Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

608 results about "Cavity pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cavity Pressure. Cavity pressures are a function of the cavity geometry, the wall thickness of the part, the materials selected for the part and the process parameters used for the selected material.

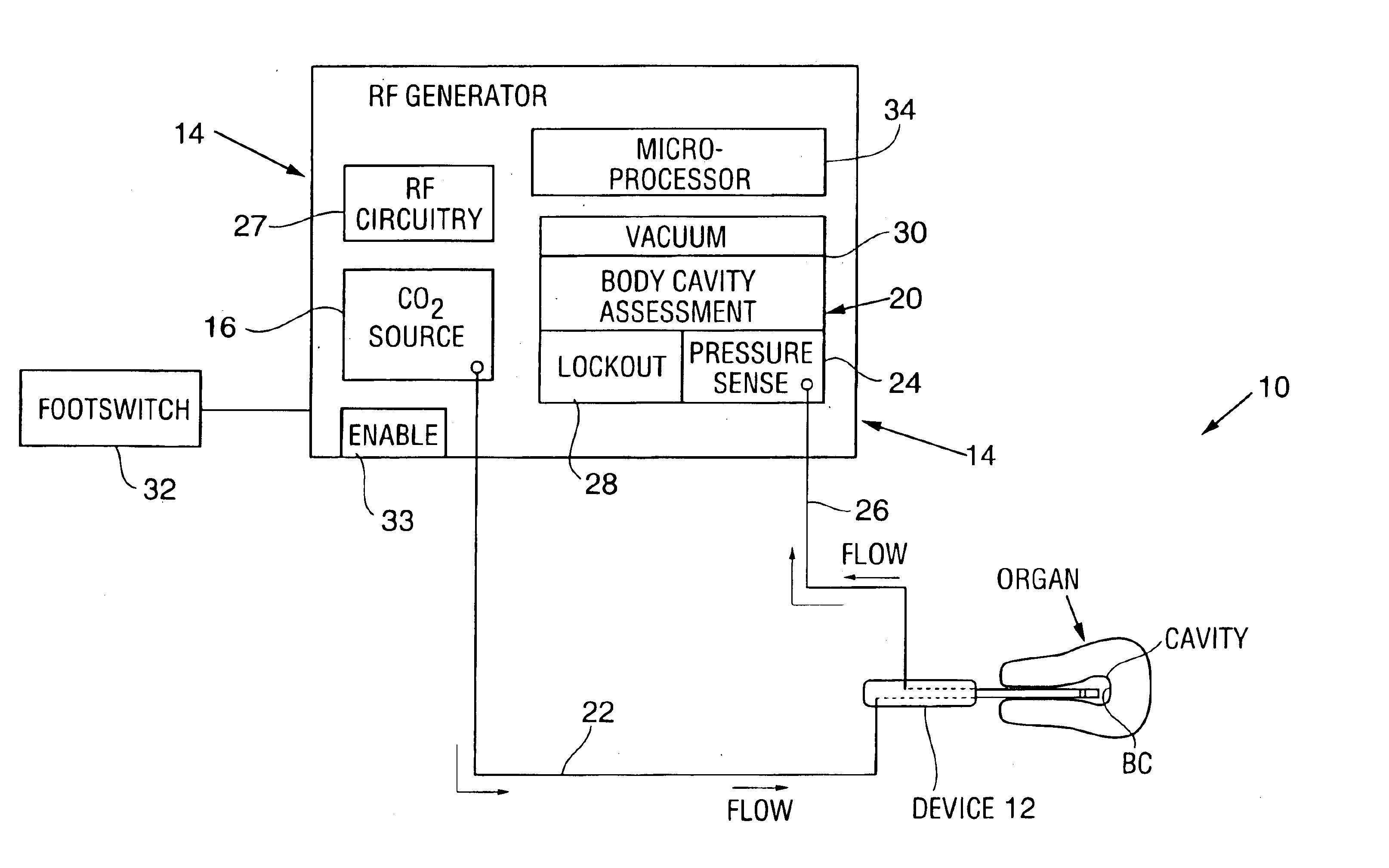

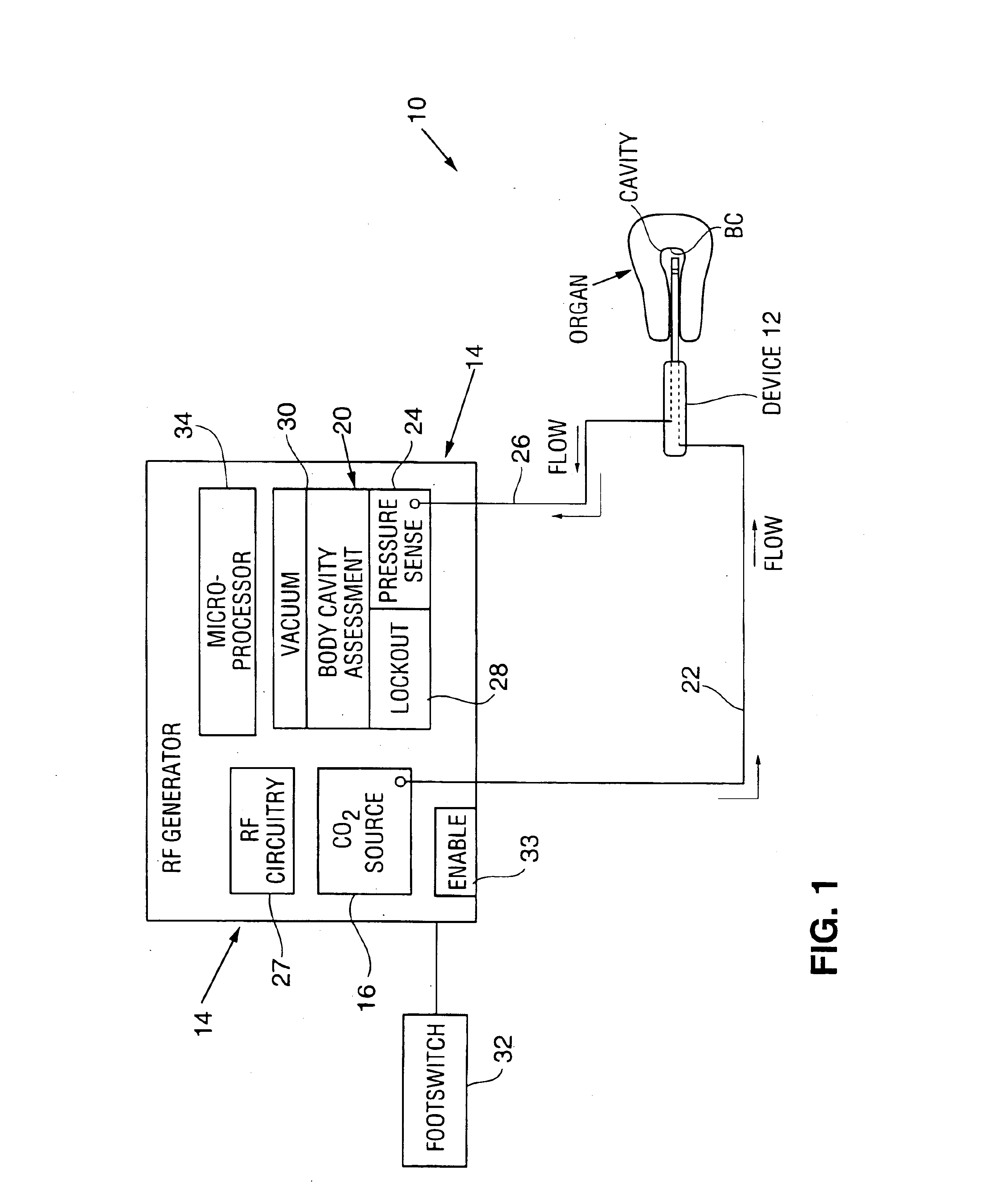

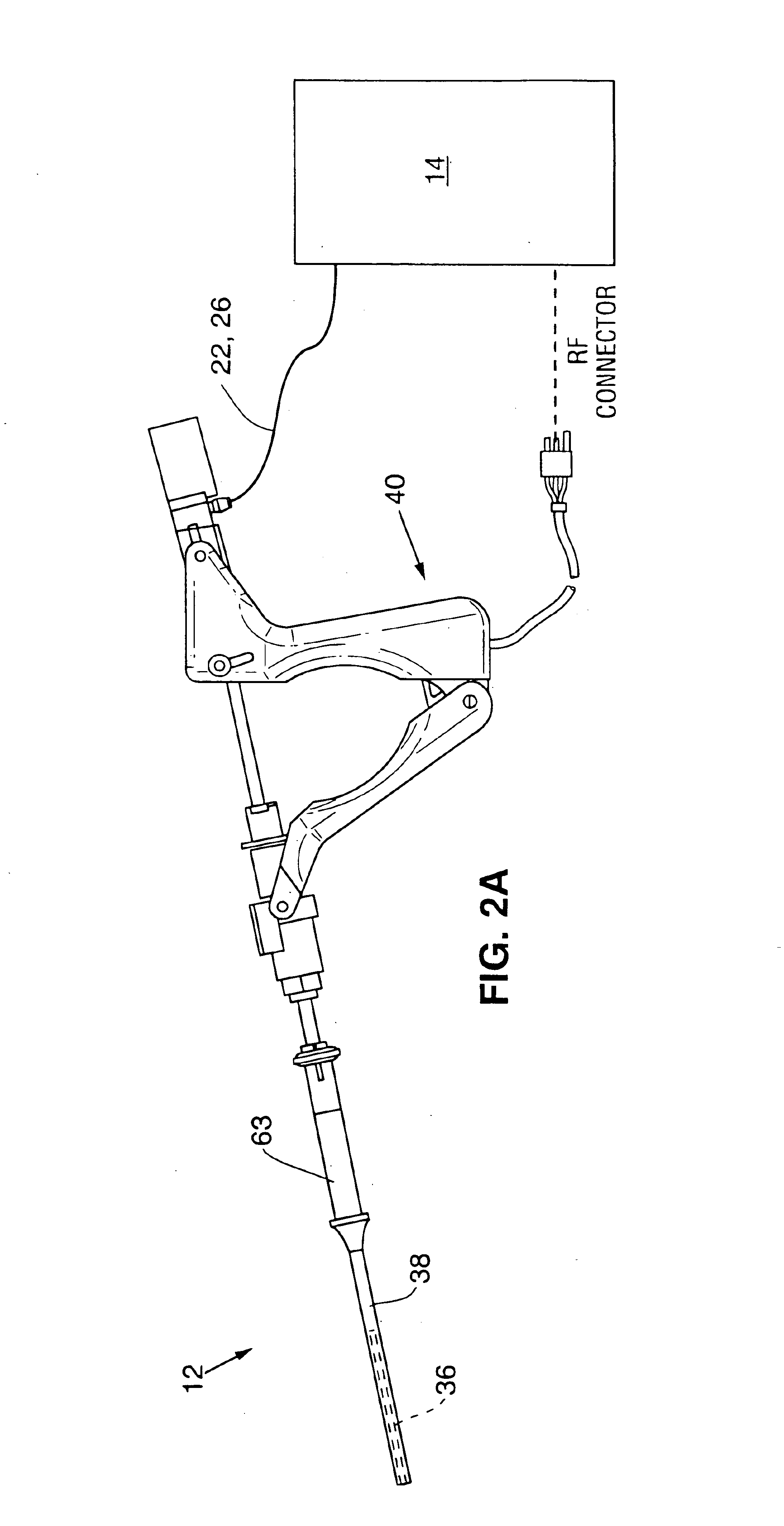

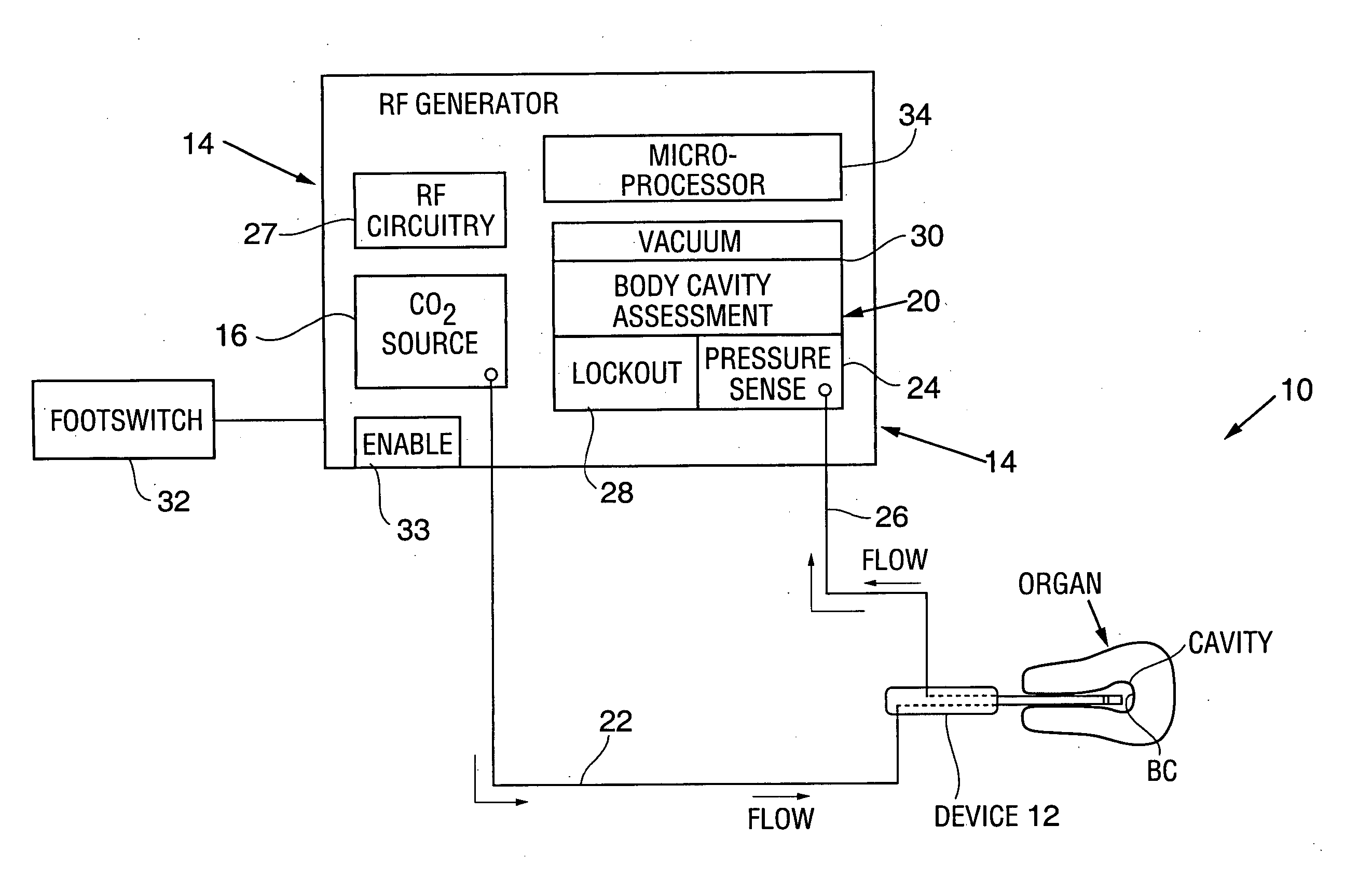

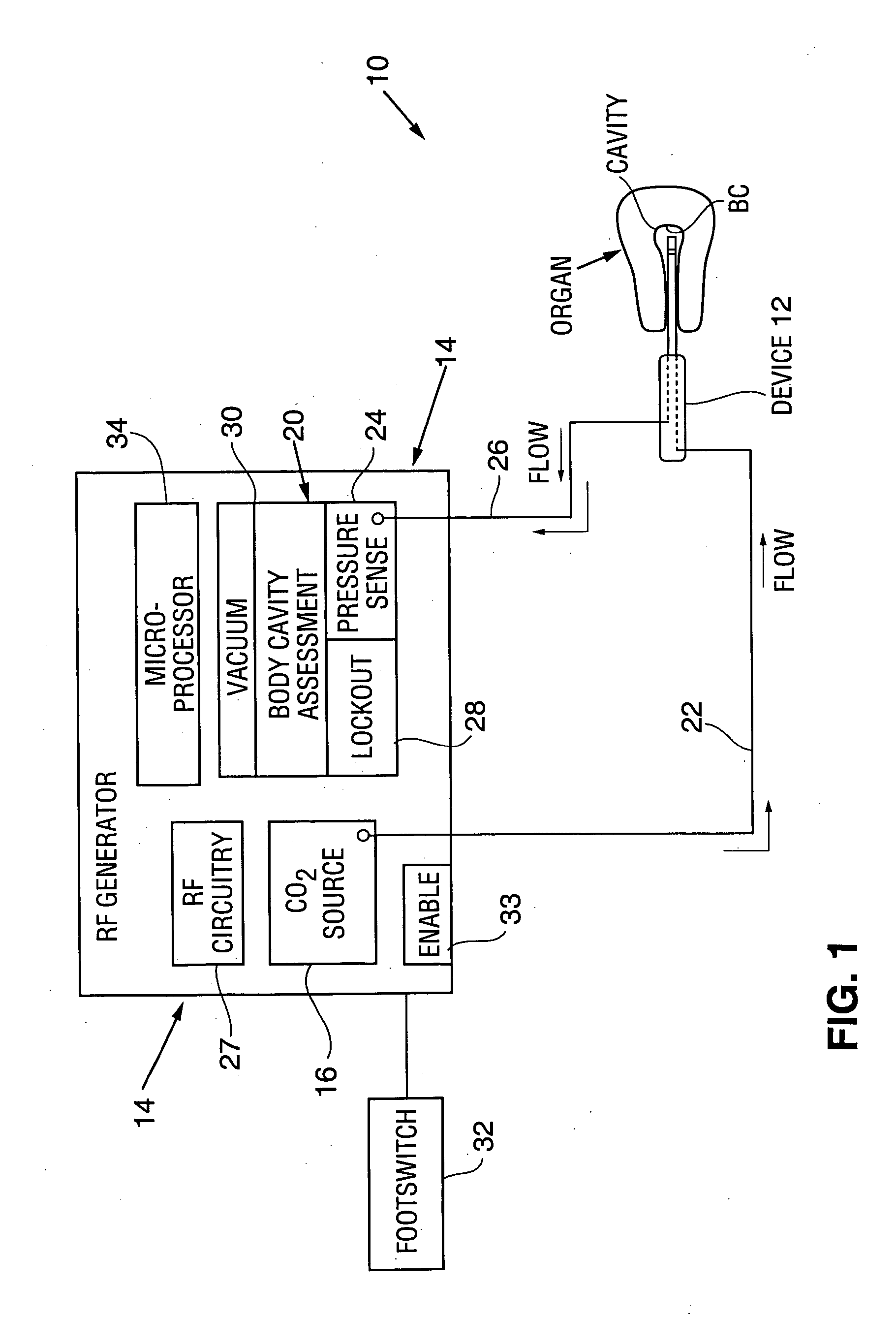

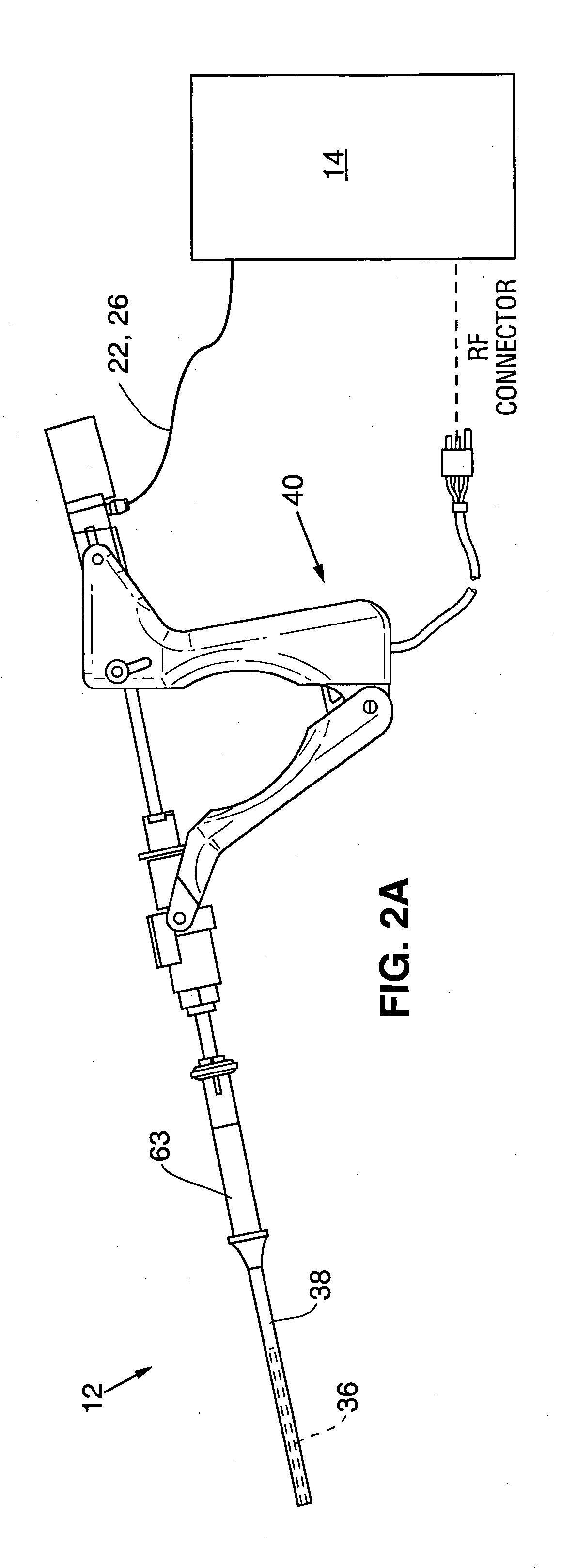

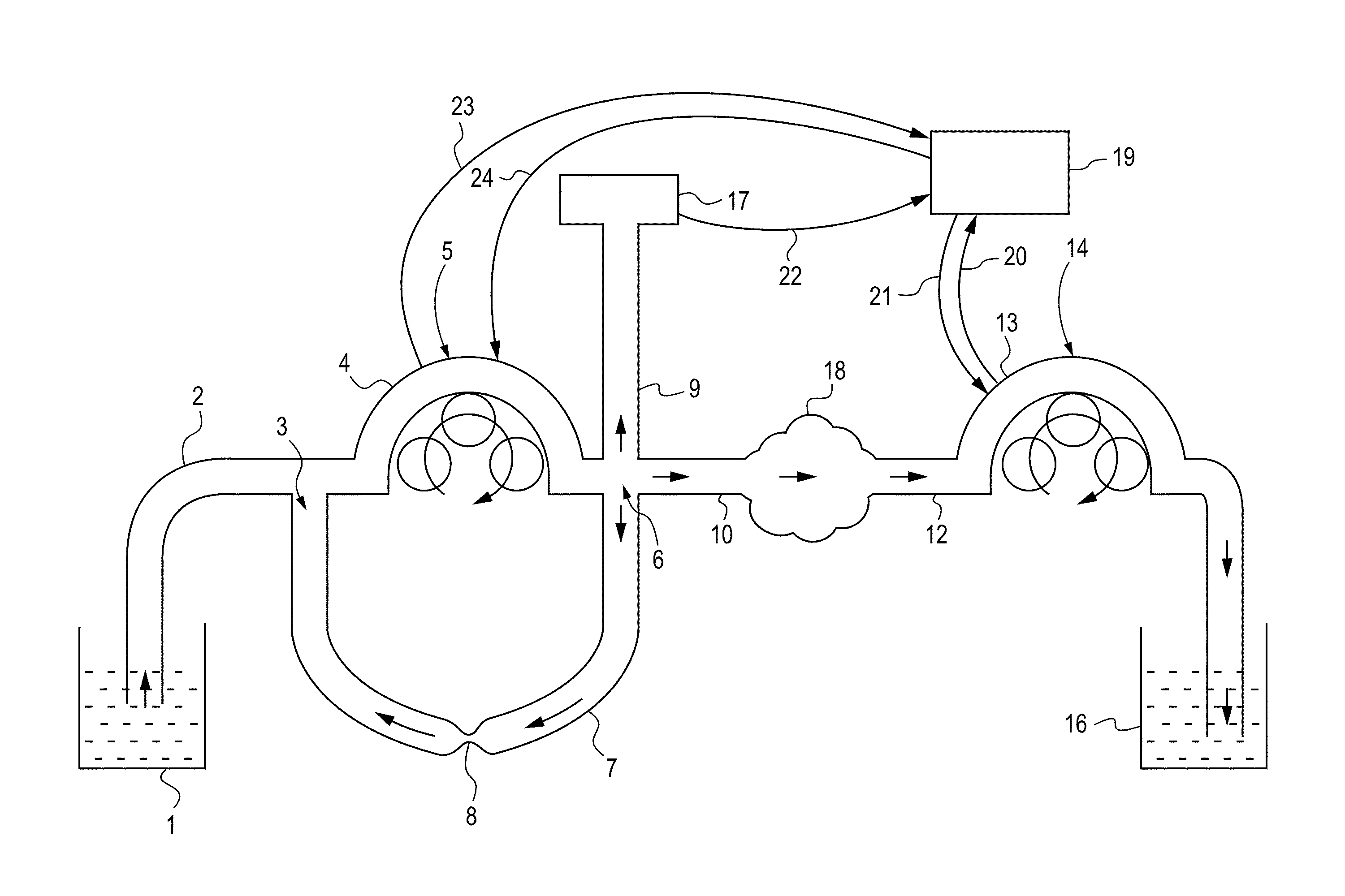

System and method for detecting perforations in a body cavity

A system and method for detecting perforations in a body cavity. In accordance with the method of the invention, a fluid (liquid or gas) is delivered into a body cavity to slightly pressurize the cavity. A pressure sensing system monitors the pressure within the cavity for a predetermined test period. If cavity pressure is not substantially sustained during the test period, the physician is alerted to further assess the cavity for perforations before initiating treatment within the cavity. In a preferred form of the system, a medical treatment system such as an RF ablation system is provided with perforation detection functionality. The system preferably includes a pre-test and post-test lockout system. The lockout system prevents RF power delivery unless, during a predetermined test period, the pressure sensing system determines that no perforation exists, or unless a previously performed perforation detection procedure determined a perforation was present but the lockout system was subsequently overridden by the physician.

Owner:HOLOGIC INC

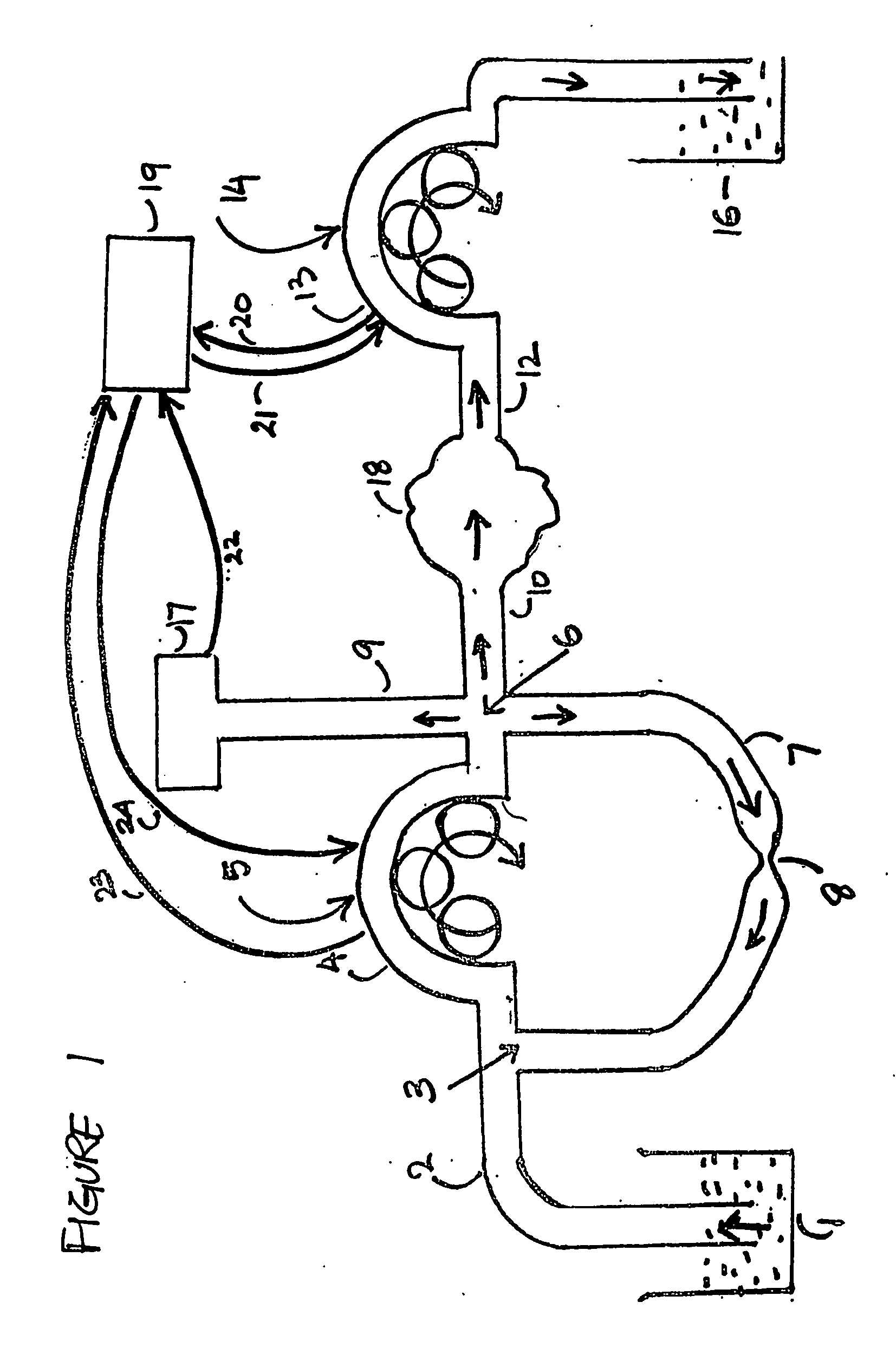

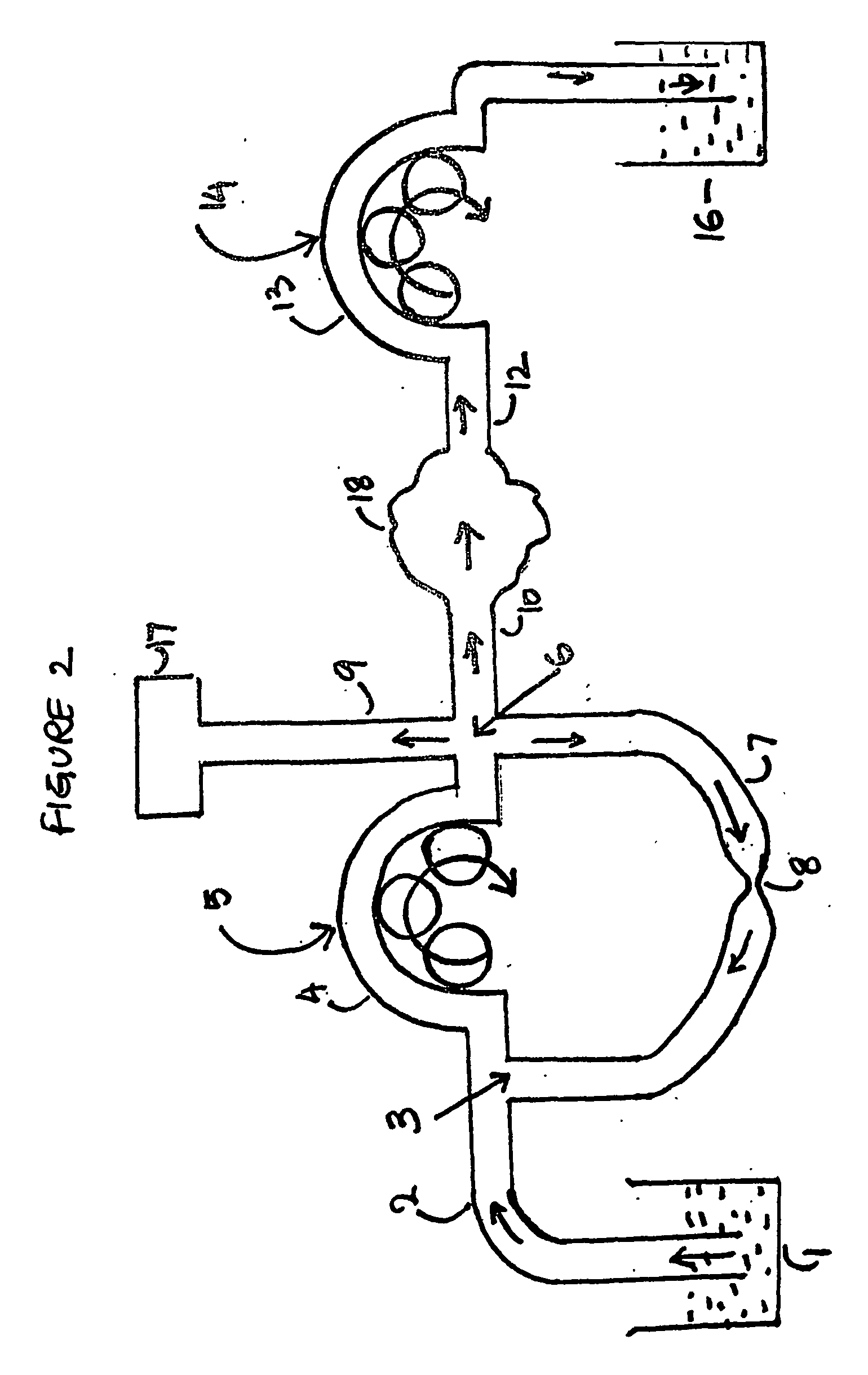

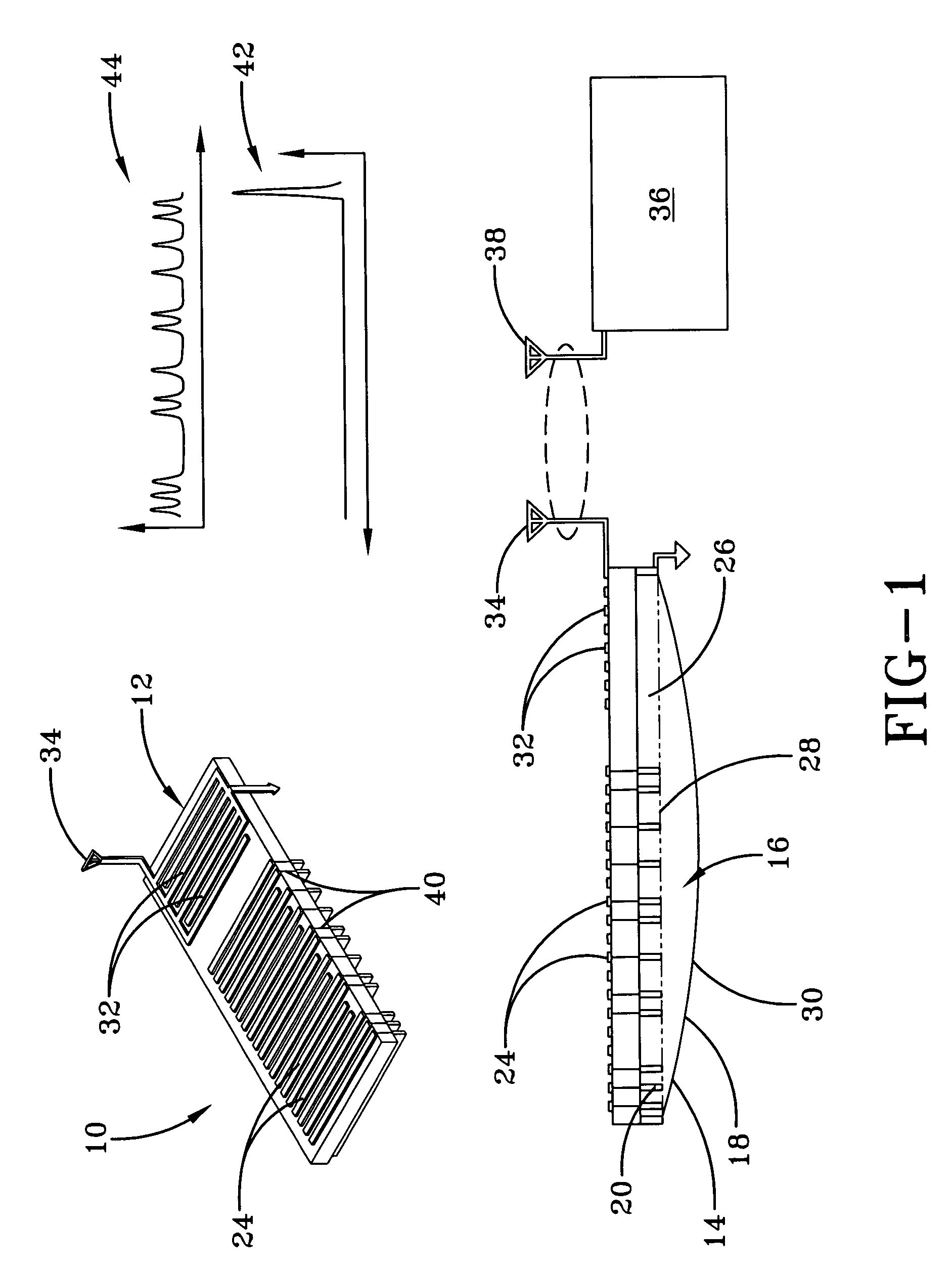

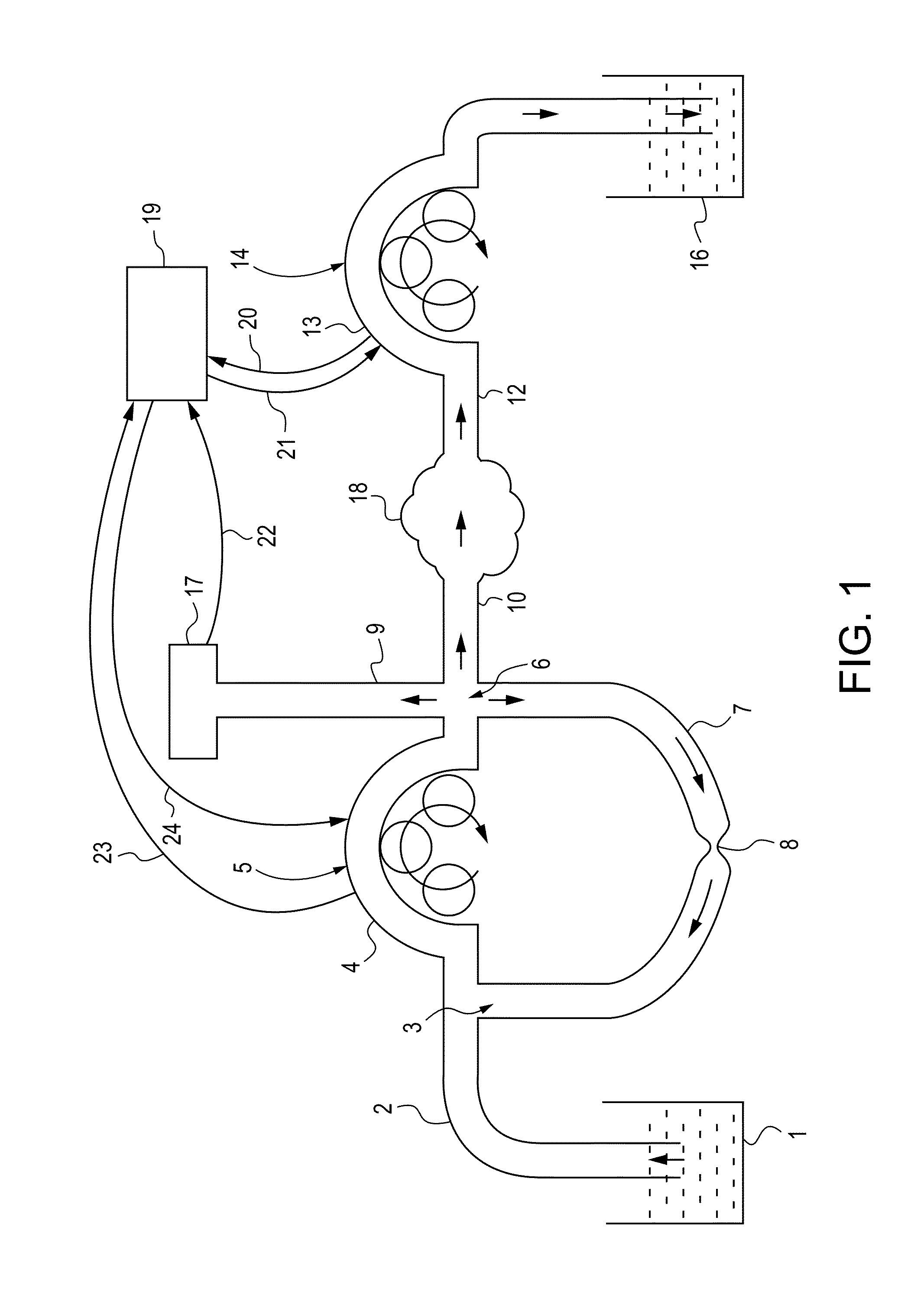

System for distending body tissue cavities by continuous flow irrigation

ActiveUS20070021713A1Shorten the timeMinimize exposureEnemata/irrigatorsMedical devicesContinuous flowEndoscopic Procedure

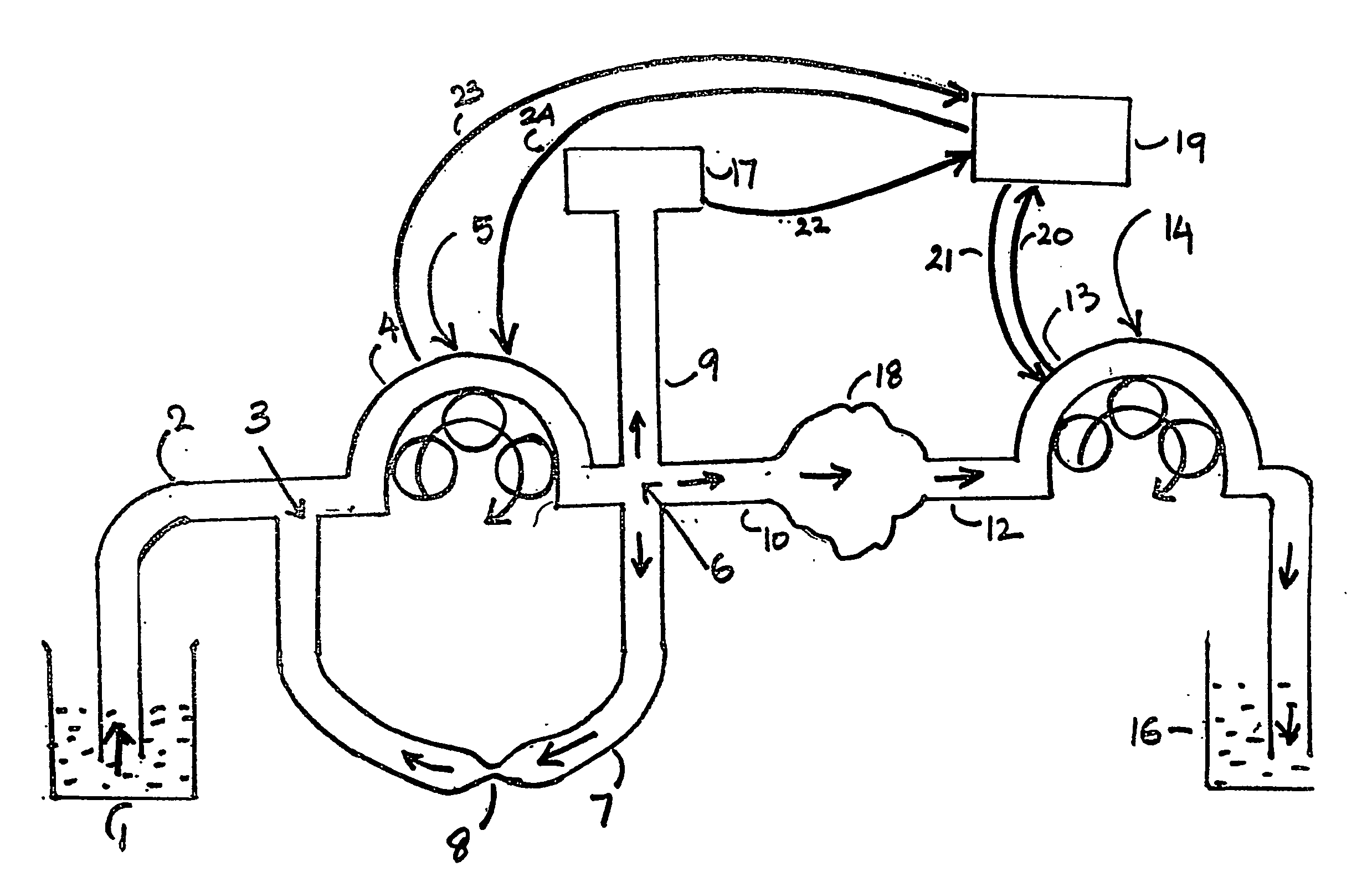

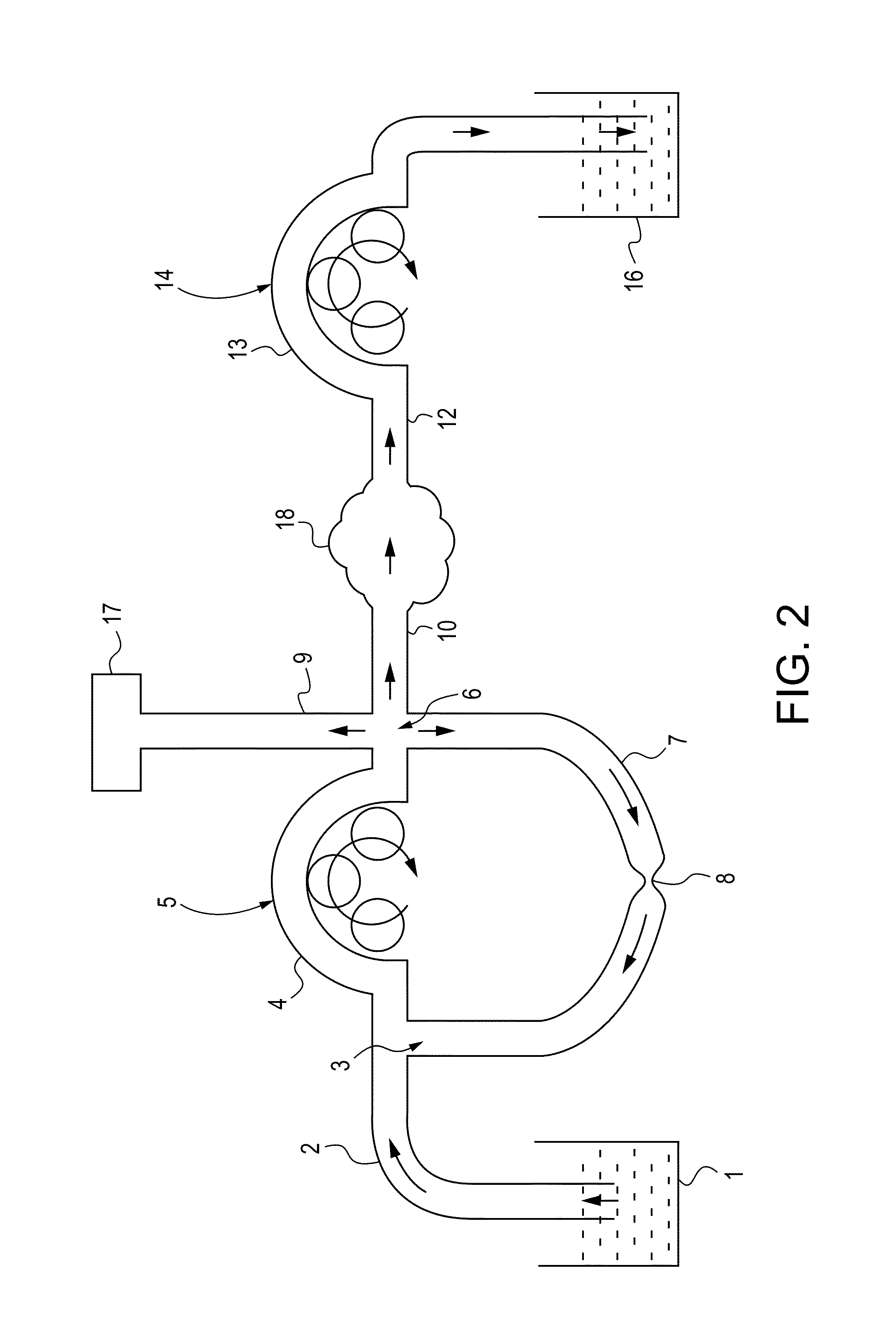

The present invention provides a system and a method for distending a body tissue cavity of a subject by continuous flow irrigation such that minimal or negligible fluid turbulence is present inside the cavity, such that any desired cavity pressure can be created and maintained for any desired outflow rate. The present invention also provides a method for accurately determining the rate of fluid loss, into the subject's body system, during any endoscopic procedure without utilizing any deficit weight or fluid volume calculation or flow rate sensor. The system and the methods of the present invention described above can be used in any endoscopic procedure requiring continuous flow irrigation few examples of such endoscopic procedures being hysteroscopic surgery, arthroscopic surgery, trans uretheral surgery, endoscopic surgery of the brain and endoscopic surgery of the spine.

Owner:ARTHREX

Chip-scale atomic clock (CSAC) and method for making same

A clock including: a portable, at least partially evacuated housing; a cell being positioned within the housing and including an internal cavity having interior dimensions each less than about 1 millimeter, an intra-cavity pressure of at least about 760 Torr, and containing a metal atomic vapor; an electrical to optical energy converter being positioned within the housing to emit light through the metal atomic vapor; an optical energy intensity detector being positioned within the housing to receive the light emitted by the converter through the metal atomic vapor; at least one conductive winding around the cavity to stabilize the magnetic field experienced in the cavity dependently upon the detector; and, an output to provide a signal from the housing dependently upon the detector detecting the light emitted by the converter through the metal atomic vapor.

Owner:SARNOFF CORP

System and method for detecting perforations in a body cavity

A system and method for detecting perforations in a body cavity. In accordance with the method of the invention, a fluid (liquid or gas) is delivered into a body cavity to slightly pressurize the cavity. A pressure sensing system monitors the pressure within the cavity for a predetermined test period. If cavity pressure is not substantially sustained during the test period, the physician is alerted to further assess the cavity for perforations before initiating treatment within the cavity. In a preferred form of the system, a medical treatment system such as an RF ablation system is provided with perforation detection functionality. The system preferably includes a pre-test and post-test lockout system. The lockout system prevents RF power delivery unless, during a predetermined test period, the pressure sensing system determines that no perforation exists, or unless a previously performed perforation detection procedure determined a perforation was present but the lockout system was subsequently overridden by the physician.

Owner:NOVACEPT

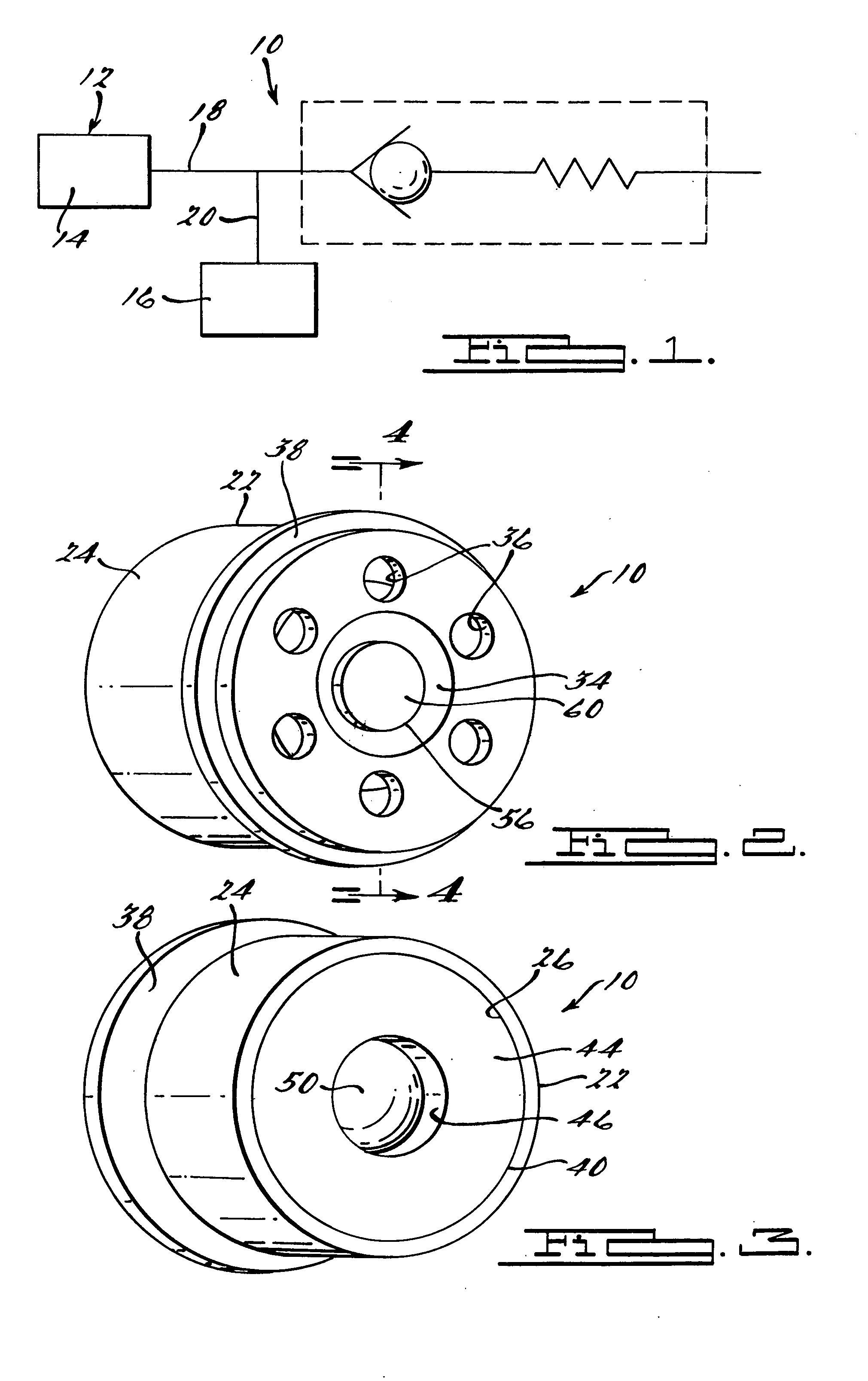

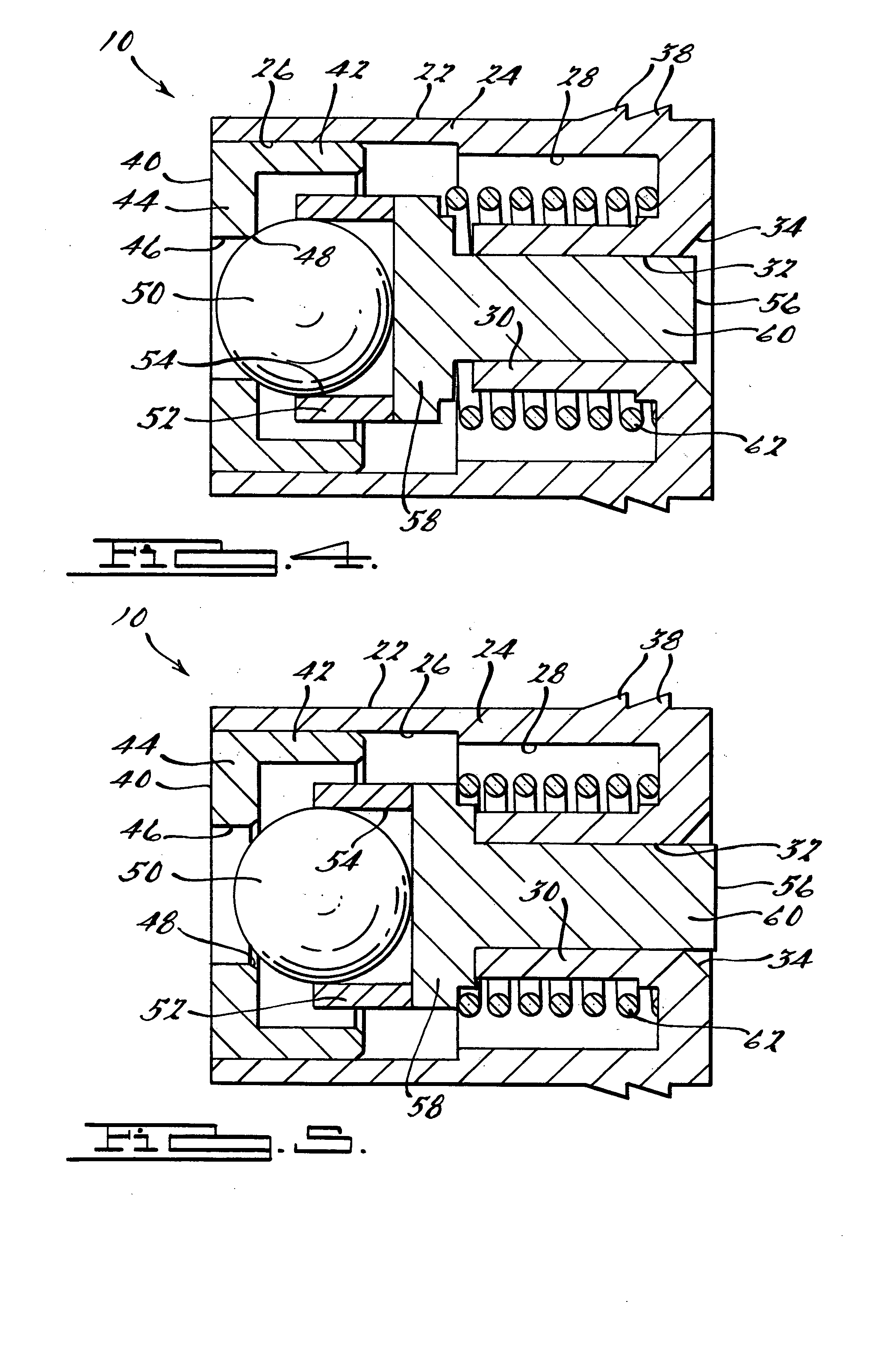

Pressure regulator assembly

InactiveUS20050061372A1Reduce in quantityLow costCheck valvesLow pressure fuel injectionEngineeringCavity pressure

A pressure regulator assembly for a fluid system includes a housing having at least one cavity therein and a valve seat disposed in the at least one cavity and having an aperture extending therethrough. The pressure regulator assembly also includes a movable valve member disposed in the at least one cavity of the housing. The valve member has a closed position to engage the valve seat to prevent fluid from flowing into the at least one cavity and an open position to disengage the valve seat to allow fluid to flow into the at least one cavity. The pressure regulator assembly further includes a biasing mechanism disposed in the at least one cavity to bias the valve member toward the valve seat to close the aperture. The valve seat and the valve member and the biasing mechanism are aligned linearly along an axis of the valve housing.

Owner:MCGRATH DENNIS P +3

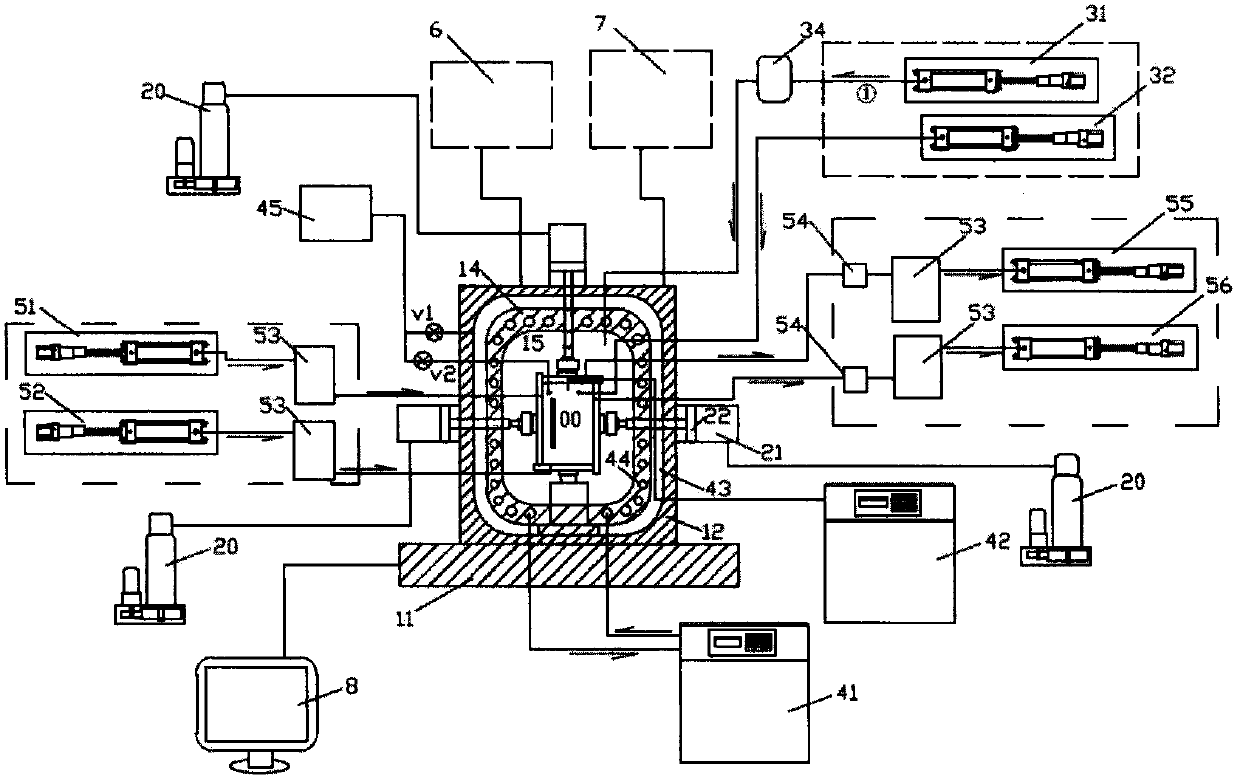

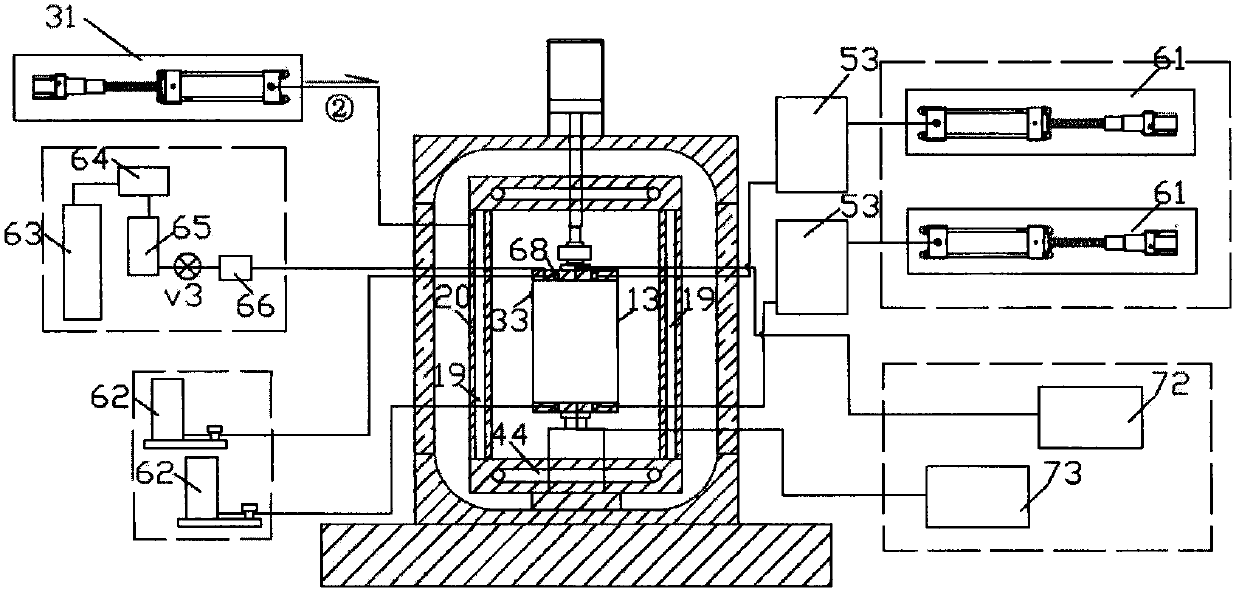

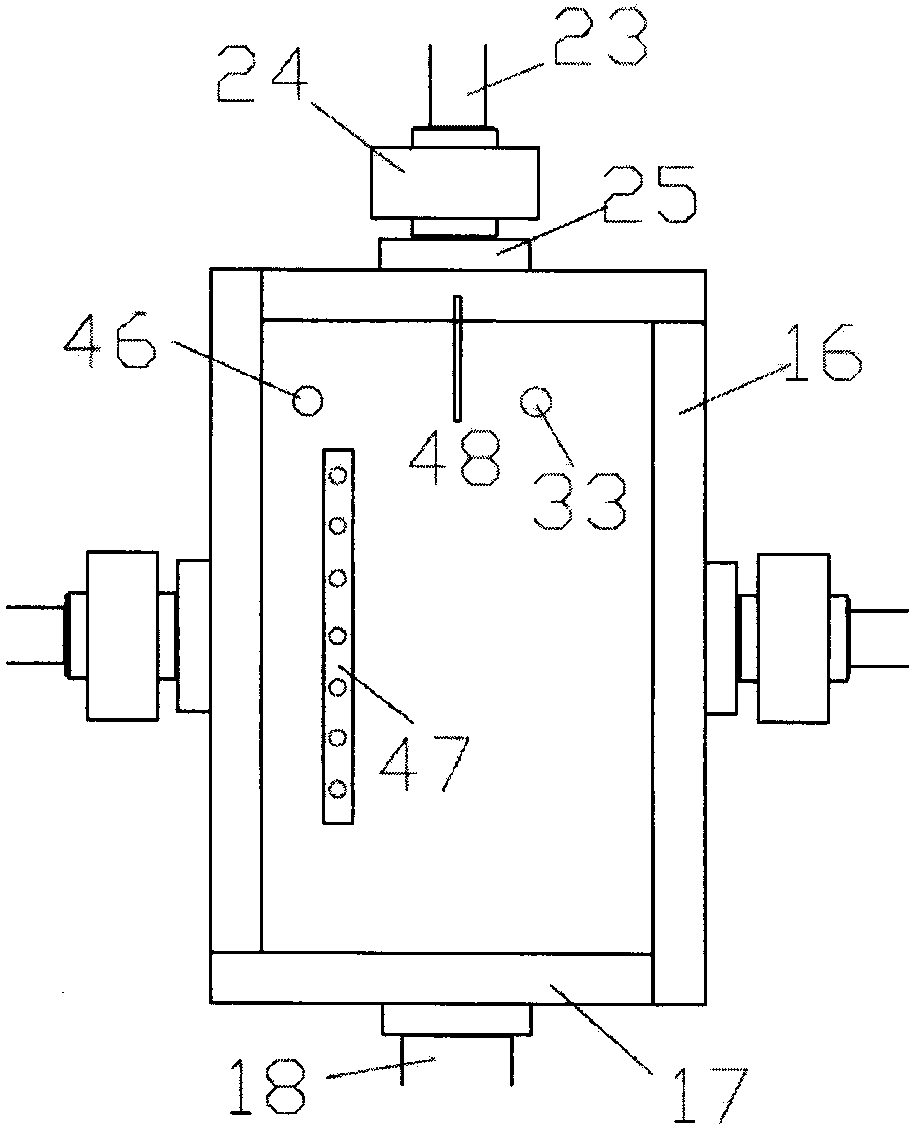

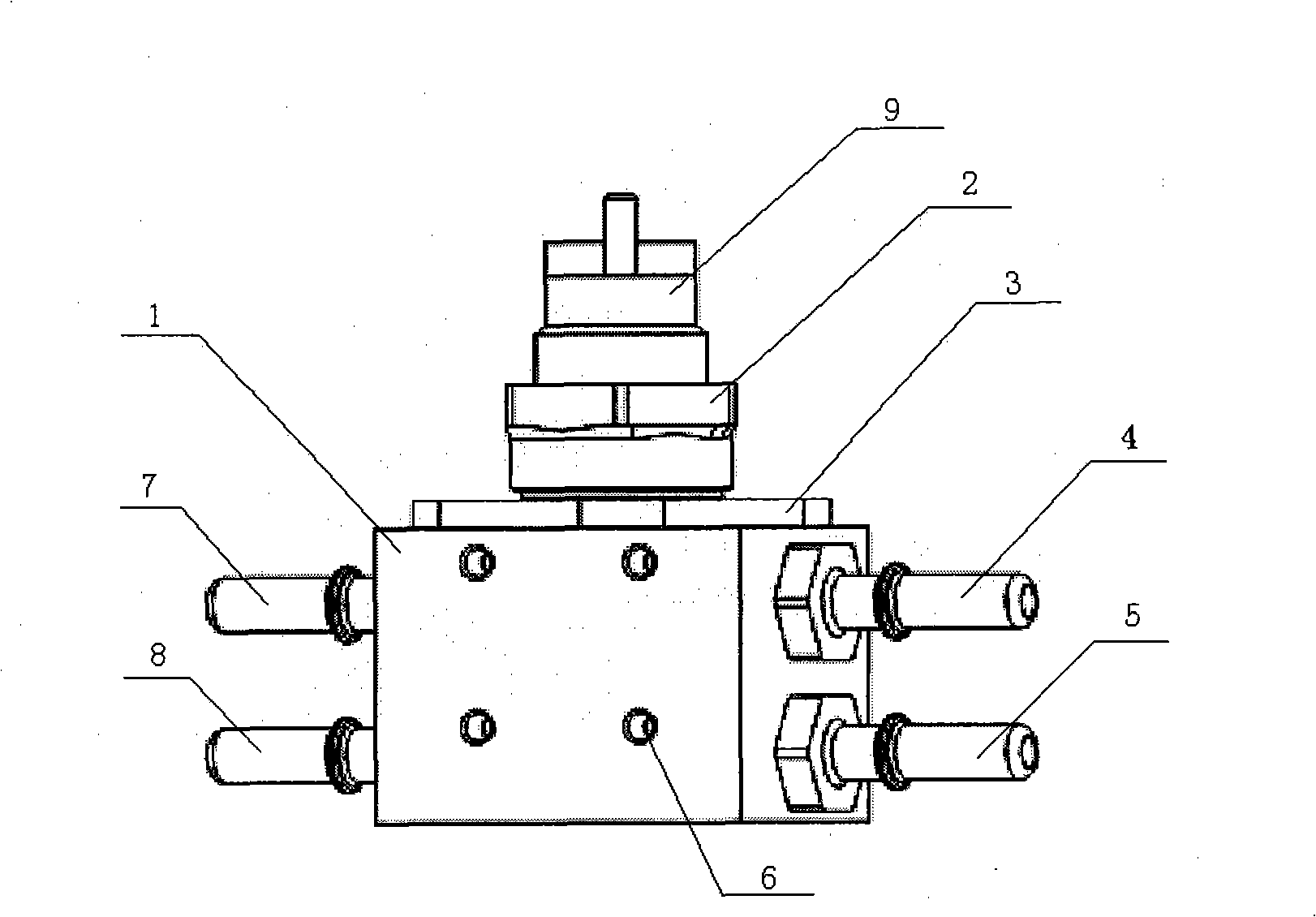

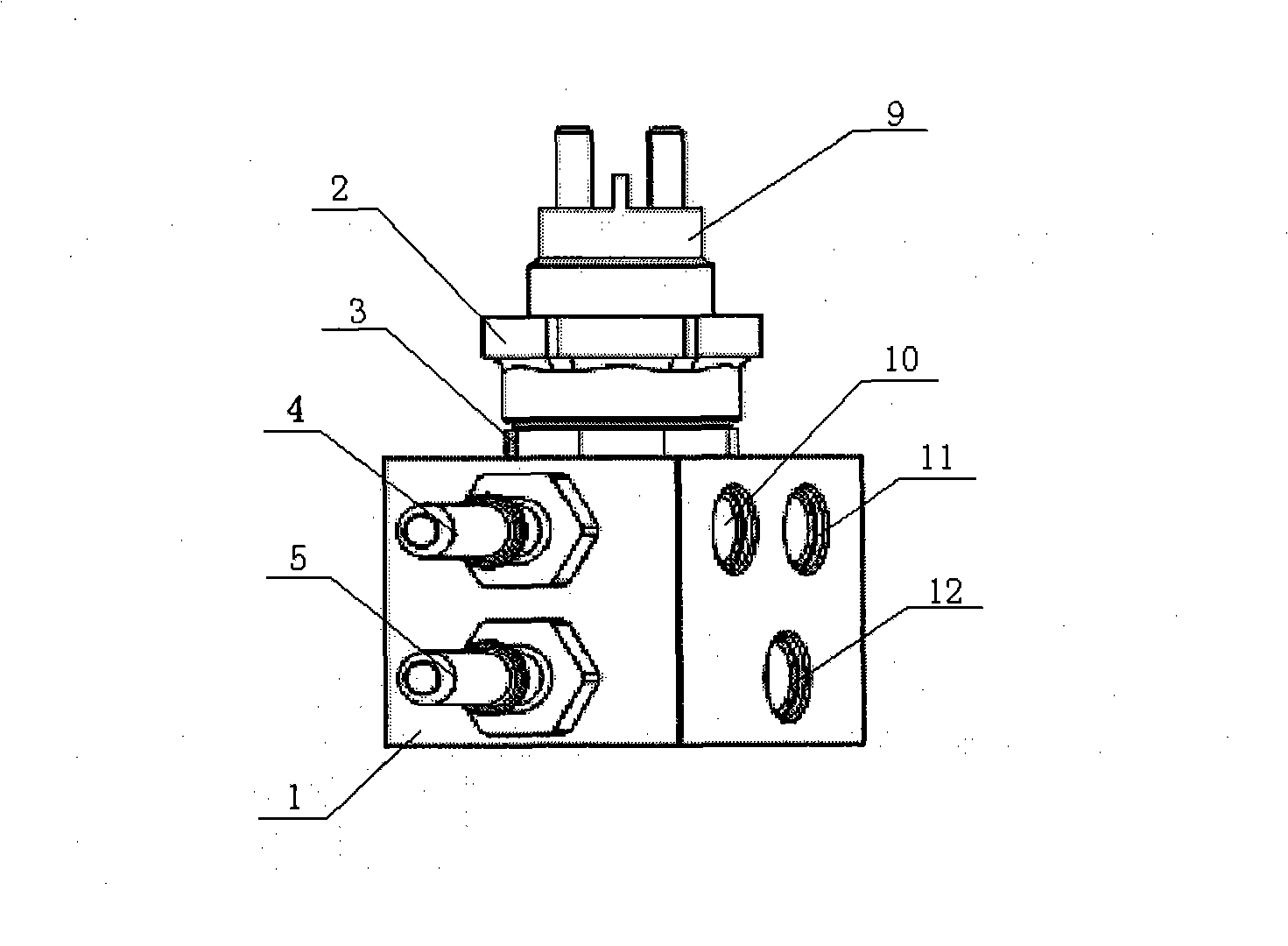

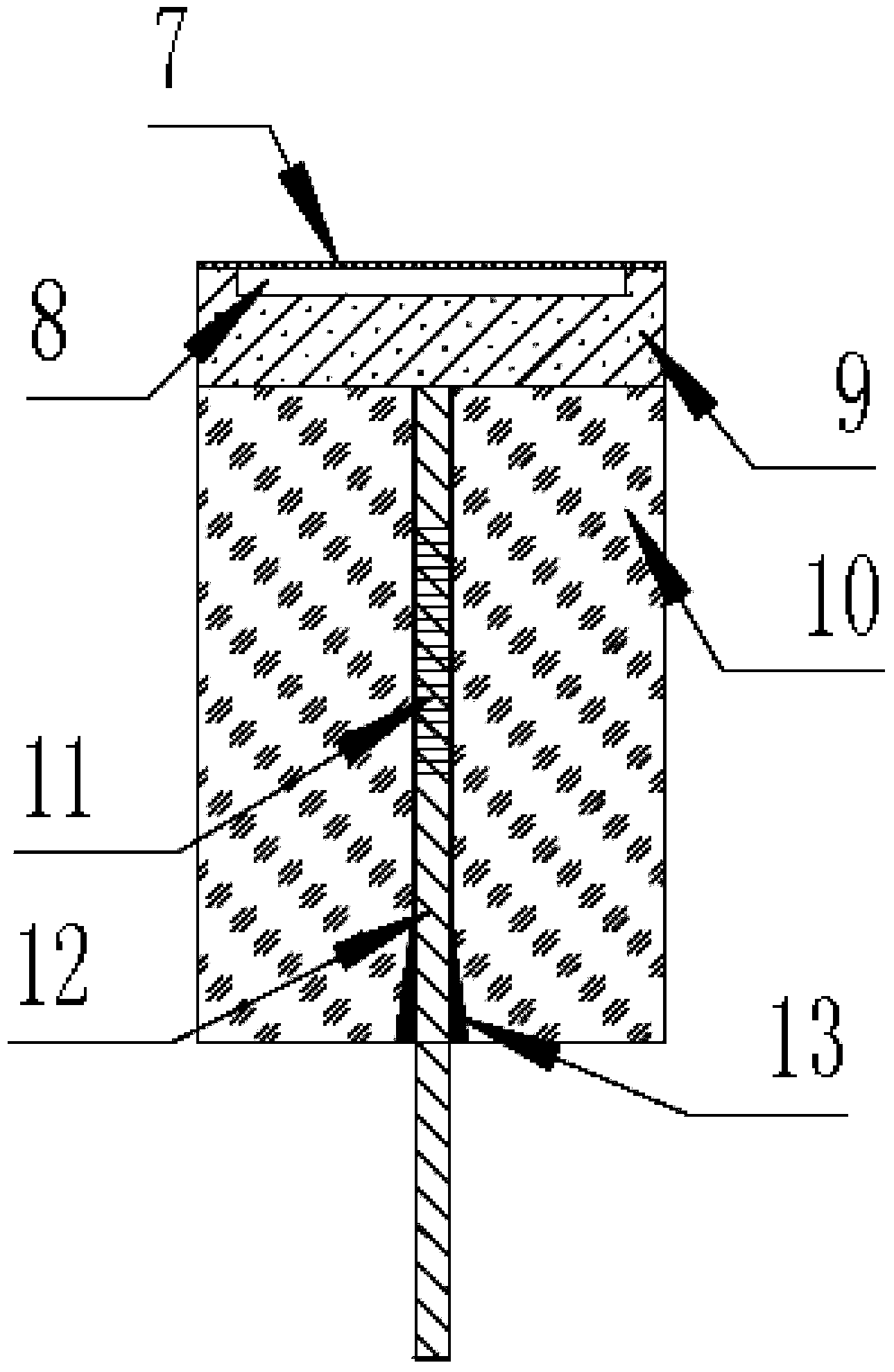

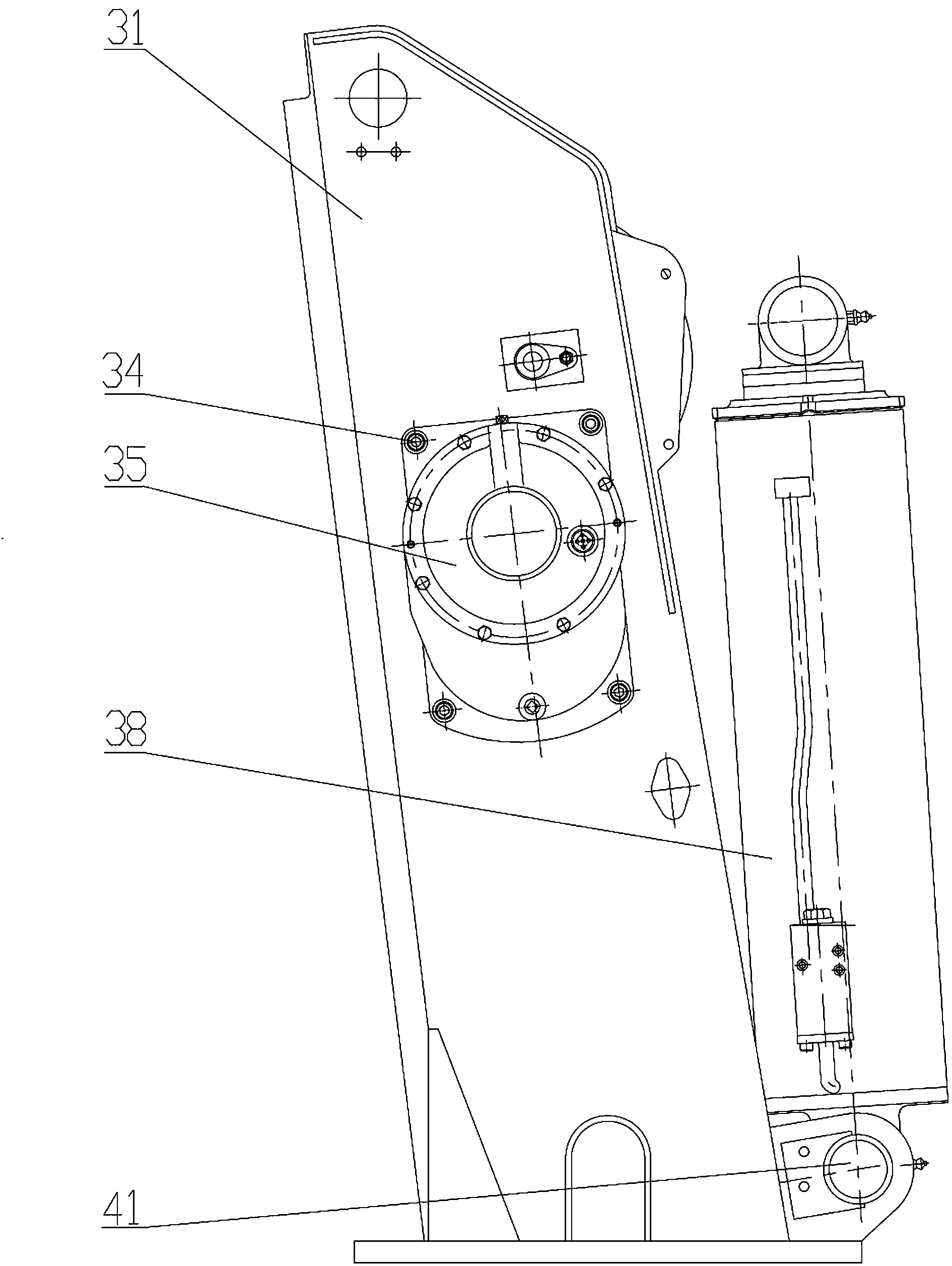

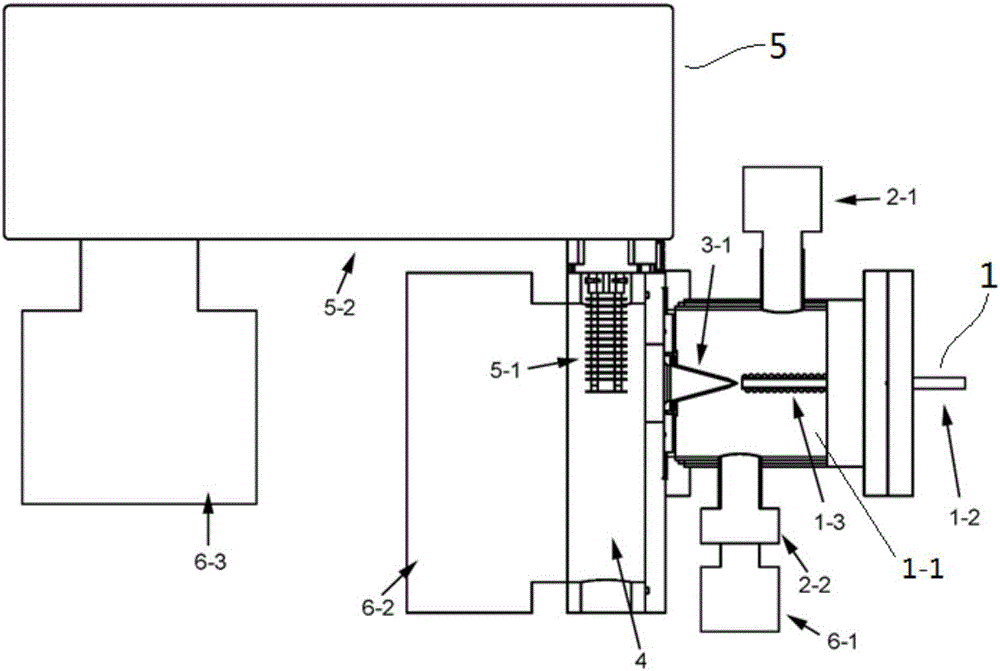

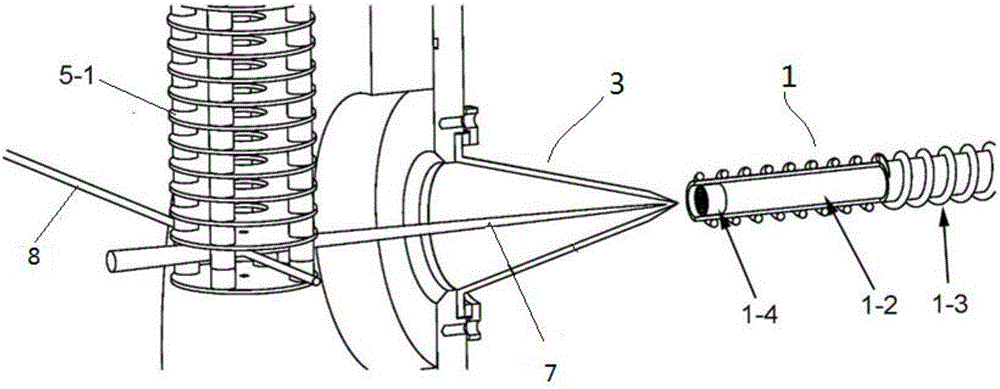

Multi-field coupling true triaxial test system and experiment method implemented by same

ActiveCN107576562AImprove accuracyRealize dockingMaterial strength using tensile/compressive forcesPermeability/surface area analysisDecompositionMulti field

The invention discloses a multi-field coupling true triaxial test system and an experiment method implemented by the same. The multi-field coupling true triaxial test system is characterized by comprising a true triaxial double-cavity pressure chamber (1), an axial loading system (2), a confining pressure / back pressure loading system (3), a temperature control system (4), a permeation control system (5), a gas loading system (6), a bending element experiment system (7) and a computer (8). The multi-field coupling true triaxial test system and the experiment method have the advantages that stress fields and seepage fields are controlled, and accordingly simulation research can be carried out on seepage anisotropy of rock and soil mass; influence of environmental factors on freezing nucleusor frozen soil samples can be simulated under the effects of temperature fields, the seepage fields and the stress fields; research can be carried out on the physical and mechanical properties of unsaturated frozen soil under the effects of the temperature fields and the stress fields; simulation research can be carried out on change of the physical and earth properties of sediments in generationand decomposition procedures of natural hydrates under multi-field coupling conditions, and simulation research can be carried out on mutual displacement effects between hydrate gas in the sediments and underground water; simulation research can be carried out on the physical and mechanical properties of unsaturated soil under the multi-field coupling conditions.

Owner:南京泰克奥科技有限公司

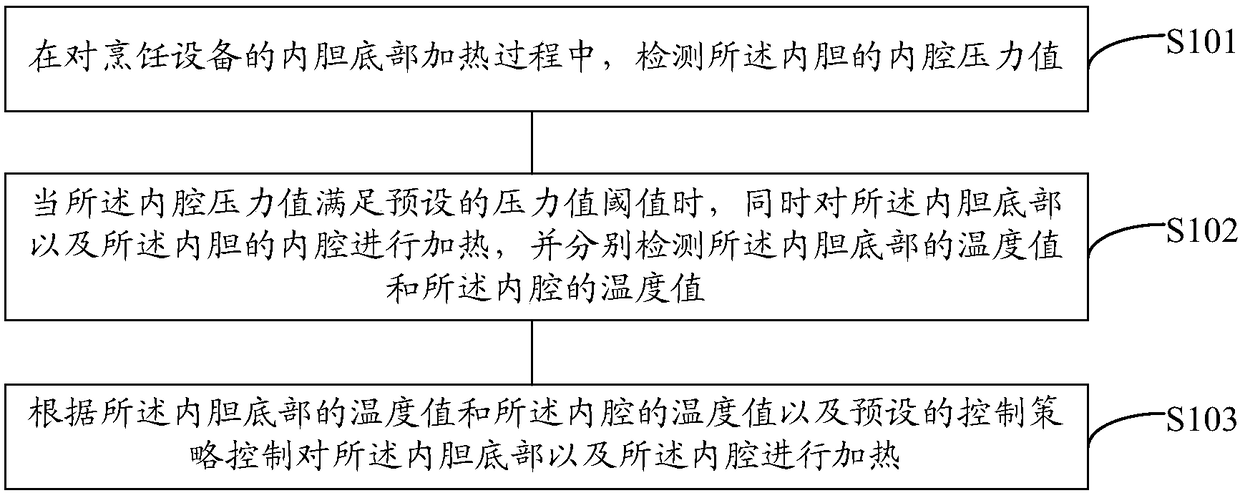

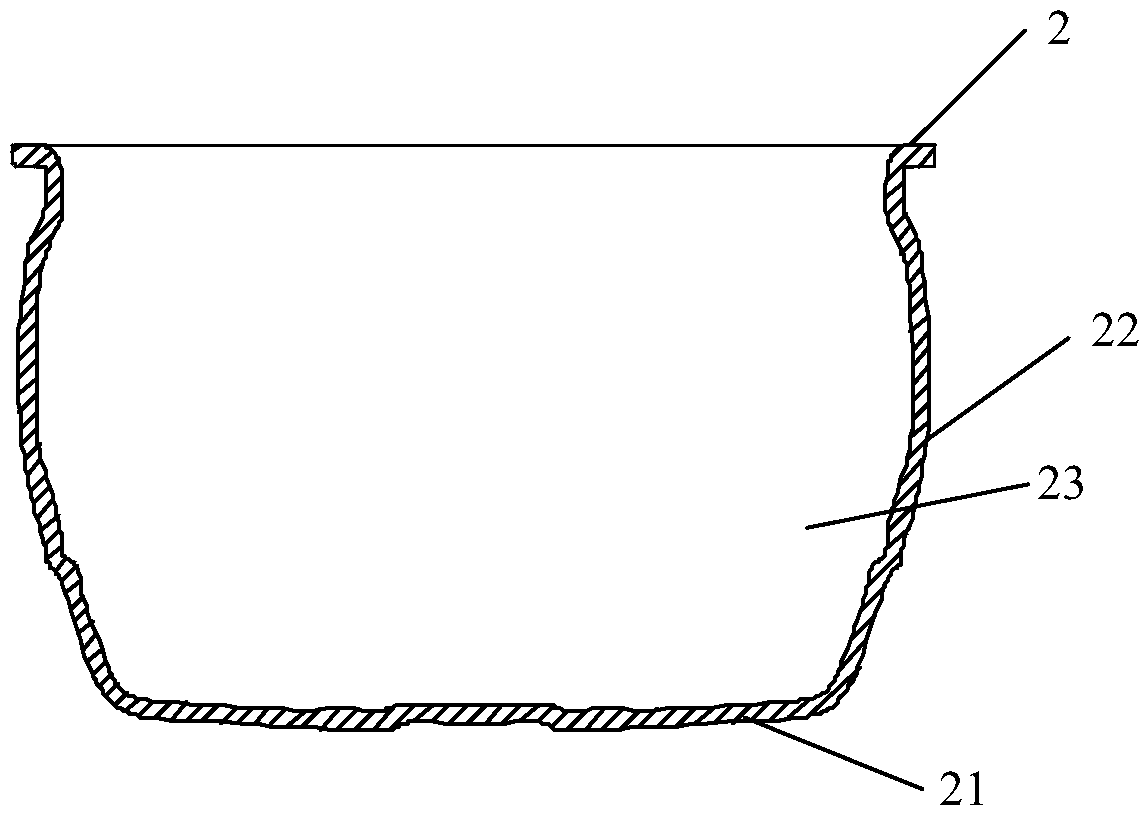

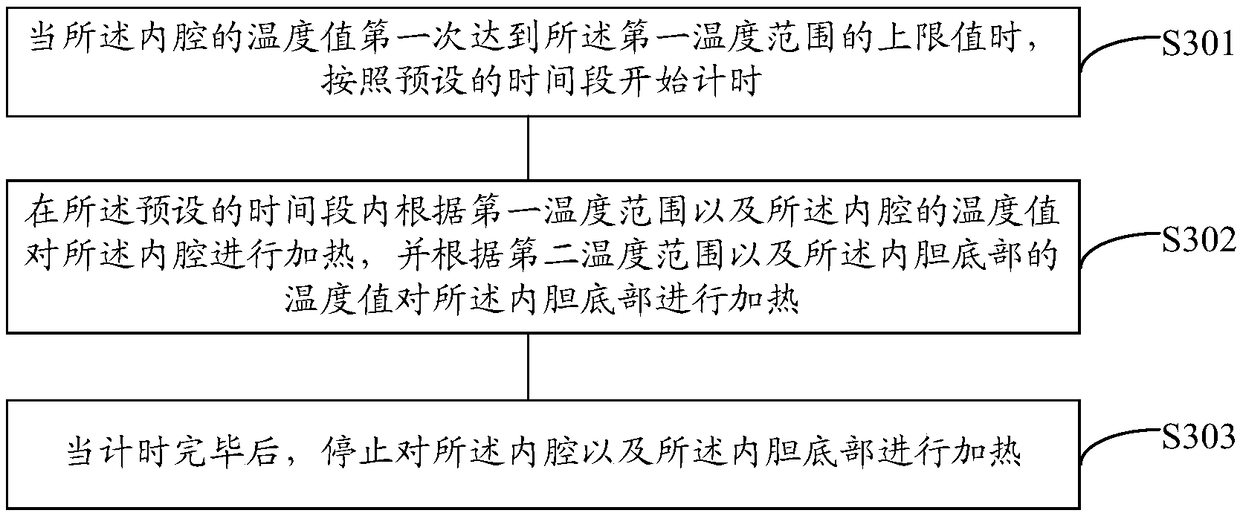

Control method and device

PendingCN108720577AGreat tasteImprove efficiencyRoasters/grillsPressure-cookersProcess engineeringCavity pressure

The embodiment of the invention discloses a control method and device. The control method can include the steps that in the process that the bottom of an inner container of a cooking device is heated,an inner-cavity pressure value of the inner container is detected; when the inner-cavity pressure value meets a preset pressure threshold value, the bottom of the inner container and an inner cavityof the inner container are simultaneously heated, and a temperature value of the bottom of the inner container and a temperature value of the inner cavity are detected respectively; according to the temperature value of the bottom of the inner container, the temperature value of the inner cavity and the preset control strategy, the bottom of the inner container and the inner cavity are controlledto be heated. Whole cooking food materials can be heated accordingly, the decocting, baking and roasting function of an electric pressure cooker for the cooking food materials is achieved, the taste of the cooking food materials can also be better than that of common cooking food materials, and the using efficiency and the cooking effect of the electric pressure cooker are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

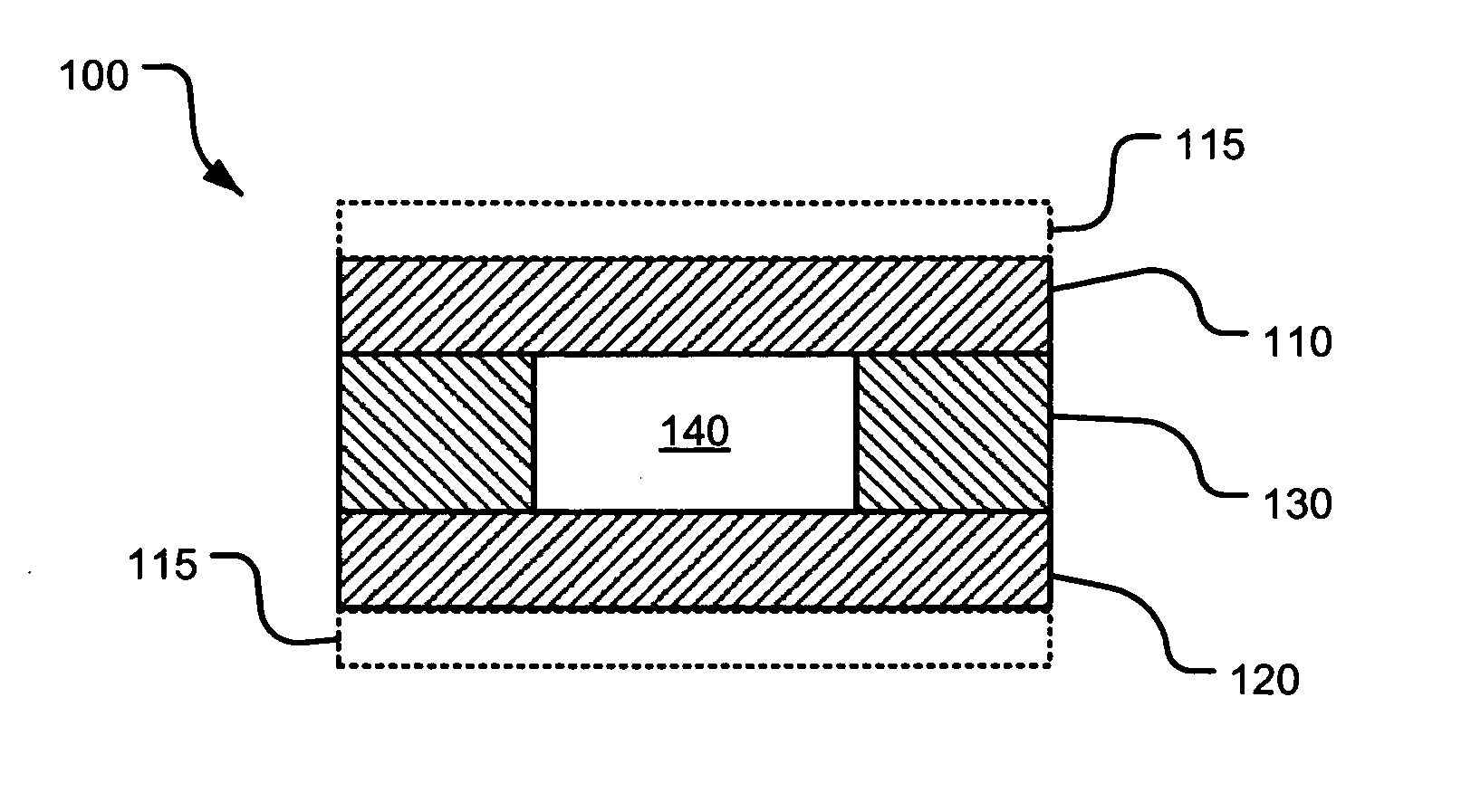

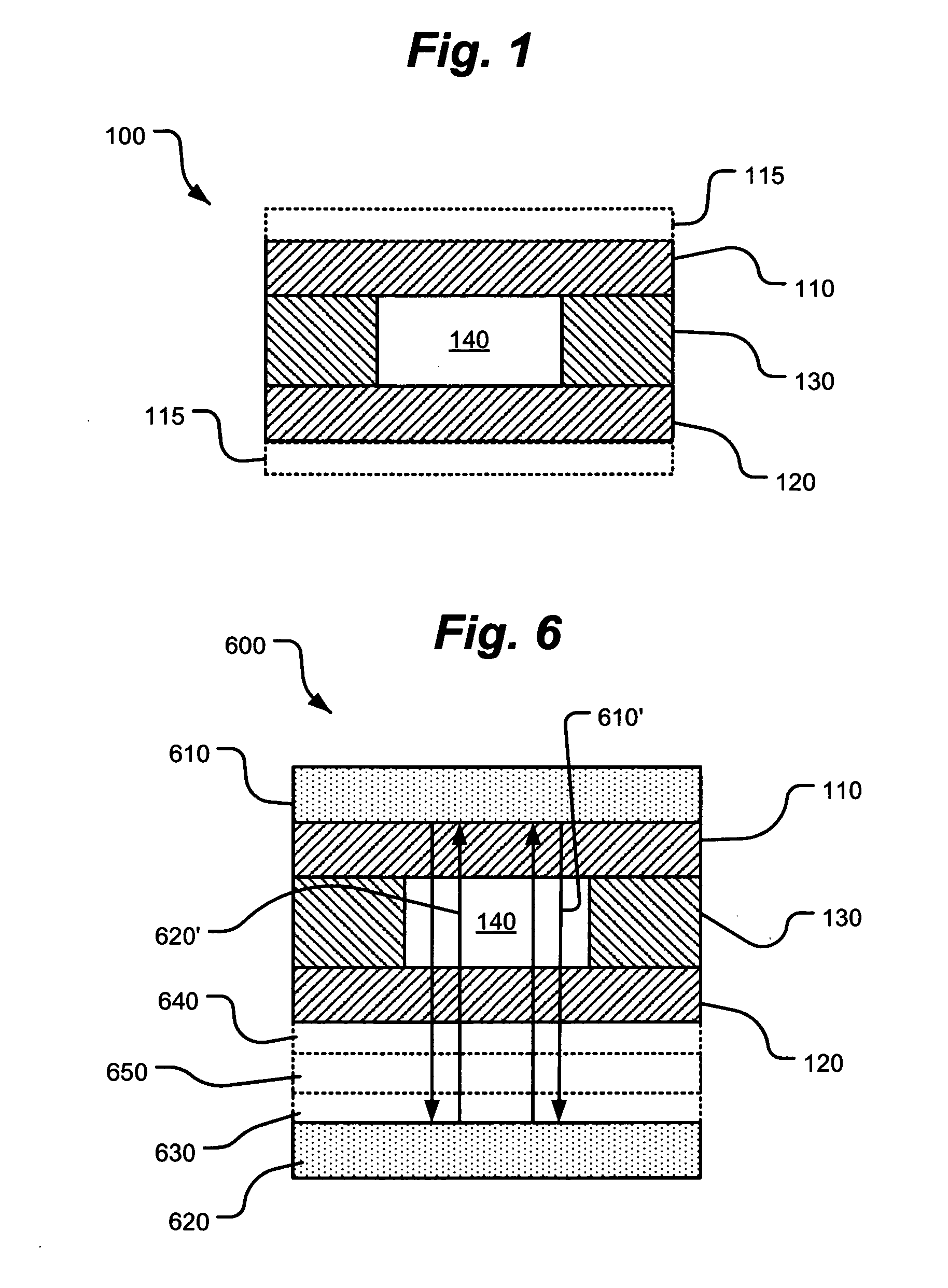

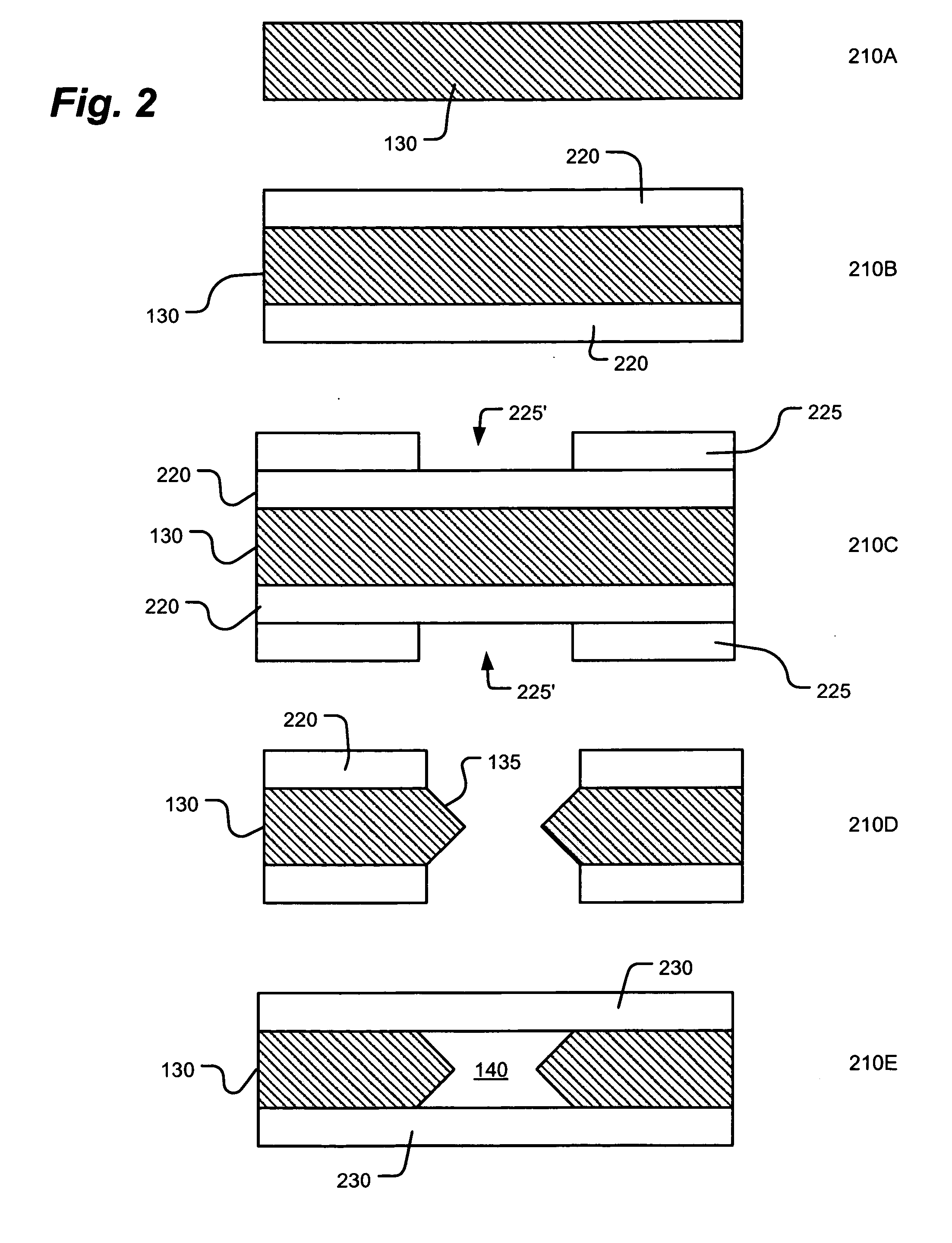

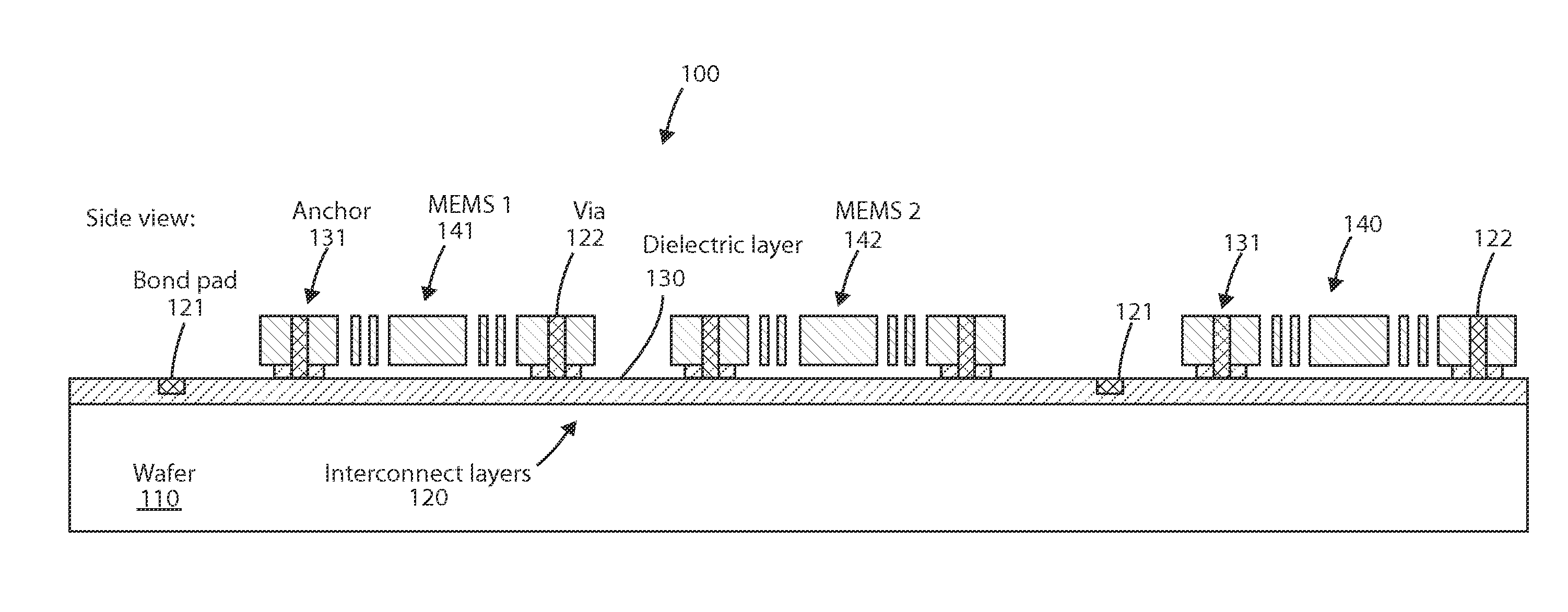

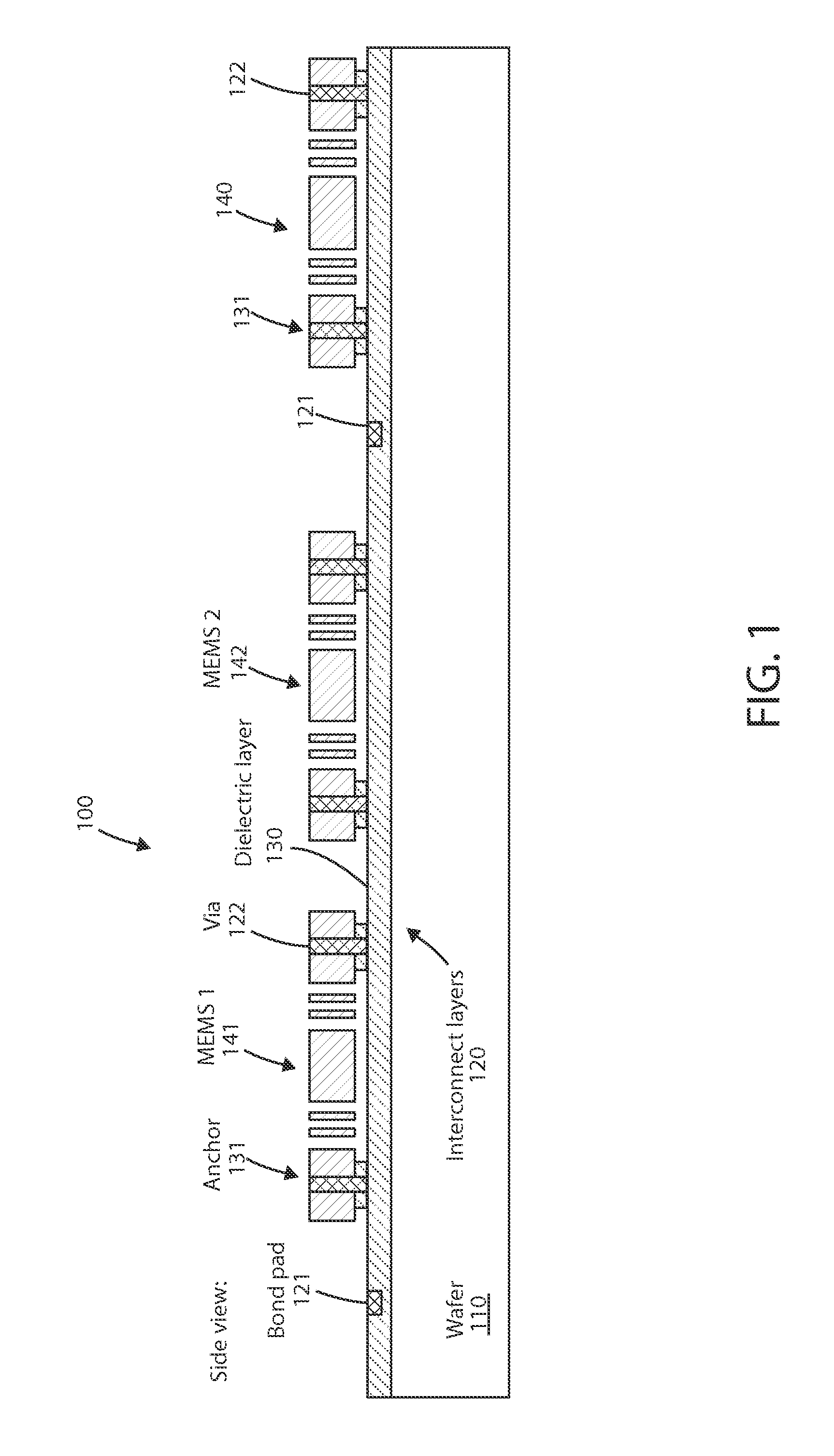

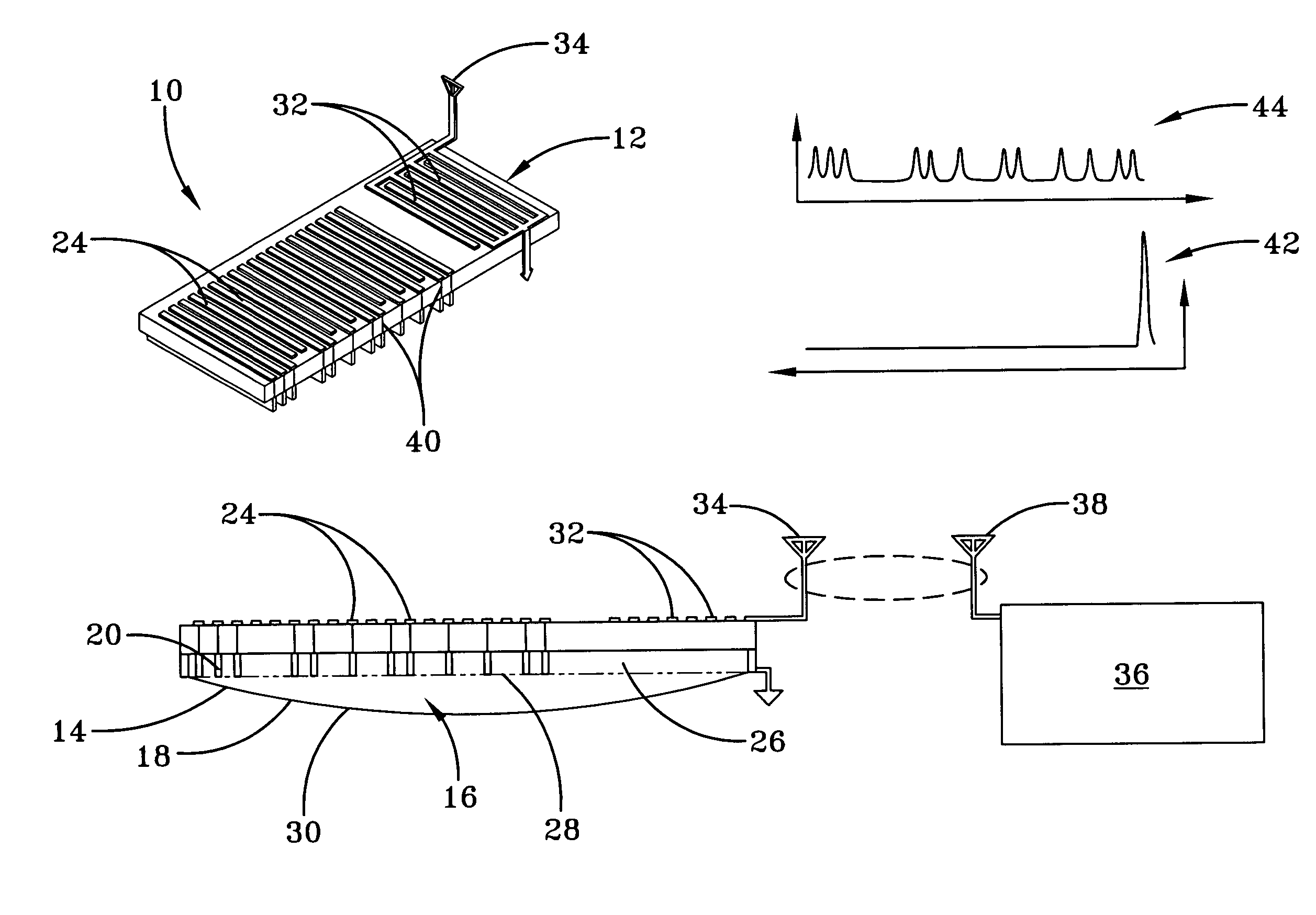

Method to package multiple MEMS sensors and actuators at different gases and cavity pressures

ActiveUS20140227816A1Increase dampingPerformanceDecorative surface effectsSemiconductor/solid-state device manufacturingCavity pressureMems sensors

A method for fabricating a multiple MEMS device. A semiconductor substrate having a first and second MEMS device, and an encapsulation wafer with a first cavity and a second cavity, which includes at least one channel, can be provided. The first MEMS can be encapsulated within the first cavity and the second MEMS device can be encapsulated within the second cavity. These devices can be encapsulated within a provided first encapsulation environment at a first air pressure, encapsulating the first MEMS device within the first cavity at the first air pressure. The second MEMS device within the second cavity can then be subjected to a provided second encapsulating environment at a second air pressure via the channel of the second cavity.

Owner:MOVELLA INC

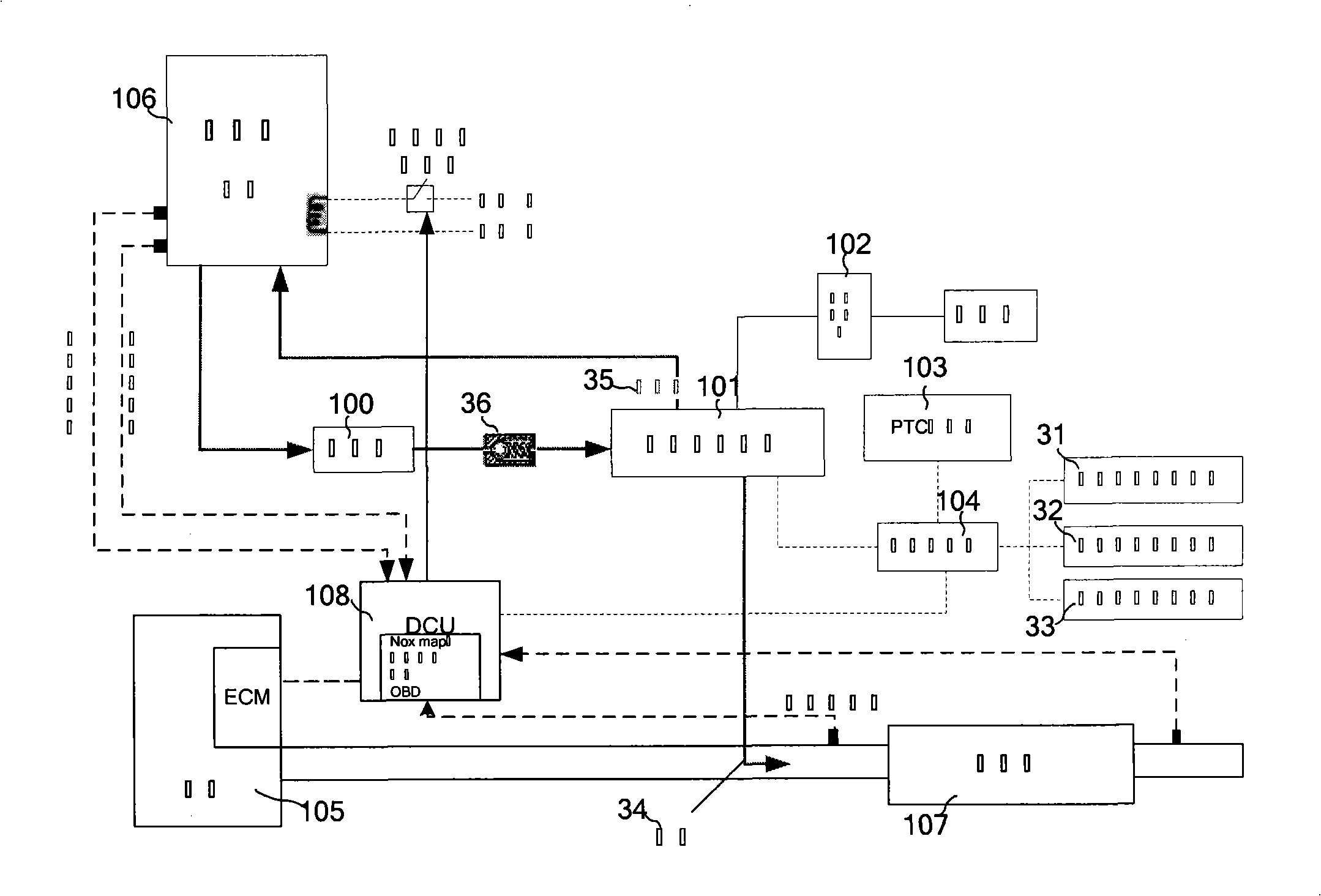

Air mixing and metering system for processing vehicle exhaust

ActiveCN101493027AGuaranteed reliabilityHigh measurement accuracyExhaust apparatusDispersed particle separationDiaphragm pumpSolenoid valve

The invention relates to an air incorporation measurement system used for vehicle exhaust-gas disposal. The system is characterized in that the measurement system comprises a measurement supply unit, a measurement drive part, an air solenoid valve, a spillover valve, a urea tank, a pressure accumulation cavity temperature sensor, a mixing cavity pressure sensor, a DCU control part, and a catalyst, etc. The measurement supply unit is connected with the catalyst, the air solenoid valve is connected with a quick coupling, an outlet quick coupling is connected with a nozzle by a pipeline, urea solution in the urea tank is conveyed to the measurement supply unit by a membrane pump, a reflux inlet is connected with the spillover valve by the quick coupling, the reflux flows to the urea tank, a compressed air inlet is connected with a compressed air source, and a mixing outlet sprays gas-liquid mixture into an exhaust duct through the nozzle by means of being connected with the pipeline. Themeasurement system of the invention features compact structure, small volume, light weight and accurate measurement, thus saving much space for vehicle layout while maintaining relatively high measuring accuracy and fog effect and ensuring reliability of normal operation in different areas and environments.

Owner:KAILONG HIGH TECH

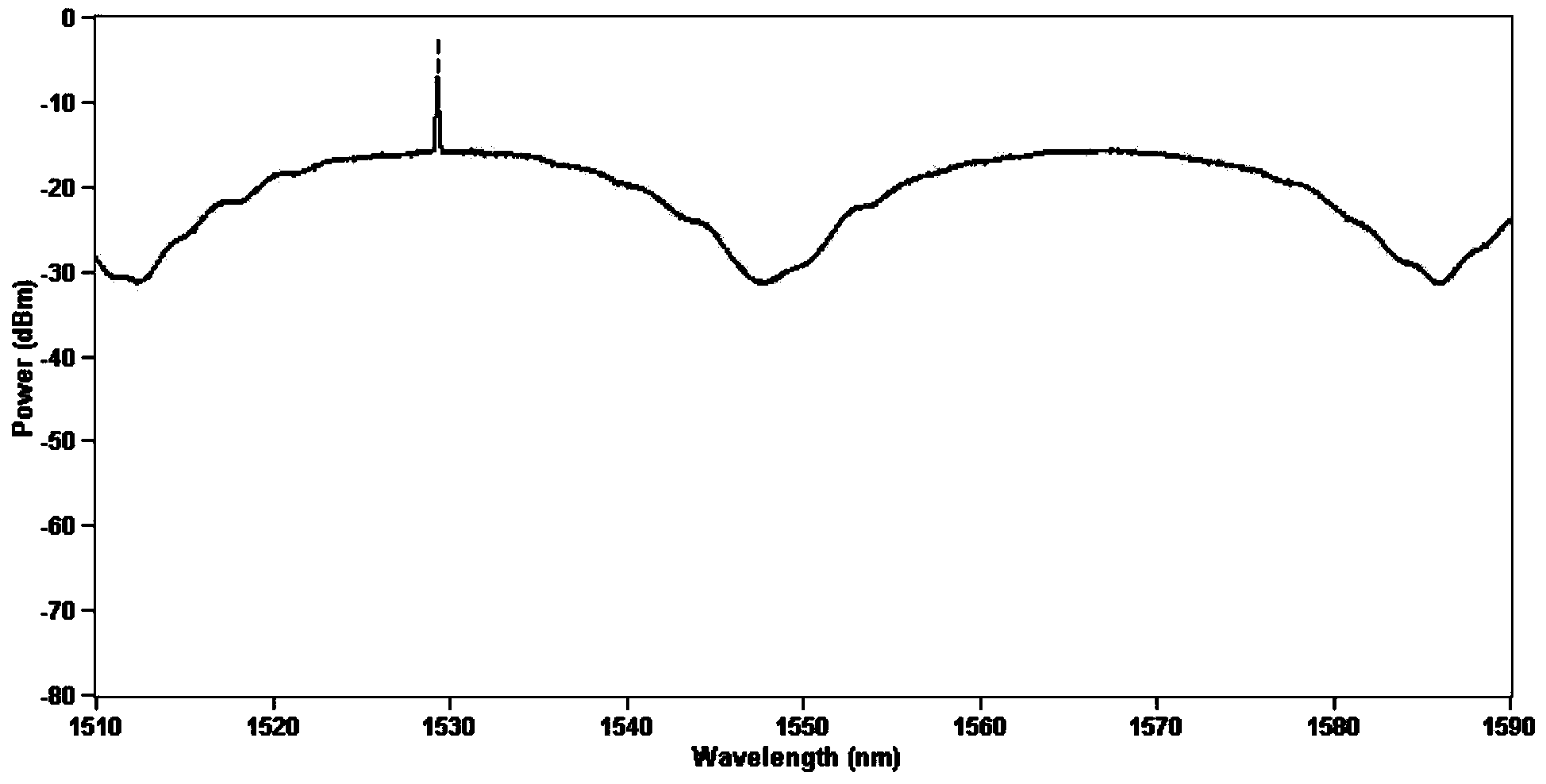

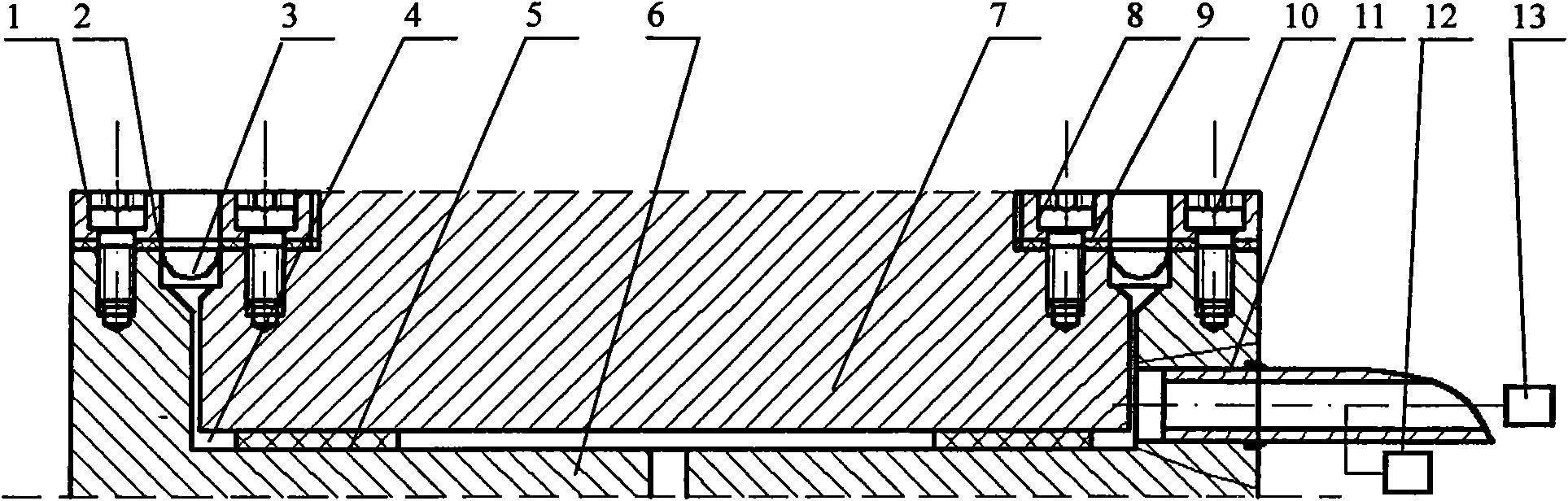

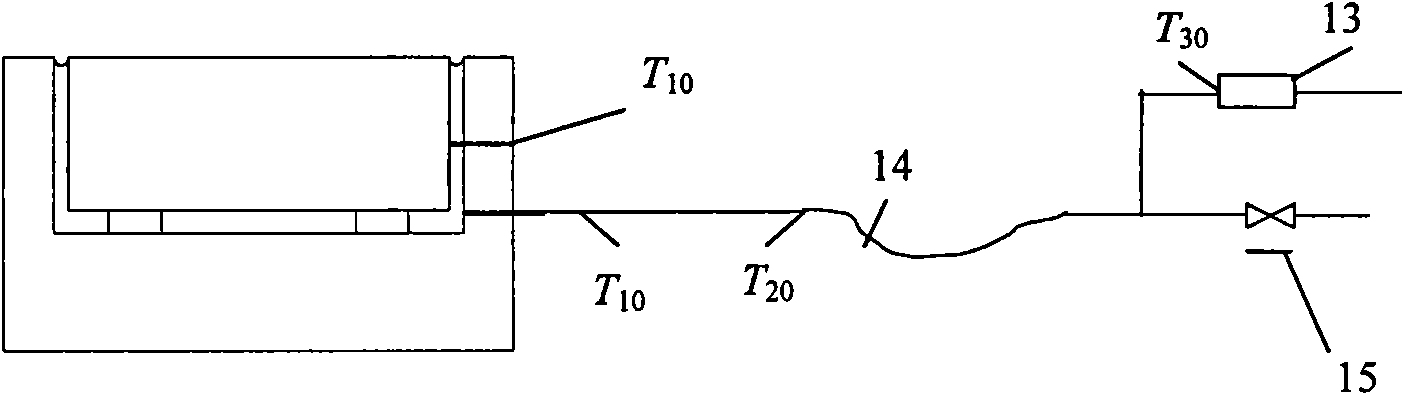

Optical fiber F-P (Fabry-Perot) cavity pressure sensor with temperature self compensation

InactiveCN103644987AForce measurement by measuring optical property variationGratingSelf compensation

The invention belongs to the technical field of optical fiber sensing, and relates to an optical fiber F-P (Fabry-Perot) cavity pressure sensor with temperature self compensation. The F-P cavity pressure sensor with temperature self compensation adopts an optical fiber with an optical grating as a transmission optical fiber and adopts an optical F-P cavity as a pressure sensitive element, wherein the F-P cavity sensitive element is a non-intrinsic optical fiber F-P cavity, and the optical fiber gating and the optical F-P cavity are connected in a mode of glue bonding or carbon dioxide laser welding. According to the mode of pressure sensing, the sensor is divided into side pressure type optical fiber F-P cavity pressure sensors with temperature self compensation and end pressure type optical fiber F-P cavity pressure sensors with temperature self compensation.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

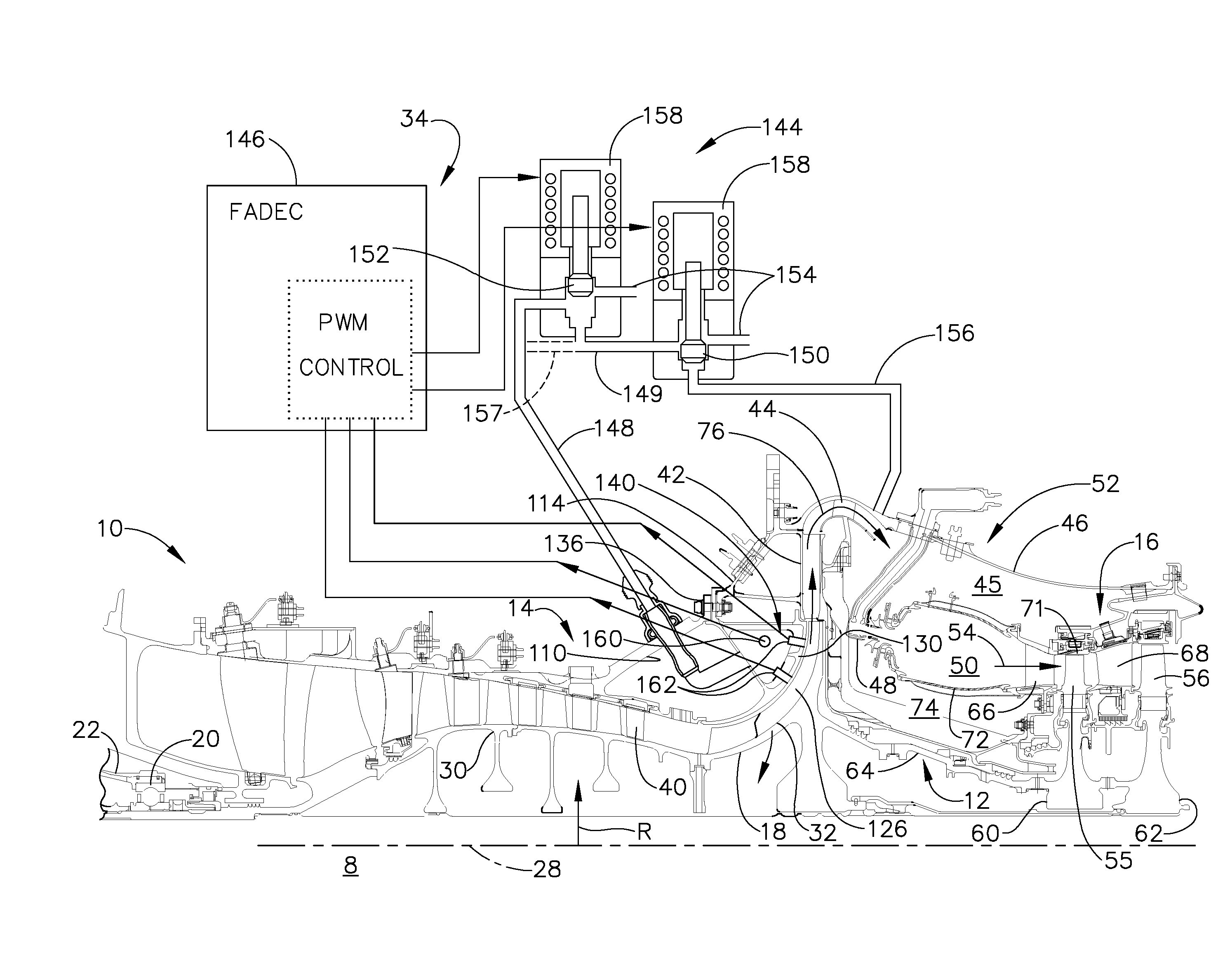

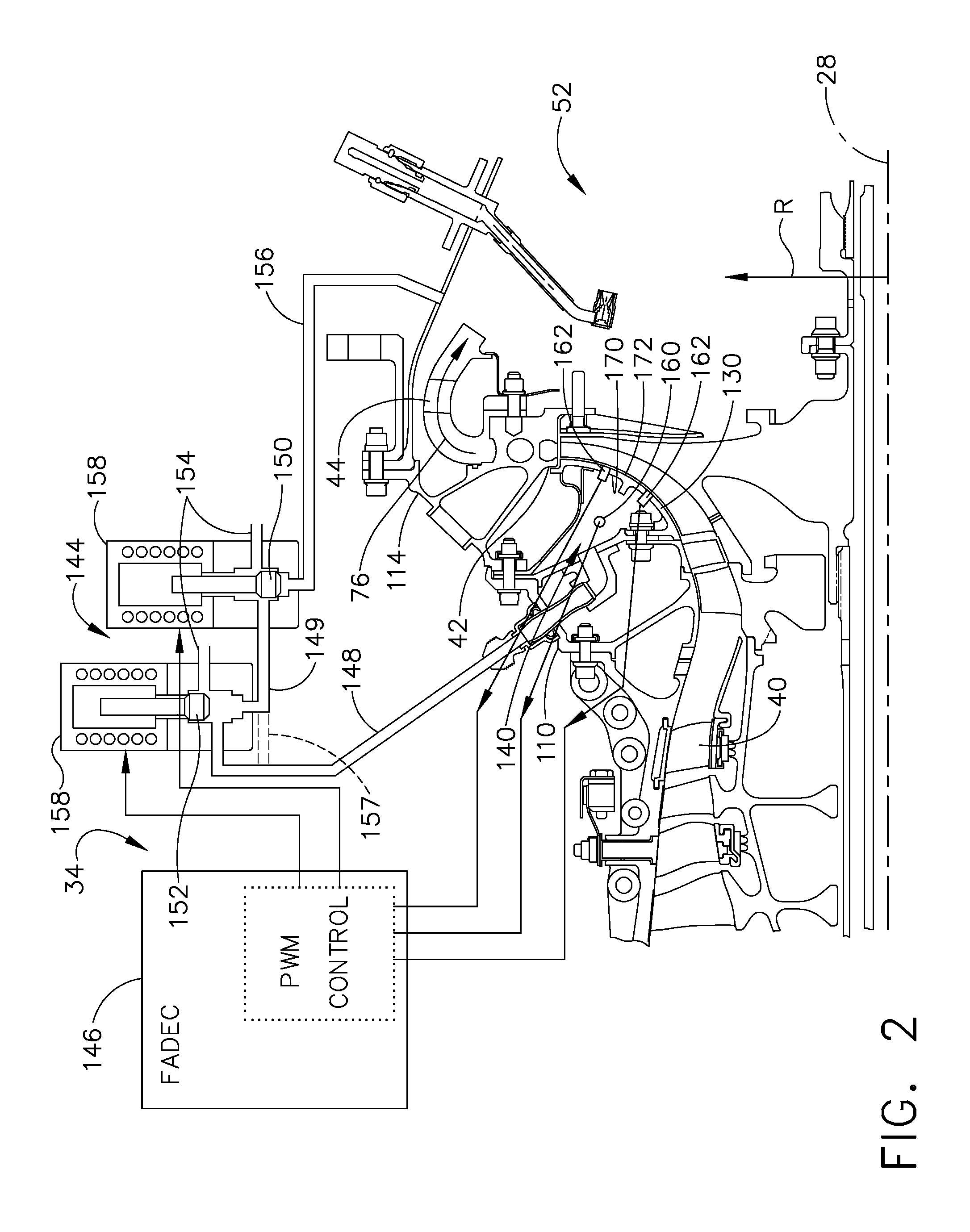

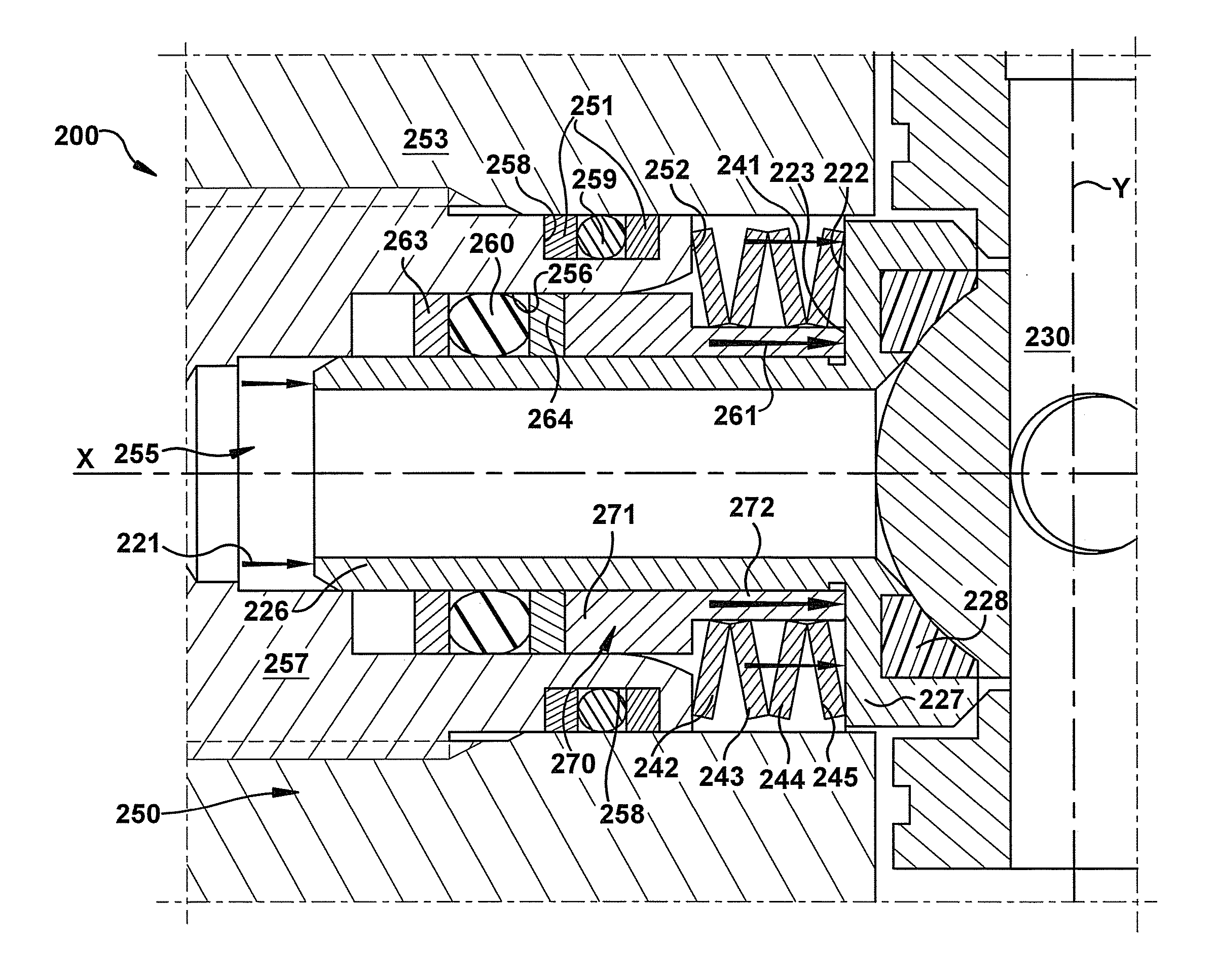

Active clearance control for a centrifugal compressor

Apparatus and method of operating a centrifugal compressor and active control system includes a centrifugal compressor with compressor blades mounted on an impeller, an annular cavity bounded in part by a shroud adjacent to the blades, and an active control system for controlling a clearance between the shroud and the blades by controlling a cavity pressure in the cavity. An electronic controller for controlling a control pressure valve for pressurizing using a source of compressor discharge pressure air and depressurizing the cavity respectively may open and close the valves using pulse width modulation. Pressure and clearance sensors positioned for measuring the cavity pressure the blade tip clearance respectively in signal supply communication with the electronic controller may be used. The shroud may be supported by radially spaced apart annular radially outer and inner supports connected to a casing by a bolted joint bounding the cavity.

Owner:GENERAL ELECTRIC CO

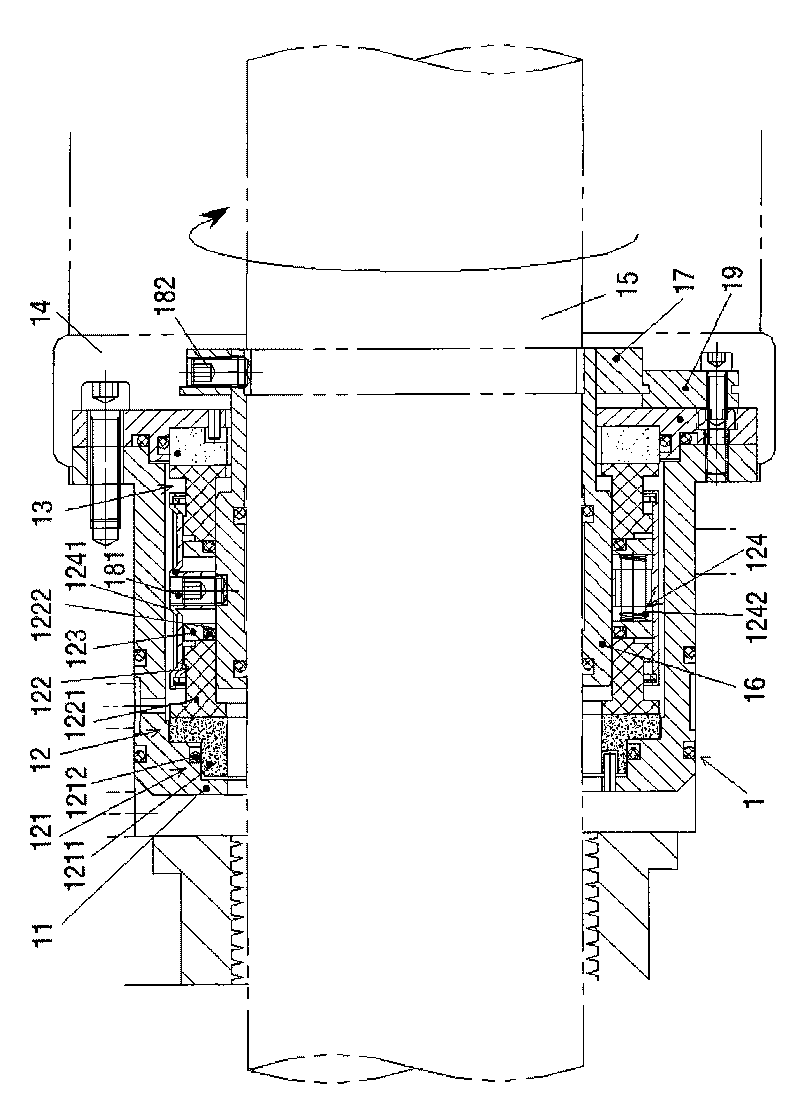

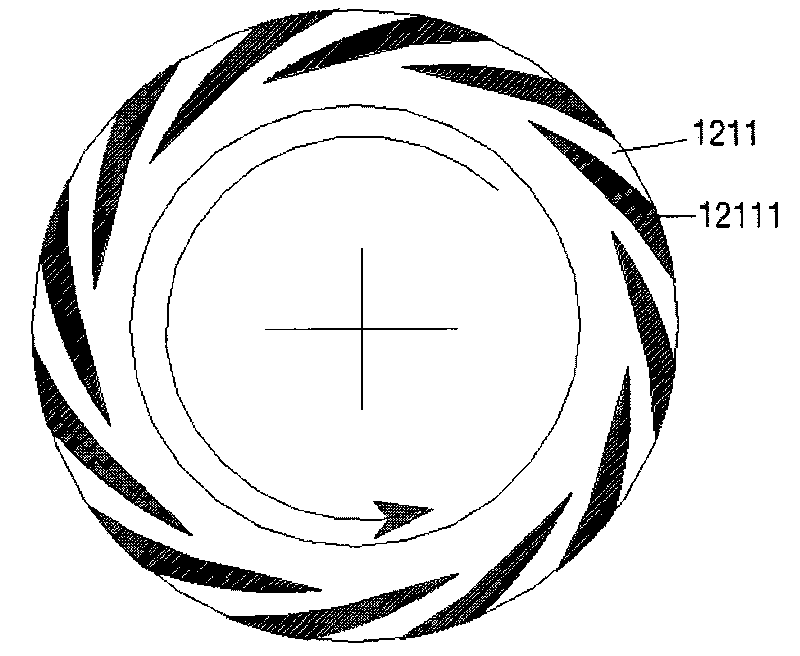

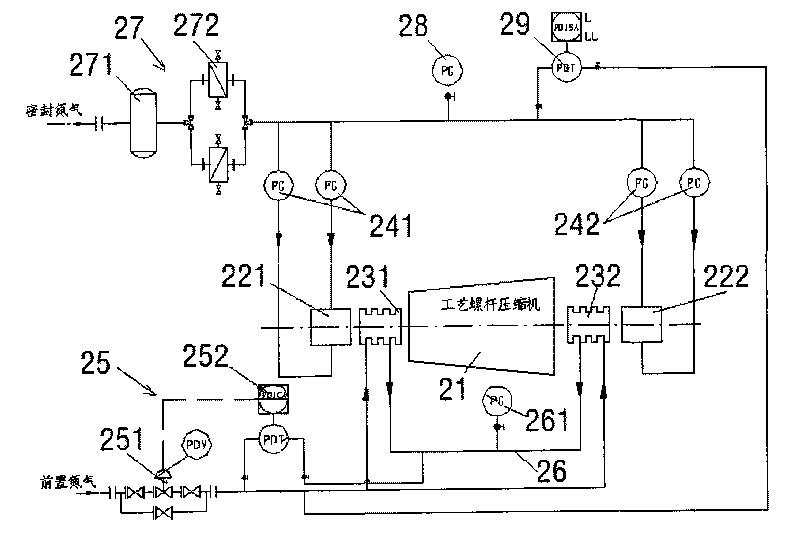

Dry gas sealing device for technical screw compressor and application system thereof

InactiveCN101713461AImprove performanceGuaranteed uptimeEngine sealsRotary piston pumpsNitrogenDry gas seal

The invention discloses a dry gas sealing device for a technical screw compressor and an application system thereof. The dry gas sealing device is characterized by comprising two sets of single sealing mechanisms with the same structure, wherein each set of single sealing mechanism comprises a static ring component, a moving ring component, a push ring and a spring component, wherein the static ring component is fixedly connected with a gland, and the moving ring component, the push ring and the spring component are fixedly connected with a shaft sleeve. The application system comprises a technical screw compressor, two dry gas sealing devices, two labyrinth sealing devices, two groups of gas flowmeters of sealed gas, a front-end gas input device and a sealed gas input device, wherein the two dry gas sealing devices and the two labyrinth sealing devices are symmetrically arranged at two ends of the shaft of the technical screw compressor. The invention also discloses an application method of the application system.The dry gas sealing device for the technical screw compressor of the invention has self adaptation and non-contact characteristics, can ensure reliable operation of dry gas sealing by matching the combined application system which has balancing cavity pressure relief, labyrinth seal obstruction, front-end nitrogen protection and dry gas sealing, and is especially suitable for high-pressure technical screw compressors with high rotary speed.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Testing method of leakage rate of high-temperature sealing gasket and testing device thereof

InactiveCN101666700AFix the leakAccurate measurementMeasurement of fluid loss/gain rateCavity pressureEngineering

The invention relates to a testing method of the leakage rate of a high-temperature sealing gasket and a testing device thereof, which establishes the corresponding testing method of the leakage rateof the high-temperature sealing gasket. The testing method and the testing device thereof perfect the testing method of the leakage rate of the high-temperature gasket, have reasonable structure, ensure the high precision in measuring the pressure of a leakage detecting cavity, and overcome the problem of large experimental error because the leakage detecting cavity is not tightly sealed, so the leakage rate test of the high-temperature gasket can be realized easily. The structure of the leakage detecting cavity is improved, and the testing method of the leakage rate of the high-temperature gasket by using a low-pressure region as the leakage detecting cavity is established. The invention plays a positive role in researching the sealing performance of the high-temperature gasket and promoting the progress of the sealing technique, and well meets the requirements of the high-speed development of the modern industry for gasket sealing.

Owner:NANJING UNIV OF TECH

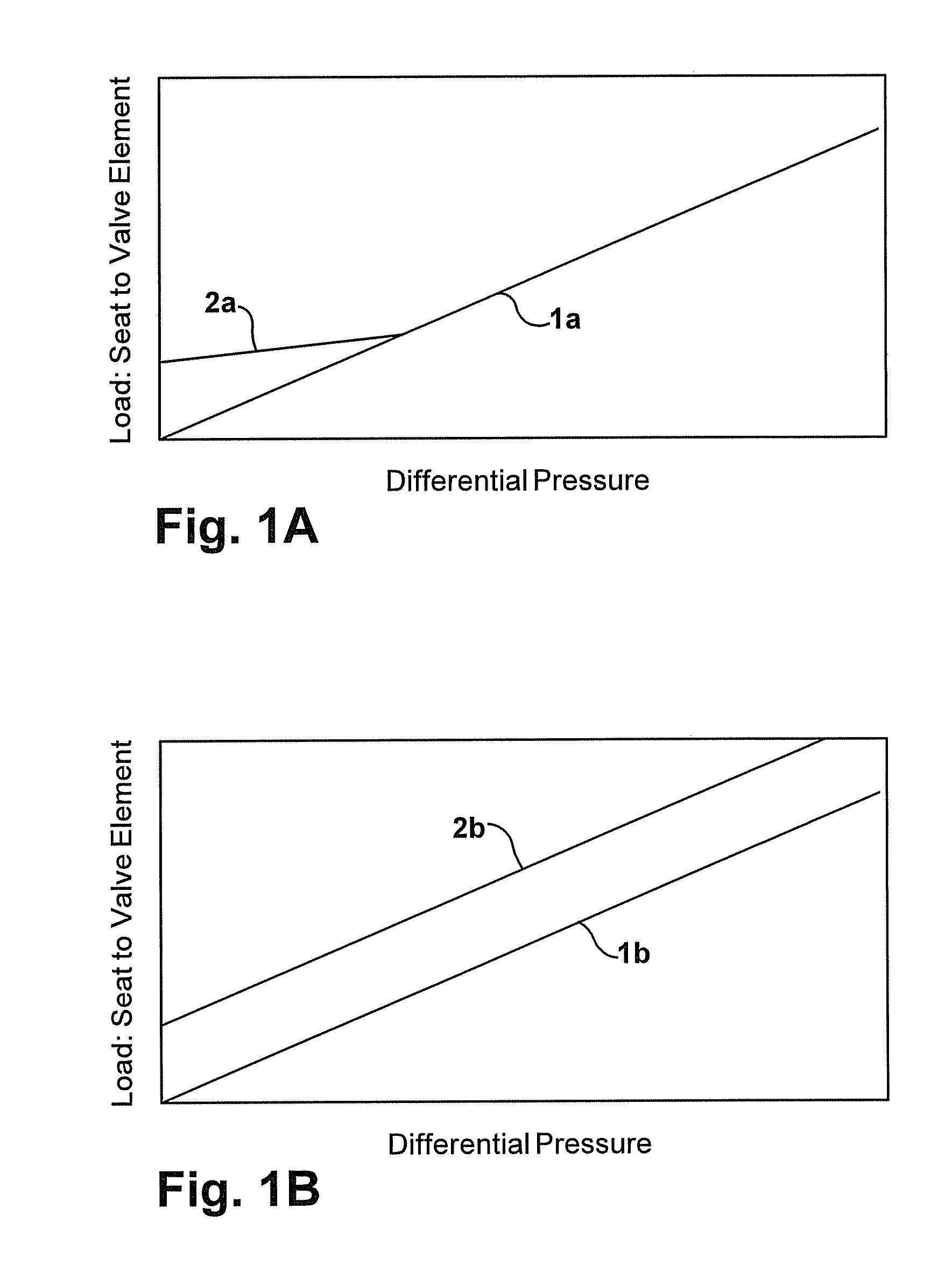

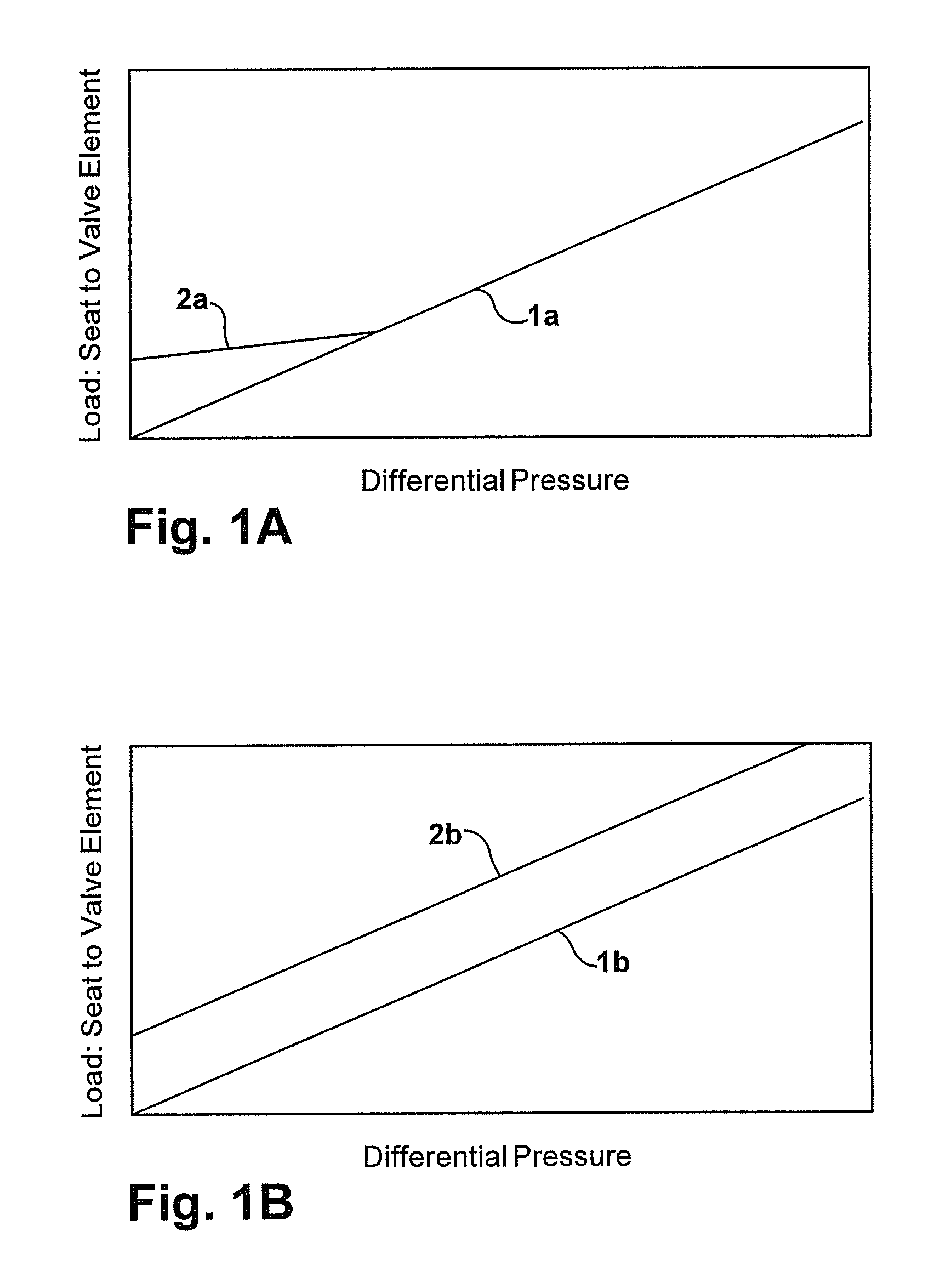

Valve sealing arrangements and methods

A valve includes a valve body, a valve element to selectively control flow through the valve, and a seal member and seat member together providing a fluid-tight seal between a valve cavity and a fluid passage in the valve body. A live-loaded biasing member is adapted to apply a live-loaded sealing force to the seat member to bias the seat member toward sealing engagement with the valve element. When the pressure in the fluid passage exceeds the pressure in the valve cavity, an unbalanced passage pressure load biases the seat member toward sealing engagement with the valve element. When the pressure in the valve cavity exceeds the pressure in the fluid passage, an unbalanced cavity pressure load biases the seat member toward sealing engagement with the valve element. The live-loaded sealing force is in parallel with each of the unbalanced passage pressure load and the unbalanced cavity pressure load.

Owner:SWAGELOK CO

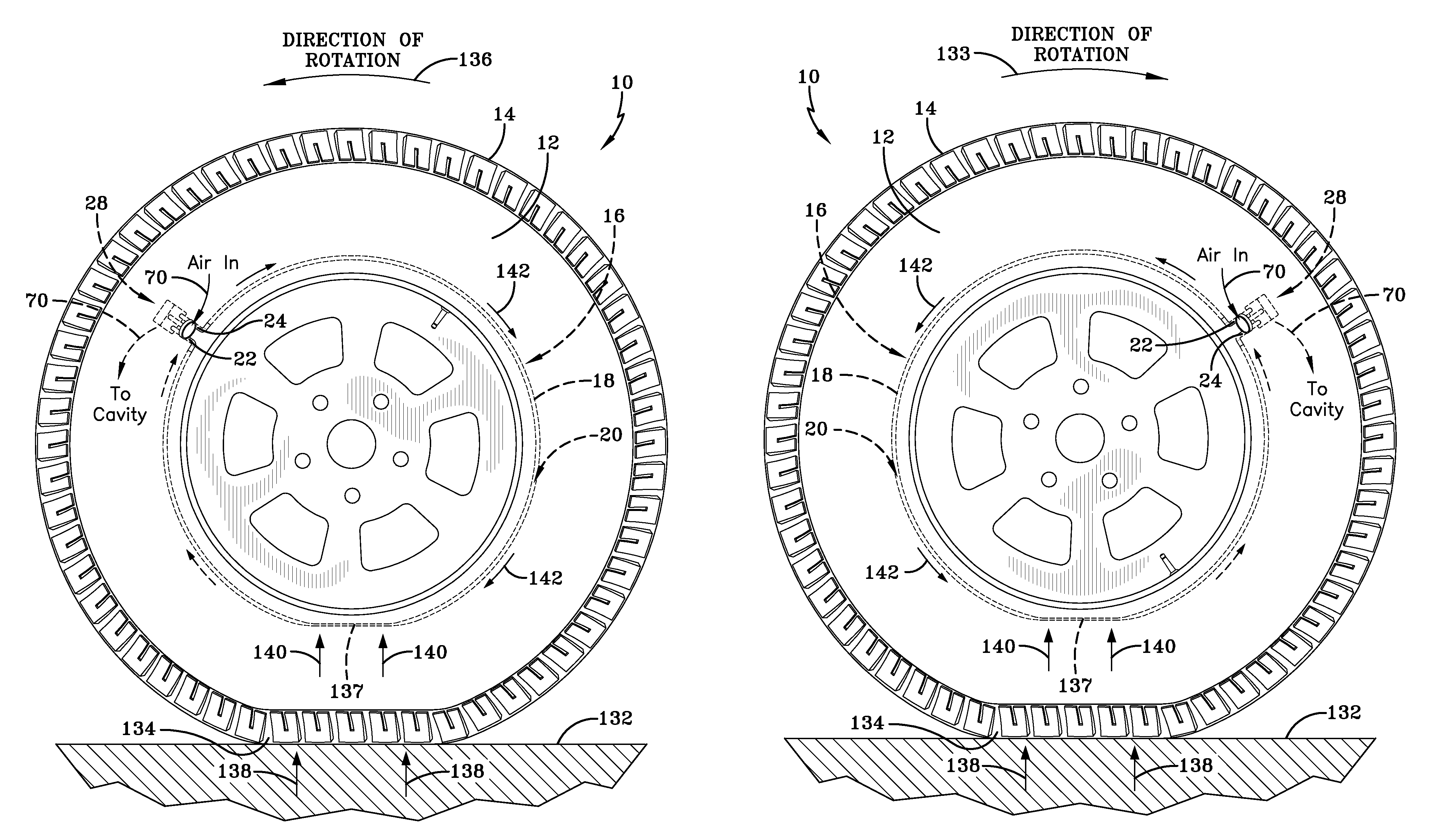

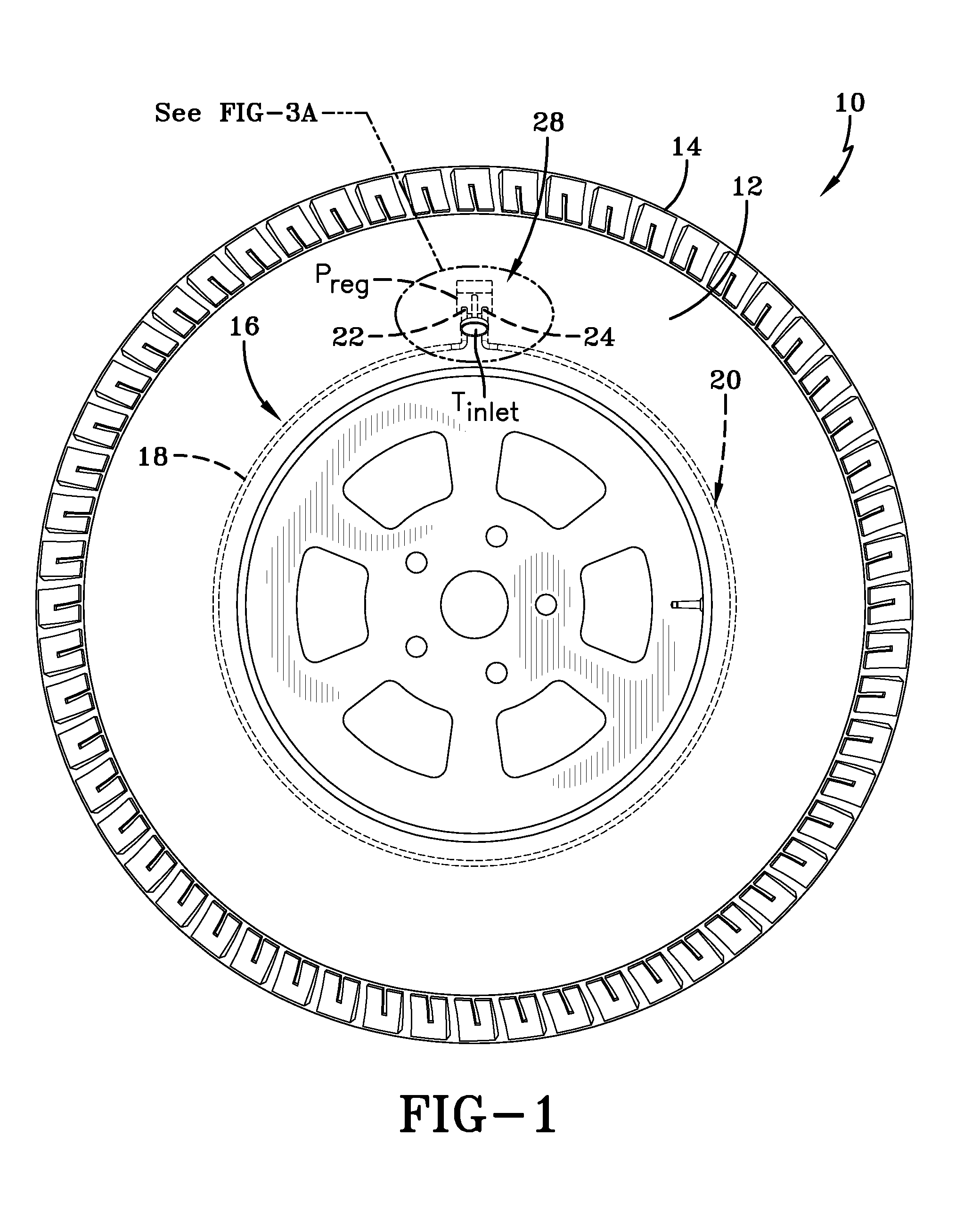

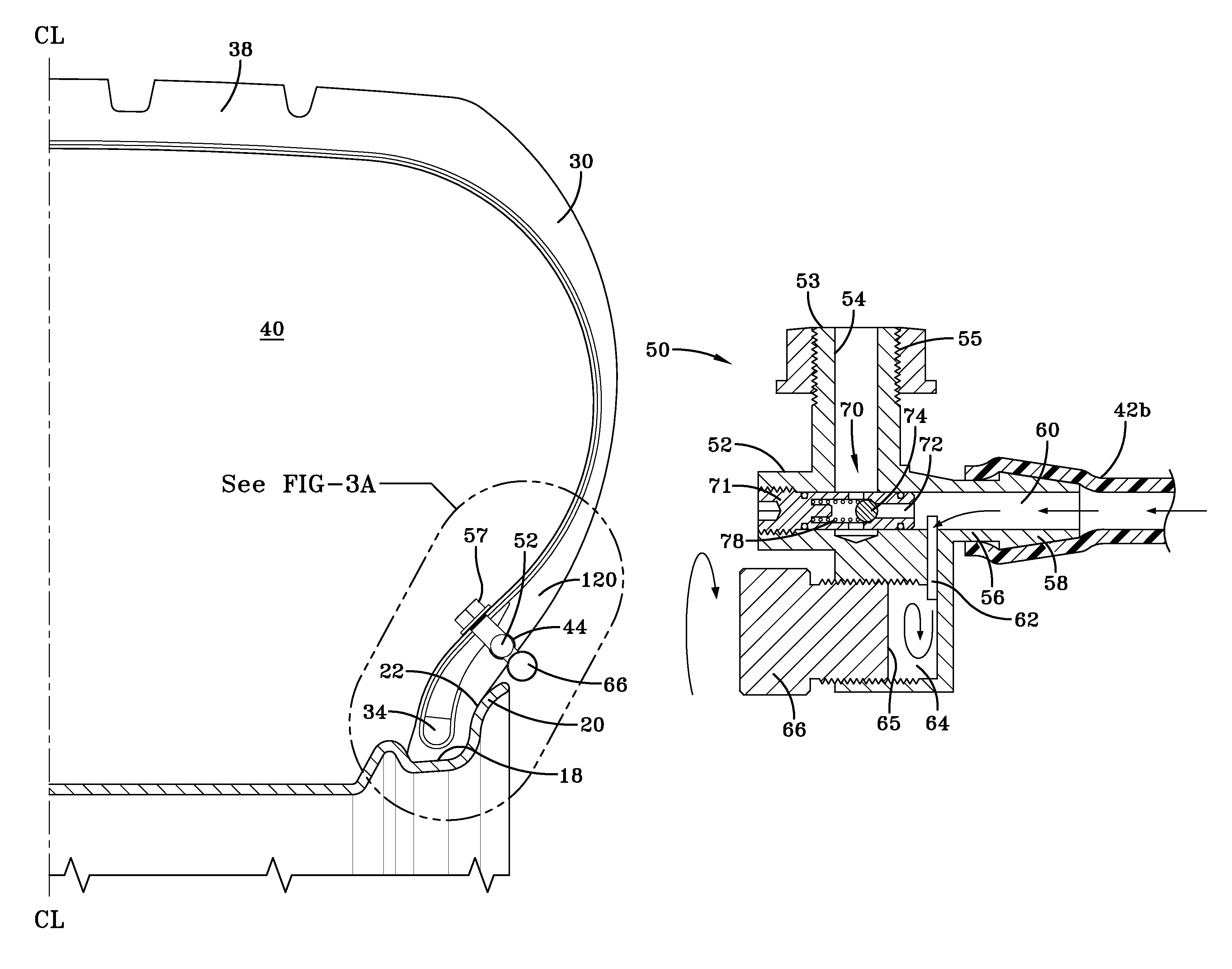

Self-inflating tire

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation. The invention further includes an outlet device for regulating the tire cavity pressure and flow into the cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

Performance testing device and testing method for petroleum drilling impact device

InactiveCN103048074AEasy to testApparatus for force/torque/work measurementForce methodCavity pressure

The invention discloses a performance testing device and a method for a petroleum drilling impact device. The testing device comprises a to-be-tested impact device, which comprises a mud pump, a sensor and a data processing unit; wherein the mud pump is connected with the liquid entrance end of the to-be-tested impact device, and by the adoption of an impact force method, the sensor is used for directly determining the impact force and the impact frequency of the to-be-tested impact device of a different model. According to the performance testing device, a mode combining the sensor and data converter is adopted, a impact force method is adopted, and the impact force and the impact frequency of the to-be-tested impact device of a different model can be directly measured; a pressure sensor can also be used for measuring the drilling liquid entrance pressure, the exit pressure, and the upper cavity pressure and the lower cavity pressure of a cylinder body, and a flow sensor is used for measuring the exit flow of the impact device. By measuring the pressure difference of a cylinder body upper cavity and a cylinder lower cavity, impact power and an impact end speed are calculated. The testing method has the advantages of accuracy, rapidness and convenience.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sinking extruded granular feed of penaeus uannamei and preparation method thereof

InactiveCN101779723AReduce feed factorStrong changes in physical and chemical propertiesAnimal feeding stuffAnti nutrientsSteam pressure

The invention discloses sinking extruded granular feed of penaeus uannamei. The density of the sinking extruded granular feed is more than 1.03, and the curing degree is 100 percent. Brown fishmeal, squid liver paste, shrimp shell meal, flour, not-genetically-modified soybean meal, canola meal, peanut meal, cassava block, mineral gunk, vitamin gunk, calcium dihydrogen phosphate, fish oil, calcium propionate, phospholipids oil and DDGS are adopted as raw materials, the feed base stock which is proportioned by weight part is regulated for 160 to 200 seconds by a double-shaft extruding full-curing bulking machine under the conditions that the steam pressure is 0.4 to 0.5MPa, the moisture is 19 to 23 percent and the temperature is 85 to 90 DEG C, and then is cured at a curing temperature of 135 DEG C, the cavity pressure of 3MPa and the curing time of 90 to 120 seconds. The sinking extruded granular feed has fewer animal raw materials and has low feed coefficient which is less than or equal to 1.1. All anti-nutrient factors in the feed are completely destroyed, the stability in the water is more than 12 hours, and the feed is completely cured.

Owner:NINGBO TECH BANK

Intelligent lorry crane with intelligent operation control system

ActiveCN102923584AReduce weightEnsure safetyCranesLoad-engaging elementsInformation processingSolenoid valve

An intelligent lorry crane with an intelligent operation control system comprises a column assembly, a boom assembly, a hydraulic oil tank assembly, a steel wire rope, a rear supporting leg assembly, a lifting hook assembly, a frame assembly, and an oil pump; according to the invention, a program controller is mounted on an automotive chassis; a length sensor, an angle sensor, a limit switch, and a second balance valve are mounted on the boom assembly; an upper cavity pressure sensor, a lower cavity pressure sensor, and a first balance valve are mounted on the column assembly; a multi-way valve, a normal open solenoid valve, a tilt sensor, an oil temperature sensor, a central rotation slip ring, and an alarm are mounted on the frame assembly; the program controller is connected with a Canbus bus; the Canbus bus is respectively connected with the length sensor, the angle sensor, the upper cavity pressure sensor, the lower cavity pressure sensor, and the limit switch through the central rotation slip ring; the oil temperature sensor, the tilt sensor, the normal open solenoid valve, and the alarm below the frame are respectively connected by corresponding branch lines in the Canbus bus. The invention adopts advanced electronic technology and information processing technology, has multiple display functions, can perform alarming and protection of system faults, and greatly improve the technical performance and quality of the lorry crane.

Owner:长沙铃豹智能机器有限公司

Bypass air maintenance tire and pump assembly

An air maintenance tire and pump assembly includes a pair of inline valves are positioned on respective opposite sides of an in-tire air passageway inlet junction and a pair of outlet valves positioned at a downstream side of a respective inline valve. A bypass valve is further provided extending between the downstream valve sides of the inline valves, the bypass valve operative to open and bypass the flow of inlet air through the outlet valves to the tire cavity in the event that a tire cavity pressure is greater than a preset pressure level and close when a tire cavity pressure is less than the preset pressure level.

Owner:THE GOODYEAR TIRE & RUBBER CO

Expanded pellet feed for trionyx sinensis and preparation method thereof

The invention discloses an expanded pellet feed for the trionyx sinensis. The curing degree of the expanded pellet feed is 100 percent. The expanded pellet feed is prepared from domestic white fish meal, America white fish meal, imported eel-grade red fish meat, flour, cassava pieces, soy beans, non-transgenic soybean meal, fermented soybean meal, pregelatinization starch, milk powders, mineral premix, vitamin premix, monocalcium phosphate, calcium propionate and phosphatide oil by using a twin-screw extruding fully-curing expansion machine to firstly carry out quenching and tempering on the materials for 160 to 200 seconds under the conditions that a vapour pressure is between 0.4 and 0.5MPa, a humidity is between 19 and 23 percent, and a temperature is between 85 and 90 DEG C, and then carry out curing on obtained product under the conditions that a curing temperature is 180 DEG C, a cavity pressure is between 22 and 28atm and a curing time is between 25 and 30 seconds. Each kilogram of mineral premix comprises Mg, Na, K, Fe, Cu, Mn, Zn, Se, Co and I. The expanded pellet feed for the trionyx sinensis has the advantages of reasonable configuration of various elements required by nutrition and growth, complete curing, resistance to cause damage to all nutritional factors, low cost, higher stability in water and higher digestibility.

Owner:NINGBO TECH BANK

Passive tire pressure sensor and method

InactiveUS20050028595A1Inflated body pressure measurementFluid pressure measurement using elastically-deformable gaugesEngineeringSurface acoustic wave

A surface acoustic wave device includes a micro-machined pressure transducer for monitoring tire pressure. The device is configured having a micro-machined cavity that is sealed with a flexible conductive membrane. When an external tire pressure equivalent to the cavity pressure is detected, the membrane makes contact with ridges on the backside of the surface acoustic wave device. The ridges are electrically connected to conductive fingers of the device. When the detected pressure is correct, selected fingers on the device will be grounded producing patterned acoustic reflections to an impulse RF signal. When the external tire pressure is less than the cavity reference pressure, a reduced reflected signal to the receiver results. The sensor may further be constructed so as to identify itself by a unique reflected identification pulse series.

Owner:THE GOODYEAR TIRE & RUBBER CO

System for distending body tissue cavities by continuous flow irrigation

ActiveUS8652089B2Improve efficiencyImprove securityEnemata/irrigatorsSurgeryEndoscopic ProcedureContinuous flow

The present invention provides a system and a method for distending a body tissue cavity of a subject by continuous flow irrigation such that minimal or negligible fluid turbulence is present inside the cavity, such that any desired cavity pressure can be created and maintained for any desired outflow rate. The present invention also provides a method for accurately determining the rate of fluid loss, into the subject's body system, during any endoscopic procedure without utilizing any deficit weight or fluid volume calculation or flow rate sensor. The system and the methods of the present invention described above can be used in any endoscopic procedure requiring continuous flow irrigation few examples of such endoscopic procedures being hysteroscopic surgery, arthroscopic surgery, trans uretheral surgery, endoscopic surgery of the brain and endoscopic surgery of the spine.

Owner:ARTHREX

Active clearance control for a centrifugal compressor

Apparatus and method of operating a centrifugal compressor and active control system includes a centrifugal compressor with compressor blades mounted on an impeller, an annular cavity bounded in part by a shroud adjacent to the blades, and an active control system for controlling a clearance between the shroud and the blades by controlling a cavity pressure in the cavity. An electronic controller for controlling a control pressure valve for pressurizing using a source of compressor discharge pressure air and depressurizing the cavity respectively may open and close the valves using pulse width modulation. Pressure and clearance sensors positioned for measuring the cavity pressure the blade tip clearance respectively in signal supply communication with the electronic controller may be used. The shroud may be supported by radially spaced apart annular radially outer and inner supports connected to a casing by a bolted joint bounding the cavity.

Owner:GENERAL ELECTRIC CO

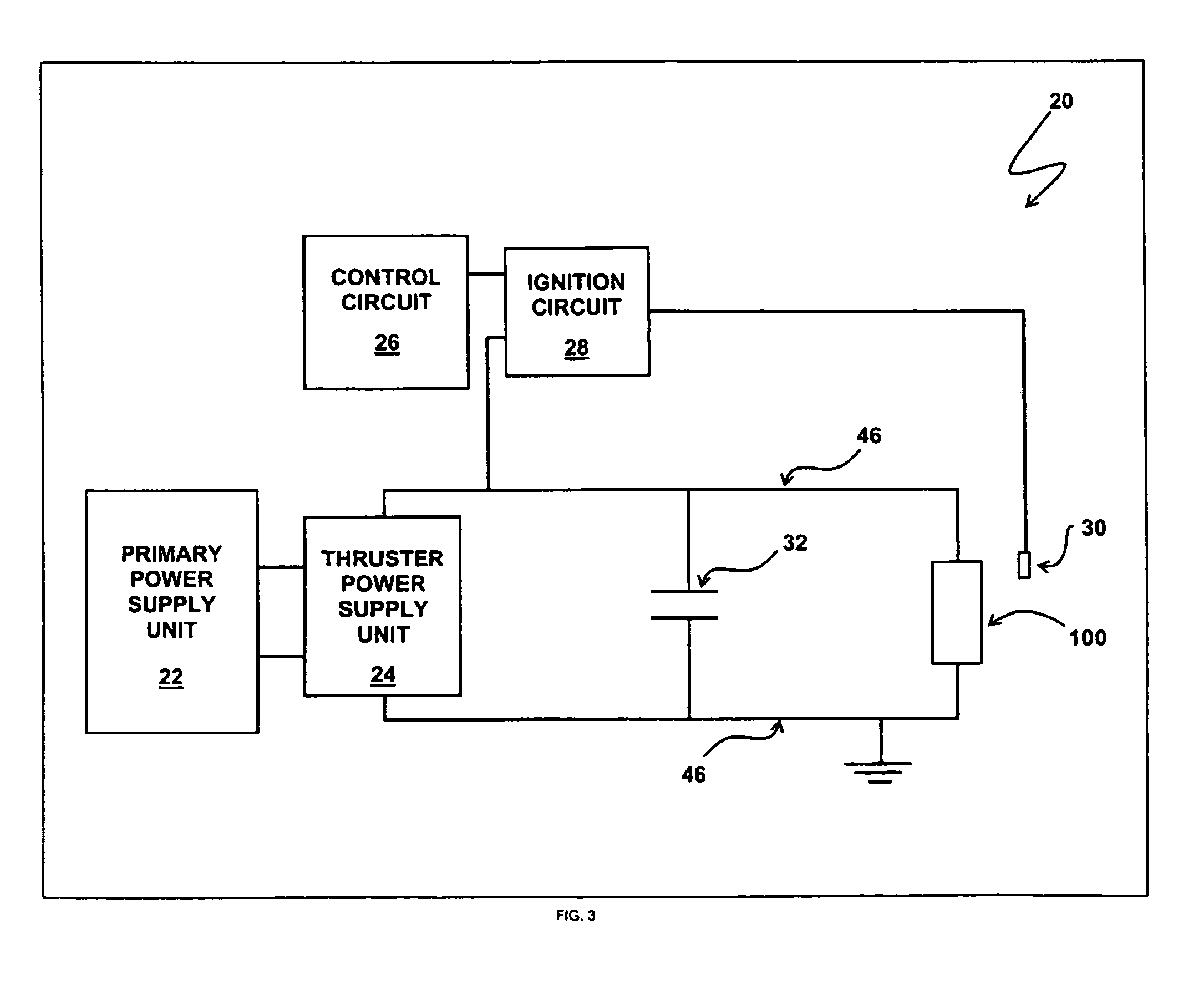

Advanced pulsed plasma thruster with high electromagnetic thrust

ActiveUS7530219B1Reduce resistanceHigh currentMachines/enginesUsing plasmaElectrical resistance and conductanceCoaxial geometry

A pulsed plasma thruster provides for an advanced lightweight design with solid propellant and predominately electromagnetic thrust in a coaxial geometry. Electromagnetic forces are generated in a plasma by current flowing from a small central electrode to an electrically conducting diverging nozzle electrode. The thruster employs a series of electric current pulses of limited duration and varying frequency between the pair of electrodes creating a series of electric arcs. The electric arcs pass over a propellant surface located between the electrodes, forming a plasma, which is then exhausted from the device to produce thrust. The thruster maintains a low plasma resistance and cavity pressure, which in turn yields strong electromagnetic body forces, resulting in a high efficiency and consistent pulse-to-pulse performance.

Owner:CU AEROSPACE

Valve sealing arrangements and methods

Owner:SWAGELOK CO

Self-inflating tire

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation. The invention further includes an outlet device for regulating the tire cavity pressure and flow into the cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

Transmission cavity pressure control system and method

InactiveCN101470447AReduce consumptionStable pressureFluid pressure control with auxillary non-electric powerFluid pressure control using electric meansLoop controlControl system

The invention discloses a pressure control system of a transmission chamber and a method thereof. The transmission chamber is equipped with a charging air passage and an evacuating air passage, wherein the evacuating air passage is provided with an evacuating speed control device, and pressure in the transmission chamber is controlled through controlling evacuating speed of the evacuating air passage in the transmission chamber. The evacuating speed control device is connected with a controller, the transmission chamber is equipped with a pressure sensor connected with the controller, firstly detecting pressure signals in the transmission chamber, then comparing the pressure signals with the set pressure parameters, and on-line adjusting the evacuating speed of the evacuating air passage in real time through closed-loop control algorithms such as PID and the like, finally, the purpose of control pressure in the transmission chamber is achieved. Besides, the system is stable in pressure control and low in nitrogen consumption.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Injection mold cavity pressure control system and method

The invention discloses an injection mold cavity pressure control system and method. The injection mold cavity pressure control system comprises a high-pressure nitrogen source, wherein the high-pressure nitrogen source is connected with a mould air inlet through a pipeline, a first pressure reducing valve is arranged on the part, which is close to the high-pressure nitrogen source, of the pipeline, the pipeline is divided into two paths after passing through the first pressure reducing valve, one path is connected with an air control regulating valve through a second pressure reducing valve, a first pressure meter and an electronic pressure controller, the other path is connected with the air control regulating valve through a second pressure meter, the outlet of the air control regulating valve is connected with the mould air inlet, a third pressure meter, a pressure sensor and a pressure relieving pipeline unit are sequentially arranged on the pipeline, the electronic pressure controller, the pressure relieving pipeline unit and the pressure sensor are connected with a data processing and controlling system, and the data processing and controlling system is connected with an injection molding machine signal unit. The invention also discloses a control method of the injection mold cavity pressure control system. The injection mold cavity pressure control system has the characteristics of high pressurizing rate and pressure relieving rate of a mould cavity, capabilities of maintaining high pressure of the mould cavity and controlling the acting time of the high pressure of the mould cavity, and the like.

Owner:SHANDONG UNIV

Self-inflating tire

A self-inflating tire assembly includes an air tube connected to a tire and defining an air passageway, the air tube being composed of a flexible material operative to allow an air tube segment opposite a tire footprint to flatten, closing the passageway, and resiliently unflatten into an original configuration. The air tube is sequentially flattened by the tire footprint in a direction opposite to a tire direction of rotation to pump air along the passageway to an inlet device for exhaust from the passageway or to an outlet device for direction into the tire cavity. The inlet device is positioned within the annular passageway 180 degrees opposite the outlet device such that sequential flattening of the air tube by the tire footprint effects pumping of air along the air passageway with the tire rotating in either a forward or reverse direction of rotation. The invention further includes an outlet device for regulating the tire cavity pressure and flow into the cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

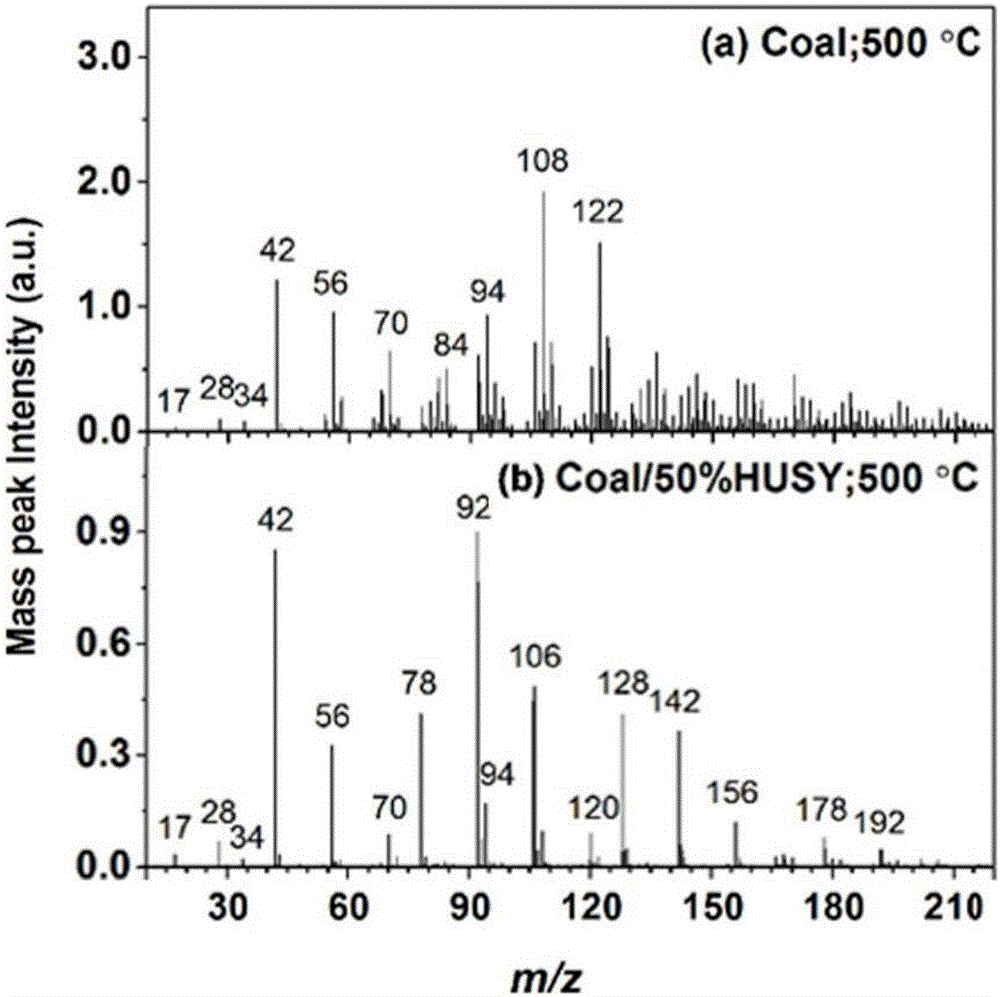

Device for in-situ detection of catalytic reaction intermediate and product and detection method

InactiveCN105717189AReal-timeRealize analysisMaterial analysis by electric/magnetic meansVacuum pumpingControl system

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com