Extrusion forming method of low-order lignite

A technology for extrusion molding and lignite, which is applied in the field of lignite briquette preparation, can solve the problems of the influence of molding equipment or process, the limited use range of briquette, and the high cost of binder, and achieves low production cost, good scalability, and adhesion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

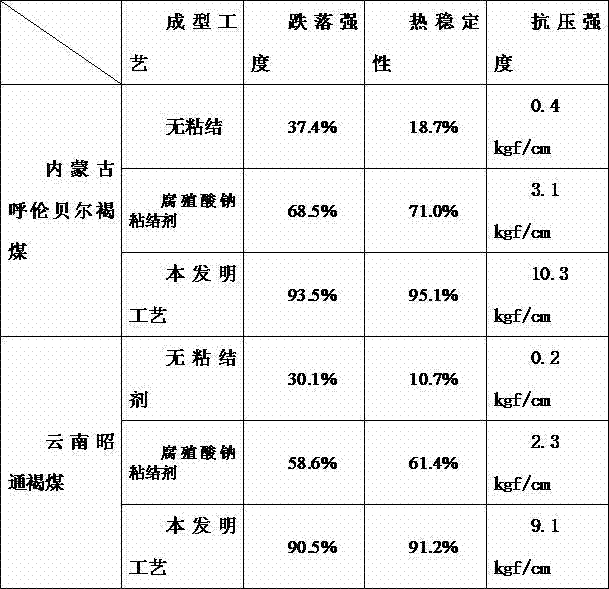

Examples

Embodiment 1

[0032] Example 1 The lignite lumps are crushed and screened to a particle size of ≤3mm, and the corn flour accounting for 1% of the coal mass and the water accounting for 5% of the coal mass are heated to 80-100°C to mature into corn paste. Add the binder corn paste to the lignite and stir evenly, control the molding moisture to 30%, and then send it to a screw extrusion coal rod machine for extrusion molding. The obtained coal rods are dried by airflow at 60-100°C for 6 hours to obtain briquettes. It is tested that the coal stick has a water content of 4.6%, a drop strength of 83.1%, a thermal stability of 81.6%, and a compressive strength of 7.3kgf / cm (linear pressure).

Embodiment 2

[0033] Example 2 The lignite lumps are crushed and screened to a particle size of ≤3mm, and the cornmeal accounting for 6% of the coal mass and the water accounting for 25% of the coal mass are heated to 80-100°C and matured into corn paste. Add the binder corn paste into the lignite and stir evenly, control the molding moisture to 45%, and then send it to a screw extrusion coal rod machine for extrusion molding. The obtained coal rods are dried by airflow at 60-100°C for 7 hours to obtain briquettes. It is tested that the coal stick has a water content of 14.7%, a drop strength of 95.1%, a thermal stability of 90.6%, and a compressive strength of 9.7kgf / cm (linear pressure).

Embodiment 3

[0034] Example 3 The lignite block is crushed and screened to a particle size of ≤3mm, and the wheat flour accounting for 2% of the coal mass and the water accounting for 10% of the coal mass are heated to 80-100°C and matured into a paste. Add the paste binder into lignite and stir evenly, control the molding moisture to 35%, and then send the material into a screw extrusion coal rod machine for extrusion molding, and the obtained coal rods are dried by airflow at 60-100°C for 6 hours to obtain briquettes product. It is tested that the coal stick has a water content of 9.3%, a drop strength of 89.1%, a thermal stability of 85.6%, and a compressive strength of 8.1kgf / cm (linear pressure).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com