A method for solid-liquid bonding of dissimilar bulk amorphous alloys

A technology of amorphous alloys and large blocks, which is applied in the field of connecting dissimilar bulk amorphous alloys, can solve the problems of complex operation steps, poor economical practicability, and various process parameters, and achieve controllable chemical composition, wide application, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: This embodiment is a method for connecting dissimilar bulk amorphous alloys in a solid-liquid state, which is specifically carried out in the following steps: respectively prepare bulk amorphous alloy ingots A by vacuum smelting copper mold casting and B, and then adopt the method of solid-liquid connection to make bulk amorphous alloys A and B realize solid-liquid connection in the mold with bracket inside, and finally obtain the round bar of heterogeneous bulk amorphous alloy;

[0024] The method of adopting the method of solid-liquid connection to realize the solid-liquid connection of bulk amorphous alloys A and B in the mold with brackets inside is:

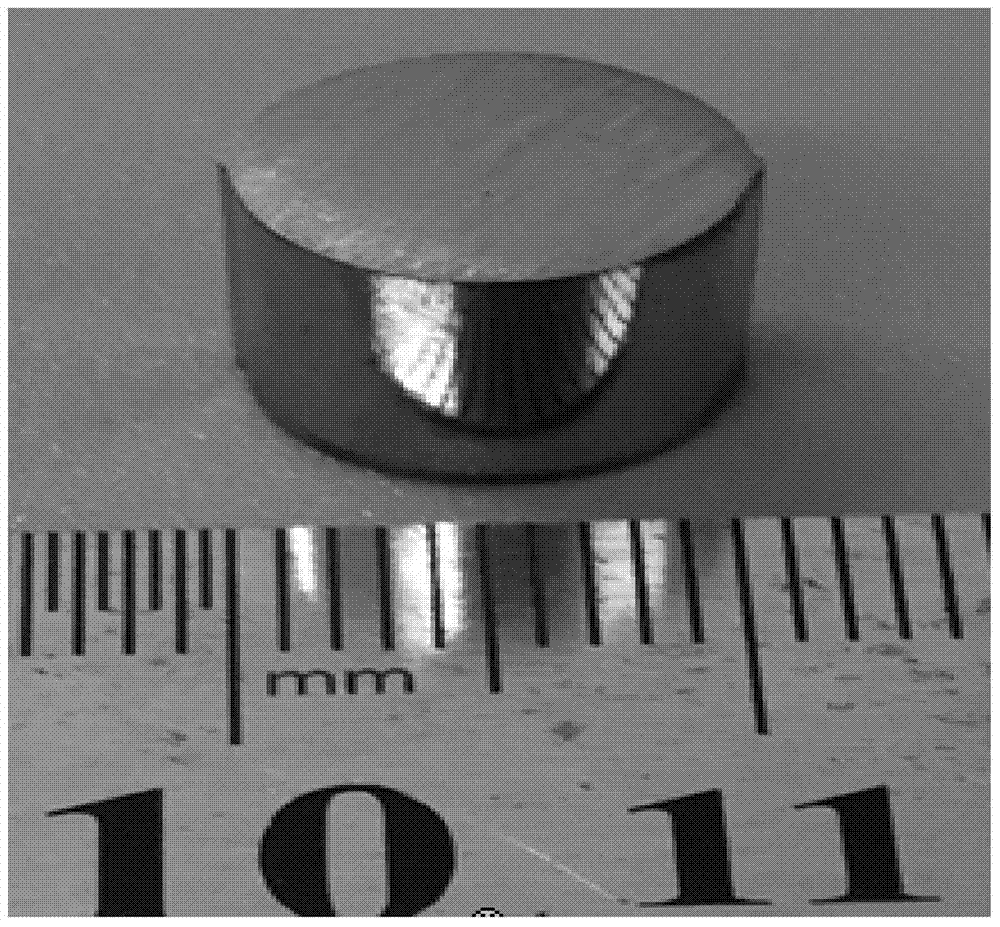

[0025] In the magnetron tungsten electric arc furnace, the large amorphous alloy ingot A melt is poured into the mold Ⅰ, cooled to room temperature, and a solid amorphous alloy cylinder A with a diameter of a and a length of h is obtained, and the solid amorphous alloy The alloy cylinder A is pu...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mold I and mold II are made of red copper. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the vacuum smelting copper mold casting method is completed in a magnetron tungsten arc furnace by arc melting. Others are the same as those in Embodiment 1 or 2.

PUM

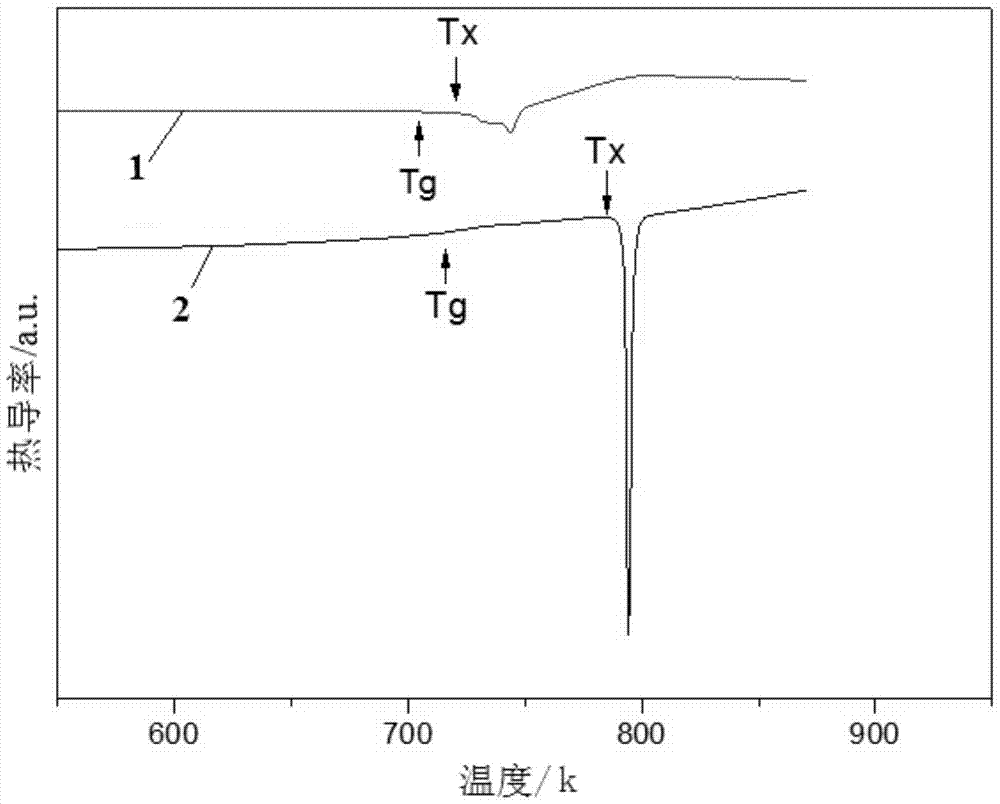

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com