Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Crystal structure intact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene

InactiveCN102491314AImprove permeabilityImprove diffusion abilityGrapheneBulk chemical productionCrystal structureHigh pressure

The invention relates to a method for preparing graphene, characterized by carrying out explosion treatment for one or more times on carbonaceous materials by using fluids under supercritical state. By using the fluids under supercritical state to penetrate and dissolve the carbonaceous materials and having the aid of sudden release of high pressure hot steam, the shearing and peeling between layers of the carbonaceous materials are promoted to realize the preparation of graphene. Compared with using ball milling, mechanical peeling, high temperature and high pressure to prepare graphene in the prior art, the invention has the advantages of mild process conditions (low pressure), short process time, large area of prepared graphene, and complete preserved crystal structure. According to the invention, the content of graphene which comprises less than 5 layers is higher than 90 %, and the batch production of graphene powder products can be really realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

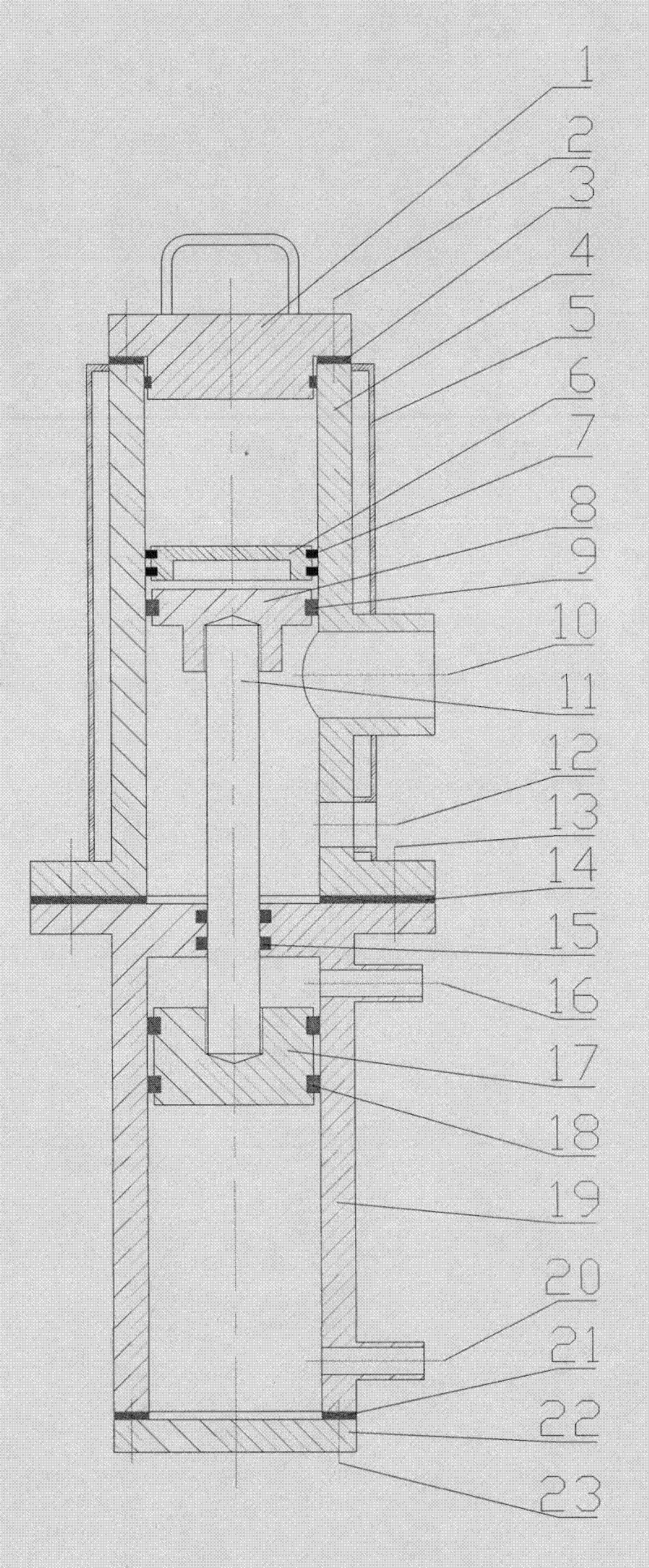

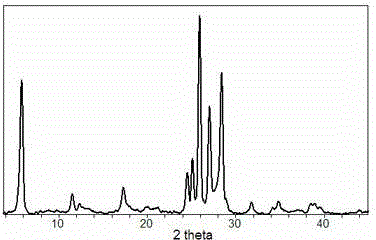

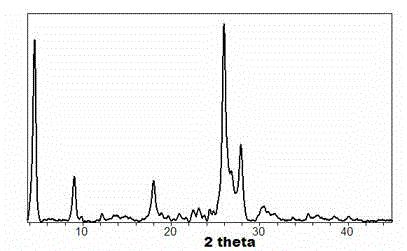

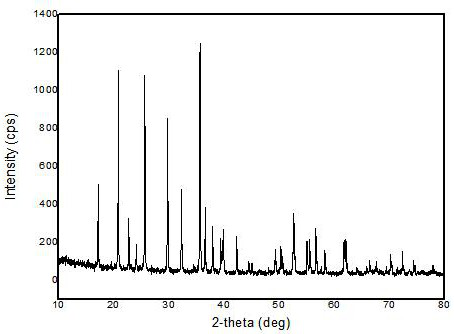

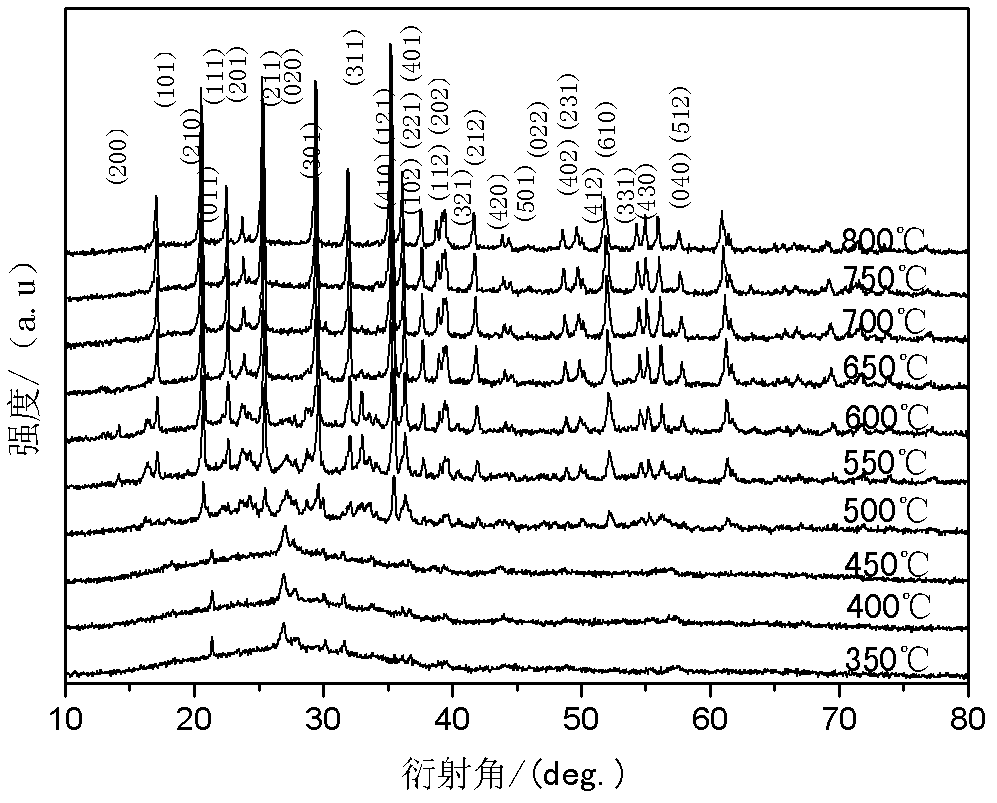

SCM-5 molecular sieve and preparation method thereof

ActiveCN104445246AImprove thermal stabilityCrystal structure intactCrystalline aluminosilicate zeolitesMolecular sieveIsomerization

The invention relates to an SCM-5 molecular sieve and a preparation method thereof, for mainly solving the problems of porous materials of novel structures which are not related to in the prior art. By adopting the technical scheme that the SCM-5 molecular sieve is prepared from the following chemical components in a mole ratio: xO2 and nY2O3, wherein X is silicon or germanium, Y is at least one of the elements such as aluminum, boron, gallium and iron, n is greater than or equal to 0.0 and less than or equal to 0.40, the interplanar spacing of the SCM-5 molecular sieve has maximum values of X-ray diffraction peaks when d is equal to 11.20+ / -1.0., 7.35+ / -0.20., 5.50+ / -0.15., 3.60+ / -0.10. and 3.39+ / -0.04., the technical problem is relatively well solved, and the prepared SCM-5 molecular sieve has a relatively good application prospect in catalytic cracking of heavy oil and isomerization of organic molecules.

Owner:CHINA PETROLEUM & CHEM CORP +1

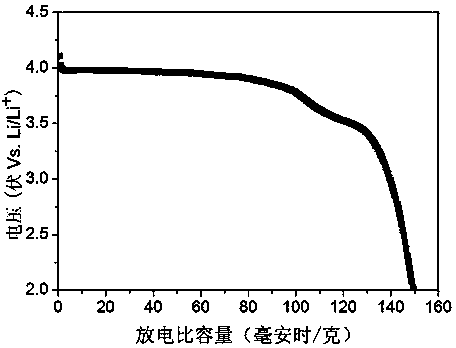

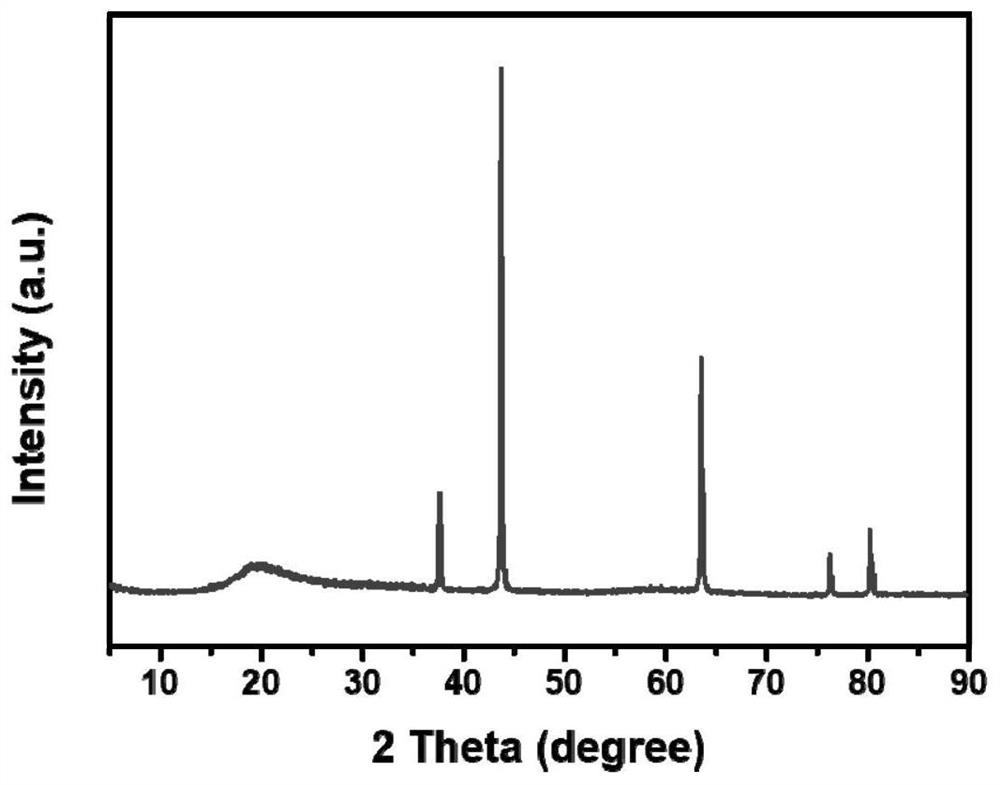

Lithium manganese phosphate positive electrode material and preparation method thereof

The invention relates to a lithium manganese phosphate positive electrode material and a preparation method thereof. The positive electrode material has morphology of square particles with a particle size of 0.5-1mum. The preparation method comprises the steps that: phosphorus and manganese source materials are weighed with a molar ratio of 1-1.2:1; a carbon source compound accounting for 5-15% of the total mass of the phosphorus and manganese source materials and a surfactant accounting for 1-10% of the total mass are adopted, such that a suspension liquid with a solid content of 10-50% is prepared; a hydrothermal reaction, filtration, washing, and drying are sequentially carried out, such that a manganese phosphate precursor is obtained; the precursor is sufficiently mixed with the lithium source; high-temperature sintering is carried out under the protection of a nitrogen atmosphere, and natural cooling is carried out. The material provided by the invention has a complete crystal structure, and has no impurity peak. Under 0.1C current under room temperature, an initial discharge capacity reaches 150mAh / g. The material has good circulation performance.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Production process of silicon wafter for solar cell with waste IC chips

InactiveCN1810394ALess impuritiesImprove photoelectric conversion efficiencyWaste processingSolid waste disposalMetal silicideSilicon oxide

The production process of silicon chip for solar cell with waste integrated circuit chips includes the following steps: treating waste integrated circuit chips with HCl and H2SO4 to eliminate Mg, Al, Mn, Zn, Cr, Fe, Ni, Sn, Pb and other metals with activity higher than hydrogen; treating with HNO3 to eliminate Cu, Hg, Ag and other transition metals; treating with mixed acid of HF and HNO3 to eliminate metal silicide, silicon oxide and silicon nitride; single-side thinning and double-side thinning to eliminate active area and silicon chip with original resistivity; cleaning, classifying, detecting and grading to obtain silicon chip for solar cell. The process can obtain silicon chip with less impurity and intact crystal structure for producing solar device with high photoelectronic conversion efficiency.

Owner:浙江东源电子有限公司

Preparation method for graphene

The invention discloses graphene and a preparation method thereof. The preparation method comprises the following steps: (1) providing a metal substrate, cleaning the metal substrate, putting the metal substrate into the reaction chamber of chemical vapor deposition equipment, introducing protective gas into the reaction chamber after sealing, stopping introduction of protective gas and carrying out vacuum-pumping so as to allow the reaction chamber to be in a vacuum state; (2) heating the metal substrate to 400 to 500 DEG C, starting an ultraviolet source, allowing the ultraviolet source to irradiate the surface of the metal substrate, introducing a carbon-containing fluid, carrying out a heat-preserved reaction for 10 to 100 min, stopping introduction of the carbon-containing fluid and stopping heating after completion of the reaction, carrying out cooling to room temperature, opening the chemical vapor deposition equipment and taking the metal substrate out so as to obtain the metal substrate with grown graphene on its surface; and (3) soaking the metal substrate with grown graphene on its surface in a corrosive liquid, removing the metal substrate, carrying out filtering, taking a filter residue and carrying out cleaning and drying so as to obtain graphene. The method adopts a chemical vapor phase process for deposition preparation of graphene on the substrate, guarantees the lamellar structure of graphene, simplifies preparation steps and has small energy consumption and low cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for preparing Nano cerium oxdie, and application in chemical mechanical polishing chip of gallium arsenide

InactiveCN1760132ASmall granularityEvenly distributedAqueous dispersionsRare earth metal compoundsCerium nitrateWafering

A process for preparing cerium oxide nanoparticles includes such steps as proportionally dissolving cerium nitrate and hexamethylenetetraamine (HMT) respectively in alcohol and distilled water, mixing, stirring, sealing, heating at 70-90 deg.C for 1-2 hr, cooling, ageing for 1-2 hr, filter, washing deposit, and drying at 60-80 deg.C for 6-10 hr. The obtained CeO2 nanoparticles can be used to prepare the polishing liquid for polishing the semiconductor wafer of gallium arsenide.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

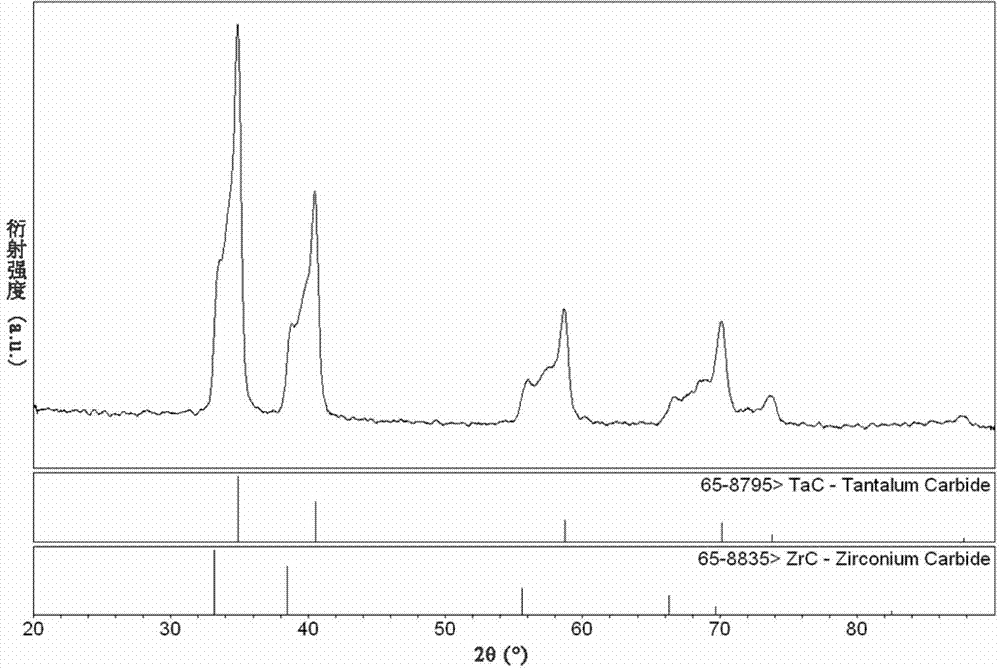

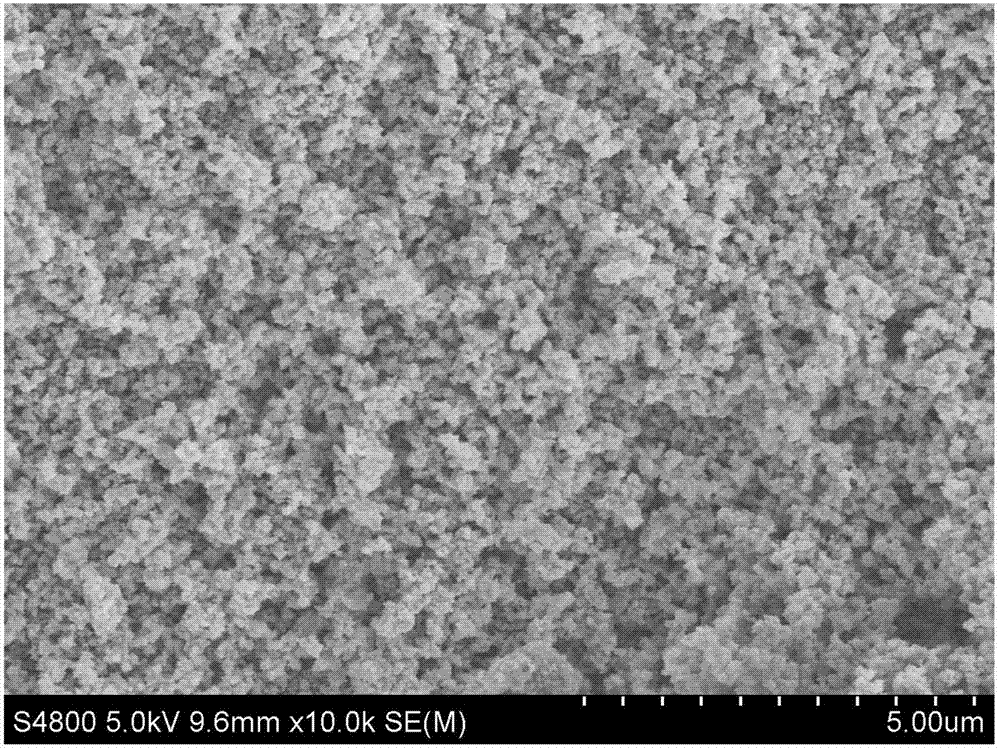

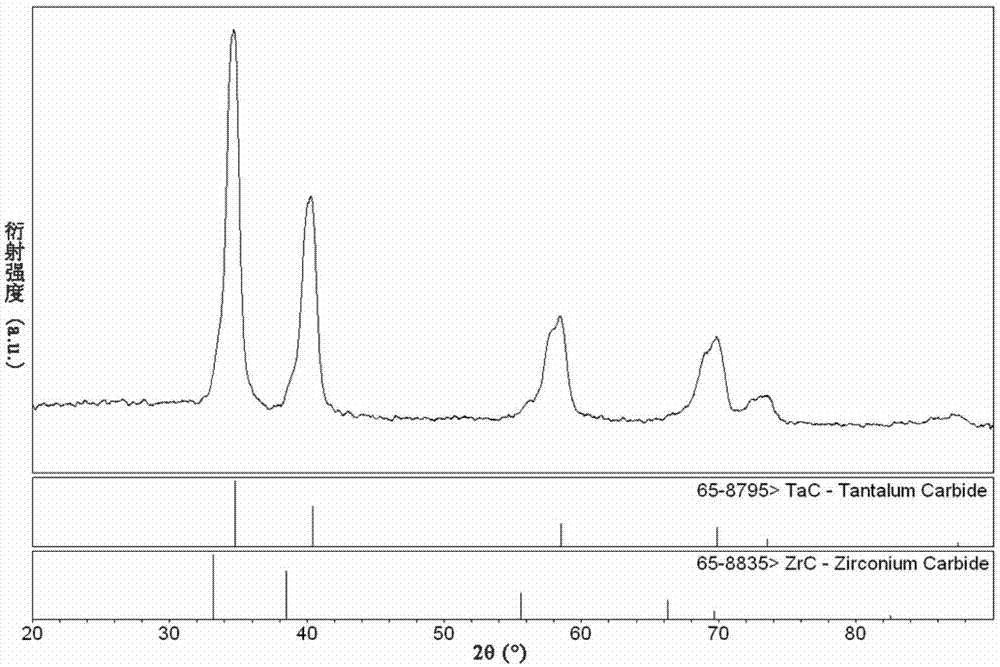

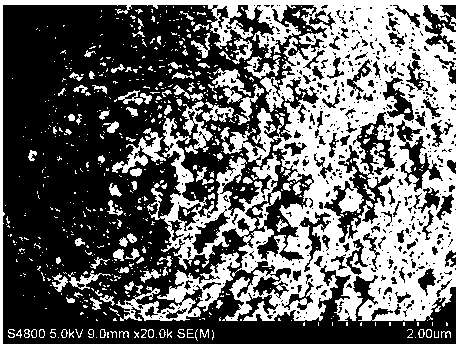

Ta-Zr-C ternary ceramic and preparation method thereof

The invention discloses a Ta-Zr-C ternary ceramic and a preparation method thereof. The Ta-Zr-C ternary ceramic provided by the invention is of Ta-Zr-C continuous single-phase solid solution ceramic powder. The preparation method comprising the following steps of (1) proportioning precursor solution; (2) preparing sol; (3) aging; (4) drying; and (5) calcining the dried material at a high temperature and in steps. The Ta-Zr-C ternary ceramic provided by the invention has the characteristics that the grain size is small, the components are uniform, the purity is high and the like, and the preparation method provided by the invention has the excellent advantages that the requirement of the process equipment is simple, the temperature requirement is low, the cost is low and the like.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing lithium manganese phosphate positive material of lithium battery by spray pyrolysis

The invention relates to a method for preparing a lithium manganese phosphate positive material of a lithium battery by spray pyrolysis and belongs to the technical field of the positive materials of lithium batteries. According to the method, homogeneous nucleation of lithium manganese phosphate is promoted through the high-temperature spray pyrolysis under the condition of an inert atmosphere, so as to reduce the temperature and the time of the follow-up reaction to obtain the lithium manganese phosphate positive material with excellent electrochemical performance. The method disclosed by the invention is simple; and since raw materials are mixed in molecular ion level and the temperature and the time of the follow-up reaction are reduced after the high-temperature spray pyrolysis, the obtained lithium manganese phosphate material has the advantages of high purity, complete crystal structure, fine and uniform particles and the excellent electrochemical performance.

Owner:DONGFANG ELECTRIC CORP LTD

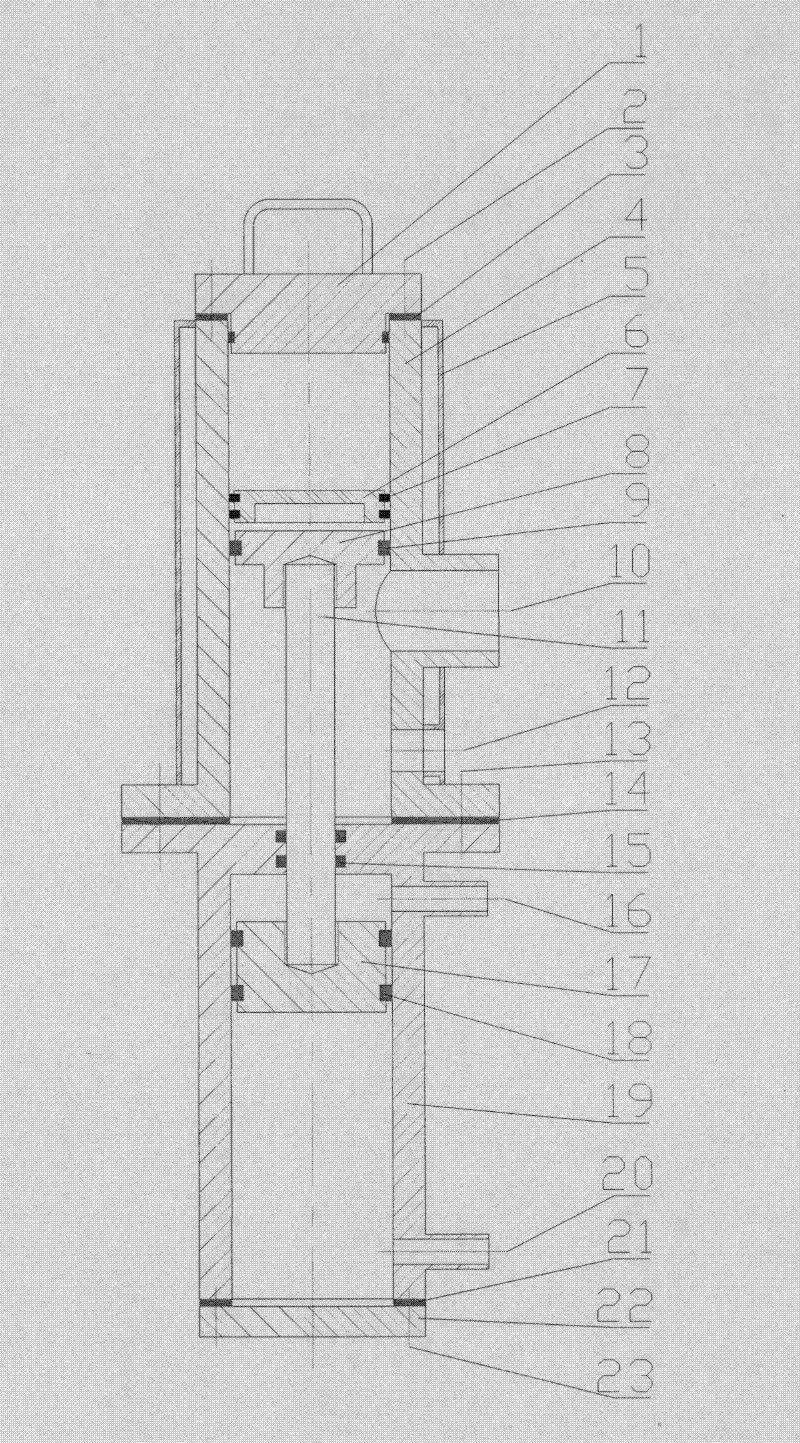

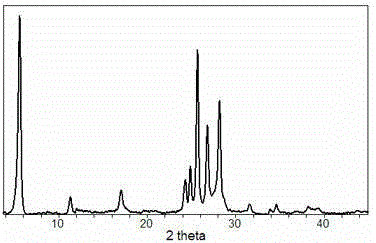

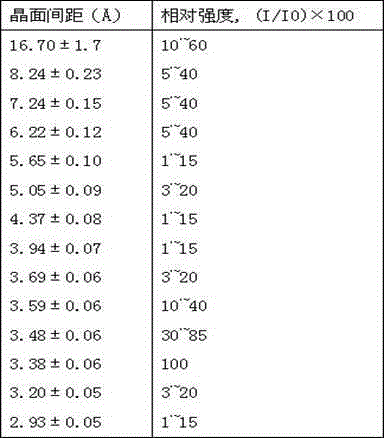

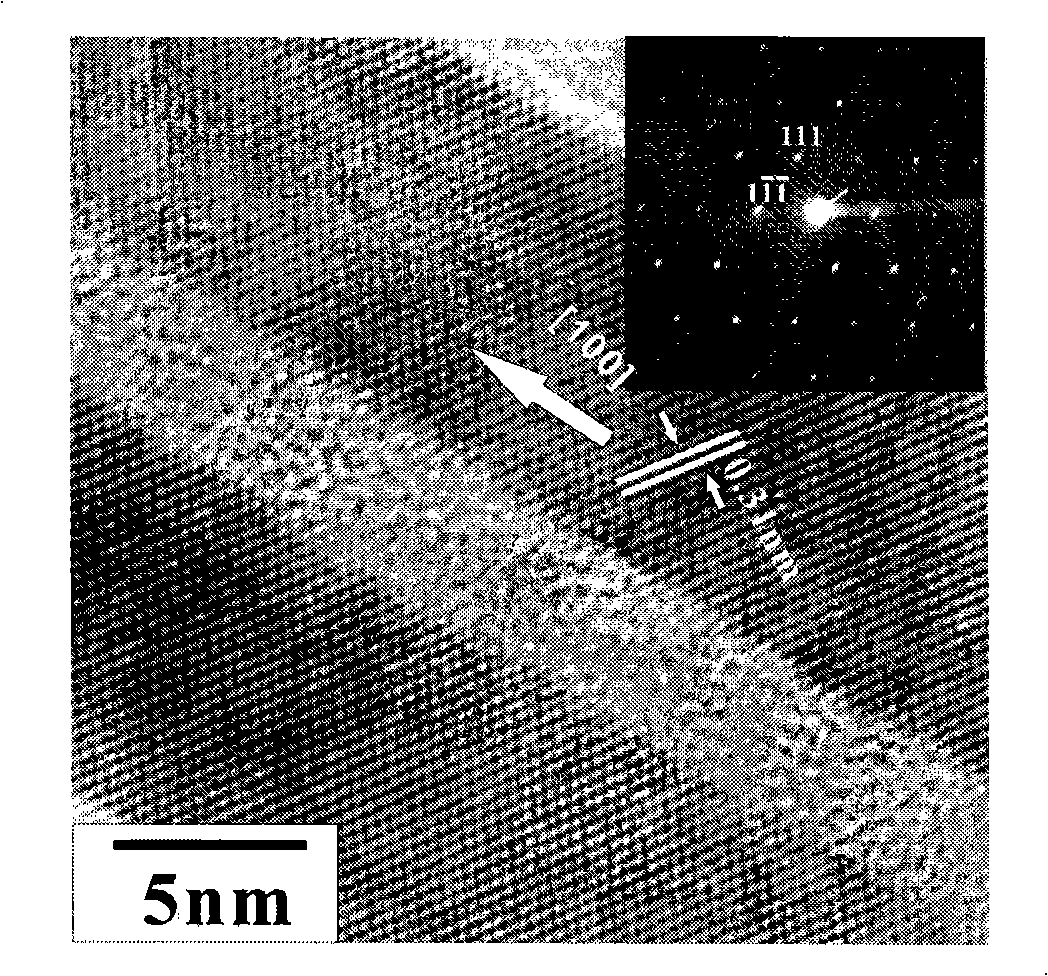

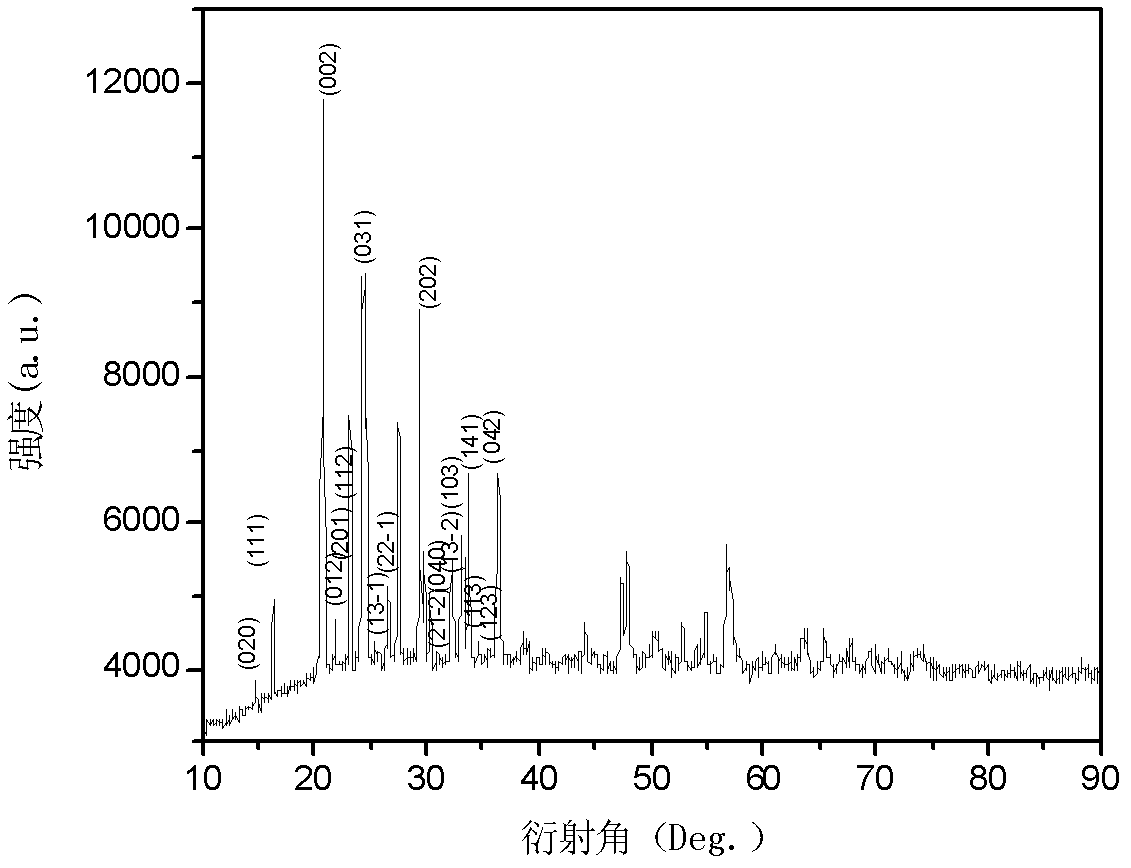

SCM-3 molecular sieve and preparation method thereof

ActiveCN104445263AImprove thermal stabilityCrystal structure intactMolecular-sieve and base-exchange compoundsMolecular sieveIsomerization

The invention relates to an SCM-3 molecular sieve and a preparation method thereof, which mainly solve the technical problems of the molecular sieve SCM-3 having a new structure not involved in the prior art. The invention provides a technical scheme of a new SCM-3 molecular sieve which comprises the following chemical compositions in mole ratio: XO2:nY2O3, wherein X is silicon or germanium; Y is at least one of elements such as aluminum, boron, gallium, iron and the like; 0.002<=n<=0.25; and the maximum value of an X-ray diffraction peak exists when the interplanar distance of the SCM-3 molecular sieve d=16.70+ / -1.7A, d=8.24+ / -0.23A, d=7.24+ / -0.15A, d=6.22+ / -0.12A, d=3.59+ / -0.06A, d=3.48+ / -0.06A and d=3.38+ / -0.06A. Thus, the technical scheme well solves the technical problems. The synthesized SCM-3 molecular sieve has favorable application prospects in the aspects of catalytic cracking of heavy oil and isomerization reaction of organic molecules.

Owner:CHINA PETROLEUM & CHEM CORP +1

Precursor of polynary positive electrode material for lithium ion battery, and preparation method thereof

InactiveCN103274480AHigh densityHigh sphericityCell electrodesCobalt compoundsReaction temperatureSlurry

The invention discloses a precursor of a polynary positive electrode material for a lithium ion battery, and a preparation method thereof. The precursor comprises NixCo(1-x-y-z)MnyWz(OH)2 (0<x<0.3,0<y<0.3,0<z<0.1), wherein W represents one of Al , Mg, Ti, Sr, Zr and W. The preparation method comprises the following steps of preparing a mixed salt solution A according to proportions, parallel-flowing the salt solution A and ammonium sulfate according to a certain proportion into a reactor with pure water by using sodium hydroxide and ammonium sulfate as a complexing agent; stirring the solution in the reactor continuously; controlling temperature and pH value of the reaction; introducing slurry in the reactor into another container through an overflow port for ageing; filtering precipitate and drying. The precursor has high density, high sphericility and complete crystal structure. The precursor has simple synthesis process, low cost and controllable granularity, and can be industrialized easily.

Owner:NANTONG RESHINE NEW MATERIAL

Preparation method of graphite

InactiveCN103387222AIncrease productionImprove mechanical propertiesGrapheneOxidation-Reduction AgentSulfur

The invention provides a preparation method of graphite. The method comprises the following steps: placing intercalation graphite in a sealed reactor, wherein an insert substance between the layers of the intercalation graphite is an explosive substance, and the addition of the intercalation graphite is 1-5 g / L according to the volume of the reactor; heating the sealed reactor to 280-500 DEG C to induce explosion reaction on the explosive substance; after reaching the heating temperature, maintaining for 1-5 min and stopping the heating; and cooling, discharging gas and collecting a solid product namely the graphite. The invention employs simple equipment and simple feasible operations, and is easy to realize large-scale industrial production. The prepared graphite has high yield, good mechanical property, strong conductivity, and does not contain corrosive elements such as sulfur and chlorine; and the graphite has the advantages of little defect and complete crystal structure compared with the graphite prepared by a common redox method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Nano line array in multiplayer structure, and preparation method

InactiveCN1872660ACrystal structure intactHighly controllableIndividual molecule manipulationNanometreSemiconductor

An array of semiconductor nanowires with multi-layer structure features that said nanowire structure is a multi-layer nanowires formed by alternative arrangement of metal / semiconductor or semiconductor / semiconductor, and said multi-layer nanowires are arranged parallelly and perpendicularly to form an array. Its preparing process includes preparing multi-layer metallic nanowire array and sulfurizing or oxidizing gas-solid reaction.

Owner:SUN YAT SEN UNIV

Preparation method of graphene

InactiveCN103663428AFacilitate strippingReduce the number of layersGrapheneMass ratioUltrasonic dispersion

The invention provides a preparation method of graphene, which comprises the following steps: (1) mixing graphite and an ionic liquid in a mass ratio of 1:(0.5-5), and carrying out ultrasonic dispersion for 10-48 hours to obtain intercalation graphite of which the intercalation compound is the ionic liquid, wherein the ionic liquid is an imidazole ionic liquid or pyrrolidine ionic liquid; and (2) putting the intercalation graphite in a reactor in an inert gas protective atmosphere, heating to 700-900 DEG C, keeping for 0.5-1 hour, cooling to room temperature in the inert gas protective atmosphere, and collecting the solid product which is the graphene. The method has the advantages of simple equipment and simple and feasible operation, and can easily implement large-scale industrial production; the prepared graphene has the characteristics of high yield, smaller number of layers, favorable mechanical properties and high conductivity; and compared with the common graphene prepared by a redox process, the graphene prepared by the method provided by the invention has the advantages of fewer defects, complete crystal structure and the like.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method for nano-tube

InactiveCN101284667ASimple processCrystal structure intactSilicon compoundsDeposition temperatureRare-earth element

The invention is a method for preparing a silicon nanotube, which takes the mixed powder of SiO, Si, etc. as the starting material and a small amount of rare earth elements as an indirect catalyst, evaporates the material under the conditions of high temperature and low air pressure, and causes the silicon atoms to accumulate and nucleate at a proper deposition temperature, thereby preparing the hollow-structured silicon nanotube. The method for preparing the silicon nanotube has the advantages of simple process, low-cost equipment, complete crystal structure of the nanotube, and capability for meeting the industrial requirements. The successful preparation of the nanotube provides a practicality foundation for the nanuotube to be widely applied in nanoelectronic devices in the future, and the theoretical research of the nanotube is verified from the experiment.

Owner:FUDAN UNIV

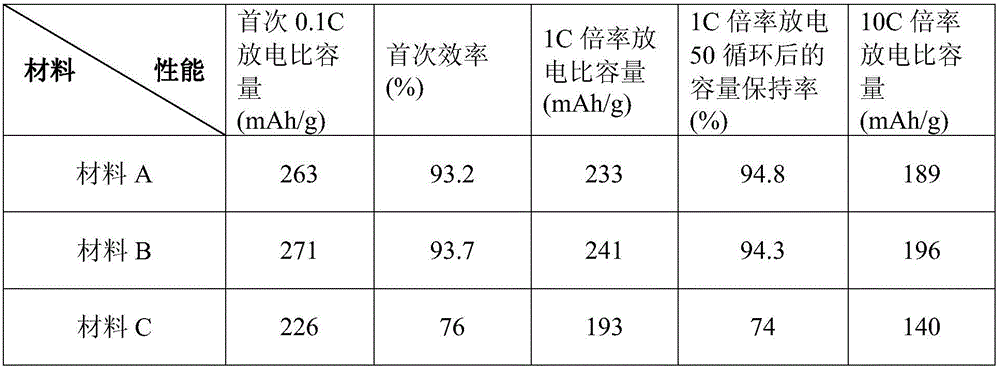

Modified lithium-rich manganese-based positive electrode material and preparation method thereof

The invention discloses a modified lithium-rich manganese-based positive electrode material and a preparation method thereof, and belongs to the technical field of positive electrode materials for lithium-ion batteries. The preparation method comprises the steps of fully mixing a lithium-rich manganese-based precursor, a lithium salt and a doped metal compound, and then burning a mixture to prepare the modified lithium-rich manganese-based positive electrode material; and carrying out pretreatment of heat preservation on a lithium-rich manganese-based precursor at 300-650 DEG C for 2-6 hours before mixing. A pretreatment step of the precursor is added to an existing preparation technology of the lithium-rich manganese-based positive electrode material, a crystal structure of the precursor is more complete and an aluminum element is doped, so that the initial coulomb efficiency of the positive electrode material can be significantly improved and is improved by 15-20% in comparison with that of an un-pretreated material; and the rate capability is also greatly improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

Preparation method of cobalt carbonate and preparation method of cobaltosic oxide

InactiveCN109319846ALarge grainCrystal structure intactCobalt oxides/hydroxidesCobalt carbonatesGranularityCobalt(II,III) oxide

The invention discloses a preparation method of cobalt carbonate and a preparation method of cobaltosic oxide. The preparation method of the cobaltosic oxide comprises the following steps of preparingan ammonium bicarbonate solution; preparing a cobalt chloride solution; adding a preset amount of deionized water into the reaction container; heating the deionized water to the preset temperature; adding partial ammonium bicarbonate solution into the reaction container; regulating the acidity-basicity of the solution in the reaction container until the pH is 7.1 to 7.6; adding the cobalt chloride solution and the rest ammonium bicarbonate solution into the reaction container; performing stirring reaction to generate cobalt carbonate; filtering solution in the reaction container and cobalt carbonate to obtain cobalt carbonate; washing the cobalt carbonate; roasting the cobalt carbonate to obtain cobaltosic oxide powder. The preparation method of the cobaltosic oxide has the advantages that the raw material price is low; the realization is easy; the controllable degree is high; the prepared cobaltosic oxide has uniform granularity and appearance.

Owner:HUAIHUA UNIV

Preparation method of magnetic powder

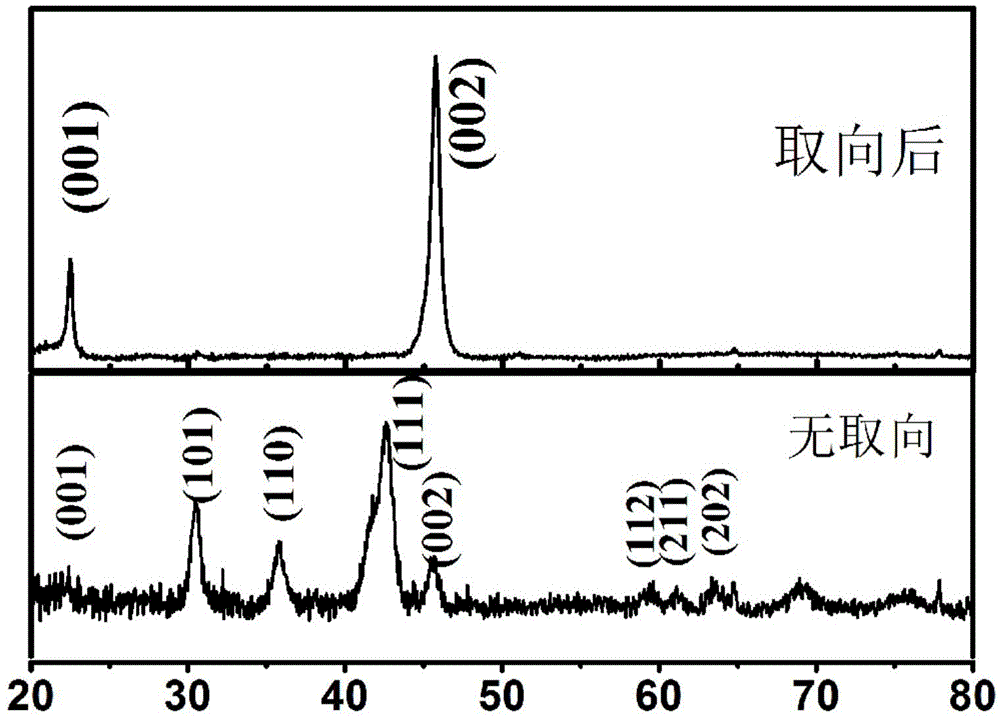

ActiveCN104646677AStrong textureCrystal structure intactInorganic material magnetismOrganic solventCrystal structure

The invention provides a preparation method of magnetic powder. The method comprises the following steps: (a) adding a magnetic material, milling balls, an organic solvent and a selectively added surfactant into a ball milling tank; (b) sealing the ball milling tank, and then, carrying out ball milling, wherein a ball milling process is of speed-gradually-increased staged ball milling and at least comprises two ball milling stages, and the time of ball milling of each stage is 0.5-24 hours; (c) taking out the milling balls, pouring a ball-milled product into a vessel, flushing and drying, thereby obtaining the magnetic powder. Compared with the traditional single-speed-adopted ball milling manner, the preparation method has the advantages that the magnetic powder with higher texture degree and more-complete crystal structure can be obtained due to a multistage different-speed ball milling method; the preparation method of the magnetic powder, provided by the invention, is simple in steps, new equipment is not required to be added, and implementation can be achieved by only changing ball milling speed during ball milling and controlling corresponding ball milling time, so that the application is very extensive.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

High-nickel ternary positive electrode material with high electrical property consistency, preparation method thereof and application thereof

InactiveCN109713252ACrystal structure intactNarrow particle size distributionCell electrodesSecondary cellsChemical structureLithium-ion battery

The invention relates to the field of lithium-ion batteries and particularly relates to a high-nickel ternary positive electrode material with high electrical property consistency, a preparation method thereof and an application thereof. The high-nickel ternary positive electrode material with high electrical property consistency is characterized in that the chemical structural formula is LixNiaCobMcRdO2, wherein R is a doping element, x is larger than 0.95 and smaller than 1.15, a is larger than 0.60 and smaller than 0.85, b is larger than 0 and smaller than 0.2, c is larger than 0 and smaller than 0.2, the sum of a, b and c is larger than or equal to 0.98 and smaller than or equal to 1.00, d is larger than or equal to 0 and smaller than or equal to 0.1, and M is Mn or Al. The high-nickelternary positive electrode material has high particle size consistency, and the physical performance and electrochemical performance of a high-nickel lithium-ion secondary battery can be effectivelyimproved.

Owner:高点(深圳)科技有限公司 +1

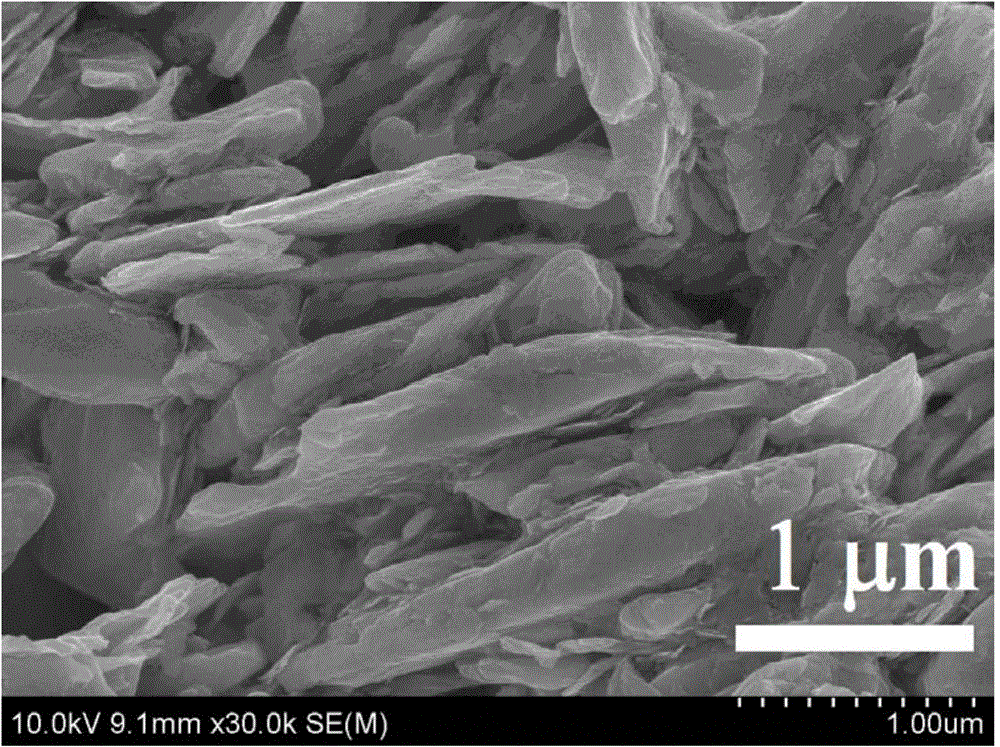

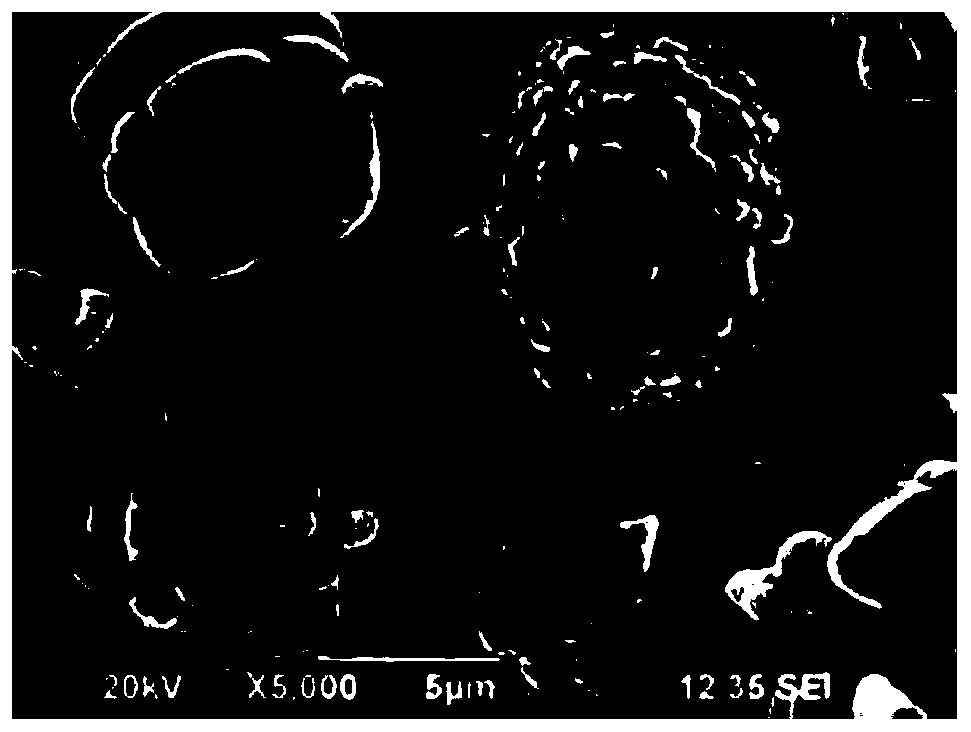

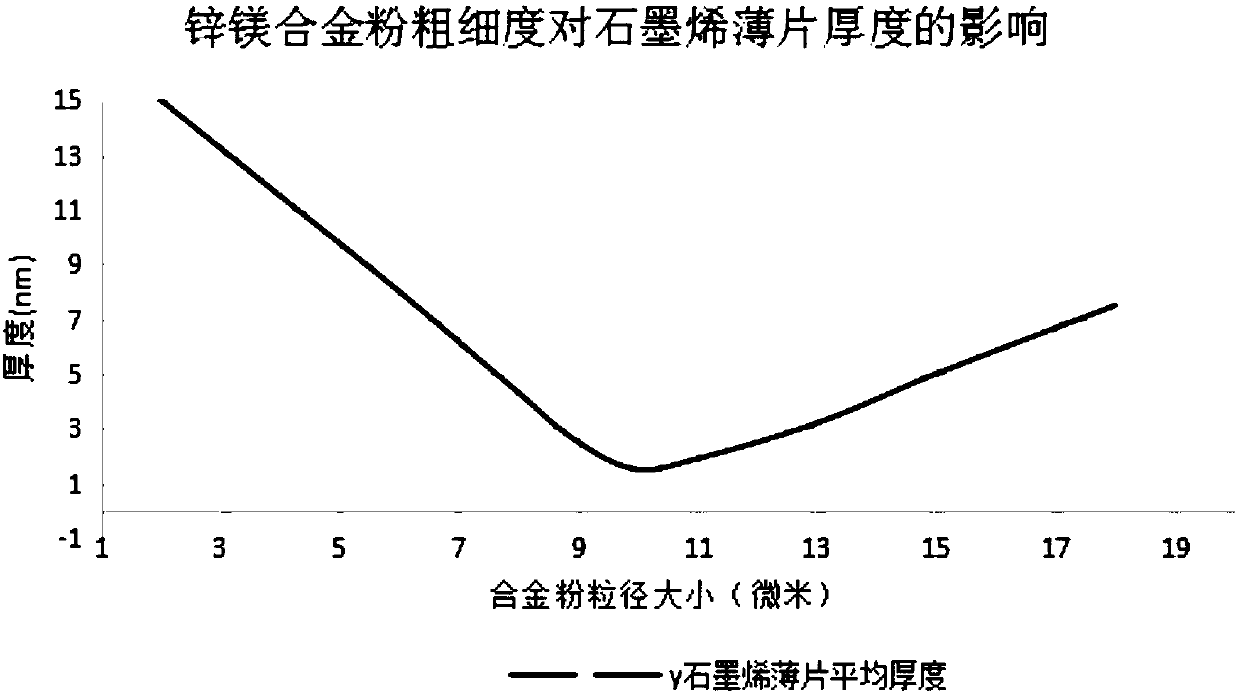

Graphene physical stripping production method and graphene produced through method

The invention provides a graphene physical stripping production method and a graphene produced through the method. The method comprises the steps that high-purity flaky graphite is used as a raw material for producing graphene, steel balls and zinc-magnesium alloy powder is used as a ball-milling stripping medium, and the flaky graphite and the ball-milling stripping medium are put into a ball grinding mill and are subjected to ball-milling stripping under nitrogen protection; after completion of stripping, graphene flakes subjected to ball-milling stripping are separated out through air classification under inert gas shielding. The whole production process is easy to operate and free of generation of pollutants.

Owner:李文辉

Method for preparing graphene

ActiveCN102765717BEfficient strippingQuality improvementGrapheneBulk chemical productionPresent methodSolvent

Disclosed is a method for preparing graphene. In particular, the method comprises: using n-hexane or propane as a supercritical solvent, filling graphite powder or graphite powder and a cosolvent into an autoclave, sealing the autoclave by selecting an appropriate rupture disk, adding n-hexane or propane after the autoclave is vacuumized, keeping in a supercritical state for a period of time at a temperature and a pressure, then increasing the temperature and the pressure slightly or increasing the pressure alone,, and a collector collecting rushed-out materials instantly for treatment to prepare a graphene product after the rupture disk bursts when the pressure exceeds the pressure which the rupture disk can bear. In the present method, pressure relief occurs in milliseconds, and thereby efficient strip of graphite can be achieved. The method belongs to a physical process, does not cause large damage on the structure of graphene, is simple in the preparation process, does not require a large quantity of inorganic acids and oxidants, and is free of "three wastes". The prepared graphene crystal is intact in structure, good in quality, and capable of achieving large-scale industrial production of graphene.

Owner:余美群

Preparation method of graphene

InactiveCN103359713AReduce defectsCrystal structure intactGrapheneDefective grapheneCrystal structure

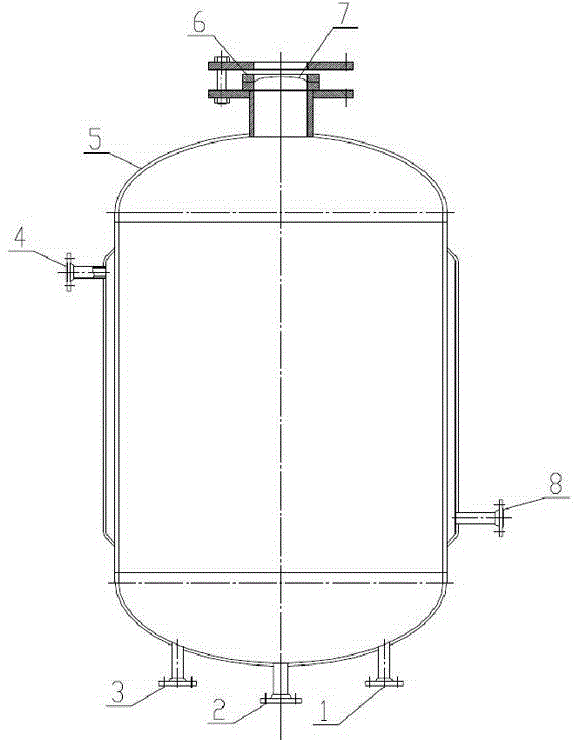

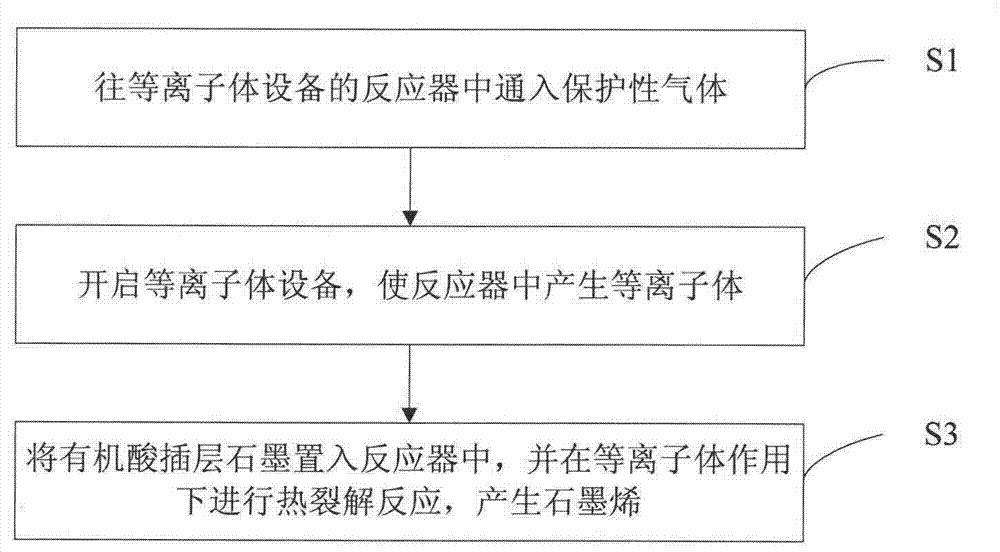

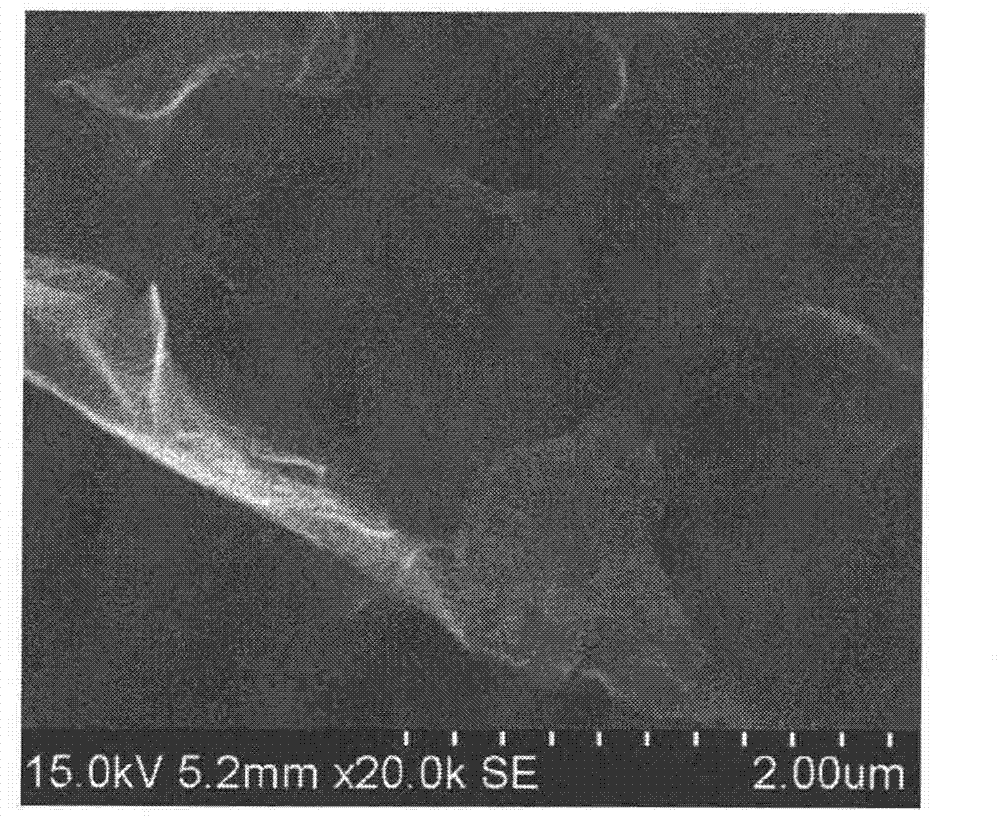

The invention belongs to the field of graphene, and discloses a preparation method of graphene, which comprises the following steps: introducing protective gas into a reactor of plasma equipment; starting the plasma equipment to generate plasma in the reactor; and adding organic acid intercalated graphite into a reactor, and carrying out pyrolysis reaction under the action of plasma to obtain the graphene. By using the method for preparing the graphene by quickly pyrolyzing organic acid intercalated graphite, the prepared graphene has the advantages of fewer defects and complete crystal structure, and is free of sulfur, chlorine and other corrosive elements; and meanwhile, the invention has the advantages of favorable stripping effect, centralized number of layers, simple equipment, and simple and feasible operation, and can easily implement automatic and industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

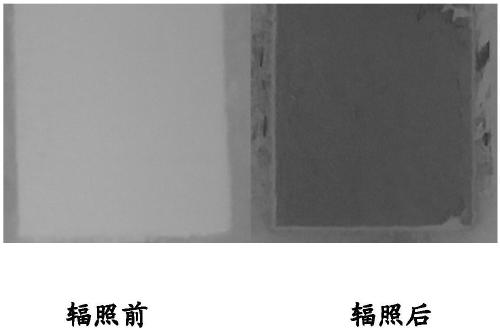

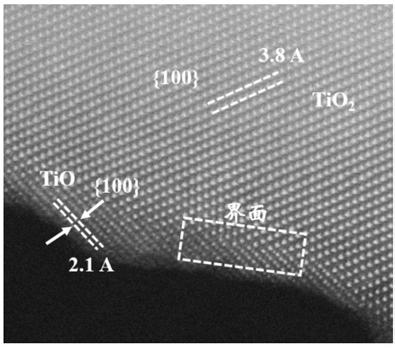

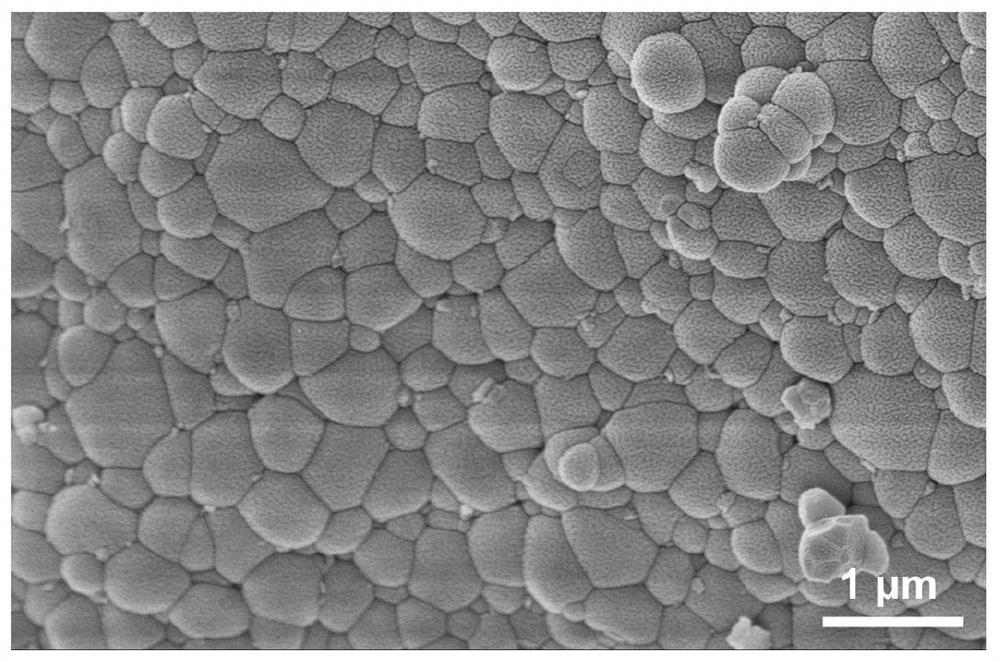

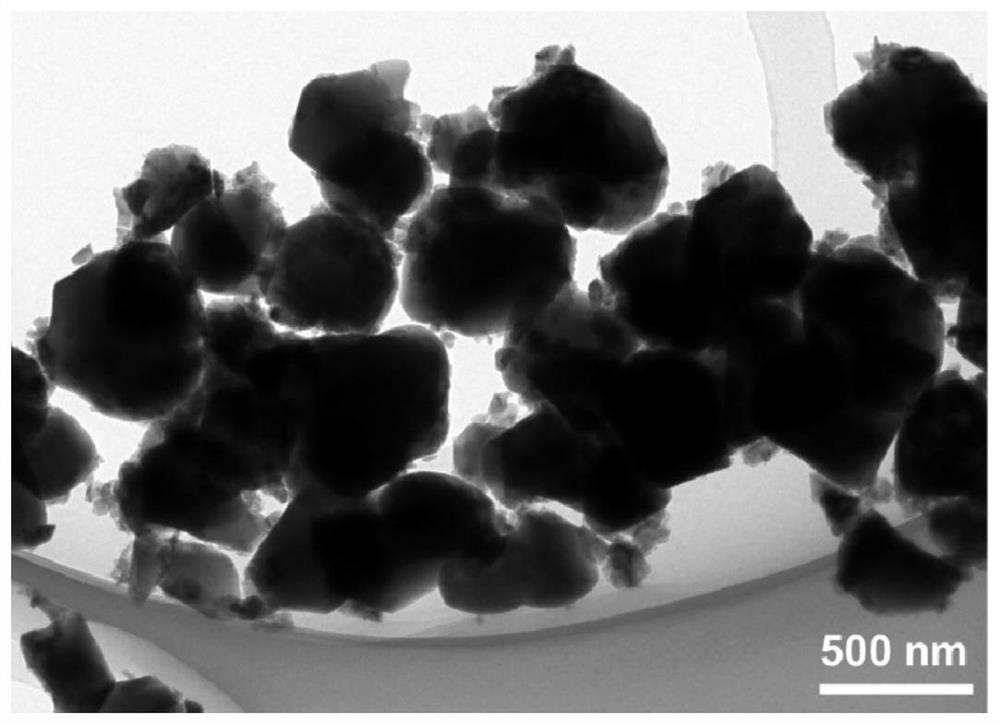

Preparation method of blue titanium dioxide particles

ActiveCN111170362APreparation process cleaningShort reaction timeTitanium dioxideThin membranePicosecond

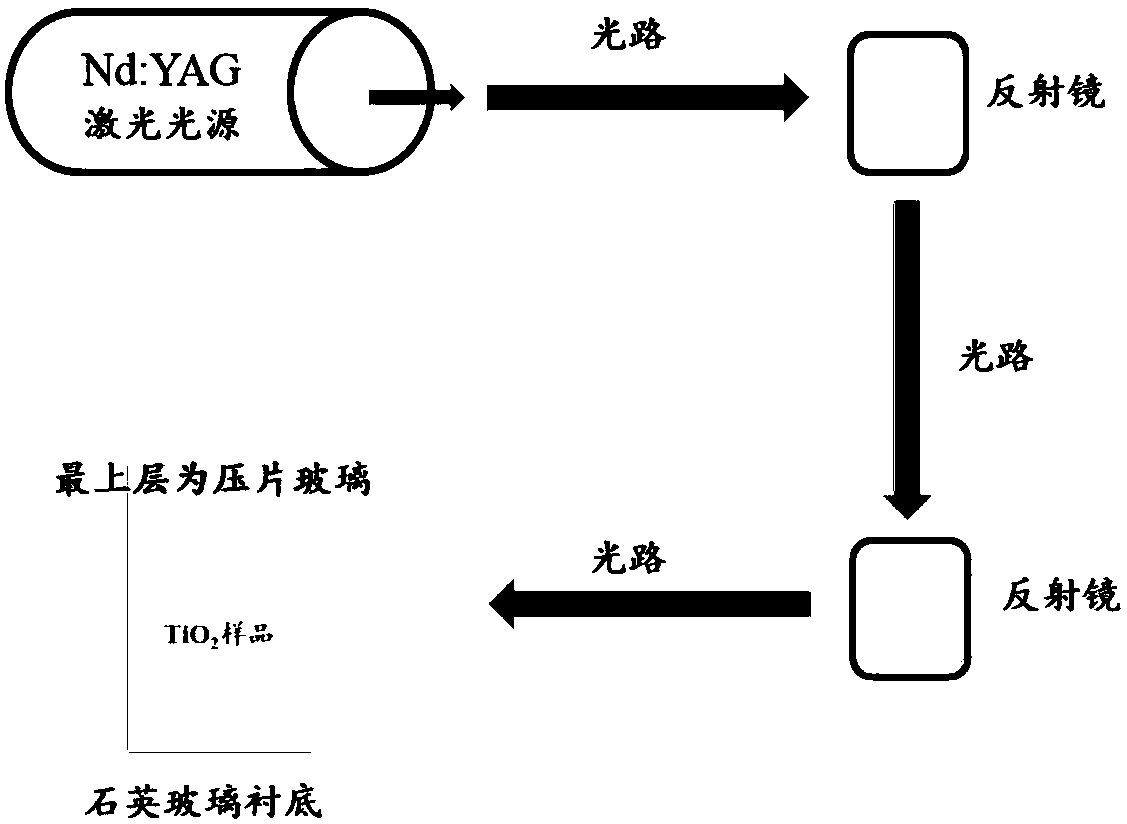

The invention provides a preparation method of blue titanium dioxide particles. The method comprises the following steps: 1) removing surface impurities of TiO2 particles; 2) tabletting the TiO2 particles treated in the step 1), so that the surfaces of the tabletted TiO2 particles are flat; 3) irradiating the TiO2 particles treated in the step 2) for 3-10 seconds by using rapid laser with a pulsewidth of picoseconds or nanoseconds to obtain TiO2 particles with TiO films growing on the surfaces in situ; and 4) uniformly mixing the TiO2 particles treated in the step 3) again, and repeating thestep 2) and the step 3) until the whole TiO2 particles are uniform in blue color. According to the method, the preparation process is clean and free of pollution, the required single reaction time isextremely short and is only 3-10 seconds, and the preparation efficiency is high; the prepared blue titanium dioxide particles have good color stability in natural air and show good electrical transport performance, the photocurrent density is improved by about 3 times compared with that of the raw material TiO2, and the current impedance is obviously reduced.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

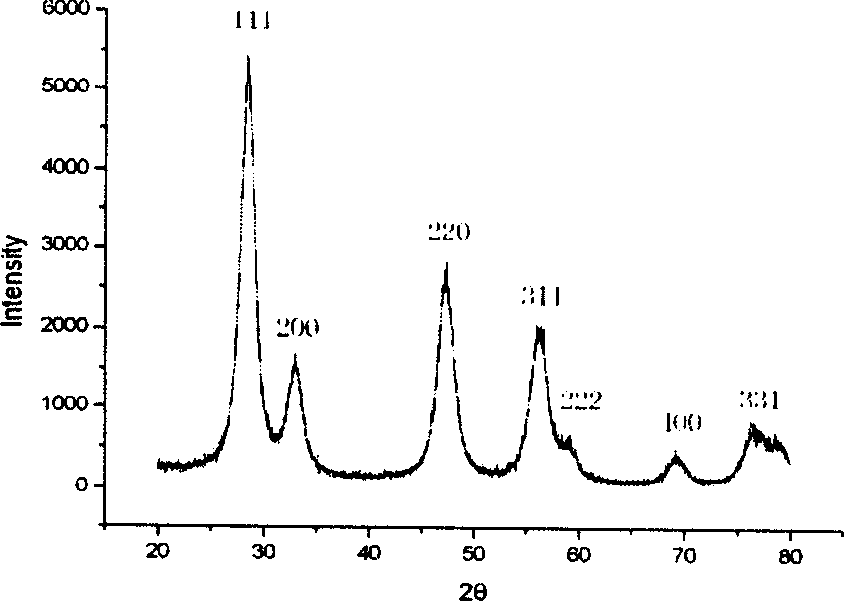

Single crystal type IV-VI-VIII group lithium-rich disordered rock salt structure positive electrode material and preparation method thereof

PendingCN112680791AStable structureCrystal structure intactPolycrystalline material growthCell electrodesManganateManganese

The invention discloses a single crystal type IV-VI-VIII group lithium-rich disordered rock salt structure positive electrode material and a preparation method thereof. The general formula of the positive electrode material is Li<1+a>TiW<c>Ni<d>O<2>, wherein a is greater than 0.1 and smaller than 0.3, b is greater than 0.1 and smaller than 0.4, c is greater than 0.1 and smaller than 0.4, d is greater than 0.1 and smaller than 0.4 , and the sum of a+4b+6c+2d is equal to 3. The single crystal type material is composed of IV group elements, VI group elements and VIII group elements, is specifically composed of titanium of the IV group elements, tungsten of the VI group elements and nickel of the VIII group elements, and has a more stable three-dimensional disordered cation skeleton structure, a more complete crystal structure, higher compaction density and a smaller specific surface area compared with a traditional ternary lithium nickel cobalt manganate positive electrode material; and therefore, the material has good rate capability and cycle performance, and can be used in lithium ion batteries.

Owner:北京理工大学重庆创新中心 +1

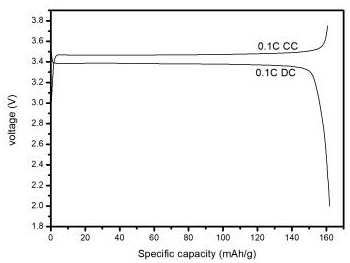

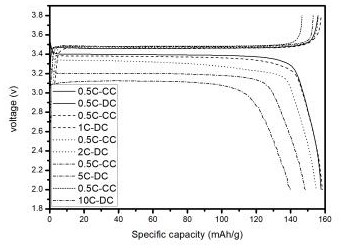

Preparation method of high-rate lithium iron phosphate positive electrode material

ActiveCN113929070AExcellent rate performanceImprove cycle stabilitySecondary cellsPositive electrodesDopantLithium iron phosphate

The invention relates to a high-rate lithium iron phosphate positive electrode material and a preparation method thereof. The preparation method comprises the steps: firstly, weighing an iron source and a lithium source according to a molar ratio of 1:1-1:1.05, then weighing a carbon source accounting for 5-15% of the total mass of the iron source and the lithium source and a metal ion doping agent accounting for 0-1% of the total mass of the iron source and the lithium source, adding water, carrying out ball milling and sanding, controlling sanding D50 to be 100-200 nm, and then spraying to obtain a precursor; and putting the precursor into a sintering furnace, introducing nitrogen for protection at the same time, sintering at 650-700 DEG C, cooling to obtain a sintered material, crushing the sintered material, and screening to remove iron to obtain the lithium iron phosphate. The prepared lithium iron phosphate has good rate capability and cycling stability, the 0.1 C discharge capacity of the lithium iron phosphate reaches 160 mAh / g, the 10 C discharge capacity of the lithium iron phosphate reaches 140 mAh / g, the microstructure of the positive electrode material is spherical-like particles, and the average value of primary particles is 100 nm.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

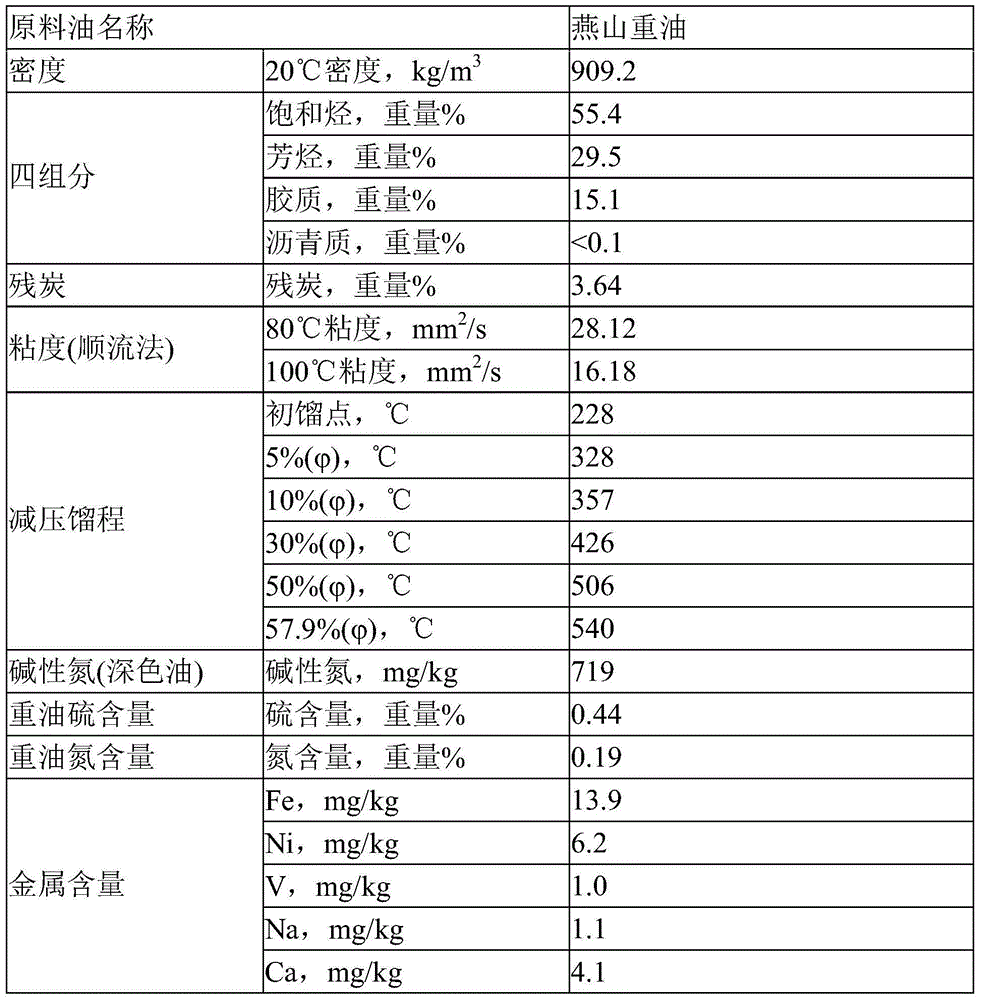

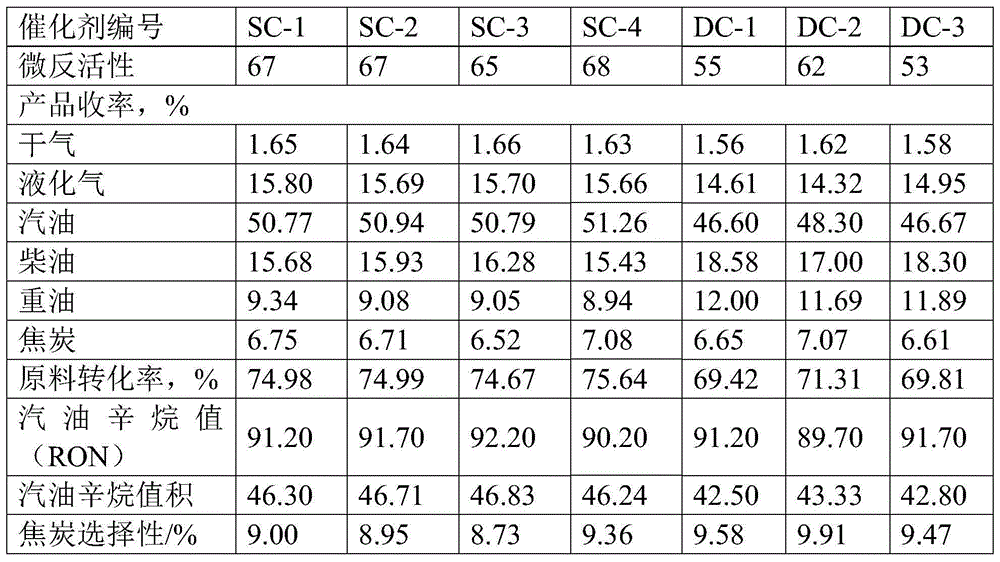

Catalyst for heavy oil catalytic cracking, preparation method thereof, and method for catalytic cracking of heavy oil

ActiveCN106268918BImprove stabilityGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsGas phaseFuel oil

Owner:CHINA PETROLEUM & CHEM CORP +1

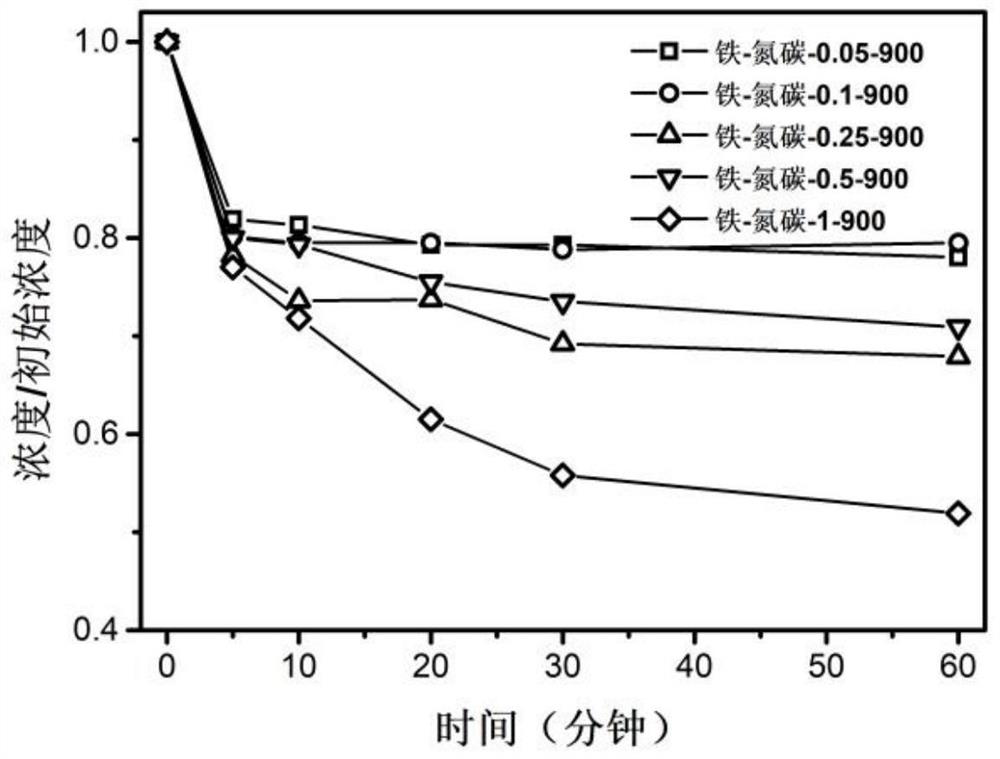

Preparation and application of iron-nitrogen co-doped porous carbon material

PendingCN114053998ALarge specific surface areaMany catalytically active sitesPhysical/chemical process catalystsOther chemical processesMetal-organic frameworkSewage treatment

The invention discloses preparation and application of an iron-nitrogen co-doped porous carbon material. Ferrocene, zinc nitrate and 2-methylimidazole are weighed and dissolved in methanol, ferrocene-loaded ZIF-8 metal organic framework powder is prepared at normal temperature, and then high-temperature treatment is performed in a protective atmosphere to obtain the iron-nitrogen co-doped porous carbon material. The iron-nitrogen-carbon material prepared by the preparation method disclosed by the invention has excellent sewage treatment performance.

Owner:ZHEJIANG UNIV

Heavy oil catalytic cracking catalyst, preparation method of heavy oil catalytic cracking catalyst and heavy oil catalytic cracking method

ActiveCN106268918AImprove stabilityGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsGas phaseFuel oil

The invention relates to a heavy oil catalytic cracking catalyst and its preparation method and a heavy oil catalytic cracking method. The heavy oil catalytic cracking catalyst comprises 10-40% by dry base weight of small crystal grain gas phase ultrastable high-silica rare earth Y-type zeolite, 10-60% by dry base weight of clay and 13-60% of by oxide weight of an inorganic oxide, the inorganic oxide contains at least one active alumina, the average diameter of the alumina crystal grains is in a range of 0.1-0.8 micrometers, a lattice constant is in a range of 24.5-24.6 angstroms and a silica-alumina ratio is in a range of 7-10. The small crystal grain gas phase ultrastable high-silica rare earth Y-type zeolite comprises, by weight, 6-16% of a rare earth oxide and less than 2% of sodium oxide. The Y-type zeolite is prepared from small crystal grain Y-type zeolite through gas phase ultrastable treatment, washing and rare earth ion exchange. The average aperture of the active alumina is in a range of 5-25nm. The catalytic cracking catalyst has good stability and good catalytic cracking coke selectivity and can produce a gasoline product with a high gasoline octane number and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-energy catalytic physical stripping preparation method of graphene

The invention relates to a high-energy catalytic physical stripping preparation method of graphene, relates to the technical field of graphene materials, and solves the problem that a conventional physical stripping method is high in cost and not easy to be mass-produced. The method specifically comprises the following steps: performing preliminary infiltration on pure water, performing first high-energy ultrasonic preliminary stripping, adding SiC for ball milling, then performing second high-energy catalysis for stripping, classifying graphene flakes by gas flow classification and spray-drying to obtain the graphene; by infiltration, ultrasonic treatment, SiC ball milling, addition of a surfactant and the secondary high-energy ultrasonic treatment, the graphene is stripped layer by layer, the process is mild, and basically no crushing and wear phenomena occur; the prepared graphene crystal lattice structure is complete and processed by a physical stripping method, the graphene flakesare present in a completely powdery form, the storage and use environments are not restricted, and the industrial production cost is relatively low, thereby facilitating the wider application of graphene in various industries.

Owner:大同墨西科技有限责任公司

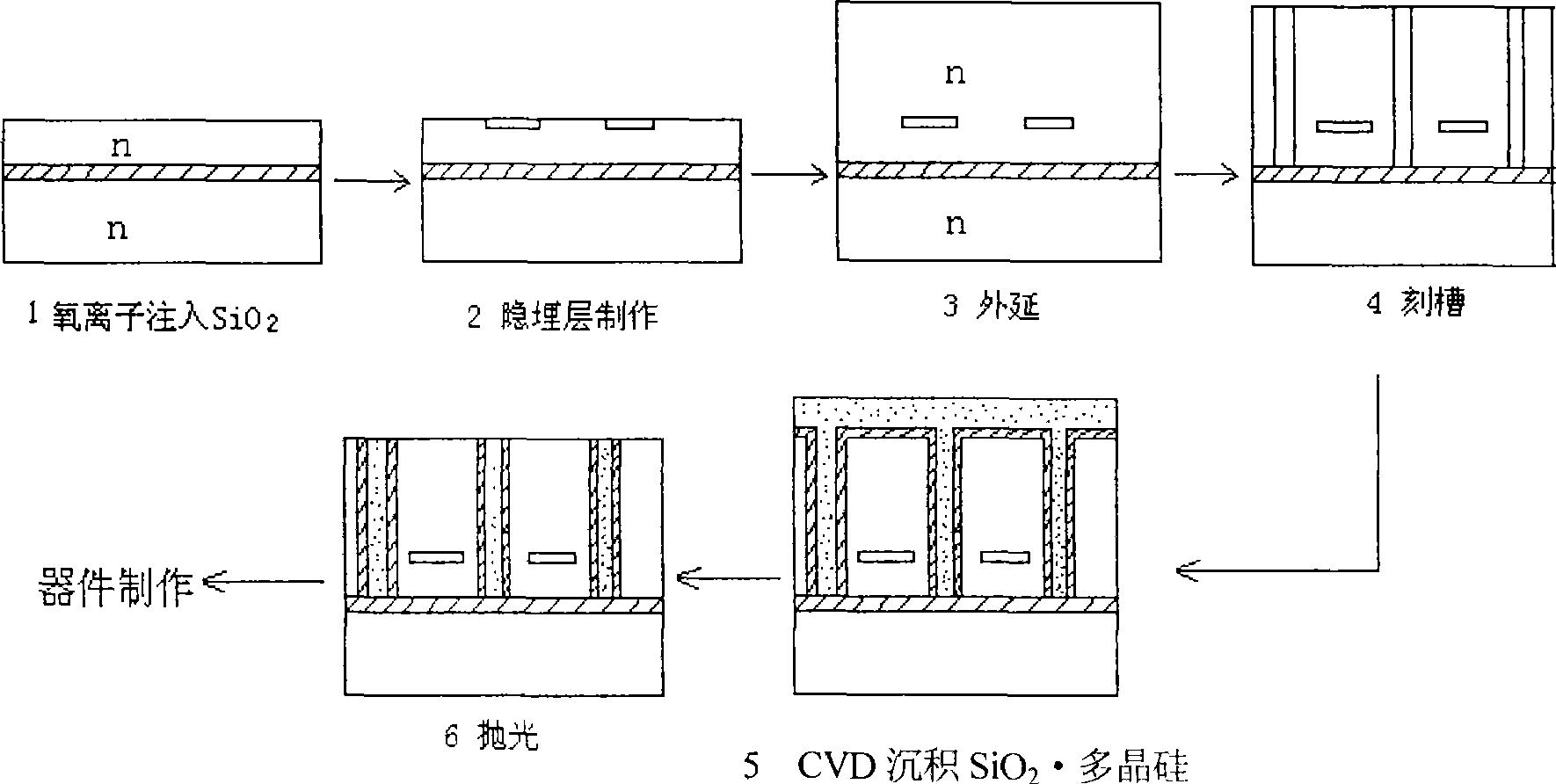

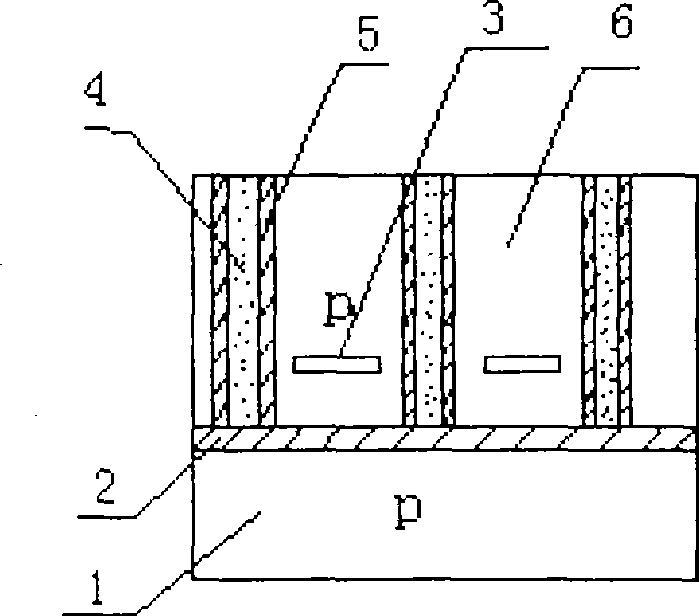

Dielectrically isolated integrated circuit extending wafer and preparation method thereof

InactiveCN101425522AImprove performanceImprove high temperature resistanceSolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureSilicon dioxide

The invention mainly relates to a dielectric isolation epitaxial wafer and a preparation method thereof. The N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer comprises N-shaped / P-shaped monocrystalline silicon (1) with backing material. A sandwich oxide layer (2) is arranged on the monocrystalline silicon (1). The invention is mainly characterized in that the dielectric isolation epitaxial wafer further comprises an N-shaped / P-shaped silicon epitaxial layer (6); a buried layer (3) is arranged in the silicon epitaxial layer (6); the silicon epitaxial layer (6) is divided into mutually-insulating isolation blocks by silicon dioxide (5), polysilicon (4) and the sandwich oxide layer (2). The invention also discloses a preparation method of the N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer. The preparation method comprises the following steps: preparing a silicon chip on an insulating body, preparing the buried layer with low resistance, extending outwardly, notching, growing the silicon dioxide and the polysilicon, and polishing. Because the high temperature time is shortened greatly during the preparation, the invention has the advantages of more complete crystal structure and more accurate process control, and can be used for manufacturing circuits with high performance and special requirements.

Owner:TIANSHUI HUATIAN MICROELECTRONICS

Preparation method of anode material lithium iron (II) phosphate for lithium ion cell

ActiveCN103187567AChemical composition is easy to controlAvoid uncontrollableCell electrodesPhosphateSlurry

The invention discloses a preparation method of anode material lithium iron (II) phosphate for a lithium ion cell. The preparation method mainly comprises the following two steps: (1) synthesis of precursor Li3Fe2(PO4)3, blending a lithium source, an iron source and a phosphorus source according to that the molar ratio of Li to Fe to P is 3:2:3, taking deionized water, absolute ethanol or acetone as a medium, ball-milling for 0.5-24 h, drying the obtained slurry, thermally treating for 3-24 hours at the temperature of 500-900 DEG C to obtain the precursor Li3Fe2(PO4)3; and (2) blending the obtained precursor Li3Fe2(PO4)3 and iron powder according to the molar ratio of 1:1, taking deionized water, absolute ethanol or acetone as the medium, ball-milling for 0.5-24 h, drying the obtained slurry, placing the dried slurry into a high-temperature furnace, under the atmosphere of inoxidizability, baking the dried slurry for 5-24 h at the temperature of 500-800 DEG C, and at last preparing the lithium iron (II) phosphate material. By adopting the principle that the lithium iron (II) phosphate material is synthesized by oxidation reduction between zero-valent iron and ferric iron source Li3Fe2(PO4)3 at high temperature, firstly, the pure phase Li3Fe2(PO4)3 intermediate is synthesized in advance, and then reacted with the zero-valent iron to synthesize the lithium iron (II) phosphate, so that the reaction process is easy to control. The synthesized product Li3Fe2(PO4)3 is high in chemical purity, good in electrochemical performance and high in batch stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com