Preparation method of hydrocracking catalyst

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc. The distribution of hydrogen active metals is not easy to control, etc., to achieve good performance, improved interaction, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

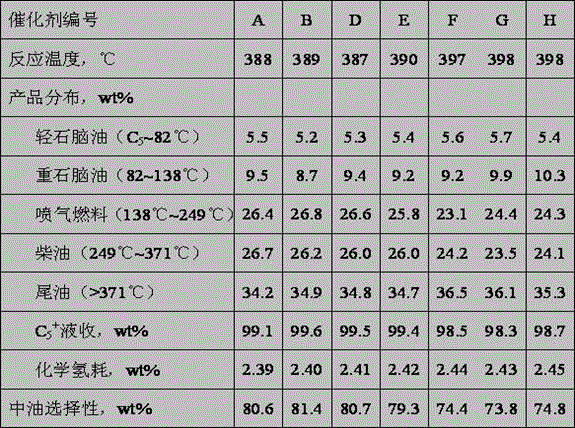

Examples

Embodiment 1

[0037] 480 milliliters of nickel chloride solution containing NiO of 45 g / L, containing Al 2 o 3 350 ml of 130g / L aluminum chloride solution, containing ZrO 2 150 milliliters of 100 g / L zirconium oxychloride solution was mixed in solution tank 1, diluted with 800 milliliters of clean water, and configured as solution A. will contain WO 3 88g / L ammonium metatungstate 950ml and containing Al 2 o 3 400 milliliters of aluminum chloride solution of 130g / L is mixed in the solution tank 2, adds 800 milliliters of clean water to dilute, and adds 600 milliliters containing SiO under stirring condition 2 100g / L dilute water glass solution, configure solution B. Add benzylamine and ammonia water to solution A under stirring, the molar ratio of benzylamine to active metal Ni is 0.8, the gelling temperature is kept at 50°C, the pH value is controlled at 7.6 at the end, and the gelling time is controlled at 60 minutes to generate Nickel, Aluminum Precipitate Slurry I. Add 1000mL of...

Embodiment 2

[0039] According to the method of embodiment 1, press the component content ratio of catalyst B in table 1, add nickel nitrate, titanium chloride, aluminum nitrate solution in dissolving tank 1, prepare working solution A, add nitric acid in dissolving tank 2 Aluminum, ammonium metatungstate and dilute water glass prepare working solution B, wherein dilute water glass contains SiO 2 500 ml of 110 g / L dilute water glass solution. Add phenethylamine and ammonia water to solution A under stirring, the molar ratio of phenethylamine to active metal Ni is 1.2, the gelling temperature is maintained at 60°C, the pH value is controlled at 7.8 at the end, and the gelling time is controlled at 50 minutes. Slurry I containing nickel and aluminum precipitates is generated. Add 1200mL of clean water into the reaction tank, add phenethylamine, ammonia water, and solution B into the reaction tank in parallel, the molar ratio of phenethylamine to active metal W is 1.4, keep the gel forming te...

Embodiment 3

[0041] According to the method of embodiment 1, press the component content ratio of catalyst C in table 1, add nickel chloride, aluminum chloride solution in dissolving tank 1, prepare working solution A, add aluminum chloride in dissolving tank 2 , ammonium molybdate, and dilute water glass to prepare working solution B, wherein the dilute water glass contains SiO 2 600 ml of 100 g / L dilute water glass solution. Add ethanolamine and ammonia water to solution A under stirring, the molar ratio of ethanolamine to active metal Ni is 1.5, the gelling temperature is kept at 40°C, the pH value is controlled at 8.0 at the end, and the gelling time is controlled at 60 minutes to form nickel-containing, Aluminum Precipitate Slurry I. Add 1200mL of clean water into the reaction tank, add ethanolamine, ammonia water, and solution B into the reaction tank in parallel, the molar ratio of ethanolamine to active metal W is 0.5, keep the gelling temperature at 55°C, and flow in parallel dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com