Sludge pyrolysis recycling system and pyrolysis method

A technology for resource utilization and sludge, which is applied in the fields of pyrolysis sludge treatment, dewatering/drying/concentrating sludge treatment, and by-product vaporization, etc. Realize the effect of sludge resource utilization, uniform heating and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0043] Aiming at the problems of uneven heating, low thermal efficiency and insufficient system processing capacity existing in the existing sludge pyrolysis technology, the present invention provides a novel sludge pyrolysis reaction system and pyrolysis method, which have the advantages of uniform heating, high efficiency and low price, and easy characteristics of industrialization.

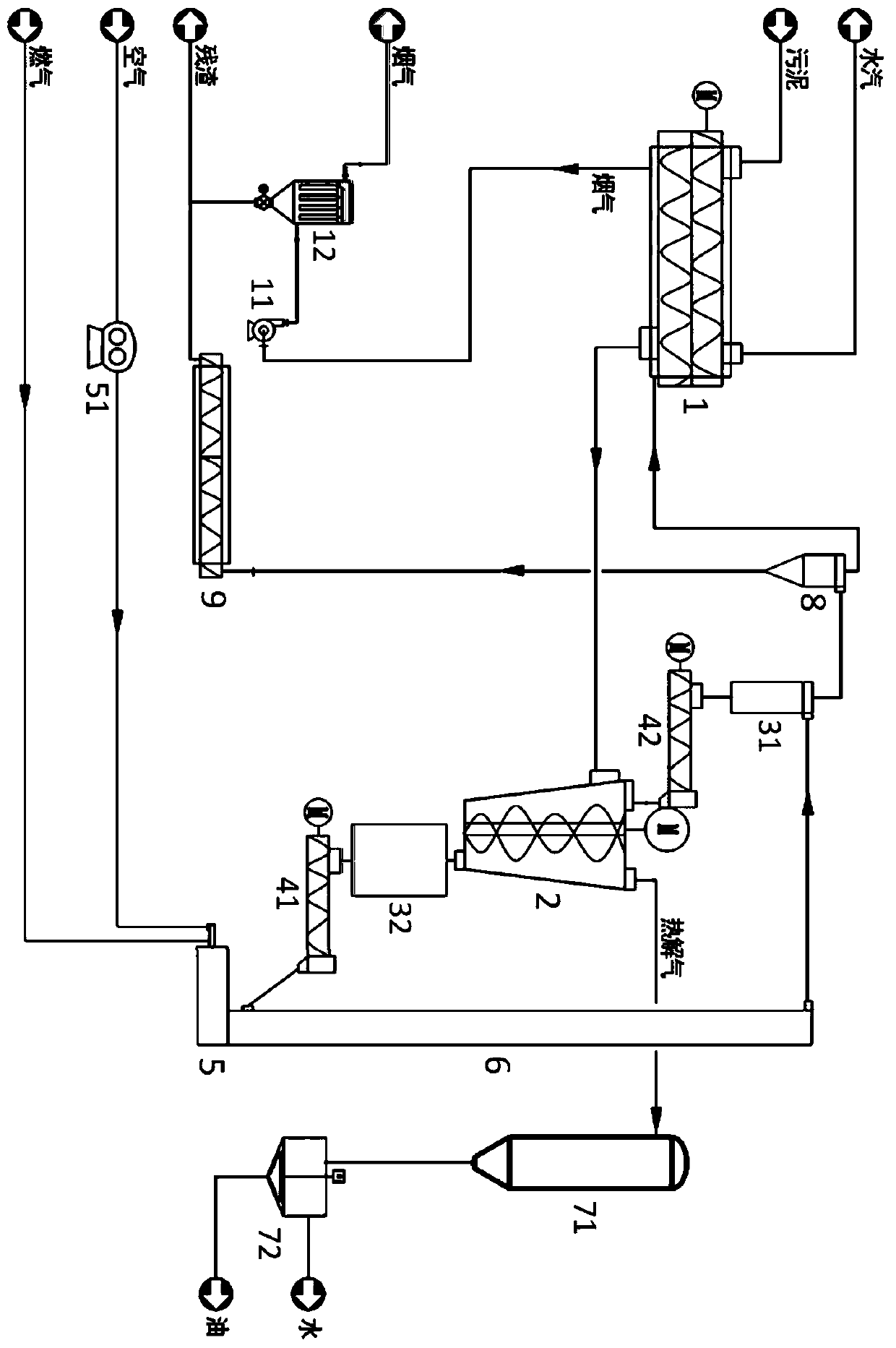

[0044] In order to realize the above-mentioned technical solution, an embodiment of the present invention provides a sludge pyrolysis recycling system, such as figure 1 Shown is its basic structure, including pre-drying device 1, feed carrier hopper 31, discharge carrier hopper 32, pyrolysis reactor 2, hot smoke furnace 5, heating riser 6, condenser 71, oil-water separator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com