Air mixing and metering system for processing vehicle exhaust

A technology of exhaust treatment and metering system, which is applied in the direction of air quality improvement, exhaust devices, mechanical equipment, etc., can solve the problems of complex and large structure, low integration, unfavorable layout, etc., achieve strong versatility and ensure reliability , high metering accuracy and atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

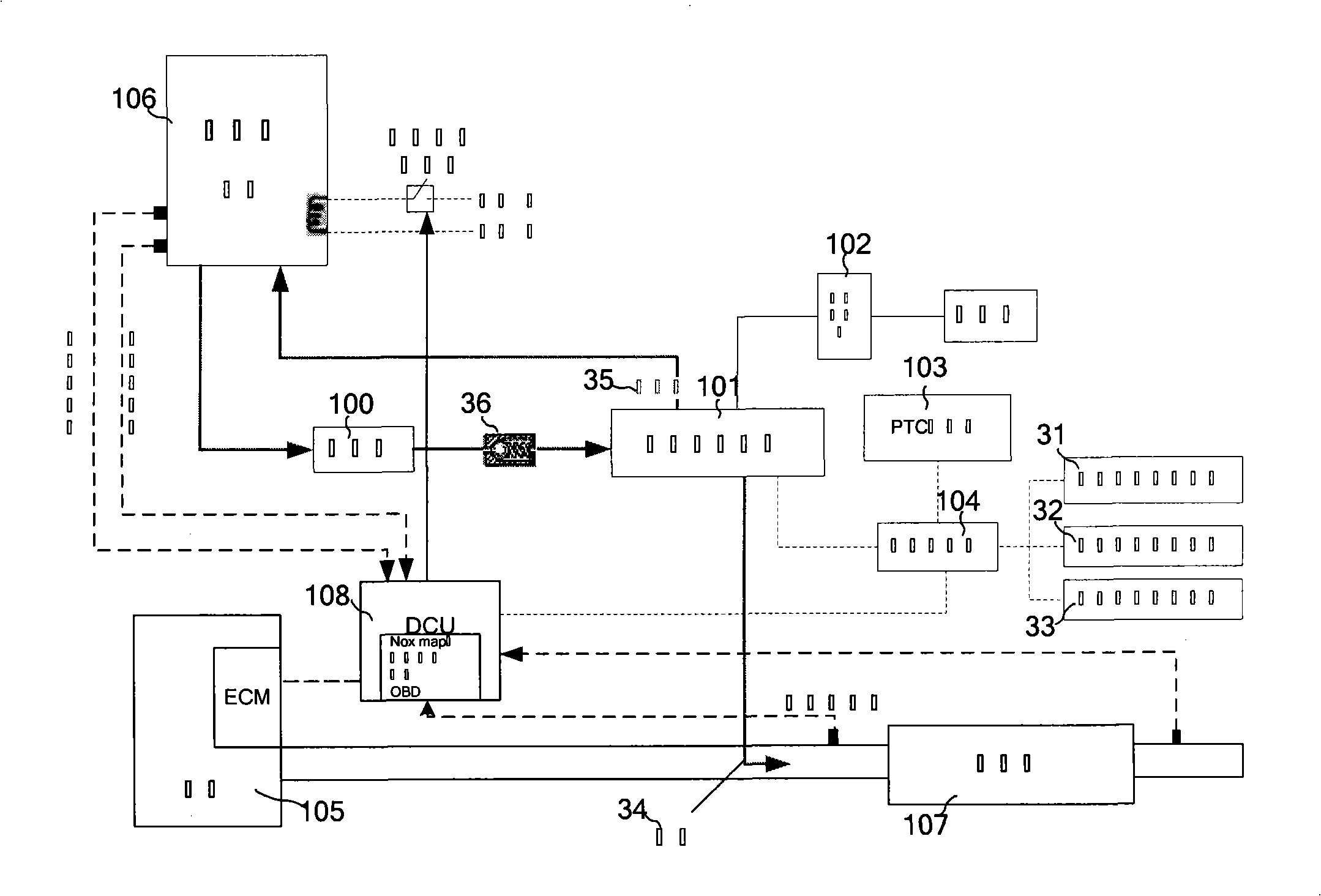

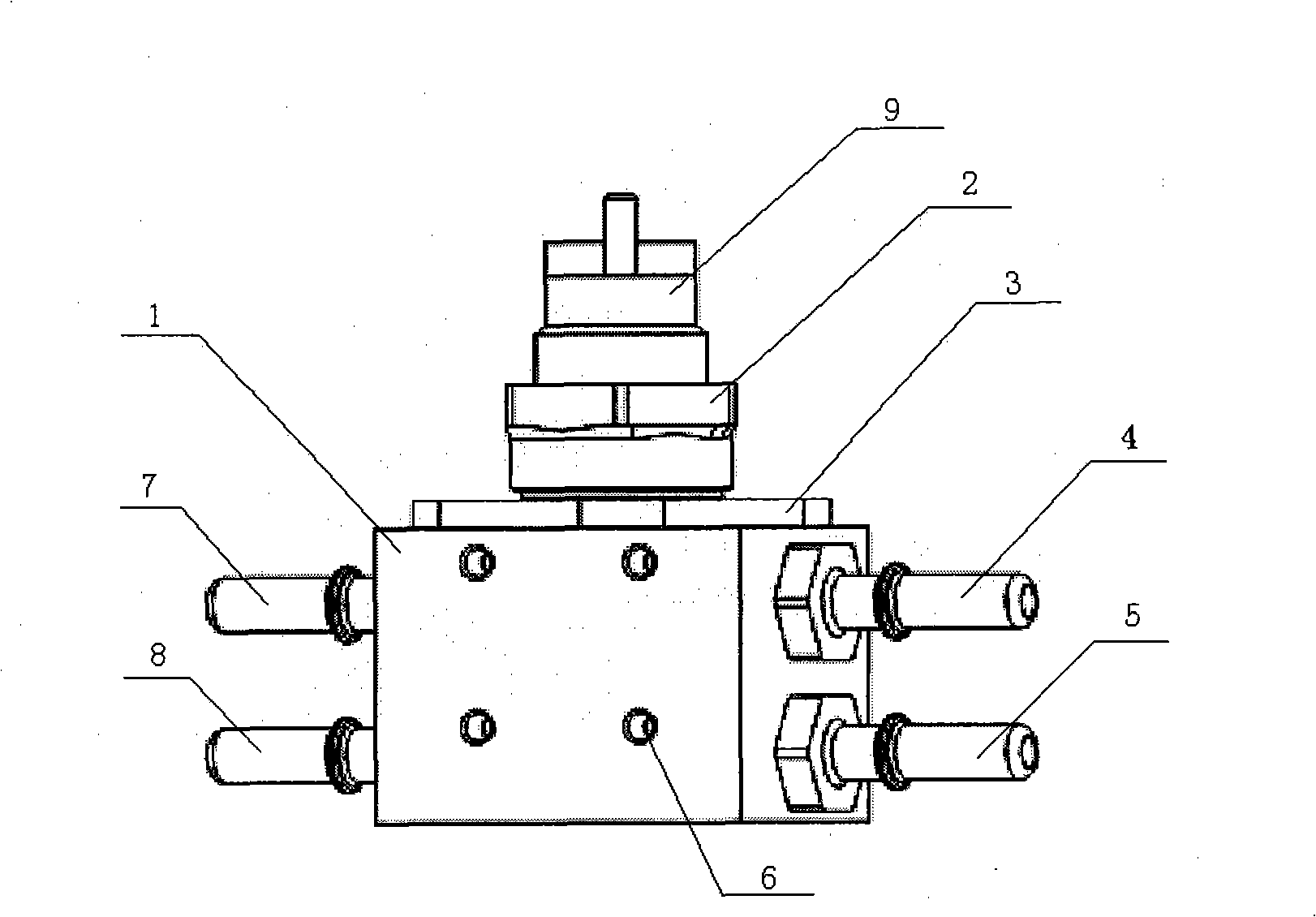

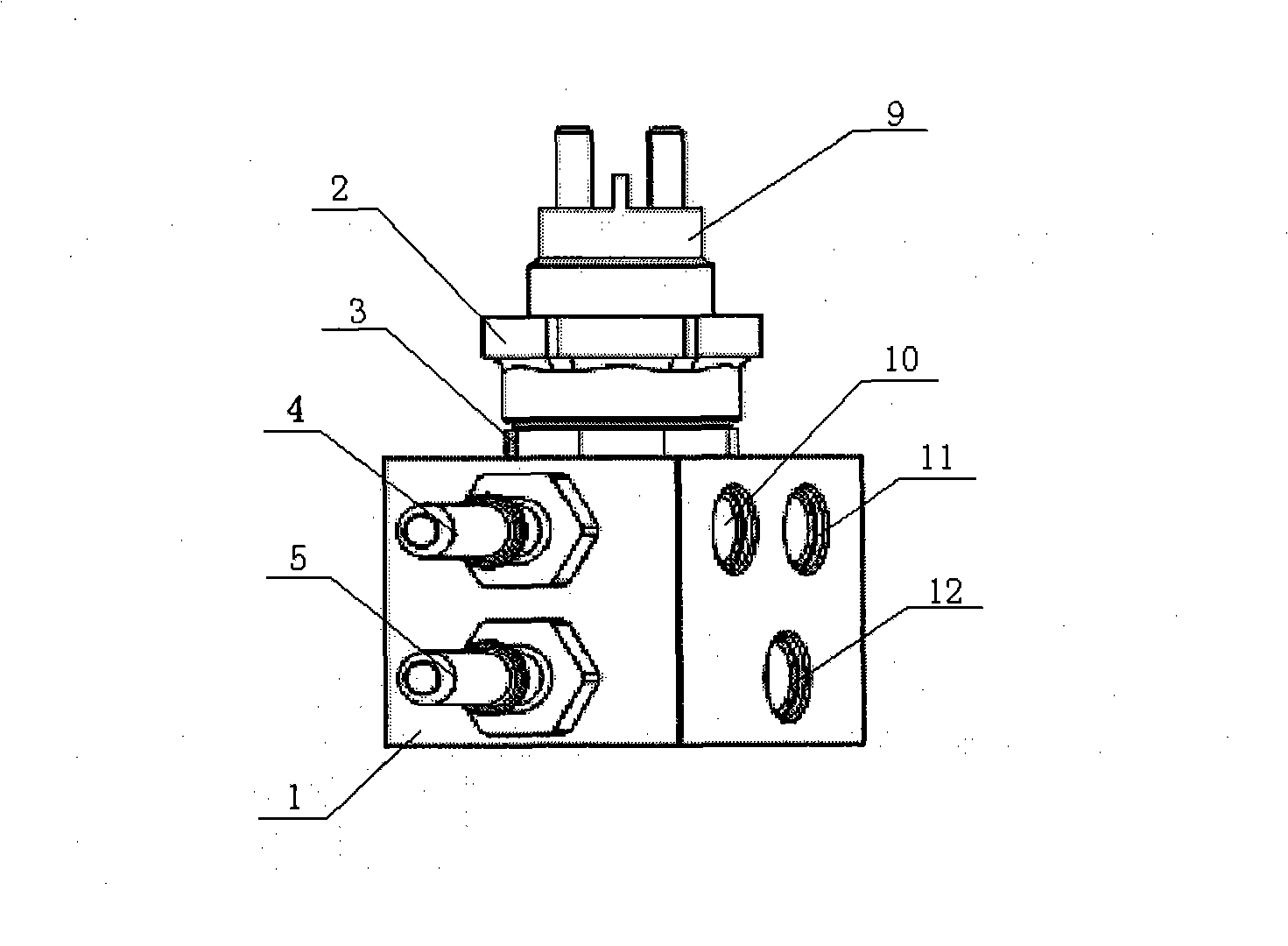

[0028] Such as Figure 1 to Figure 6 As shown, it includes a diaphragm pump 100, a metering supply unit 101, an air solenoid valve 102, a PTC heater 103, a metering drive part 104, an engine 105, a urea tank 106, a catalytic converter 107, a DCU control part 108, a metering unit body 1, an electromagnetic Iron tight cap 2, flange 3, urea solution inlet quick connector 4, compressed air inlet quick connector 5, four threaded ports for installing PTC heater 6, urea solution overpressure return quick connector 7, mixing outlet quick connector 8, Electromagnetic coil part 9, accumulator chamber temperature sensor interface 10, accumulator chamber pressure sensor interface 11, mixing chamber pressure sensor interface 12, spring upper seat 13, spring 14, spring lower seat 15, armature 16 (armature upper end face 16A, armature lower end face 16B), gasket 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com