Preparation method of anode material lithium iron (II) phosphate for lithium ion cell

A lithium ferrous phosphate and lithium ion battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low specific capacity, impurities or heterogeneous phases in the product, and difficult control of the reaction process, so as to achieve a complete crystal structure, The effect of high chemical purity and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

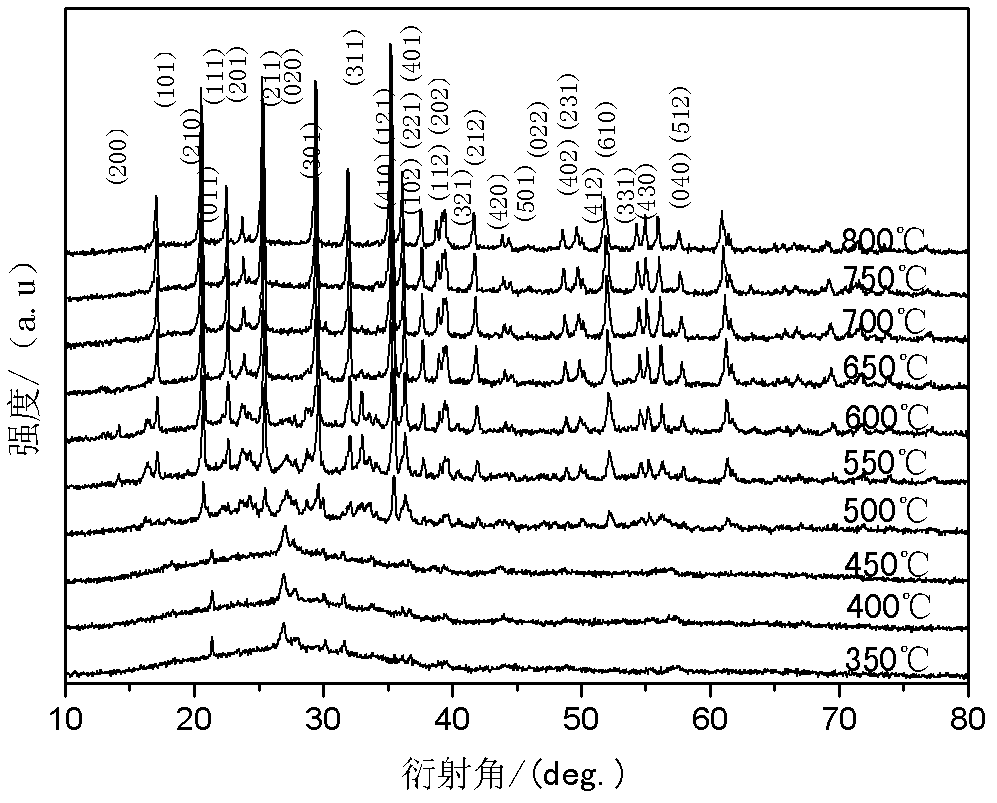

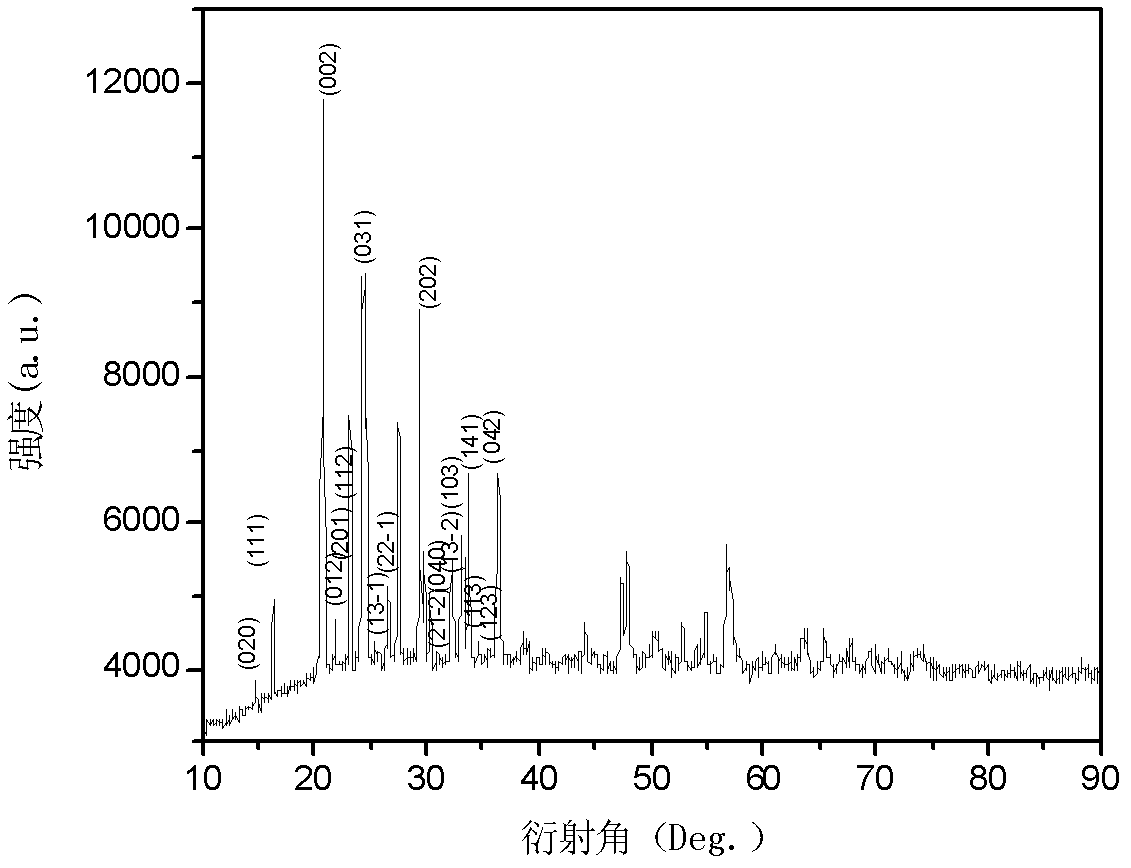

[0036] Lithium carbonate, ferric oxide and ammonium dihydrogen phosphate were prepared according to the Li:Fe:P molar ratio of 3:2:3, and then ball milled in ethanol medium for 100 minutes to obtain a slurry; the slurry was vacuum dried to obtain a precursor , Put the precursor in a pot and put it in a muffle furnace for roasting at a heating rate of 5°C / min, holding at 700°C for 5 hours, and cooling to room temperature with the furnace to obtain Li 3 Fe 2 (PO 4 ) 3 Precursor;

[0037] Will Li 3 Fe 2 (PO 4 ) 3 The precursor and iron powder are ball-milled in ethanol medium at a molar ratio of 1:1 for 30 minutes to obtain a slurry; the slurry is vacuum-dried to obtain a precursor, and the precursor is roasted in a nitrogen-protected vacuum pit furnace and heated The speed is 5°C / min, the temperature is kept at 600°C for 5 hours, and the furnace is cooled to room temperature to obtain lithium iron phosphate material.

[0038] Assemble the simulated battery to the LiFePO prepar...

Embodiment 2

[0043] Lithium hydroxide, ferric nitrate and diammonium hydrogen phosphate are mixed according to the Li:Fe:P molar ratio of 3:2:3, and then ball milled in acetone medium for 12 hours to obtain a slurry; the above slurry is spray-dried to obtain a precursor, Put the precursor bowl into the muffle furnace for roasting, the heating rate is 5℃ / min, the temperature is kept at 900℃ for 3h, and the furnace is cooled to room temperature to obtain Li 3 Fe 2 (PO 4 ) 3 Precursor;

[0044] Will Li 3 Fe 2 (PO 4 ) 3 The precursor and iron powder are ball milled in an aqueous medium at a molar ratio of 1:1 for 12 hours to obtain a slurry; the slurry is spray-dried to obtain a precursor, and the precursor is mixed with nitrogen and hydrogen with a hydrogen content of 5% The mixed atmosphere is placed in a pit furnace for roasting, the heating rate is 5°C / min, the temperature is kept at 600°C for 10 hours, and the furnace is cooled to room temperature to obtain the lithium iron phosphate ma...

Embodiment 3

[0047] The iron oxalate and lithium dihydrogen phosphate are mixed according to the Li:Fe:P molar ratio of 3:2:3, and the slurry is obtained after ball milling in ethanol medium for 24 hours; the above slurry is spray-dried to obtain the precursor, and the precursor is packed The bowl is put into a muffle furnace for roasting, the heating rate is 5℃ / min, the temperature is kept at 800℃ for 15h, and the furnace is cooled to room temperature to obtain Li 3 Fe 2 (PO 4 ) 3 Precursor;

[0048] Will Li 3 Fe 2 (PO 4 ) 3 The precursor and iron powder are ball-milled in acetone medium at a molar ratio of 1:1 for 24 hours to obtain a slurry; the slurry is spray-dried to obtain a precursor, and the precursor is baked in a pit furnace in a nitrogen atmosphere , The heating rate is 5℃ / min, the temperature is kept at 800℃ for 5h, and the furnace is cooled to room temperature to obtain lithium iron phosphate material.

[0049] Assemble the simulated battery to the LiFePO prepared above 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com