Cu-SSZ-13 catalyst, and preparation method and application thereof

A cu-ssz-13, catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited use, large impact on the ecological environment, etc., and achieve wide temperature window, water Good thermal stability, the effect of improving hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare a nitric acid solution with pH = 1, add Cu-SSZ-13 molecular sieve prepared by in situ synthesis to the solution, and stir in a water bath at 80°C for 12 hours, then perform suction filtration and wash three times to obtain a filter cake, and filter The cake was dried in an oven at 110°C for 6 hours, and finally baked in air at 600°C in a muffle furnace for 6 hours to obtain a powdered Cu-SSZ-13 catalyst. The prepared catalyst is pressed into tablets, ground, sieved, and 20-40 meshes are taken for later use.

Embodiment 2

[0044] Prepare a hydrochloric acid solution with a pH value of 0, add Cu-SSZ-13 molecular sieve prepared by in situ synthesis to the solution, and stir in a water bath at 25°C for 24 hours, then perform suction filtration and wash 3 times to obtain a filter cake, and The filter cake was dried in an oven at 110°C for 6h, and finally calcined in air at 550°C for 14h in a muffle furnace to obtain a powdered Cu-SSZ-13 catalyst. The prepared catalyst is pressed into tablets, ground, sieved, and 20-40 meshes are taken for later use.

Embodiment 3

[0046] Prepare a sulfuric acid solution with a pH value of 4, add Cu-SSZ-13 molecular sieve prepared by in situ synthesis to the solution, and stir in a water bath at 90°C for 5 hours, then perform suction filtration and wash 3 times to obtain a filter cake, and The filter cake was dried in an oven at 110°C for 6h, and finally calcined in air at 800°C for 3h in a muffle furnace to obtain a powdered Cu-SSZ-13 catalyst. The prepared catalyst is pressed into tablets, ground, sieved, and 20-40 meshes are taken for later use.

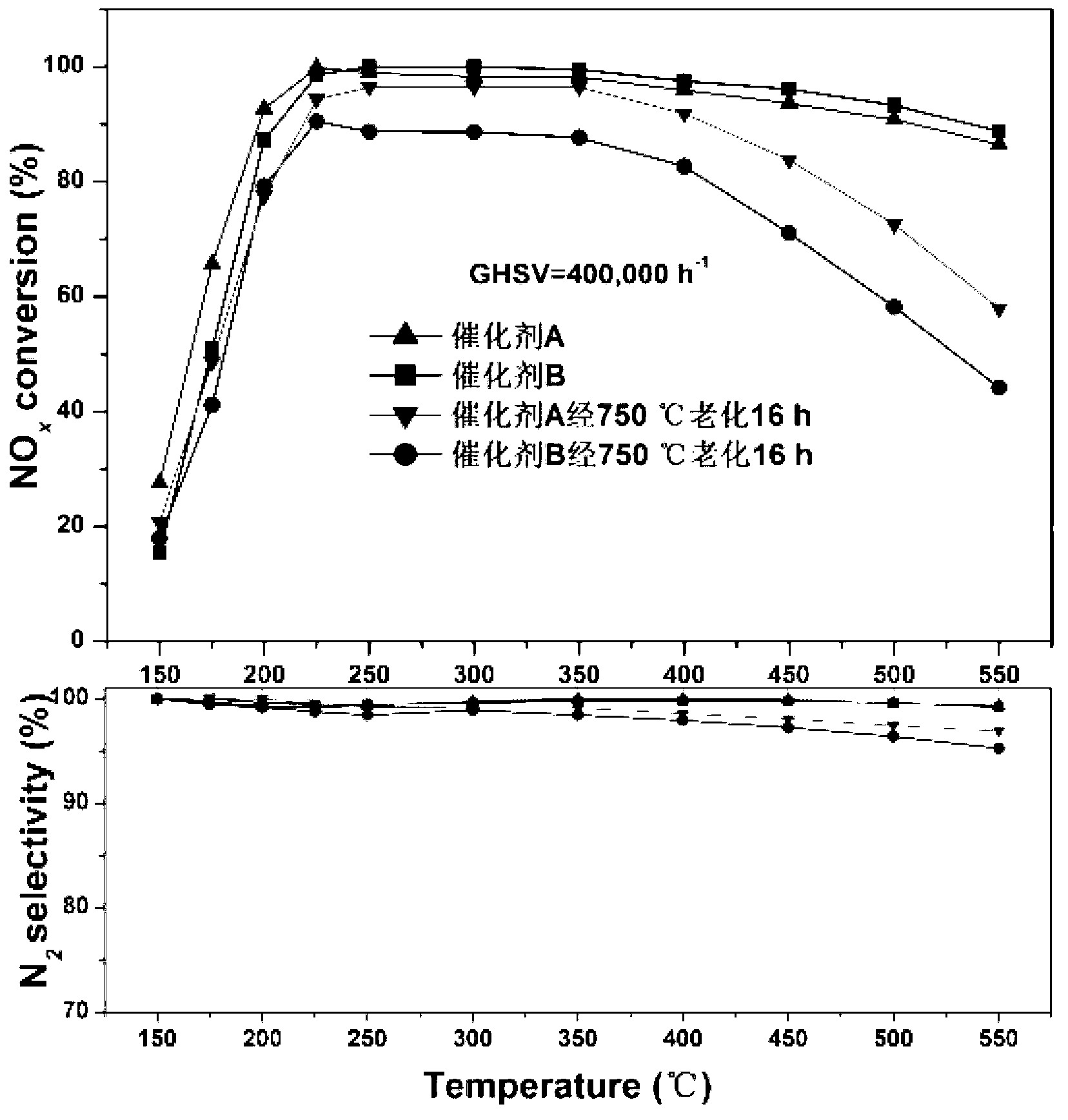

[0047] The amount of catalyst used is 50 mg respectively, and the composition of the reaction mixture is: [NO]=[NH 3 ]=500ppm, [O 2 ]=5%, N 2 As balance gas, the total gas flow rate is 500mL / min, and the corresponding space velocity is 400,000h -1 , The reaction temperature is 150-550°C. NO and NH 3 and by-product N 2 O, NO 2 All were measured using an infrared gas cell. The number of the Cu-SSZ-13 catalyst obtained by using the acidic solution water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com