Method for preparing 10-undecylenic acid and heptanal by catalytic cracking

A technology of catalytic cracking and heptanal, applied in chemical instruments and methods, molecular sieve catalysts, preparation of carbon-based compounds, etc., can solve the problems of high viscosity, difficult gasification, and poor fluidity of castor oil, and achieve lower reaction temperature and higher yield. efficiency, reducing the effect of polymerization and isomerization reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

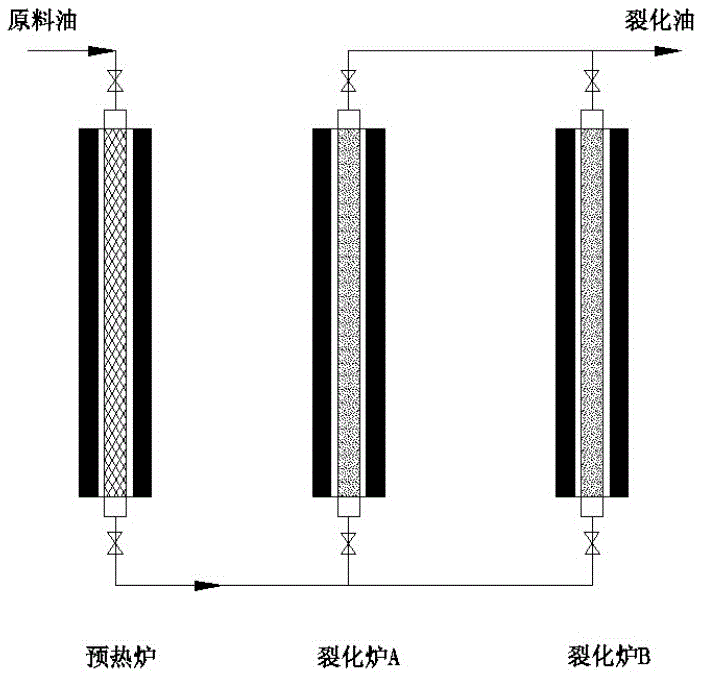

[0025] The preheating furnace adopts Φ30×1000mm stainless steel tube, filled with ceramic Raschig ring filler, and the cracking furnace adopts Φ40×1000mm stainless steel tube, filled with cracking catalyst I. The temperature inside the preheating furnace and the cracking furnace is automatically controlled by a temperature controller. The preheating temperature and cracking temperature are detected respectively at the outlet of the preheating furnace and the cracking furnace.

[0026] Methyl ricinoleate was added dropwise at 5.8ml / min, water was added dropwise at 6.0ml / min, mixed into the preheating furnace, heated to 250°C, introduced into the cracking furnace, catalytically cracked at 420°C, the cracked mixed gas was condensed and collected and weighed Heavy, 10-undecylenic acid methyl ester and heptanal content were analyzed by gas chromatography. The calculated yield of methyl 10-undecylenate was 46.5%, and the yield of heptanal was 25.7%.

Embodiment 2

[0028] The preheating furnace adopts Φ30×1000mm stainless steel tube, filled with ceramic Raschig ring filler, and the cracking furnace adopts Φ40×1000mm stainless steel tube, filled with cracking catalyst II. The temperature inside the preheating furnace and the cracking furnace is automatically controlled by a temperature controller. The preheating temperature and cracking temperature are detected respectively at the outlet of the preheating furnace and the cracking furnace.

[0029] Methyl ricinoleate was added dropwise at 4.5ml / min, water was added dropwise at 6.0ml / min, mixed into the preheating furnace and heated to 350°C, introduced into the cracking furnace, catalytically cracked at 480°C, the cracked mixed gas was condensed and collected and weighed Heavy, 10-undecylenic acid methyl ester and heptanal content were analyzed by gas chromatography. The calculated yield of methyl 10-undecylenate was 48.3%, and the yield of heptanal was 26.4%.

Embodiment 3

[0031] The preheating furnace adopts Φ30×1000mm stainless steel tube, filled with ceramic Raschig ring filler, and the cracking furnace adopts Φ40×1000mm stainless steel tube, filled with cracking catalyst I. The temperature inside the preheating furnace and the cracking furnace is automatically controlled by a temperature controller. The preheating temperature and cracking temperature are detected respectively at the outlet of the preheating furnace and the cracking furnace.

[0032] Methyl ricinoleate was added dropwise at 7.5ml / min, water was added dropwise at 5.0ml / min, mixed into the preheating furnace and heated to 280°C, introduced into the cracking furnace, catalytically cracked at 460°C, the cracked mixed gas was condensed and collected and weighed Heavy, 10-undecylenic acid methyl ester and heptanal content were analyzed by gas chromatography. The calculated yield of methyl 10-undecylenate was 45.8%, and the yield of heptanal was 24.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com