Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Not easy to raise dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

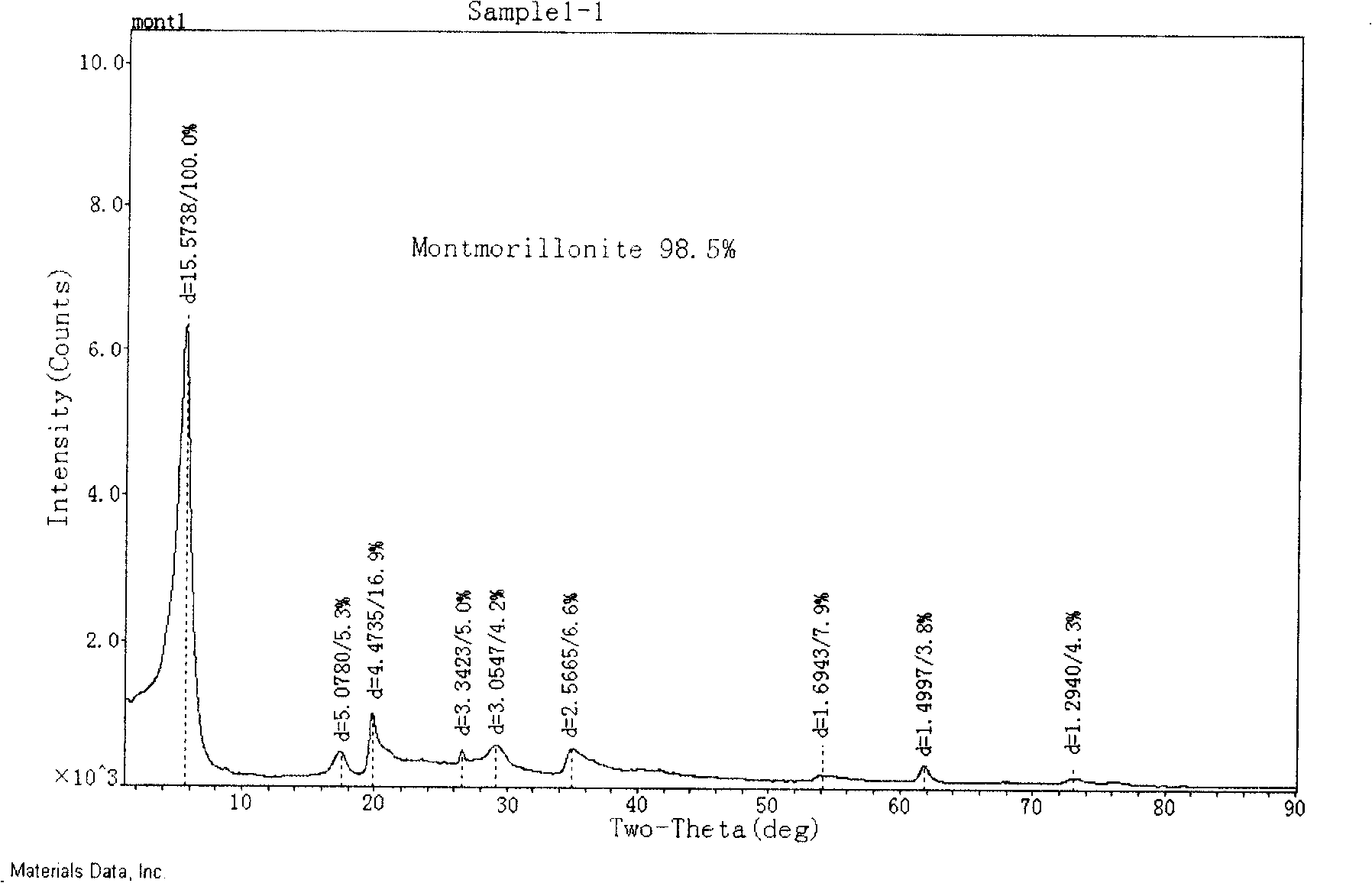

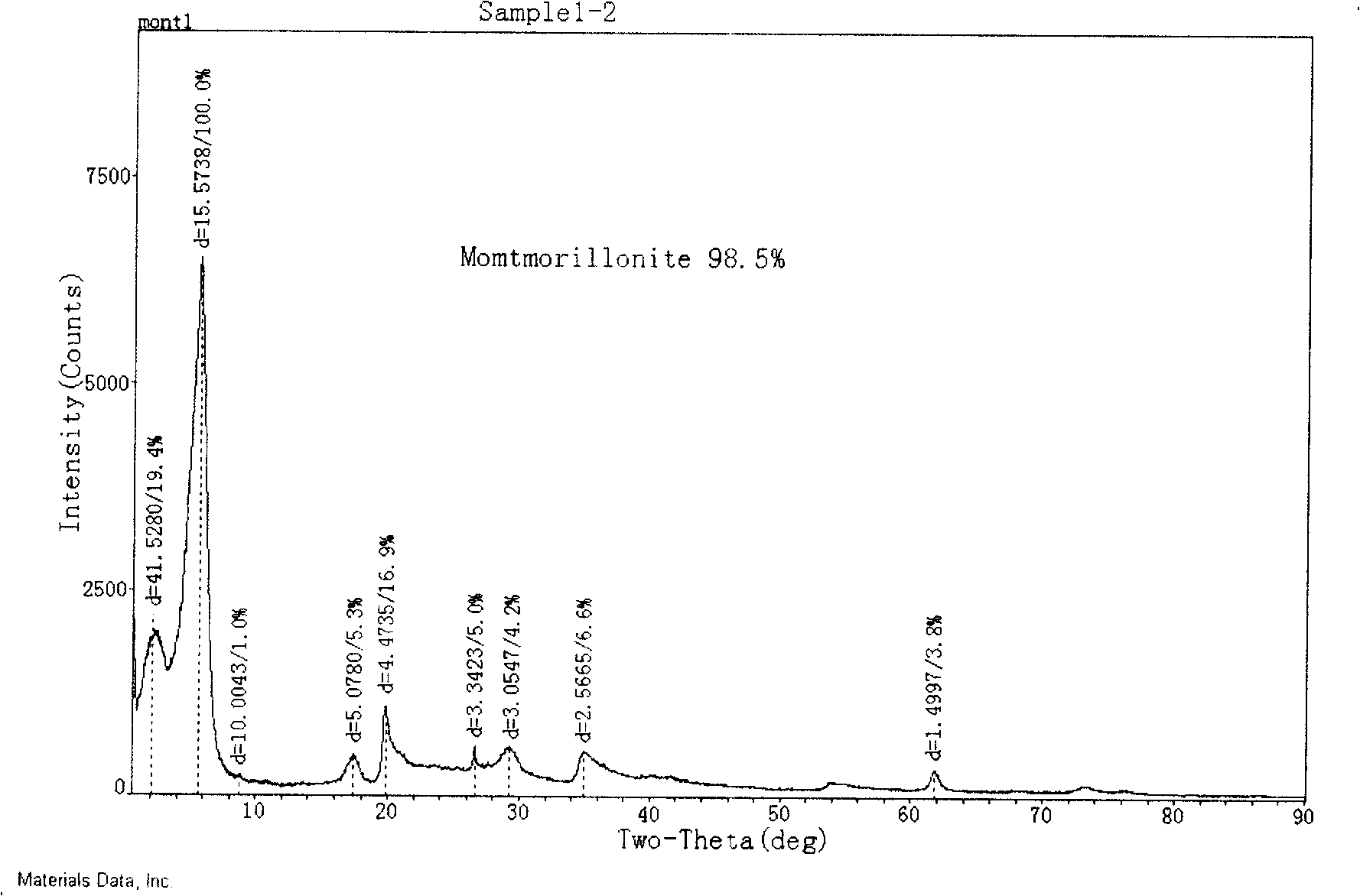

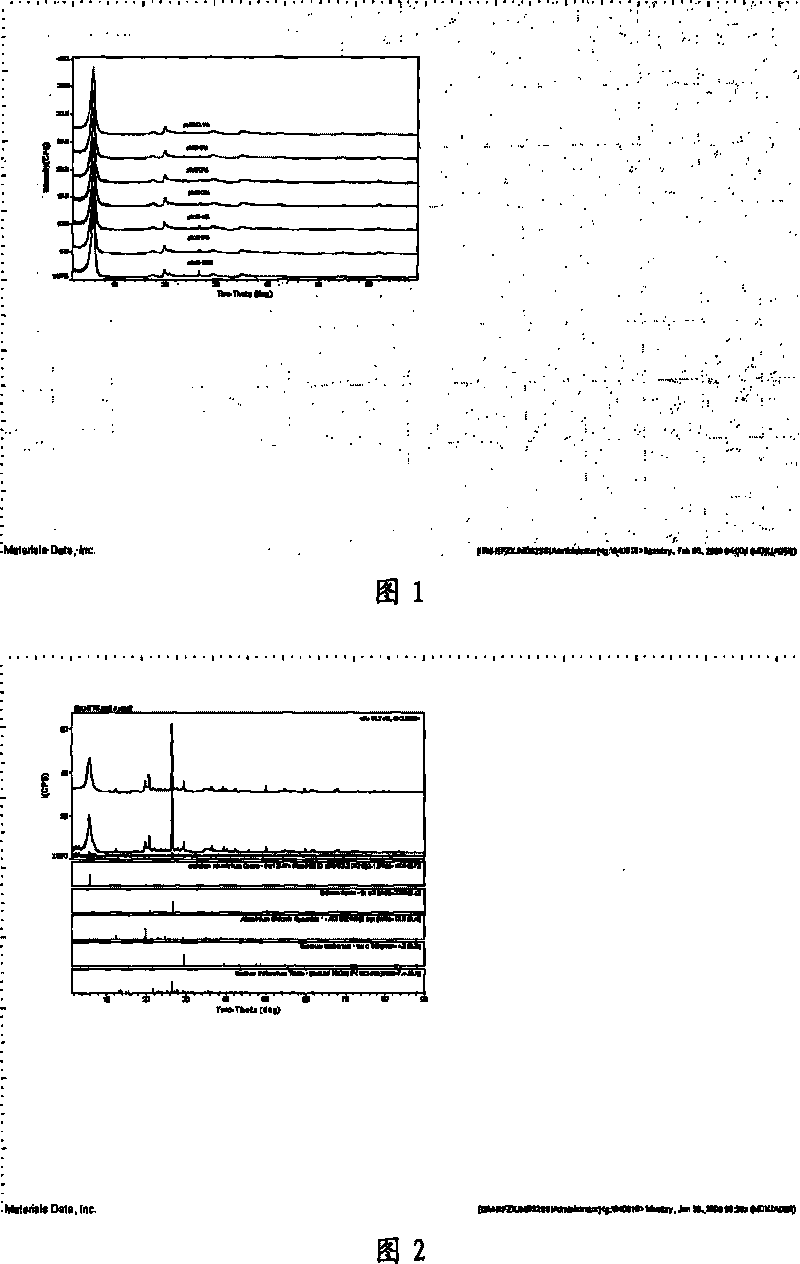

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

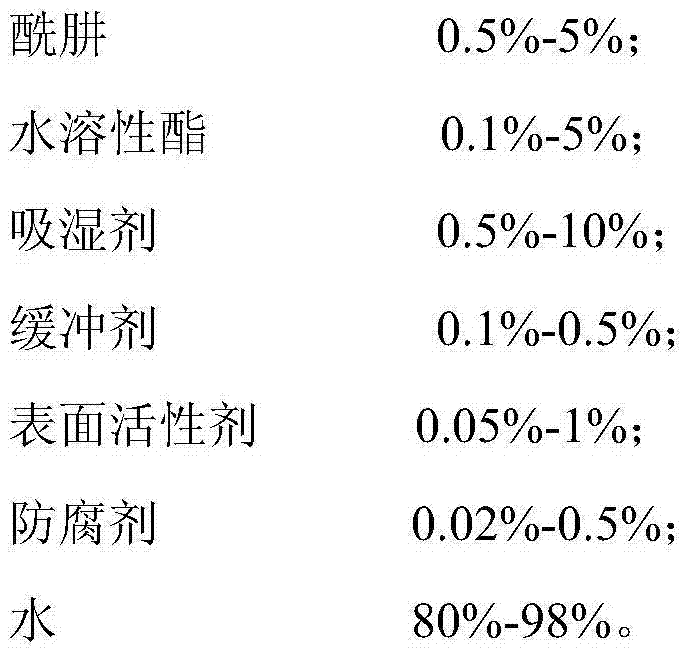

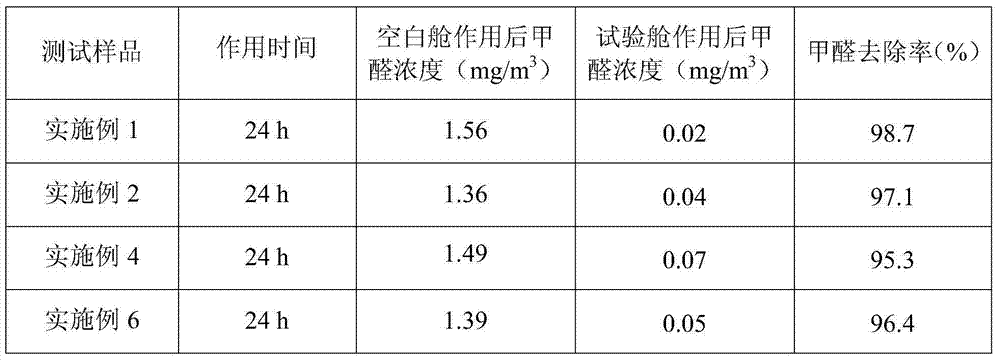

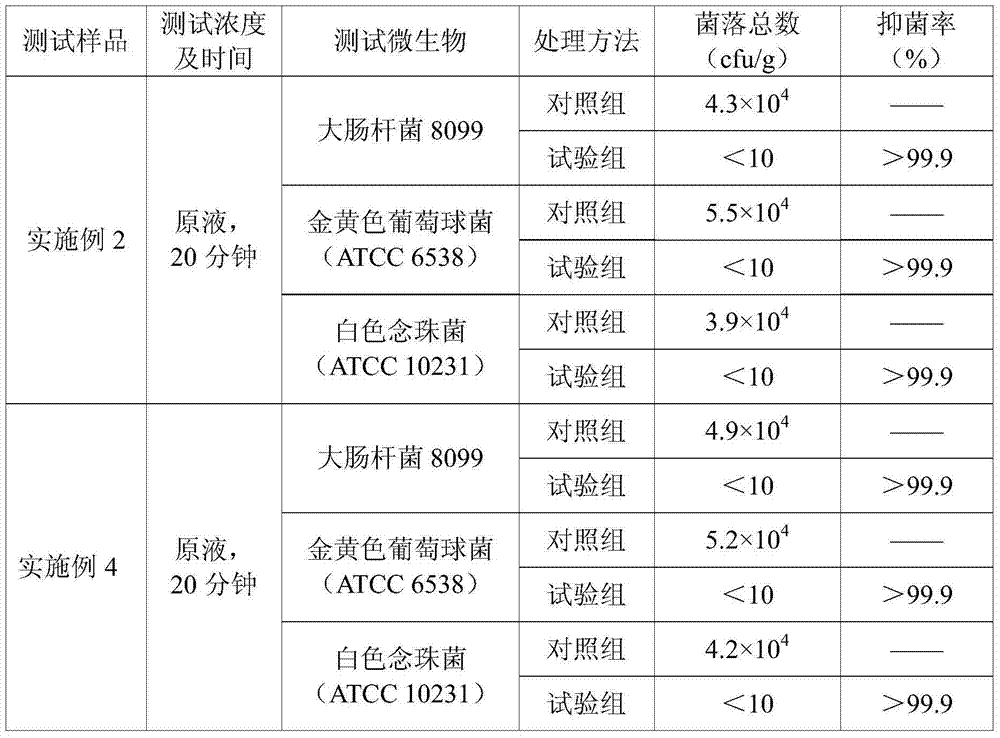

Efficient low-toxicity formaldehyde scavenger

ActiveCN104324583ANon-toxic or low toxicityNon-oxidizingDispersed particle separationScavengerPreservative

The invention discloses an efficient low-toxicity formaldehyde scavenger containing the following raw material components by weight: 0.5%-5% of hydrazide, 0.1%-5% of a water-soluble ester, 0.5%-10% of a moisture absorbent, 0.1%-0.5% and of a buffer, 0.05%-1% of a surface active agent, 0.02%-0.5% of a preservative and 80%-98% of water. The free hydrazine content in the efficient low-toxicity formaldehyde scavenger product is controlled in the range as low as possible by the manner of fine selection of the hydrazide raw material, control of free hydrazine content, adding of the water-soluble ester, adding of the buffer, and the like, and the efficient low-toxicity formaldehyde scavenger product has better security. The efficient low-toxicity formaldehyde scavenger product is good in formaldehyde removal effect, safe to people and objects, and simple in production process, and can be used for governance of the problem of formaldehyde exceeding the standard in new decorated residence or furniture.

Owner:广州超威生物科技有限公司

Method for preparing light porous sintering material by red mud and plant residues

The invention relates to a method for preparing a light porous sintering material by red mud and plant residues. The method comprises the following steps: by using the red mud with the water content being less than or equal to 65wt% and the plant residues with the water content being less than 70wt%, preparing and mixing materials; rolling and mixing; moulding; and sintering to obtain the light porous sintering material. The method which utilizes waste red mud and plant residues wide in source and large in output can produce serial products such as water permeable paving products, filtering products, products for sound absorbing materials, catalytic products, light panels or heat-insulating and sound-proofing bricks which are wide in purpose and high in value with low cost. The method has industrial competitiveness and good investment economical benefit. Meanwhile, not only are a lot of clay resources and non-renewable fuel coal as building materials and chemical product raw materials saved to realize industrial emission reduction of Co2, but also the pollution of waste pollutants red mud and plant residues to water, soil and air can be effectively solved, and secondary disasters are prevented.

Owner:长沙紫宸科技开发有限公司

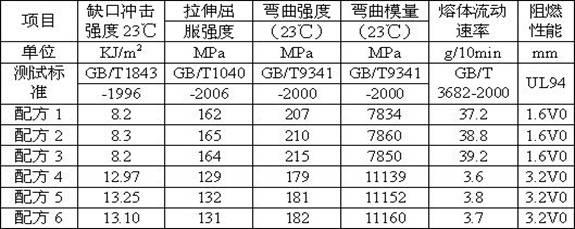

Multi-functional plastic masterbatch and preparation method thereof

The invention discloses a multi-functional plastic masterbatch and a preparation method thereof. The multi-functional plastic masterbatch comprises the following compositions in percentage by weight: 75-90% of inorganic fillers, 3-14% of carrier, 1-10% of pigment toners, 1-5% of dispersing agent and 0.5-2% of ntioxidant. The multi-functional plastic masterbatch disclosed by the invention has the characteristics of easiness for dispersion, high flame retardant efficiency and low production cost.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

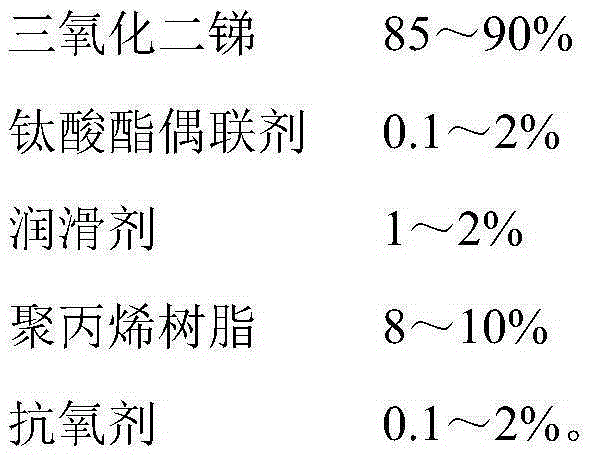

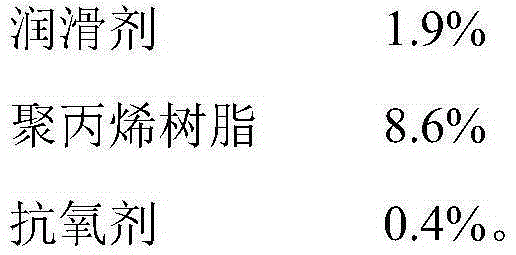

Antimony trioxide master batch and preparation method thereof

The invention discloses antimony trioxide master batch and a preparation method thereof. The antimony trioxide master batch comprises the following components by mass percent: 85 to 95 percent of nano antimony trioxide, 3 to 14 percent of carrier, and 0.1 to 5 percent of modified ethylene bis-fatty-acid amide. The high-efficiency antimony trioxide master batch prepared by the invention has the characteristics of easiness in dispersion, high flame-retardant efficiency and low production cost, and has smaller influence on the physical and mechanical properties, the heat resistance, the processability and the surface color of a composite material than the traditional antimony trioxide master batch.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

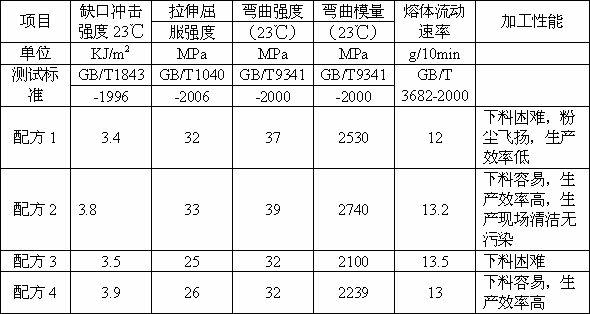

Special halogen-free flame-retardant master batch for polypropylene and preparation method for halogen-free flame retardant master batch

The invention discloses a special halogen-free flame-retardant master batch for polypropylene and a preparation method for the halogen-free flame retardant master batch. Components of the master batch comprise, in mass percent, 75-90% of phosphorus-nitrogen halogen-free flame retardant, 8-22% of carrier and 0.1-5% of modified ethylene bis-fatty acid amide. By the aid of the master batch, quality instability of materials due to non-uniform mixing of powder and granules is effectively avoided, easiness in generation of chippings or powder during granule cutting is avoided, production efficiency is improved, and production cost is lowered. Adopting a continuous banburying-extrusion production process leads production efficiency to be high. The master batch effectively solves the problems of easiness in moisture absorption, degradation and foaming of halogen-free flame retardant, so that storage time of the phosphorus-nitrogen halogen-free flame retardant is prolonged, and processability of the phosphorus-nitrogen halogen-free flame retardant is improved. Besides, the special halogen-free flame-retardant master batch for the polypropylene has the advantages of easiness in dispersion, high flame-retardant efficiency and low production cost, and has less influence on physical and mechanical properties, heat resistance, processability and surface color of composite materials than a special traditional halogen-free flame-retardant master batch for polypropylene.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

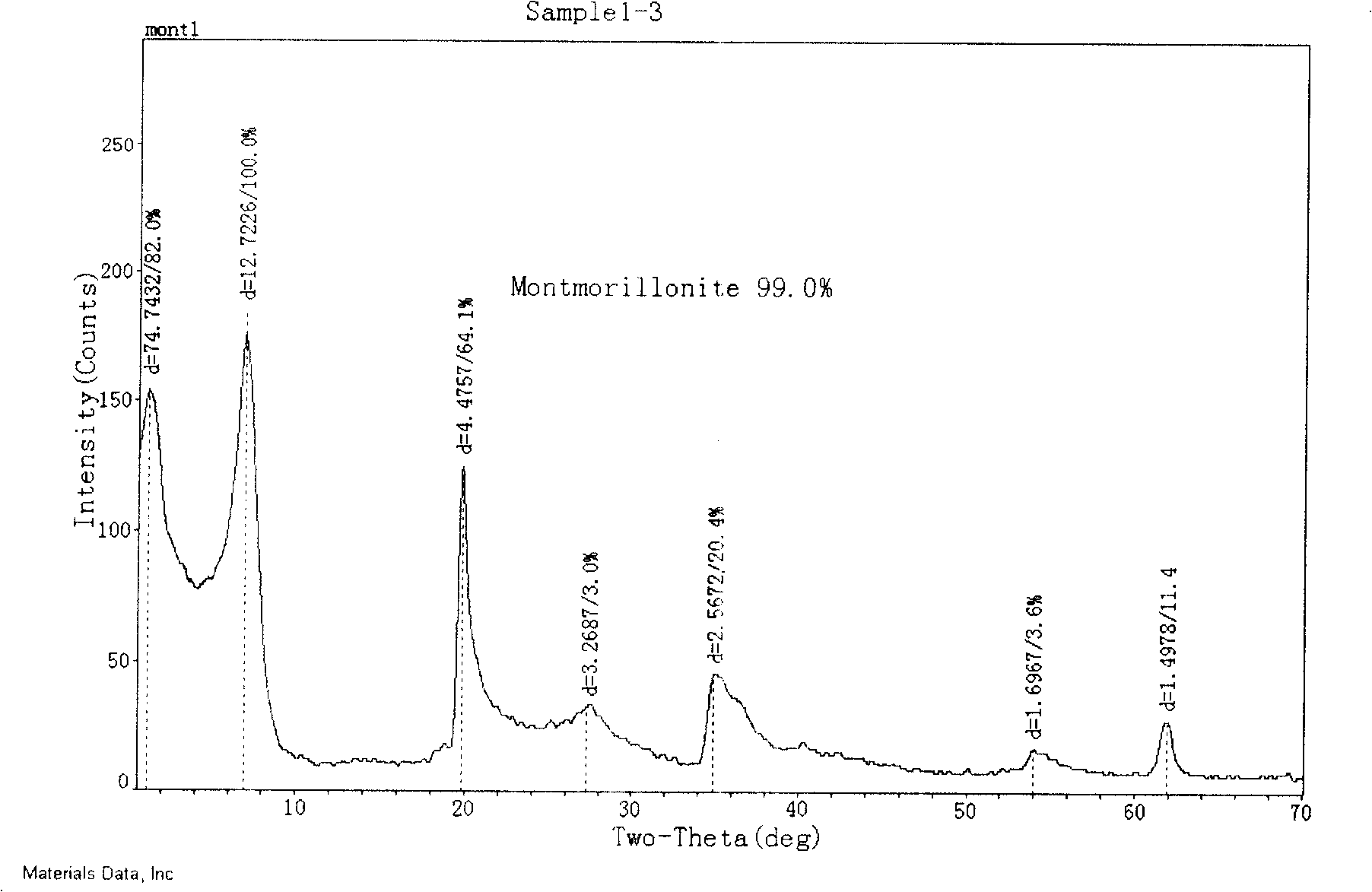

Method for purifying montmorillonite, purified montmorillonite and combination thereof

ActiveCN101340979BReduce moisture contentAvoid cakingWet separationClaywaresPhysical chemistryMontmorillonite

A method for purification and separation of inorganic mineral, especially for purification and separation of montmorillonite from natural bentonite is provided. The said method is simple, and uses high-speed centrifugal device to well solve the problems present in purification of montmorillonite that a-quartz and cristobalite are difficult to be separated and removed and purified slurry is difficult to be concentrated and dehydrated. The purity of montmorillonite thus obtained is not less than 95%.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

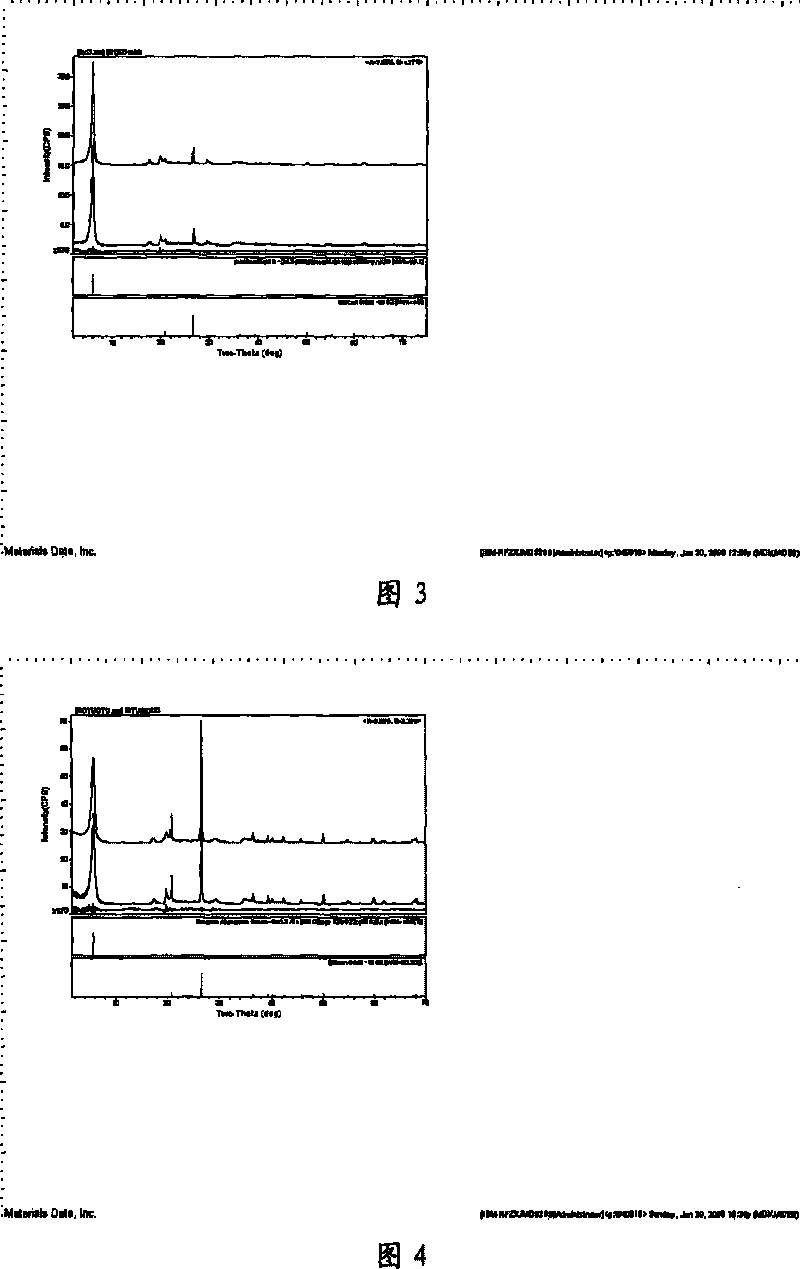

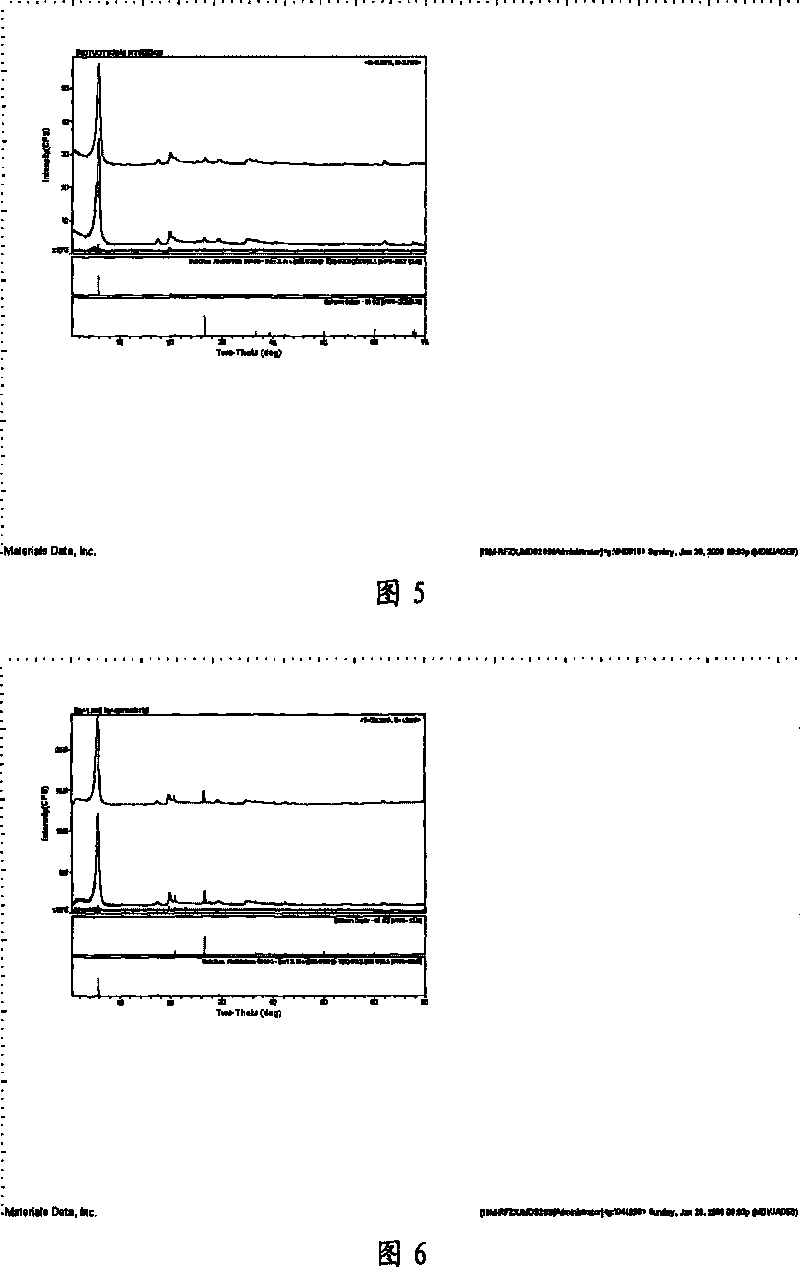

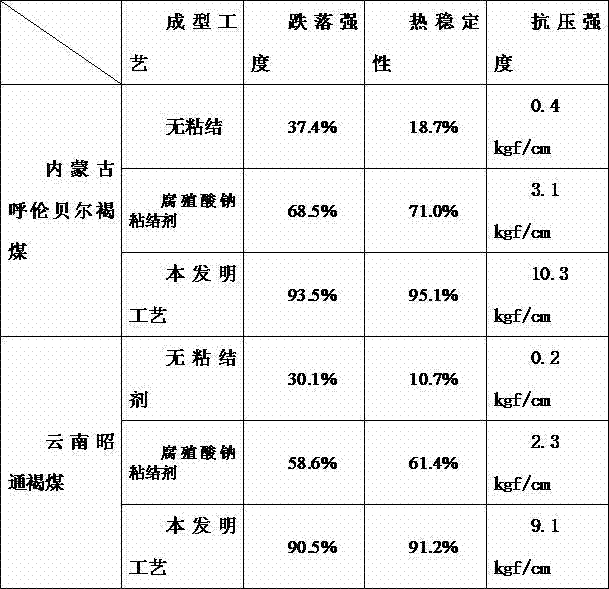

Extrusion forming method of low-order lignite

The invention discloses an extrusion forming method of low-order lignite, relates to the field of lignite and coal briquette preparation, and particular relates to a preparation method which is applicable to lignite and coal briquette with high ash content and gel substances. The method comprises the following steps: (1) crushing and screening lignite blocks to be less than or equal to 3mm; (2) adding a binding agent into the lignite raw material according to a certain ratio, uniformly stirring and subsequently extruding to form the lignite in a coal rod machine; and (3) drying the formed coal rod at 60-100 DEG C till the moisture is less than 15% so as to obtain a coal briquette product, wherein the binding agent refers to a starch binding agent. The method is simple in process, the binding agent is easy to obtain, and an ordinary coal rod machine is used as the extrusion forming equipment for extrusion forming, the dried coal rod product is high in mechanical strength and good in thermal stability, and can be used in a coal gas generator taking the place of lump coal, and the requirements of synthesis ammonia generation process on granularity and mechanical strength of the coal briquette can be met, so that the lignite resource can be scientifically and reasonably utilized, and the production cost can be lowered.

Owner:YUNNAN CHEM RES INST

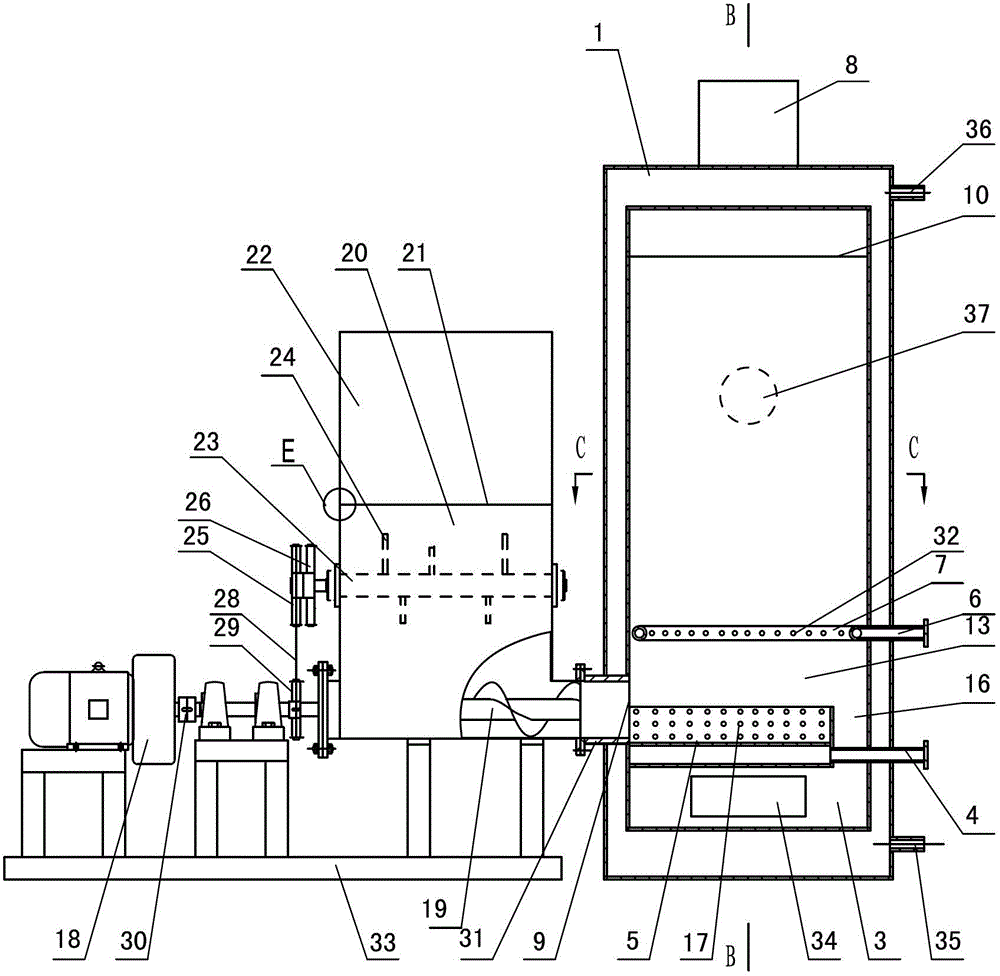

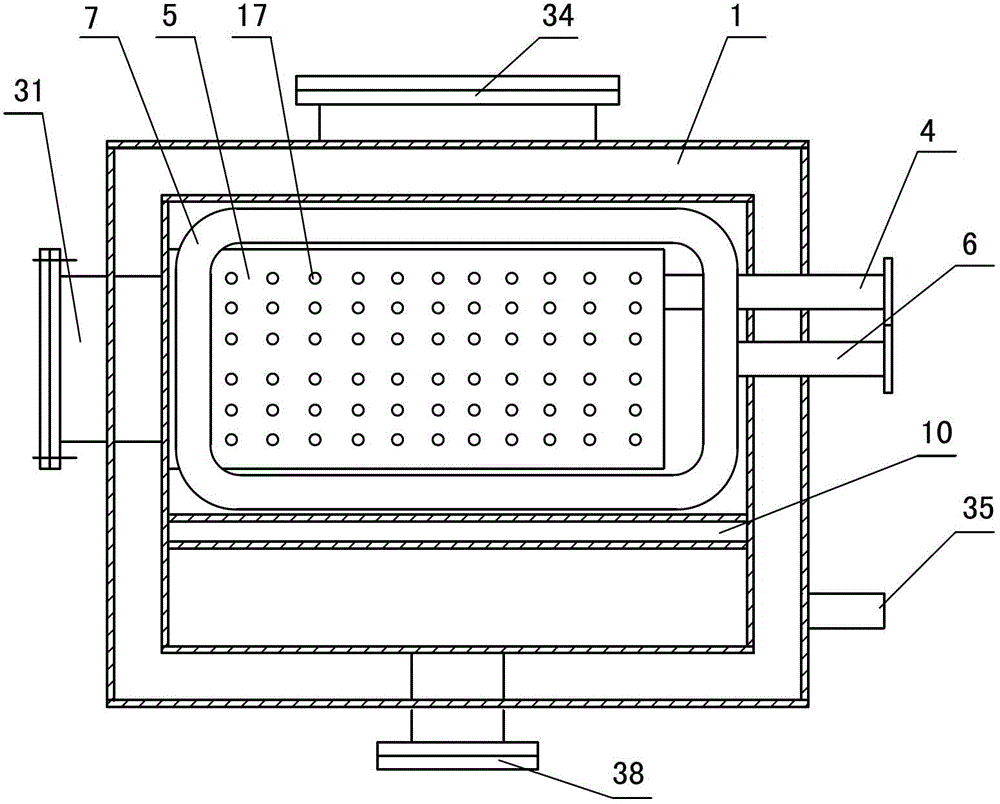

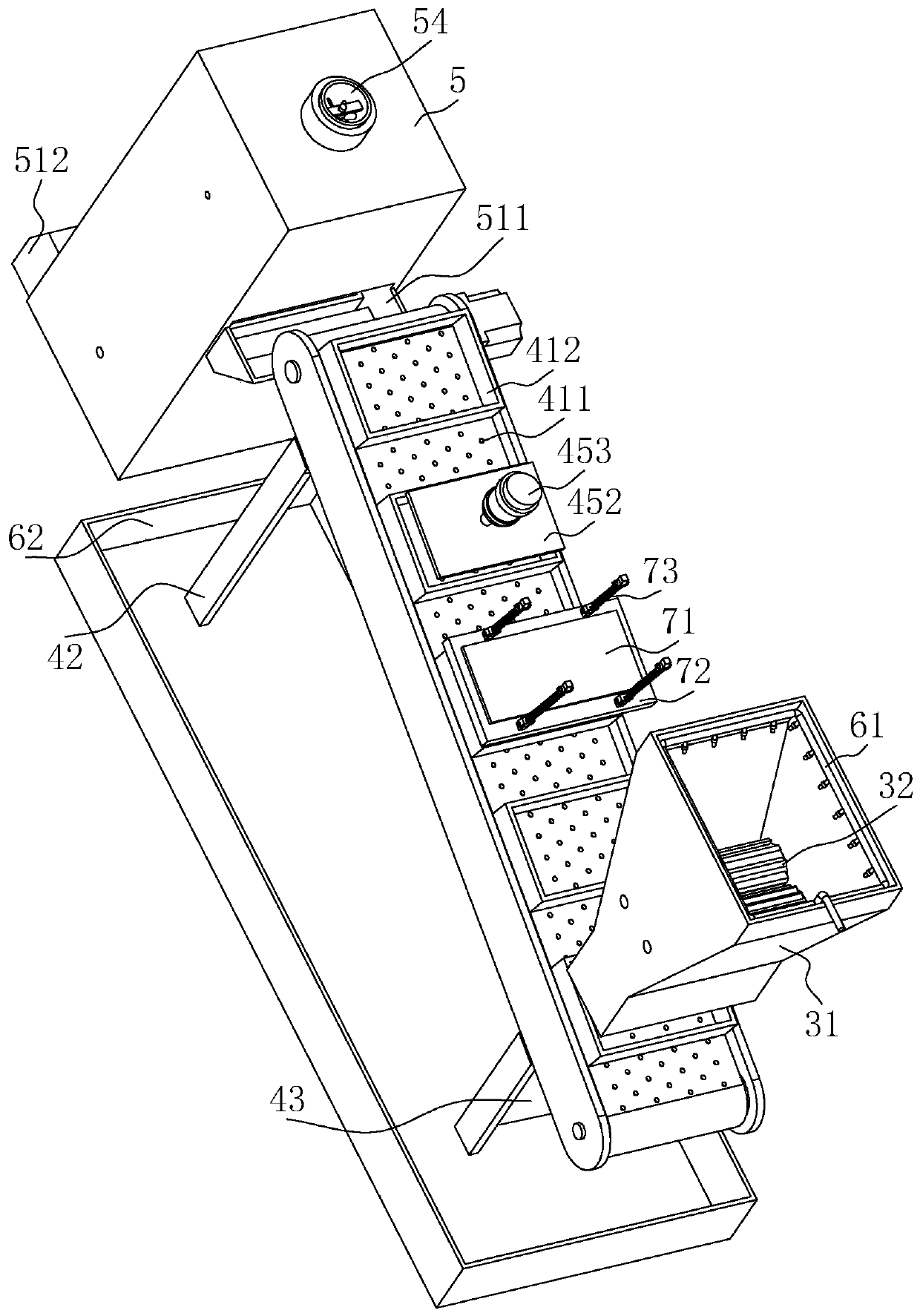

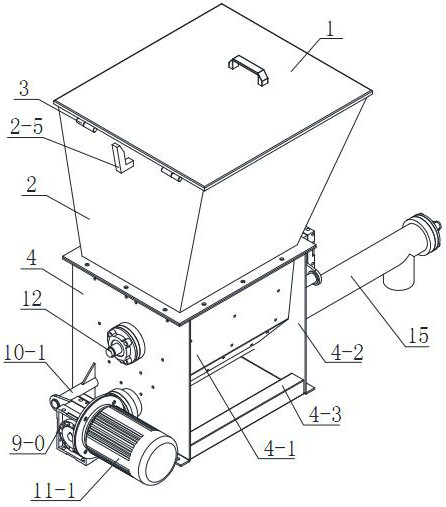

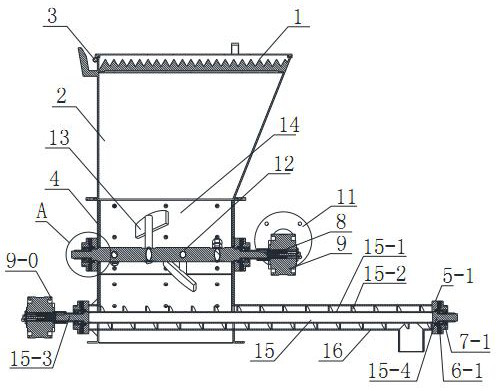

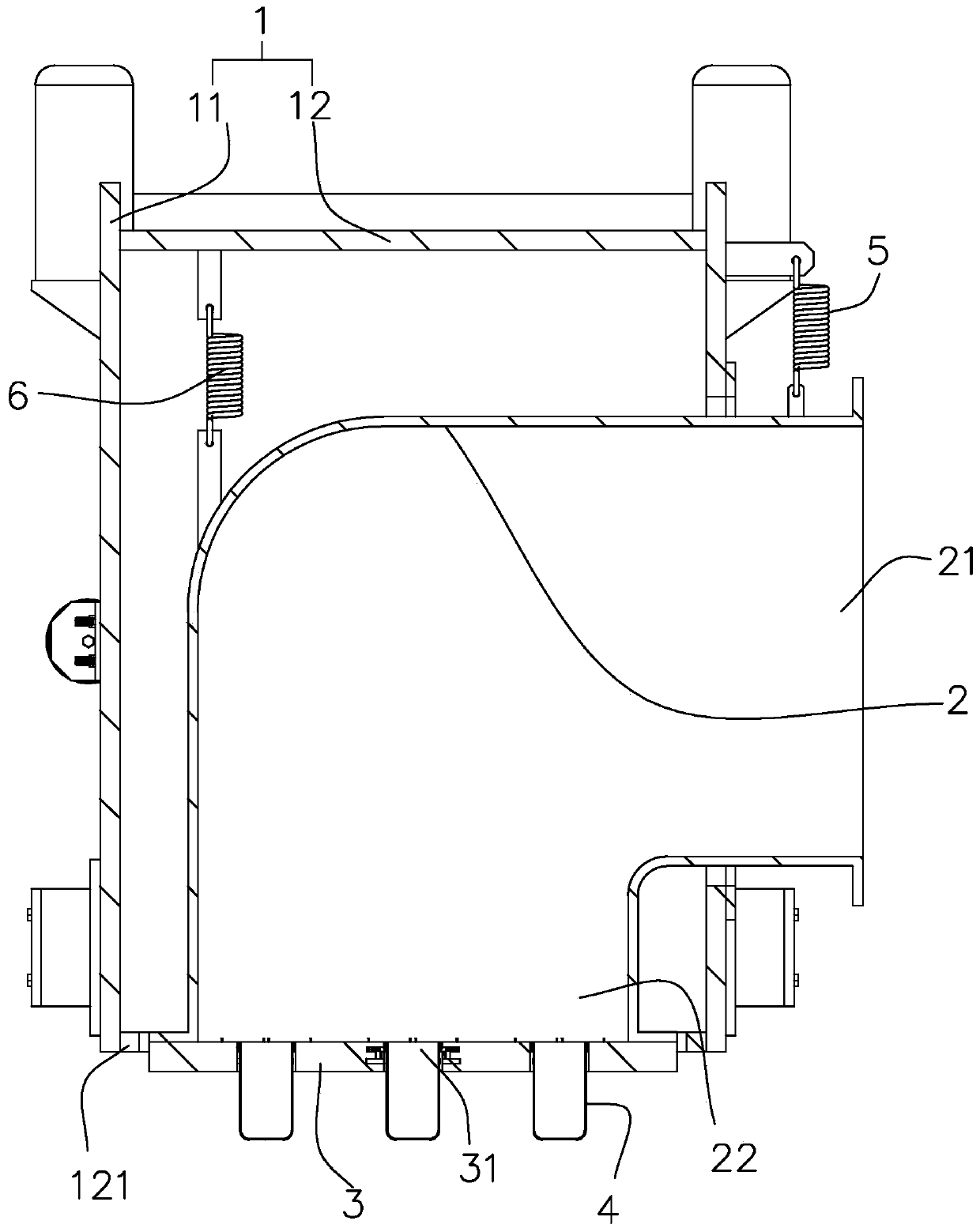

Small-sized biomass chopped-material direct-fired water boiler

InactiveCN102914046AImprove adaptabilityWon't clogWater heatersLump/pulverulent fuel feeder/distributionFlue gasHearth

The invention provides a small-sized biomass chopped-material direct-fired water boiler. The water boiler comprises an automatic feeding mechanism and a boiler body, wherein the automatic feeding mechanism consists of a loading box, a feed box, two horizontally placed ejecting rollers and a spiral auger, a draw plate is arranged at the bottom of the loading box, the feed box is positioned below the loading box, the ejecting rollers are mounted in the feed box and provided with radiant pick teeth, and the spiral auger of which the output end is communicated with a feed inlet of the boiler body through a feeding pipe is positioned below the ejecting rollers; and the boiler body consists of a dust collection room, a primary air inlet pipe, a primary air room positioned above the dust collection room and communicated with the primary air inlet pipe, a secondary air inlet pipe, a flue gas steering plate, a secondary air distribution pipe positioned above the primary air room and communicated with the secondary air inlet pipe, a smoke exhaust pipe arranged at the top of a hearth, a flue gas entrained flow air inlet pipe positioned on the side wall of the smoke exhaust pipe and a water jacket on the outer wall of the hearth. The small-sized biomass chopped-material direct-fired water boiler has the advantages of simple structure, low fuel and running costs, cleanliness and convenience in use and high heat efficiency, and is suitable for heating, bathing and the like in wide rural-urban fringe zones and small towns.

Owner:SHANDONG UNIV OF TECH

Movable building rubbish regenerating treatment system

InactiveCN111515228AImprove adhesionNot easy to looseConstruction waste recoveryUsing liquid separation agentBrickArchitectural engineering

The invention relates to the technical field of building rubbish recovery, in particular to a movable building rubbish regenerating treatment system. The movable building rubbish regenerating treatment system comprises a container, and a smashing device, a forming device, a compacting device and a drying device are arranged in the container. The smashing device is used for smashing concrete to form recycled aggregate, and the smashing device comprises a feeding hopper. Paired smashing rolls are arranged at the bottom of the feeding hopper, and a clearance between the two smashing rolls forms asmashing channel. A forming frame for enabling the recycled aggregate to form rectangular blocks is arranged on a conveying belt. The compacting device comprises a bearing plate fixed below the conveying belt, and a pressing plate for pushing the forming frame are arranged above the bearing plate and the conveying belt. According to the movable building rubbish regenerating treatment system, concrete block and other building rubbish can be smashed and compacted into blocky regeneration bricks; and due to the fact that the recycled aggregate in the generation bricks is bonded firmly, the situation that dust is raised from the recycled aggregate, an air pollution is caused is not likely to happen, and the effect of environmentally friendliness is achieved.

Owner:深圳市绿悦环保科技有限公司

High-gloss anti-precipitation flame-retardant polypropylene material and preparation method thereof

The invention discloses flame-retardant masterbatch suitable for a flame-retardant polypropylene material, a preparation method of the flame-retardant masterbatch and a high-gloss anti-precipitation flame-retardant polypropylene material based on flame-retardant masterbatch preparation. Tetrabromobisphenol S bis-(2,3-dibromopropyl) ether masterbatch is adopted as the flame-retardant masterbatch and prepared by taking micropore polypropylene as an adsorbing agent and a masterbatch carrier through a fusing adsorption method. Flame-retardant polypropylene based on flame-retardant masterbatch preparation is prepared from 57%-70% of polypropylene resin, 24%-40% of the tetrabromobisphenol S bis-(2,3-dibromopropyl) ether masterbatch and 3%-6% of antimonous oxide masterbatch. The high-gloss anti-precipitation flame-retardant polypropylene material prepared through the method has the advantages of being high in gloss, easy to mold and disperse, capable of resisting precipitation, low in cost, high in flame-retardant efficiency and the like and can be widely applied to shells of electrons, electric appliances and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Production method for brown coal binding and forming

The invention discloses a production method for brown coal binding and forming, and relates to a binding agent suitable for low-order brown coal forming and a preparation method of the coal briquette. The method comprises the following steps: (1) crushing and screening the brown coal block until the size is smaller than or equal to 3 mm; (2) dissolving polyvinyl alcohol, carboxymethyl cellulose and sodium silicate into water according to a certain ratio, and preparing a composite binding agent; (3) adding the binding agent according to a certain proportion to the brown coal raw material, stirring uniformly, and then conducting cold extrusion forming in a coal rod extrusion machine; (4) drying the formed coal rod at the temperature of 60-120 DEG C until the moisture is smaller than 10% so as to obtain the coal briquette product. The production method disclosed by the invention is simple in technology; the binding agent is wide in source, convenient to prepare, and low in cost; the coal briquette product is high in cold intensity and heat intensity both, can substitute lump coal to be supplied to a gas generator, and further can meet the requirements on the granularity and the strength for the synthesis ammonia gas-making section.

Owner:YUNNAN CHEM RES INST

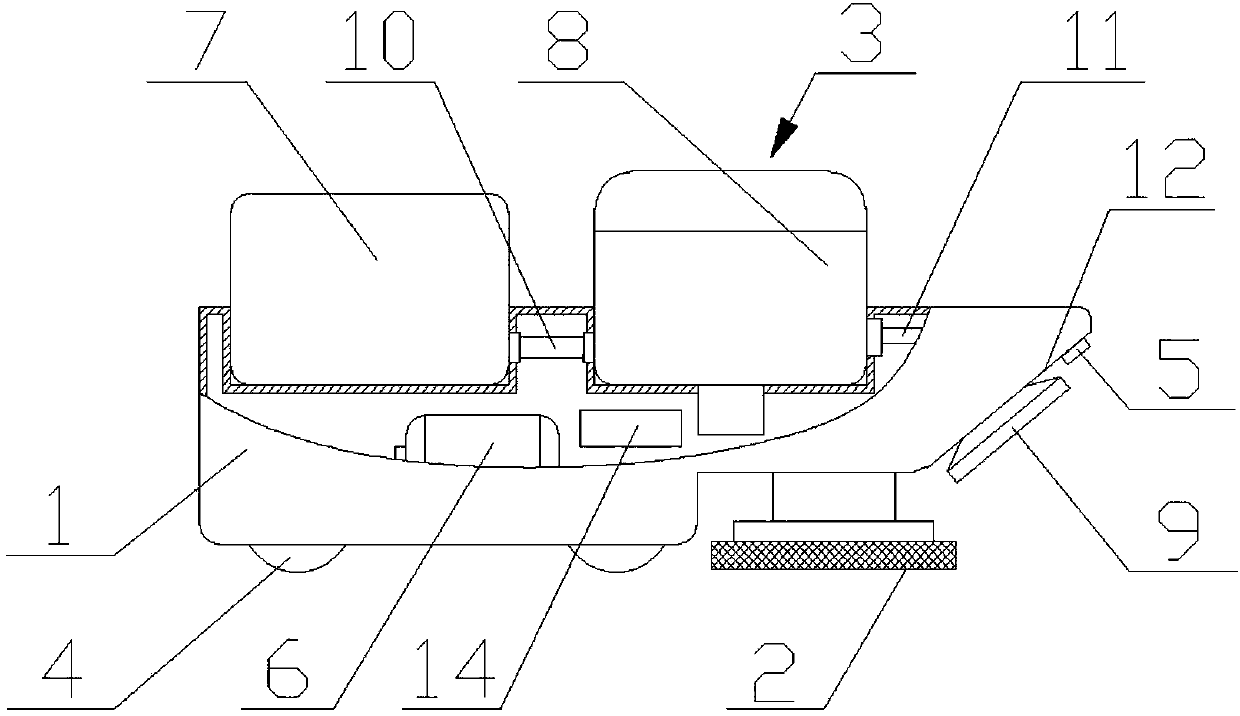

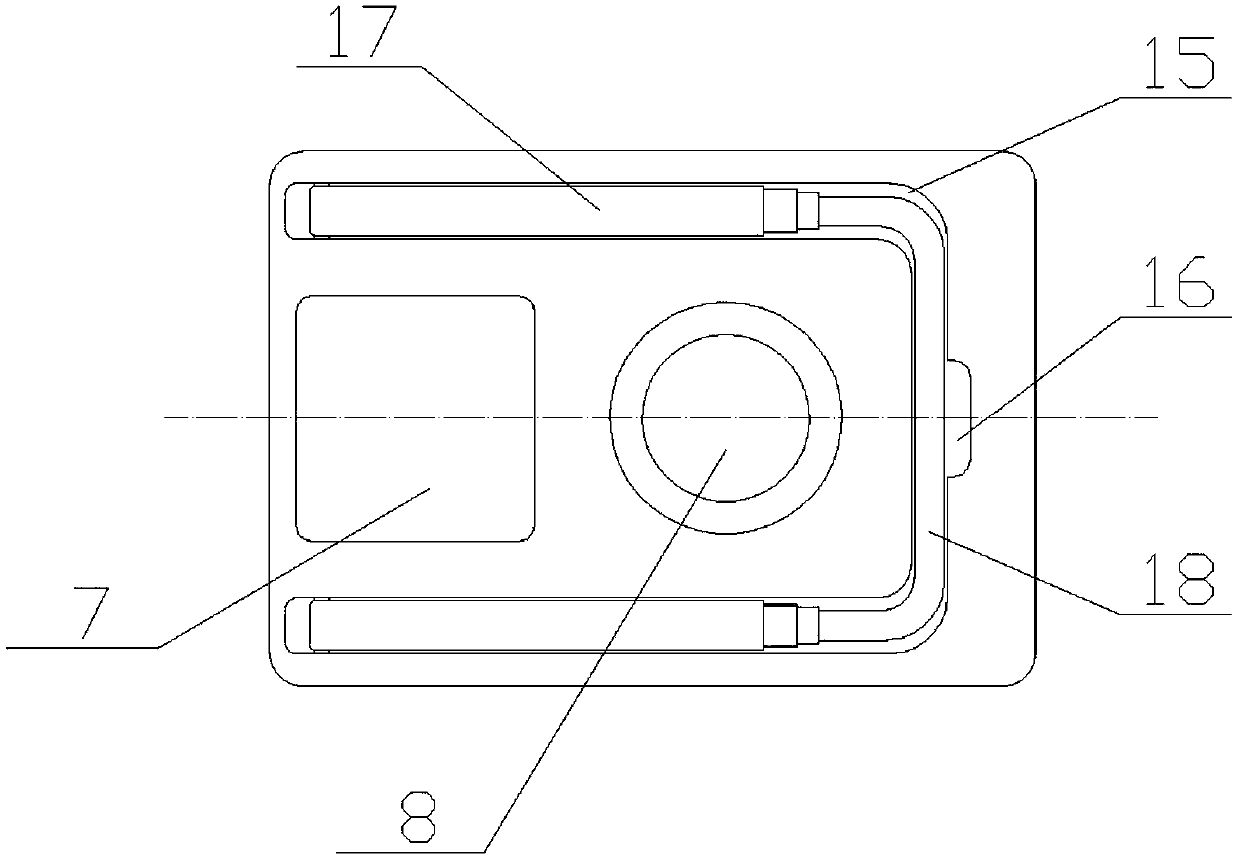

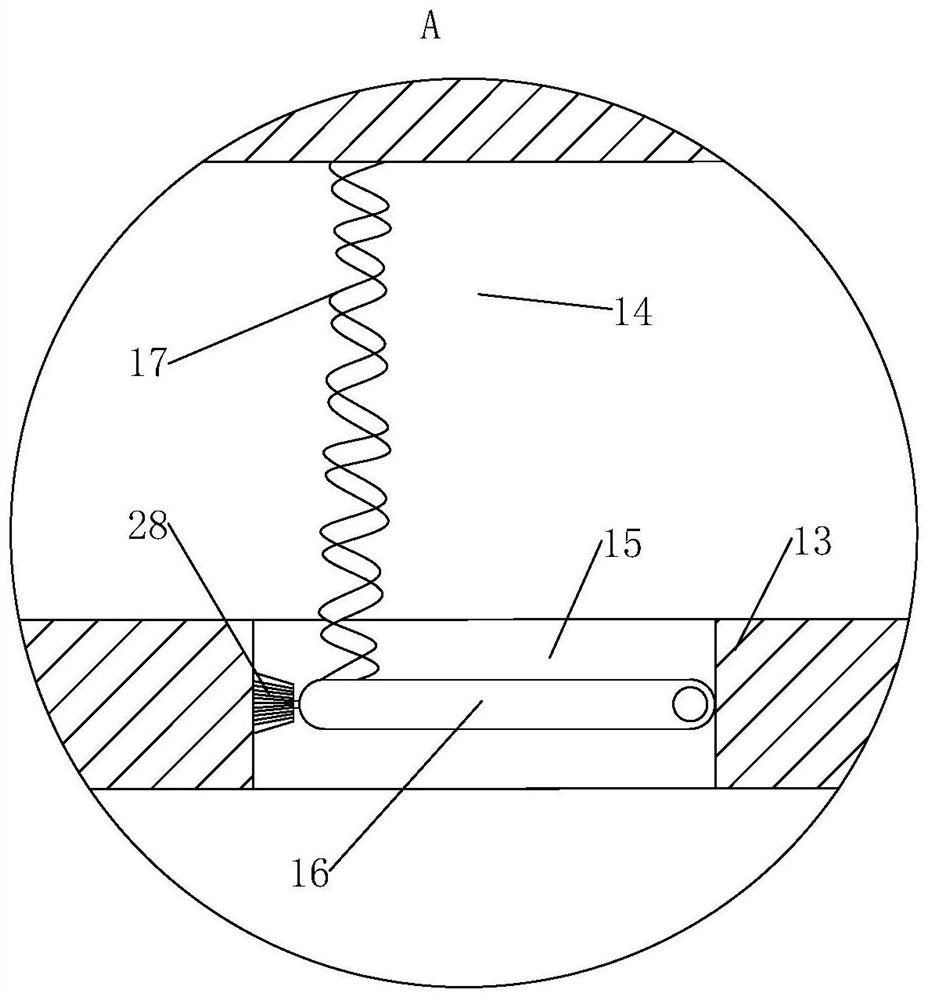

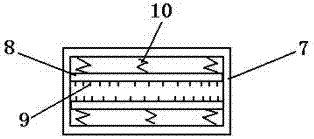

Mopping machine

PendingCN107550410ANot easy to raise dustMop the floor cleanMachine detailsFloor-scrubbing machinesHandrailEngineering

The invention discloses a mopping machine. The mopping machine comprises a machine body (1) and cleaning cloth (2) detachably installed on the machine body (1). The mopping machine further comprises awatering mechanism (3) installed on the mopping machine (1) and a telescopic handrail (14) which can be swung and connected with the machine body (1). The watering mechanism (3) comprises a water tank (7), a water pump (8) and a sprinkler head (9). The mopping machine is further provided with wheels (4), a walking unit (6) for driving the wheels (4) to be rotated or steered and a sensor (5) for detecting a barrier. The handrail (14) can be received in the machine body (1) in the unused state. The mopping machine is capable of automatically executing the watering and mopping operations, and executing the artificial mopping.

Owner:代诗杰

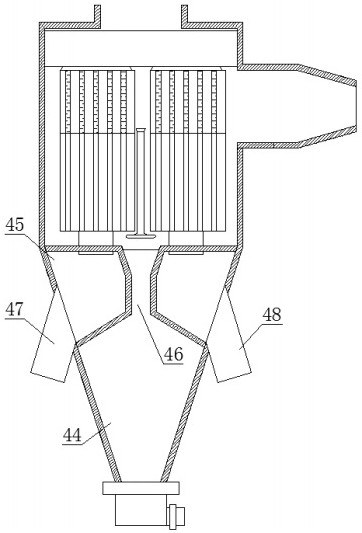

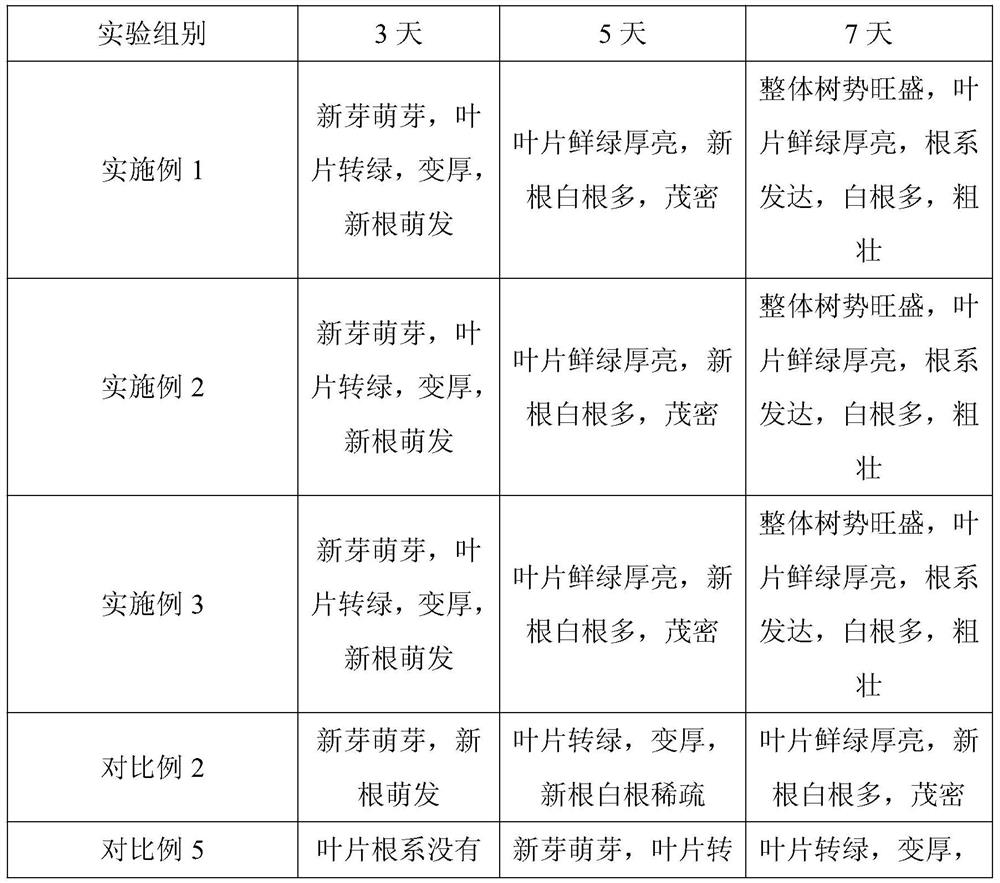

Classification type cyclone dust collection device with multi-section vortex tube combination and implementation method thereof

ActiveCN113426590AAct as a barrierEasy accessUsing liquid separation agentSingle direction vortexDrive wheelGear wheel

The invention relates to the technical field of cyclone dust collection equipment, discloses a classification type cyclone dust collection device with a multi-section vortex tube combination, and also discloses an implementation method of the classification type cyclone dust collection device with the multi-section vortex tube combination. The classification type cyclone dust collection device with the multi-section vortex tube combination comprises a supporting frame and a dust collecting barrel fixedly installed at the upper end of the supporting frame. Through the matching of a driving wheel, a belt piece and a driven wheel, a gear A is fixedly installed at the lower end of the driven wheel, a gear B is installed on one side of the gear A in a meshed mode, and the lower end of the gear B is fixedly connected with a second worm; through the matching of the gear A and the gear B, the second worm installed at the lower end of the gear B can rotate, the second worm and a first worm are opposite in rotating directions, the diameter of the driven wheel is larger than the diameter of the driving wheel, namely, the rotating speed of the second worm is lower than the rotating speed of the first worm, the strength of cyclone generated when the rotating speed is low is small, only small-particle dust can be sucked in, and on the contrary, the first worm can suck large-particle dust; and the large particles and the small particles are discharged through a dust removal port respectively.

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG

Brominated polystyrene masterbatch and preparation method thereof

ActiveCN102627812AImprove flame retardant performanceSmall mechanical propertiesMasterbatchPolymer science

The invention discloses a brominated polystyrene masterbatch and a preparation method thereof. The brominated polystyrene masterbatch is prepared from the following components, by mass, 85-95% of brominated polystyrene, 3-14% of a carrier and 0.1-5% of modified ethylene bisfatty acid amide. The brominated polystyrene masterbatch prepared in the invention can effectively avoid unstable material quality caused by nonuniform mixing of powder and pellets; the preparation method which adopts a mixing-extruding continuous production technology has the advantages of high production efficiency, low production cost, clean production, good dispersion effect, substantial improvement of the loading amount of the brominated polystyrene masterbatch, and good mixing effect; and the brominated polystyrene masterbatch prepared in the invention has the characteristics of easy dispersion, high flame resisting efficiency, and low production cost, and has influences on physical and mechanical properties, the heat resistance, the processing performance and the surface color of a composite material smaller than influences of brominated polystyrene powder.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

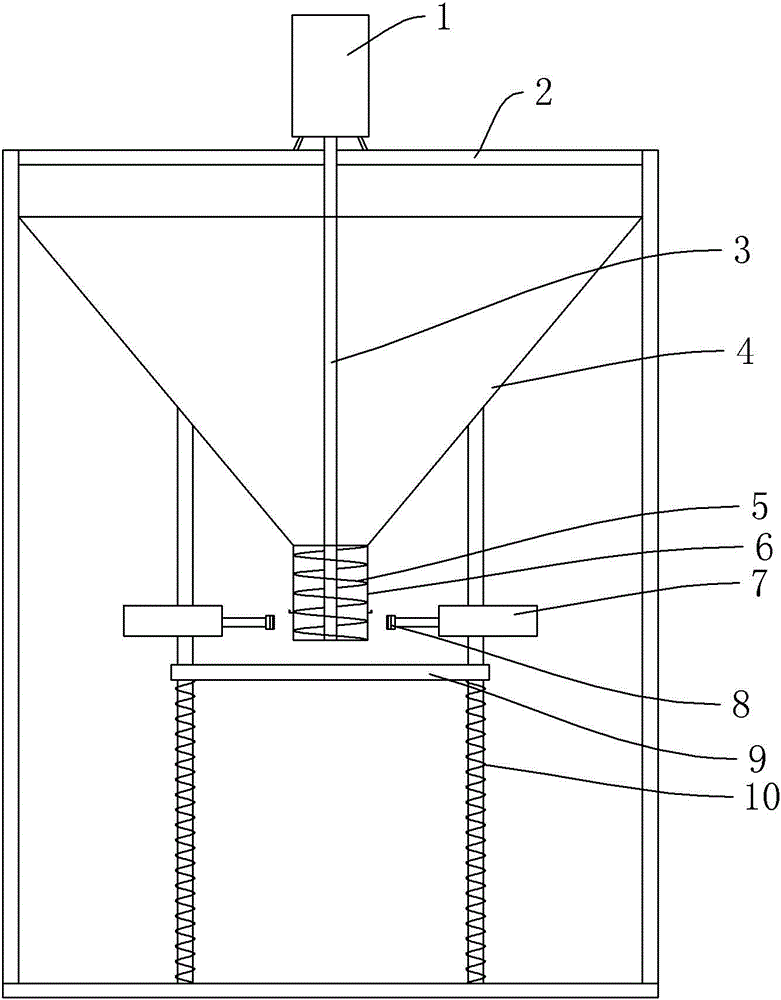

Buffer type steel slag powder bagging device

InactiveCN105217088ANot easy to raise dustPrevents bending from losing elasticitySolid materialSlagElectric machinery

The invention relates to machining equipment of steel slag powder, in particular to a buffer type steel slag powder bagging device. The buffer type steel slag powder bagging device comprises a bracket, wherein a motor and a bin are arranged on the bracket; a vertical discharge pipe is arranged at the lower end of the bin; a rotating shaft is arranged in the discharge pipe; the upper part of the rotating shaft is rotationally connected with the bracket; the rotating shaft is connected with the motor; a spiral blade is arranged on the rotating shaft, and is in clearance fit with the discharge pipe; a cylinder is arranged on the bracket; an arched clamping block is arranged at one end, near the discharge pipe, of the cylinder; a bearing plate is arranged below the discharge pipe, and is slidingly connected with the bracket; and a spring for enabling a descending height of the bearing plate to be equal to a loading height of steel slag powder is arranged at the lower part of the bearing plate. The buffer type steel slag powder bagging device has the following beneficial effects: the steel slag powder is not easy to generate raise dust in bagging; and the working environment is improved.

Owner:重庆市富环建筑材料有限责任公司

High-soluble soybean peptide dry powder and preparation method thereof

InactiveCN105941823AImprove solubilityGood dispersionVegetable proteins working-upParticulatesSolubility

The invention relates to the technical field of soybean peptide products, in particular to a preparation method of high-soluble soybean peptide dry powder. The preparation method of the high-soluble soybean peptide dry powder includes: enzymatically hydrolyzing soybean protein isolate to obtain soybean peptide solution, and drying and granulating the soybean peptide solution to obtain soybean peptide dry powder; drying includes spray drying and then roller drying, and granulating includes granulating via hot blast eddy circulation during roller drying. The soybean peptide dry powder has good solubility and dispersity in water and is free of clustering or knotting, and an obtained solution is uniform, tender and clear. The preparation method provided herein enables low and stable water content for the soybean peptide dry powder through repeated drying and granulating and also enables good solubility and dispersity for the soybean peptide dry powder, obtained particulate powdered soybean peptide is large in particle size, dusts rarely and is more convenient and safer to use and easy to control.

Owner:刘新旗 +1

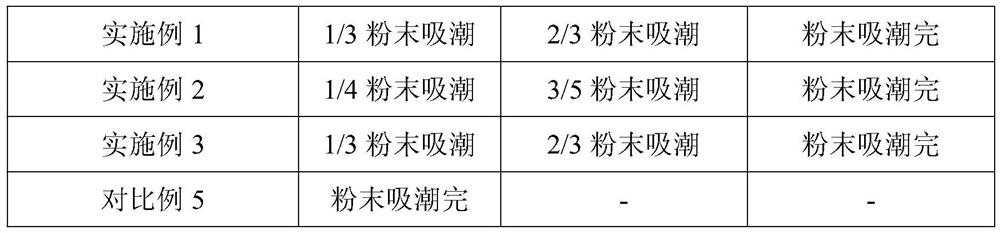

Novel efficient biochemical potassium fulvate and preparation method thereof

PendingCN112299924ANot easy to raise dustSolve the problem of moisture absorptionCalcareous fertilisersAnimal corpse fertilisersBrown algaeOligosaccharide

The invention discloses a preparation method of novel efficient biochemical potassium fulvate, and the method comprises the following steps of: (1) adding yeast into molasses, fermenting alcohol or yeast, and extracting alcohol or yeast to obtain a residual concentrated solution; (2) adding quick lime into the residual concentrated solution prepared in the step (1), improving the pH value of the product, and performing filtering to obtain filtrate; (3) adding amidonitrogen, small molecular peptide amino acid, deep sea fish protein, alginic acid, brown algae oligosaccharides, bacillus licheniformis, bacillus mucilaginosus and medium trace elements into the filtrate prepared in the step (2), and then fully mixing the substances for uniform reaction to prepare a mixture; and (4) carrying outmicro-spray drying on the mixture prepared in the step (3) to prepare the novel efficient biochemical potassium fulvate. The novel efficient biochemical potassium fulvate is pure organic, fully water-soluble, fast in absorption, fast in effect, fast in root promotion, fast in seedling strengthening and fast in green leaf, and can be widely popularized and applied.

Owner:广西百龙腾生物科技有限责任公司

Flowing anti-caking auxiliary agent for powder paint and preparation method thereof

InactiveCN107083099AImprove production environmentReduce manufacturing costEpoxy resin coatingsPolyester coatingsWaxGas phase

The invention discloses a flowing anti-caking auxiliary agent for powder paint. The flowing anti-caking auxiliary agent for powder paint is prepared from the following raw material ingredients in parts by weight: 20 to 40 parts of precipitation process white carbon black, 5 to 15 parts of gas phase process white carbon black, 10 to 30 parts of polyamide wax and 10 to 30 parts of N,N-ethylene Bis-stearamide. The invention also discloses a preparation method of the flowing anti-caking auxiliary agent for powder paint.

Owner:江西杰克西新材料有限公司

Carrier-free aluminum hydroxide flame retardant master batch and preparation method thereof

InactiveCN111073056ANot easy to raise dustHigh decomposition temperatureOrganic solventAluminium hydroxide

The invention relates to the technical field of flame retardant synthesis, and particularly discloses a carrier-free aluminum hydroxide flame retardant master batch and a preparation method thereof. The carrier-free aluminum hydroxide flame retardant master batch comprises the following preparation raw materials in parts by weight: 90-99 parts of aluminum hydroxide, 0.1-1.5 parts of a coupling agent, 0.5-3 parts of a surface treating agent, 10-30 parts of an organic solvent and 1-3 parts of a binder. The coupling agent and the surface treating agent are used for carrying out surface treatmenton the aluminum hydroxide, so that the prepared aluminum hydroxide is not prone to raise dust, the decomposition temperature of the aluminum hydroxide is high, and the application range and the processing temperature of the aluminum hydroxide flame retardant are enlarged; the dispersity of aluminum hydroxide in a high-molecular polymer system is also improved; and finally, the preparation processis simple, the cost is relatively low, the dust pollution is greatly reduced, and the preparation method is worthy of popularization.

Owner:HEFEI ZHONGKE FLAME RETARDANT NEW MATERIAL

Urban atmospheric environment quality monitoring system

PendingCN113804837AGood removal effectImpact Monitoring DataDispersed particle filtrationAnalysing gaseous mixturesAir pumpEngineering

The invention belongs to the technical field of atmospheric monitoring, and particularly relates to an urban atmospheric environment quality monitoring system which comprises a box body, wherein one side of the box body is communicated with an air inlet pipe, the other side of the box body is provided with a fixing plate, the fixing plate is provided with an air extracting pump, and one end of the air extracting pump is communicated with an exhaust pipe; a groove is formed in the right inner wall of a first cavity, a monitoring probe is arranged in the groove, a hydraulic telescopic rod is installed at the top of the first cavity, a lifting block is arranged at the lower end of the hydraulic telescopic rod, a second cavity is formed in the lifting block, and a through hole is formed in the lower end face of the lifting block; a dust hood is mounted at the lower end of the lifting block, and the lifting block is provided with cleaning velvet; and a supporting plate is installed in the first cavity and provided with a flow guide block, a filter plate is arranged between the supporting plate and the bottom of the first cavity, dust removal liquid is arranged between the filter plate and the bottom of the first cavity, and a water pump is arranged on the left side of the box body. According to the invention, the problem of inaccurate data obtained after measurement due to residual original gas and impurities in the box body after the monitoring of the existing monitoring equipment is completed can be solved.

Owner:刘东

Cleaning device on tribenuron-methyl packing machine

InactiveCN107499866AEasy to absorbNot easy to raise dustCleaningPackagingTribenuron-methylEngineering

The invention discloses a cleaning device on a tribenuron-methyl packaging machine, which comprises a collection tank, a water tank, a drying box and a friction device; The conveyor belt below passes through the water tank, the drying box and the friction device in sequence. The friction device includes a bracket, and a frame is arranged on the bracket. The conveyor belt passes through the gap between the two beading strips, the opposite surfaces of the two beading strips are provided with furs, and the beading strips are connected to the long sides of the frame by springs. The present invention collects the tribenuron-methyl particles on the conveyor belt through the collection tank, melts the tribenuron-methyl powder adsorbed on the conveyor belt into water through the water tank, and after drying the conveyor belt through the drying box, the friction device rubs the conveyor belt to make it electrostatically charged. , easy to absorb tribenuron-methyl powder, less prone to dust.

Owner:ZHEJIANG PIONEER CROPSCI CO LTD

Method for preparing flame retardant by utilizing modifying technology and compounding technology

The invention discloses a method for preparing a flame retardant by utilizing a modifying technology and a compounding technology, and belongs to the technical field of flame retardant preparation. The flame retardant is prepared from the following raw materials: polybutylene terephthalate, antimonous oxide, magnalium layered double hydroxide, subcarbonate, organic ammonium bromide, methyl silicone oil, acrylic ester and a dispersant. The flame retardant is prepared by polybutylene terephthalate drying, surface modification of the antimonous oxide, surface modification of magnalium layered double hydroxide, mixing, granulating, screening, drying and the like. According to the method, the modifying and synergizing technical means is adopted, the addition amount of the flame retardant is 10-20 percent, the antimony part is substituted by comprehensive compounding; and in the development of the product in the invention, the consumption of antimony can be greatly reduced, and the utilization limit of the antimony resource can be prolonged.

Owner:广西华锑科技有限公司

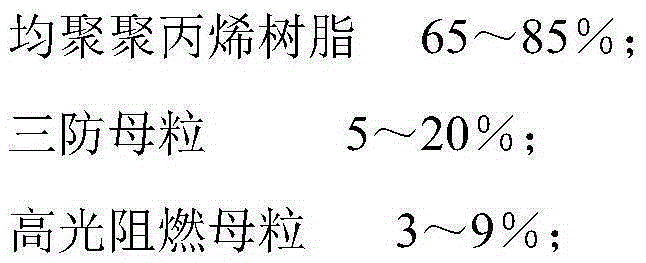

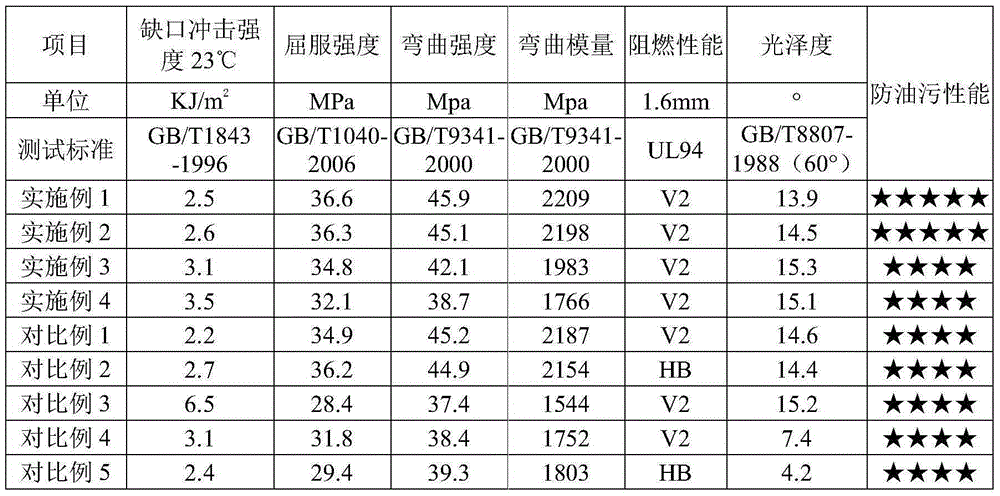

High-glossiness anti-flaming polypropylene material easy to clean and preparation method thereof

The invention provides a high-glossiness anti-flaming polypropylene material easy to clean and a preparation method thereof. Firstly, high-glossiness anti-flaming master batch and dolomite master batch are prepared, the high-glossiness anti-flaming master batch, the dolomite master batch, fluorinated acrylate master batch and polypropylene resin are subjected to melt extrusion and pelleting through an extruder to obtain the high-glossiness anti-flaming polypropylene material easy to clean, and the prepared high-glossiness anti-flaming polypropylene material easy to clean has the advantages of being high in anti-flaming efficiency, good in glossiness, easy to form, resistant to water and oil, easy to clean and the like, and can be widely applied to the fields of household appliances such as warmers, air blowers, bread makers, ovens and electric cookers.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Stirring spiral conveying device

InactiveCN112248243AEasy to replacePrevent dust from enteringRotary stirring mixersTransportation and packagingCylinder blockPipe

The invention discloses a stirring spiral conveying device which comprises a conical feeding hopper, a stirring cylinder body and a spiral conveying pipe. The stirring spiral conveying device is usedfor stirring and conveying powder, a stirring knife stirring and scattering manner and a pipeline spiral conveying manner are combined, the stirring spiral conveying device can be suitable for stirring and conveying various types of powder, and stirring and conveying are conducted with power and do not influence each other. A wear-resistant lining plate added to a stirring cylinder body is easy toreplace, and the labyrinth design at the joint of a stirring shaft prevents dust entering and dust raising. The stirring spiral conveying device is reasonable in structure, has the beneficial effectsof being convenient to use, high in applicability, easy to scatter, convenient to disassemble and assemble, easy to adjust and the like, and can rapidly and effectively scatter powder and convey thepowder to the next procedure.

Owner:ZHUHAI SHIGAOMA MASCH EQUIP CO LTD

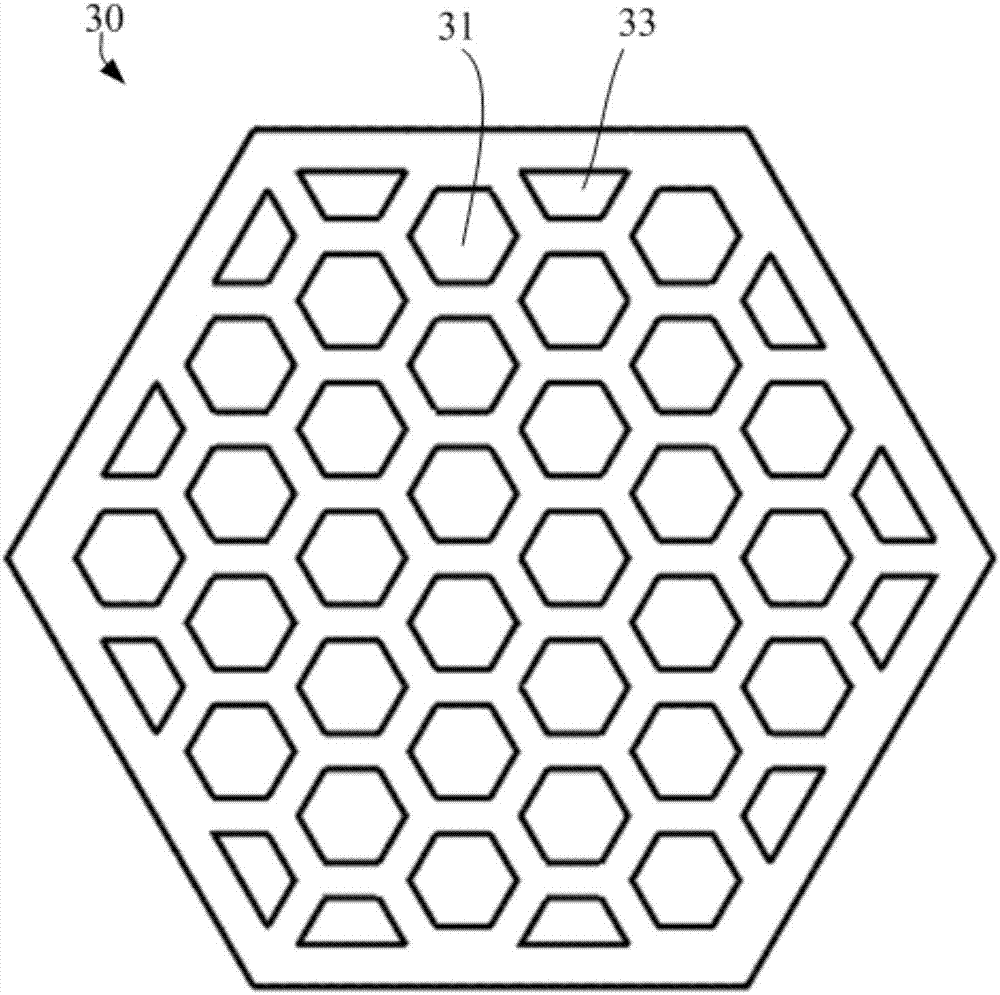

Prefabricated building block

PendingCN107503258AHigh strengthNot prone to cracking problemsSingle unit pavingsPaving gutters/kerbsWater storageArchitectural engineering

The invention relates to the technical field of building materials, in particular to a prefabricated building block. The prefabricated building block comprises a water permeable surface layer and support layers, wherein the support layers are polygonal prisms, the outer contour of the cross section of the support layers is orthohexagnal, and a plurality of first open holes are formed in the support layers and penetrate the upper and lower surfaces of the support layers, accordingly, the water-permeable function can be realized through the first open holes, and the water storage function can be realized by matching with the water-impermeable ground after installation. Rainwater can enter the first open holes in the support layers through the water permeable surface layer to be stored. When the water quantity is small, the stored water can keep a road in a wet state through evaporation, so that the probability of flying dust on the road is low, the specific heat of the road is increased, the surface temperature is reduced, and the heat island effect is relieved. The support layers are polygonal prisms, and the outer contour of the cross section of the support layers is orthohexagnal, so that when the road is assembled, tightness between the supporting layers is high, flatness is higher, the problem of uneven settlement of a foundation can be effectively solved, and the structure stability is maintained.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

A kind of frost dye on grass and preparation method thereof

ActiveCN104448931BImprove dye uptakeImprove dyeing effectOrganic dyesEnvironmental resistanceSulfonate

The invention provides a fur-with-frost dye and a preparation method thereof. The fur-with-frost dye is prepared from the following raw materials in parts by mass: 20-50 parts of acid dye, 10-20 parts of ammonium sulfate, 2-10 parts of fluorescent whitening agent, 2-5 parts of penetrant, 2-5 parts of sodium xylene sulfonate, 10-20 parts of white dextrin and 20-35 parts of anhydrous sodium sulfate; the preparation method of the fur-with-frost dye comprises the following steps: (A) weighing the raw materials and mixing for 1-3 hours to obtain a first powdery mixture; (B) pouring the first mixture into a pelletizer for pelleting to obtain the granular fur-with-frost dye. The dye-uptake of the prepared fur-with-frost dye is increased in the dyeing process, the content of the dye in the waste liquid is effectively reduced and the harm to the environment and the human body is reduced. The dye is prepared into the granular form, and therefore, the dust is greatly reduced and the harm to the using environment and the operating workers is reduced; the prepared fur-with-frost dye has excellent dyeing property and environmental protection performance.

Owner:BEIJING FANBO CHEM

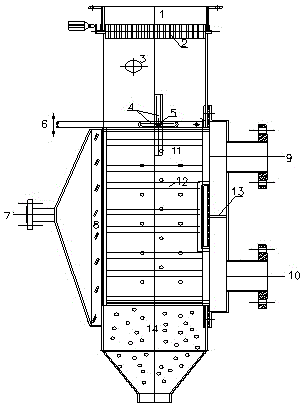

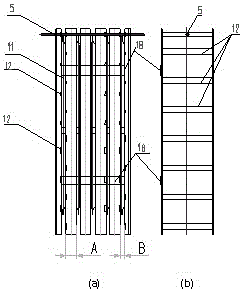

A falling pyrolyzer

The invention relates to a falling-type pyrolyzer which comprises a feed opening, a uniform blanking mechanism, a preheating section, a main reactor, a blanking auxiliary mechanism and a charcoal discharge section from top to bottom. The waste or biomass, of which the size is less than 30mm and the water content is 35% or below, is sent into the preheating section by the uniform blanking mechanism, and sent to the main reactor by the preheating section. The preheating section is provided with a vapor outlet. The main reactor is composed of vertical plates or membrane-type vertical tube heat transfer surfaces, and the interval is 1.4-3 times of the maximum particle size; by the aid of the blanking auxiliary mechanism, one side is provided with a heat source port, and the other side is provided with a volatile matter filter layer perpendicular to the heat transfer surface and a discharge port. The generated coke falls into the charcoal discharge section, the unpyrolyzed material is pyrolyzed at the charcoal discharge section, and the retention time is controlled through the charcoal discharge speed. When cold charcoal needs to be discharged, the charcoal discharge section is converted into the cooling section, and a coolant passes through at the cold source side. The falling-type pyrolyzer can adapt to the thermal expansion and cold shrinkage, and has the advantages of no leakage, high capacity and space saving.

Owner:TONGJI UNIV

A ventilation slot dust removal trolley

ActiveCN108996270BNot easy to flow outGuaranteed working environmentLoading/unloadingDust controlWorking environment

The invention relates to a matching device of dust removal equipment and discloses a dust removal trolley for a ventilation tank. The dust removal trolley comprises a vehicle body. An inverted L-shaped air inlet bent pipe is arranged in the vehicle body. The air inlet bent pipe comprises an air inlet end and an air outlet end. A partition is arranged in the air outlet end. A plurality of air outlets are formed in the partition. Dust collection bags are arranged in the air outlets. The dust collection bags are detachably connected with the air outlets. Due to the arrangement of the dust collection bags, dust enters the dust collection bags for collection and does not directly fall into the ventilation tank, so that on one hand, dust is not easy to raise and flow out, and on the other hand,even if a small amount of dust is generated, the dust floats in an air inlet pipe and does not diffuse from the vehicle body to the outside of the vehicle body, so that the working environment in factories can be ensured.

Owner:江阴华尔威机械有限公司

Method for manufacturing lightweight porous sintered material from red mud and plant residues

The invention relates to a method for preparing a light porous sintering material by red mud and plant residues. The method comprises the following steps: by using the red mud with the water content being less than or equal to 65wt% and the plant residues with the water content being less than 70wt%, preparing and mixing materials; rolling and mixing; moulding; and sintering to obtain the light porous sintering material. The method which utilizes waste red mud and plant residues wide in source and large in output can produce serial products such as water permeable paving products, filtering products, products for sound absorbing materials, catalytic products, light panels or heat-insulating and sound-proofing bricks which are wide in purpose and high in value with low cost. The method has industrial competitiveness and good investment economical benefit. Meanwhile, not only are a lot of clay resources and non-renewable fuel coal as building materials and chemical product raw materials saved to realize industrial emission reduction of Co2, but also the pollution of waste pollutants red mud and plant residues to water, soil and air can be effectively solved, and secondary disasters are prevented.

Owner:长沙紫宸科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com