Stimulus-responsive self-repair anticorrosive coating material and preparation method

A stimuli-responsive, anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve the problems of high surface energy, no corrosion inhibition of steel, and decreased anti-corrosion performance of coatings, so as to improve the loading rate. And the effect of encapsulation rate, anti-corrosion performance improvement, and bonding performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

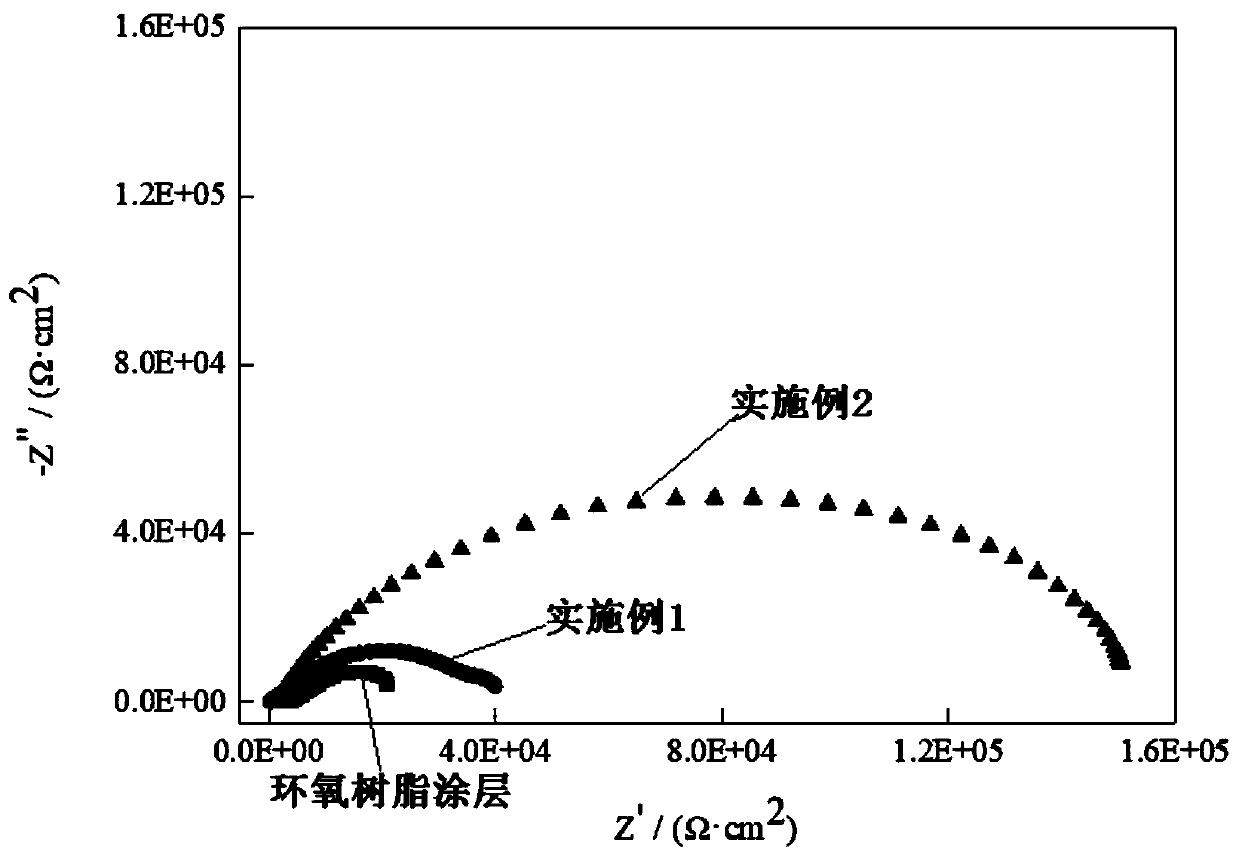

[0049] A method for preparing a stimulus-responsive self-repairing anti-corrosion coating material, comprising the following steps:

[0050] 1. Preparation of CuO microcapsules:

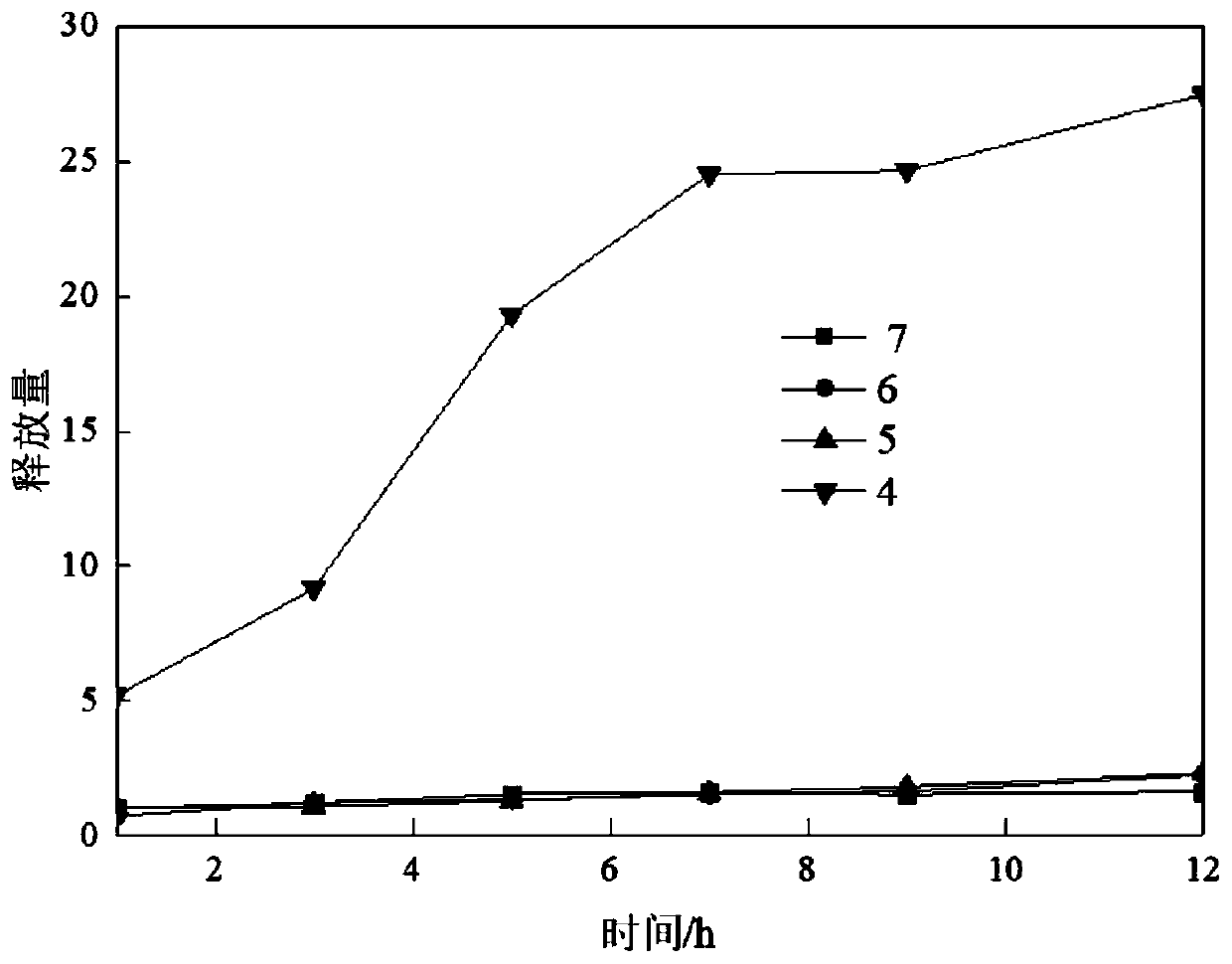

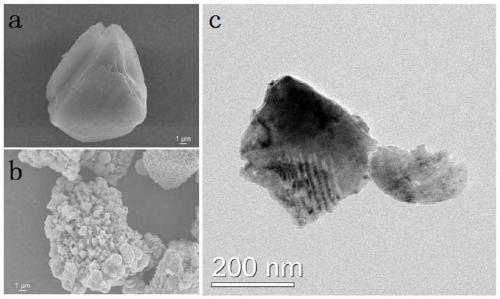

[0051] Measure methanol and N,N-dimethyldivinylamide (DMF) with a volume ratio of 1:1, and mix them thoroughly as a solvent; then, weigh 25g of 1,3,5-benzenetricarboxylic acid (BTC) and 35g Copper nitrate trihydrate was added to the mixed solution, and after it was completely dissolved, the solution was placed in the reaction kettle for 12 hours at 120°C; after the reaction kettle was cooled, it was filtered, washed and dried to obtain the Cu-MOF material; the Cu-MOF material was placed in a muffle Calcinate in a furnace at 600°C for 4 hours to obtain porous CuO; dissolve 10 g of benzotriazole (BTA) in deionized water, then add porous CuO, stir at a low speed of 300-600 rpm / min for 5 hours to encapsulate the corrosion inhibitor, filter and wash to collect samples, CuO microcapsules were obtained.

...

Embodiment 2

[0057] A method for preparing a stimulus-responsive self-repairing anti-corrosion coating material, comprising the following steps:

[0058] 1. Preparation of CuO microcapsules:

[0059] Measure methanol and N,N-dimethyldivinylamide (DMF) with a volume ratio of 1:1, and mix them thoroughly as a solvent; then, weigh 20g of 1,3,5-benzenetricarboxylic acid (BTC) and 30g Copper nitrate trihydrate was added to the mixed solution, and after it was completely dissolved, the solution was placed in the reaction kettle at 90°C for 12 hours; after the reaction kettle was cooled, it was filtered, washed and dried to obtain the Cu-MOF material; the Cu-MOF material was placed in a muffle Calcinate in a furnace at 500°C for 4 hours to obtain porous CuO; dissolve 10 g of benzotriazole (BTA) in deionized water, then add porous CuO, stir at a low speed of 300-600 rpm / min for 5 hours to encapsulate the corrosion inhibitor, filter and wash to collect samples, CuO microcapsules were obtained.

...

Embodiment 3

[0065] A method for preparing a stimulus-responsive self-repairing anti-corrosion coating material, comprising the following steps:

[0066] 1. Preparation of CuO microcapsules:

[0067] Measure methanol and N,N-dimethyldivinylamide (DMF) with a volume ratio of 1:3, and mix them thoroughly as a solvent; then, weigh 20g of 1,3,5-benzenetricarboxylic acid (BTC) and 30g Copper nitrate trihydrate was added to the mixed solution, and after it was completely dissolved, the solution was placed in the reaction kettle for 10 hours at 80°C; after the reaction kettle was cooled, it was filtered, washed and dried to obtain the Cu-MOF material; the Cu-MOF material was placed in a muffle Calcinate in a furnace at 400°C for 3 hours to obtain porous CuO; dissolve 10 g of benzotriazole (BTA) in deionized water, then add porous CuO, stir at a low speed of 300-600 rpm / min for 4 hours to encapsulate the corrosion inhibitor, filter and wash to collect samples, CuO microcapsules were obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com