Preparation method of high-medium oil selective hydrocracking catalyst

A technology of catalytic materials and composite catalytic materials, which is applied in the field of preparation of composite catalytic materials and selective hydrogenation catalysts, can solve the problems of poor balance between cracking activity and medium oil selectivity, unfavorable activity and stability of hydrocracking catalysts, Uniform distribution of acid centers and other adverse effects, to solve the problems of agglomeration and filtration, improve accessibility, and reduce the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of Small Particle Y Molecular Sieve

[0038] This embodiment provides a method for preparing a small particle Y molecular sieve, and the specific synthesis steps are as follows:

[0039] Mix sodium metaaluminate, silicate solution (water glass), sodium hydroxide and deionized water in a molar ratio of Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=18:1:16:336 ratio mixing, stirring evenly, standing and aging for 20-50h to obtain the directing agent;

[0040] In an ice-water bath (0°C), mix a certain amount of sodium metaaluminate, sodium hydroxide and deionized water, stir evenly, then add a certain amount of silicate solution, so that the molar ratio of the system is Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=8: 1: 3.2: 300, after high-speed stirring for 30min, the synthetic mother liquor was obtained;

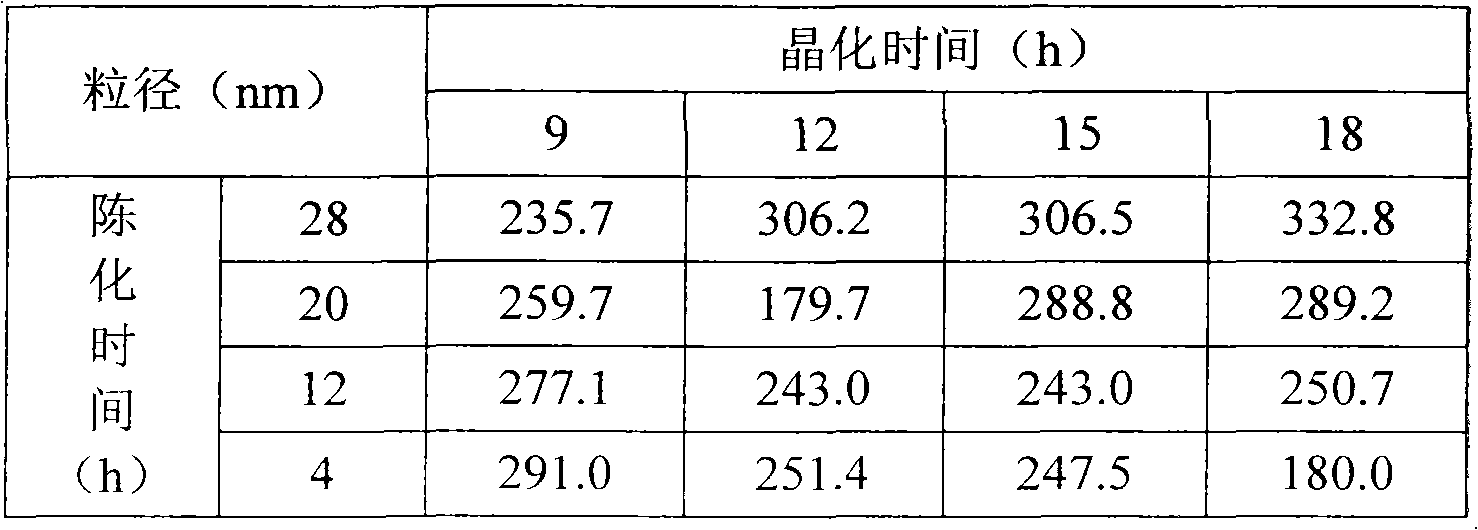

[0041] Add the above-mentioned directing agent in the synthesis mother liquor, wherein the directing agent / (directing agent+mother liquor) is 5-20% by weight, so t...

Embodiment 2

[0046] This embodiment provides a method for preparing a Y molecular sieve / amorphous silicon aluminum oxide composite carrier, which uses the remaining crystallization liquid as the silicon source and aluminum nitrate as the aluminum source, and includes the following specific steps:

[0047] Get 40g of the small particle Y molecular sieve precipitate prepared by Example 1, place it in a constant temperature reactor at 90°C, add 50mL of deionized water and 33mL of ammonium nitrate solution (NH 4 + ion concentration is 6.0mol / L), after stirring for 3 hours, the temperature was lowered to 60°C, and at the same time, 21mL of aluminum nitrate solution (as Al 2 o 3 The concentration of the meter is 1.27mol / L) and dilute ammonia solution (the volume ratio of concentrated ammonia water to deionized water is 5:7), so that the pH value of the mixed solution is between 7-8, after stirring for 20min, add 164mL of Crystallization residual liquid (that is, all the crystallization residua...

Embodiment 3

[0051] This example provides a method for preparing a Y molecular sieve / amorphous silicon-aluminum oxide composite carrier, which is based on sodium silicate and crystallization residual liquid with SiO 2 A mass ratio of 0.5 is mixed as a silicon source, and aluminum nitrate is an aluminum source, including the following specific steps:

[0052] Take 50g of the precipitated small particle Y molecular sieve prepared in Example 1, place it in a constant temperature reactor at 90°C, add 50mL of deionized water, stir evenly, and then add 42.5mL of ammonium nitrate solution (NH 4 + ion concentration is 6.0mol / L), after stirring for 3 hours, the temperature of the reactor was lowered to 60°C, and at the same time, 43.5mL of aluminum nitrate solution was added dropwise (in the form of Al 2 o 3 The concentration of the meter is 1.27mol / L) and dilute ammonia solution (the volume ratio of concentrated ammonia water to deionized water is 5:7), so that the pH value of the mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com