Method for preparing high silica alumina ratio NaY molecular sieve

A technology with high silicon-aluminum ratio and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite and octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of low silicon utilization rate and difficult removal of cesium ions, shorten the crystallization time, The effect of good structural stability and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take by weighing 209.31g sodium hydroxide solid (purity 99%) and be dissolved in 541.76g water, then add 35.53g aluminum hydroxide powder (purity 99%), be heated to boiling and stir reaction, reaction solution outward appearance is clear and transparent promptly reaction is finished, cooling After that, it is a high alkali sodium metaaluminate solution.

[0032]Weigh 97.78g of sodium hydroxide solid and dissolve it in water, then add 78.06g of aluminum hydroxide powder, heat to boiling and stir for reaction, the reaction solution is clear and transparent in appearance and the reaction is complete. After cooling, add deionized water to 500mL to obtain Low alkali sodium metaaluminate solution.

[0033] Take by weighing 235.30g aluminum sulfate solid (Al 2 (SO 4 ) 3 18H 2 O) In a beaker, add deionized water to dissolve, heat and stir until the solution is clear, and after cooling, add deionized water to 400mL to obtain aluminum sulfate solution.

[0034] Get 100mL wat...

Embodiment 2

[0041] In this example, the low alkalinity reaction gel is according to 2.70Na 2 O:Al 2 o 3 : 10.00 SiO 2 : 320H 2 The molar ratio of O is synthesized. Add 60mL of deionized water and 9.65g of directing agent to 69.21g of water glass solution, stir for 5-10 minutes, add 20.80g of aluminum sulfate solution, stir for 20-30 minutes, add 11.50g of low-alkali sodium metaaluminate solution , followed by vigorous stirring for 1 h.

[0042] In this example, the high alkalinity reaction gel is according to 5.50Na 2 O:Al 2 o 3 : 10.00 SiO 2 : 320H 2 The molar ratio of O is synthesized. Add 62mL of deionized water and 9.65g of directing agent to 69.21g of water glass solution, stir for 5-10 minutes, add 2.32g of aluminum sulfate solution, stir for another 20-30 minutes, add 27.31g of low-alkali sodium metaaluminate solution After the addition, stir vigorously for 1 hour, seal it in the beaker, raise the temperature to 100°C and keep it warm for 4 hours to crystallize, then add...

Embodiment 3

[0044] In this example, the low alkalinity reaction gel is according to 2.70Na 2 O:Al 2 o 3 : 11.90SiO2 2 : 320H 2 The molar ratio of O is synthesized. Add 60mL of deionized water and 9.65g of directing agent to 69.21g of water glass solution, stir for 5-10 minutes, add 20.80g of aluminum sulfate solution, stir for 2030 minutes, add 11.50g of low-alkali sodium metaaluminate solution, and finish adding Stir vigorously thereafter for 1 hour.

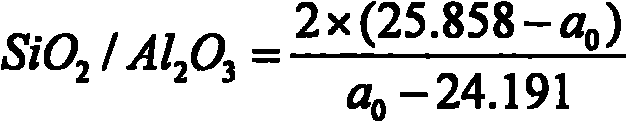

[0045] The preparation of the high alkalinity reaction gel in this example is the same as in Example 2. After the temperature is raised to and kept at 100°C for static crystallization for 4 hours, the low alkalinity reaction gel of this example is added and stirred evenly. In a stainless steel reaction kettle with a vinyl fluoride pad, the temperature was raised to and maintained at 100°C to continue static crystallization for 19 hours. The crystallinity of NaY molecular sieve measured by X-ray method is 92.4%, SiO 2 / Al 2 o 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com