Composite double microporous material and preparation thereof

A technology of microporous material and composite molecular sieve, applied in the field of composite double microporous material and its preparation, can solve the problems of poor catalyst reaction activity, no significant improvement in medium oil selectivity, no significant improvement in catalyst activity, etc. effect of temperature, improving catalytic performance, and improving medium oil selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

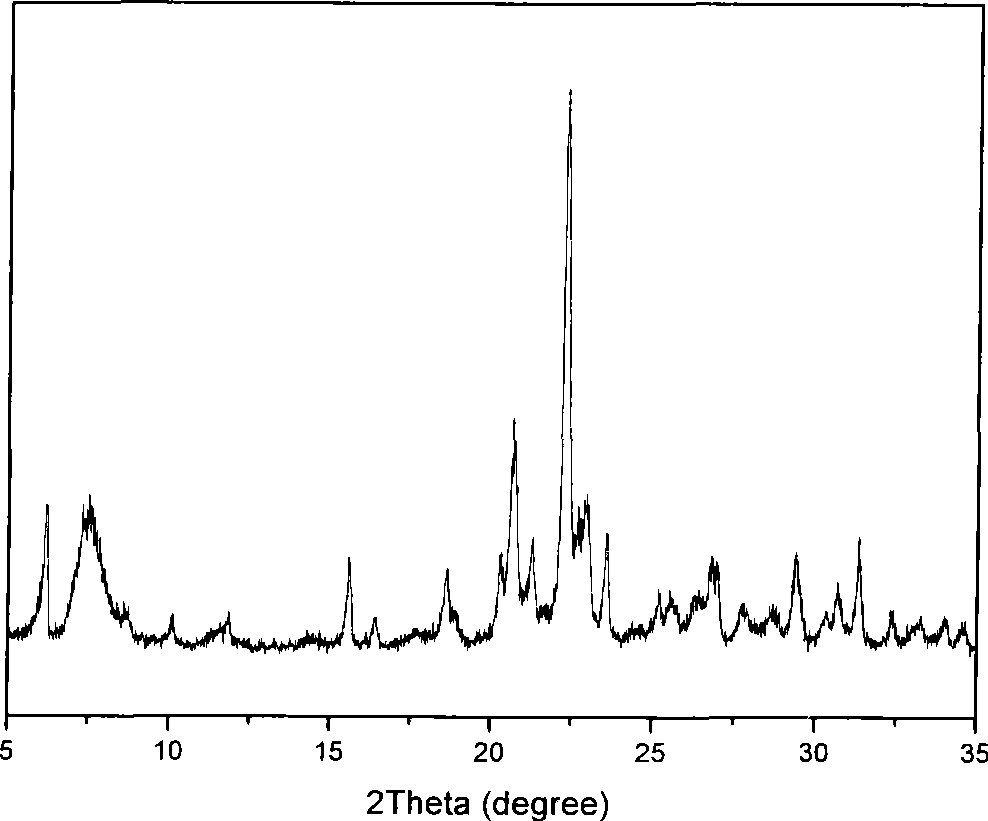

Image

Examples

Embodiment 1

[0030] (1) Carry out industrially synthesized NaY molecular sieves for high-temperature roasting. The heating process is as follows: 10 °C / min from room temperature to 300 °C, constant temperature for 1 hour, and then 5 °C / min from 300 °C to 550 °C, constant temperature roasting 5 hours.

[0031] (2) Mix 10 grams of the Y molecular sieve prepared in step (1) with 100 ml of a 0.1 mol / L aqueous sodium hydroxide solution, and stir at 40° C. for 5 hours. Filter and dry.

[0032] (3) 10 grams of the treated NaY molecular sieves were mixed with 100 ml of tetraethylammonium hydroxide aqueous solution with a concentration of 1 mol / L, stirred and heated at 70° C. for 6 hours. Mixture 1 was prepared.

[0033] (4) 80ml sodium silicate (SiO 2 concentration is 8mol / L) was added into 120ml of water, stirred evenly to prepare solution 2.

[0034] (5) Slowly add solution 2 into solid-liquid mixture 1, stir evenly to obtain a reaction gel, and put it into a synthesis kettle. Then hydrothe...

Embodiment 2

[0038] (1) Convert industrial NH 4 The Y molecular sieve is calcined at a high temperature, and the heating process is as follows: from room temperature to 300°C at 10°C / min, constant temperature for 1 hour, then from 300°C to 550°C at 5°C / min, and constant temperature calcination for 4 hours.

[0039] (2) Mix 10 grams of the Y molecular sieve prepared in step (1) with 100 ml of a 0.4 mol / L aqueous sodium hydroxide solution, and stir at room temperature for 3 hours. Filter and dry.

[0040] (3) The Y molecular sieve treated in step (2) was mixed with 100 ml of tetraethylammonium hydroxide aqueous solution with a concentration of 1 mol / L, and concentrated with stirring and heating at 70° C. for 5 hours. Mixture 1 was prepared.

[0041] (4) 90ml sodium silicate (SiO 2 concentration is 8mol / L) was added into 110ml of water, stirred evenly to prepare solution 2.

[0042] (5) Slowly add solution 2 into solid-liquid mixture 1, stir evenly to obtain a reaction gel, and put it int...

Embodiment 3

[0045] (1) The industrial ultra-stable Y molecular sieve is roasted at high temperature. The heating process is as follows: from room temperature to 300°C at 10°C / min, constant temperature for 1 hour, then from 300°C to 650°C at 5°C / min, constant temperature Roast for 6 hours.

[0046] (2) Mix 10 grams of the Y molecular sieve prepared in step (1) with 100 ml of a 0.6 mol / L aqueous sodium hydroxide solution, and stir at 40° C. for 5 hours. Filter and dry.

[0047] (3) The Y molecular sieve treated in step (2) was mixed with 100 ml of tetraethylammonium hydroxide aqueous solution with a concentration of 2 mol / L, stirred and heated at 80° C. for 4 hours. Mixture 1 was prepared.

[0048] (4) 85ml sodium silicate (SiO 2 concentration is 8mol / L) was added into 120ml of water, stirred evenly to prepare solution 2.

[0049] (5) Slowly add solution 2 into solid-liquid mixture 1, stir evenly to obtain a reaction gel, and put it into a synthesis kettle. Then hydrothermal crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com