Buffer type steel slag powder bagging device

A technology of powder bagging and steel slag, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problem that steel slag powder is easy to produce dust, and achieve the effect of not easy to raise dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

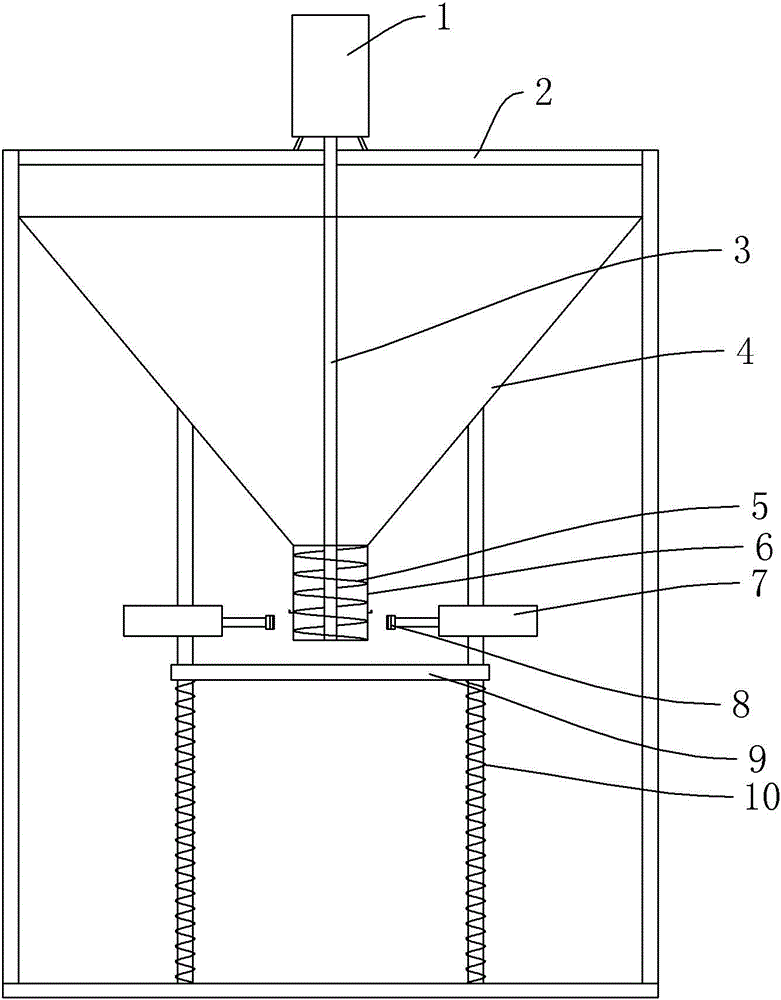

[0015] In the figure: motor 1, support 2, rotating shaft 3, feed bin 4, spiral blade 5, discharge pipe 6, cylinder 7, block 8, material receiving plate 9, spring 10.

[0016] Such as figure 1 The buffered steel slag powder bagging device shown includes a bracket 2, a motor 1 is arranged on the top of the bracket 2, and a conical silo 4 is arranged under the motor 1, and the silo 4 is fixedly connected with the bracket 2. The lower end of the feed bin 4 is provided with a vertical discharge pipe 6 , and a hook is provided on the outer wall of the discharge pipe 6 . The discharge pipe 6 is provided with a rotating shaft 3 coaxial therewith. The upper part of the rotating shaft 3 is rotationally connected with the support 2 , and its upper end is connected with the motor 1 . A helical blade 5 is arranged between the rotating shaft 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com