Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "High oil selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

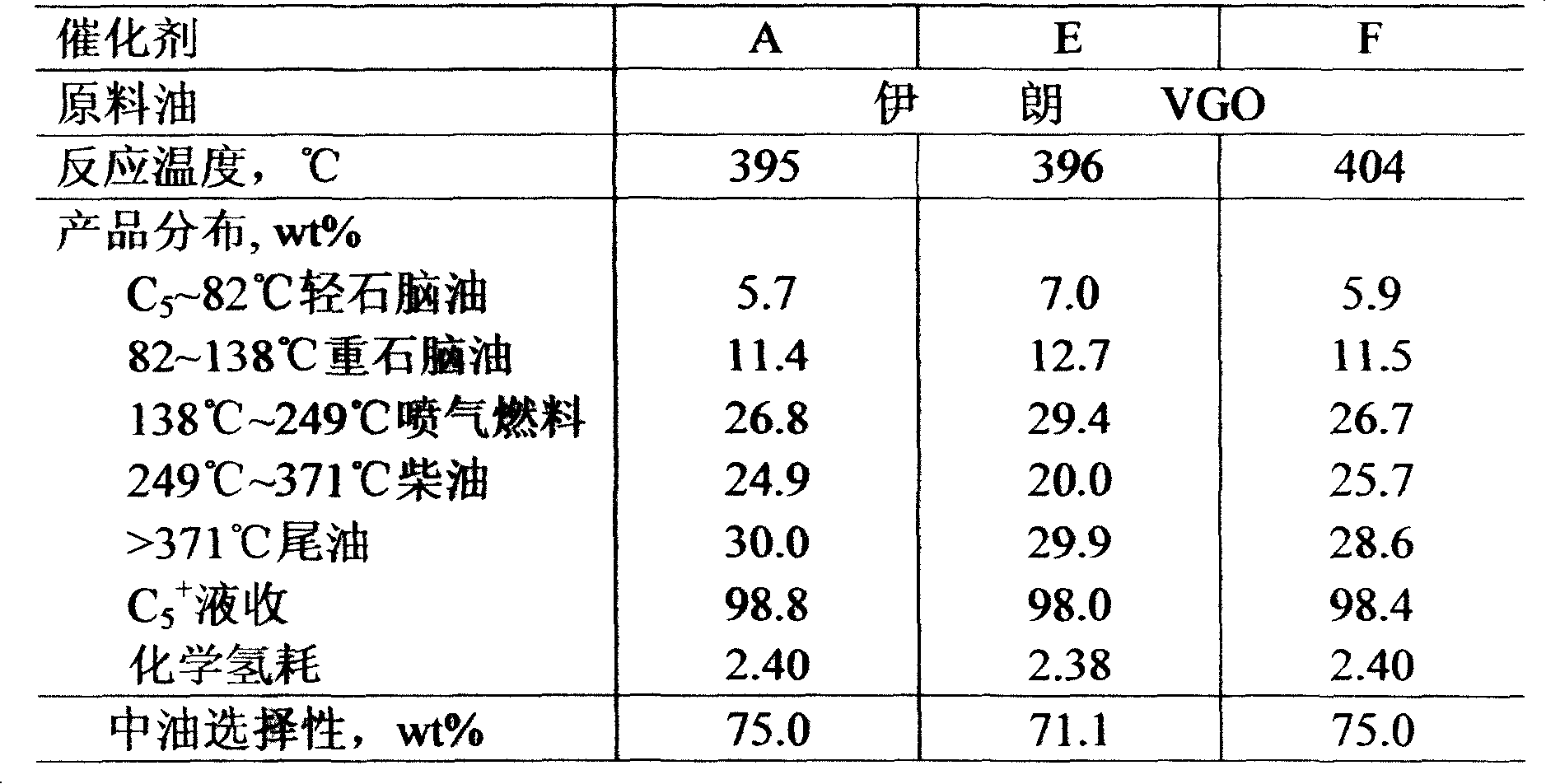

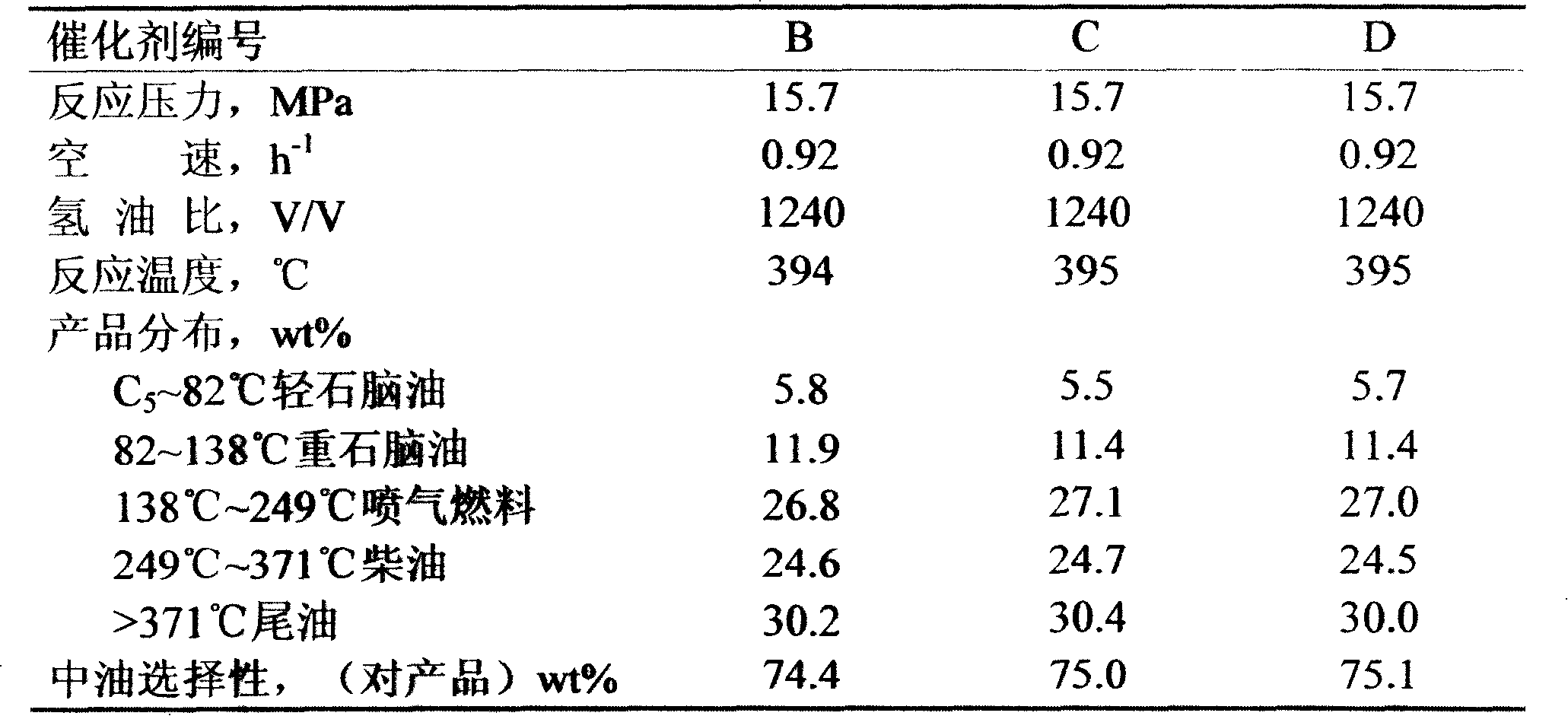

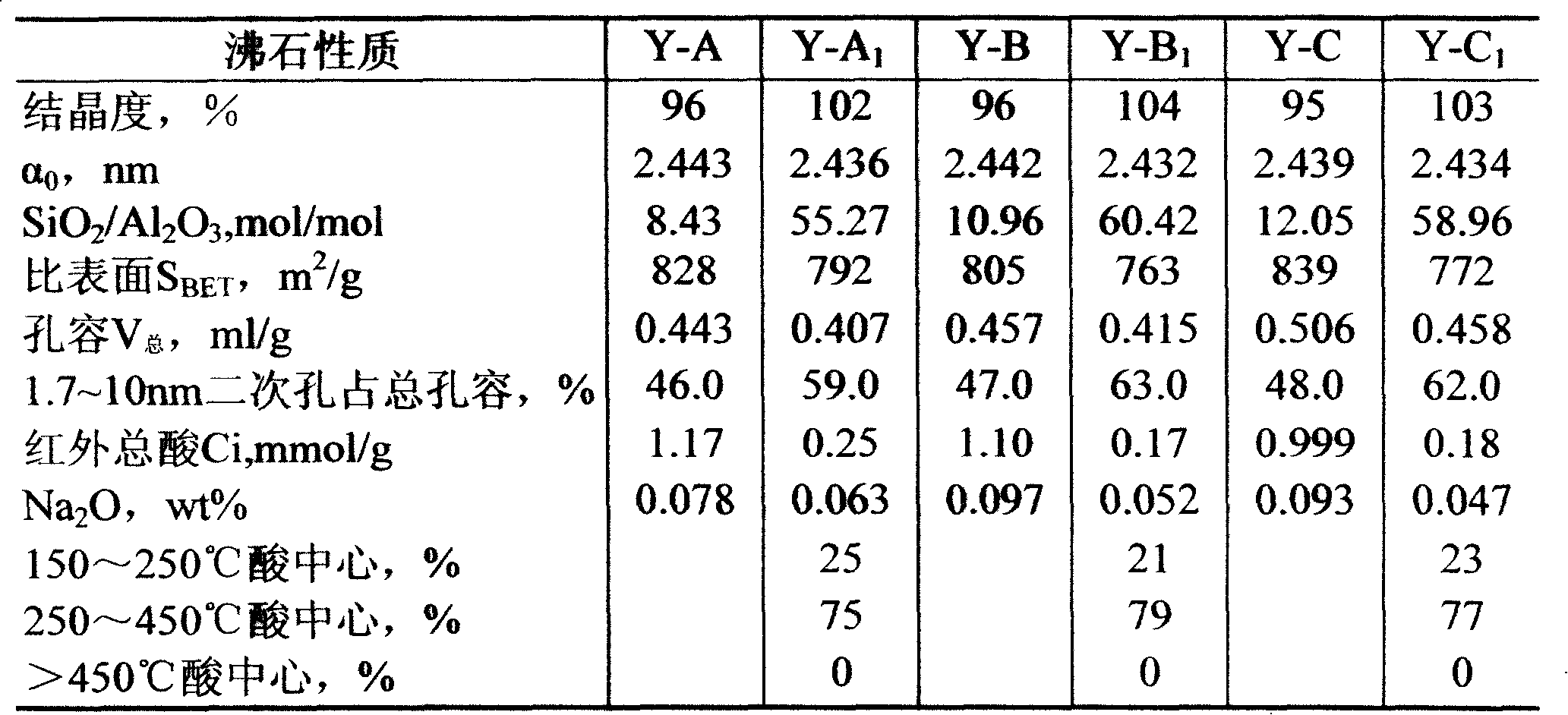

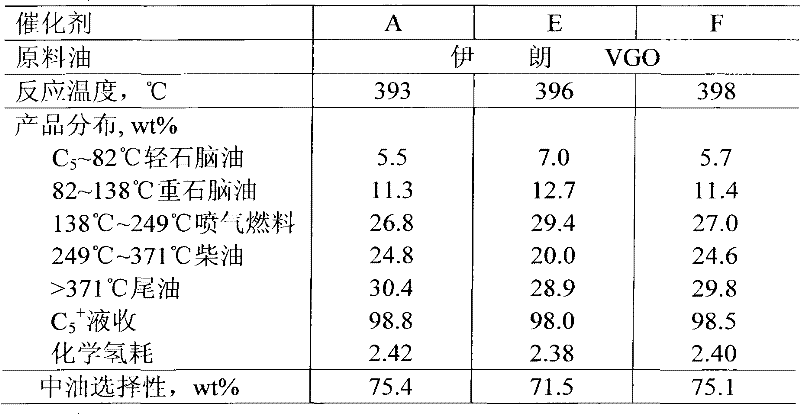

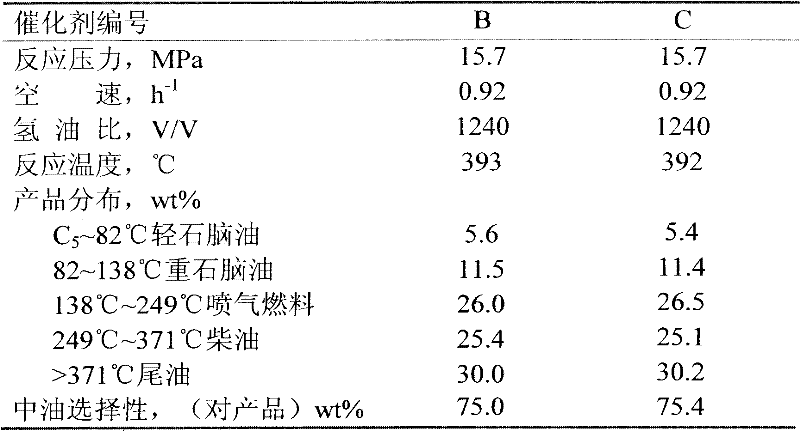

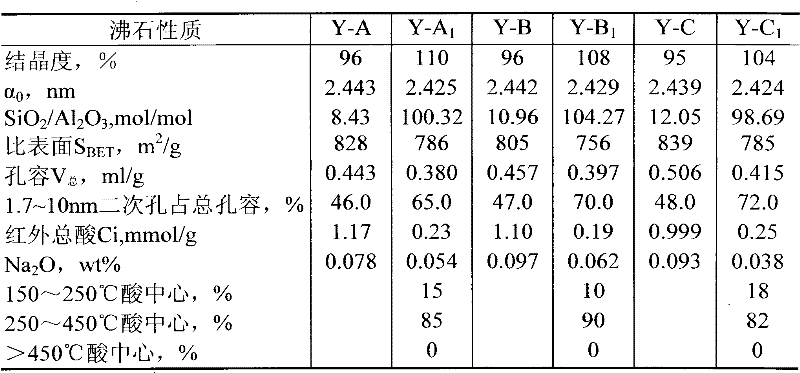

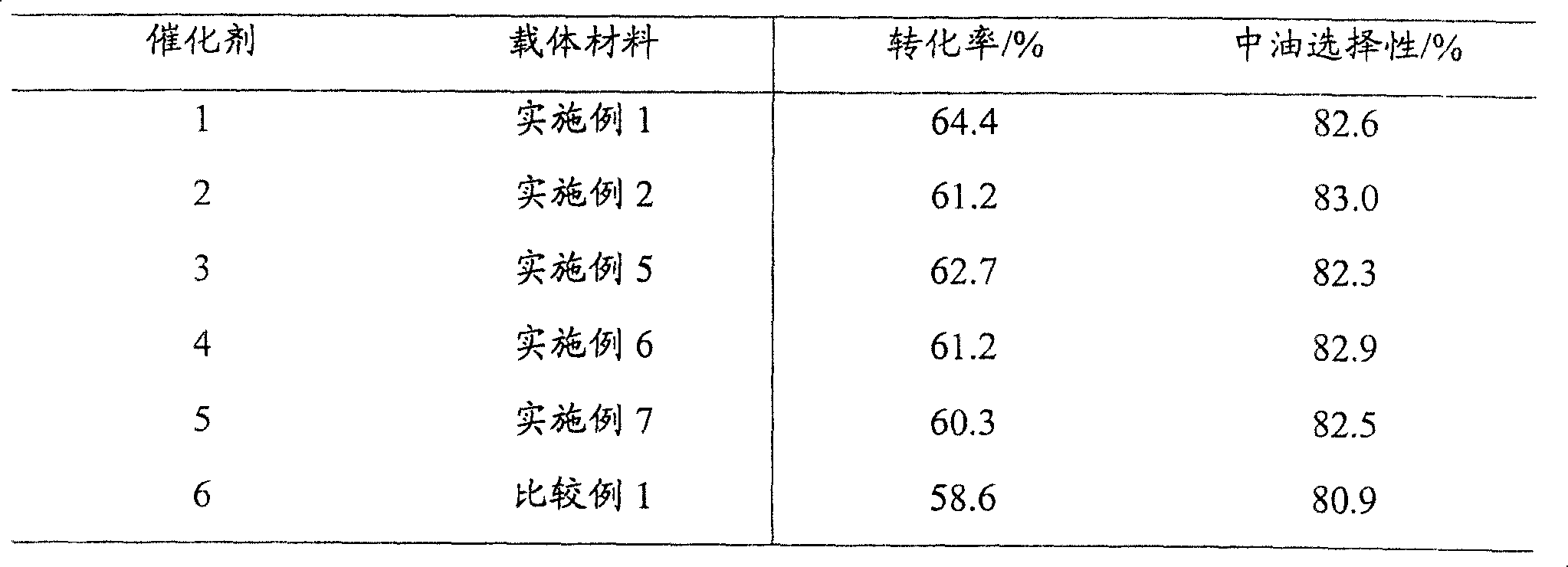

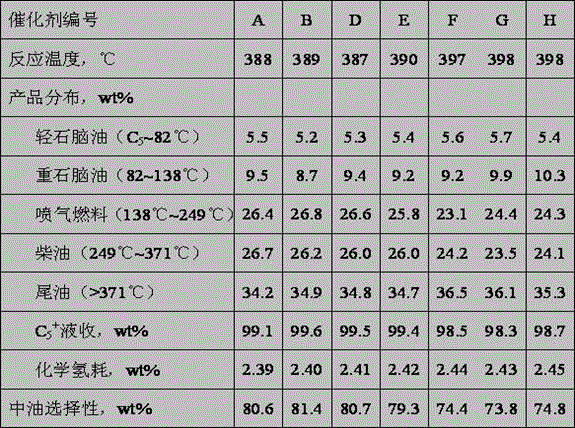

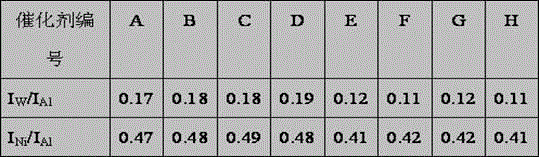

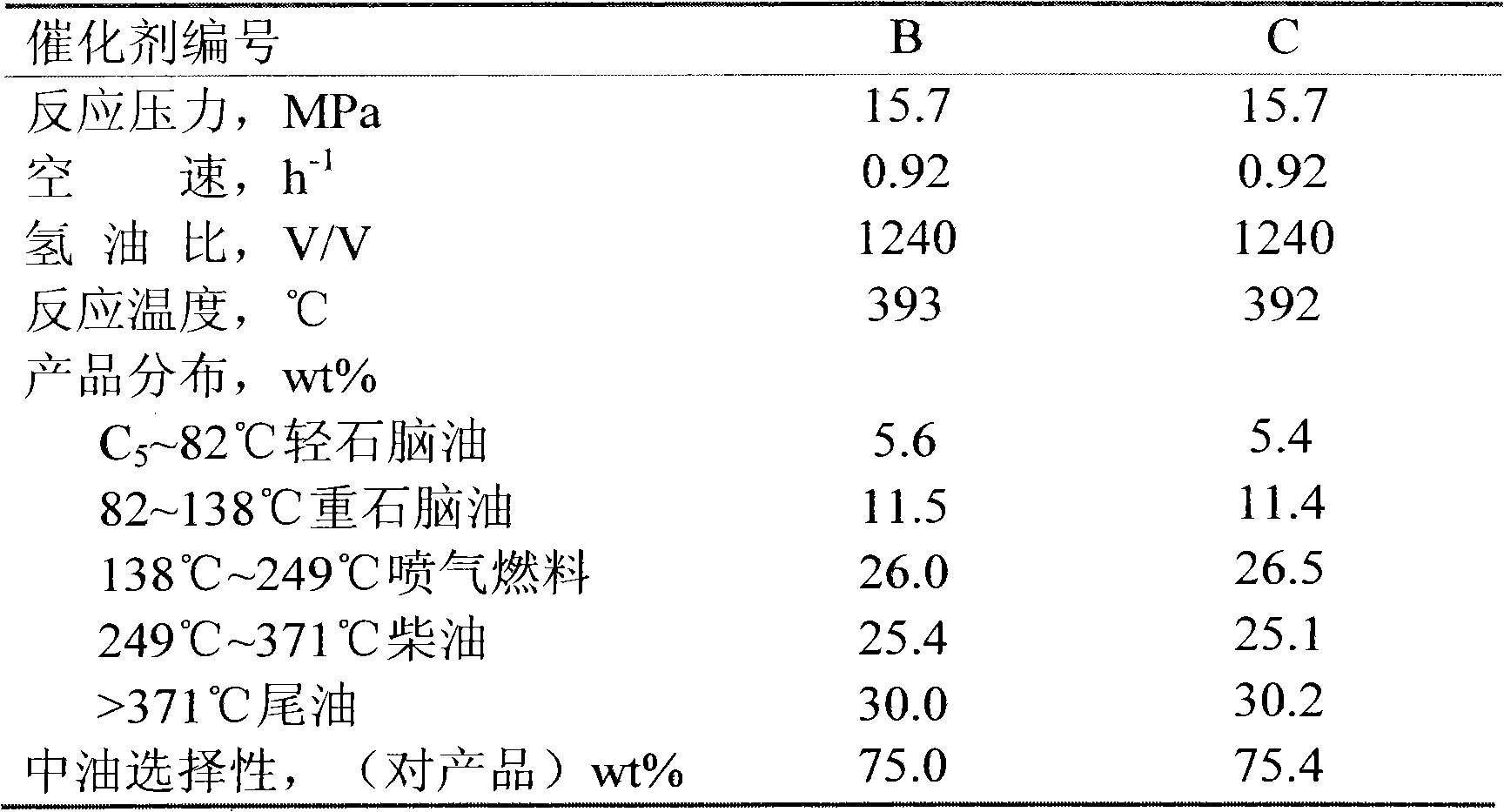

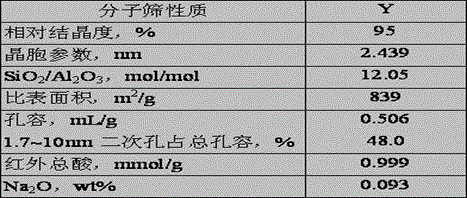

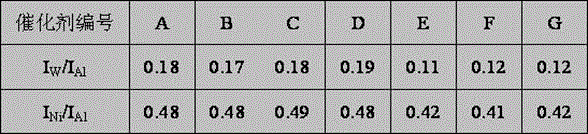

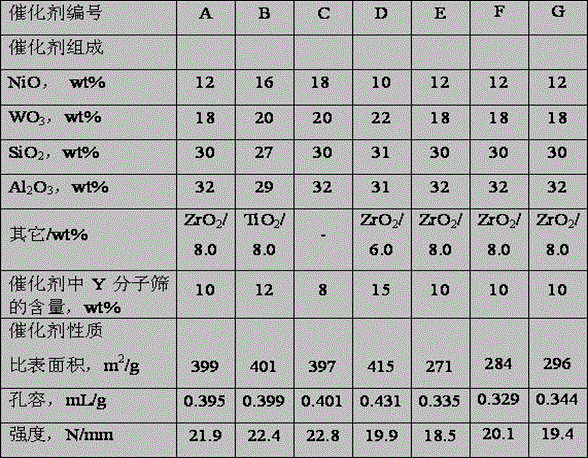

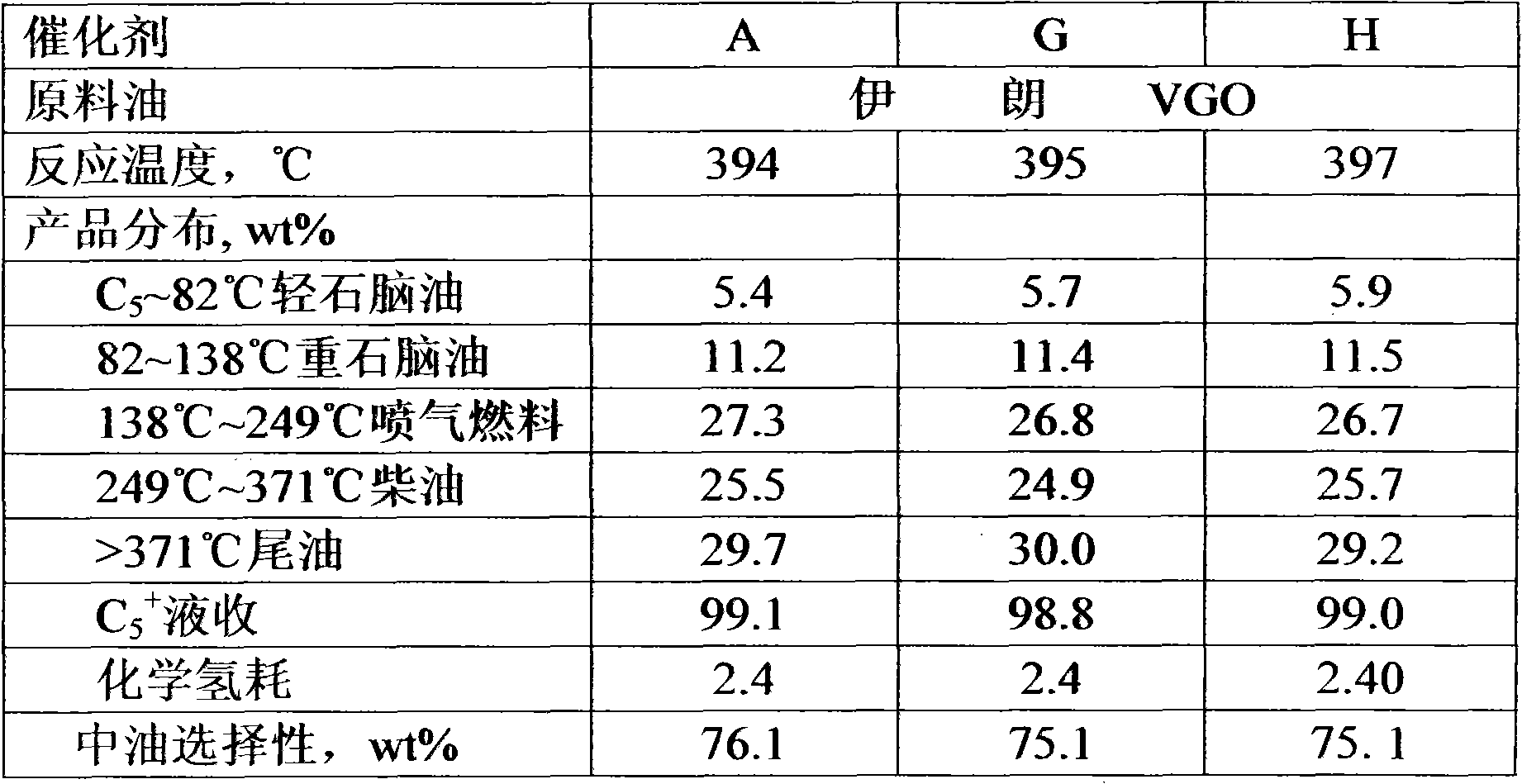

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

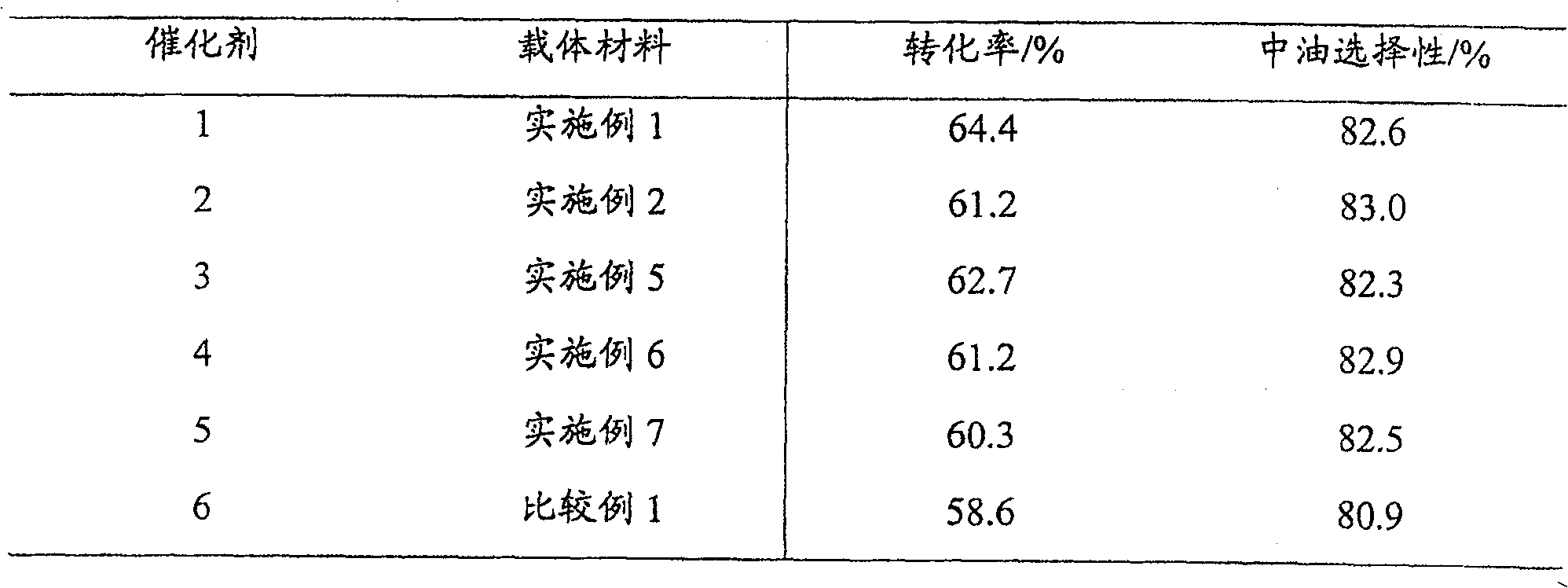

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite mesoporous molecular sieve hydrocracking catalyst and uses thereof

ActiveCN101269343AHigh activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveAdhesive

The invention relates to a composite mesoporous molecular sieve hydrocracking catalyst and the application thereof. The catalyst composed of following components of 20 to 50 percent of amorphous silica-alumina, 5 to 30 percent of alumina, 10 to 25 percent of adhesives, 10 to 40 percent of Group VIB-the metal oxides, 1 to 20 percent of Group VIII-the metal oxides, 0.1 to 10 percent of Group VA-the metal oxides, and 1 to 40 percent of composite mesoporous molecular sieve, wherein, the composite mesoporous molecular sieve is a composite molecular sieve composed of a mesoporous molecular sieve AlSBA-15 and / or AlSBA-15 / Y; the weight ratio of the composite molecular sieve AlSBA-15 / Y in the AlSBA-15 and a Y molecular sieve is 9:1 to 1:9; the weight ratio of the mesoporous molecular sieve and a pore molecular sieve is 3:1 to 1:3, the silica alumina ratio is 10:1 to 40:1, and the silica alumina ratio of the Y molecular sieve is 5:1to 20 :1. The catalyst used for hydrocracking for heavy oil shows high activity for hydrocracking and high medium oil selectivity.

Owner:PETROCHINA CO LTD

Process for preparing compound catalytic material of nanometer molecular sieve and silica-sesquioxide

InactiveCN101204663ANot easy to gatherConducive to oil conversionNanostructure manufactureMolecular sieve catalystsAluminium sulfateMolecular sieve

The invention provides a preparation method of a composite catalytic material for nanometer molecular sieve or silicon and aluminum oxides, which is characterized in that the method comprises the steps that: firstly, the nanometer molecular sieve is synthesized with directing agent, of which the depositing and dissolving process is treated with microwave and / or ultrasonic, then the serum containing the nanometer molecular sieve is added with a mixed aqueous solution of water glass and aluminum sources and then PH is adjusted to 7 to 9.5 by adding acid to form a gel. The composite catalyst material is obtained after dying and baking the gel. The aluminum source is selected from sodium metaaluminate or aluminium sulphate. The method keeps granule of the molecular sieve product smaller than 100nm and the nanometer molecular sieve thereof is resistant to aggregation. The method is free from acid sol process so that the molecular sieve is not destroyed by acid. The composite material is suitable for catalytic cracking and hydrocracking reactions of large molecules of heavy oils.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrocracking catalyst preparation method

ActiveCN104588082AEasy to useControl distributionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHigh activity

The invention discloses a preparation method of a hydrocracking catalyst. According to the method, a nickel and aluminum precipitate is prepared with a straight addition method; a tungsten, silicon and aluminum precipitate is prepared with a parallel flow precipitation method; the two precipitates are mixed, and a suspension liquid of Y type molecular sieve is added, such that the catalyst is prepared. With the method, the distributions of different hydrogenation active metals can be controlled; high-activity phase can be formed among active metals tungsten and nickel; and the interaction between active metals and the carrier can be improved. Therefore, the hydrogenation activity and the cracking activity of the obtained hydrocracking catalyst can cooperate well, and the application performance of the hydrocracking catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite double microporous material and preparation thereof

ActiveCN101376506AImprove catalytic performanceHigh selectivityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveSynthesis methods

The invention relates to a Y / Beta composite dual-microporous material. A composite molecular-sieve material has the structure that a Y molecular-sieve is taken as a kernel, a Beta molecular-sieve is taken as a shell, the two molecular-sieves are closely combined into a composite molecular-sieve particle, the Beta molecular-sieve wraps the Y molecular-sieve, and the content of the Y molecular-sieve is 30 to 70 percent in a composite molecular-sieve. The synthesis method of the composite molecular-sieve adopts a one-step crystallization method and utilizes a liquid concentration principle to lead a template agent and amorphous Si and Al in the Y molecular-sieve to form a secondary structure unit of the Beta molecular-sieve and even a Beta molecular-sieve seed crystal; then the Beta molecular-sieve grows through the guiding effect of the seed crystal. The Y / Beta composite dual-microporous material which is synthesized by adopting the method has the high composite advantage; the Beta molecular-sieve wraps the surface of the Y molecular-sieve, and the Beta molecular-sieve in the composite dual-microporous material is in the nano-scale, so the catalytic performance of the whole composite dual-microporous material is enhanced markedly; and the medium oil selectivity of the hydrocracking reaction can be increased, and the reaction temperature is reduced.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Preparation method of bulk phase hydrocracking catalyst

ActiveCN103055922BLarge specific surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePolymer science

The invention discloses a preparation method of a bulk phase hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals, silicon and organic solvents, and preparing a sodium metaaluminate alkaline solution B; filling clear water into a reaction tank and filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, controlling the pH value of pulp in the reaction tank to be 7.0-9.0, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering and drying the obtained mixture, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst. The catalyst prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high dispersibility of reactive metal components, and is especially suitable to serve as a high-activity middle oil type hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN104588085AHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsMolecular sieveActive phase

The invention discloses a preparation method of a hydrocracking catalyst. The method includes preparing nickel-aluminum precipitate by a normal precipitation method and tungsten-silicon-aluminum precipitate by a parallel-flow precipitation method, adding an organic amine in gelling process of any one step or two steps above, mixing the two precipitates, adding a molecular sieve suspension, and performing aging and forming to obtain the catalyst. The inventive method can control the distribution of different metals with hydrogenation activities, is conducive to forming a highly active phase between active metals tungsten and nickel, can improve the interaction between the active metals and a carrier, so that the hydrogenation activity and cracking activity of the obtained hydrocracking catalyst can be well coordinated, and the use performance of the hydrocracking catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-medium oil selective hydrocracking catalyst

InactiveCN101844085ASolve reunionSolve filterabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive component

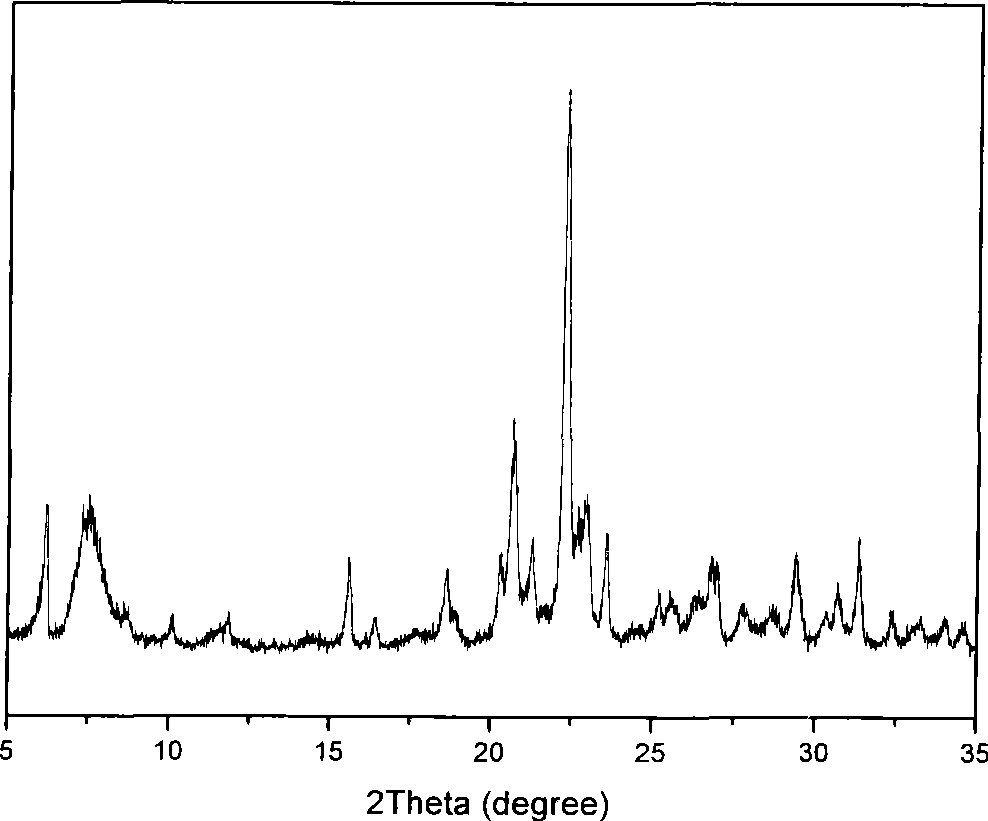

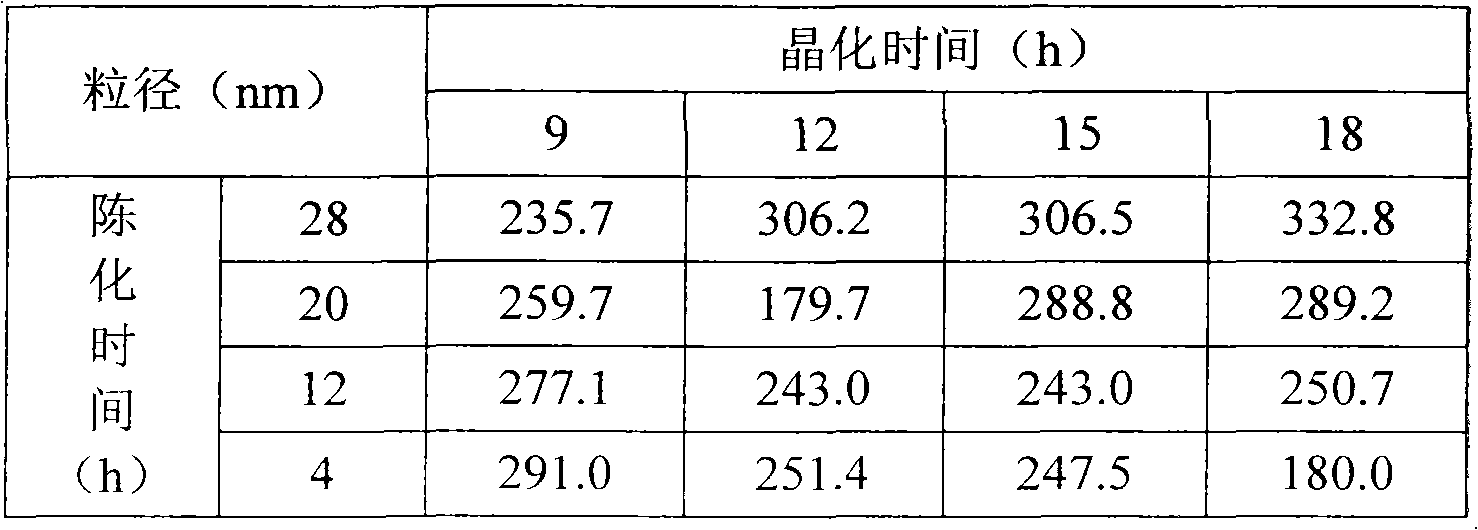

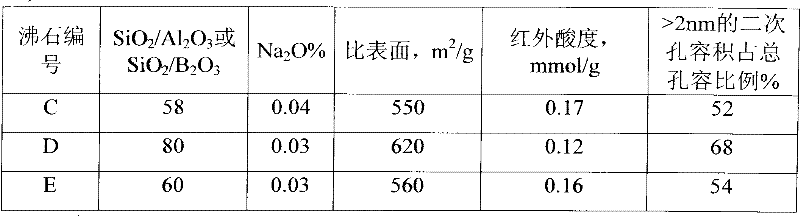

The invention relates to a preparation method of a high-medium oil selective hydrocracking catalyst. The invention firstly provides a preparation method of a Y-molecular sieve / Si-Al oxide composite catalytic material, comprising the steps of: synthesizing a Y-molecular sieve by a guide agent method, controlling the synthesis temperature of mother solution to be below 0 DEG C, the ageing time to be 4-8h, the crystallization temperature to be 90-95 DEG C and the crystallization time to be 9-18h, and obtaining slurry formed by the Y-molecular sieve and the rest crystallization liquid; carrying out ammonium exchange treatment on the Y-molecular sieve, and obtaining the mixed solution; and adding an Al source and a Si source into the mixed solution, adjusting the pH value to be 6-10 to form gel, drying the gel, and obtaining the composite catalytic material. The invention also provides the preparation method of the high-medium oil selective hydrocracking catalyst, comprising the following steps of: preparing the Y-molecular sieve / Si-Al oxide composite catalytic material according to the method; taking the composite catalytic material as a carrier for carrying active components; and obtaining the high-medium oil selective hydrocracking catalyst by drying and calcining.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method for modified B-Beta zeolite-containing hydrocracking catalyst

ActiveCN102441421AIncreased crystal synthesis and production speedReduced total synthesis timeMolecular sieve catalystsHydrocarbon oil crackingSolventAmorphous silica-alumina

The invention relates to a preparation method for a modified B-Beta zeolite-containing hydrocracking catalyst. Modified B-Beta zeolite is first prepared, the modified B-Beta zeolite and macroporous amorphous silica-alumina are uniformly mixed and added with bionder or peptizer, and after shaping, drying and baking, a catalyst carrier is prepared; the impregnation method is adopted to load hydrogenation active components, and after drying and baking, the hydrocracking catalyst is prepared. While taking account of catalyst activity and middle fraction oil selectivity, the hydrocracking catalyst prepared by the method also can be used for producing high-quality, low-freezing point diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrocracking catalyst containing heteropoly acid

ActiveCN104588119AEasy to useImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingHeteropoly acidAmorphous silicon

The invention discloses a preparation method for a hydrocracking catalyst containing heteropoly acid. The method comprises the following steps: preparing a nickel-aluminum precipitate with larger grain by using a regular addition method; preparing a tungsten-silicon-aluminum precipitate with smaller grain by using a parallel flow method; mixing the two precipitates and carrying out hydrothermal treatment; then carrying out impregnation with a heteropoly acid solution; and carrying out molding and calcination so as to prepare the hydrocracking catalyst. The method enables the catalyst to have high using performance by adjusting distribution of a hydrogenation active metal, heteropoly acid, alumina and amorphous silicon aluminum and promoting coordination and cooperation among the above-mentioned substances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for modified B-Beta zeolite-containing hydrocracking catalyst

ActiveCN102441421BIncrease productivityHigh purityMolecular sieve catalystsHydrocarbon oil crackingPtru catalystEngineering

The invention relates to a preparation method for a modified B-Beta zeolite-containing hydrocracking catalyst. Modified B-Beta zeolite is first prepared, the modified B-Beta zeolite and macroporous amorphous silica-alumina are uniformly mixed and added with bionder or peptizer, and after shaping, drying and baking, a catalyst carrier is prepared; the impregnation method is adopted to load hydrogenation active components, and after drying and baking, the hydrocracking catalyst is prepared. While taking account of catalyst activity and middle fraction oil selectivity, the hydrocracking catalyst prepared by the method also can be used for producing high-quality, low-freezing point diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst, and preparation method thereof

ActiveCN106140285AHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveAdhesive

The invention discloses a preparation method for a hydrocracking catalyst and a preparation method thereof. The catalyst comprises a carrier and a hydrogenation active metal component. The carrier comprises a beta molecular sieve, amorphous silicon aluminum and an adhesive. The beta molecular sieve has the properties that a mol ratio of SiO2 to Al2O3 is 60 to 100; a specific surface area is 505 to 850 m<2> / g; a pore volume is 0.35 to 0.60 mL / g; and relative crystallinity is 100 to 148%. After hydro-thermal treatment by water vapor, the relative crystallinity of the beta molecular sieve is 95% or above. According to the invention, the beta molecular sieve with high crystallinity, a high silica-alumina ratio and good stability is used as an acidic component of the carrier and matched with amorphous silicon aluminum; and the hydrocracking catalyst prepared from the carrier is especially applicable to one-stage tandem hydrocracking process and has the characteristics of high activity, good medium oil selectivity and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN106140251BHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrogenation cracking catalyst carrier and a preparation method thereof. The carrier comprises a beta molecular sieve, amorphous silica-alumina and a binder; the beta molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 60-100, the specific surface area is 505-850 m<2> / g, the pore volume is 0.35-0.60 mL / g, and the relative crystallinity degree is 100%-148%; the relative crystallinity degree of the beta molecular sieve subjected to water steam hydrothermal treatment is more than or equal to 95%. The beta molecular sieve with high crystallinity degree, high silica / alumina ratio and good stability is used as an acid component of the carrier and cooperates with the amorphous silica-alumina, so a hydrogenation cracking catalyst prepared by the obtained carrier has the characteristics of high activity, good medium oil selection, and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation cracking catalyst and preparation method of same

ActiveCN106140280AHigh crystallinityImprove stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The invention discloses a hydrogenation cracking catalyst and a preparation method of same. The hydrogenation cracking catalyst comprises a carrier and a hydrogenation active metal component, wherein the carrier includes [beta] molecular sieve, amorphous silica-alumina, and an adhesive. On the basis of the weight of the carrier, the carrier includes, by weight, 2-15% of the [beta] molecular sieve, 45-85% of the amorphous silica-alumina, and 13-40% of the adhesive. In the carrier, the [beta] molecular sieve, which is high in crystallization degree, high in Si / Al ratio and good in stability, is used as an acidic component and is matched with the amorphous silica-alumina, so that the hydrogenation cracking catalyst prepared with the carrier is especially suitable for a single-stage hydrogenation cracking process with high activity, good medium oil selectivity and high product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055926AImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

High activity medium oil type hydrocracking catalyst and its preparation method

ActiveCN100340640CHigh crystallinityLow cell parametersHydrocarbon oil crackingMolecular sievePolymer science

The invention relates to a hydrocracking catalyst with high activity and oil selectivity, which comprises: amorphous alumina silica as carrier; and special modified Y-shape molecular screen as acid constituent that has high crystallinity, low cell parameter, riched secondary pores, large superficial area, belongs to medium strength acid center, and has strong nitrogen-resistant and ring-splitting capacity. This invention has well activity and stability for middle distillate oil in heavy hydrocarbon single-section hydrocracking technique.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst and preparation method thereof

ActiveCN106140280BHigh crystallinityImprove stabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The invention discloses a hydrogenation cracking catalyst and a preparation method of same. The hydrogenation cracking catalyst comprises a carrier and a hydrogenation active metal component, wherein the carrier includes [beta] molecular sieve, amorphous silica-alumina, and an adhesive. On the basis of the weight of the carrier, the carrier includes, by weight, 2-15% of the [beta] molecular sieve, 45-85% of the amorphous silica-alumina, and 13-40% of the adhesive. In the carrier, the [beta] molecular sieve, which is high in crystallization degree, high in Si / Al ratio and good in stability, is used as an acidic component and is matched with the amorphous silica-alumina, so that the hydrogenation cracking catalyst prepared with the carrier is especially suitable for a single-stage hydrogenation cracking process with high activity, good medium oil selectivity and high product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN106140285BHigh crystallinityImprove stabilityCatalyst carriersMolecular sieve catalystsMolecular sieveAdhesive

The invention discloses a preparation method for a hydrocracking catalyst and a preparation method thereof. The catalyst comprises a carrier and a hydrogenation active metal component. The carrier comprises a beta molecular sieve, amorphous silicon aluminum and an adhesive. The beta molecular sieve has the properties that a mol ratio of SiO2 to Al2O3 is 60 to 100; a specific surface area is 505 to 850 m<2> / g; a pore volume is 0.35 to 0.60 mL / g; and relative crystallinity is 100 to 148%. After hydro-thermal treatment by water vapor, the relative crystallinity of the beta molecular sieve is 95% or above. According to the invention, the beta molecular sieve with high crystallinity, a high silica-alumina ratio and good stability is used as an acidic component of the carrier and matched with amorphous silicon aluminum; and the hydrocracking catalyst prepared from the carrier is especially applicable to one-stage tandem hydrocracking process and has the characteristics of high activity, good medium oil selectivity and good product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411BHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveStrong acids

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055926BImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN103100403BImprove performanceIncreased pore volume and acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive agent

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst contains a compound of amorphous silica-alumina and a Y-type molecular sieve. In NaY molecular sieve modification, before final hydrothermal treatment, amorphous silica-alumina slurry and a surfactant are introduced so that the compound is obtained. Therefore, molecular sieve and amorphous silica-alumina dispersion is uniform and molecular sieve agglomeration or channel blocking is avoided so that specific surface areas and pore volumes of a carrier and the hydrocracking catalyst are greatly improved. The preparation method reduces a strong acid amount and improves a moderately strong acid ratio and a B acid amount in case of the little change of a total acid amount, reduces excessive cracking, avoids secondary cracking, is conducive to improvement of middle distillate selectivity, and reduces a yield of low-additional value products such as dry gas, liquefied gas and light naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055927BUniform grainImprove adhesionMolecular sieve catalystsCatalyst activation/preparationDispersityMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, and preparing a sodium metaaluminate alkaline solution B; adding part of the sodium metaaluminate alkaline solution B to the acidic mixed solution A, and then filling CO2; repeating the step 2 for one-six times; then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, and aging the mixture; and filtering, drying and forming the mixture, and then washing, drying and roasting the mixture, thus preparing the hydrocracking catalyst. The method has the beneficial effects that not only can the catalyst be formed easily and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased, the dispersity of metals in the catalyst can be improved, and the capability of the catalyst in processing macromolecules in heavy oil is enhanced, so that the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055923BImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

High activity, high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324BHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing compound catalytic material of nanometer molecular sieve/silicon aluminum oxides

InactiveCN100553774CNot easy to gatherConducive to oil conversionNanostructure manufactureMolecular sieve catalystsSodium aluminateSlurry

The invention provides a method for preparing a nano-molecular sieve / silicon-aluminum oxide composite catalytic material, which is characterized in that the method comprises: firstly using a guiding agent method to synthesize a nano-molecular sieve, and the precipitation step in the synthesis is treated by microwave and / or ultrasonic waves , then add the aqueous solution of the mixture of water glass and aluminum source to the slurry containing nano-molecular sieve, add acid to adjust the pH to 7-9.5 to form a gel; then dry and roast the gel to obtain the composite catalytic material, wherein the aluminum source Selected from sodium metaaluminate or aluminum sulfate, this method keeps the particle size of the product molecular sieve below 100nm and the nano molecular sieve in it is not easy to aggregate, without going through the acidic sol process to avoid the molecular sieve being damaged by acid. The composite material is suitable for the catalysis of heavy oil macromolecules Cracking and hydrocracking reactions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of method for preparing hydrocracking catalyst

ActiveCN104588072BHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oil crackingSimple Organic CompoundsMolecular sieve

The invention discloses a preparation method for a hydrocracking catalyst. The method comprises the following steps: preparing a nickel-aluminum precipitate by using a regular addition method; preparing a tungsten-silicon-aluminum precipitate by using a parallel flow method; mixing the two precipitates, adding a Y type molecular sieve suspension and carrying out ageing; then adding an organic compound and carrying out pulping and mixing; and carrying out molding and the like so as to prepare the hydrocracking catalyst. The method enables the catalyst to have high using performance by improving the distribution of a hydrogenation active metal and coordination and cooperation between the hydrogenation active metal and a carrier and further enhancing the utilization rate of the hydrogenation active metal. The catalyst is particularly applicable as a high-and-medium oil type hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN104588086BHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHigh activity

The invention discloses a preparation method of a hydrocracking catalyst. According to the method, a nickel and aluminum precipitate is prepared with a straight addition method; a tungsten, silicon and aluminum precipitate is prepared with a parallel flow precipitation method; the two precipitates are mixed, and a suspension liquid of Y-type molecular sieve is added; and the catalyst is prepared. With the method, the pore structure of the catalyst can be optimized. The distributions of different hydrogenation active metals can be controlled; high-activity phase can be formed among active metals tungsten and nickel; and the interaction between active metals and a carrier can be improved. Therefore, the hydrogenation activity and the cracking activity of the obtained hydrocracking catalyst can cooperate well, and the application performance of the hydrocracking catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN102451744BHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oil crackingAluminateMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst. The catalyst adopts amorphous silicon alumina as a carrier, adopts a Y-shaped molecular sieve as an acidic component, adopts VIB group metal and VIII group metal as hydrogenation active metal components, adopts IVB group metal as an additive, and is prepared by combining an acidic mixed solution A with the hydrogenation active metal, silicon, aluminium and the additive and a sodium meta-aluminate alkaline solution B, performing gel formation, and adding a suspension of the Y-shaped molecular sieve. The method of the invention can increase the pore volume and the specific surface area of the catalyst, improve the metal dispersiveness in the catalyst, and provide the catalyst with high hydrocracking activity, middle oil selectivity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com