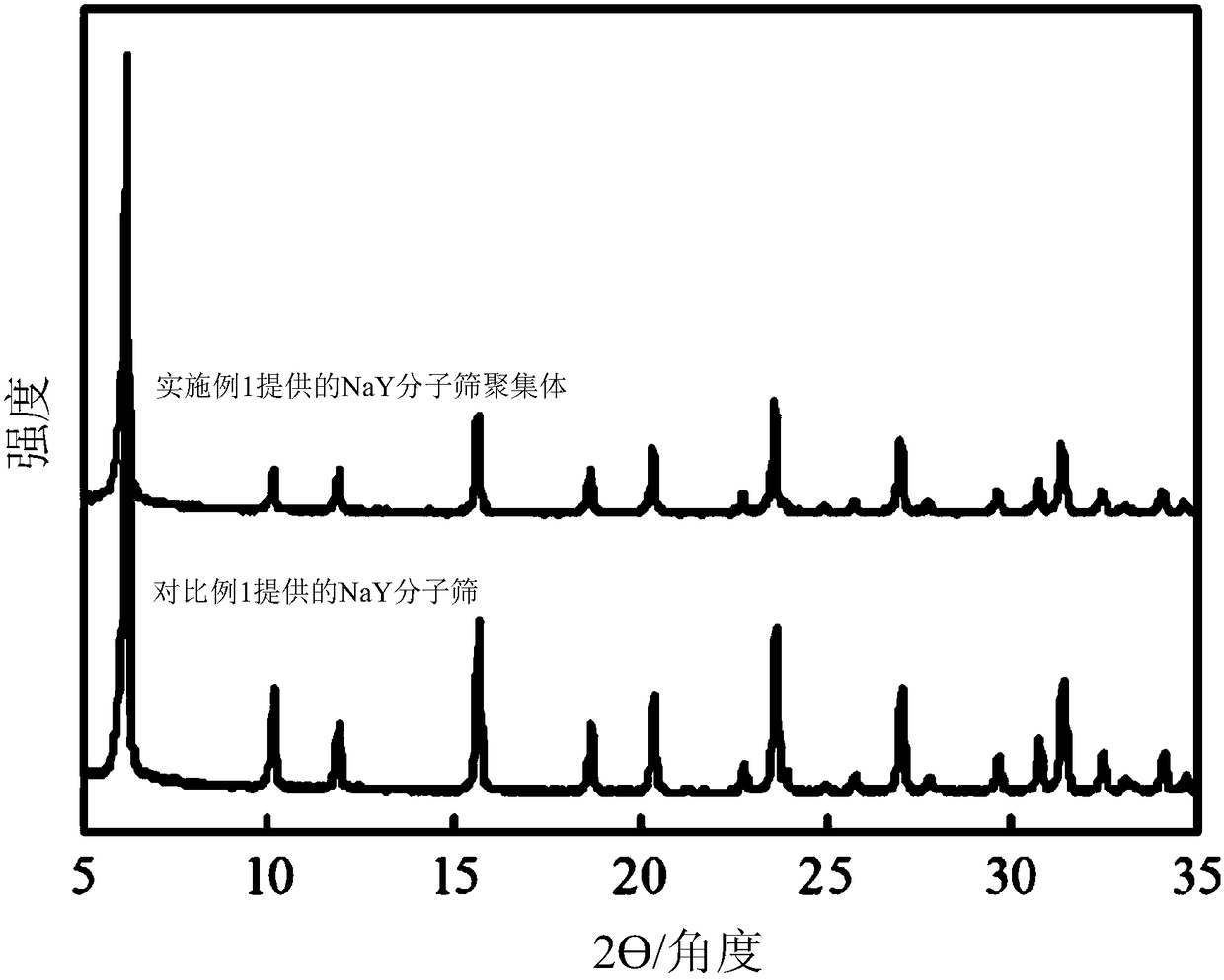

NaY molecular sieve aggregate with nano-micro structure and preparation method thereof

A molecular and collective technology, applied in the field of molecular sieve preparation, can solve the problems of low product yield, mother liquor discharge, large template material, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The present embodiment provides a kind of preparation method of the NaY molecular sieve aggregate with nanostructure, it comprises the following steps:

[0070] 1) Take by weighing 57.81g water glass (SiO in water glass 2 The content is 28.08wt%, Na 2 The content of O is 8.83wt%) to be placed in the beaker, then take by weighing 8.81g sodium hydroxide solid (Beijing Century Hongxing Chemical Co., Ltd., analytically pure) and be placed in the beaker, the two are mixed and stirred evenly, and at room temperature (27 ℃) stirring for 2 hours to prepare a highly active hydrated sodium silicate solution;

[0071] Then add 54.11g deionized water, 3.12g sodium metaaluminate (Tianjin Jinke Chemical Research Institute, Al 2 O 3 The content is 45wt%, Na 2 The content of O is 41wt%), stirs and mixes evenly, adds 3g N in the system, N-dimethyl-N-hexadecylaminopropyl silane quaternary ammonium salt [(C n h 2n+1 O) 3 SiC 3 h 6 N(CH 3 ) 2 -C x h 2x+1 ]X, wherein, n=1; x=16...

Embodiment 2

[0079] The present embodiment provides a kind of preparation method of the NaY molecular sieve aggregate with nanostructure, it comprises the following steps:

[0080] 1) The preparation method and source of raw materials of the directing agent are the same as in Example 1.

[0081] 2) Weigh 32.54g of C-type silica gel (also known as coarse-porous microsphere silica gel) and add it to 50g of deionized water, then add 53.19g of water glass, and stir at a constant temperature of 20°C for 3 hours to prepare highly active hydrated silica gel. Then take by weighing the aluminum sulfate of 15.00g sodium metaaluminate and 17.64g (Tianjin Guangfu Technology Development Co., Ltd., Al 2 SO 4 18H 2 The O content is 99%) was dissolved in the highly active hydrated silica gel, and after stirring evenly, 83.38 g of the above-mentioned directing agent was added, and the reaction gel was obtained by stirring evenly.

[0082] 3) Put the above reaction gel into a stainless steel reaction ket...

Embodiment 3

[0085] The present embodiment provides a kind of preparation method of the NaY molecular sieve aggregate with nanostructure, it comprises the following steps:

[0086] 1) The preparation method and raw material sources of the directing agent are the same as in Example 1.

[0087] 2) Weigh 40.54g of coarse-porous microsphere silica gel and add it to 86g of deionized water, stir at a constant temperature of 20°C for 3 hours to prepare highly active hydrated silica gel, then weigh 20.00g of sodium metaaluminate into the highly active hydrated silica gel After stirring evenly, add 83.38g of the above-mentioned directing agent, and stir evenly to obtain a reaction gel.

[0088] 3) Put the above-mentioned reaction gel into a stainless steel reactor lined with tetrachlorethylene, statically crystallize at 100°C for 96 hours, then filter, wash and dry to obtain the NaY molecular sieve aggregate product.

[0089] The specific surface area of the NaY molecular sieve aggregate product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com