Catalyst for straight-run naphtha aromatization and preparation method thereof

A catalyst and an aromatization technology are applied in the field of a catalyst for the aromatization of straight-run naphtha and the field of preparation thereof, which can solve the problems of poor stability of the aromatization catalyst, and achieve the advantages of being beneficial to diffusion and catalysis, uniform distribution, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation process of the catalyst used for straight-run naphtha aromatization is:

[0028] (1) Knead ZSM-5 molecular sieve raw powder and silica gel powder according to the mass ratio of 9:1, safflower powder is 1% of the mass number of molecular sieve and silica gel powder, peptize with silica sol, extrude and dry at 120°C Carrier A was prepared by calcining for 2 hours at a constant temperature of 550° C. for 4 hours.

[0029] (2) Get 30 grams of molecular sieve A and put it into the constant temperature section of the fixed-bed reactor, raise the temperature to 500°C at a rate of 5°C / min, and after the temperature is constant, use a metering pump to feed ammonia water (the concentration of ammonia water is 0.2mol / L, 0.3ml / min) was treated for 3 hours, and the molecular sieve number after the treatment was B.

[0030] (3) Take 20 grams of molecular sieve B and place it in a 500-milliliter beaker, add 200 milliliters of 10% sodium hydroxide aqueous solution, an...

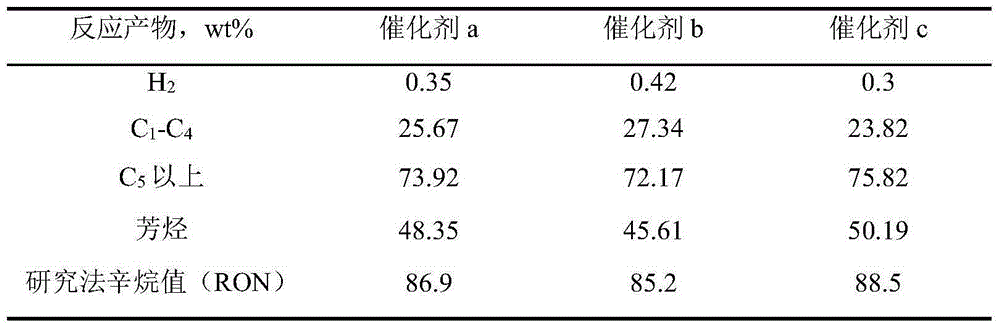

Embodiment 2

[0034] The ammonia water in step (2) was replaced with deionized water, and the rest of the preparation process was the same as in Example 1 to obtain aromatization catalyst b.

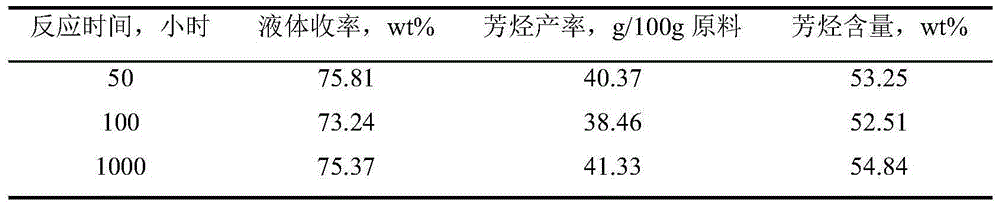

Embodiment 3

[0036] Add 500 ml of ammonium nitrate with a mass fraction of 10% and a mixed solution of lanthanum nitrate with a mass fraction of 10% in step (4), heat up to 90°C under stirring, reflux at a constant temperature for 2 hours, filter, wash, and dry at 120°C After 2 hours, put it into a muffle furnace and heat it up to 550° C., and bake it for 4 hours. Repeat the above operation twice to obtain a molecular sieve, coded as D.

[0037] In step (5), the molecular sieve D is impregnated with zinc nitrate solution for 12 hours, dried at 120° C. for 4 hours, and calcined at 550° C. for 12 hours. The rest of the preparation process is the same as that of Example 1 to obtain aromatization catalyst c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com