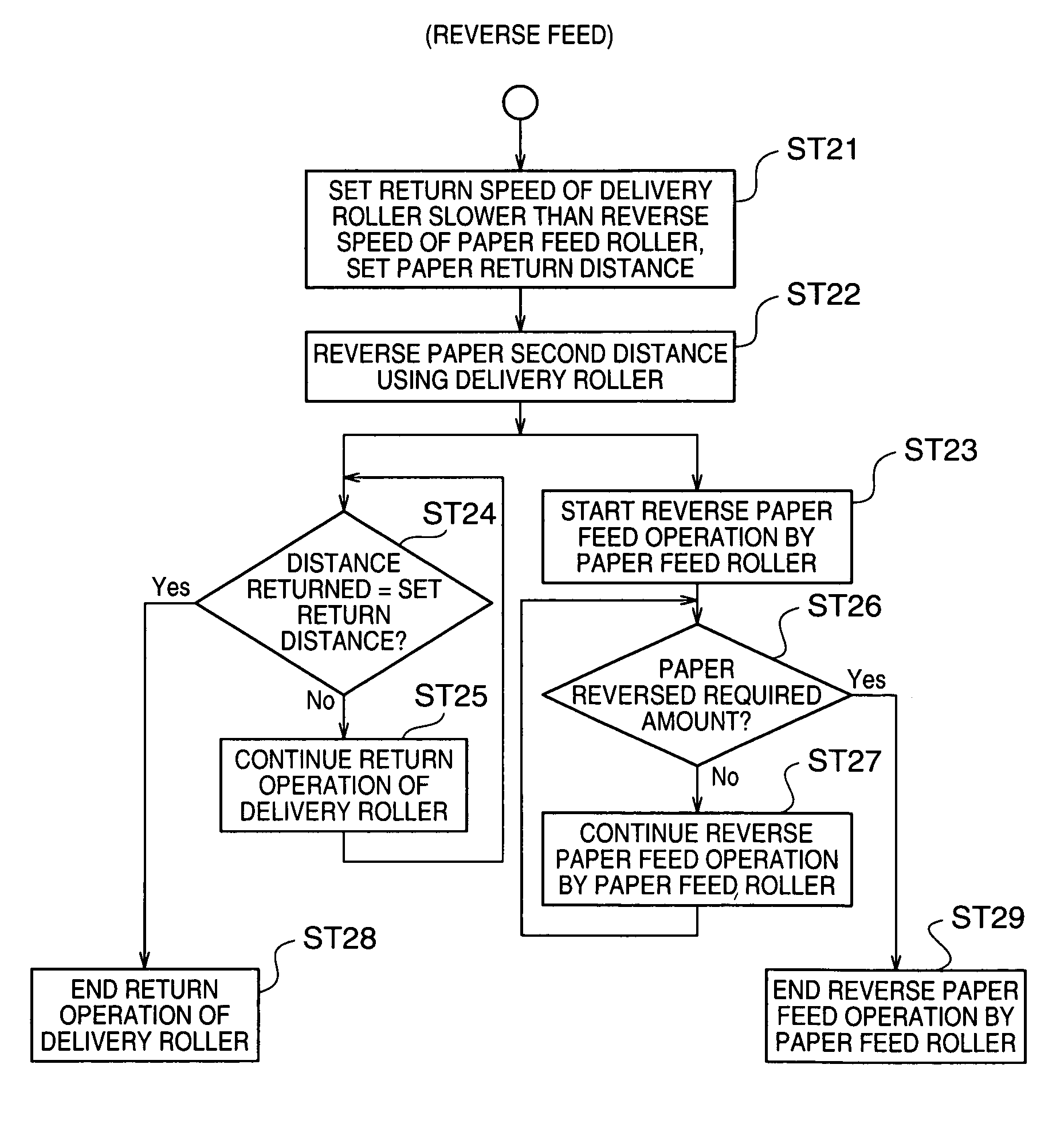

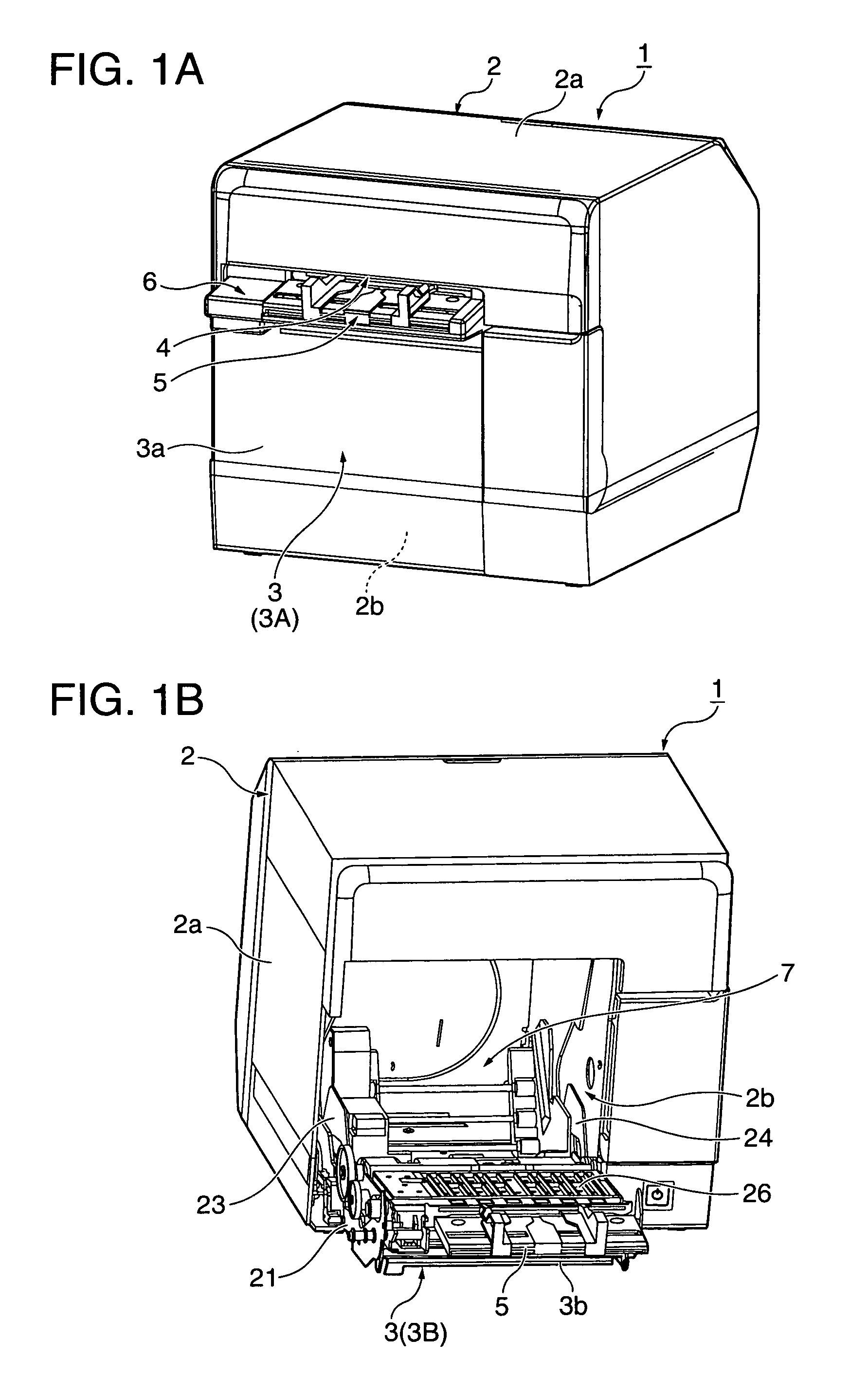

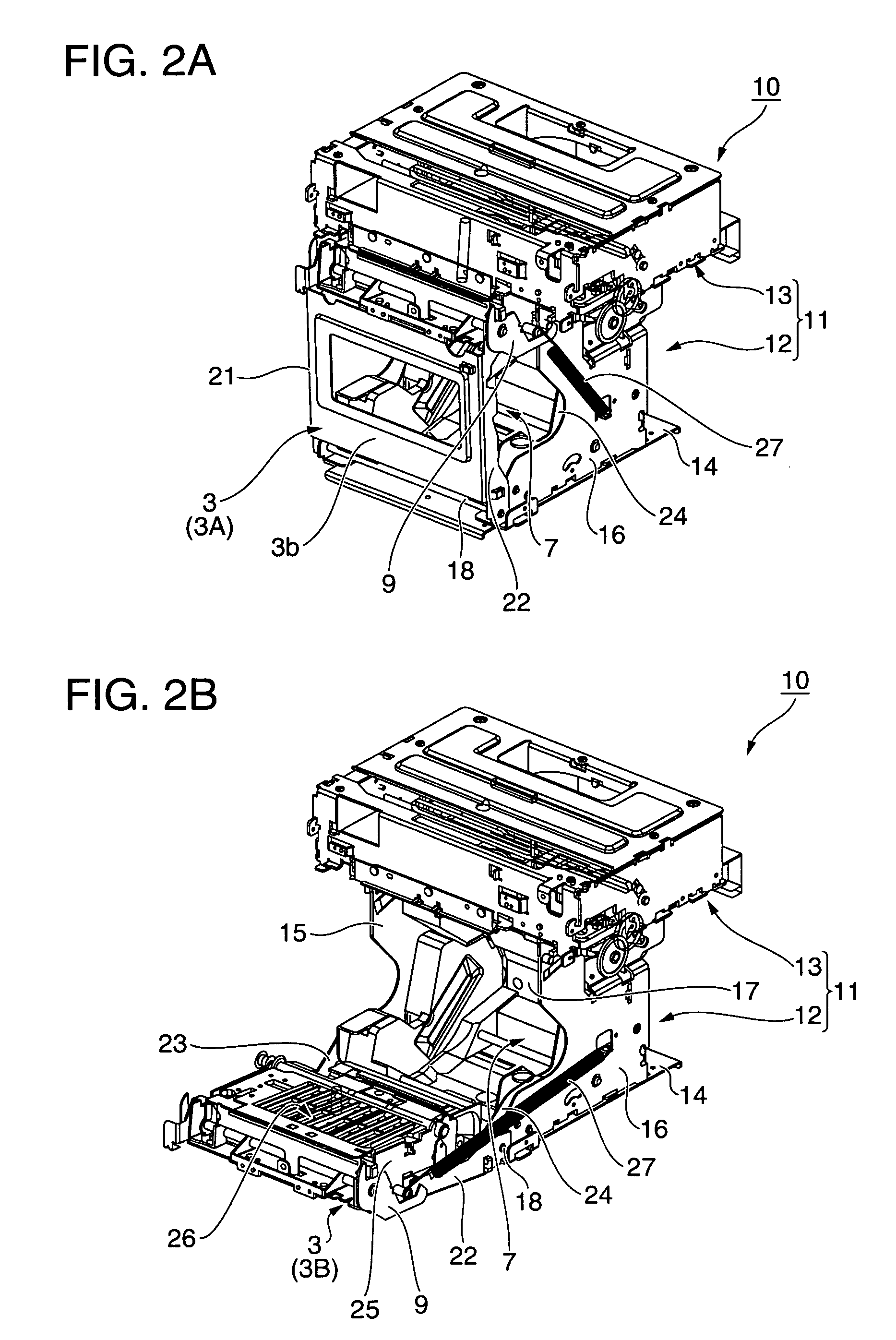

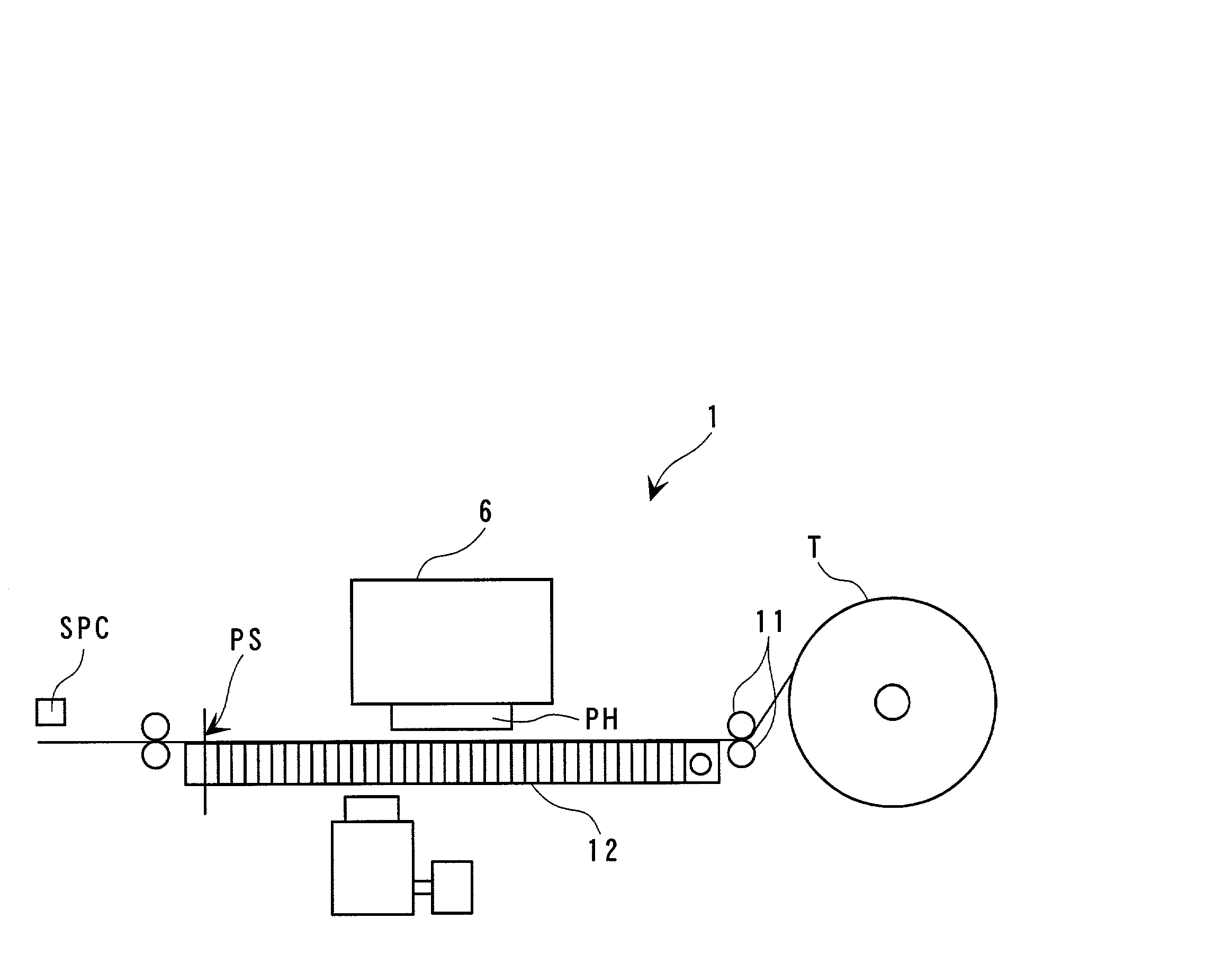

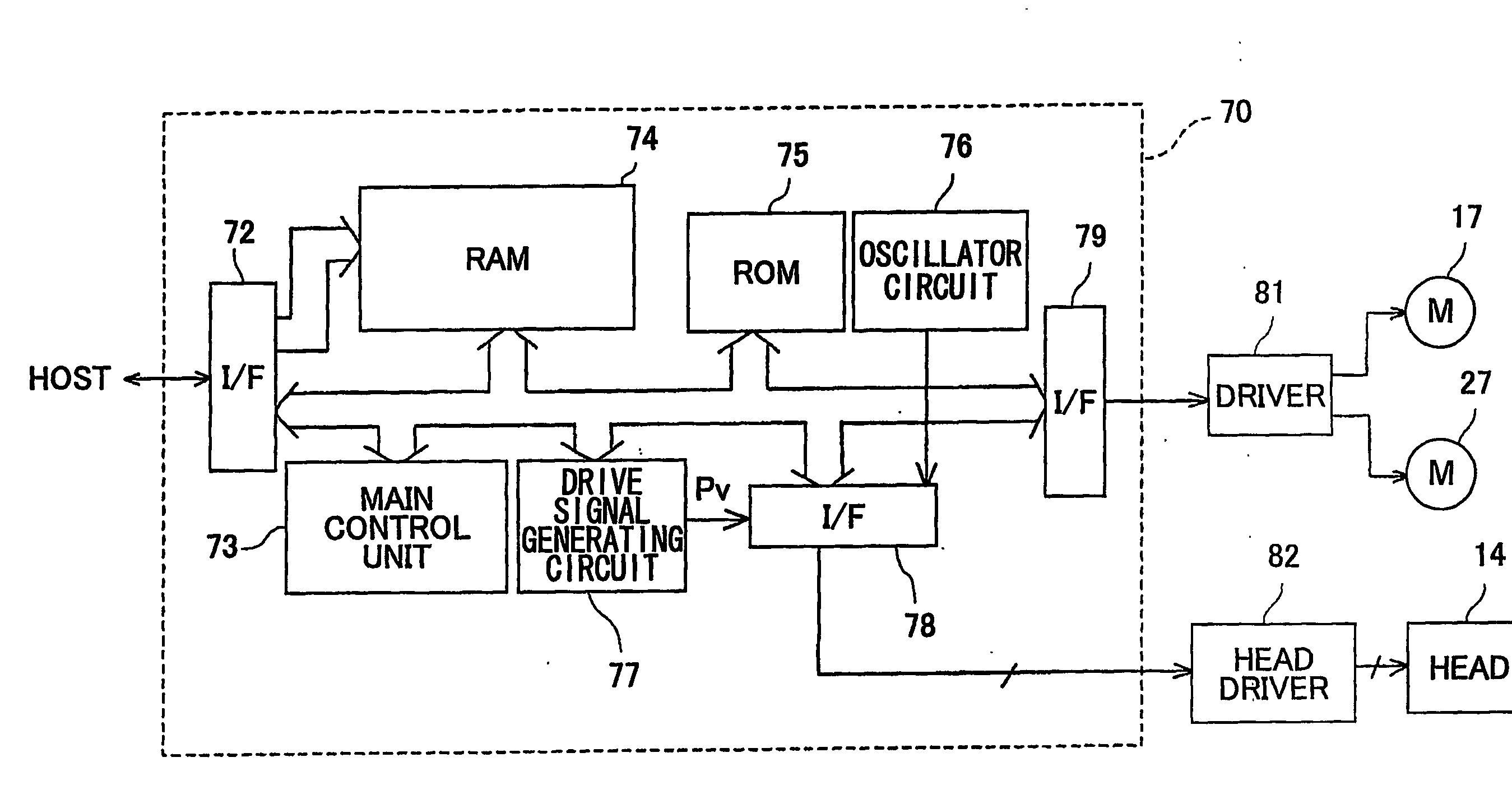

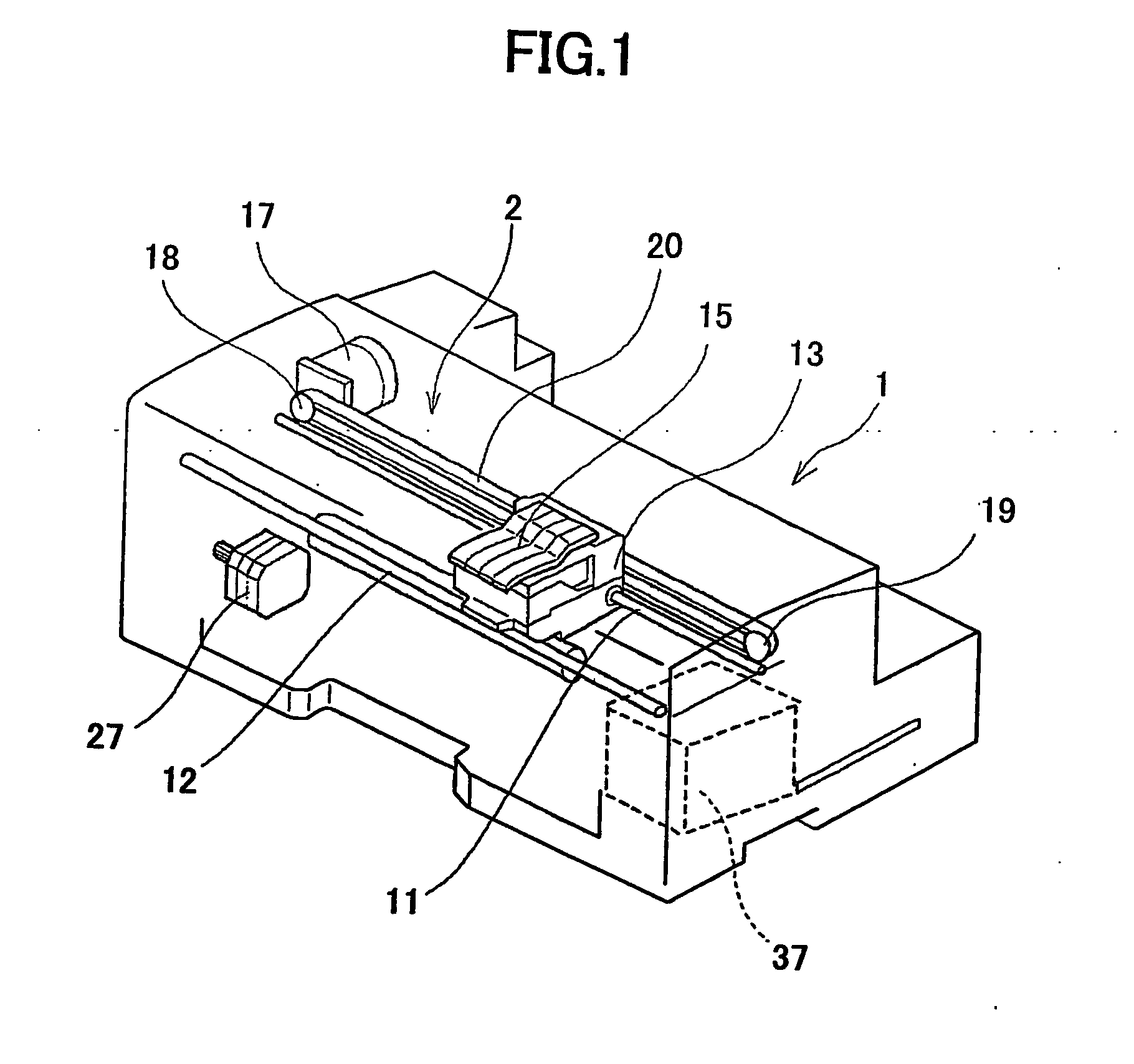

Method of controlling paper transportation in an apparatus, and an apparatus using the method

ActiveUS20090255971A1Shorten the timeReduce variationOther printing apparatusWebs handlingRolling paperDelayed time

A paper transportation control method for an apparatus enables conveying paper with appropriate tension on the paper by appropriately controlling the paper delivery operation of a delivery roller. When paper is conveyed by the paper feed roller pair 34 of a roll paper printer 1, and the tension on the paper 8a is detected to exceed an upper tension limit based on the displacement of a damping mechanism 32 (time t2), the paper delivery operation of a delivery roller pair 33 starts at a time t3 after a start operation delay time DLS (first delay time) corresponding to the feed rate V(34) passes after time t2. When the tension returns to or below the upper tension limit, the paper delivery operation stops at a time t5 after a stop operation delay time DLE (second delay time) similarly corresponding to the feed rate V(34) passes. Tension fluctuation (change in the load on the paper feed roller) can be controlled without causing chattering or fluttering in paper delivery operation control.

Owner:SEIKO EPSON CORP

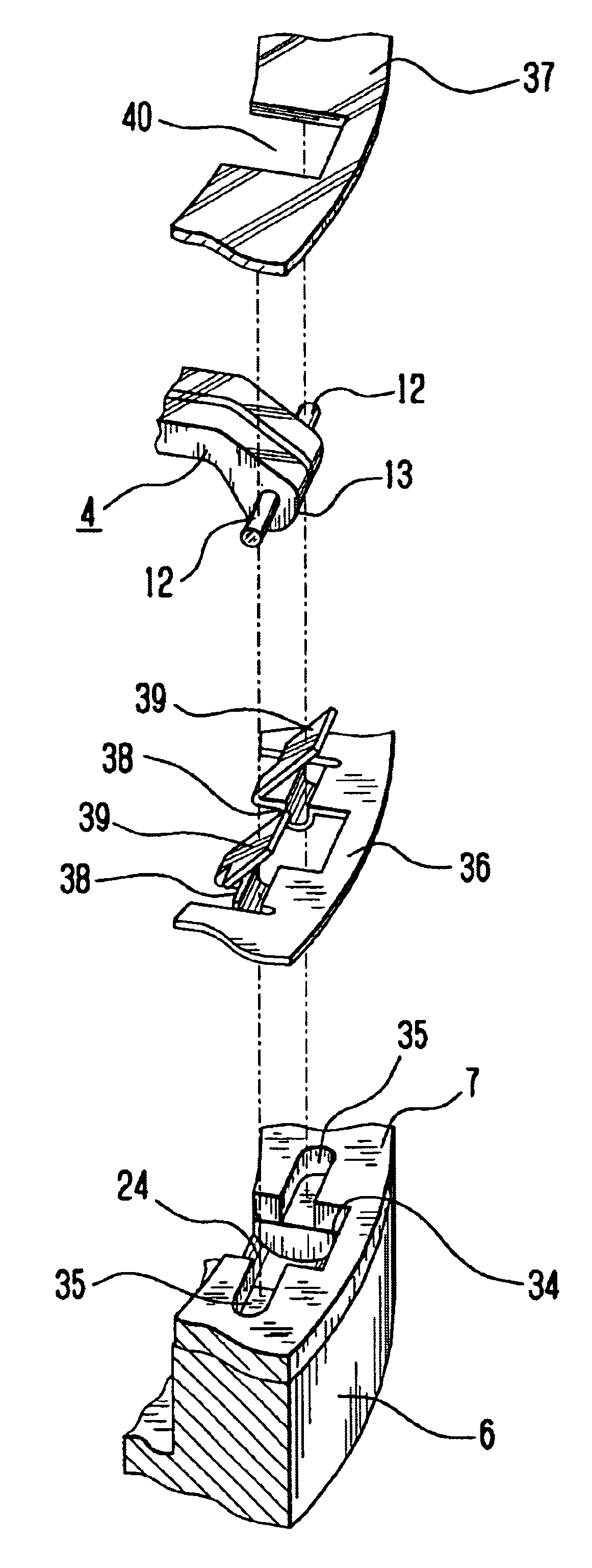

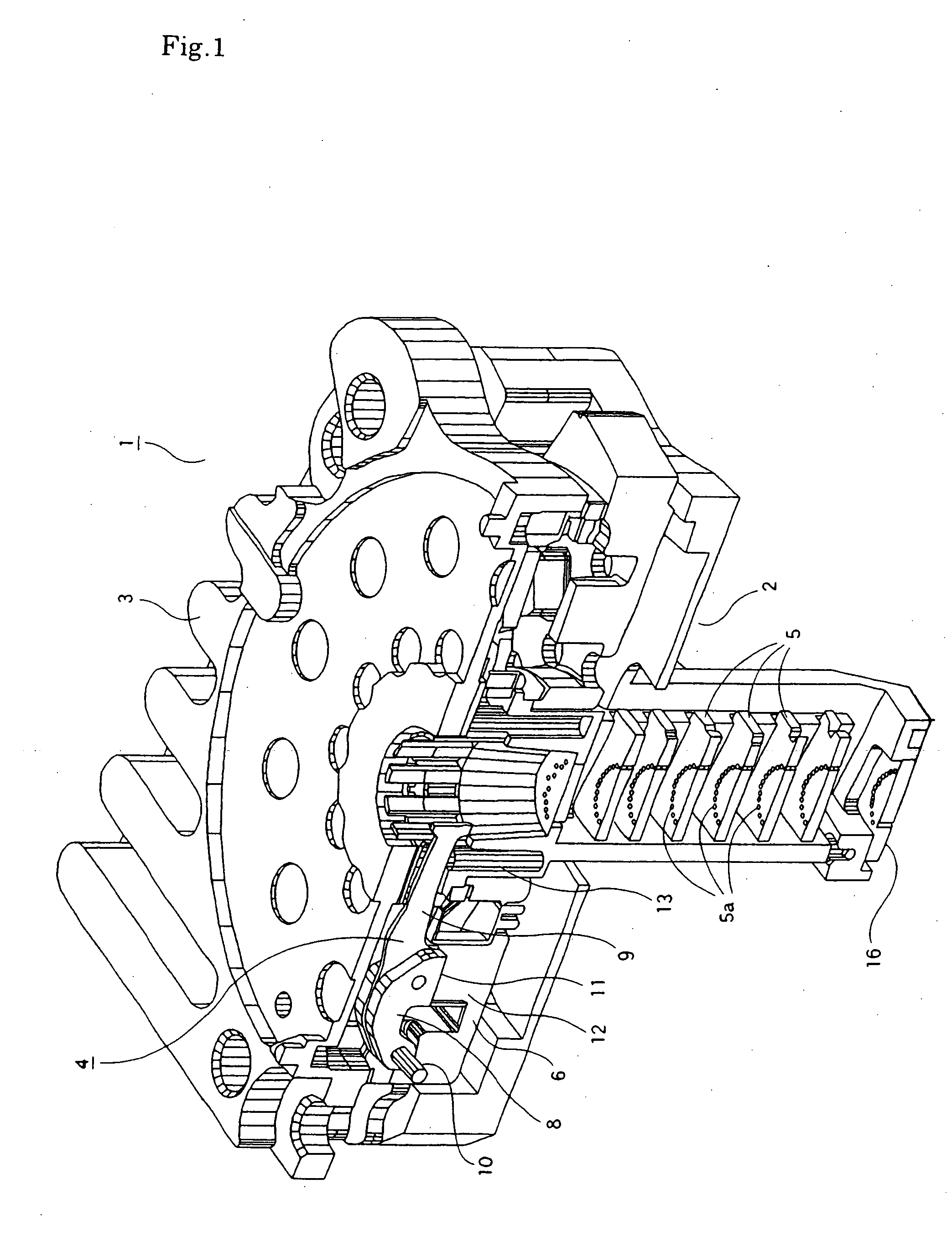

Wire dot printer head and wire dot printer

InactiveUS6848843B1Suppressing abrasion of surfaceIncrease impactPrintingEngineeringMechanical engineering

Owner:TOSHIBA TEC KK

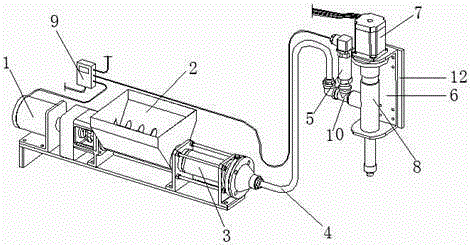

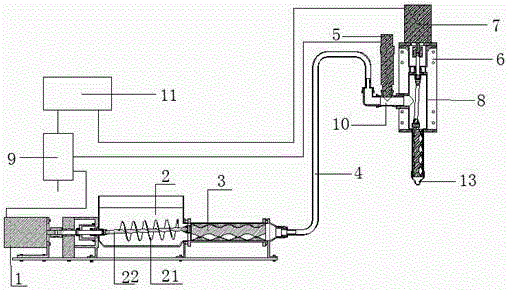

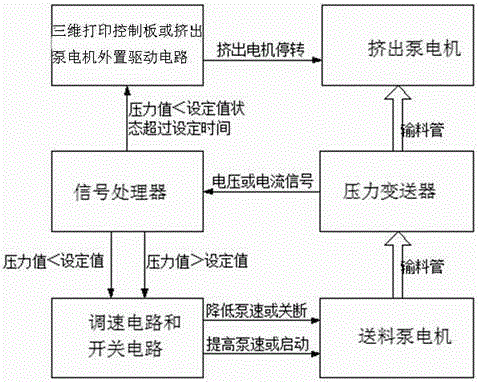

Three-dimensional printing machine fluid extrusion system and implement method thereof

ActiveCN105216333AFlexible placementHigh speed printingAdditive manufacturing apparatusCeramic shaping apparatusElectric machineryProcess engineering

The invention discloses a three-dimensional printing machine fluid extrusion system and an implement method thereof and solves problems that an existing extrusion system is large in material conveying limiting, non-uniform in extruded materials, inconvenient to operate and the like. The three-dimensional printing machine fluid extrusion system comprises a feeding mechanism, an extrusion mechanism and a feeding controlling system which can be used for controlling the feeding mechanism and the extrusion mechanism; the output end of the feeding mechanism is connected with the input end of the extrusion mechanism by a conveying pipe and a three-way pipe; another end of the three-way pipe is connected with a pressure transmitter; the pressure transmitter is connected with the feeding controlling system by a signal line; the feeding controlling system is connected with a power supply and is connected with a three-dimensional printing machine controlling plate or an external driving circuit of an extrusion machine by a material shortening signal line. The three-dimensional printing machine fluid extrusion system can be used for continuous feeding without halting, and achieving high-speed printing and precise flow control, can be suitable for viscous fluid materials such as concrete and ceramic clay, and can be suitable for being used for batch printing of middle-small objects and printing of large objects such as concrete buildings and landscape sculptures.

Owner:成都智建创融科技有限公司

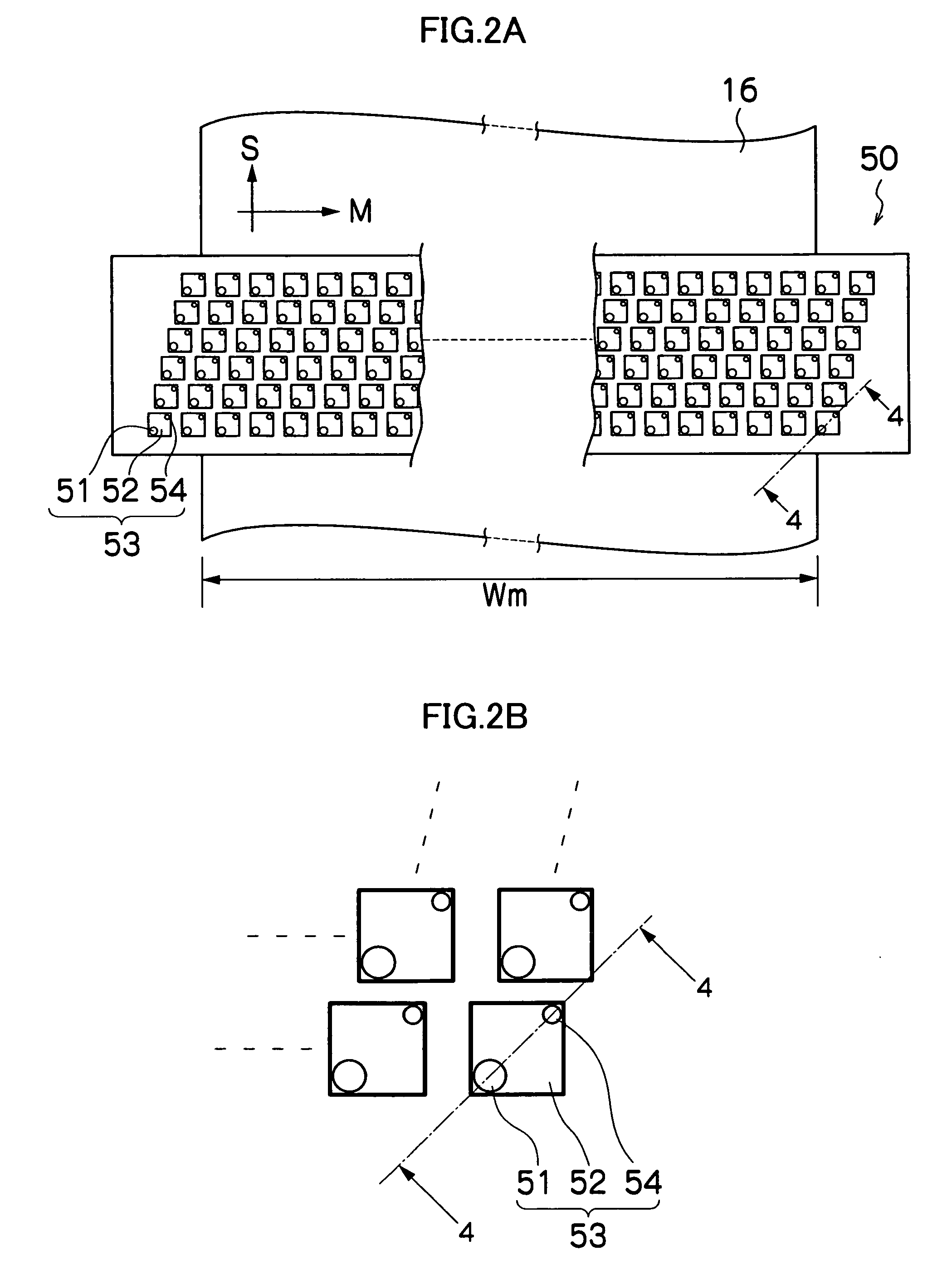

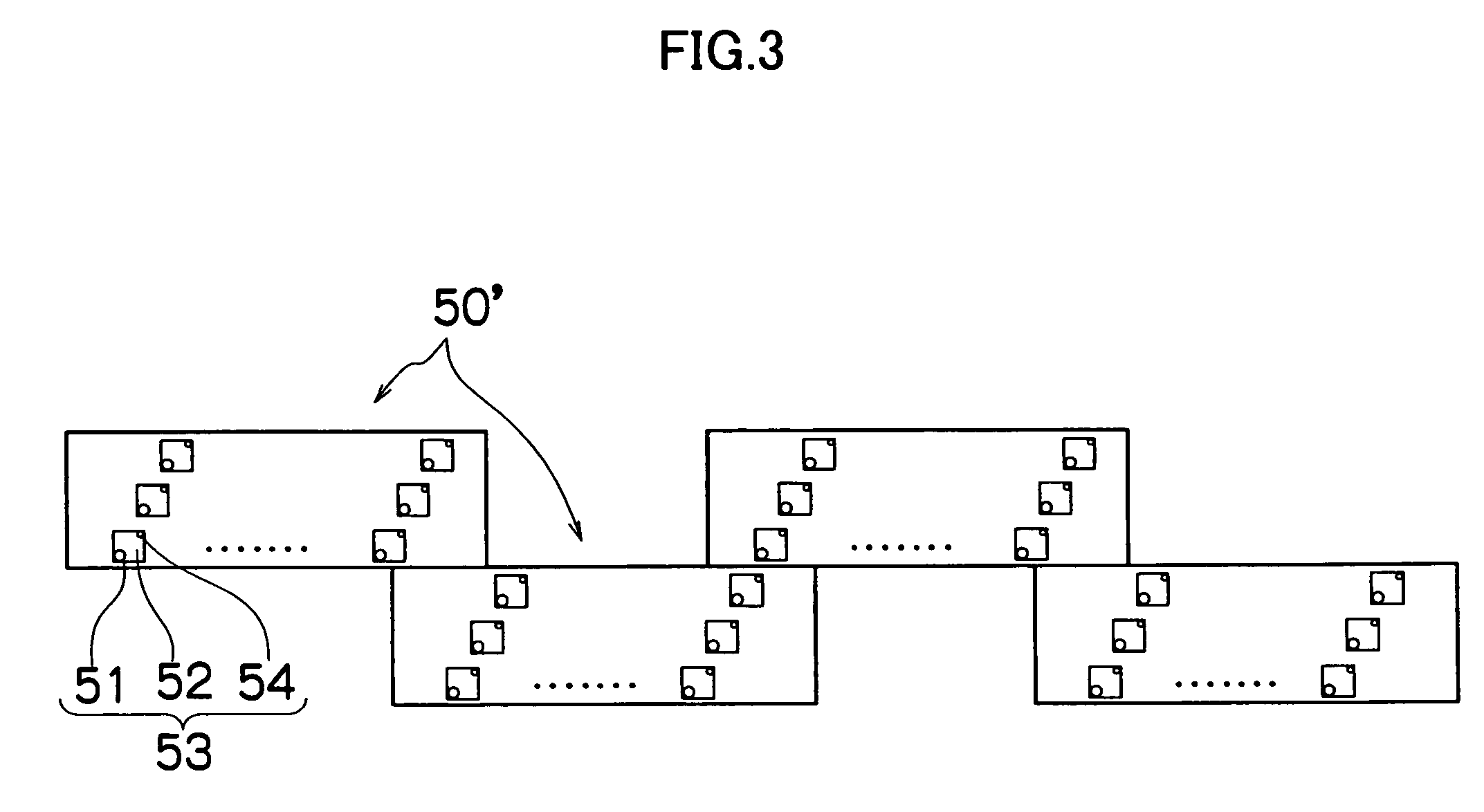

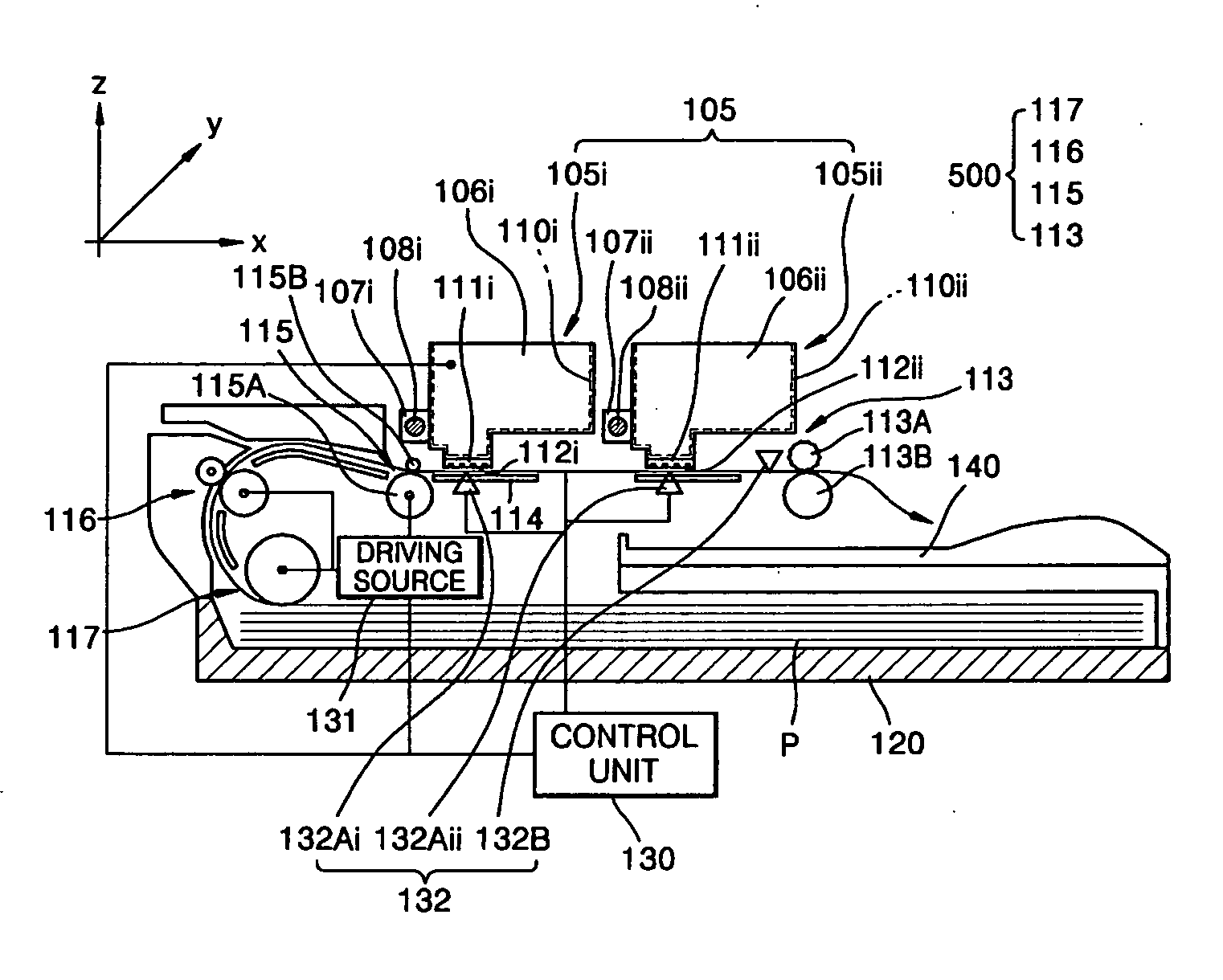

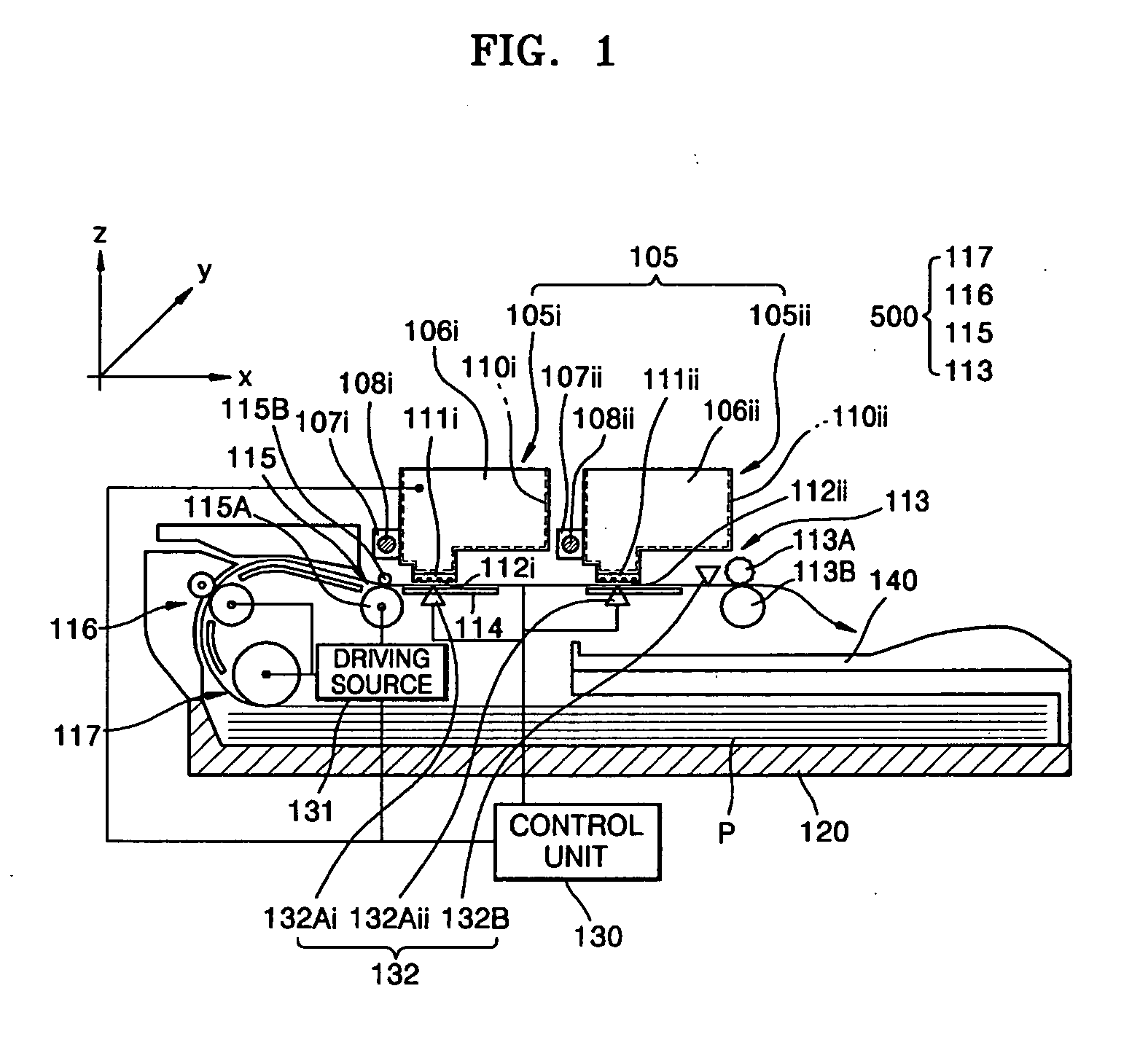

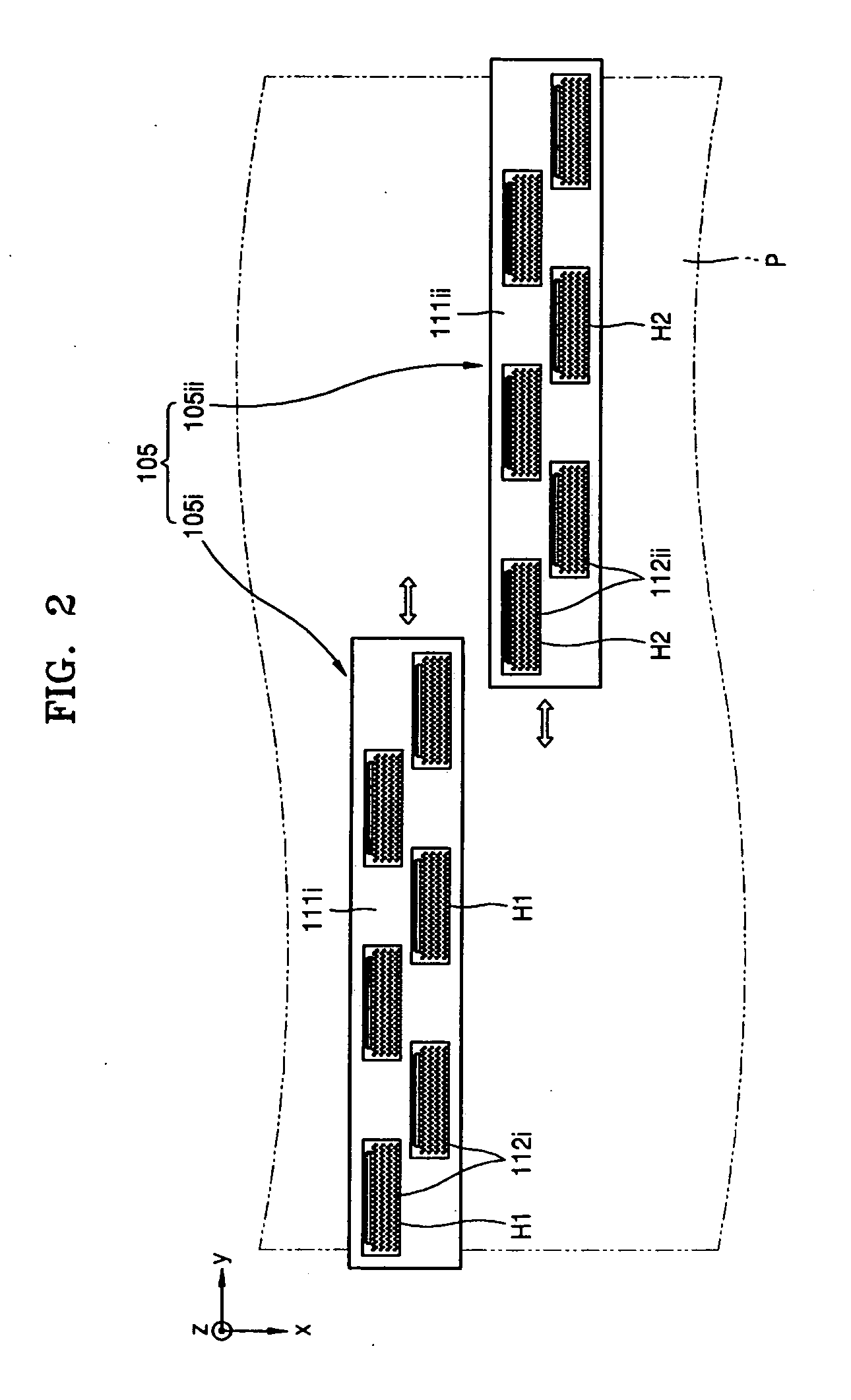

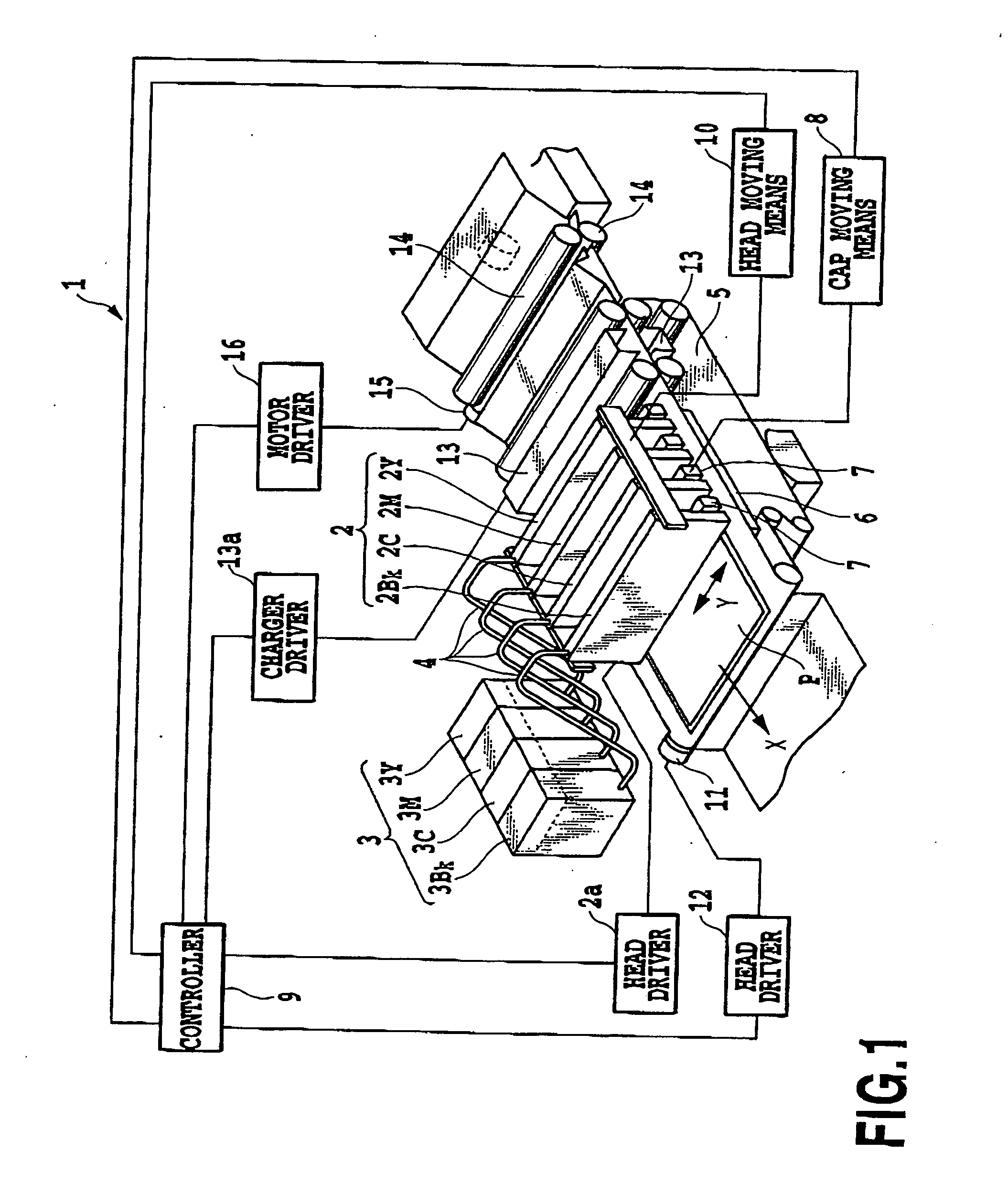

Inkjet image forming apparatus and high-quality printing method of the same

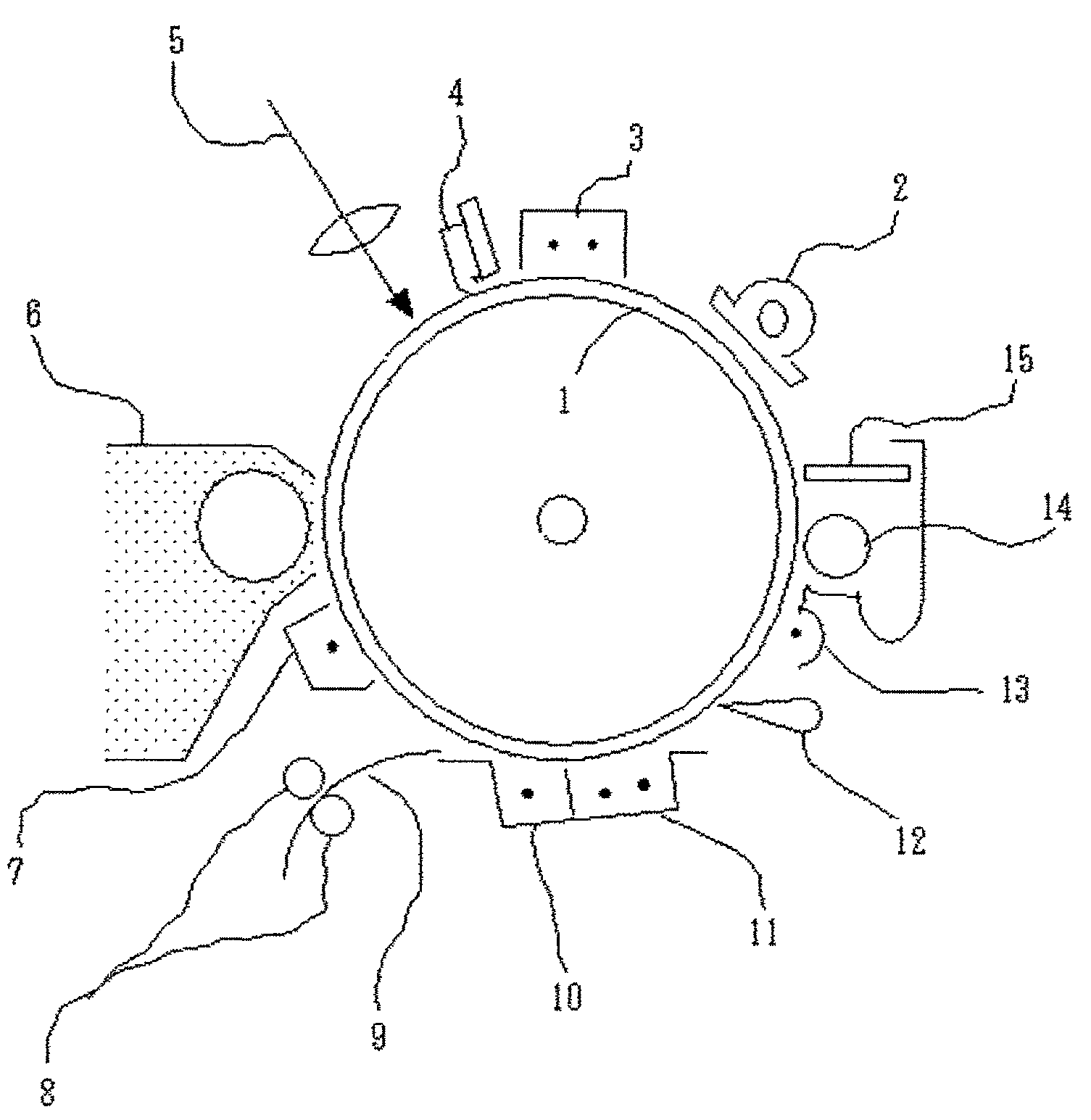

An inkjet image forming apparatus and a high-quality printing method. The inkjet image forming apparatus for high-quality printing includes a plurality of printheads with lengths equal to a half-width of a print medium are arranged in a single line along a transferring direction of the print medium transferred in a subsidiary scanning direction, and are moveable along a main scanning direction to eject ink onto the print medium to print an image, a plurality of carriages where the plurality of printheads are mounted, a plurality of carriage moving units to reciprocally move the carriages in the main scanning direction, and a control unit to generate control signals to synchronize ejecting operations of the printheads and operations of the carriage moving units so that the ink ejected from the printheads is deposited on a desired area of the print medium.

Owner:S PRINTING SOLUTION CO LTD

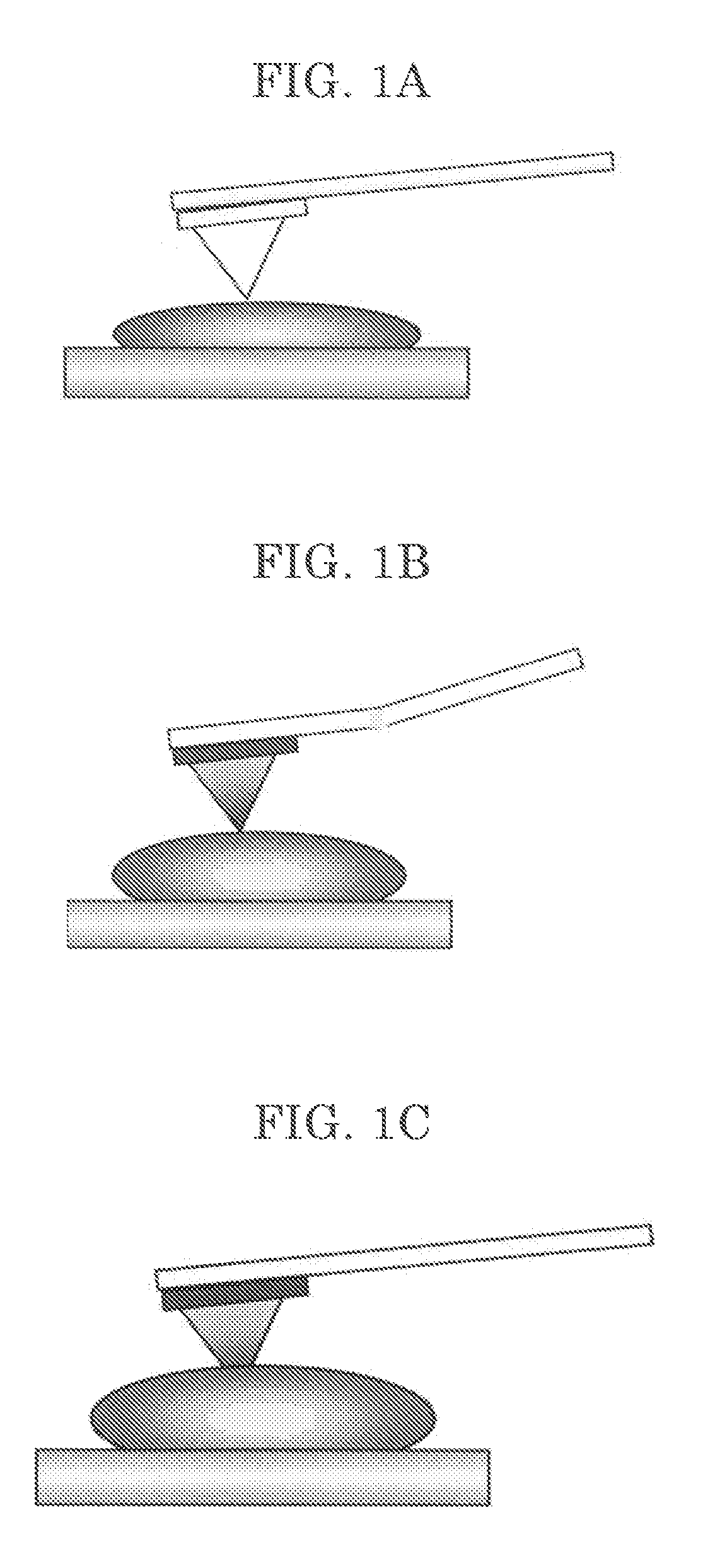

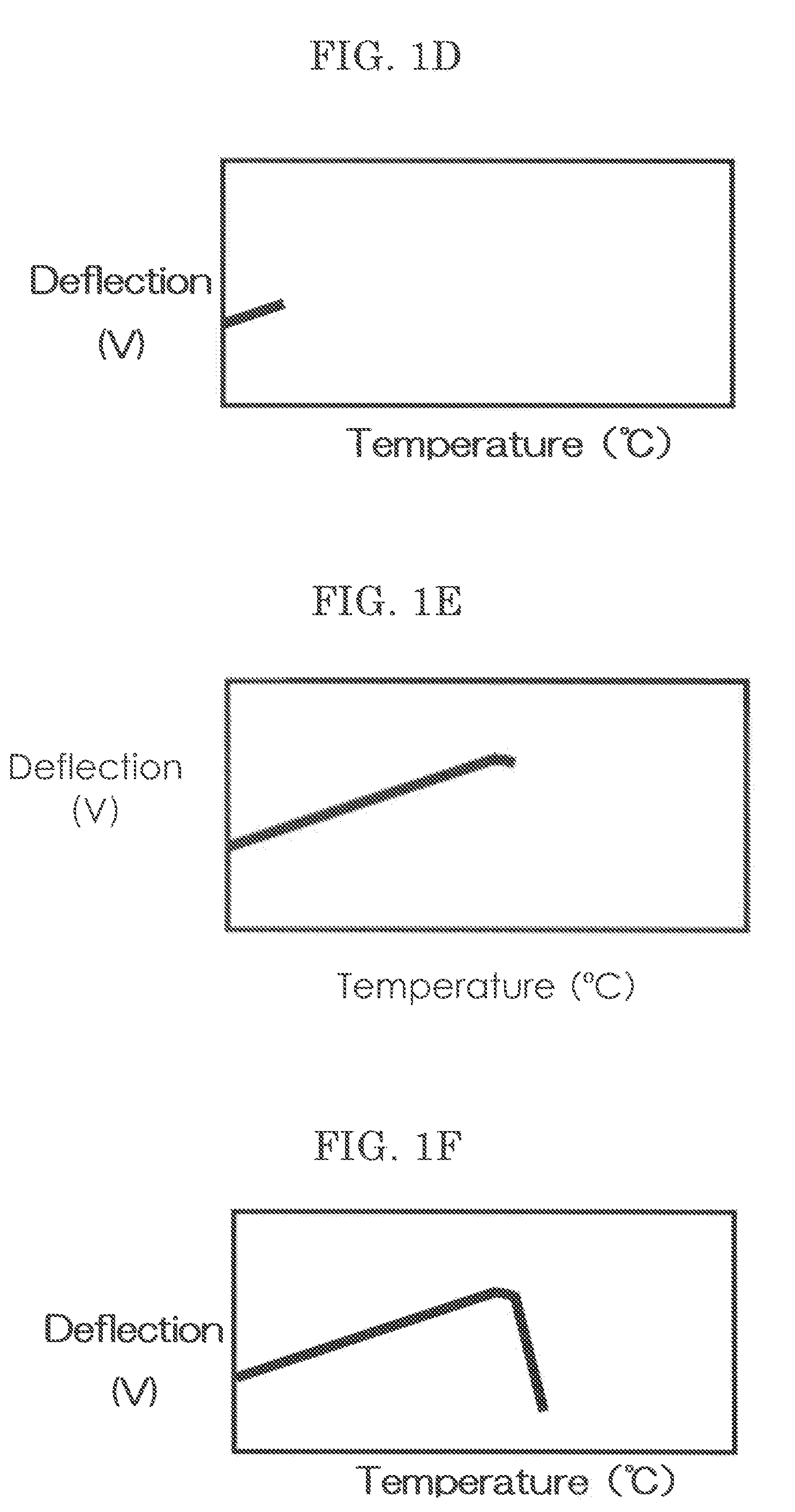

Toner, developer, and image forming method

ActiveUS20090220883A1Improve responseImprove stabilityElectrographic process apparatusDevelopersEngineeringCore shell

A toner containing at least a binder resin and a colorant, wherein the toner has a core-shell structure composed of a core, and a shell having a thickness of 0.01 μm to 2 μm on a surface of the core, and wherein the toner satisfies the following relation:1.1≦ST / CT≦2.0where ST is a softening temperature of the shell, and CT is a softening temperature of the core, both measured by a SPM probe with an integrated heater.

Owner:RICOH KK

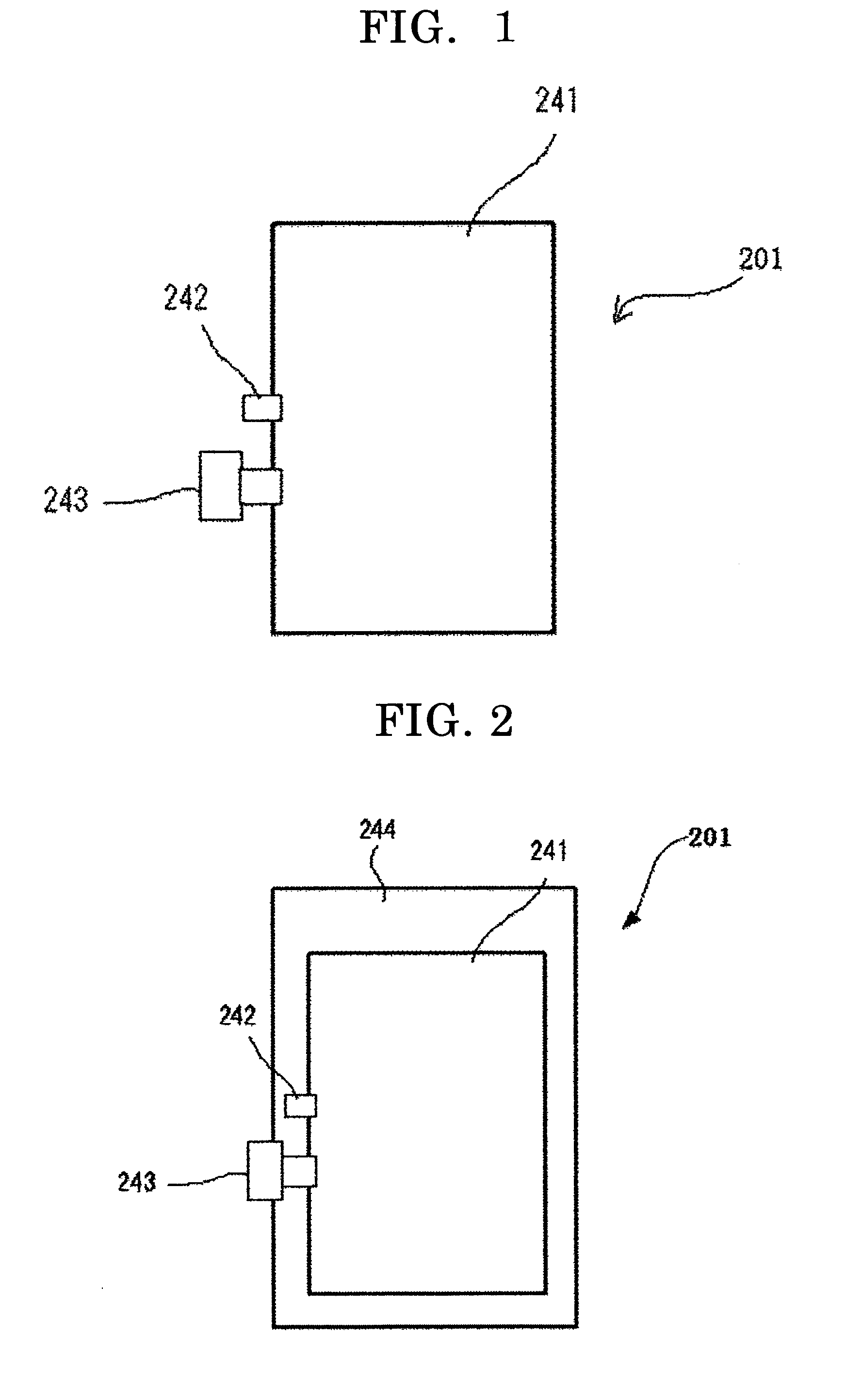

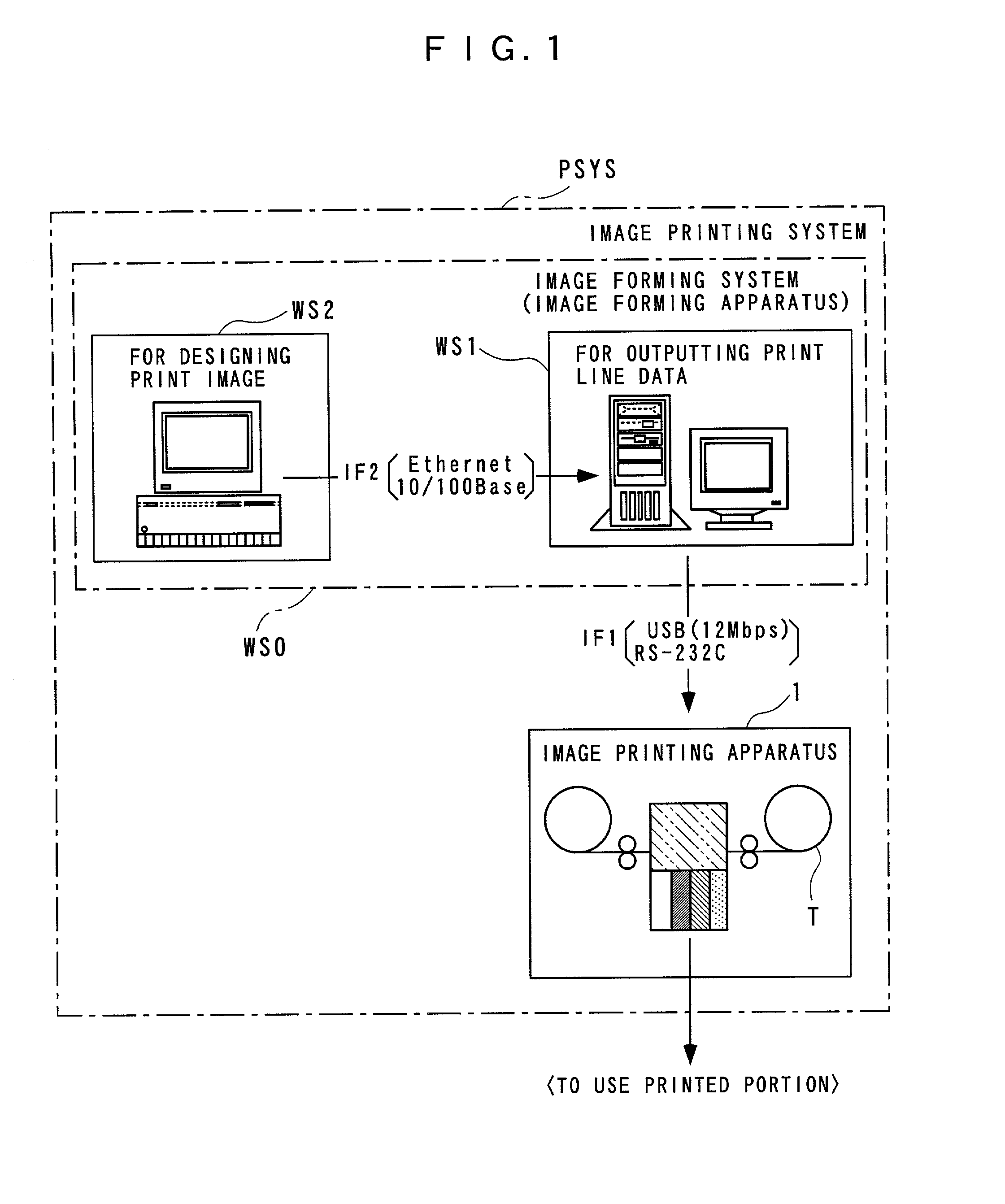

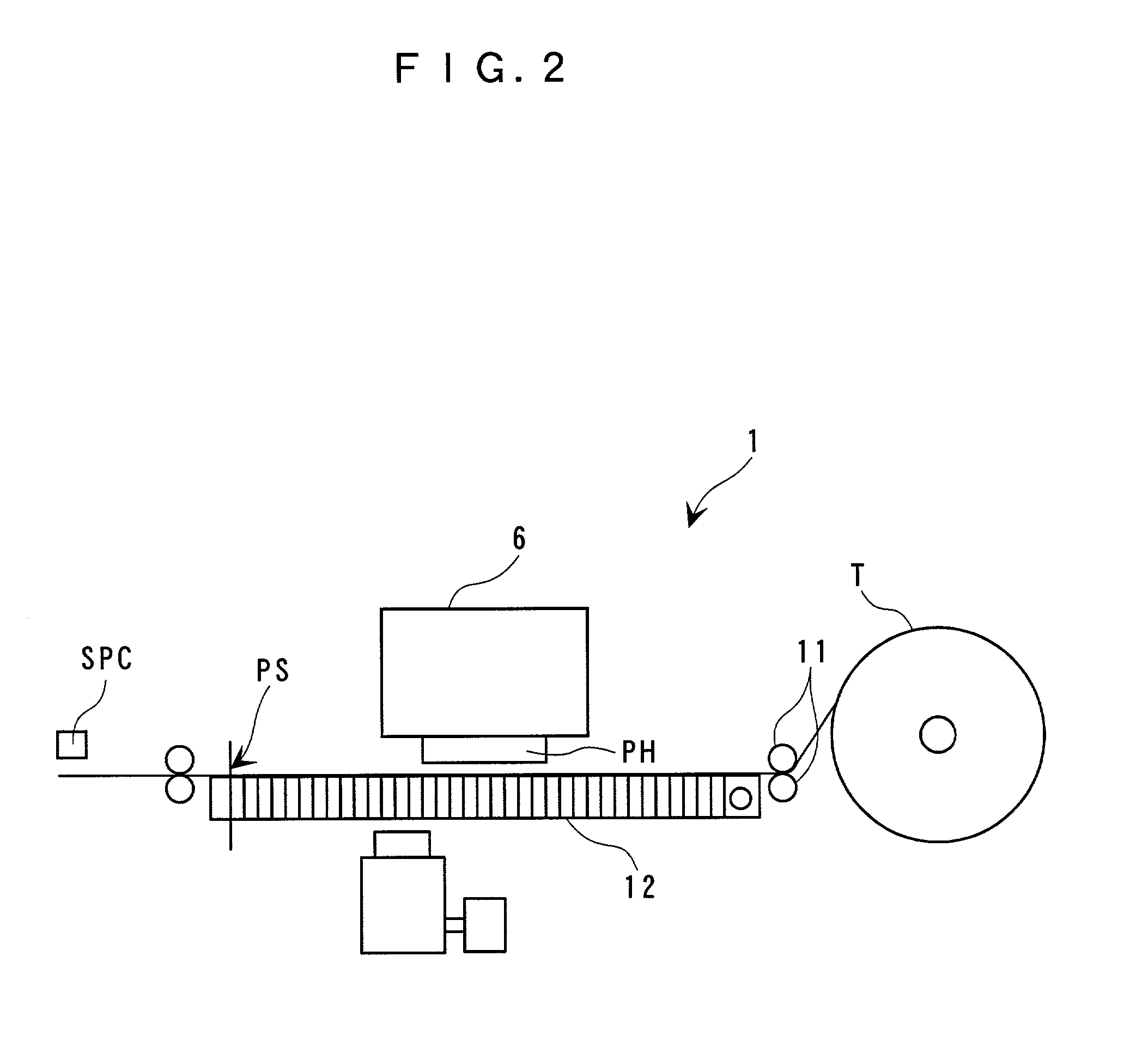

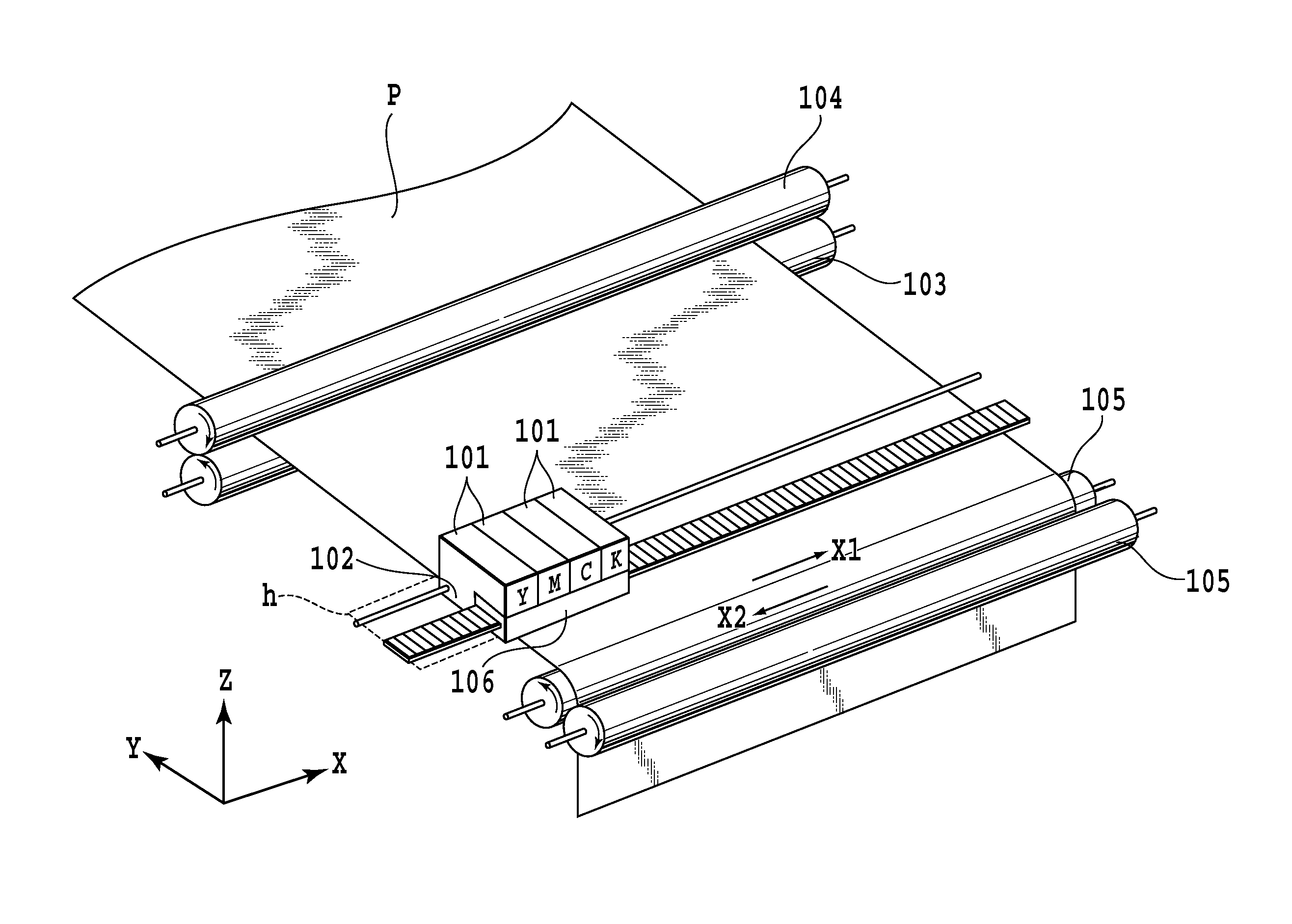

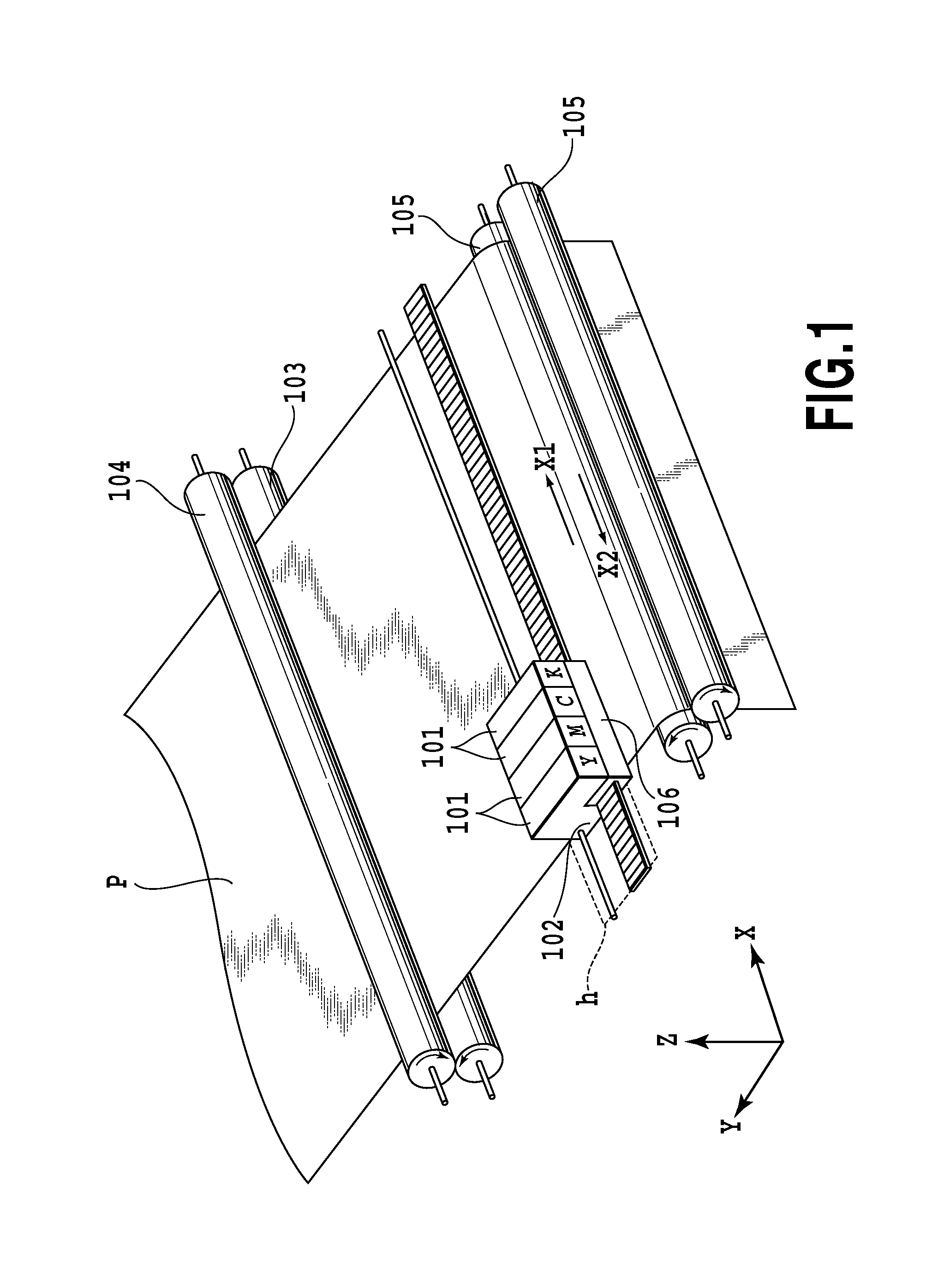

Image printing method, image printing apparatus, and image printing system, as well as label producing method, and label producing system

ActiveUS20020109862A1High speed printingDigitally marking record carriersDigital computer detailsRectangular coordinatesComputer science

There are provided an image printing method method, an image printing apparatus, an image printing system, as well as a label producing method and a label producing system, which are capable of communicating print image data representing a desired print image in units of line data items, and at the same time printing a plurality of the print images at a high speed. When N copies of a print image, where N is an integer equal to or larger than 2, are printed on a print medium side by side in a direction along an X axis of the print medium, assuming that the X axis and an Y axis are two axes orthogonal to each other or a two-dimensional rectangular coordinate system, the print image being formed of J dots in the direction along the X axis by K dots in a direction along the Y axis where J is an integer equal to or larger than 2 and K is an integer equal to or larger than 2, line data items each representing one line of J dots are sequentially received according to a predetermined communication protocol from a predetermined other end of communication opposite party, whereby K line data items corresponding to K lines in the direction along the Y axis are sequentially received. When a k-th line data item (k is an arbitrary integer defined as 1<=k<=K) of the K line data items is received, a k-th long line data item is formed which represents one line of N times J dots formed by arranging N lines of J dots side by side in the direction along the X axis, and the one line of N times J dots is printed as a k-th line on the print medium in the direction along the X axis thereof.

Owner:SEIKO EPSON CORP

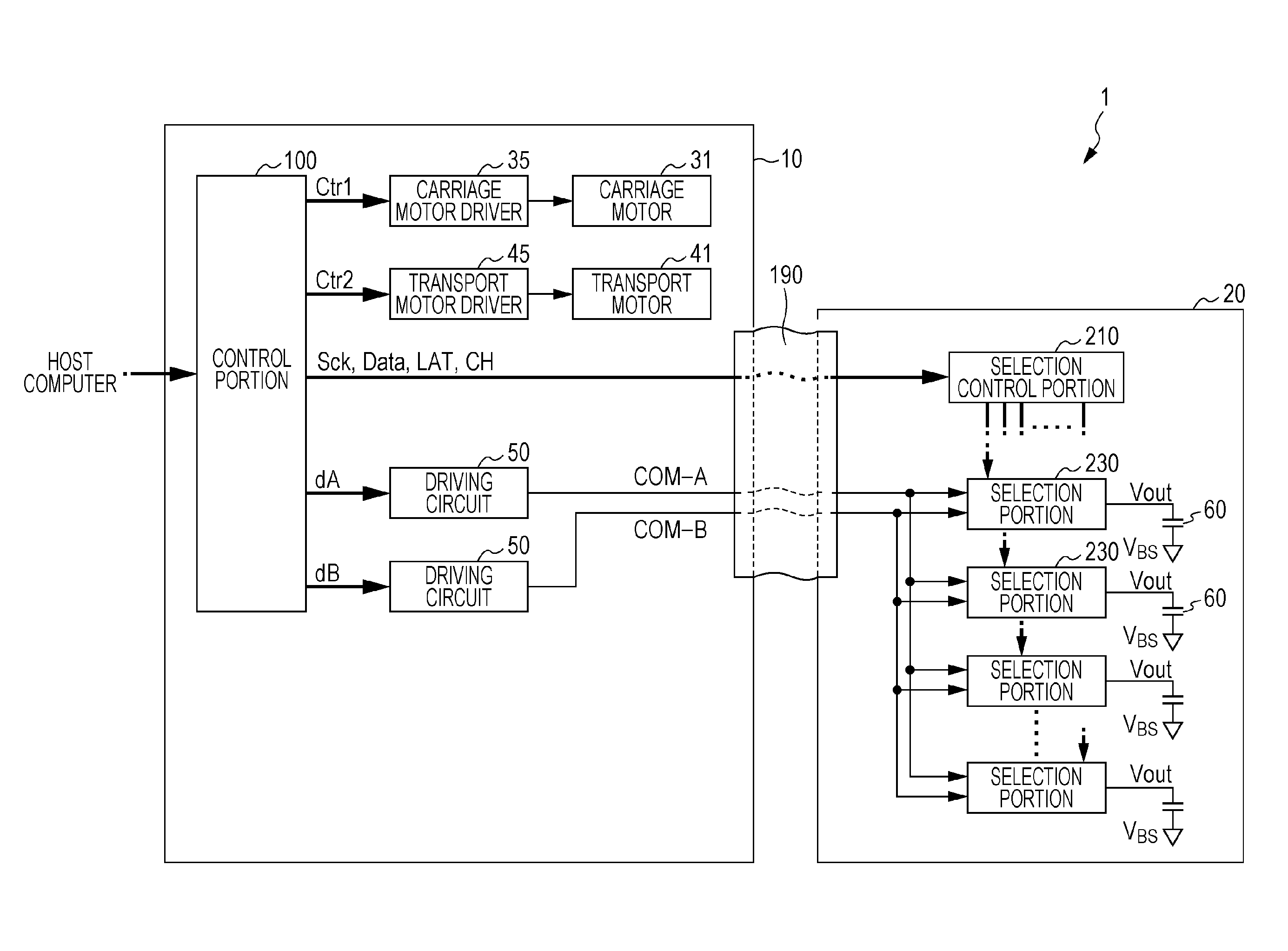

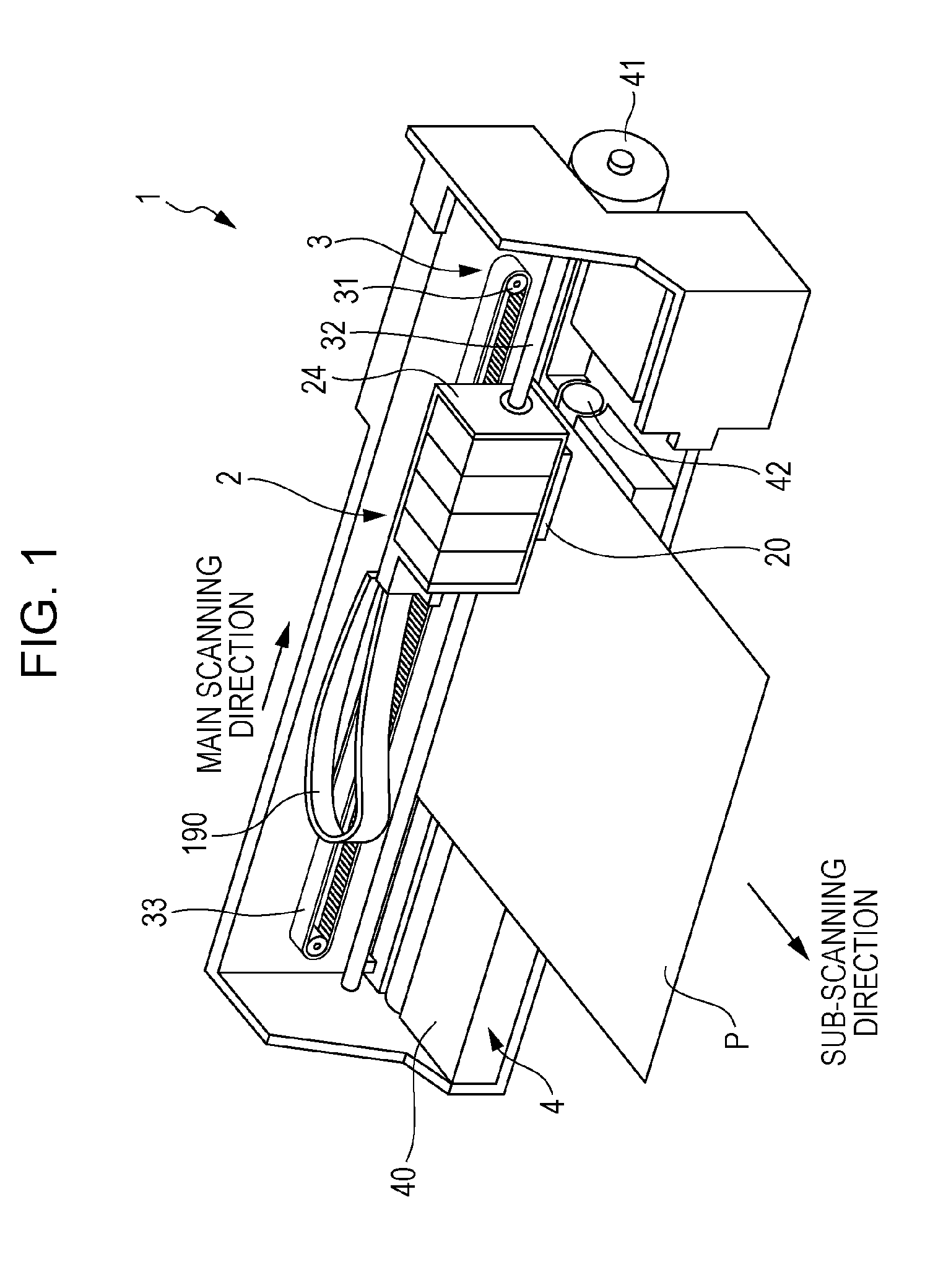

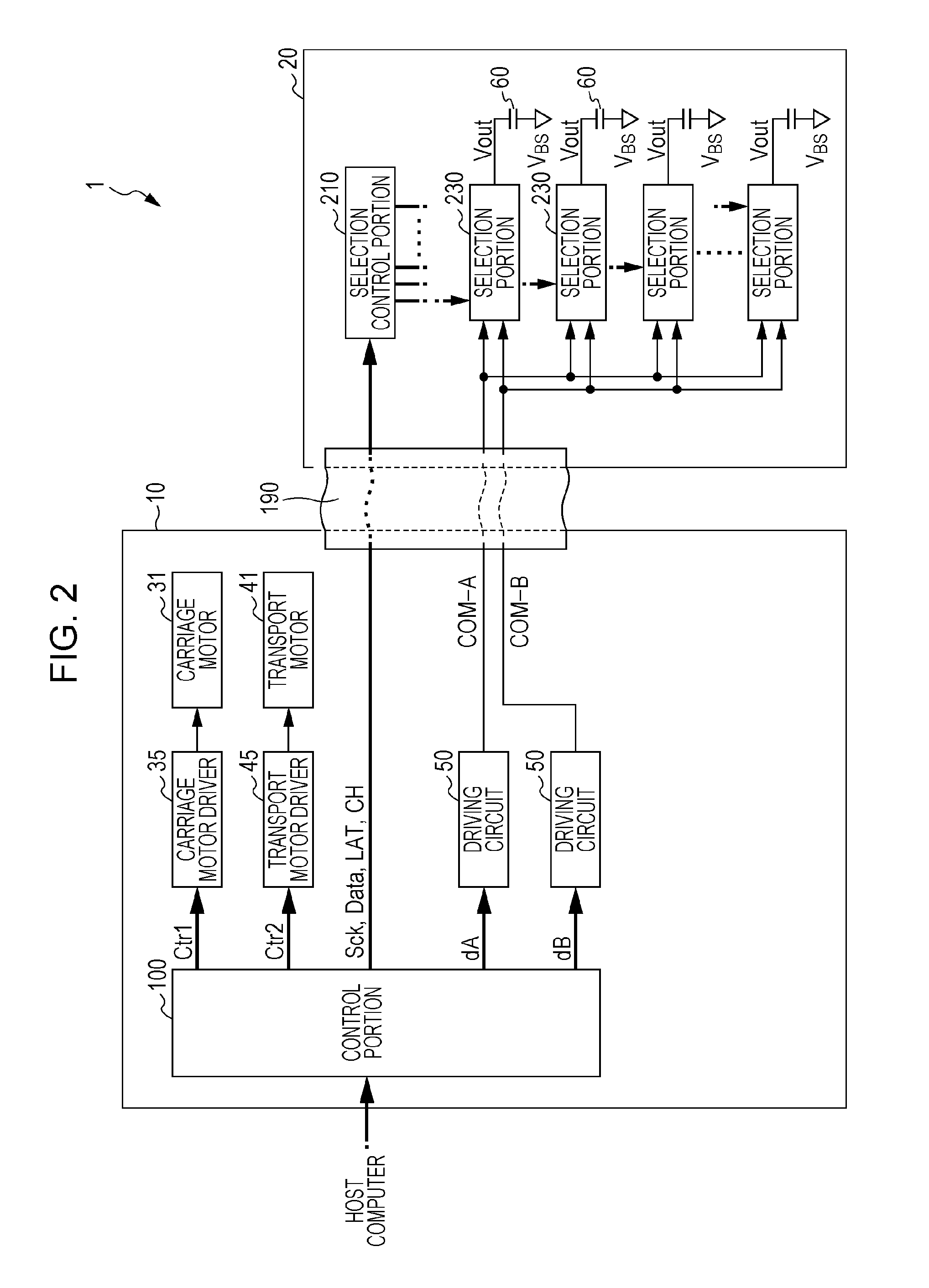

Liquid discharging apparatus, head unit, and control method of liquid discharging apparatus

ActiveUS20150246530A1High speed printingHigh-resolution printingElectronic switchingOther printing apparatusElectricityLow-pass filter

Provided is a liquid discharging apparatus which includes a modulation circuit which generates a modulation signal which is obtained by pulse-modulating a source signal, a transistor which generates an amplified modulation signal by amplifying the modulation signal, a low pass filter which generates a drive signal by smoothening the amplified modulation signal, a piezoelectric element which is displaced by receiving the drive signal, and a circuit substrate on which the transistor is mounted. The transistor includes a first electrode, a second electrode, a third electrode, and a clip which has conductivity, is electrically connected to the first electrode. Furthermore, the circuit substrate has a first land corresponding to the first electrode, a second land corresponding to the second electrode, and a third land corresponding to the third electrode. In addition, a part of the clip is connected to the third land.

Owner:SEIKO EPSON CORP

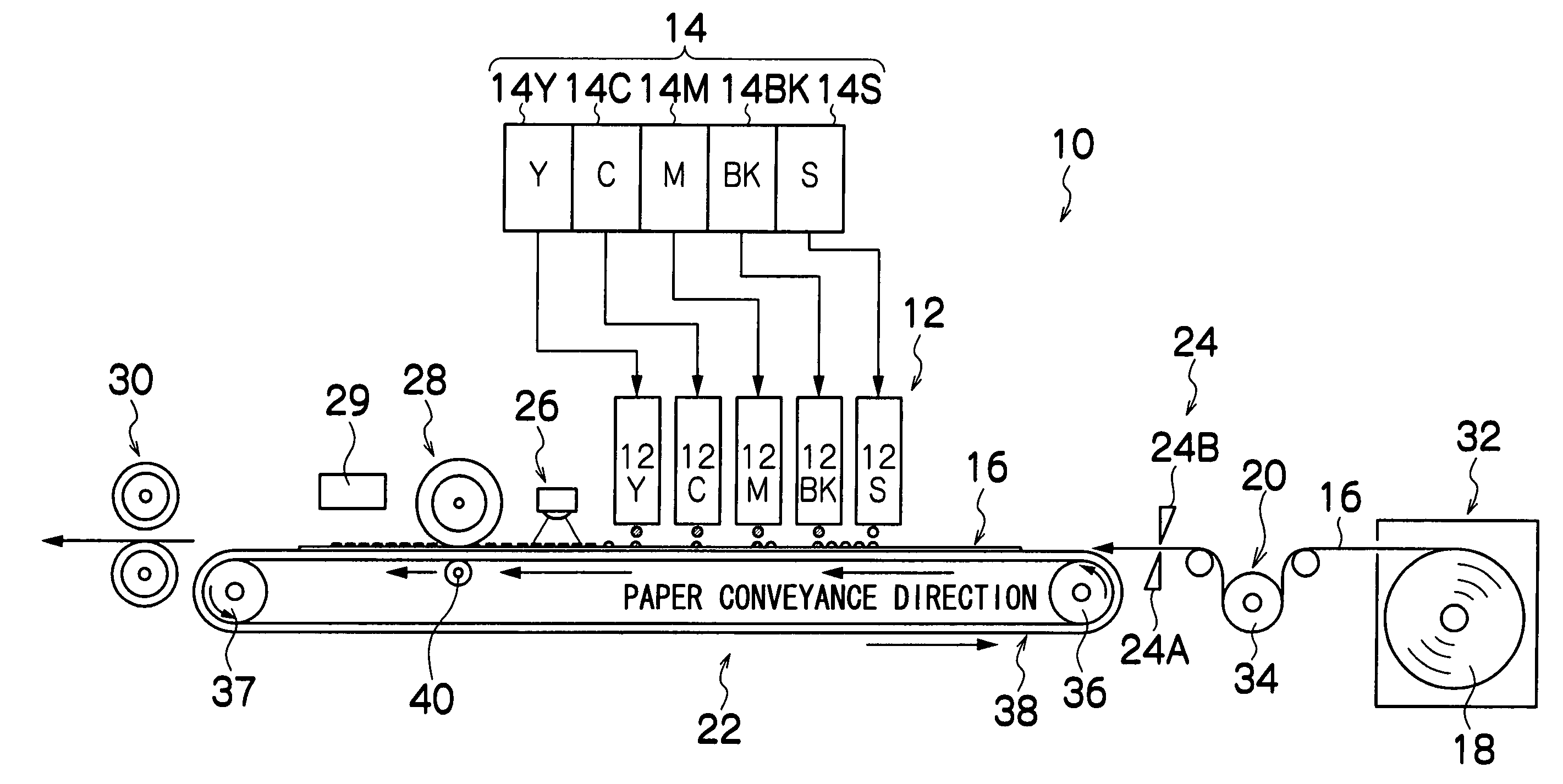

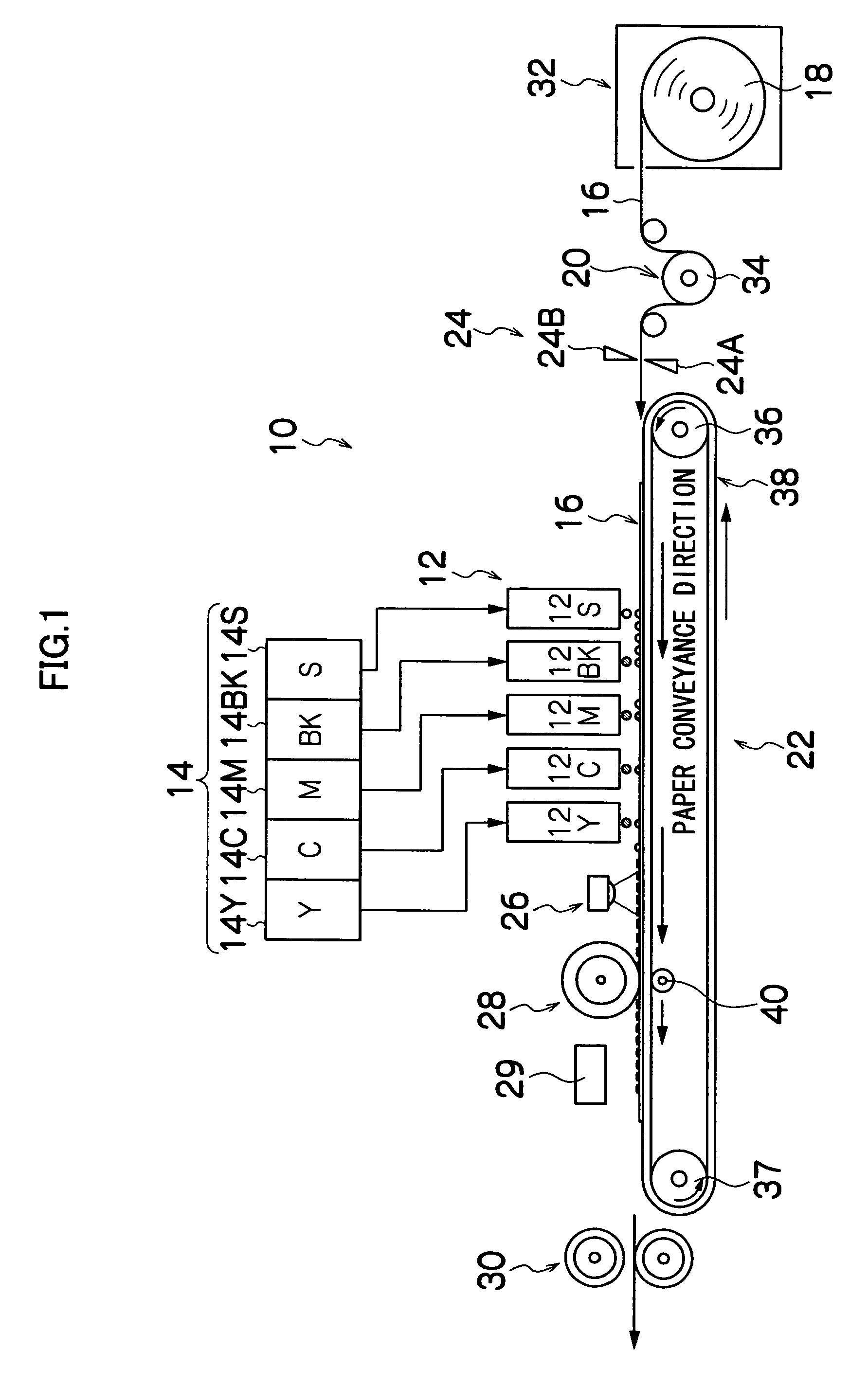

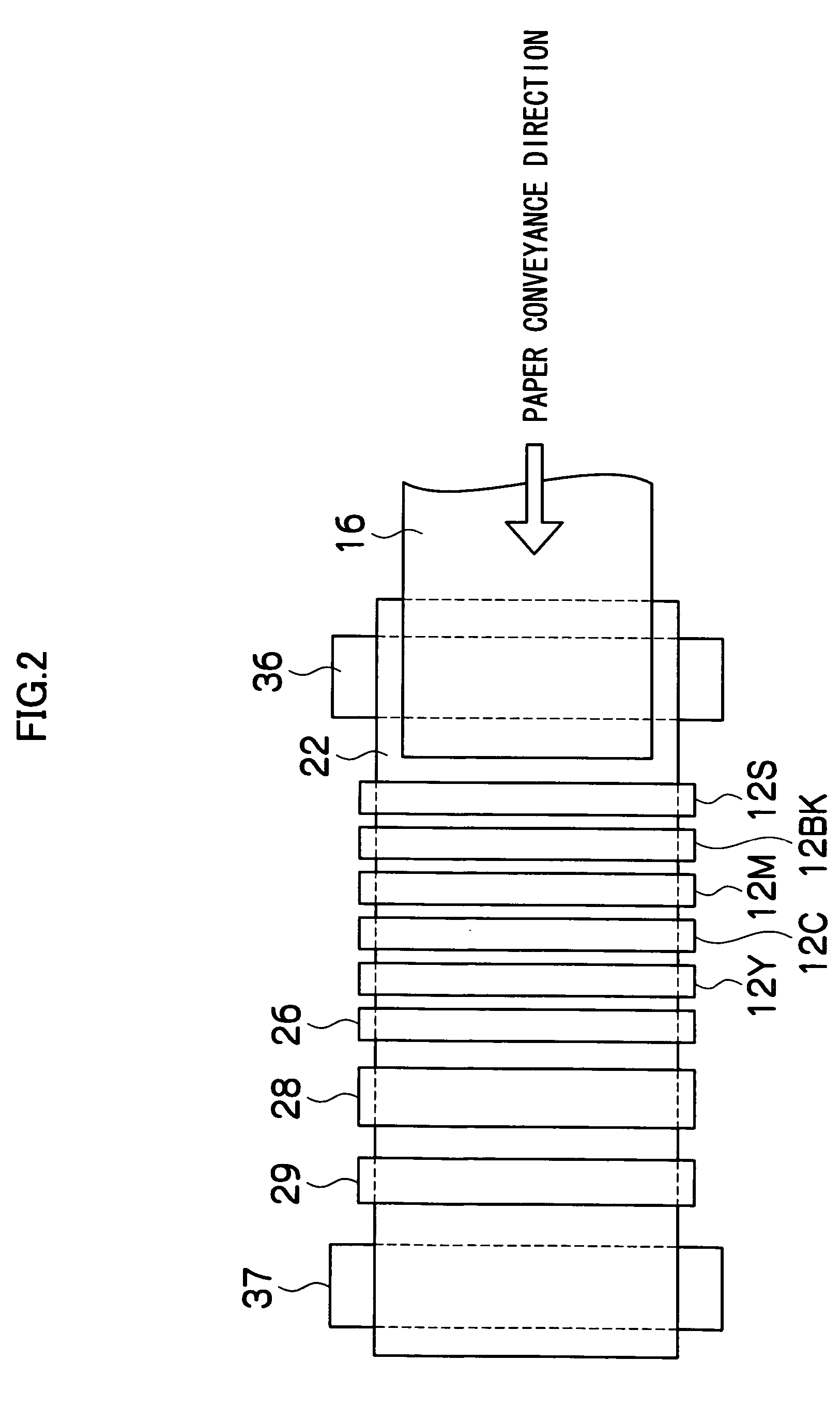

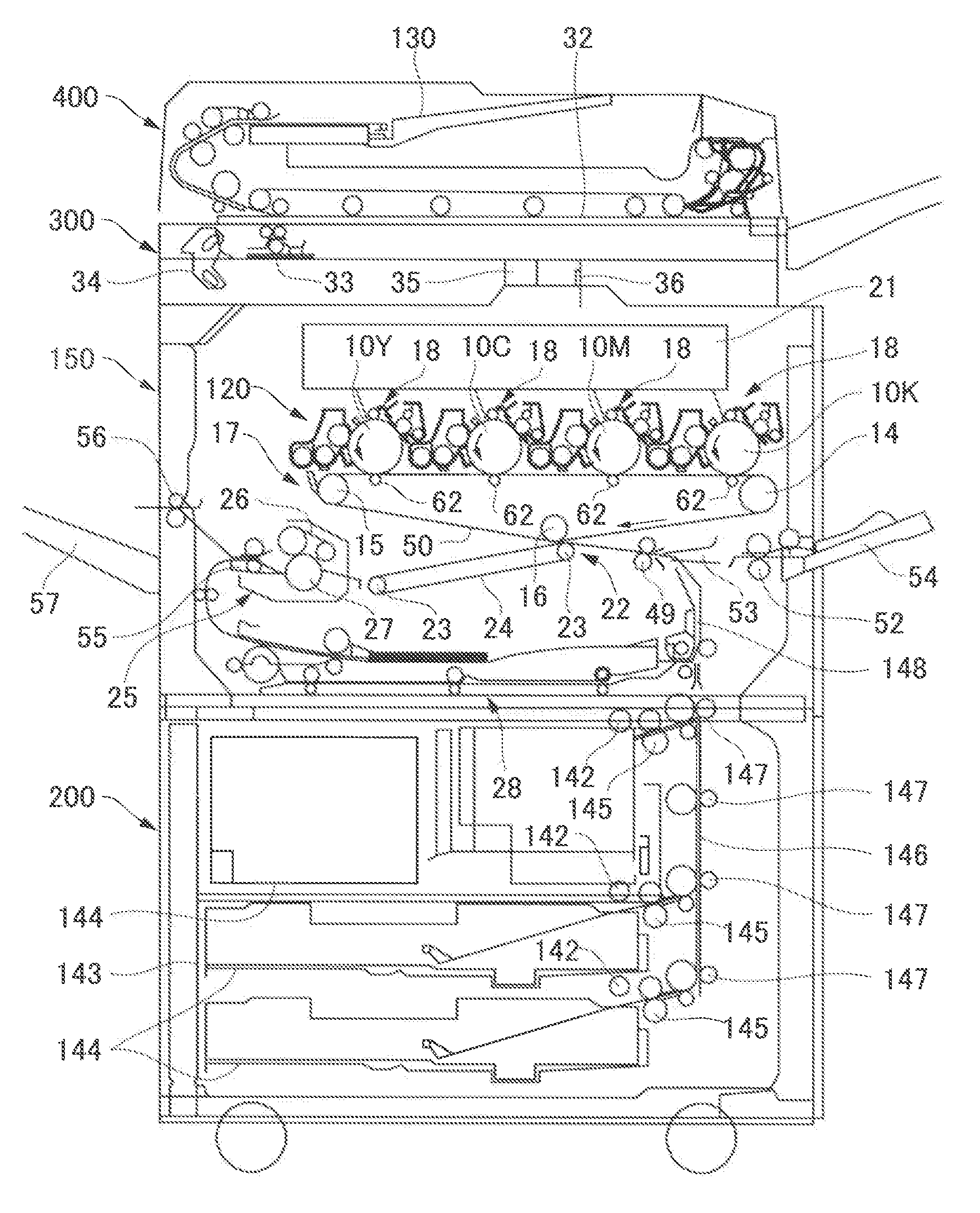

Image formation apparatus

InactiveUS20070097163A1Stably carry-outIncrease speedInking apparatusOther printing apparatusImage formationEngineering

An image formation apparatus is disclosed, wherein a time interval between a first ink drop and a second ink drop is set at 1.5×Tc, a time interval between the second ink drop and a third ink drop is set at 1.5×Tc, and a time interval between the third ink drop and a fourth ink drop is set at 2×Tc, where Tc represents the specific vibration cycle of a pressurized ink chamber.

Owner:RICOH KK

Pigment dispersion and recording ink, and ink cartridge, ink jet recording method, and ink jet recording device

InactiveCN101360799AHigh image densityHigh color saturationDuplicating/marking methodsInksWater dispersiblePolymer science

A pigment dispersion is provided that comprises a pigment, a pigment dispersant, a polymer dispersion stabilizer and water, wherein the polymer dispersion stabilizer is an alpha-olefin / maleic anhydride copolymer expressed by the formula (1) below. A recording ink is also provided that comprises the pigment dispersion, a surfactant, a water-dispersible resin, a humectant and water. in the structural formula (1), R represents an alkyl group and n is an integer of 30 to 100.

Owner:RICOH KK

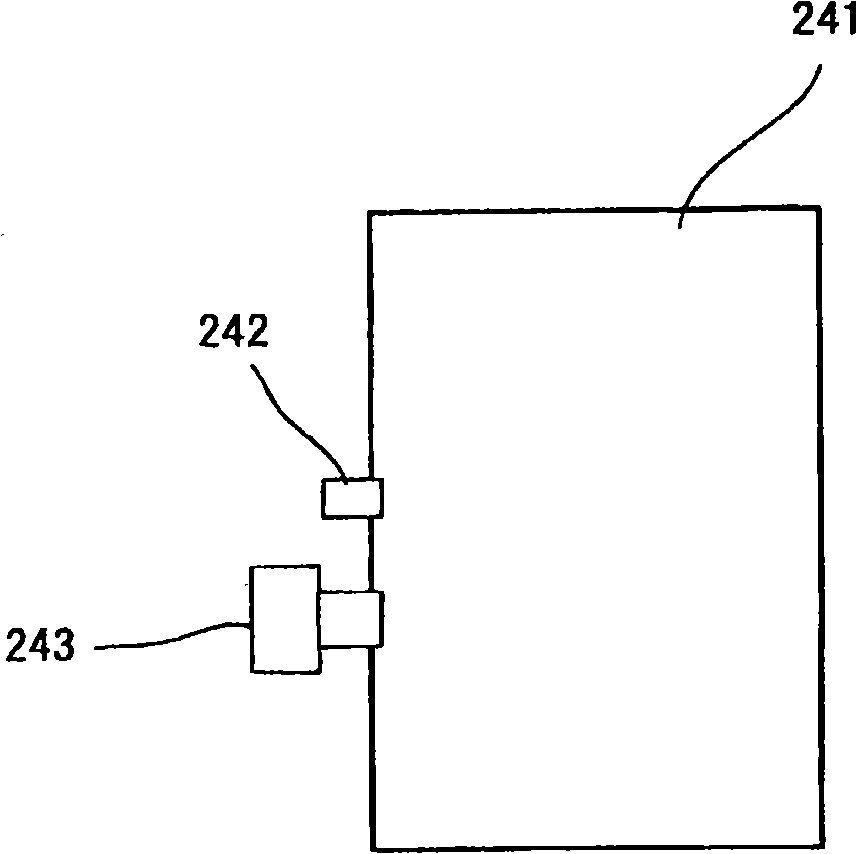

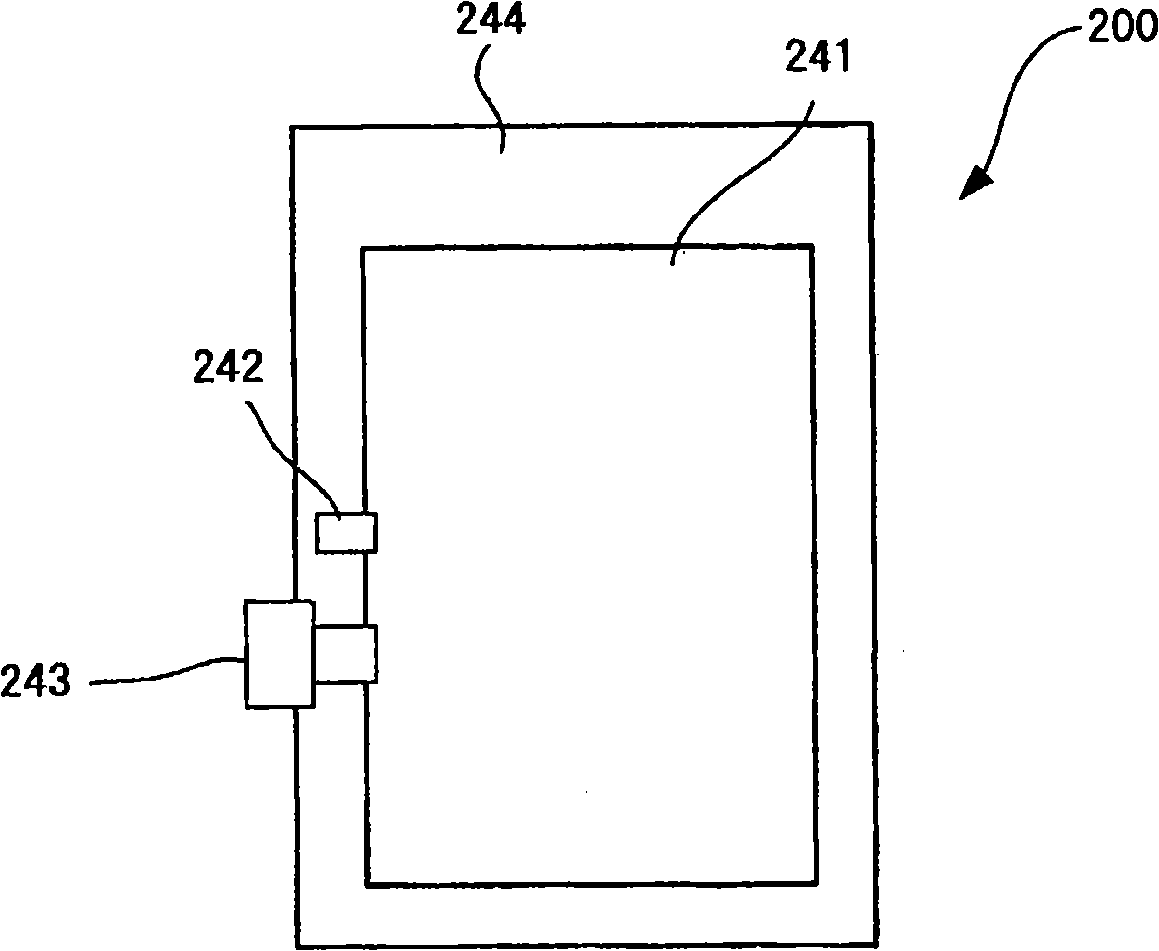

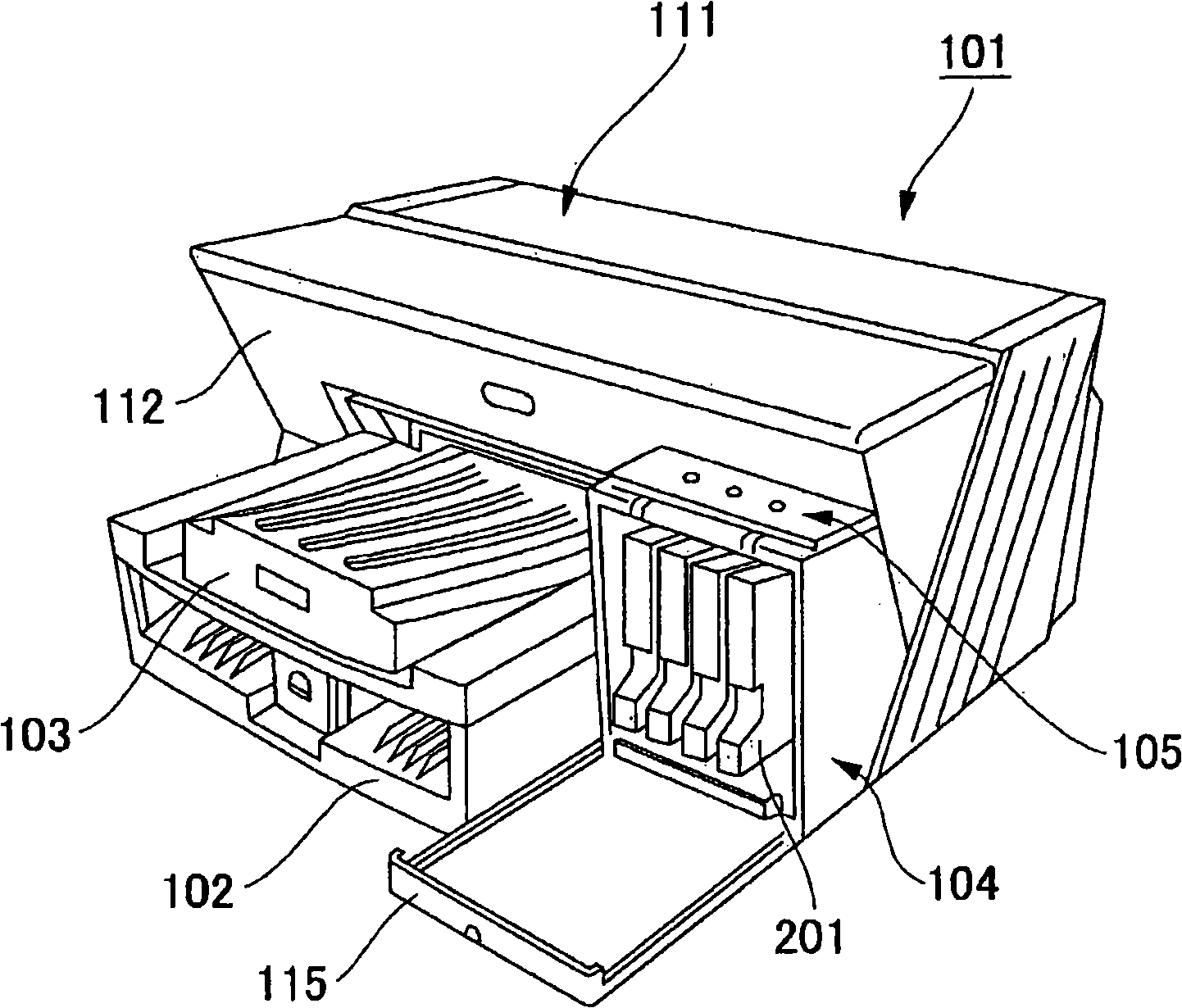

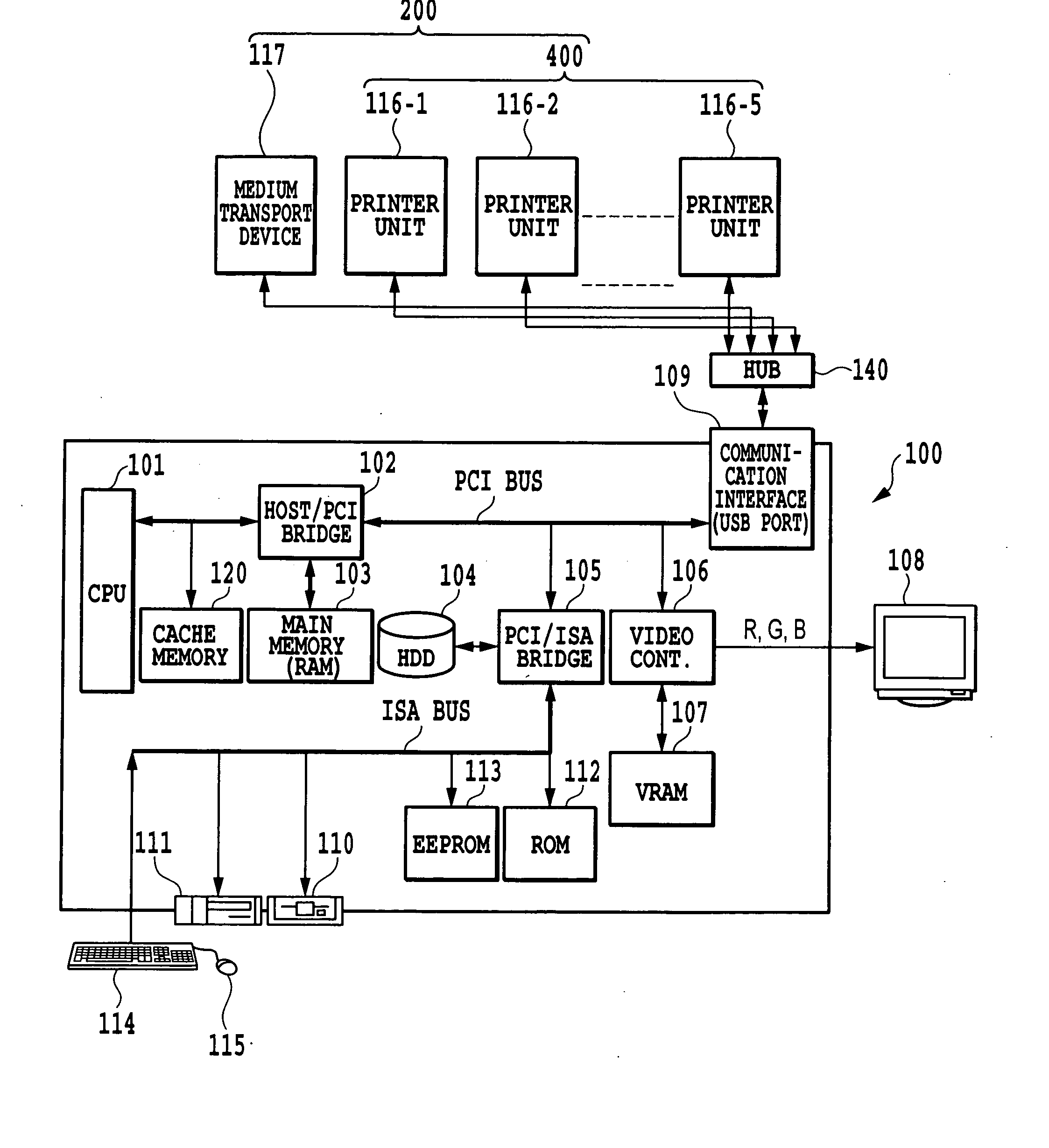

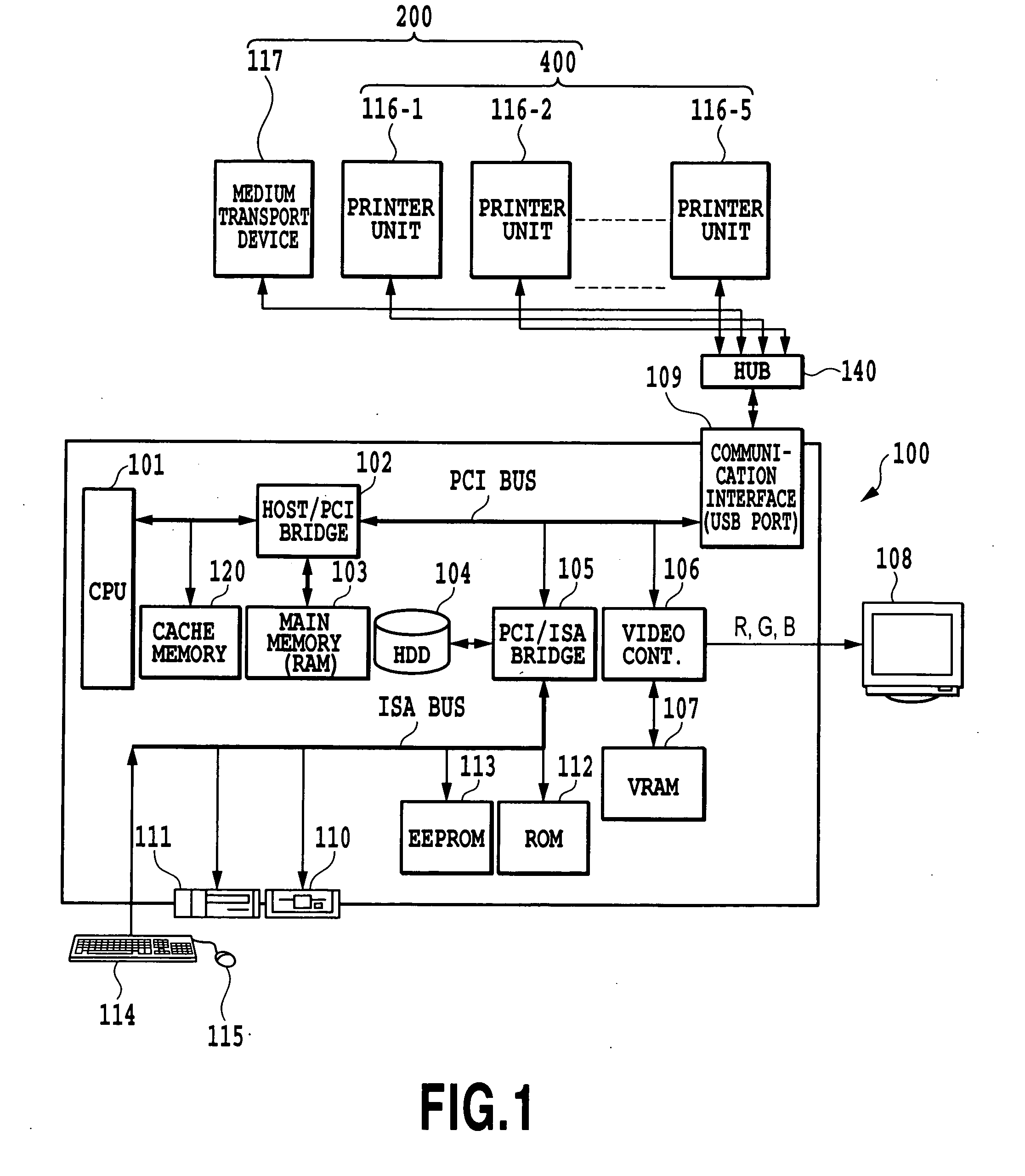

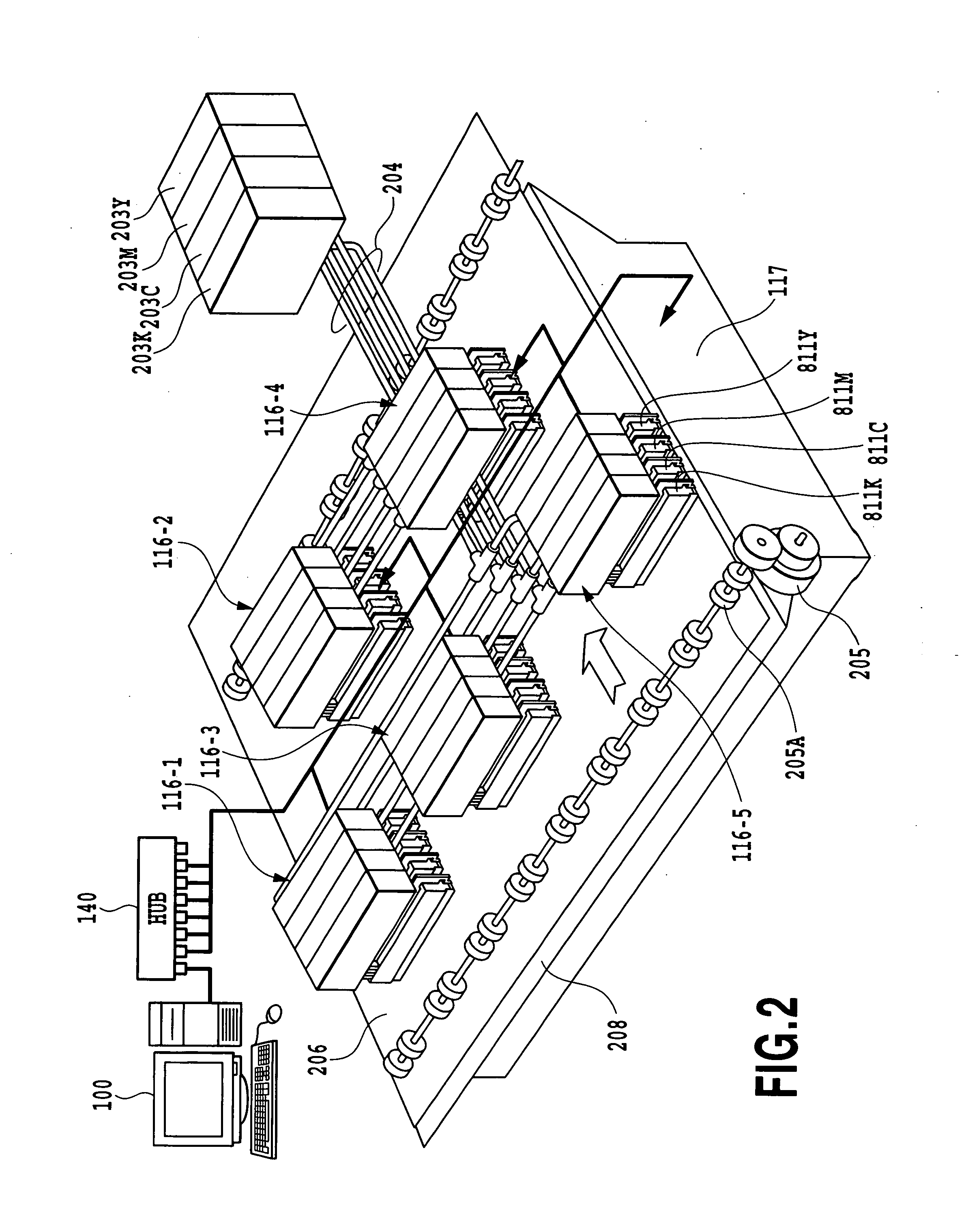

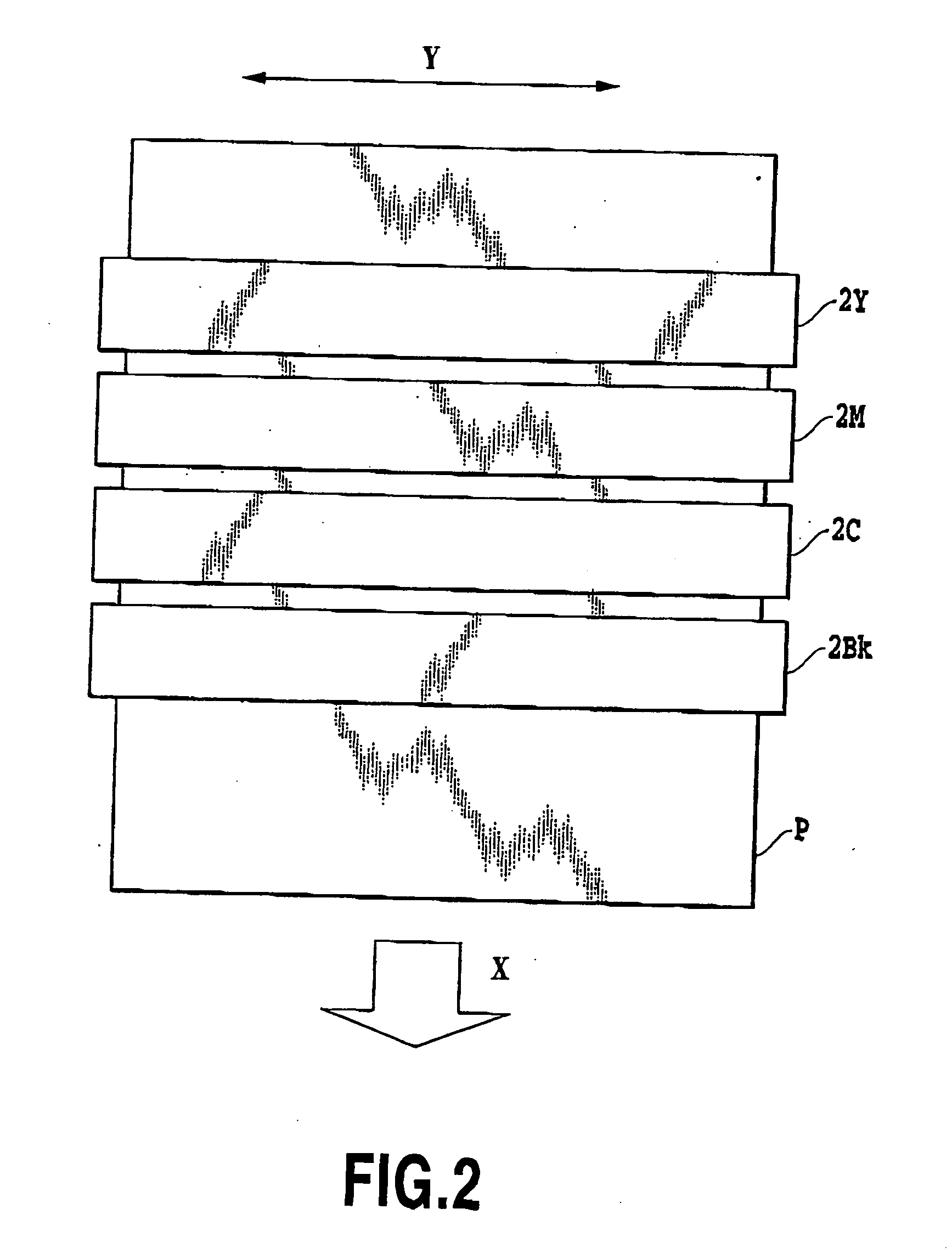

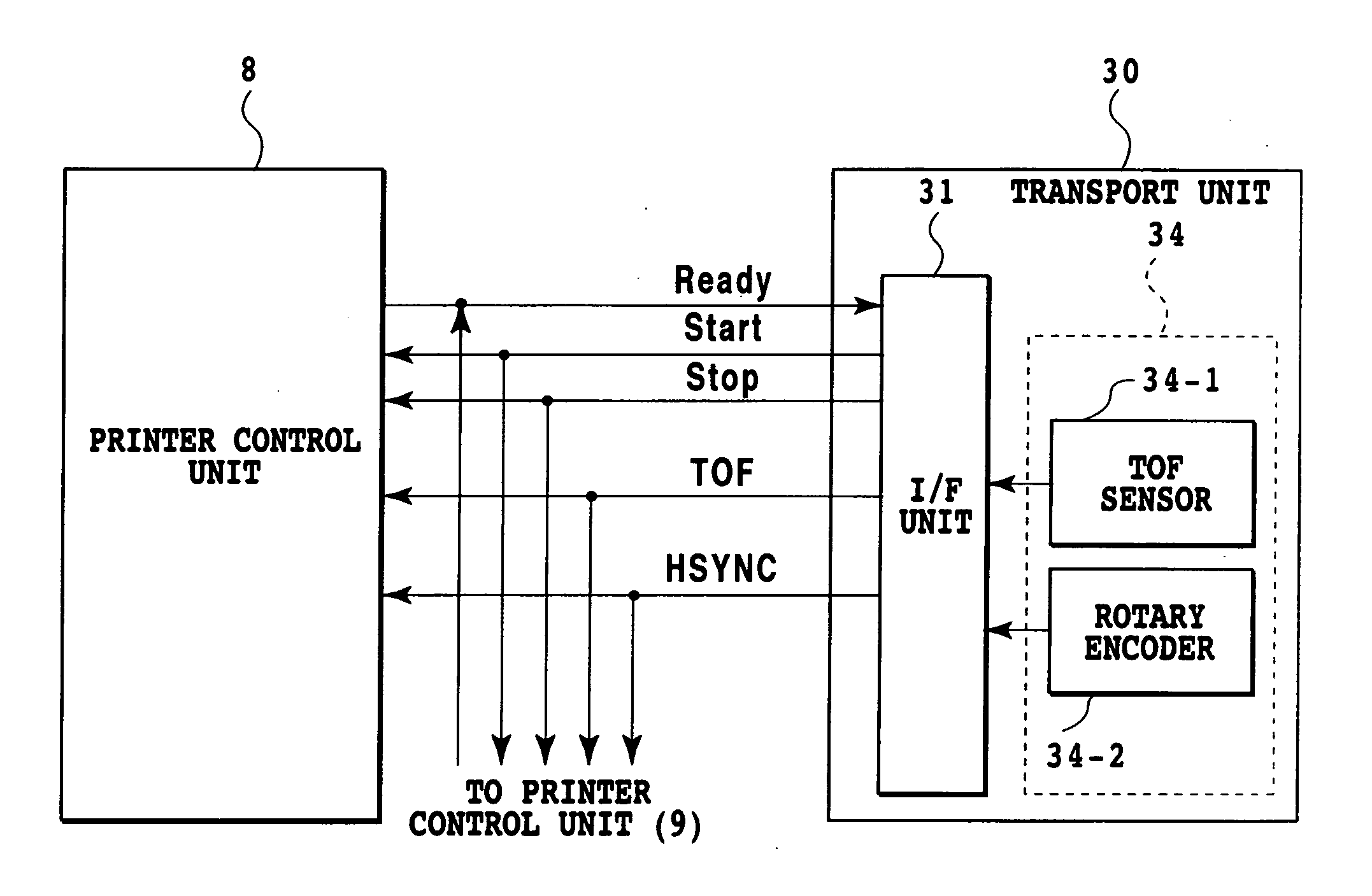

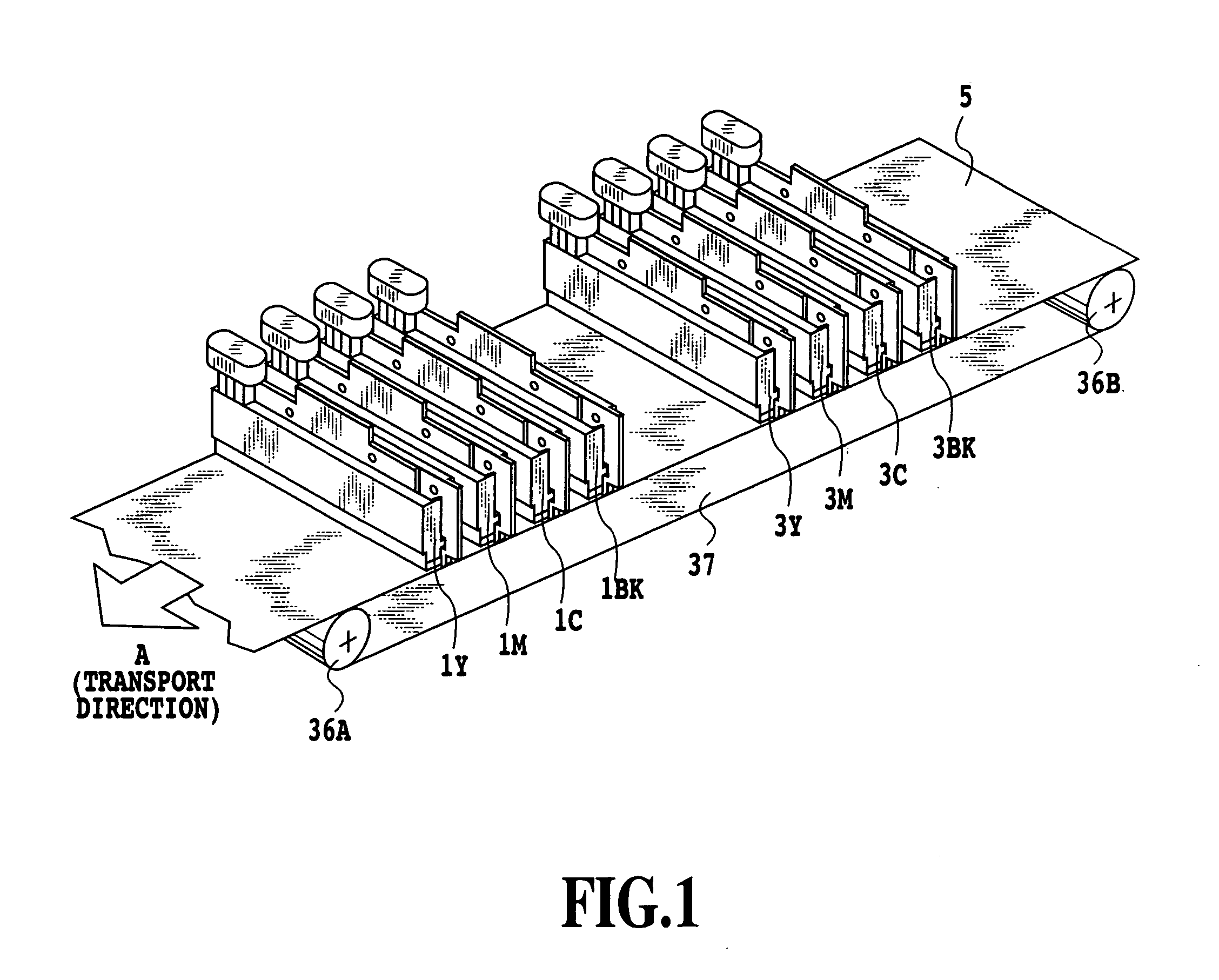

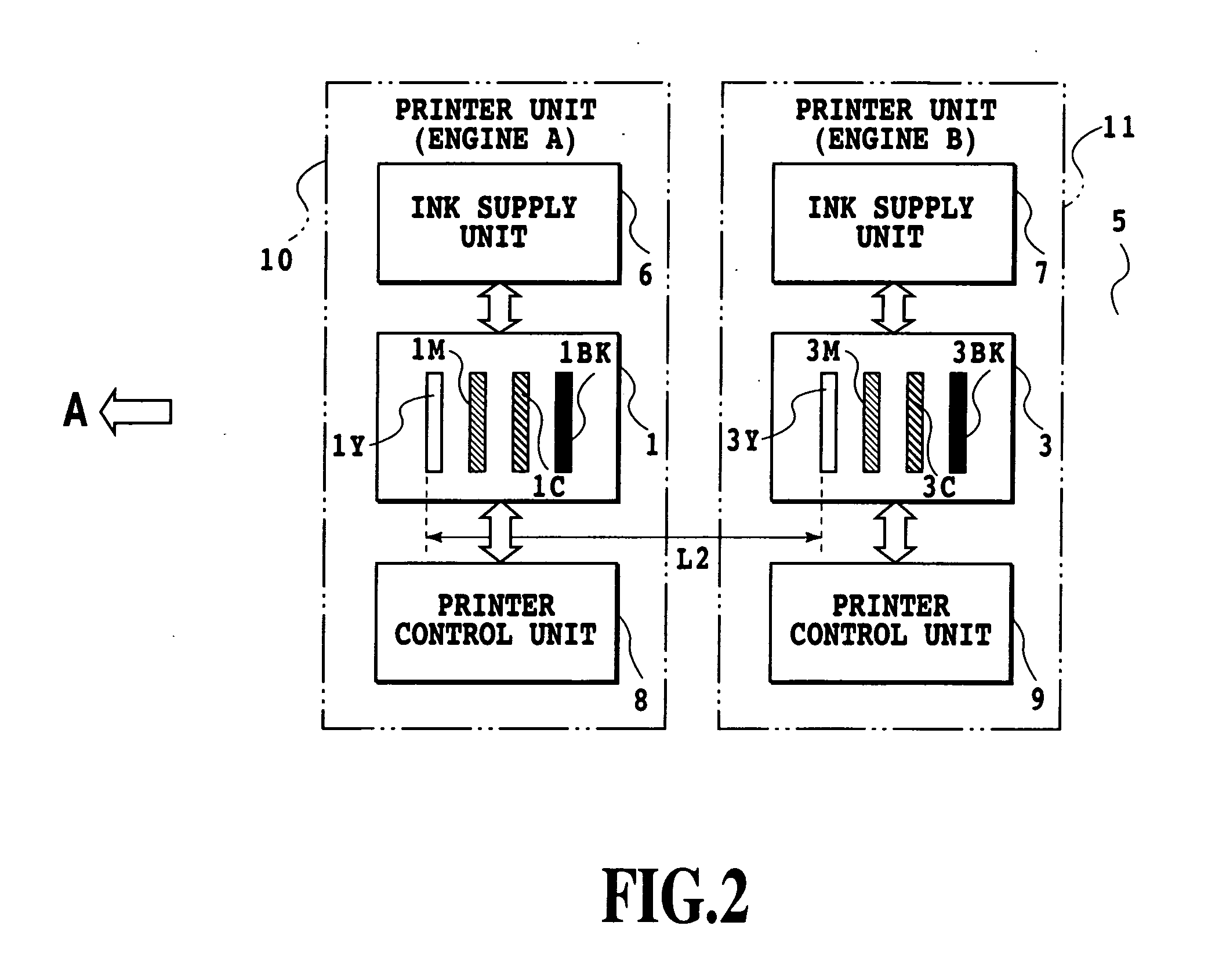

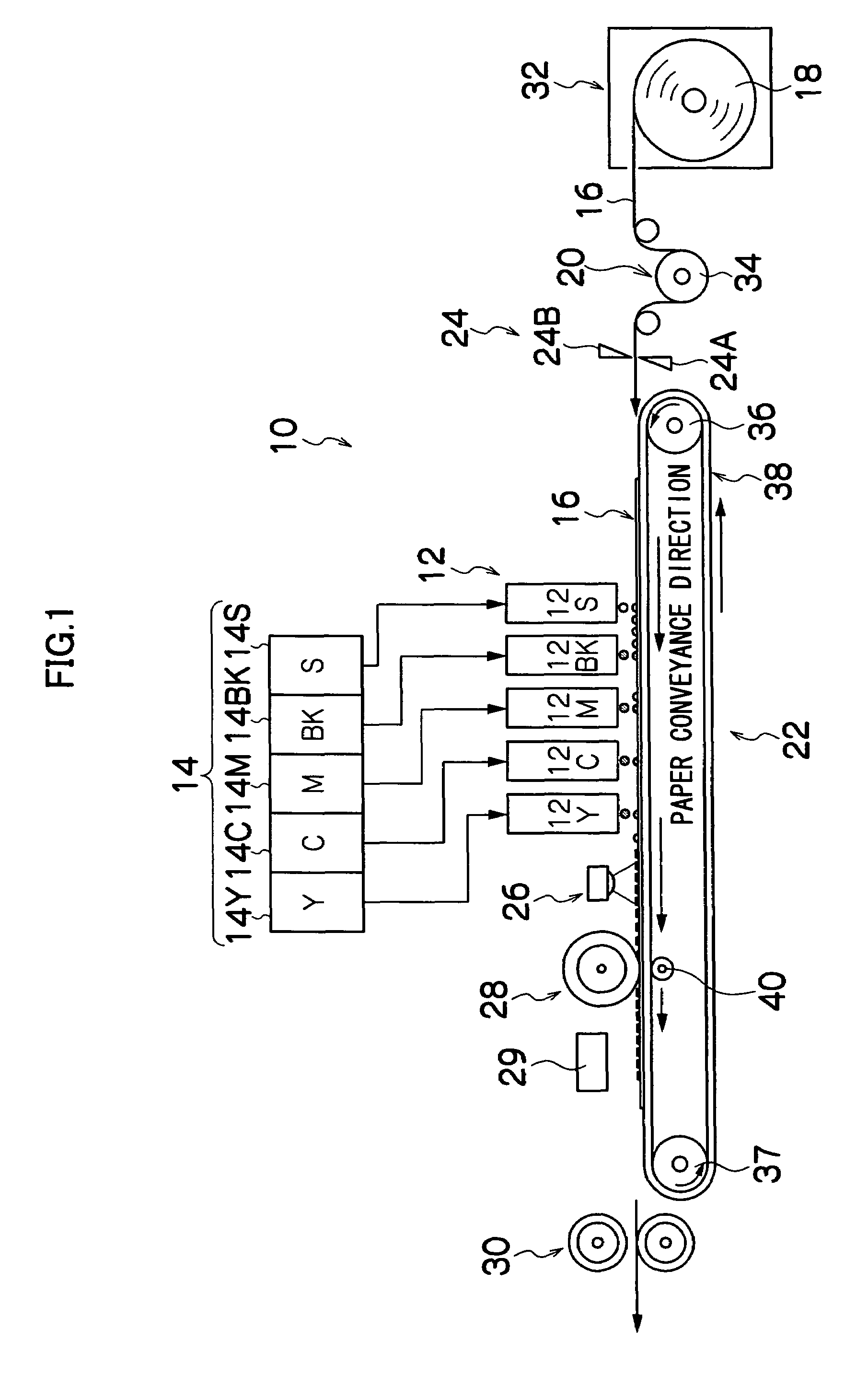

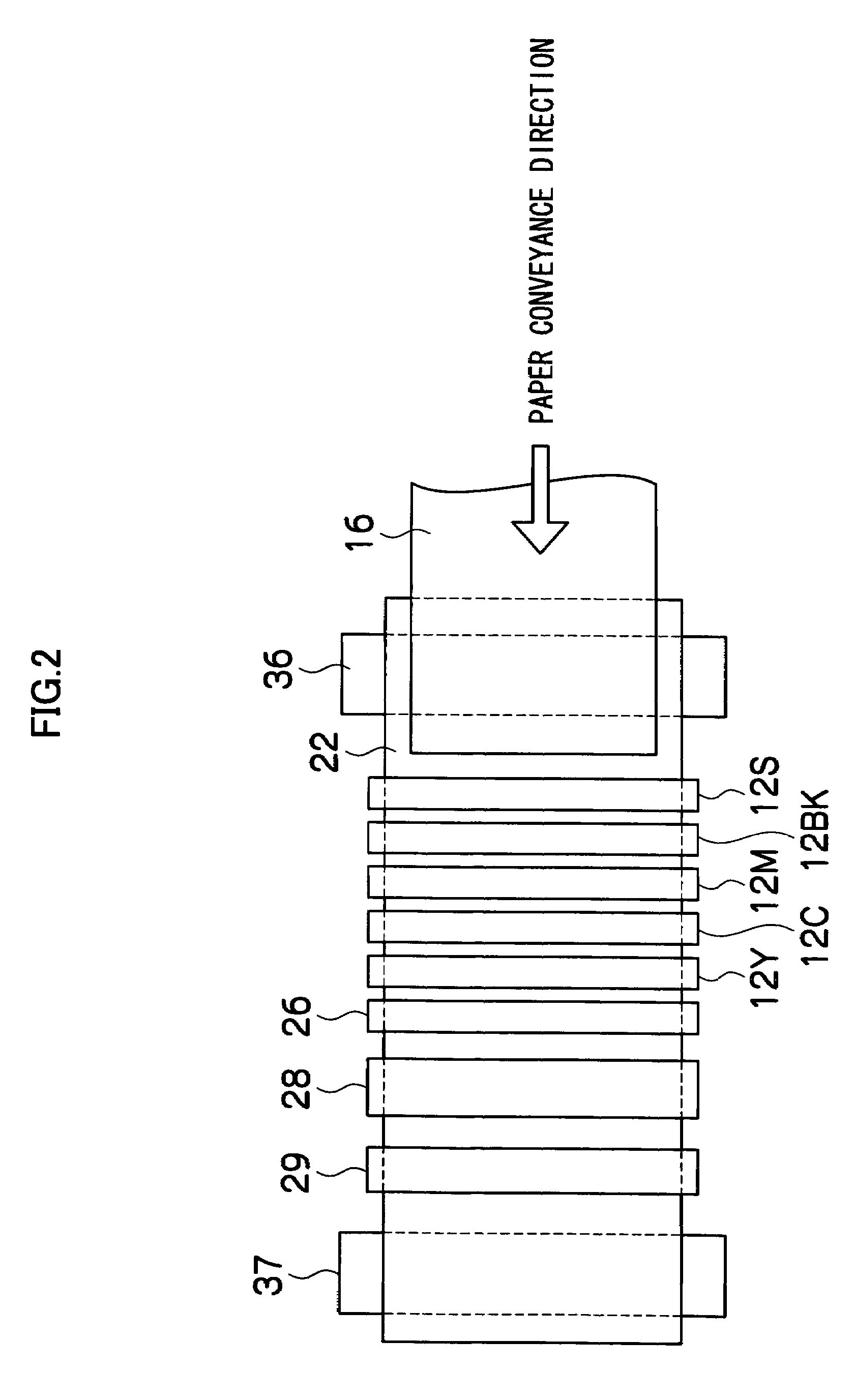

Image Forming Device, Printer Complex System and Medium Conveying Device for the Device, Information Processing Unit for Supplying Image Data to the Image Forming Device, and Image Forming System and Image Forming Method Provided with These

InactiveUS20070263244A1Quickly and easily copeFast printingTypewritersOther printing apparatusImage segmentationEngineering

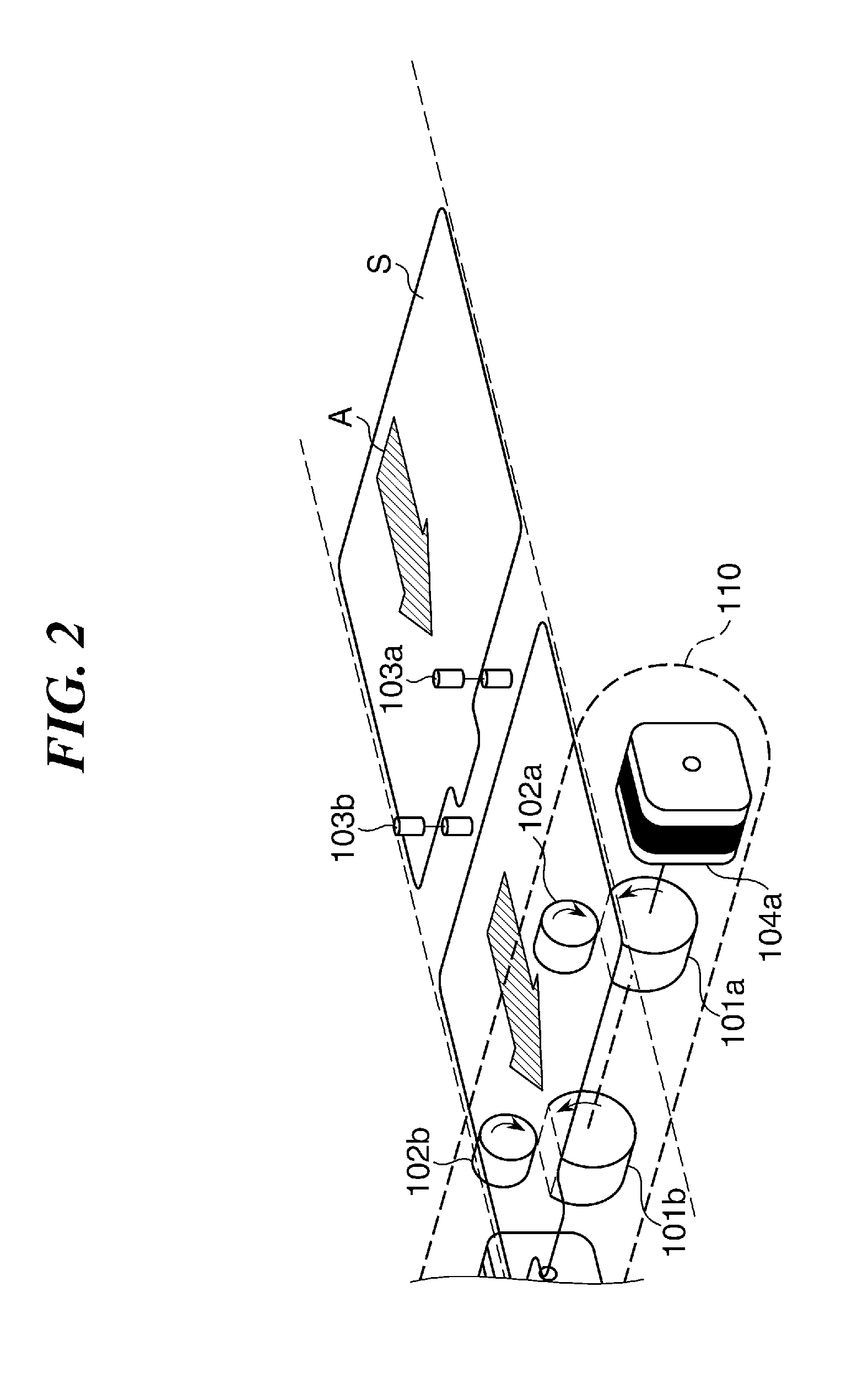

To meet a demand for changing a print medium size, particularly for increasing the size of print medium while at the same time satisfying the demand for higher printing speed. To that end, a plurality of printer units (116), which are spatially independent of each other (separate from each other) and also independent in the signal system and the ink system, are arranged in an appropriate layout to allow for a line-sequential printing. An information processing device (100) divides a generated image into a plurality of pieces of print data and transfers them to the plurality of printer units. A transport device (117) is installed to feed a large-sized print medium to an area where the plurality of printer units are arranged. The transport device transfers to each of the plurality of printer units a print timing signal corresponding to the position of each printer unit.

Owner:COPYER

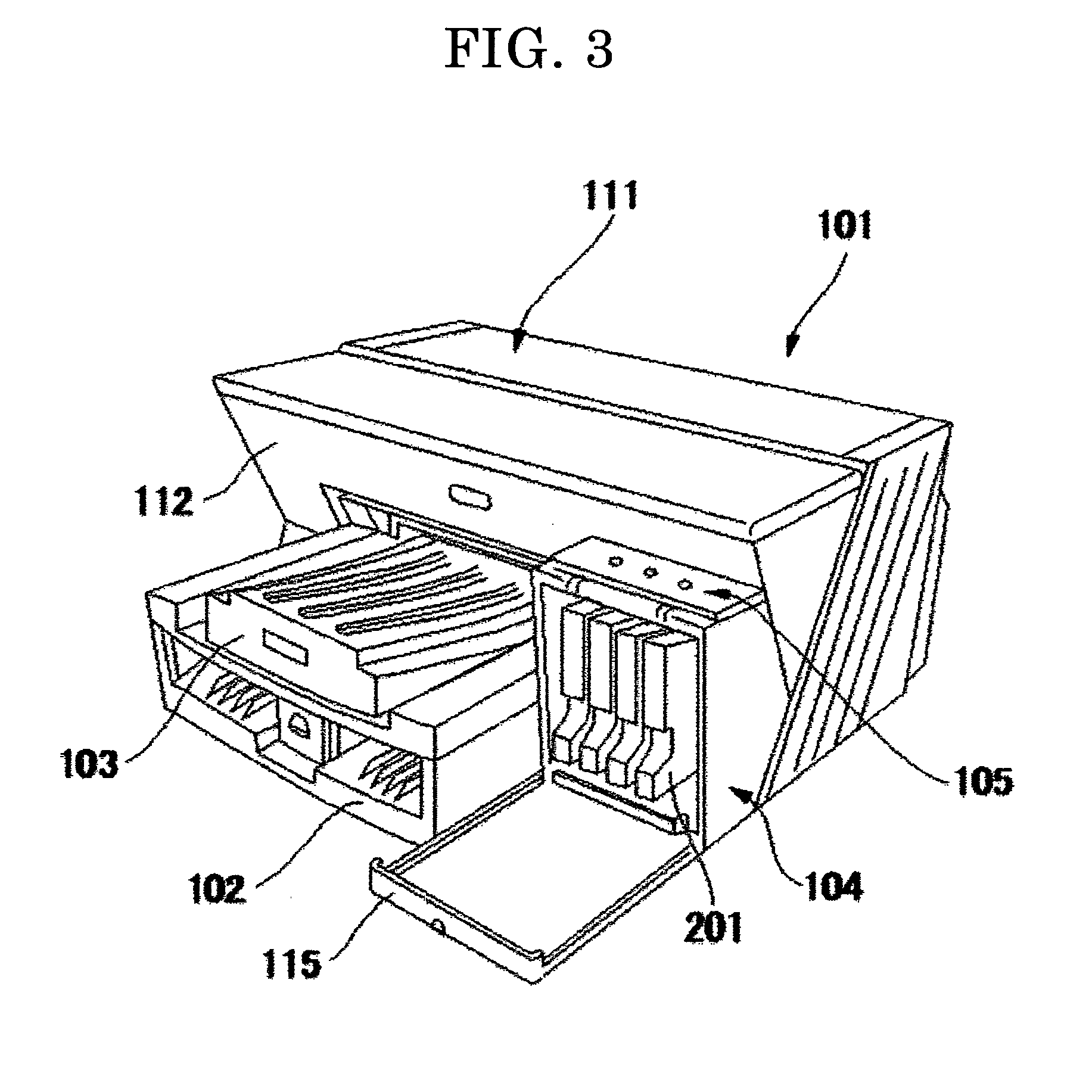

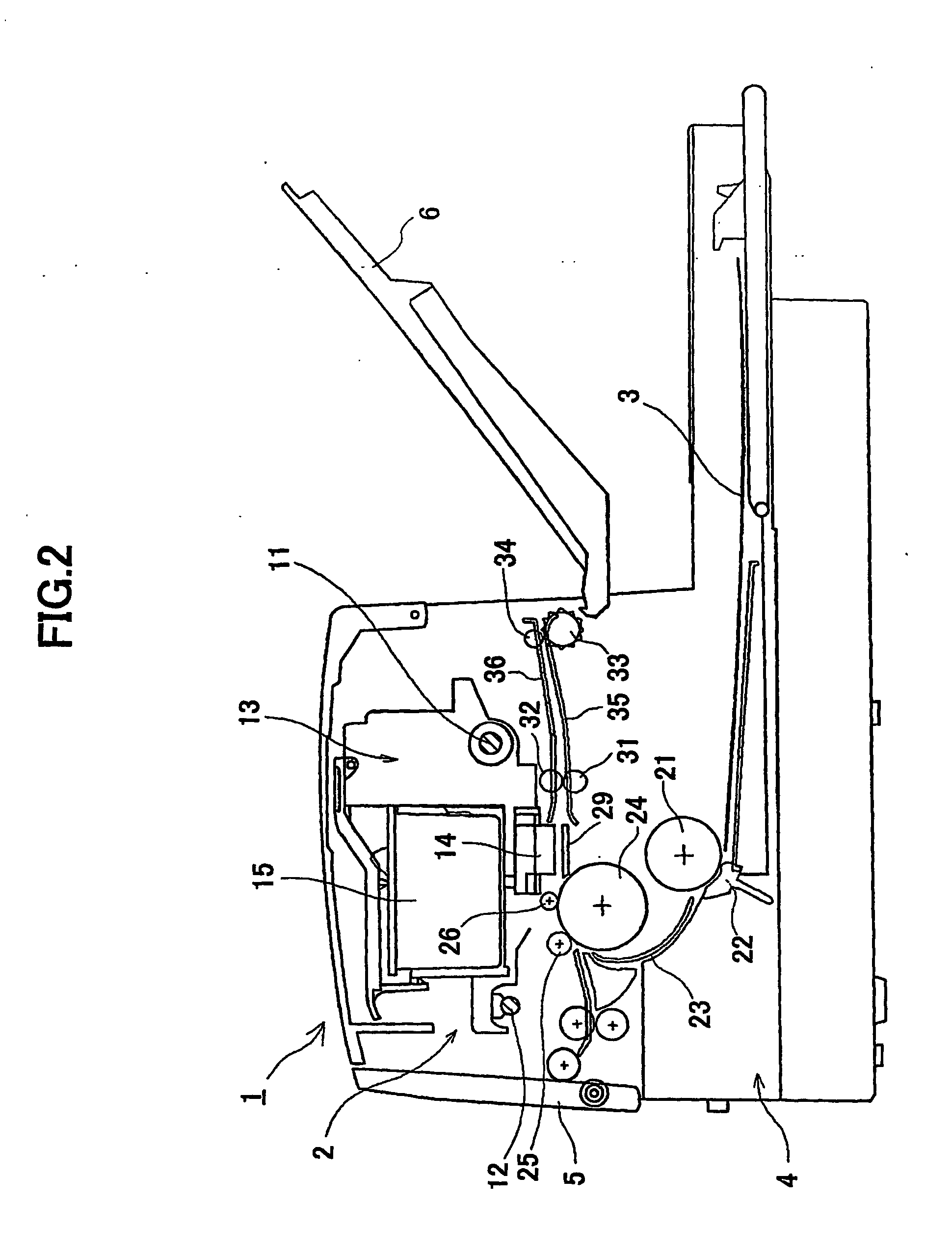

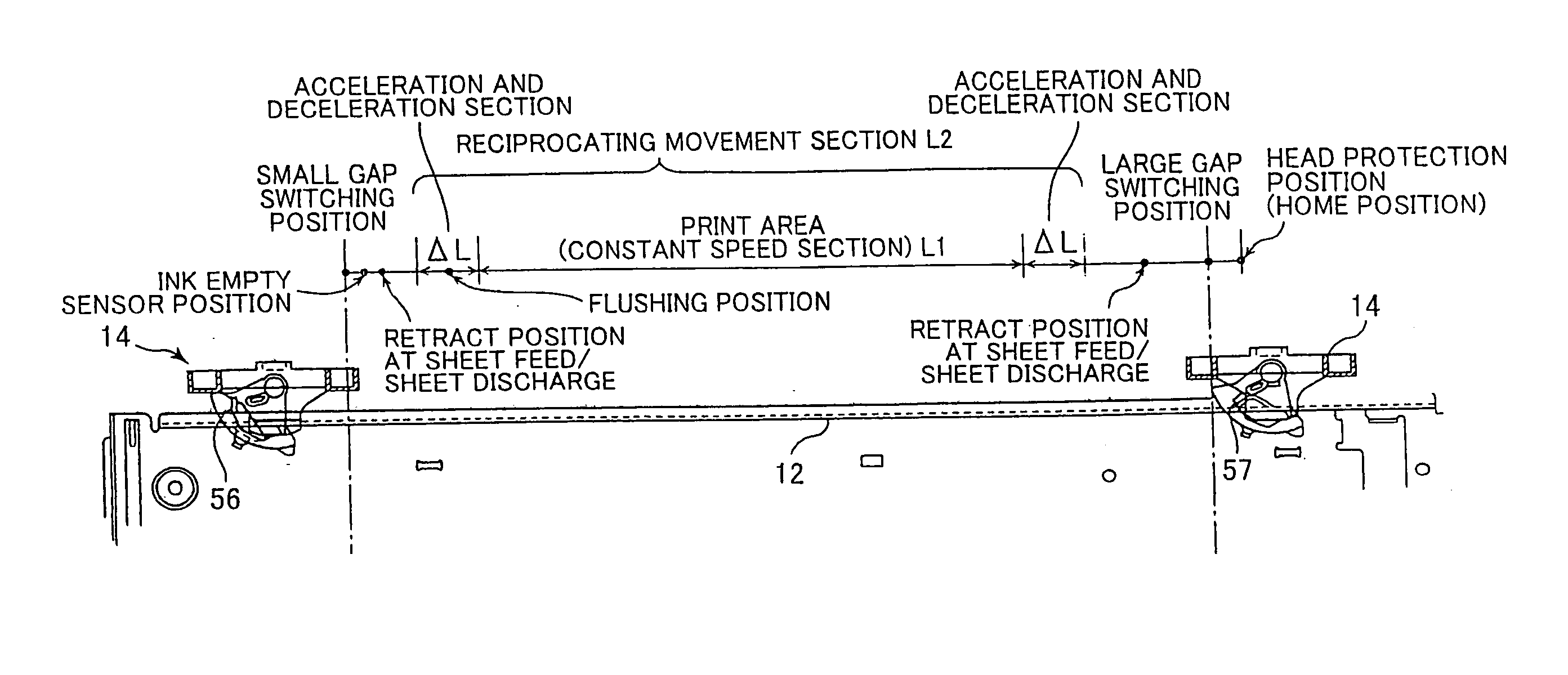

Image forming apparatus

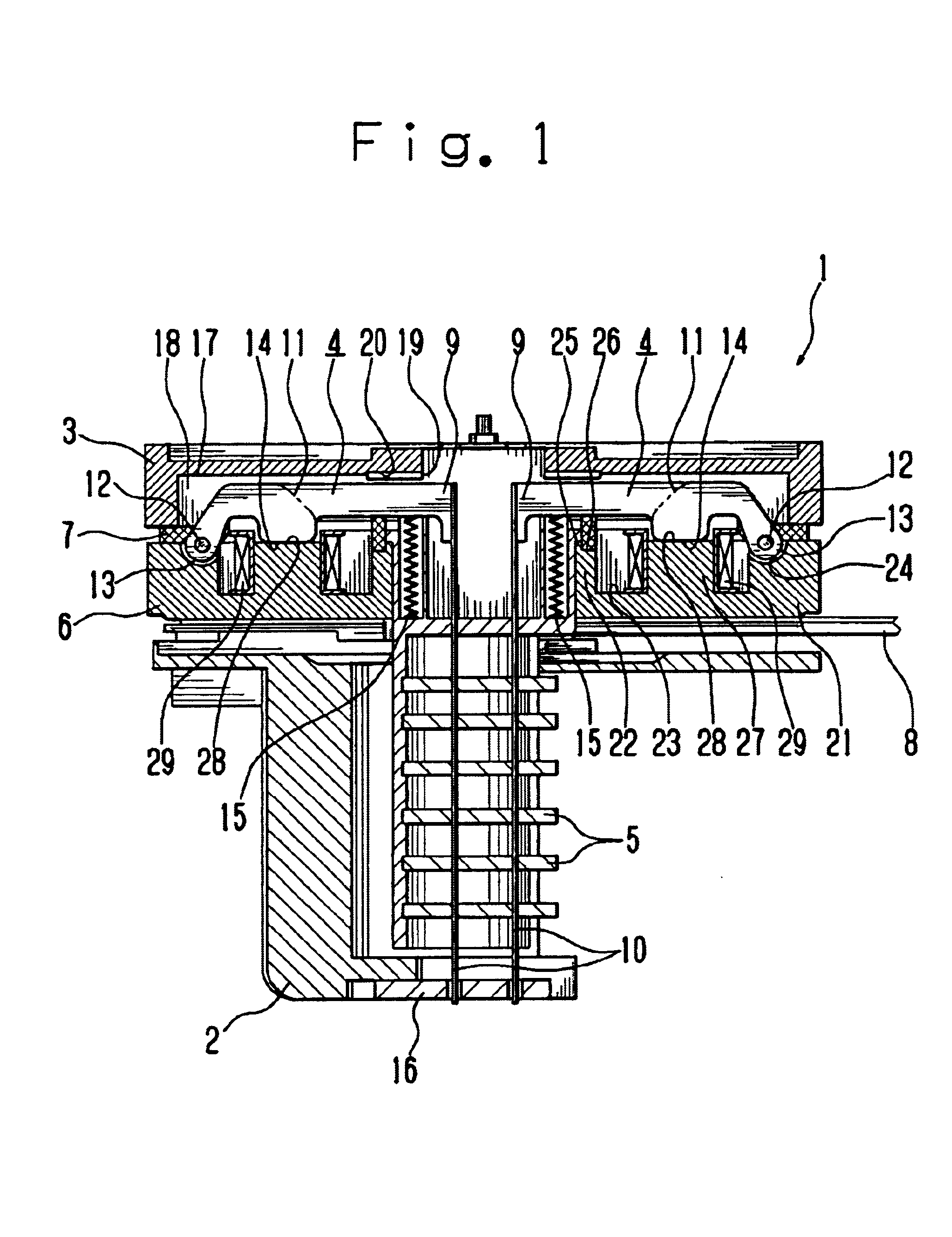

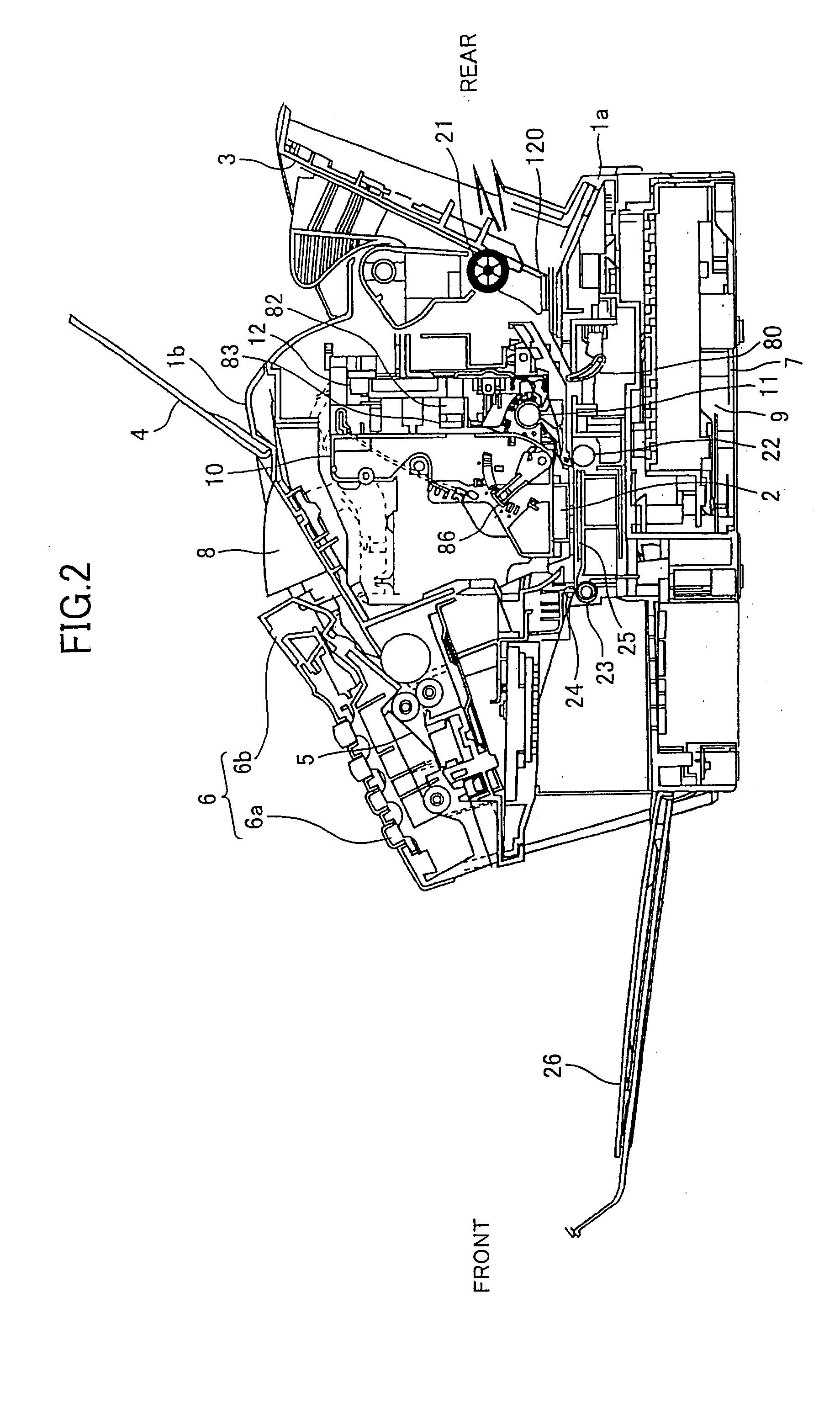

ActiveUS20050152726A1Reduce timeHigh-speed printingPower drive mechanismsOther printing apparatusRecording headEngineering

At a predetermined position during the lateral movement of a carriage 10, a gap switching mechanism 30 for switching a gap between a recording head 15 and a recording medium is provided. The recording head 15 is mounted facing downward on the carriage 10. A part close to one side on a lower end of the carriage is slidably and pivotably supported by a guide shaft 11 of a round shaft shape. A switching block member 13 provided with several abutment portions 52 and 53 with different heights, which are positioned so as to be opposed to a slide portion 12a at an upper end of a frame 12 extending in a vertical direction along a back of the carriage. The A switching block member 13 is pivotably supported by the carriage. A first pushing portion 56 is located at a left end of the frame so as to abut against the switching block member 13. A pivotal posture of the first pushing portion is changed due to the abutment to bring the abutment portion 53 into a slide contact relationship with the frame 12, so that a small gap is provided. A second pushing portion 57 is located at a right end of the frame so as to abut against the switching block member 13, a pivotal posture of the first pushing portion is changed according to the abutment to bring the abutment portion 52 into a slide contact relationship with the frame 12, so that a large gap is provided.

Owner:BROTHER KOGYO KK

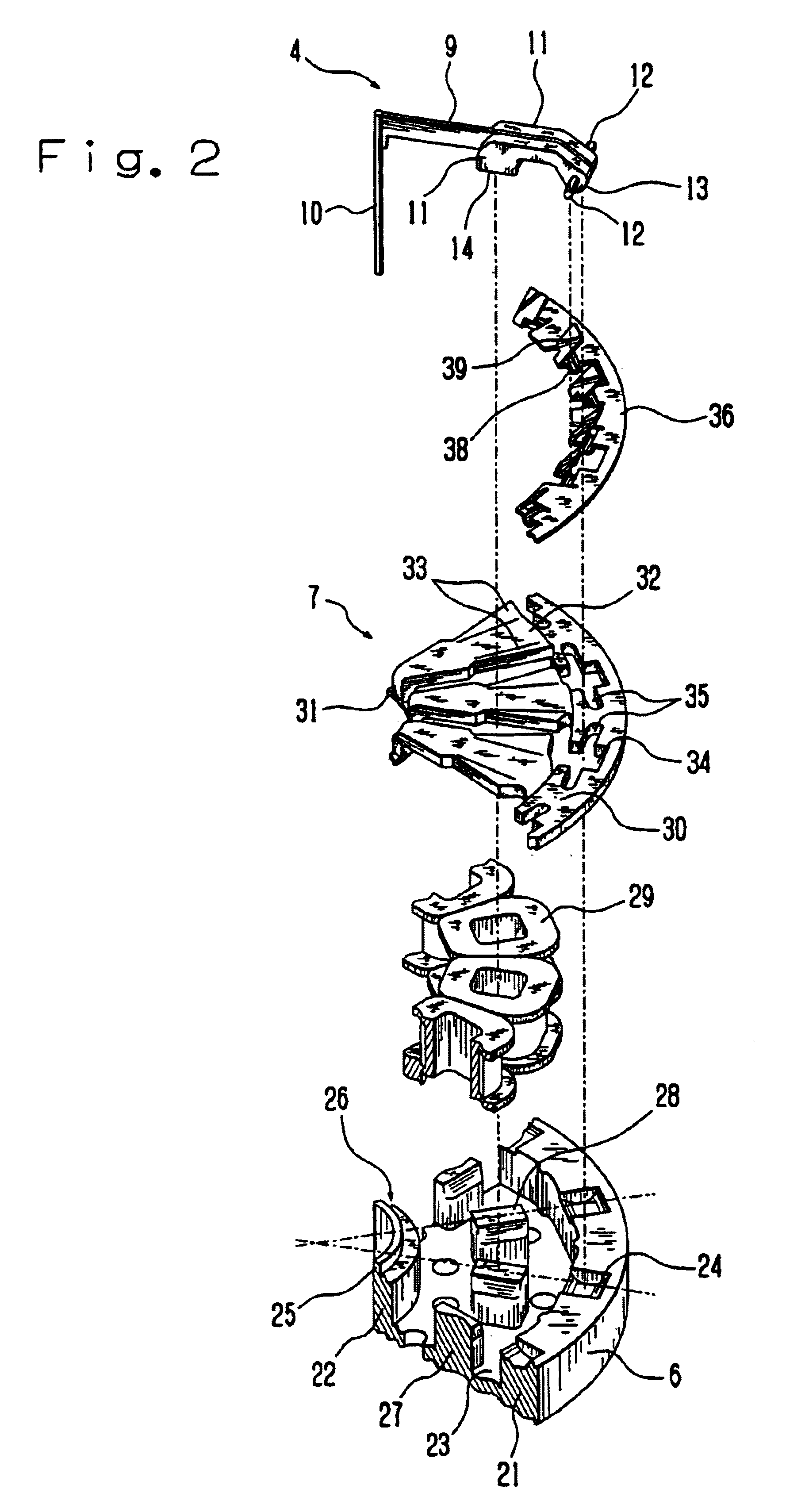

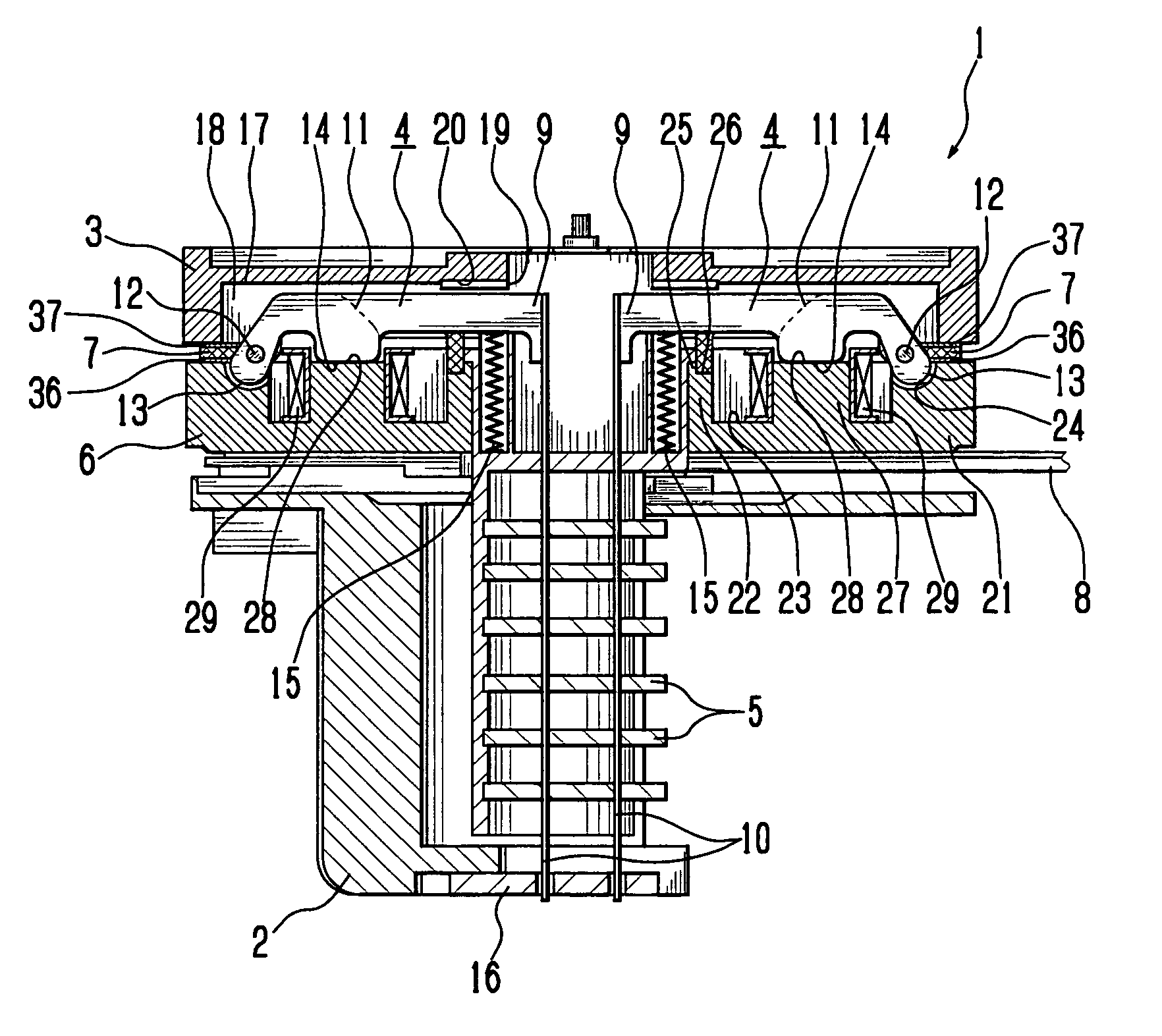

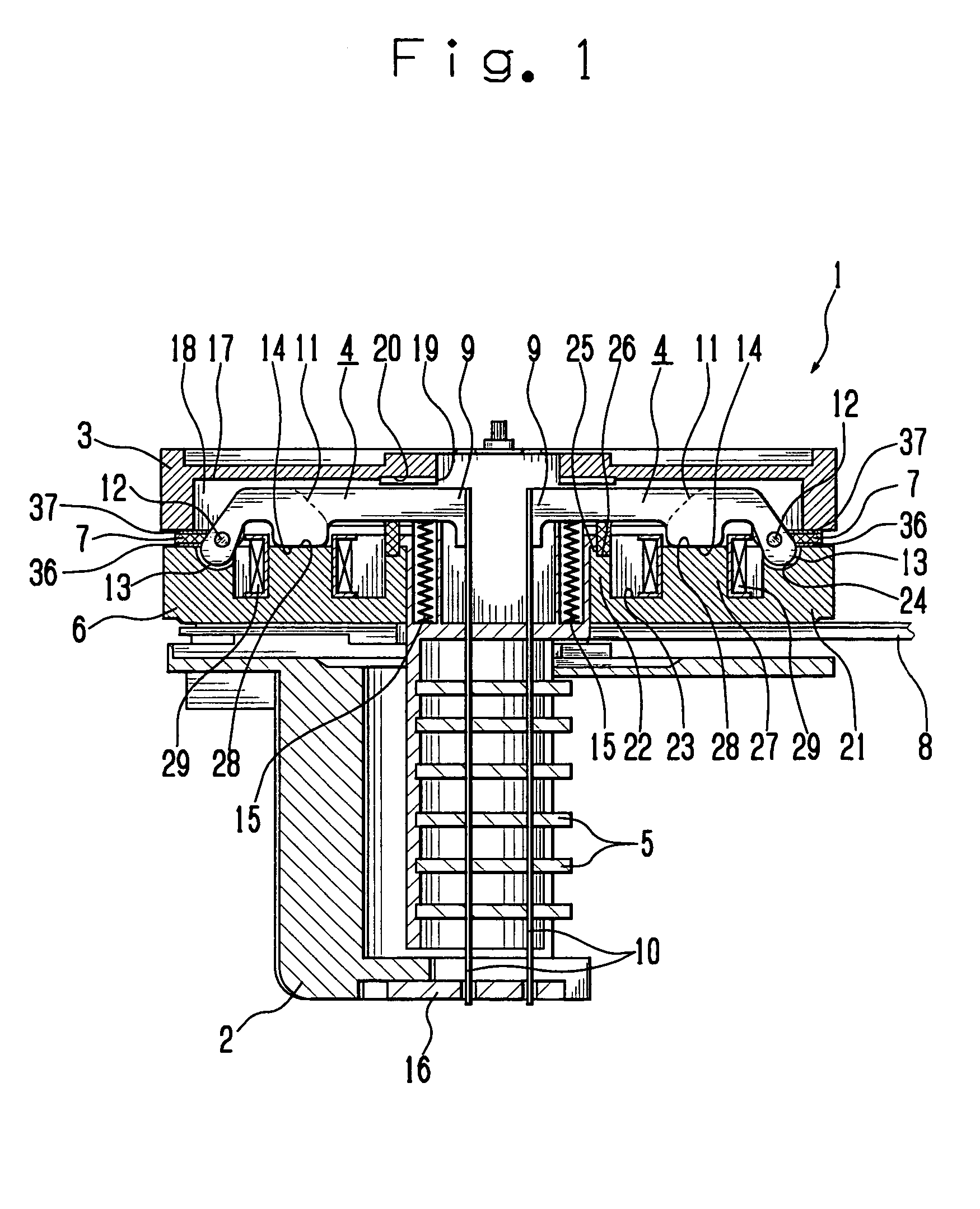

Wire dot printer head with abrasion having magnetic permeability and hardness surface

In order to realize a stable rocking operation of the armature for performing high-speed printing, between the armature spacer for accommodating and holding the support shaft of the armature which supports the printing wires, and the yoke for holding the support shafts of the plurality of armatures together with this armature spacer, there is provided the abrasion preventing member formed of material having higher magnetic permeability than that of the yoke, and hardened by surface hardening processing.

Owner:TOSHIBA TEC KK

Printing ink composition for laminate

InactiveUS20100247876A1Improve adhesionLess change in viscosityFlexible coversWrappersPolyesterCellulose acetate

There is provided an ink composition containing a colorant, a solvent, and a binder composed of 80 to 98% by weight of a polyurethane resin, 0.5 to 5% by weight of a cellulose acetate alkylate resin and 1.0 to 15% by weight of a polyvinyl butyral resin, based on the solids content, in which composition the polyurethane resin is obtained by reacting a reaction product between (A) a polyether diol compound having a Mn of 1,000 to 5,000, or a mixture of the compound and a polyester diol having a Mn of 1,000 to 5,000, and (B) a diisocyanate compound, with (C) a hydroxyldialkylamine having a molecular weight of 50 to 300 and having one hydroxyl group in a molecule, and further reacting the product with (D) a chain extending agent; and a molar ratio of the OH group of the component (C) to the NCO group of the component (B) is 0.05 to 0.35.

Owner:TOYO INK SC HOLD CO LTD

Ink jet printing apparatus and ink jet printing method

InactiveUS20090073202A1High qualityHigh-speed printingSpacing mechanismsOther printing apparatusThinningEngineering

When completing an image in a predetermined area by an odd or even number of bidirectional printing scans, this invention makes it possible to suppress lines of image defects and density variations and thereby print a high-quality image at high speed. In completing an image by an odd number of bidirectional printing scans, the print data for small ink droplets and large ink droplets are thinned using the first and second thinning pattern. The first and second thinning pattern thin the print data for small ink droplets and large ink droplets so that a difference between the total print ratio of all forward printing scans of the odd number of scans and the total print ratio of all backward printing scans of the odd number of scans when the first thinning pattern is used differs from that when the second thinning pattern is used.

Owner:CANON KK

Naphthalenetetracarboxylic acid diimide derivative and electrophotographic photoconductor having the same

ActiveUS20090068577A1Excellent electron transferrabilityAdvantageously useOrganic chemistryElectrographic process apparatusNitrogen atomCarbon atom

The present invention provides a naphthalenetetracarboxylic acid diimide derivative represented by the following general formula (1):wherein R1 and R2, which are identical or different, each represent a substituted or non-substituted alkyl group or a substituted or non-substituted aromatic hydrocarbon group; R3 represents an alkyl group having 1 to 8 carbon atoms or an aromatic hydrocarbon group; R4, R5, R6 and R7, which are identical or different, each represent a hydrogen atom, a substituted or non-substituted alkyl group, or a substituted or non-substituted aromatic hydrocarbon group; and R1 and R2 may be linked to form a substituted or non-substituted heterocyclic group including a nitrogen atom; with compounds where all of R1, R2 and R3 are a methyl group, and compounds where both of R1 and R2 are a methyl group and R3 is a 1-octyl group being excluded.

Owner:RICOH KK

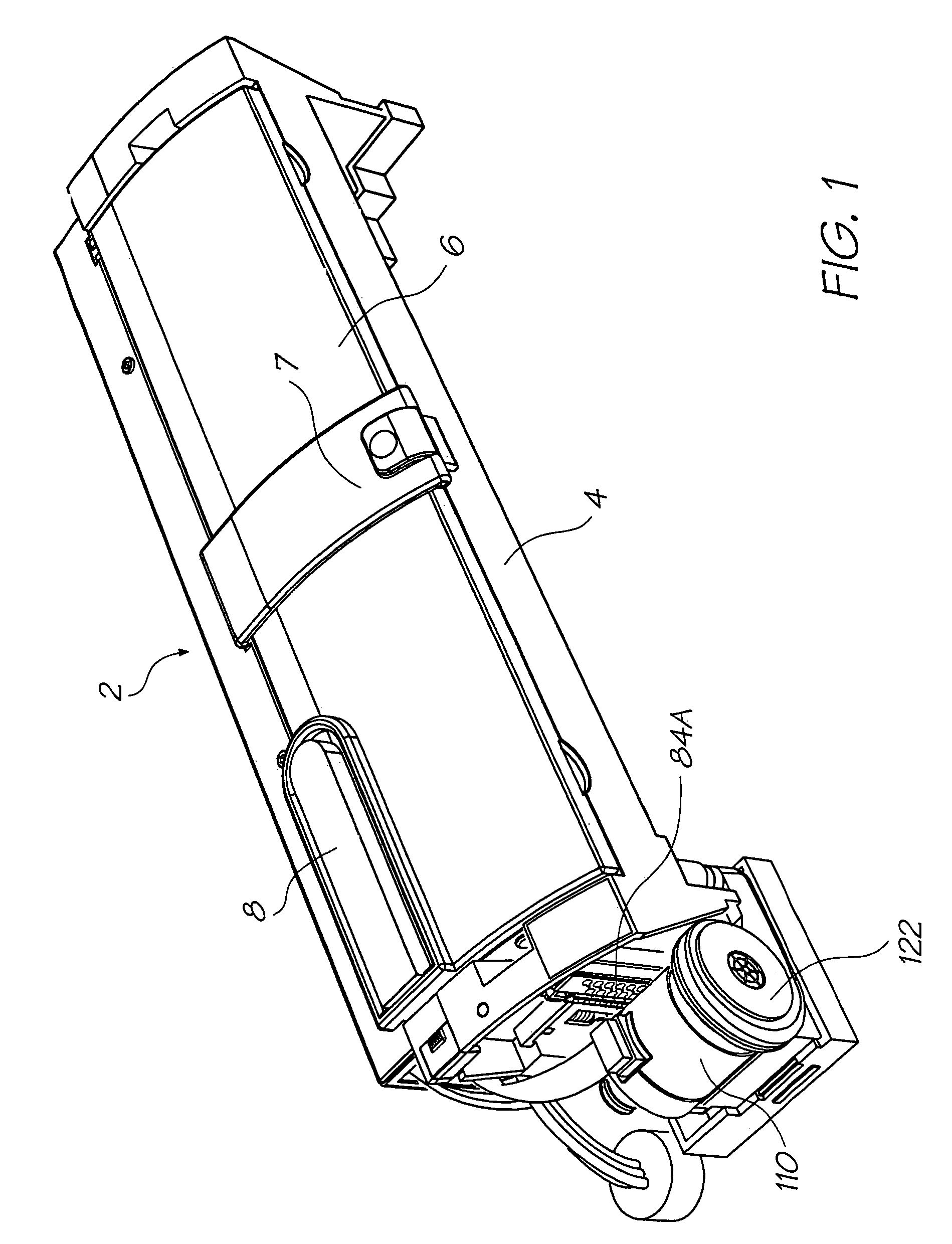

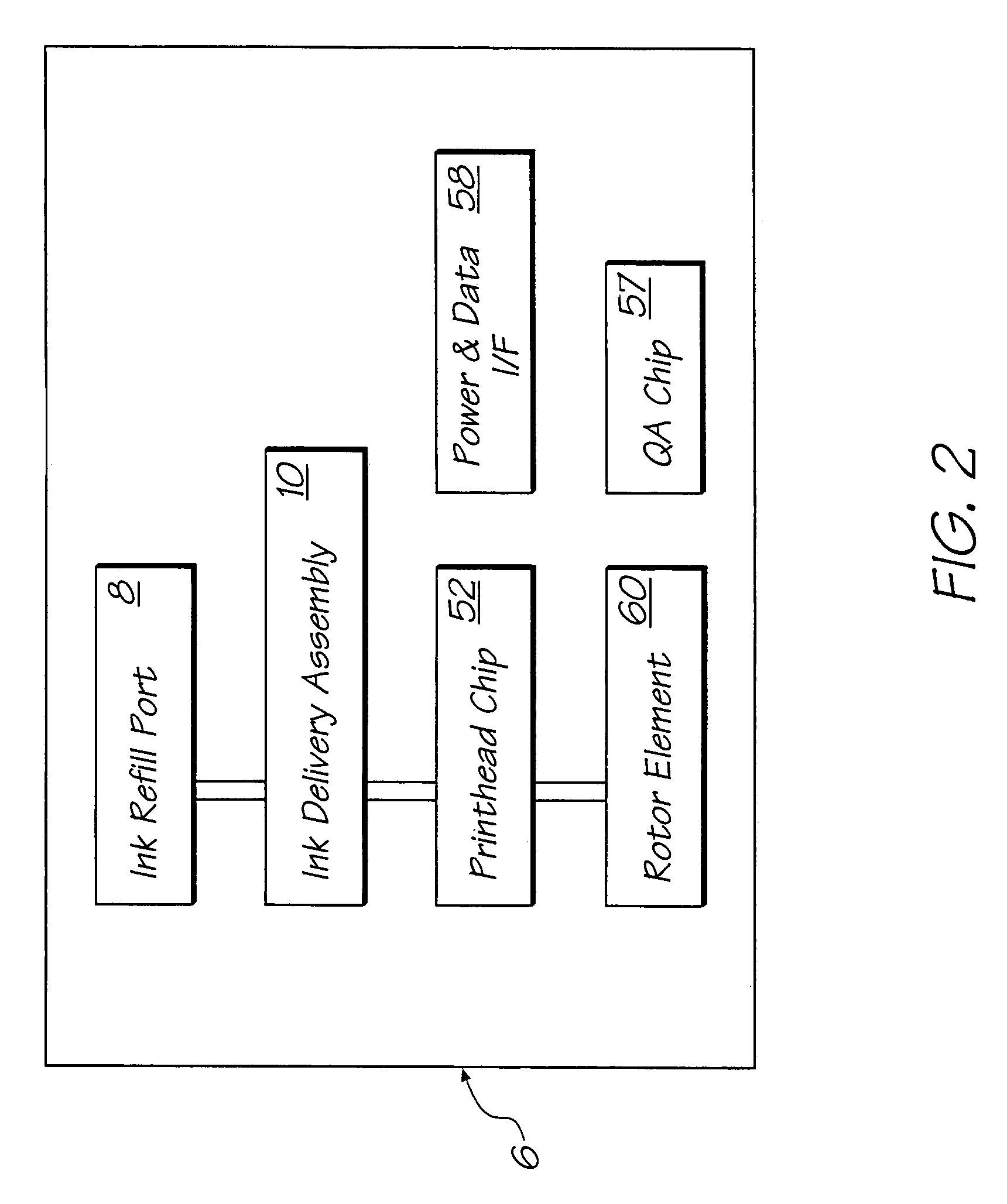

Inkjet printer cartridge with fixative delivery capabilities

An inkjet printer including a cradle; an inkjet printer cartridge releasably engaged by the cradle and including at least first and second storage reservoirs for storing an ink and an ink fixative respectively; a pagewidth printhead in fluid communication with the first and second storage reservoirs; and a controller to control application of the ink and ink fixative by said printhead in order to facilitate fixing of the ink onto a print media following delivery by said printhead.

Owner:MEMJET TECH LTD +1

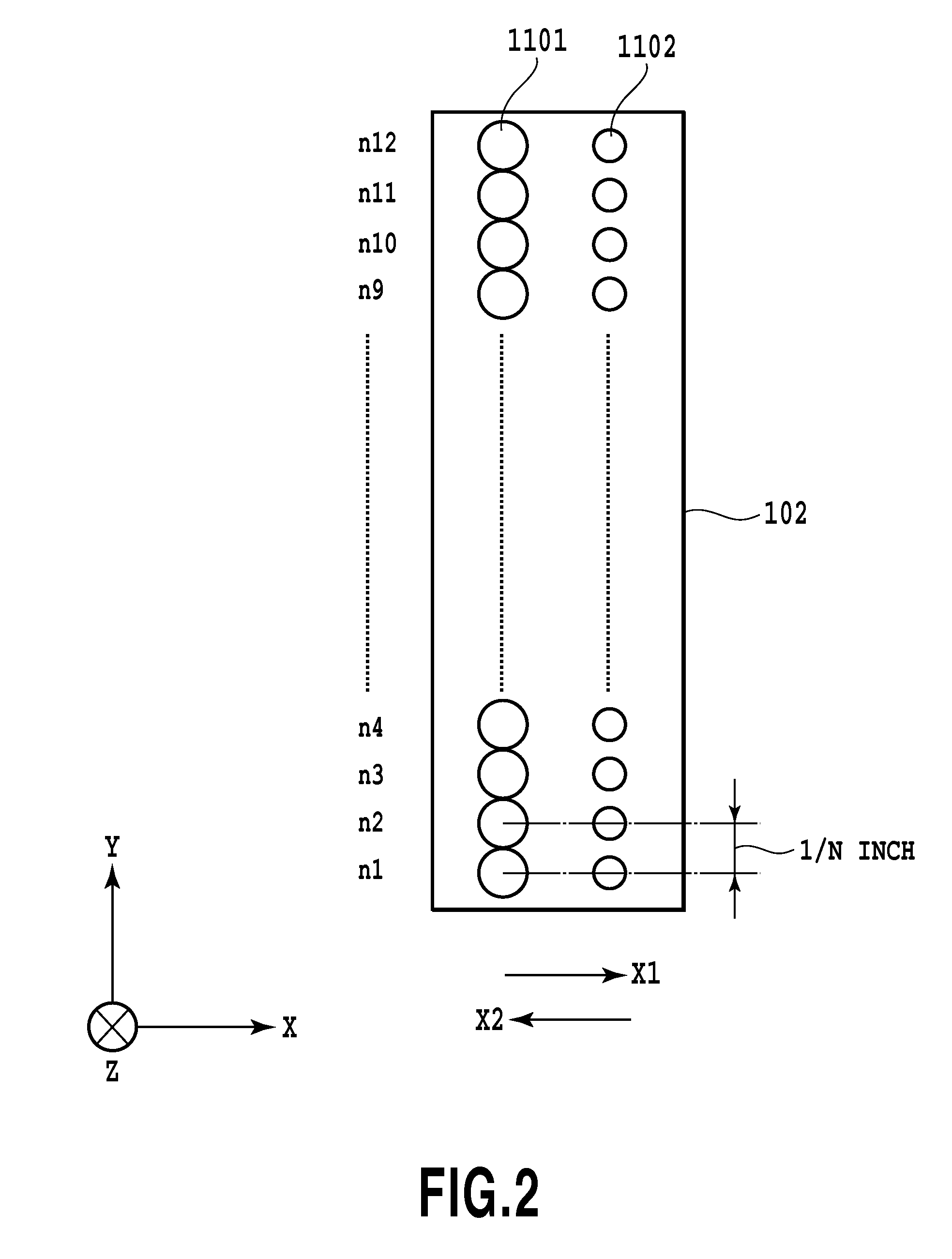

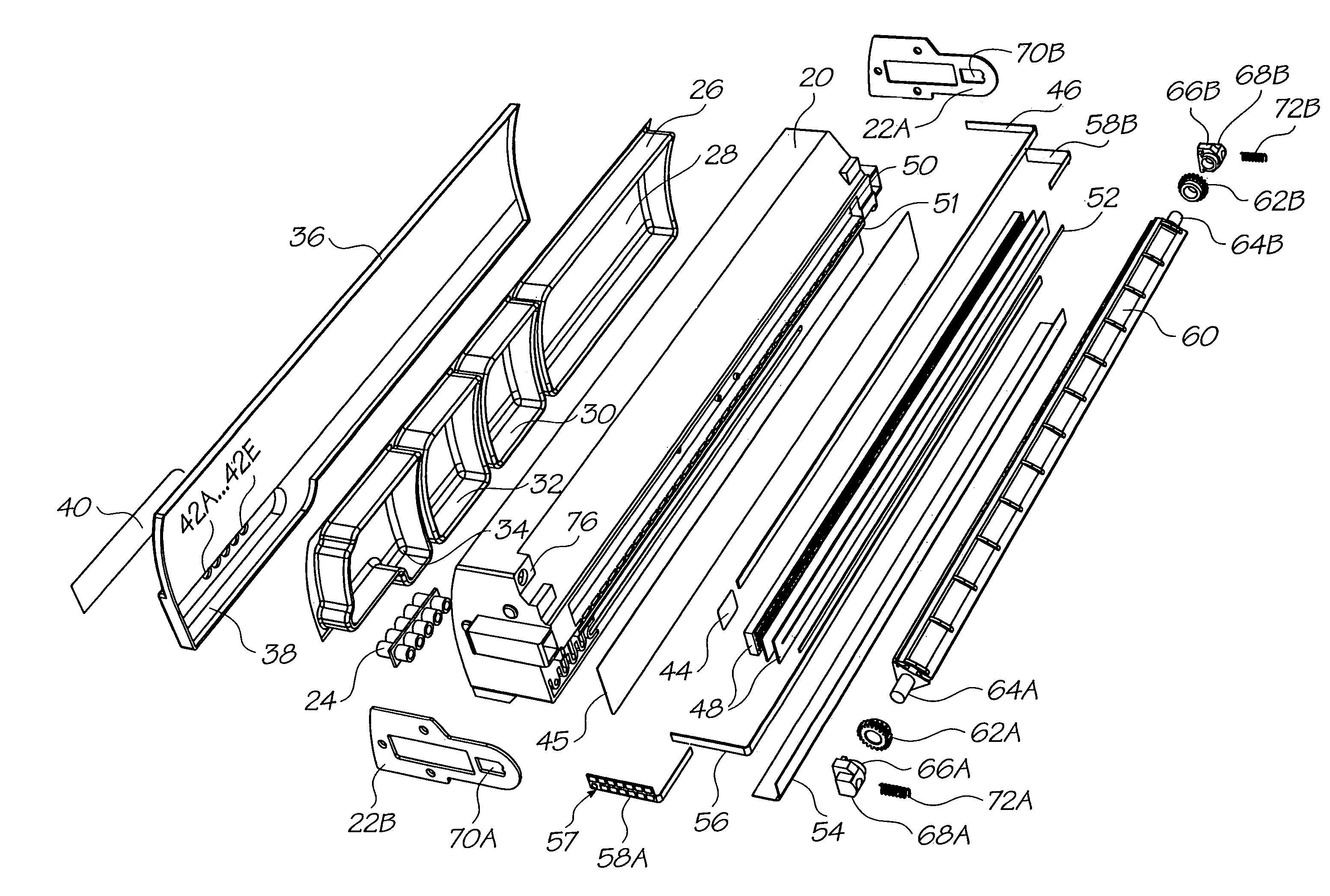

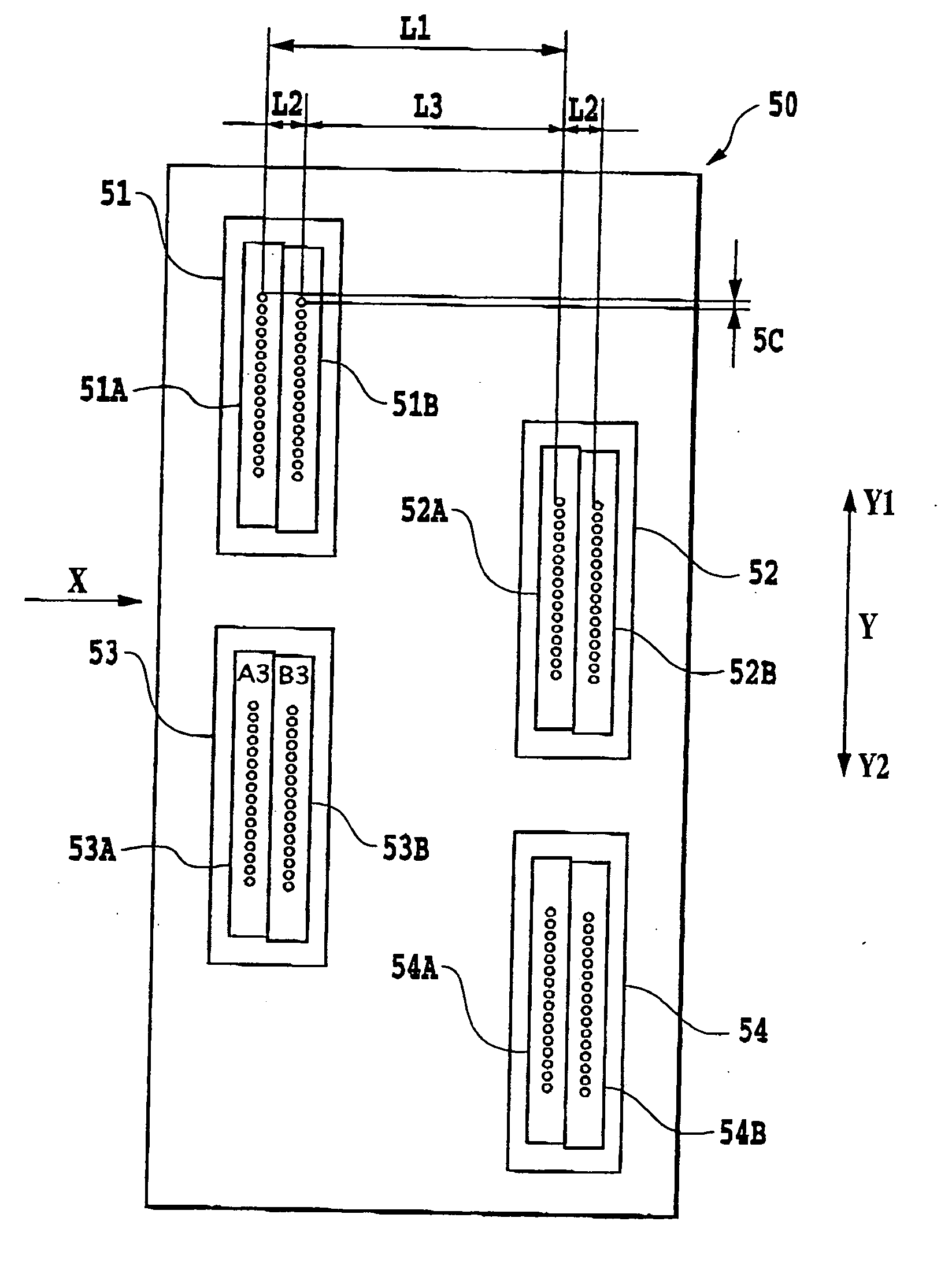

Ink jet printing apparatus, ink jet printing method and print head

InactiveUS20050140722A1Increase speedReduce manufacturing costInking apparatusEngineeringRelative motion

An ink jet print head is provided which can print a high-quality image with no density variation-caused lines at high speed and which can be manufactured at low cost and with ease. For this purpose, the print head of this invention has a plurality of nozzle groups each having at least one nozzle array arranged in a predetermined array direction Y crossing a relative motion direction X. A distance in the relative motion direction between the nozzles in each nozzle group adjoining each other in the array direction Y is set almost equal to a distance in the relative motion direction between the nozzle groups adjoining each other in the array direction Y.

Owner:CANON KK

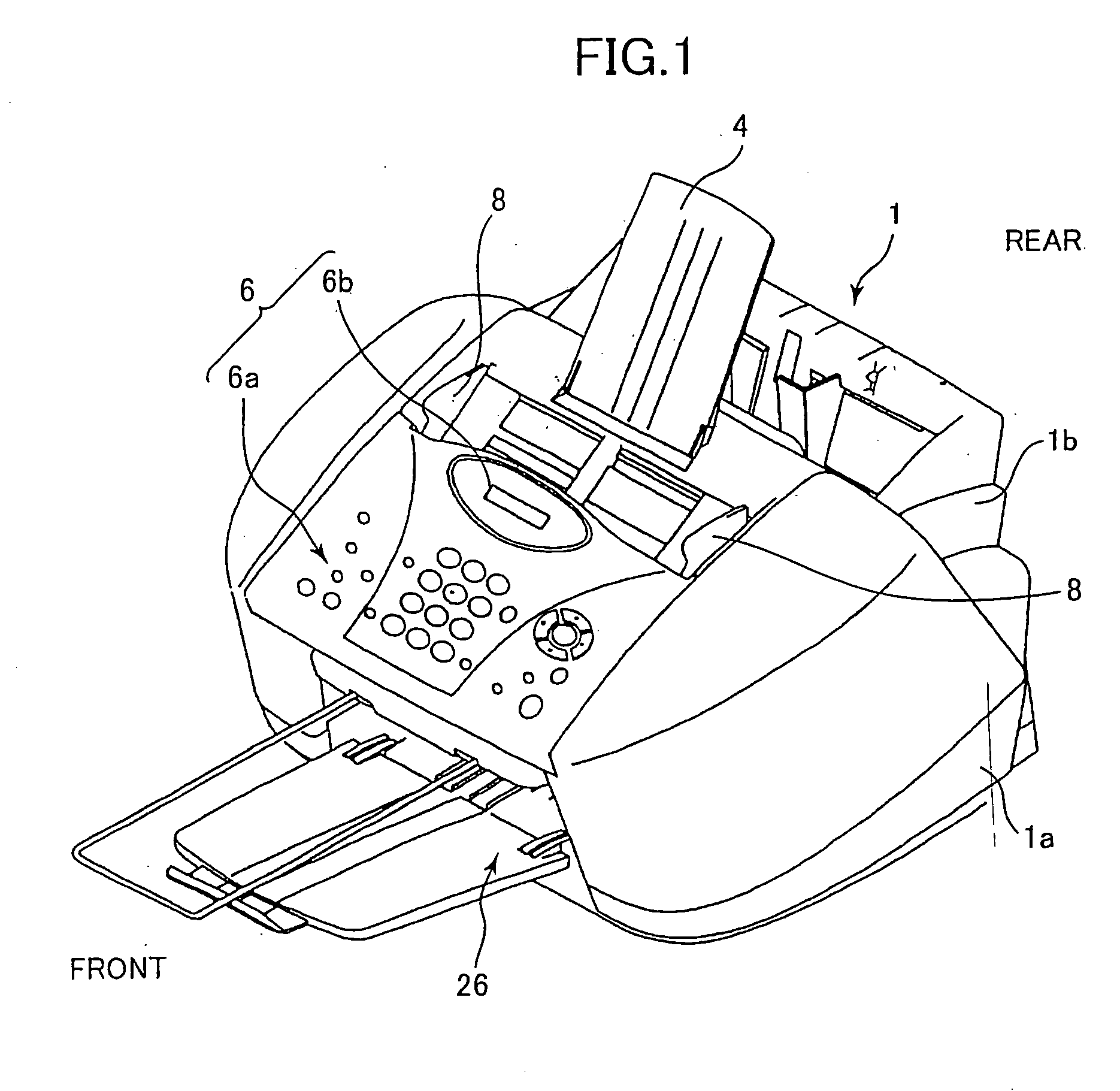

Printing apparatus, printing system, printing method, and program

InactiveUS20060033764A1Increase speedHigh speed printingOther printing apparatusHigh densityEngineering

Owner:COPYER

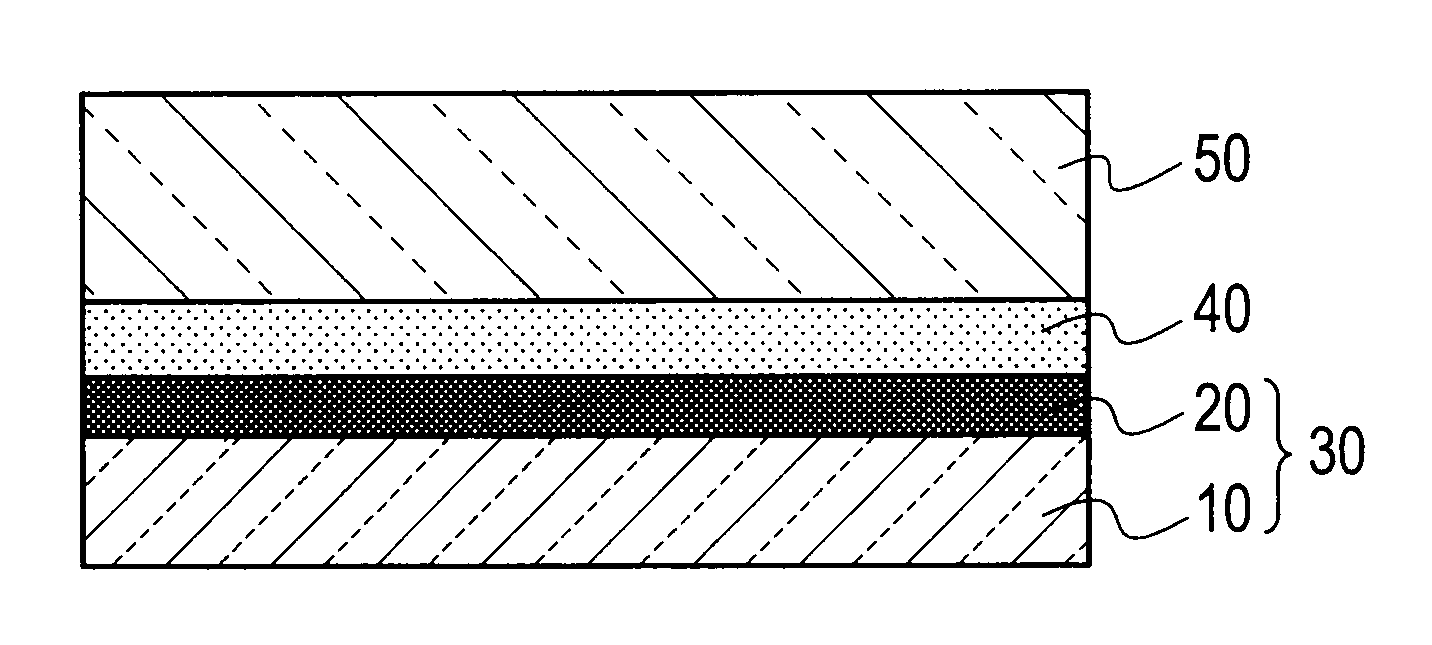

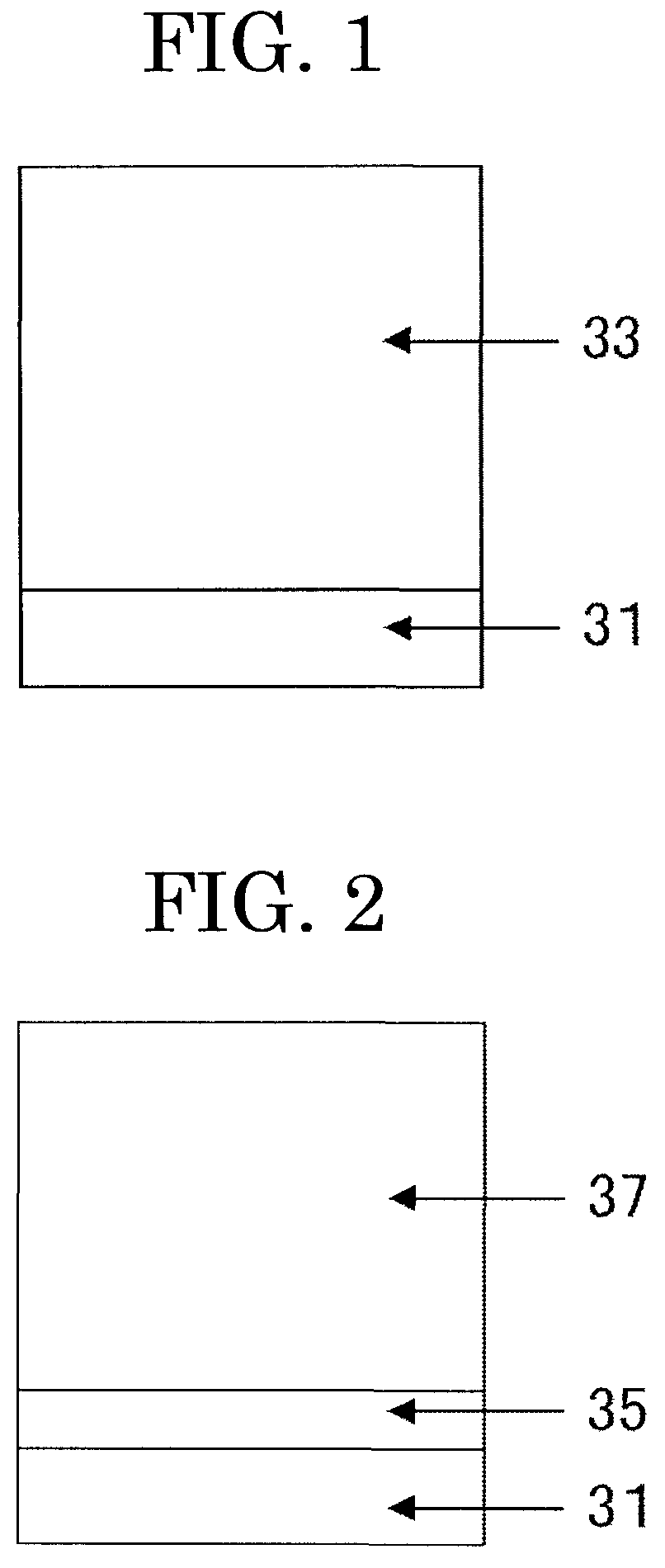

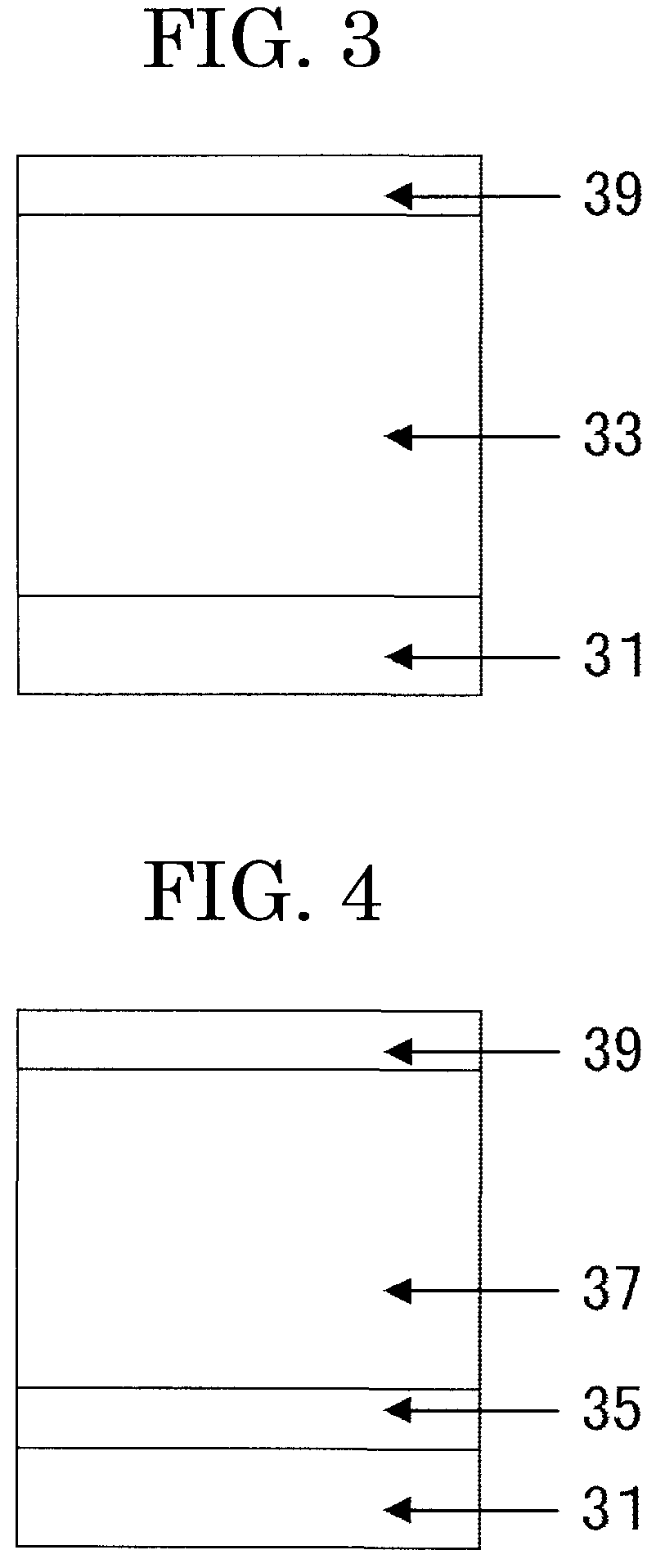

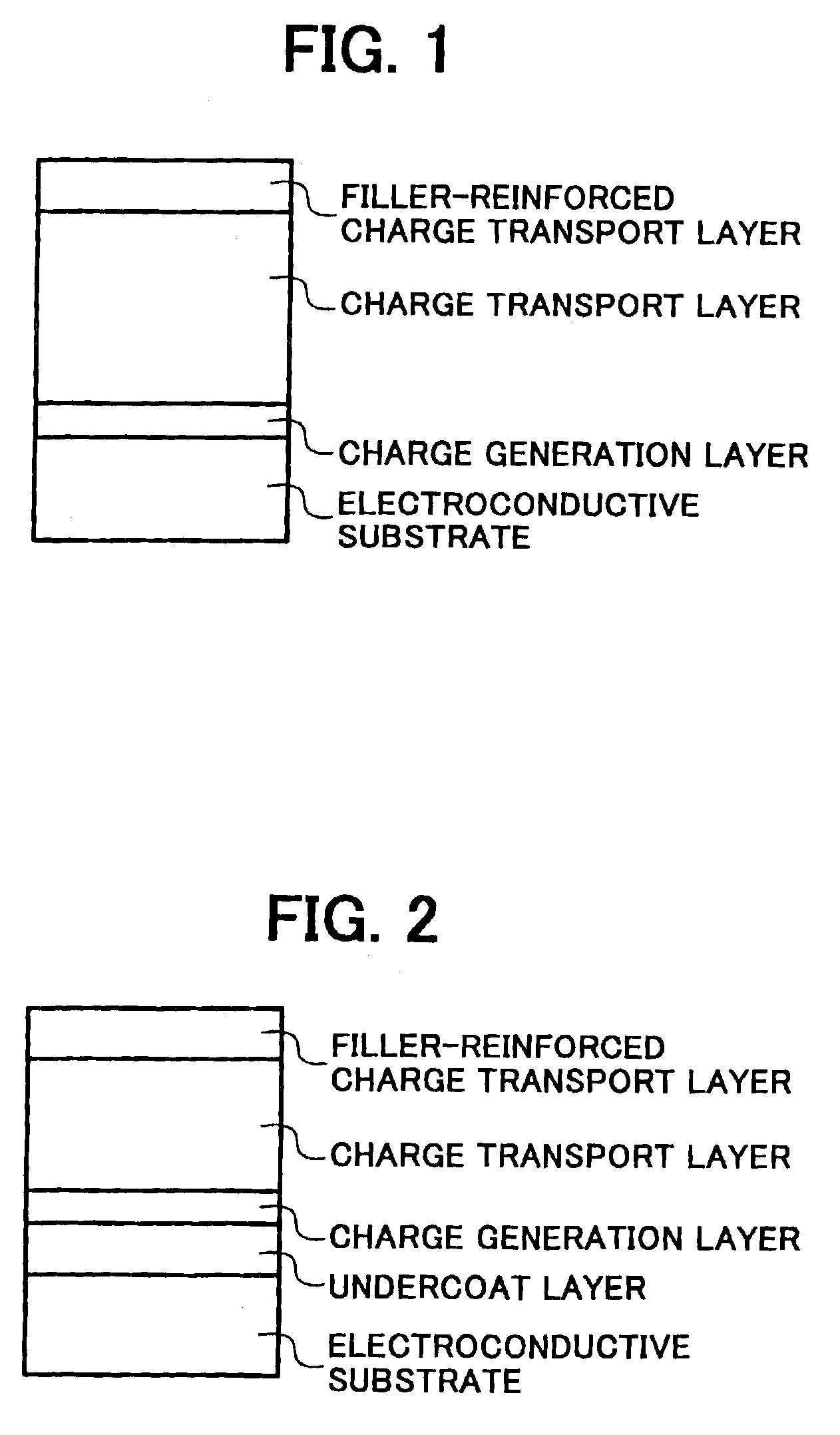

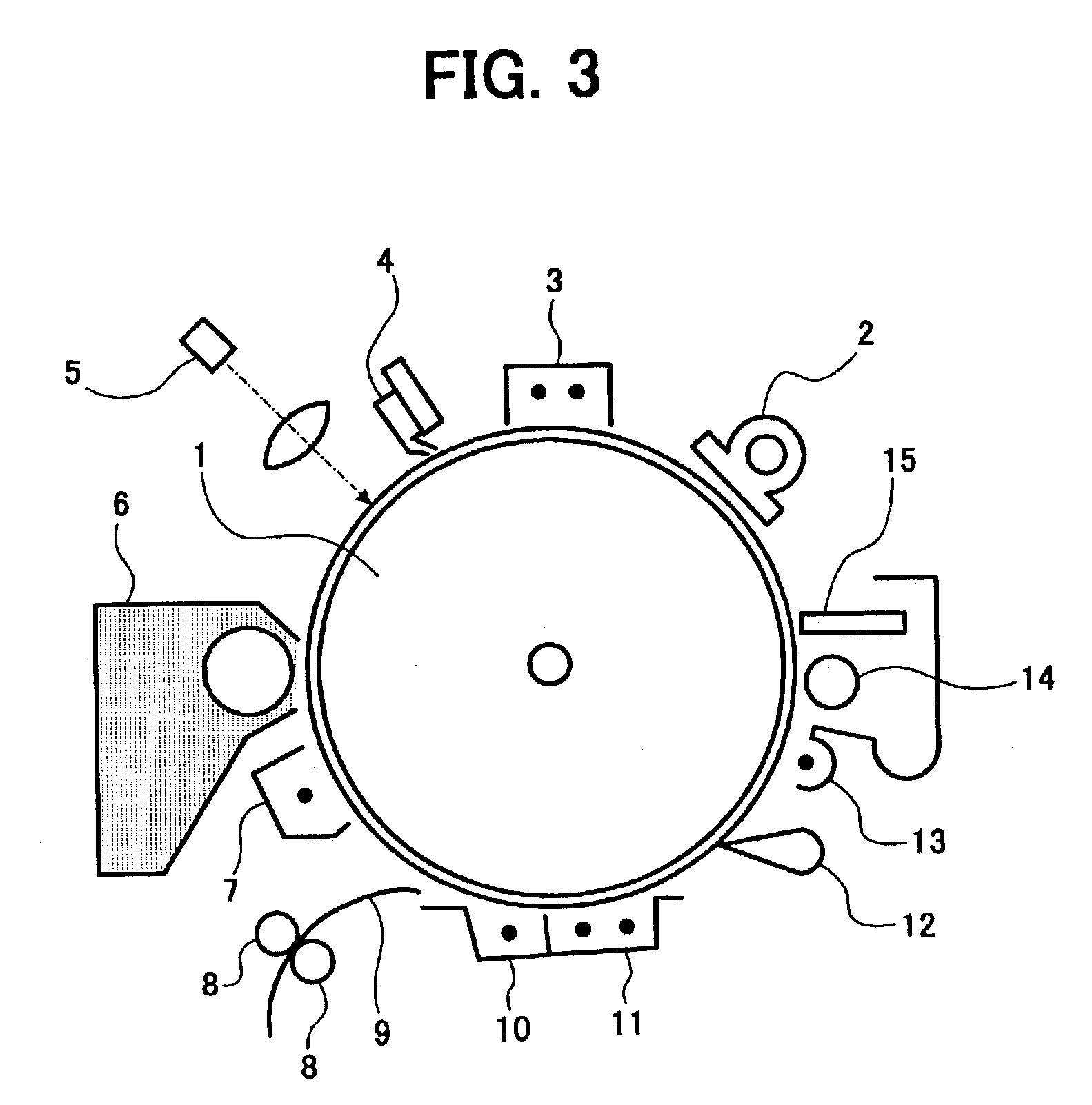

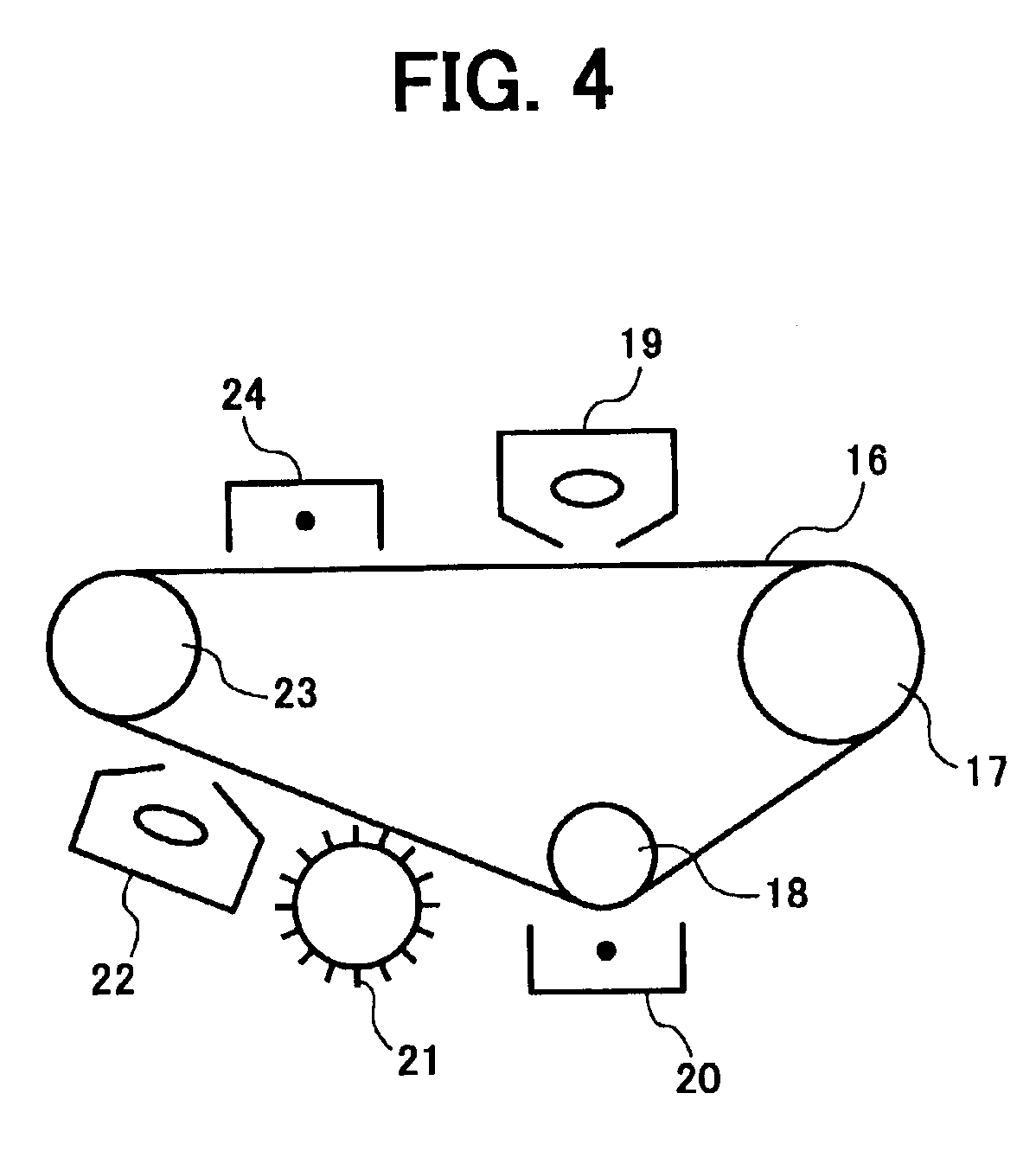

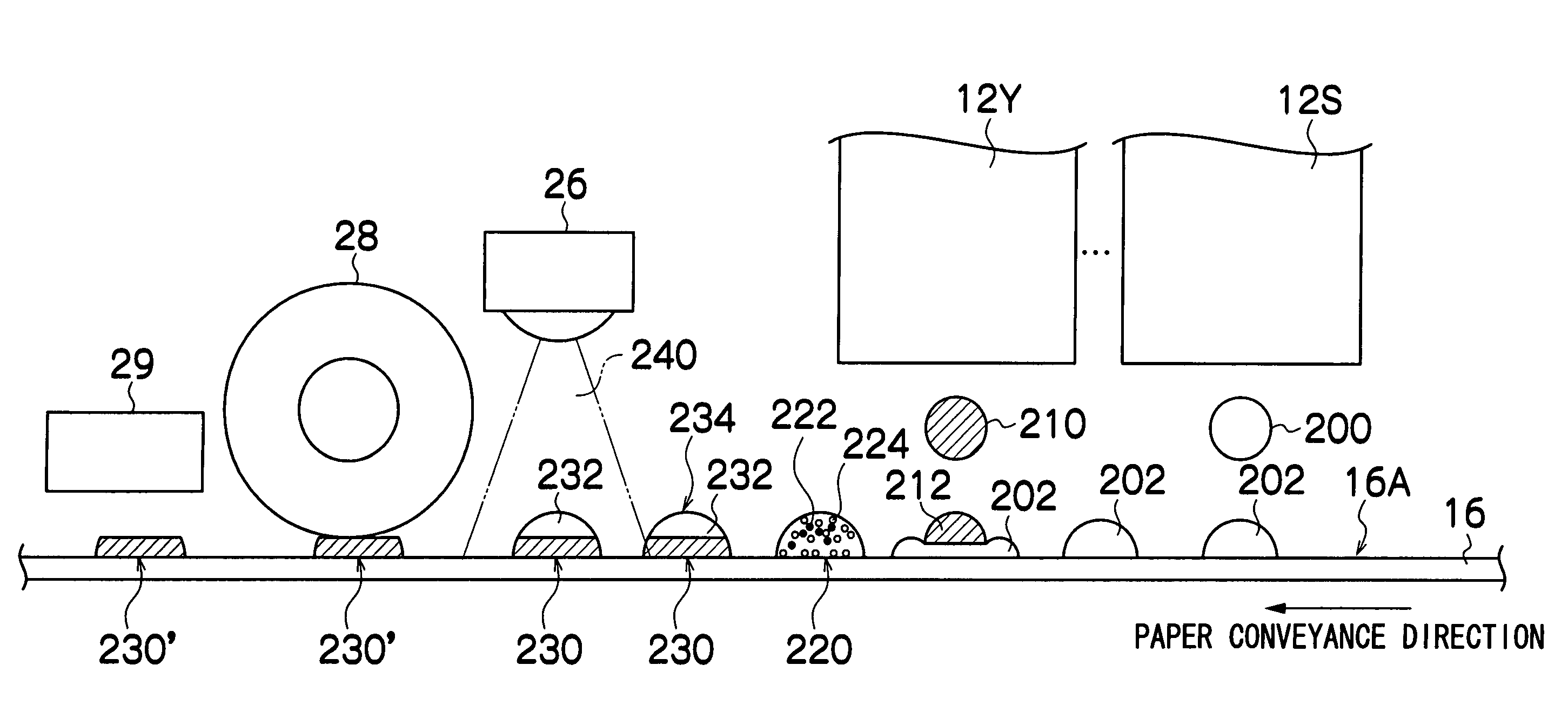

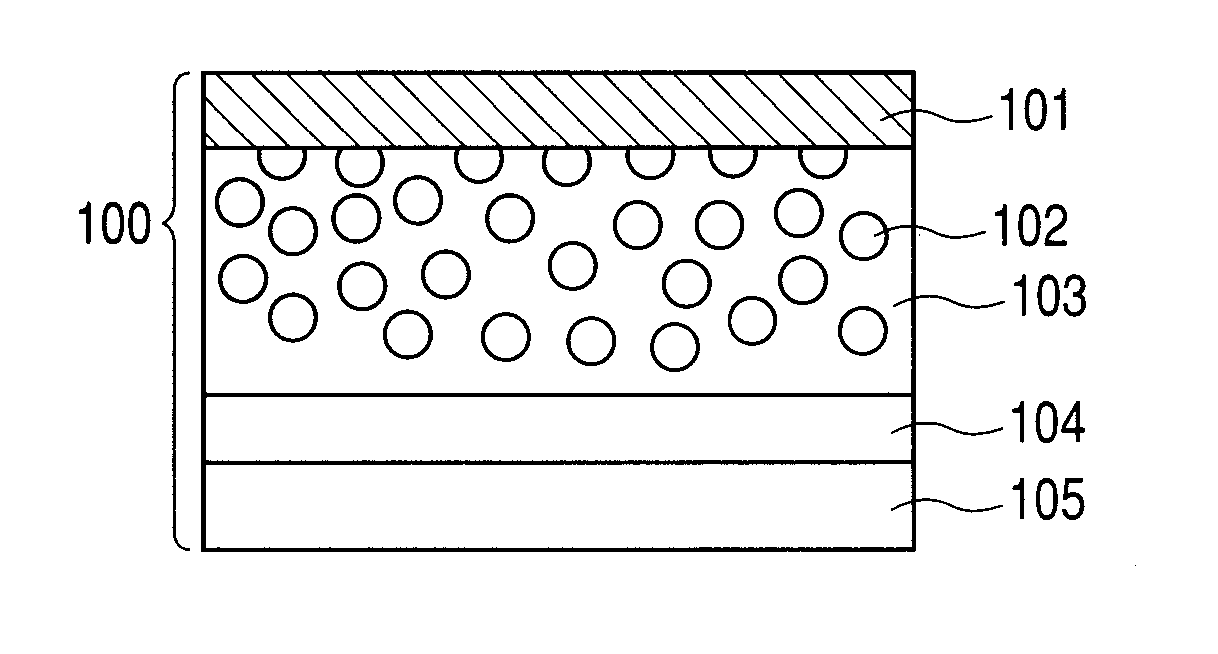

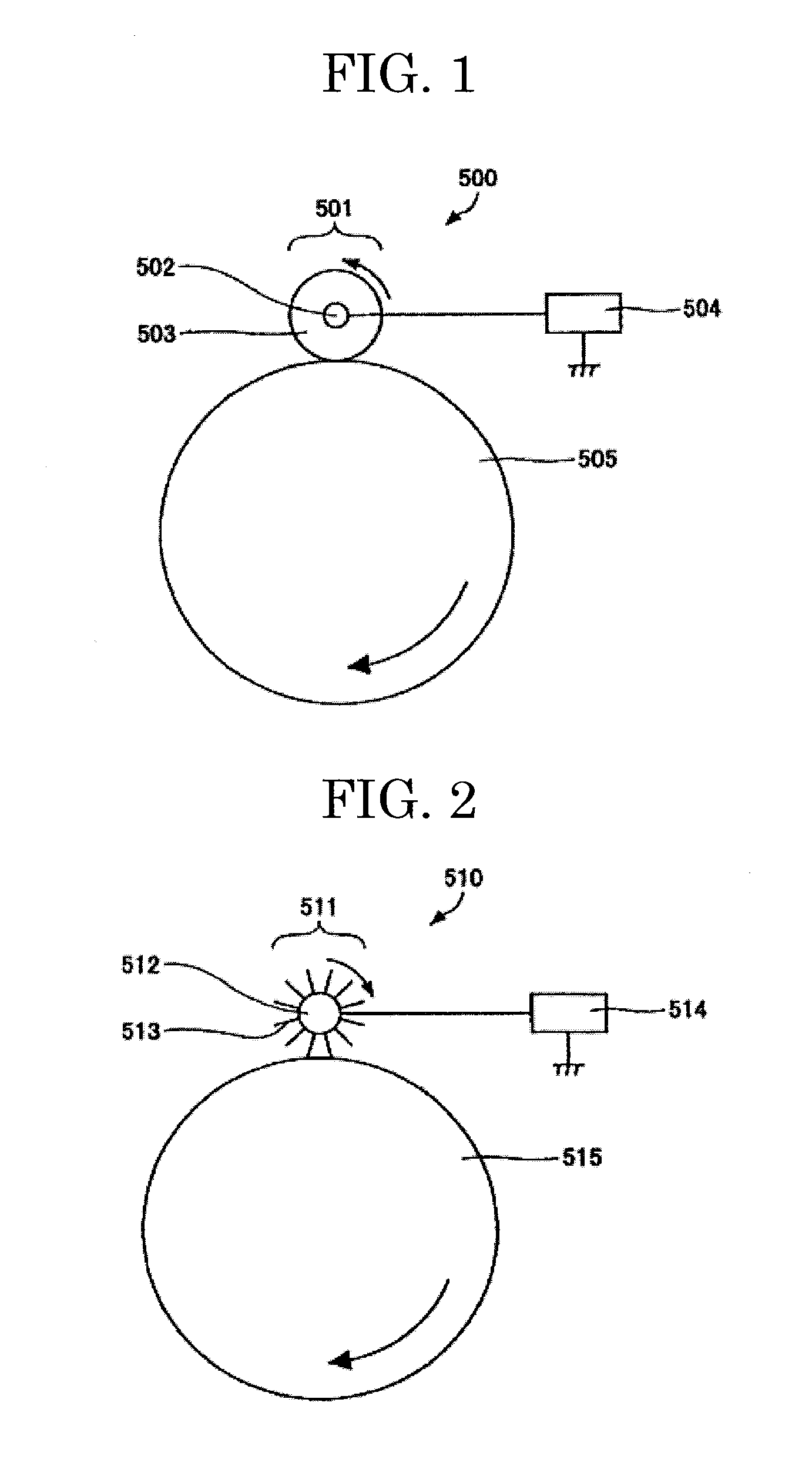

Electrophotographic photoreceptor and image forming apparatus using the photoreceptor

InactiveUS6853823B2High speed printingHigh-quality image productionRadiation applicationsElectrographic process apparatusTransport layerEngineering

An electrophotographic photoreceptor includes an electroconductive substrate. A charge generation layer overlies the electroconductive substrate. A first charge transport layer overlying the charge generation layer includes a first charge transport material (D1) and a first binder resin (R1). A second charge transport layer overlying the first charge transport layer includes a filler, a second charge transport material (D2) and a second binder resin (R2). The first and second charge transport layers have a total thickness of from 5 to 25 μm. A weight ratio (D1 / R1) of the first charge transport material (D1) to the first binder resin (R1) in the first charge transport layer is greater than a weight ratio (D2 / R2) of the second charge transport material (D2) to the second binder resin (R2) in the second charge transport layer.

Owner:RICOH KK

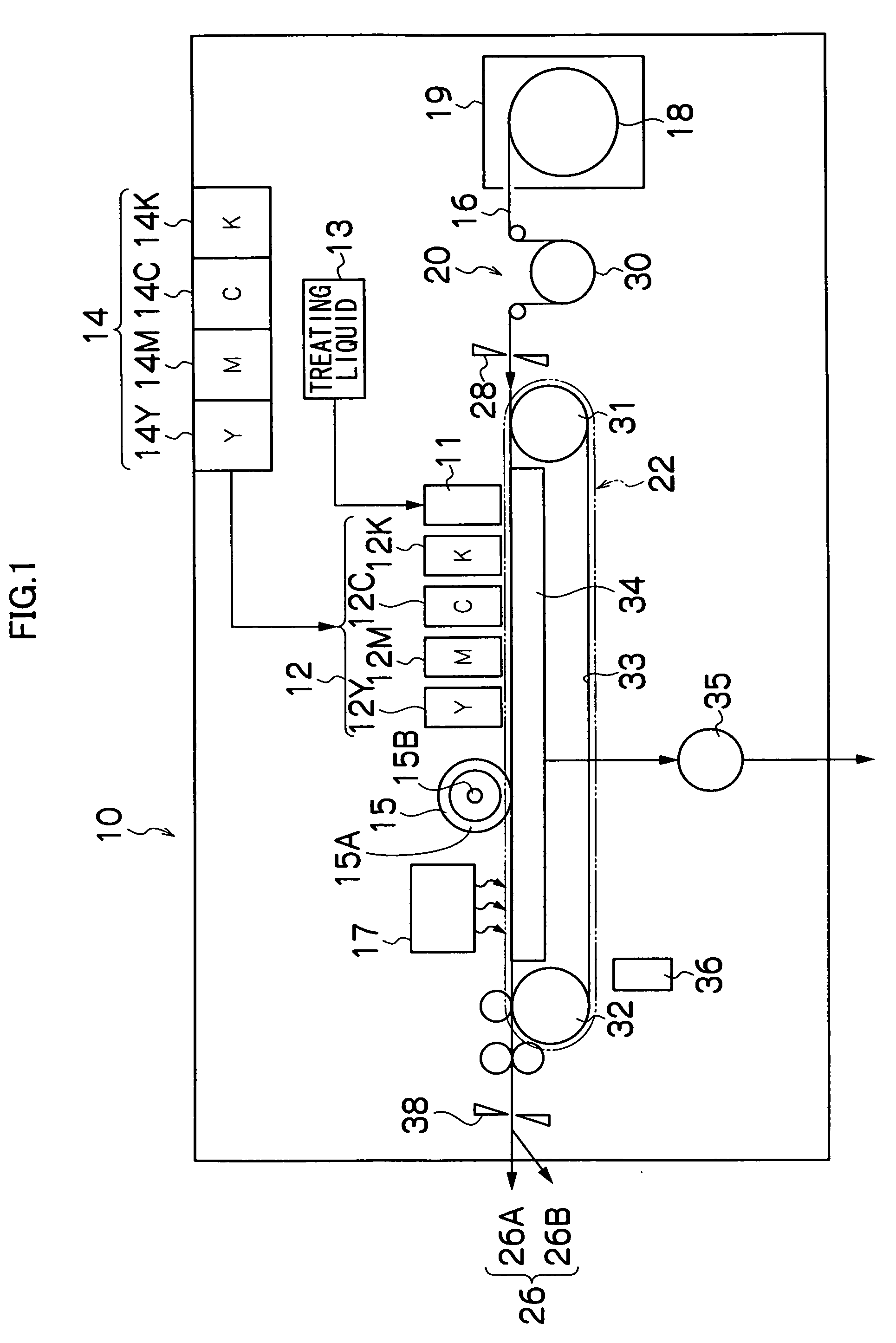

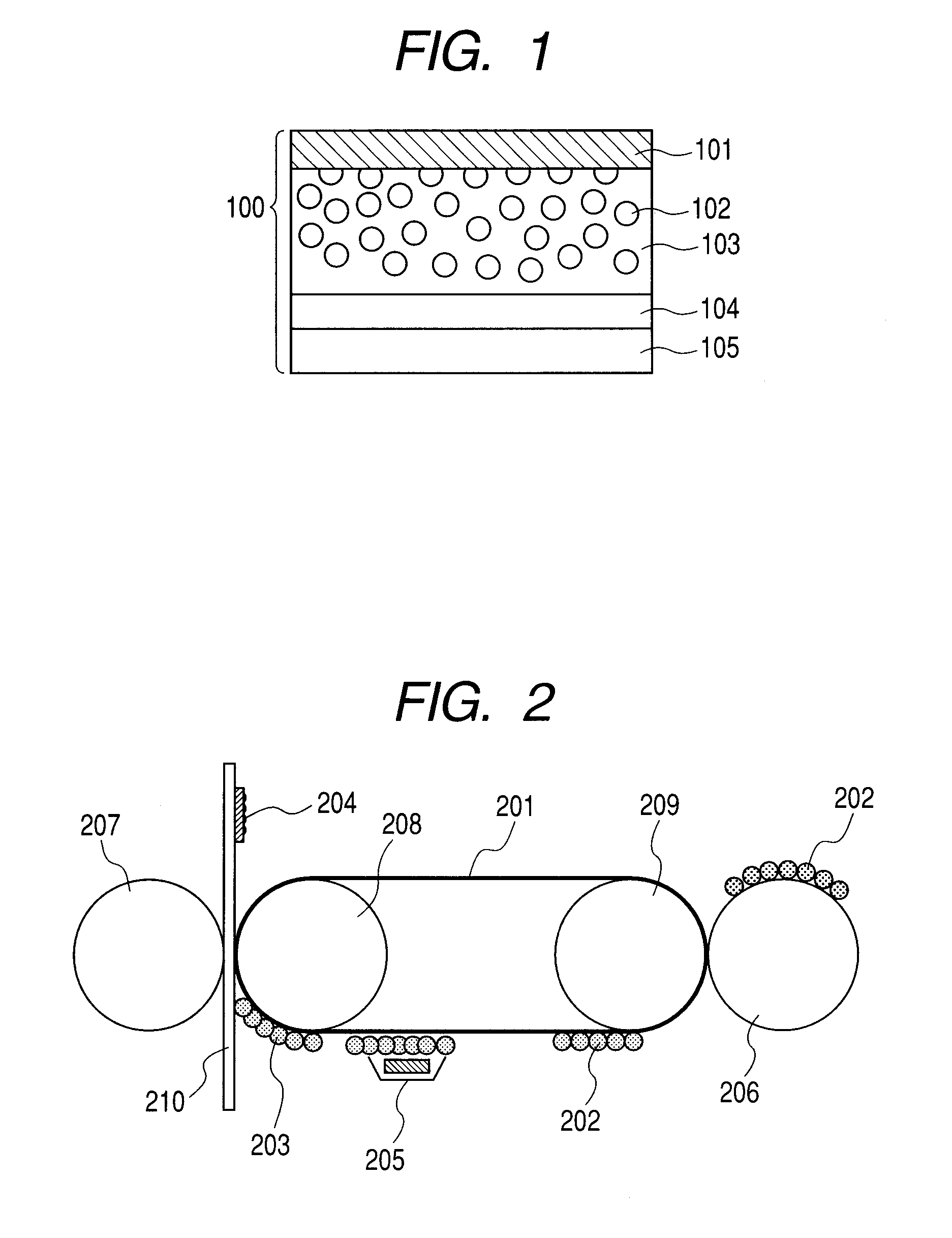

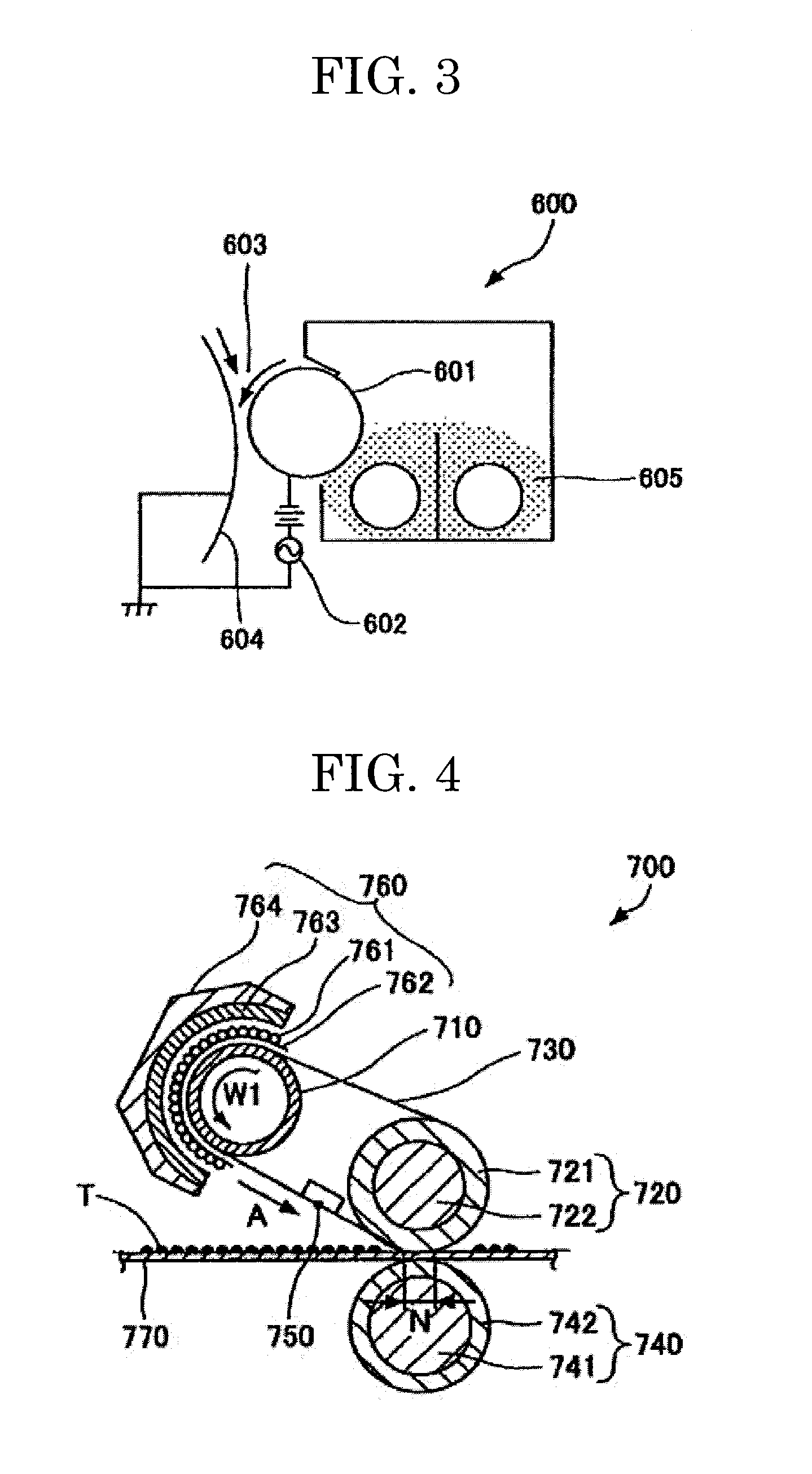

Image forming method and inkjet recording apparatus

InactiveUS7628481B2Improve efficiencyQuality improvementMeasurement apparatus componentsDuplicating/marking methodsWater basedOligomer

The image forming method includes: a treatment liquid deposition step of depositing, on a recording medium, a treatment liquid which reacts with a water-based emulsion-type ink having a water-based ink solvent, a pigment-based coloring material and at least one constituent material of a radiation-curable monomer, a radiation-curable oligomer, and a mixture material of the radiation-curable monomer and the radiation-curable oligomer; an ink ejection step of ejecting the water-based emulsion-type ink by means of an inkjet head toward the recording medium on which the treatment liquid has been deposited in the treatment liquid deposition step; a radiation irradiation step, in a state where the water-based emulsion-type ink has reacted with the treatment liquid on the recording medium after the ink ejection step and an aggregate of the pigment-based coloring material and the at least one constituent material is separated in phase from a liquid component including the water-based ink solvent, of irradiating radiation onto at least the aggregate on the recording medium, to cure the aggregate; and a liquid removal step of removing at least a portion of the liquid component from the recording medium, after the radiation irradiation step.

Owner:FUJIFILM CORP

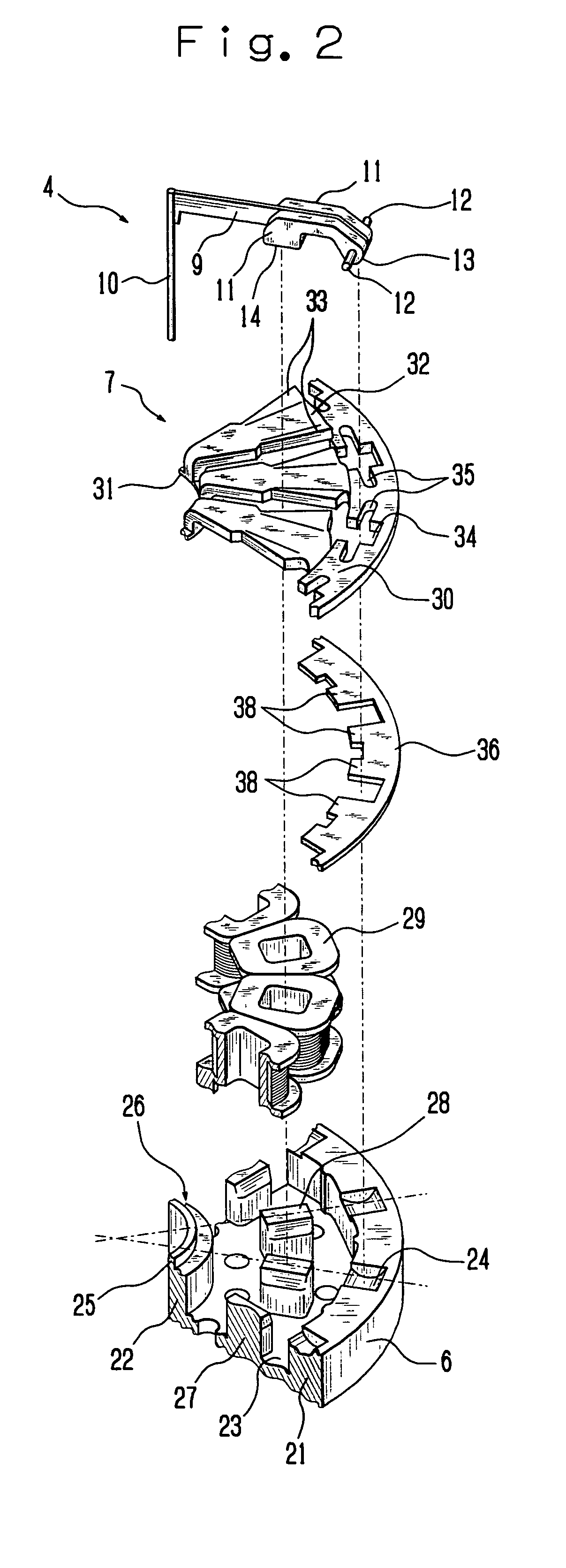

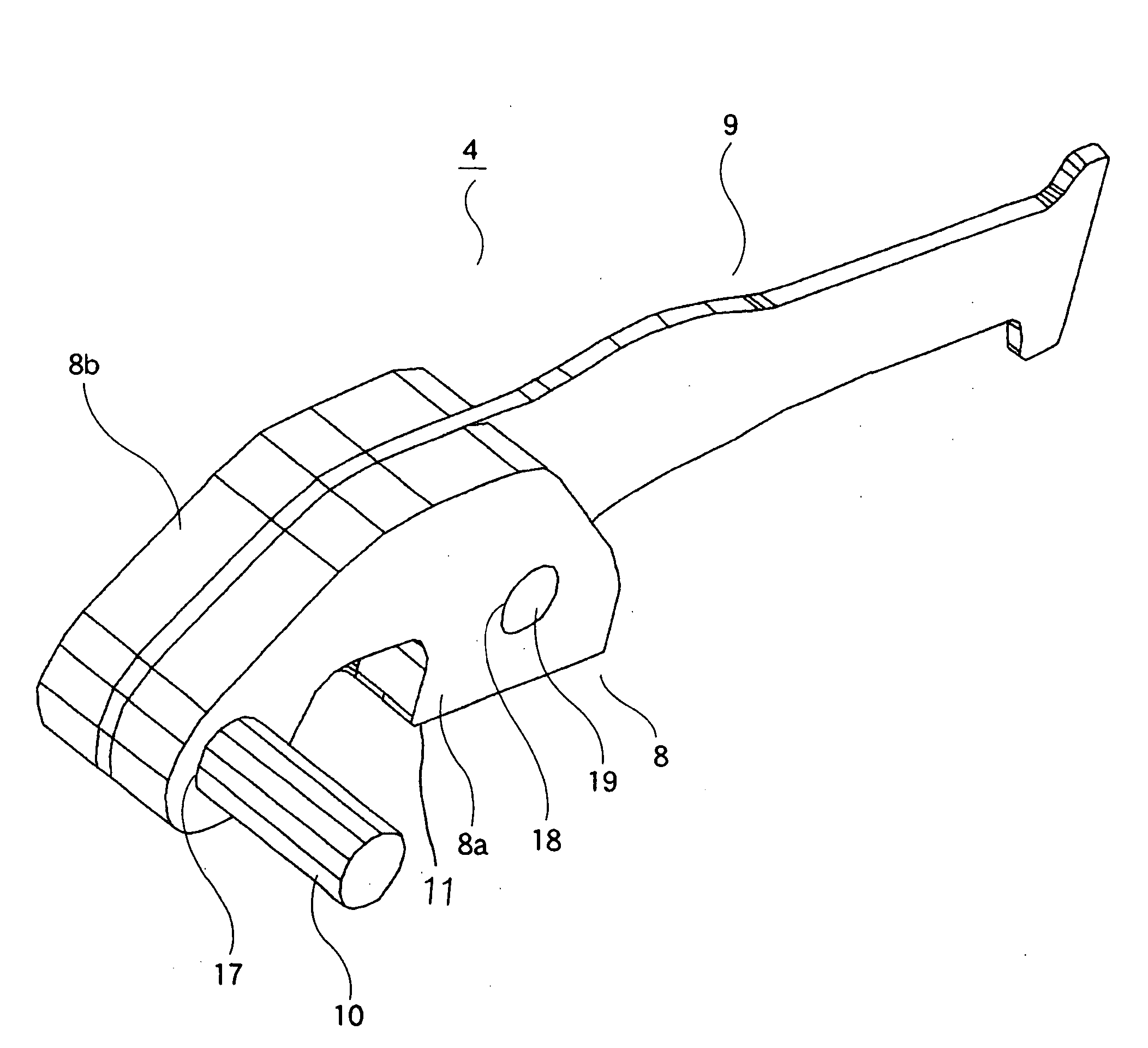

Dot head and method of manufacturing armature structure for dot head

According to a dot head of the invention, an armature structure for moving a printing needle forward and backward has the efficiency that the magnetic characteristics is excellent and mechanical intensity is high. The armature structure is manufactured in a manner that an arm member, which is formed by subjecting a plate-shaped material excellent in abrasion resistance performance and having a high intensity to a plating processing using born etc., is sandwiched at a portion thereof from both sides in a stacked manner by two armature members each of which is formed by subjecting a plate-shaped material excellent in magnetic characteristics to a plating processing using born etc. A pin formed by subjecting a piano wire to a plating processing using boron etc. is inserted with a small pressure into common through holes of the two armature members and the arm member thus stacked thereby to provisionally assemble them. A pair of electrodes are made in contact to the portions including the slightly-pressed-in pin near the pin of the provisionally assembled two armature members and the arm member, and a current is supplied to the electrodes in a state that the portions are sandwiched by the electrodes thereby to melt and harden the plated portions using boron etc. to integrate the two armature members and the arm member.

Owner:TOSHIBA TEC KK

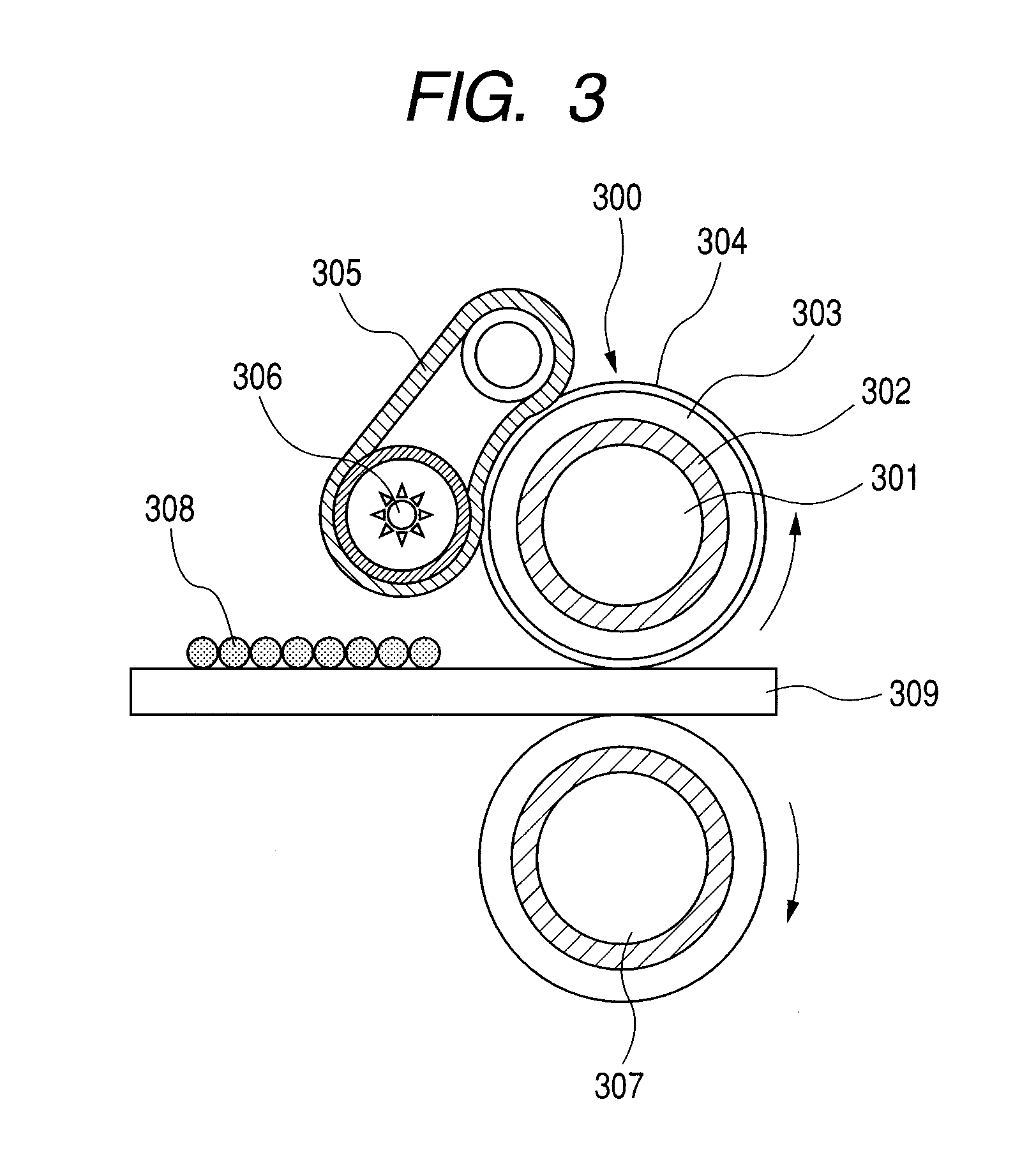

Resin composition, lamination film containing the same, and image forming apparatus that uses lamination film as component

InactiveUS20100303520A1Improve mechanical propertiesHigh speed printingElectrographic process apparatusEngineering plasticMechanical property

An object of the present invention is to provide a porous material (resin composition) having high heat insulation properties, mechanical properties, and electrical properties by controlling function of a porous film by setting a porosity size, distribution of the porosity size, and a porosity ratio of the porous film in predetermined ranges. The resin composition according to the present invention is comprised of an engineering plastic having porous structure in which not less than 80% of a total porosity is comprised of independent porosities, a mean porosity size is not less than 0.01 μm and not more than 0.9 μm, and not less than 80% of the total porosity has a porosity size within ±30% of the mean porosity size.

Owner:CANON KK

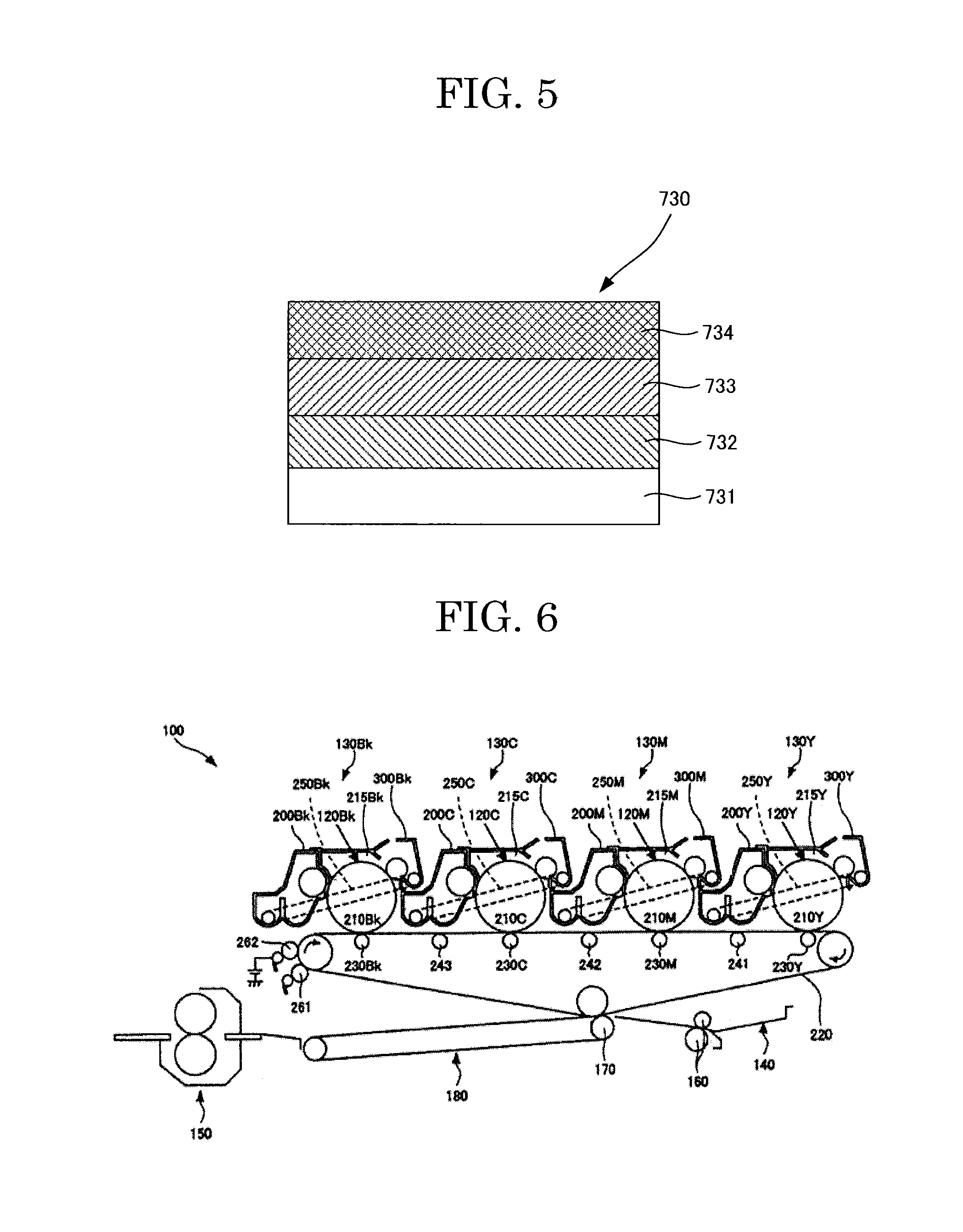

Image Forming Apparatus

ActiveUS20070071485A1Improve printing qualityIncrease speedElectrographic processImage formationEngineering

An image forming apparatus includes an image forming section that forms a toner image. A transferring section transfers the toner image formed onto a recording medium. A fixing unit is located adjacent the image forming section such that a first space is defined between the fixing unit and the image forming section. The fixing unit fixes the toner image on the recording medium. An air-chamber includes a wind exit and discharges the air through the wind exit such that the air flows into the first space. An air-propelling device propels the air to discharge through the wind exit.

Owner:OKI ELECTRIC IND CO LTD

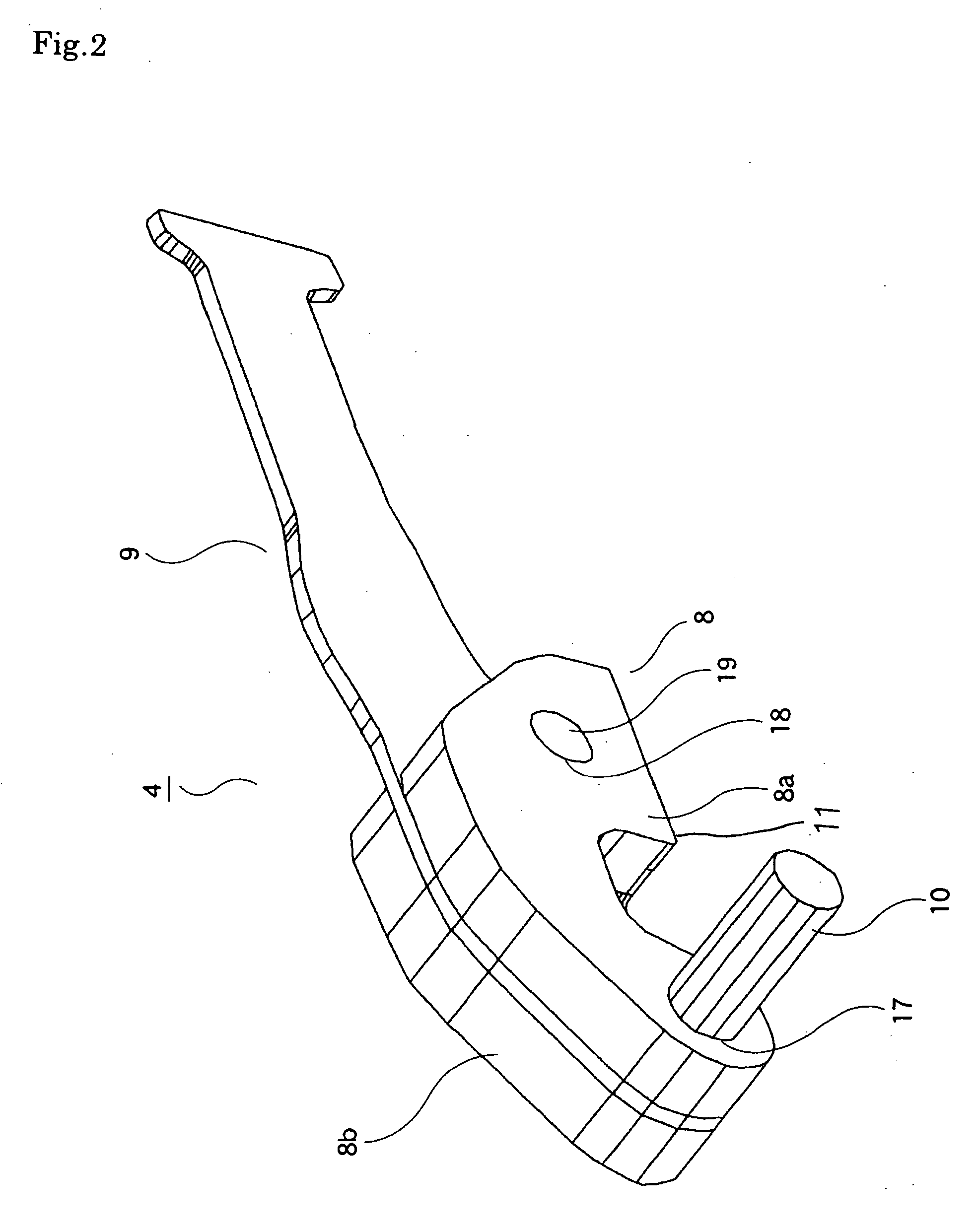

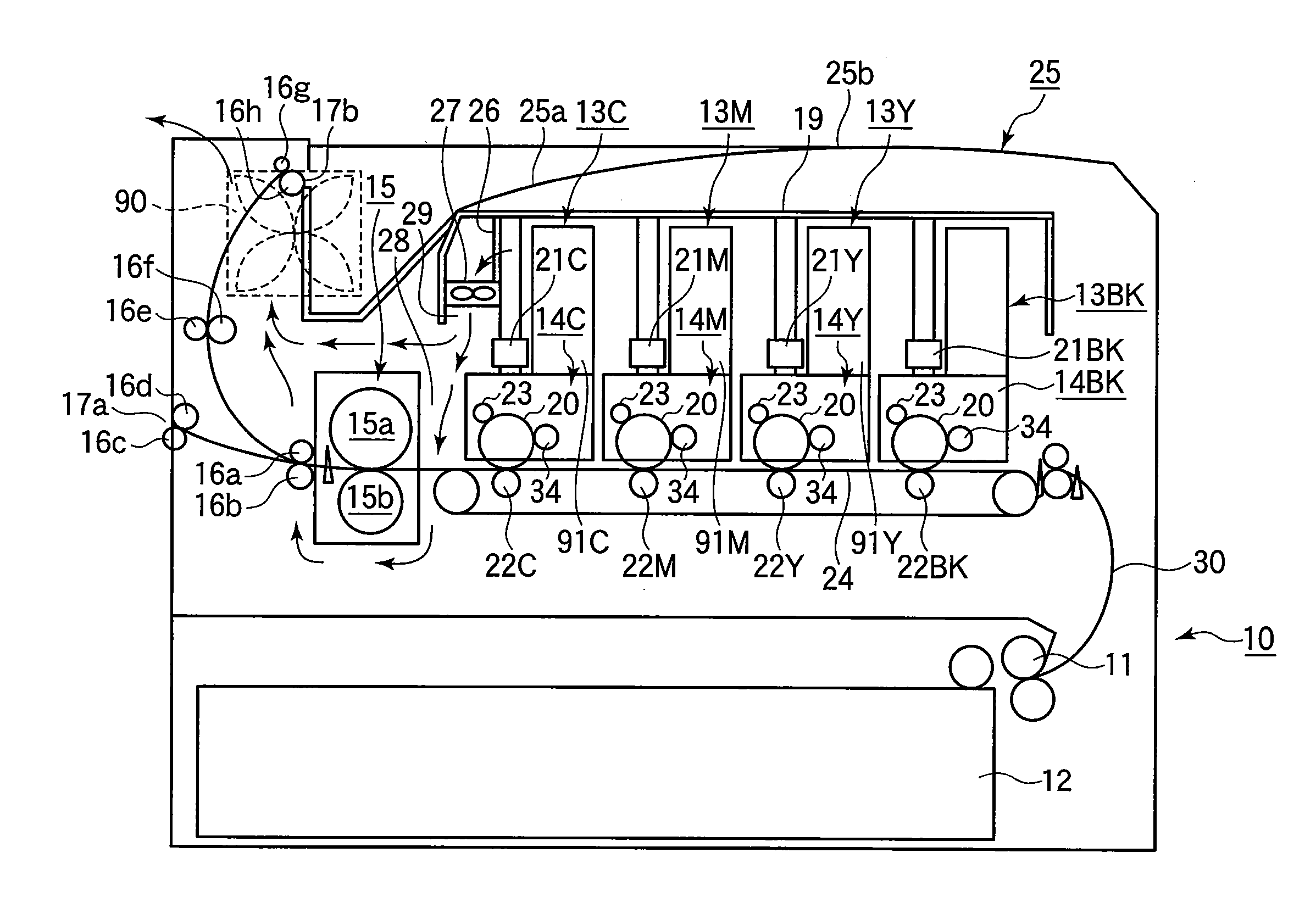

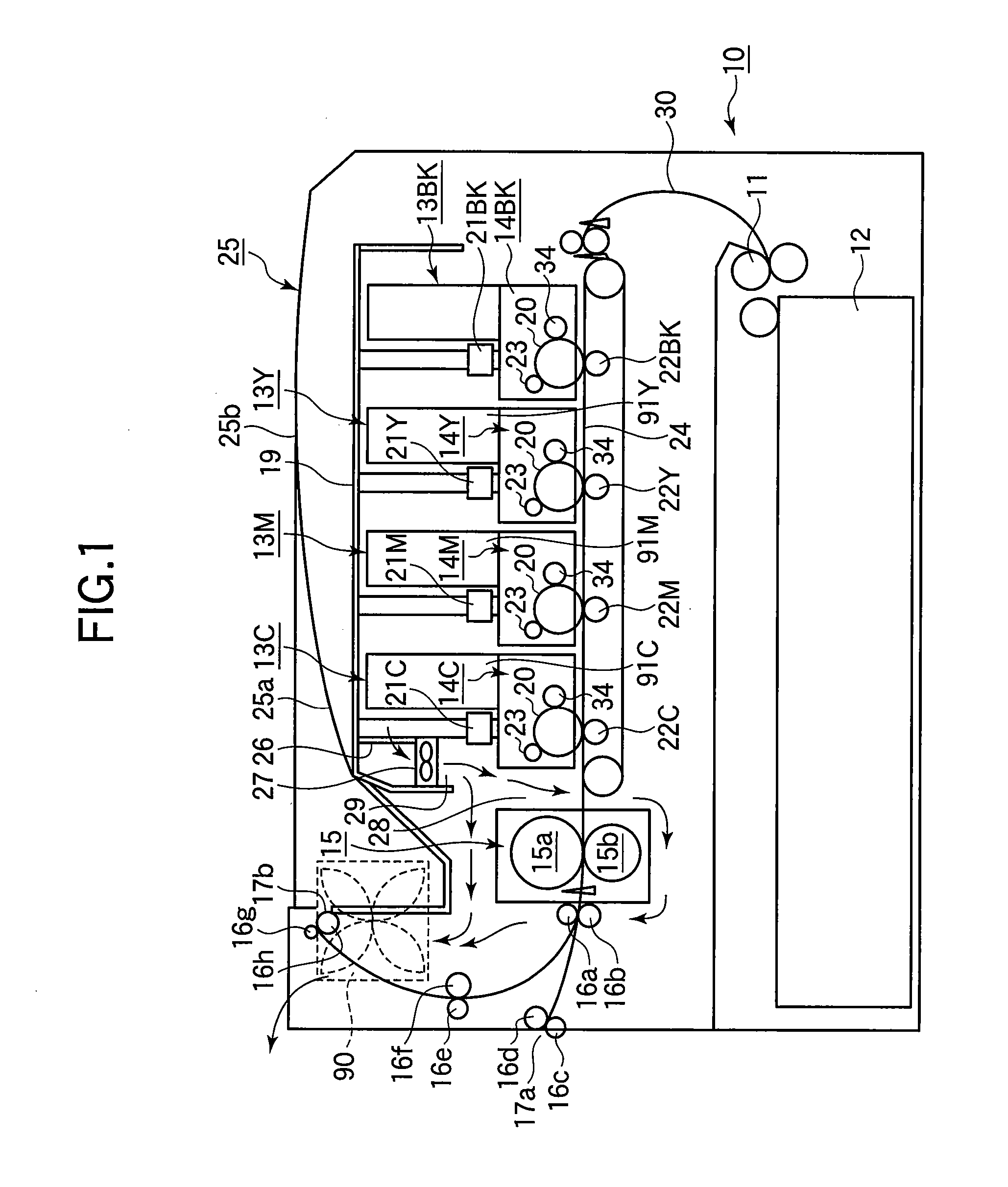

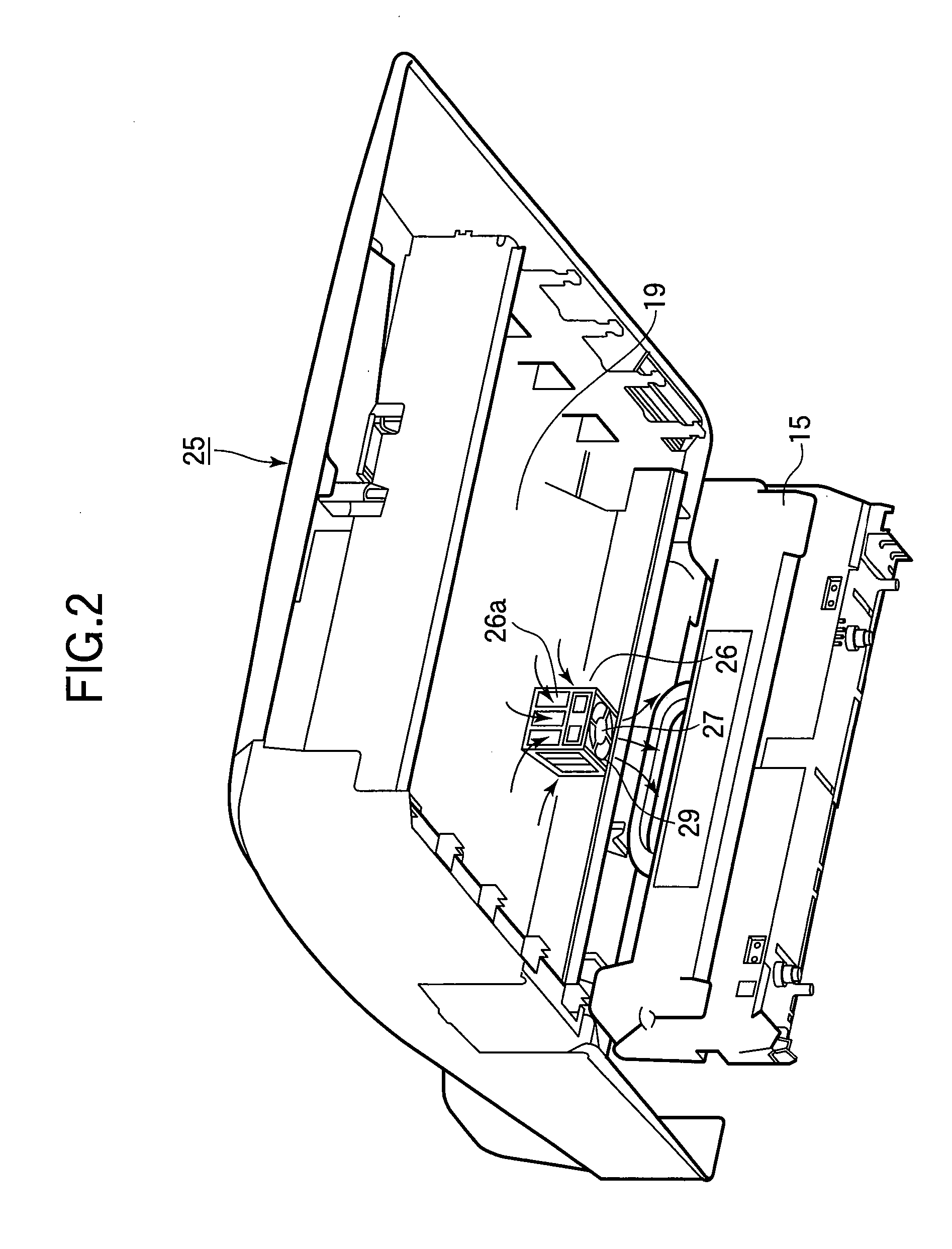

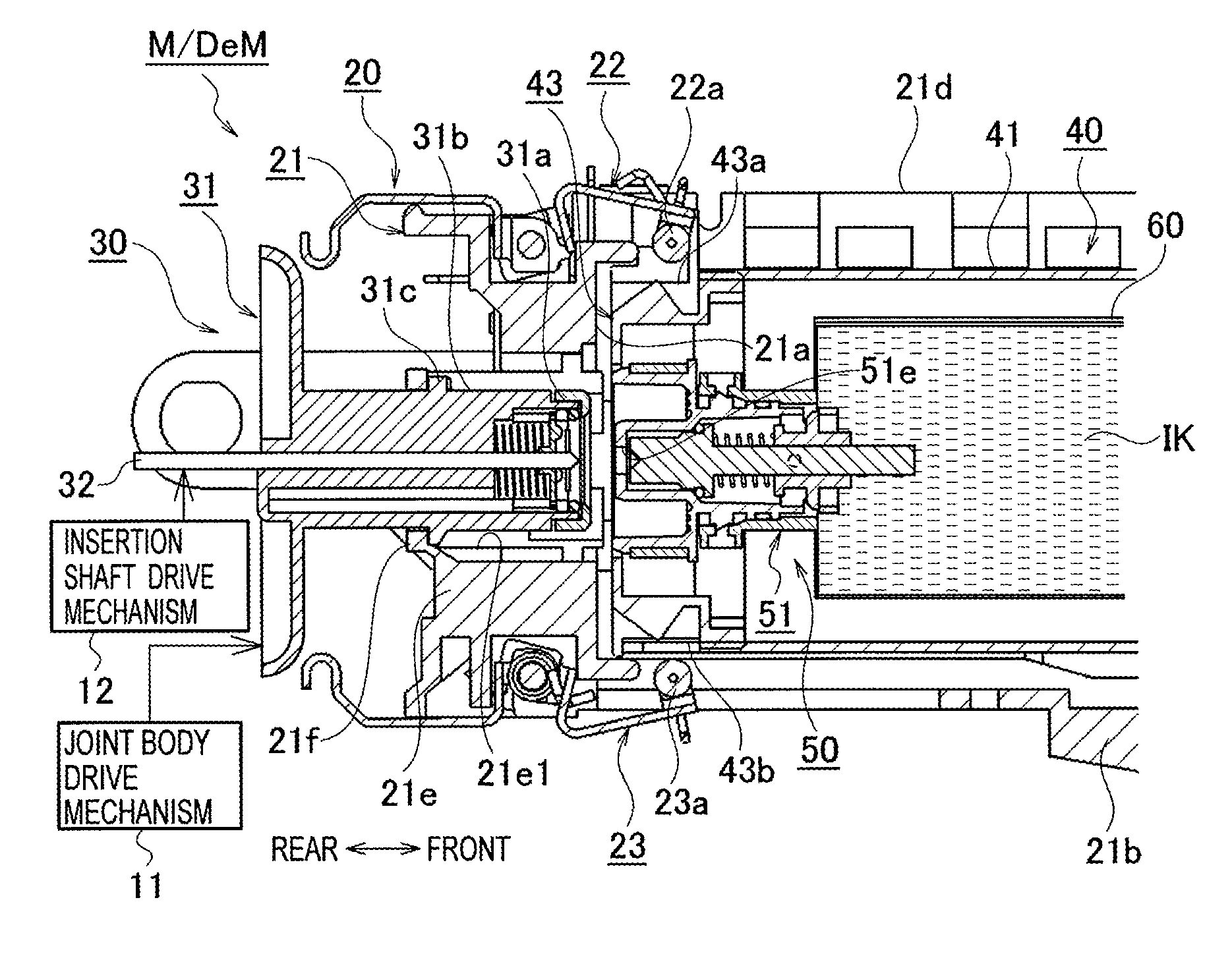

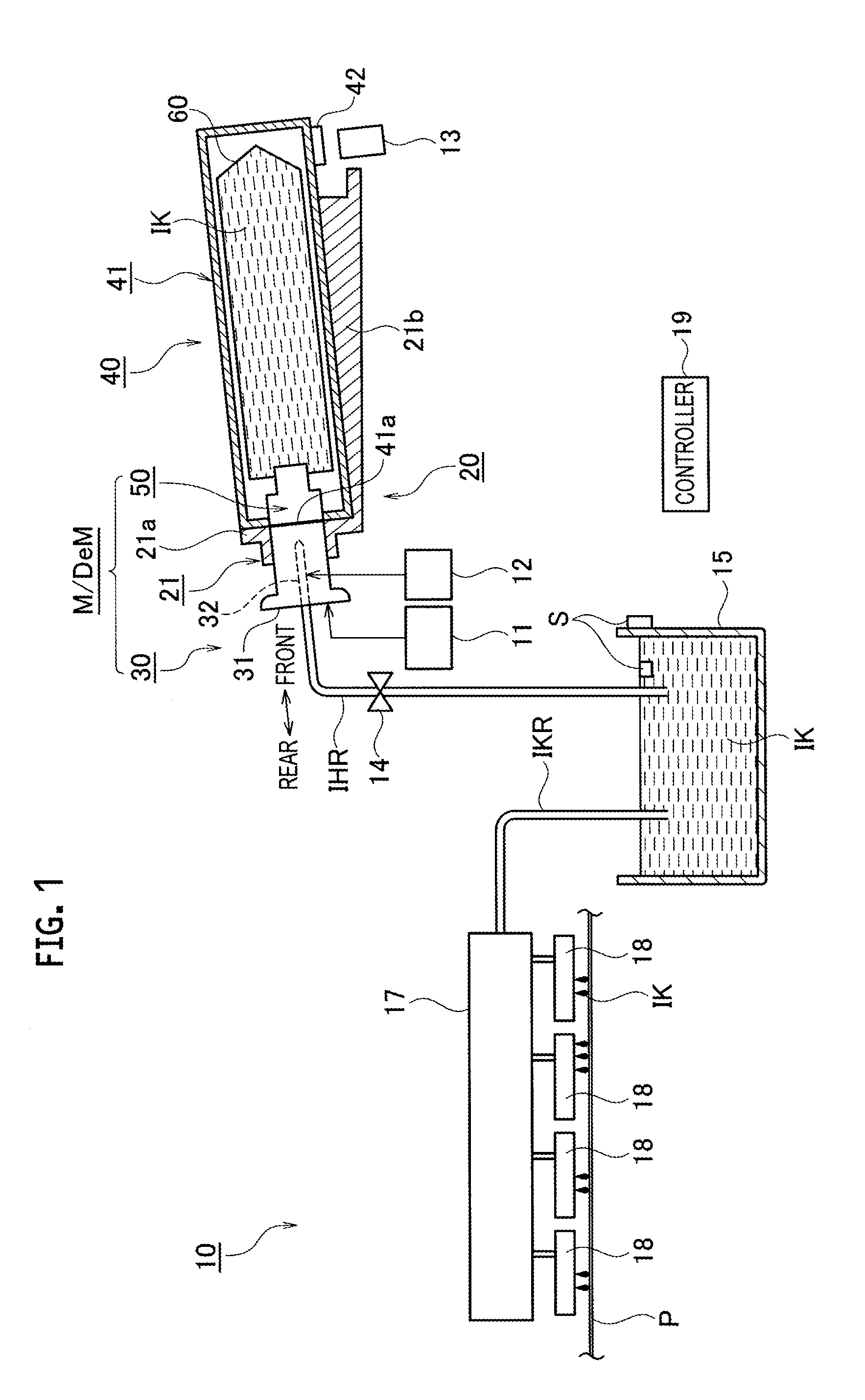

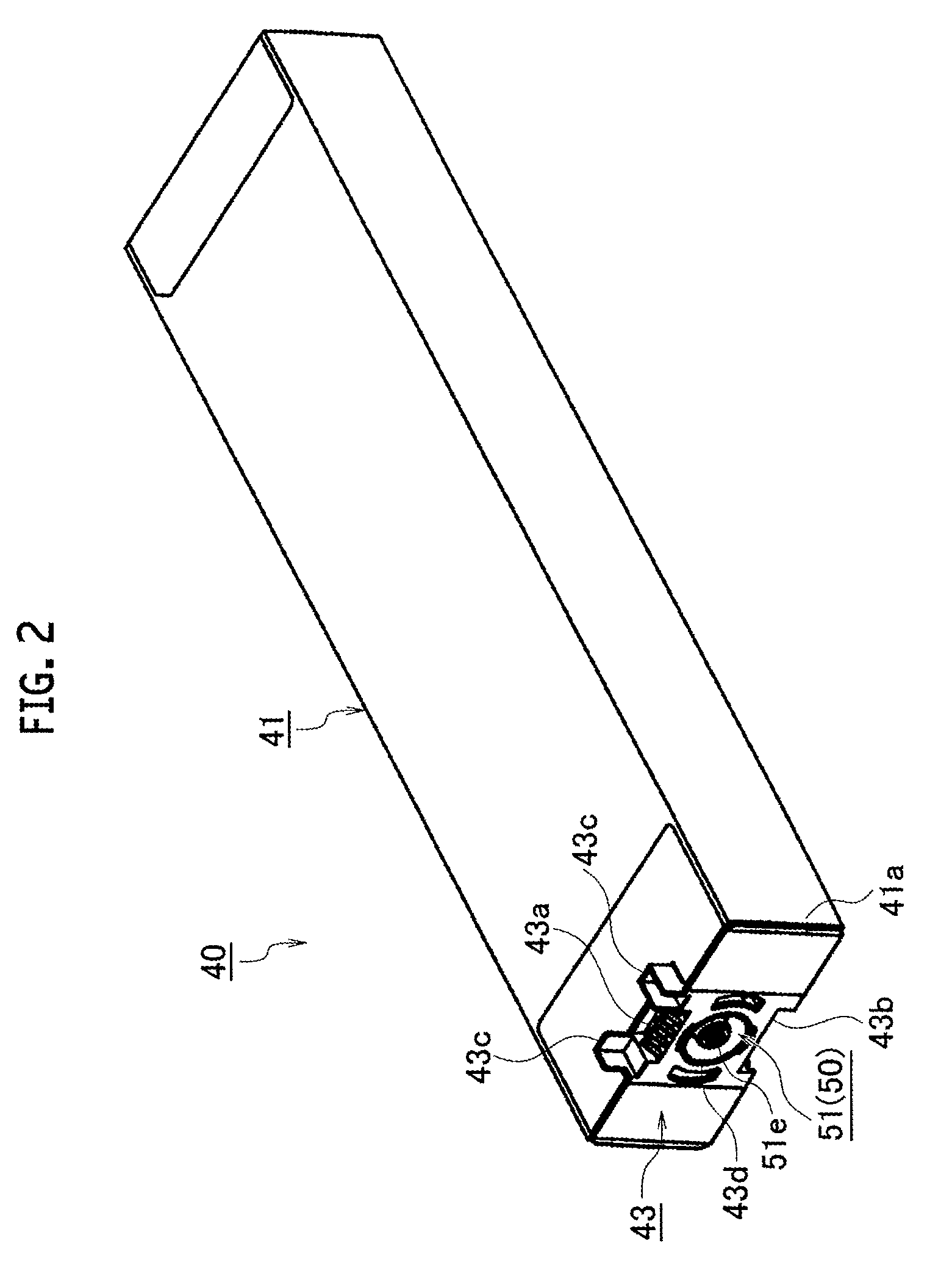

Ink cartridge and mount/demount mechanism for the same

InactiveUS9067424B1Reduce the amount requiredReduce the amount of solutionPrintingPrinting pressMechanical engineering

An ink cartridge includes: an ink storage container configured to store ink; a socket portion provided at one end of the ink storage container and configured to be fitted to and detached from a joint portion of a printing machine; an ink supply port provided in the socket portion; an inside plug configured to seal an ink passage to the ink supply port by using a biasing force coming from a direction of the ink storage container; and an inside plug lock portion configured to lock the inside plug at a position where the inside plug is pressed by an insertion shaft, and maintain a locked state of the inside plug independently of a retreating of the insertion shaft to a retreat position after a locking of the inside plug.

Owner:RISO KAGAKU CORP

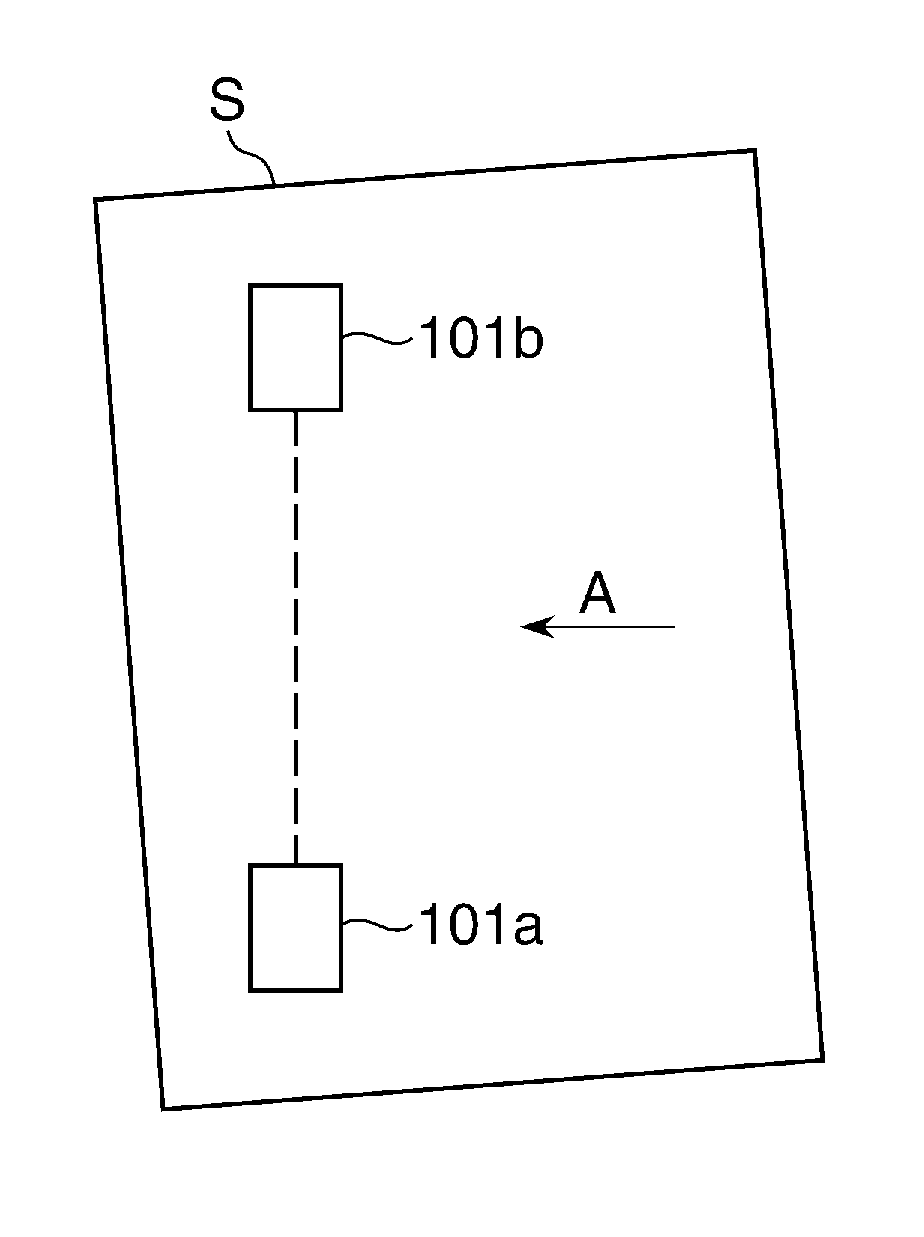

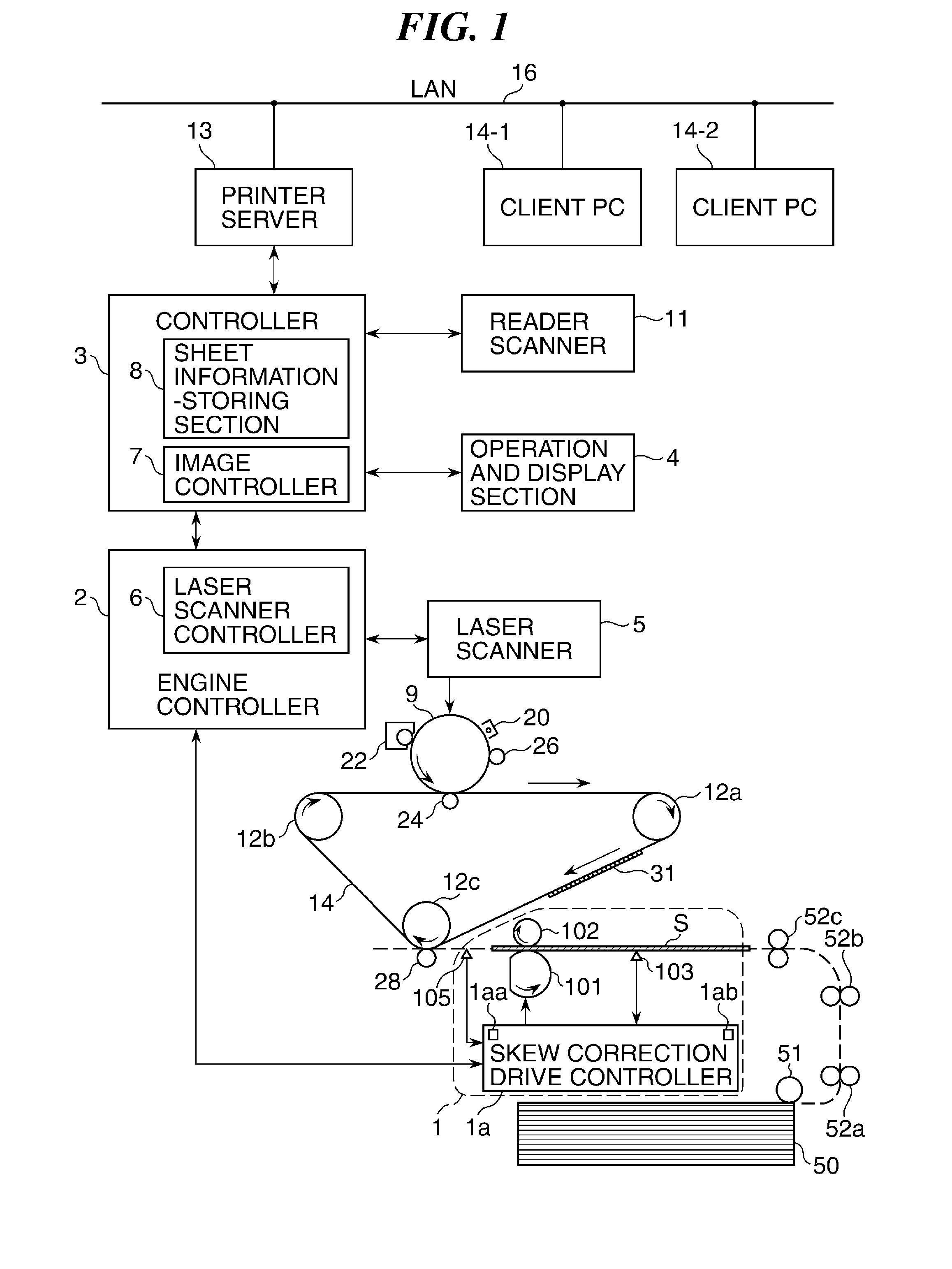

Sheet conveying device having function of correcting skew of sheet

ActiveUS20120133093A1High speedHigh accuracyRegistering devicesFunction indicatorsPaper sheetLeading edge

A sheet conveying device that makes it possible to perform printing at high speed with high accuracy by easily correcting skew of a sheet, such as an index tab sheet, without requiring troublesome operations. Sheet detection sensors for detecting a sheet and skew correction rollers for conveying the sheet are disposed in a direction crosswise to a conveying direction of the sheet. A skew correction drive controller measures a leading edge detection time between respective detections of a leading edge of the sheet by the sensors, and controls the conveying speeds of the skew correction rollers independently of each other such that a skew represented by the leading edge detection time is corrected. If the leading edge detection time is not smaller than a predetermined threshold value, the skew correction drive controller reduces a skew correction amount for correcting the skew by a predetermined amount.

Owner:CANON KK

Toner and image forming apparatus

ActiveUS20130196261A1Easy to cleanHigh speed printingDevelopersElectrographic process apparatusSilica particleInorganic particle

To provide a toner, which contains: toner base particles each containing a binder resin and a colorant; and an external additive containing inorganic particles and fatty acid metal salt particles, wherein the inorganic particles contain at least hydrophobic silica particles, wherein a liberation ratio Ya of the hydrophobic silica particles from the toner is 1% by mass to 20% by mass, and wherein a libration ratio Yb of the fatty acid metal salt particles from the toner is 30% by mass to 90% by mass.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com