Preparation method of hydrocracking catalyst

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as instability, ammonia nitrogen pollution, large precipitated particles, etc., and achieve low cost, pollution reduction, and effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

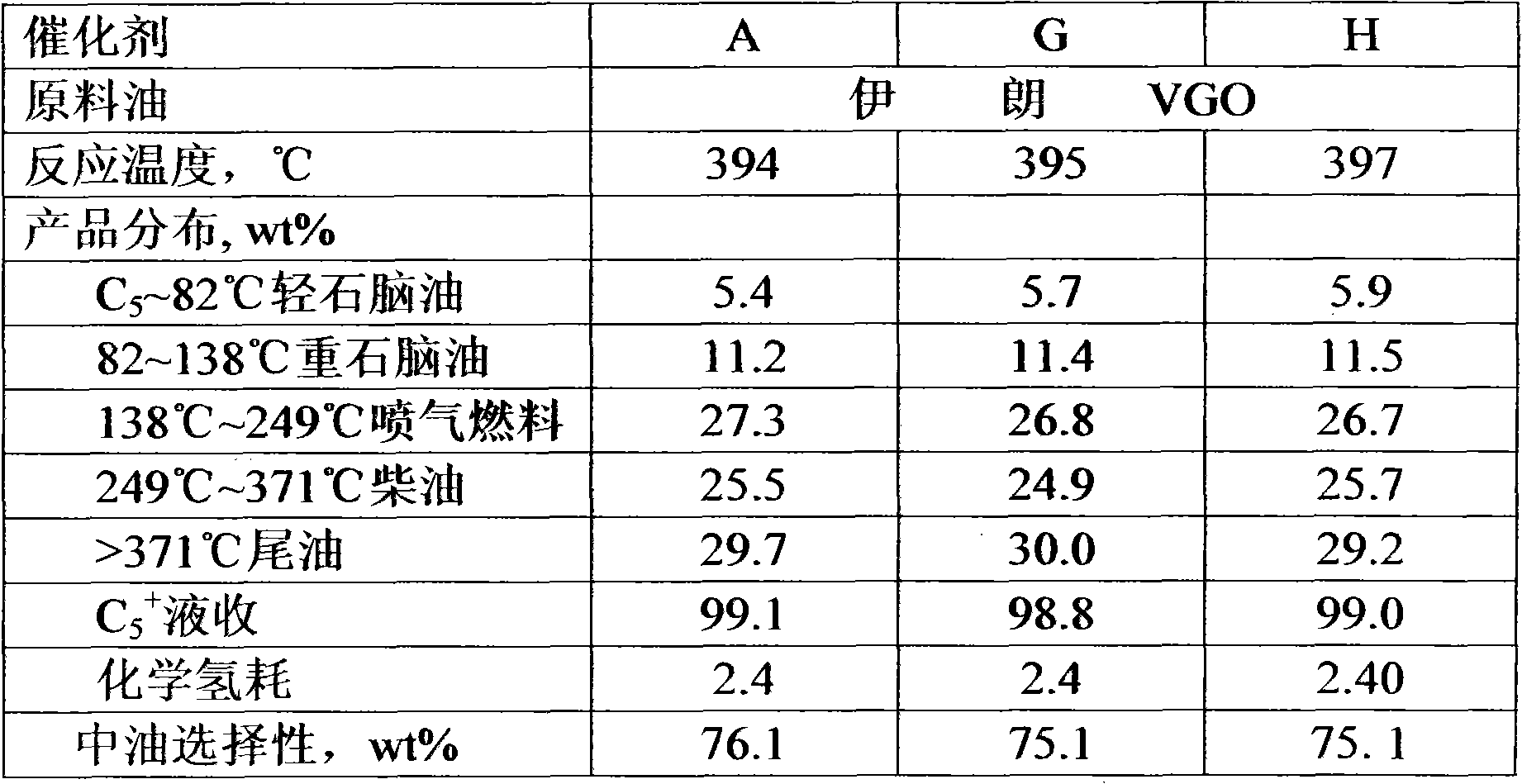

Examples

Embodiment 1

[0027] Catalyst A of the present invention, weight composition is: WO 3 22.0%, NiO 9.0%, ZrO 2 7%, SiO 2 33%, Al 2 o 3 29%, of which Y-type molecular sieve content is 20%.

[0028] Concrete preparation steps are as follows:

[0029] (1) Prepare acidic solution A: configure 200 ml of nickel chloride solution containing NiO of 140g / l, containing WO 3 85g / l ammonium metatungstate 1000ml, containing Al 2 o 3 300 ml of aluminum sulfate solution at a concentration of 90 g / l with ZrO 2 150 ml of 140 g / l zirconium oxychloride solution, mixed in a 5 liter container, diluted with 800 ml of clean water. Formulated with SiO 2 Add 550 milliliters of 75 g / l dilute water glass solution to the above mixed salt solution with stirring.

[0030] (2) Configuration of alkaline sodium metaaluminate solution B: configuration containing Al 2 o 3 The concentration is 9g / l alkaline solution 3000ml.

[0031] (3) Put the solutions of A and B side by side into the gel-forming tank to form ...

Embodiment 2

[0037] Catalyst B of the present invention, weight composition and preparation method are with embodiment 1, and aluminum sulfate is containing Al in the acidic solution 2 o 3 300 ml of aluminum sulfate solution with a concentration of 72g / l, the alkaline sodium metaaluminate solution contains Al 2 o 3 3000ml of alkaline solution with a concentration of 11g / l.

Embodiment 3

[0039] Catalyst C of the present invention, weight composition and preparation method are the same as embodiment 1, and aluminum sulfate is containing Al in the acidic solution 2 o 3 300 ml of aluminum sulfate solution with a concentration of 54g / l, the alkaline sodium metaaluminate solution contains Al 2 o 3 Concentration is 3000ml of alkaline solution of 13g / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com