Novel rubber block pyrolysis oil production system

An oil system and rubber block technology, applied in the field of a new type of rubber block pyrolysis oil production system, can solve the problems of inability to meet environmental protection requirements, difficult to meet the flue gas emission standards, no gas purification process, etc., to simplify the gas purification process and reduce operation. cost, the effect of reducing the cost of pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

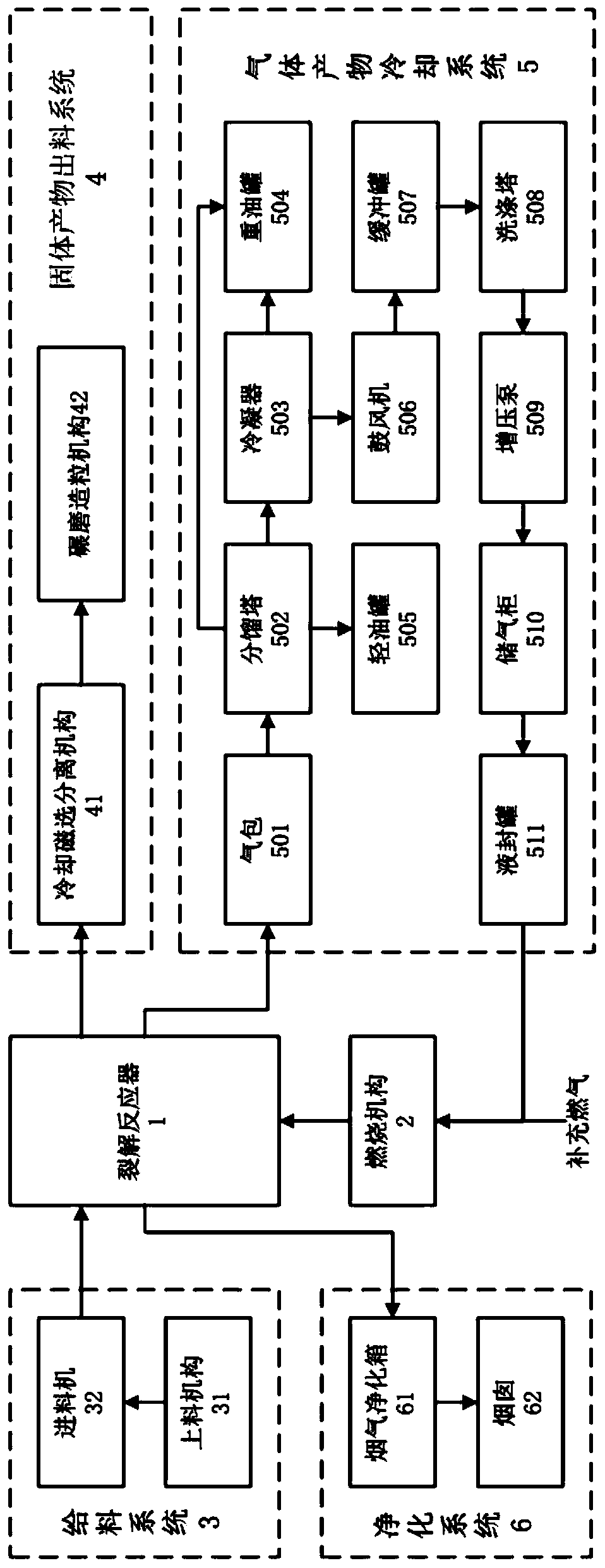

[0041] see figure 1 As shown, the embodiment of the present invention provides a novel rubber block pyrolysis oil production system, including a cracking reactor 1, a combustion mechanism 2, a feeding system 3, a solid product discharging system 4, a gas product cooling system 5, and a purification system 6;

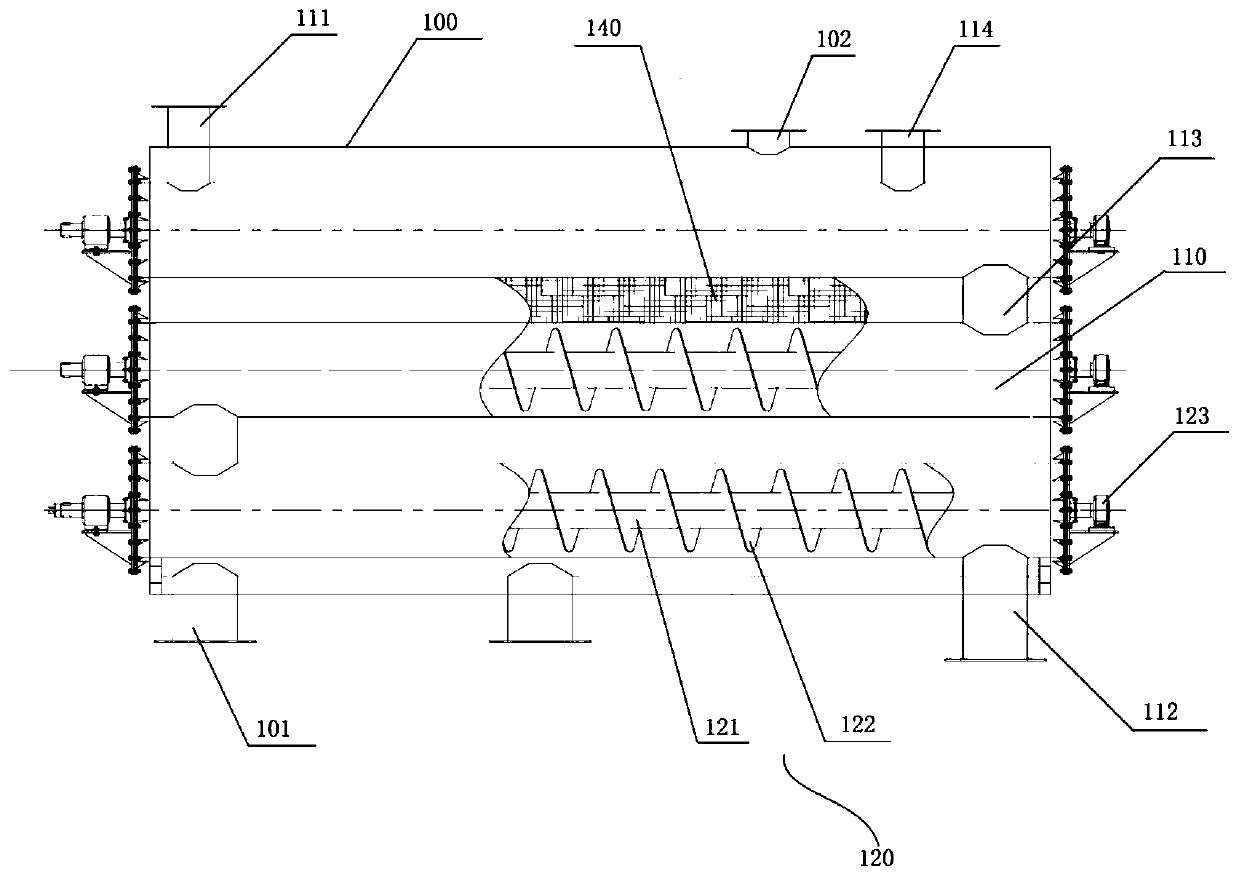

[0042] The feeding system 3 is used to send the crushed rubber blocks into the cracking reactor 1; specifically, the feeding system 3 includes a feeding mechanism 31 and a feeding machine 23. The crushed rubber block is conveyed to the elevator by the screw and enters the feeding system. The rubber block is fed by shaftless screw extrusion to ensure the sealing of the reactor and effectively prevent air from entering the furnace and cracking gas. vent. The rubber blocks entering the furnace are continuously turned while being conveyed to the discharge end through the action of the conveyor and the turner, and exchange heat with the high-temperature flue gas outside the...

Embodiment 2

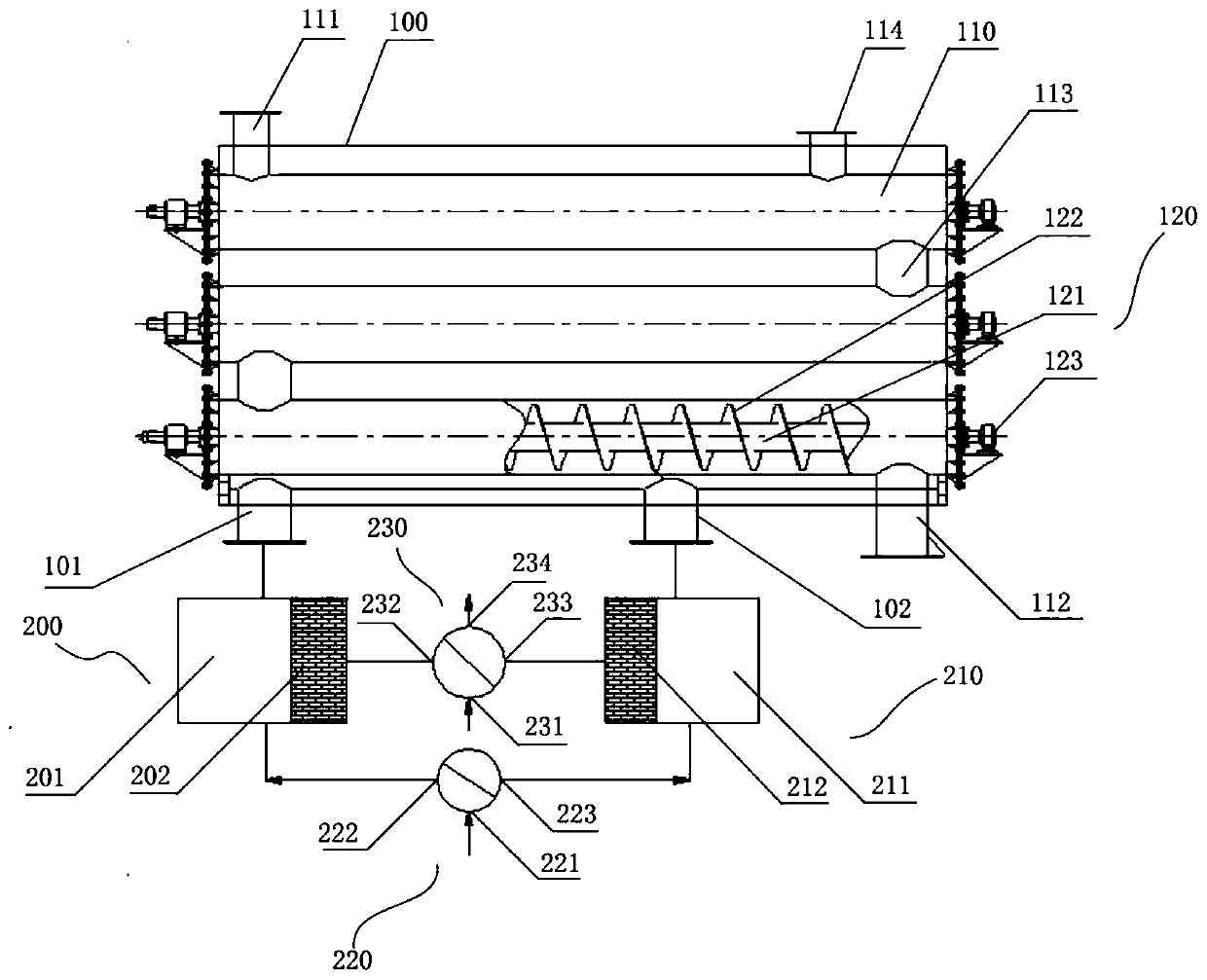

[0060] The structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the structures of the pyrolysis reactor 1 and the combustion mechanism 2 are different, and the purification system is connected to the flue gas outlet 234 of the combustion mechanism 2 .

[0061] see image 3 As shown, in this embodiment, the pyrolysis reactor includes a closed furnace body; at least two heat exchange reactors are sequentially arranged in the furnace body from top to bottom, and in this embodiment, three heat exchange reactors are sequentially arranged in the furnace body from top to bottom The heat exchange reactor is used as the primary heat exchange reactor, the secondary heat exchange reactor and the tertiary heat exchange reactor from top to bottom. Each of the above heat exchange reactors is a tube structure with both ends closed. The furnace body is provided with the first heat medium inlet and outlet and the second heat medium inlet and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com