Modified smectite and method for producing the same and its application

A technology of montmorillonite and calcium-based montmorillonite, applied in chemical instruments and methods, pharmaceutical formulas, inorganic active ingredients, etc. Means and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0248] Example 1 Preparation of modified montmorillonite

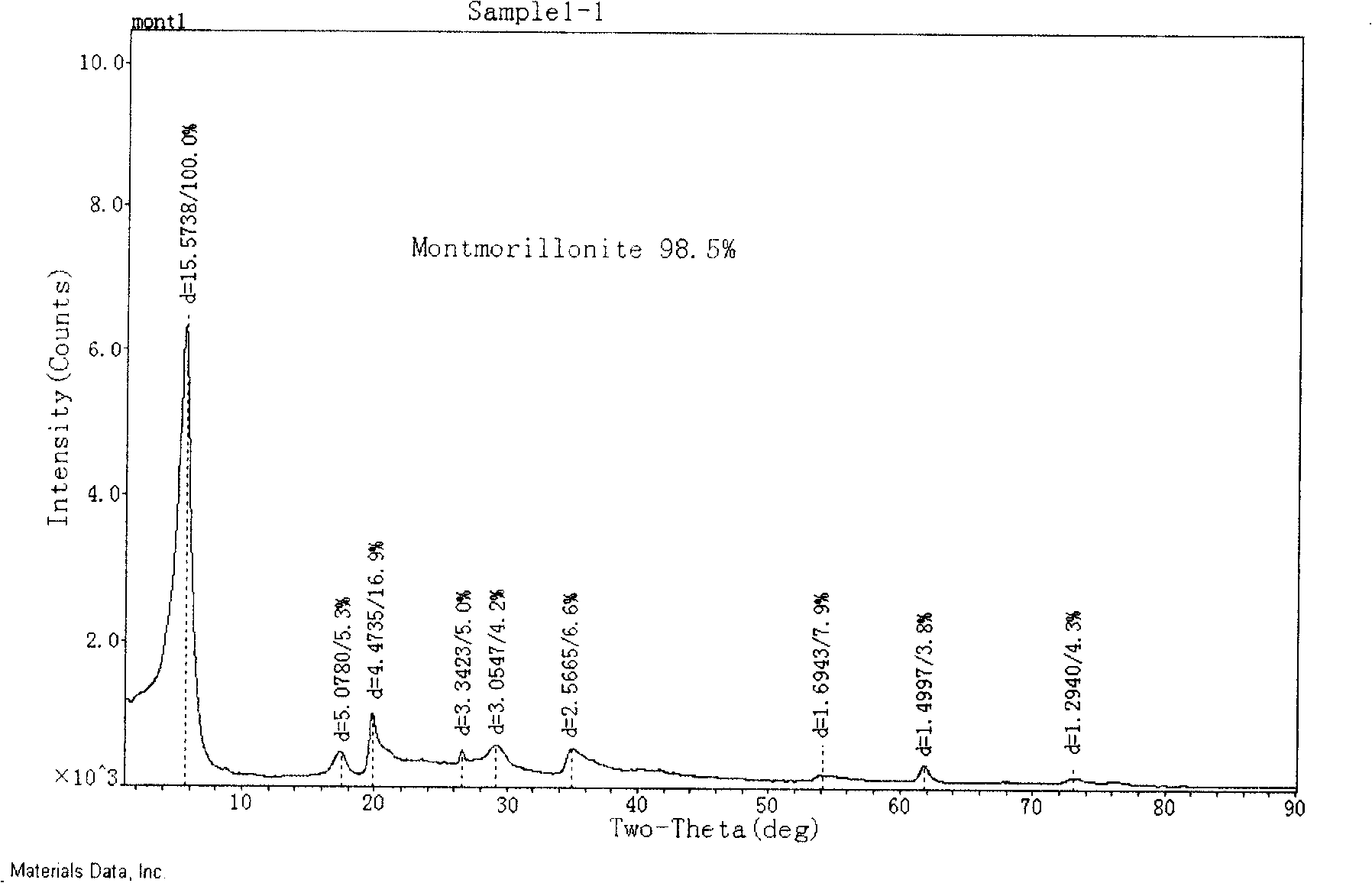

[0249] Phase analysis of purified montmorillonite, see figure 1 .

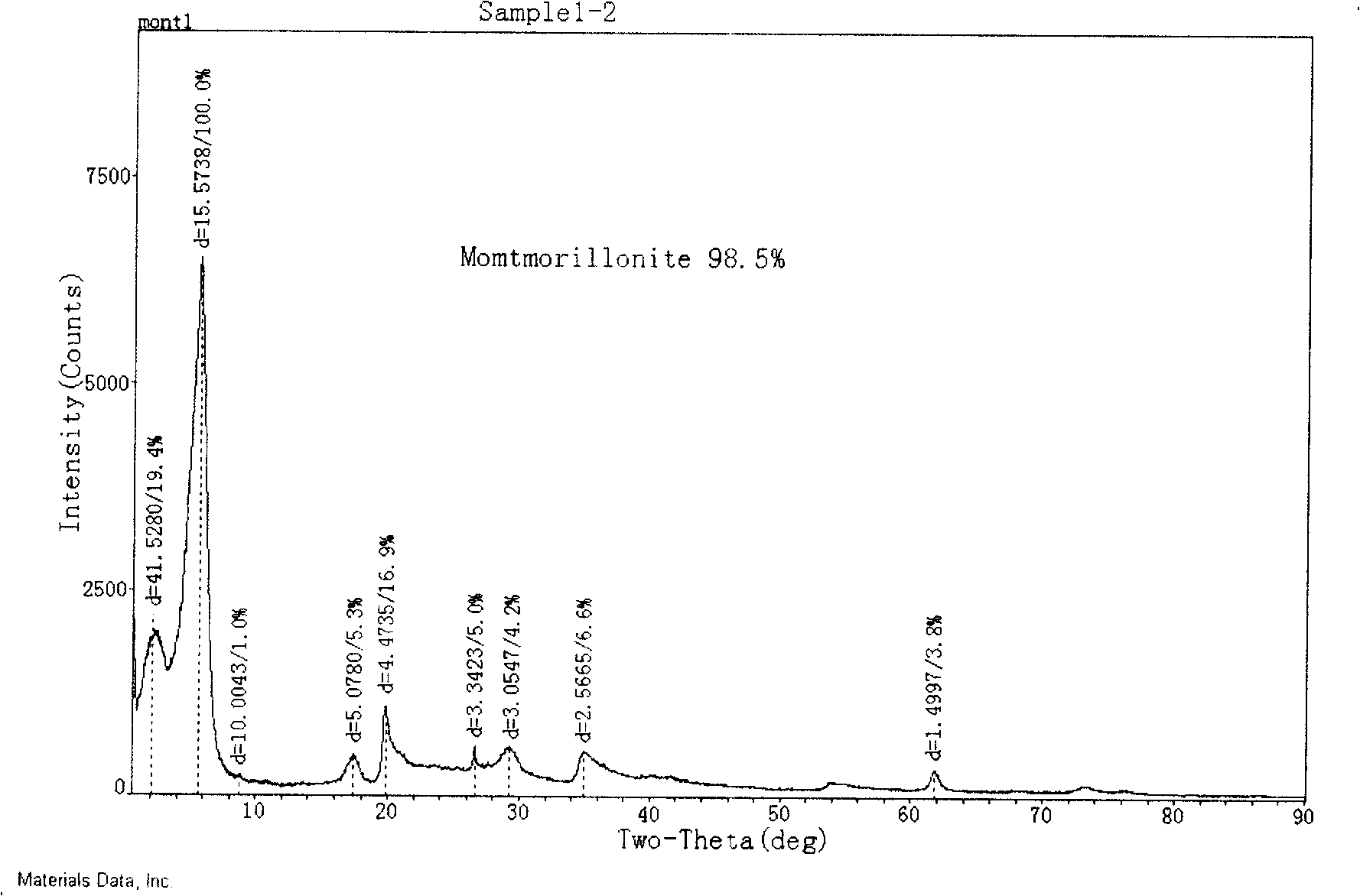

[0250] In the purification of montmorillonite, add 2mol / L mixed acid, the composition of the mixed acid is (the molar ratio of hydrochloric acid: oxalic acid: acetic acid is 4:10:6), and the mass ratio of soil: acid is 1:3 for mixing , boiled at 100°C for 5-6 hours, filtered to remove the mixed acid, washed the filter cake with deionized water to pH ≥ 4, dried at 100°C, and crushed into 300-500 meshes to obtain the modified calcium-based montmorillonite Delithification, its abundance or phase analysis see figure 2 .

[0251] Prepare the obtained modified calcium-based montmorillonite with 0.5N hydrochloric acid solution to make a slurry with a solid content of 20%, stir for 6 hours, filter to remove the acid solution, wash the filter cake with hot water at 60°C until the pH is about 5, press Filter into a filter cake with a solid content of abou...

Embodiment 2

[0252] Example 2 Preparation of modified montmorillonite

[0253] Phase analysis of purified montmorillonite, see Figure 4 .

[0254] In the purification of montmorillonite, add a mixed acid with a concentration of 1mol / L, the composition of the mixed acid is (the molar ratio of hydrochloric acid: oxalic acid: acetic acid is 3:4:3), and the mass ratio of soil: acid is 1:4. Mix, boil at 90°C for 6-8 hours, filter to remove the mixed acid, wash the filter cake with deionized water to pH ≥ 4, dry at 120°C, and grind it into 300-500 mesh to obtain the modified calcium base Montmorillonite, its abundance or phase analysis see Figure 5 .

[0255] The obtained modified calcium-based montmorillonite was mixed with 0.5N sulfuric acid solution to make a slurry with a solid content of 15%, stirred for 6 hours, filtered to remove the acid solution, and the filter cake was washed with hot water at 70°C until the pH was about 5.5. Pressure filtration into a filter cake with a solid ...

Embodiment 3

[0256] Example 3 Preparation of modified montmorillonite

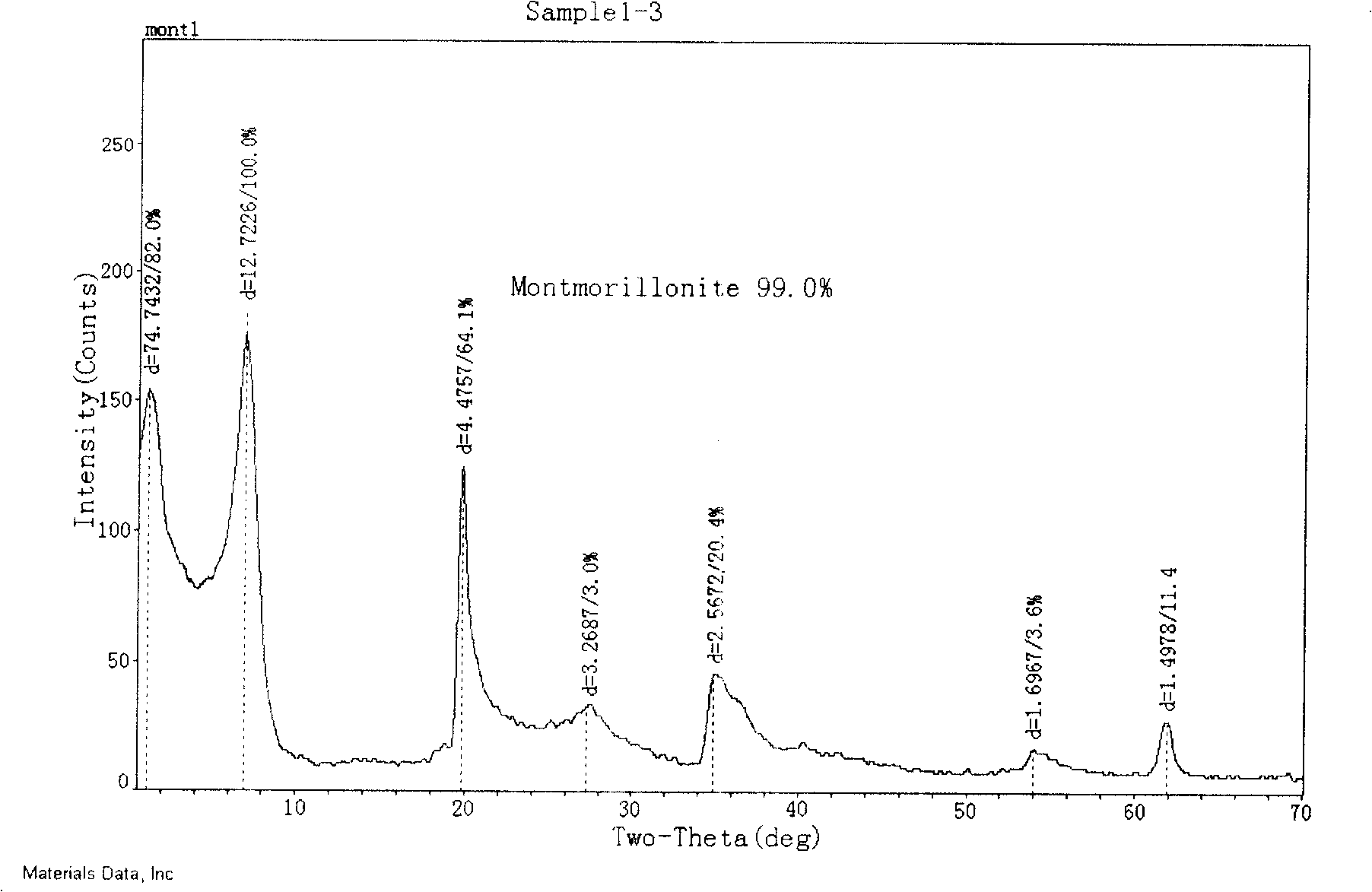

[0257] Mineral composition of raw bentonite: see Figure 7 .

[0258] The raw ore is dried, crushed, passed through a 50-mesh sieve, added water and 0.3% sodium hexametaphosphate of raw ore powder to form a slurry with a solid content of 20%, stirred for two hours, passed through a three-stage hydrocyclone, and separated and removed Coarse sand can be separated into slurry; the separated slurry is adjusted to a thin slurry with a solid content of 3% by adding water, which is separated into a disc centrifuge, and the separated thin slurry is then concentrated in another disc centrifuge, and the concentrated slurry is passed through Plate and frame filter press to obtain a filter cake with a solid content of 40-50%. The filter cake is dried at 125°C and crushed to a size above 500 mesh. For the mineral composition of purified montmorillonite, see Figure 8 .

[0259] In the purification of montmorillonite, add a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com