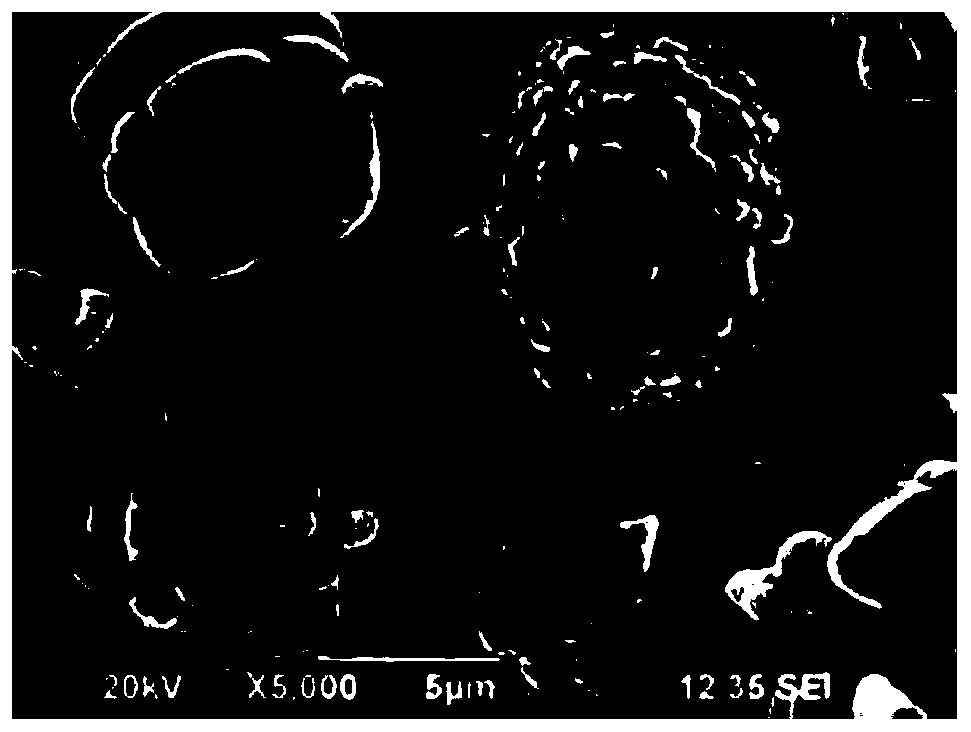

High-nickel ternary positive electrode material with high electrical property consistency, preparation method thereof and application thereof

A cathode material, high-nickel technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of limited application of high-nickel lithium-ion batteries, low storage consistency, etc., to improve physical properties and electrochemical properties, spherical The effect of good degree and high particle size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention provides a method for preparing the anode material, which comprises the following steps: (1) mixing a lithium source, a nickel-cobalt M precursor, and an R source in a molar ratio of 1.0-1.2:1:0.00-0.003, Then carry out the first sintering;

[0061] (2) subjecting the product obtained in step (1) to pulverization and classification to obtain a classification product;

[0062] (3) mixing the graded product obtained in step (2) with the remaining R source to obtain a semi-finished product;

[0063] (4) The semi-finished product obtained in step (3) is sintered for the second time, then pulverized and classified, and mixed to obtain the positive electrode material.

[0064] In a preferred embodiment of the present invention, wherein, in step (1), the lithium source is selected from one or more of lithium carbonate, lithium hydroxide monohydrate, lithium acetate and lithium oxalate .

[0065] In a preferred specific embodiment of the present inventi...

Embodiment 1

[0094] The preparation of embodiment one cathode material

[0095] (1) Use a 200L plow mixer. Turn on stirring (speed 25rpm), add 100kg of nickel-cobalt-manganese precursor (Ni 0.61 co 0.19 mn 0.20 (OH) 2 (grain size D v50 : 7 μm, effective substance content 99.5%), then take by weighing 46.1kg monohydrate lithium hydroxide powder (particle size D v50 : 25 μm, active matter content 99.5%) join in mixer, add 37.0kg deionized water by 80wt% solid content under stirring situation, then add 1.43kg basic cobalt carbonate (account for 7000ppm by adding cobalt amount in finished product), After stirring for 2 hours, further reduce the speed (5rpm) and stir for 6 hours to form a paste-like material with a certain degree of molding; Oxygen Air oxygen content 40%, flow rate 400Nm 3 / h) Put the material into a ceramic bowl for the first sintering, sintering for 10 hours, cool the material to normal temperature under the protection of dry nitrogen, weigh the weight of the incoming ...

Embodiment 2

[0101] The preparation of embodiment two cathode materials

[0102] (1) Select 200LY mixer. Start stirring (rotating speed 50rpm), add the nickel-cobalt-manganese precursor (Ni 0.61 co 0.20 mn 0.20 (OH) 2 (grain size D v50 : 7 μm, effective substance content 99.5%), then take by weighing 41.5kg lithium carbonate powder (particle size D v50 : 5 μm, active matter content 99.8%) into the mixer, add 20.0kg deionized water according to 90% solid content under stirring, further reduce the speed (3-5rpm) after stirring for 2 hours, and stir for 1 hour to form a certain shape The paste material discharging of degree; Adopt the method identical with embodiment 1 to carry out primary sintering (oxygen-enriched air oxygen content 99.5%, flow rate 200Nm 3 / h), loss on ignition is 33.8% based on raw materials;

[0103] (2) The product obtained in step (1) is pulverized with a cyclone vortex pulverizer, and the pulverized material passes through the first stage classification wheel (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com