Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Reflux flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

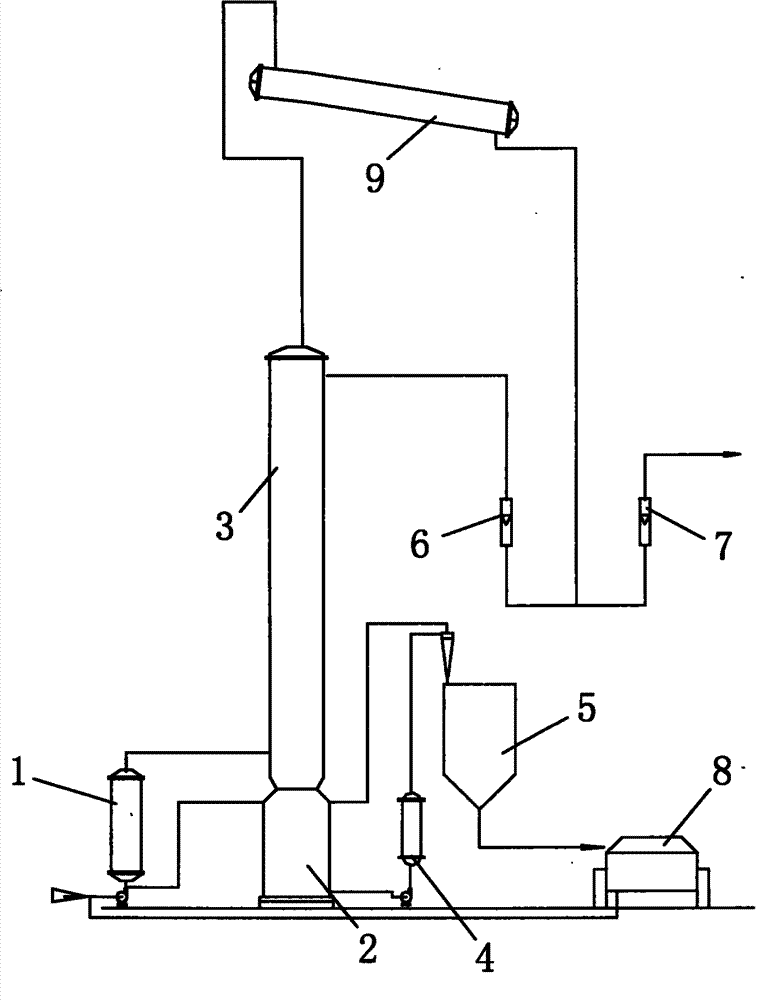

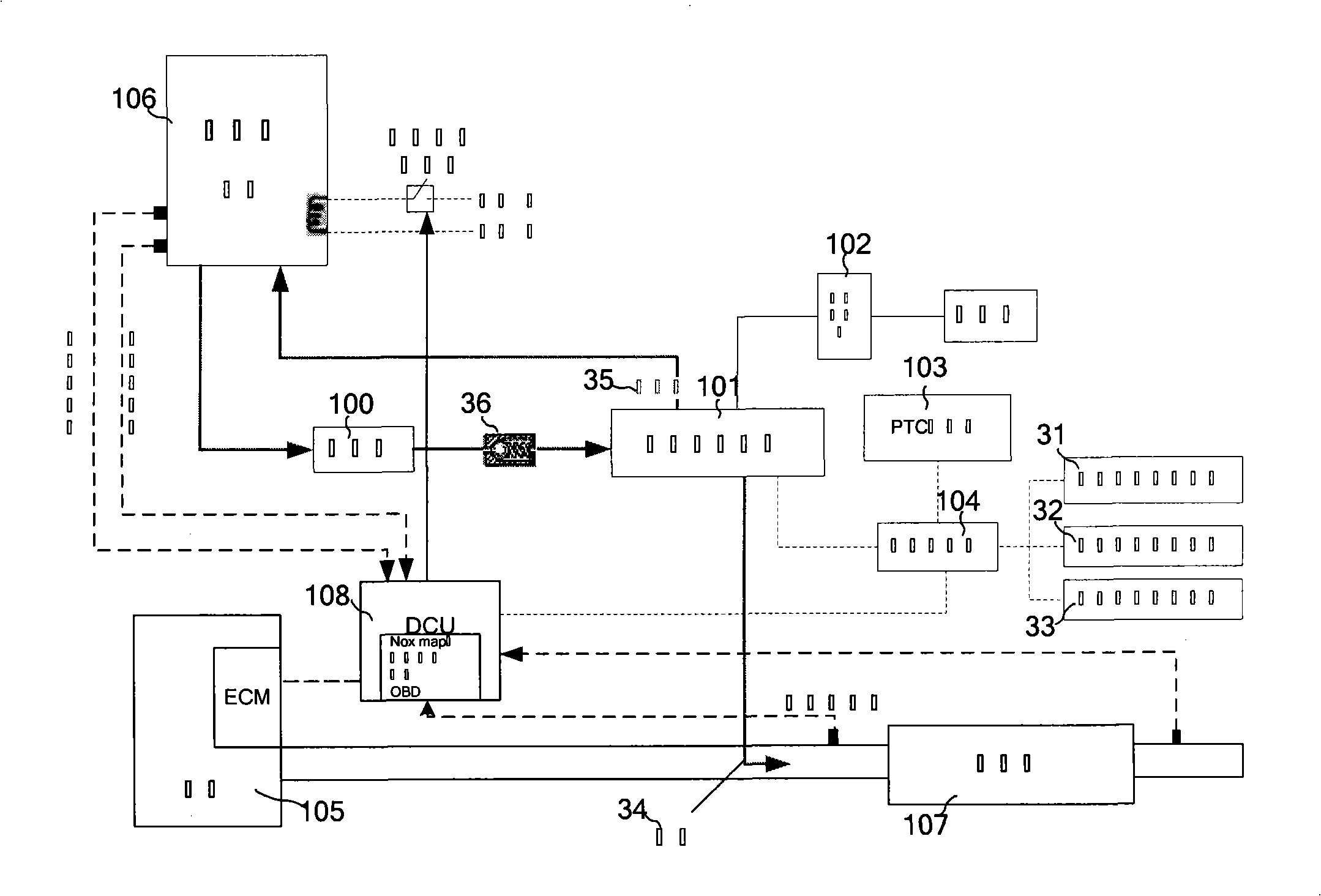

Air mixing and metering system for processing vehicle exhaust

ActiveCN101493027AGuaranteed reliabilityHigh measurement accuracyExhaust apparatusDispersed particle separationDiaphragm pumpSolenoid valve

The invention relates to an air incorporation measurement system used for vehicle exhaust-gas disposal. The system is characterized in that the measurement system comprises a measurement supply unit, a measurement drive part, an air solenoid valve, a spillover valve, a urea tank, a pressure accumulation cavity temperature sensor, a mixing cavity pressure sensor, a DCU control part, and a catalyst, etc. The measurement supply unit is connected with the catalyst, the air solenoid valve is connected with a quick coupling, an outlet quick coupling is connected with a nozzle by a pipeline, urea solution in the urea tank is conveyed to the measurement supply unit by a membrane pump, a reflux inlet is connected with the spillover valve by the quick coupling, the reflux flows to the urea tank, a compressed air inlet is connected with a compressed air source, and a mixing outlet sprays gas-liquid mixture into an exhaust duct through the nozzle by means of being connected with the pipeline. Themeasurement system of the invention features compact structure, small volume, light weight and accurate measurement, thus saving much space for vehicle layout while maintaining relatively high measuring accuracy and fog effect and ensuring reliability of normal operation in different areas and environments.

Owner:KAILONG HIGH TECH

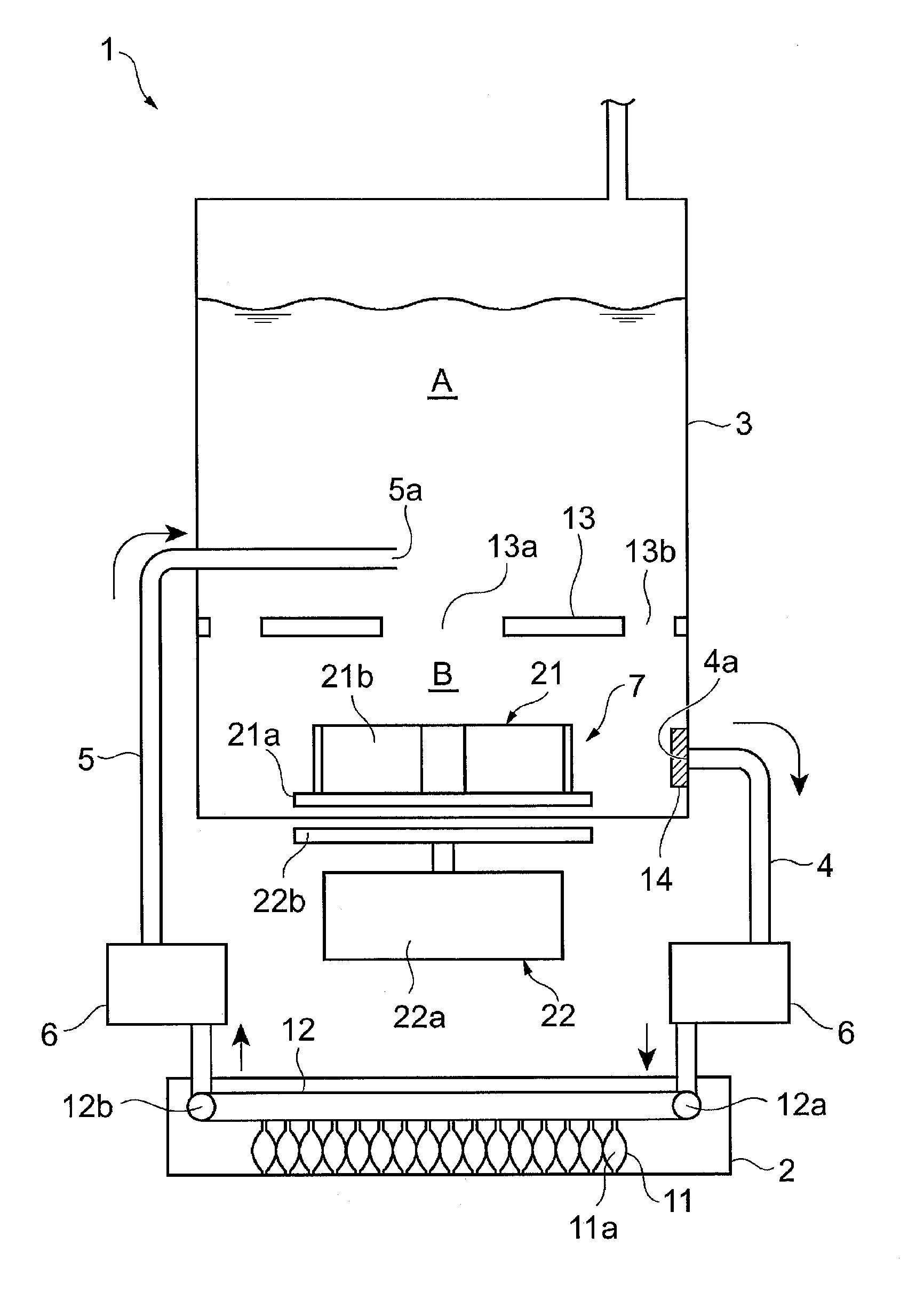

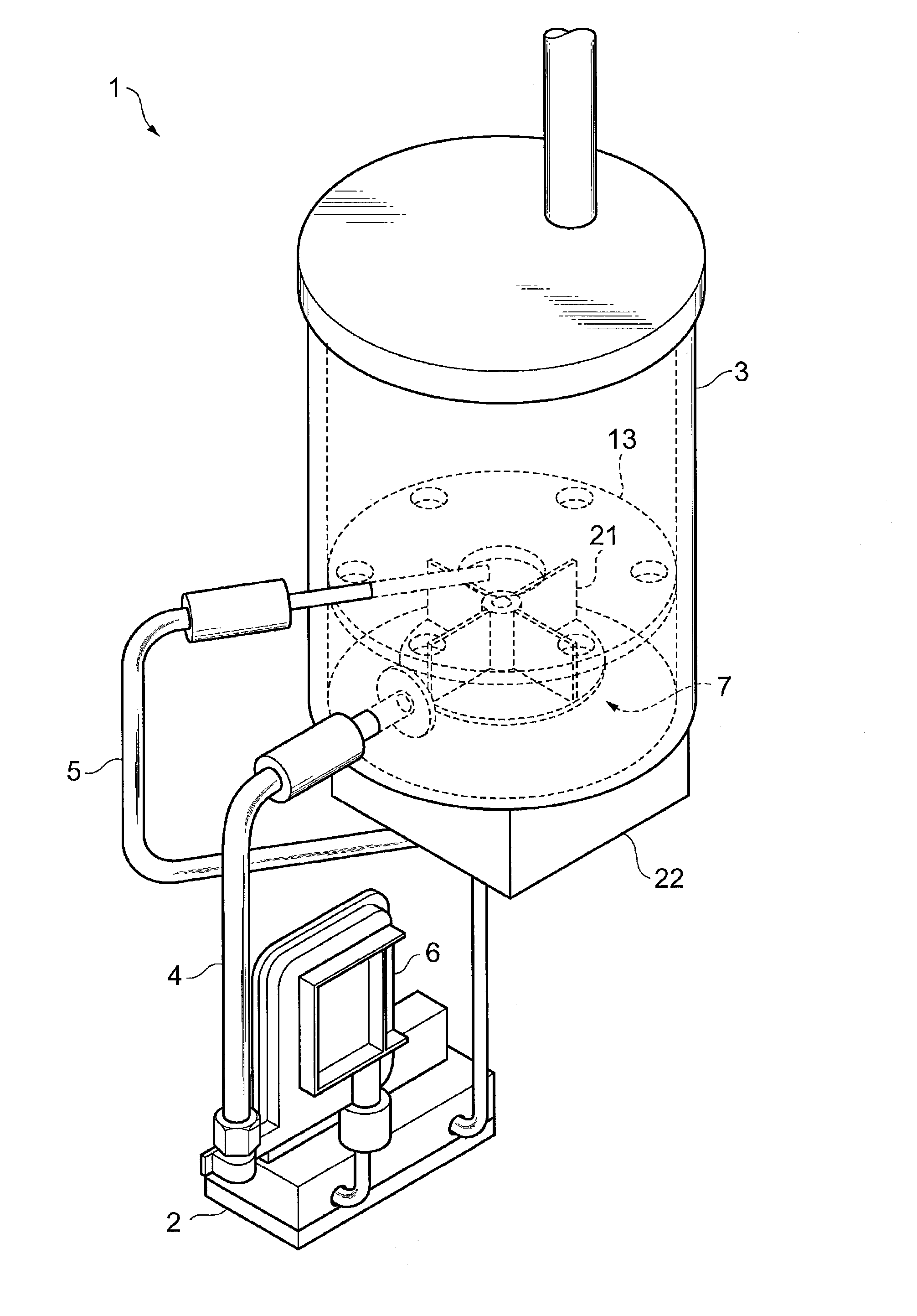

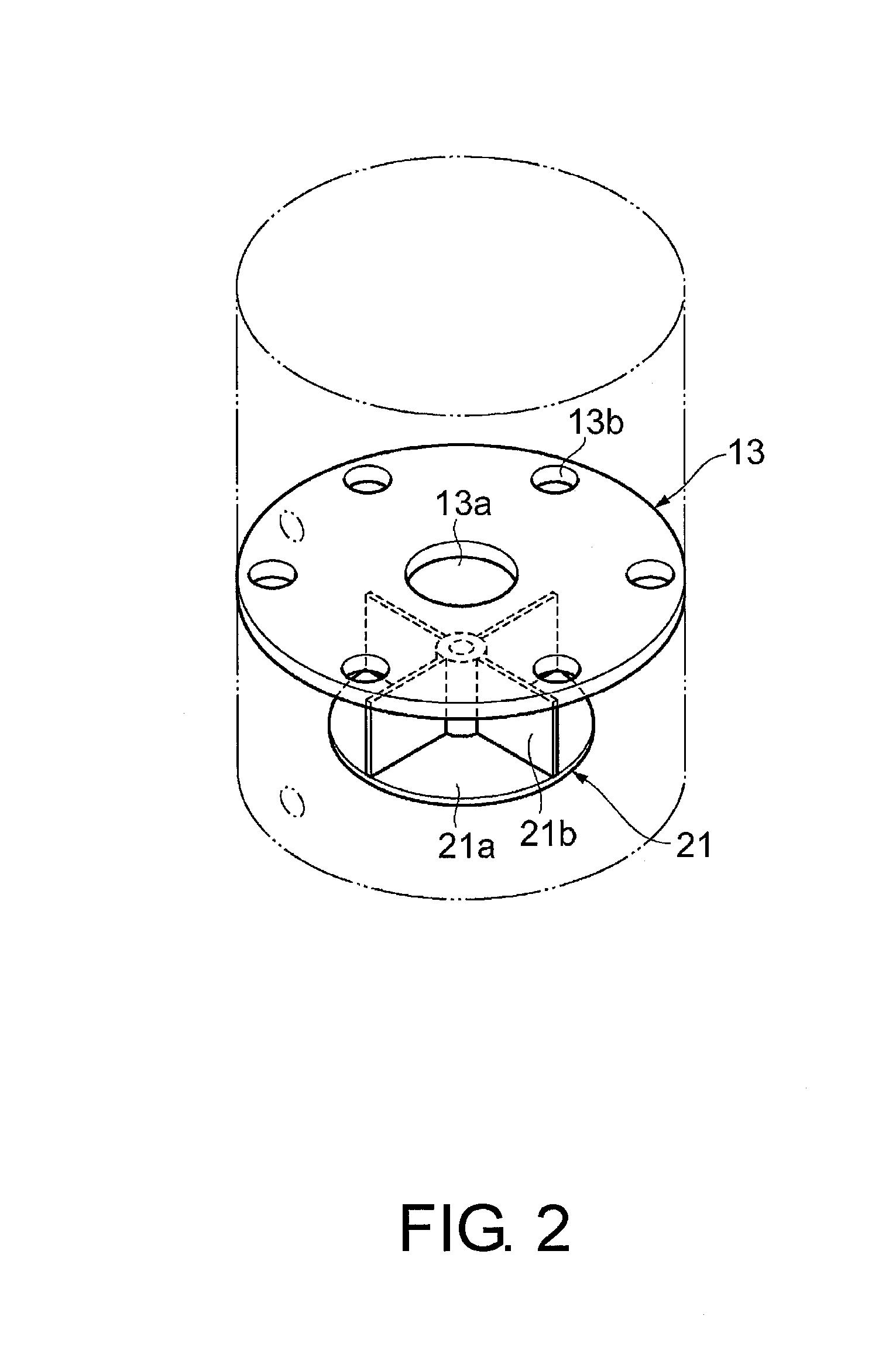

Liquid circulation system and ink-jet printer

An ink circulation system includes: an ink-jet head in which a shared ink flowing route is formed, an ink tank, a supply flowing route for supplying ink from the ink tank to the shared ink flowing route, a reflux flowing rout for refluxing the ink from the shared ink flowing route to the ink tank, and a differential pressure generating unit for generating a differential pressure in the ink tank. The differential pressure generating unit is equipped with an impeller placed inside the ink tank, and a drive unit placed outside the ink tank. Then, the drive unit operates to turn the impeller, by means of remote driving, for generating a differential pressure between a supply port of the supply flowing route and a reflux port of the reflux flowing route so as to circulate the ink through the ink flowing route.

Owner:MIMAKI ENG

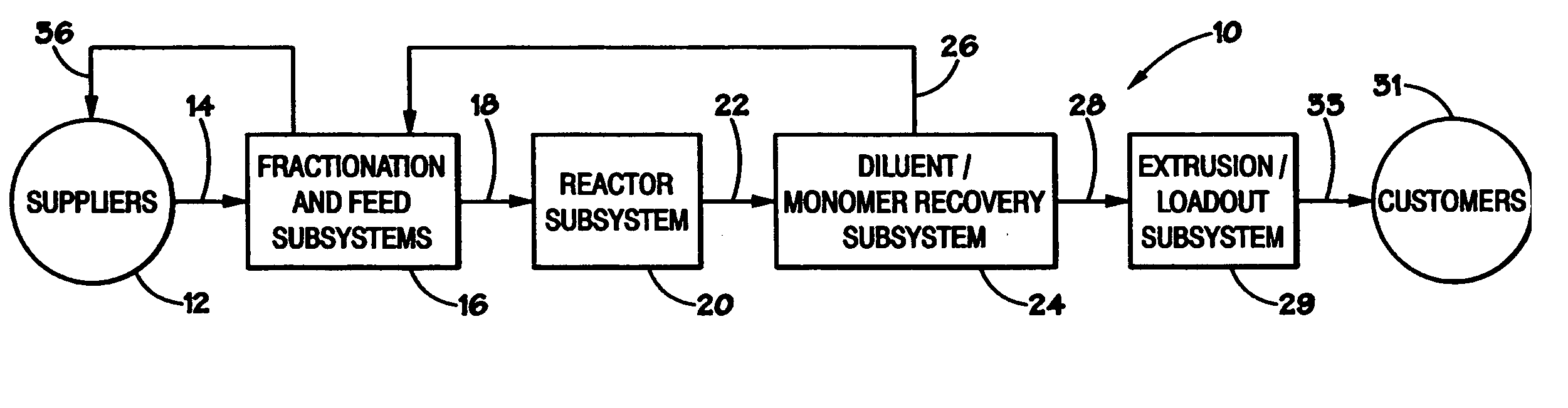

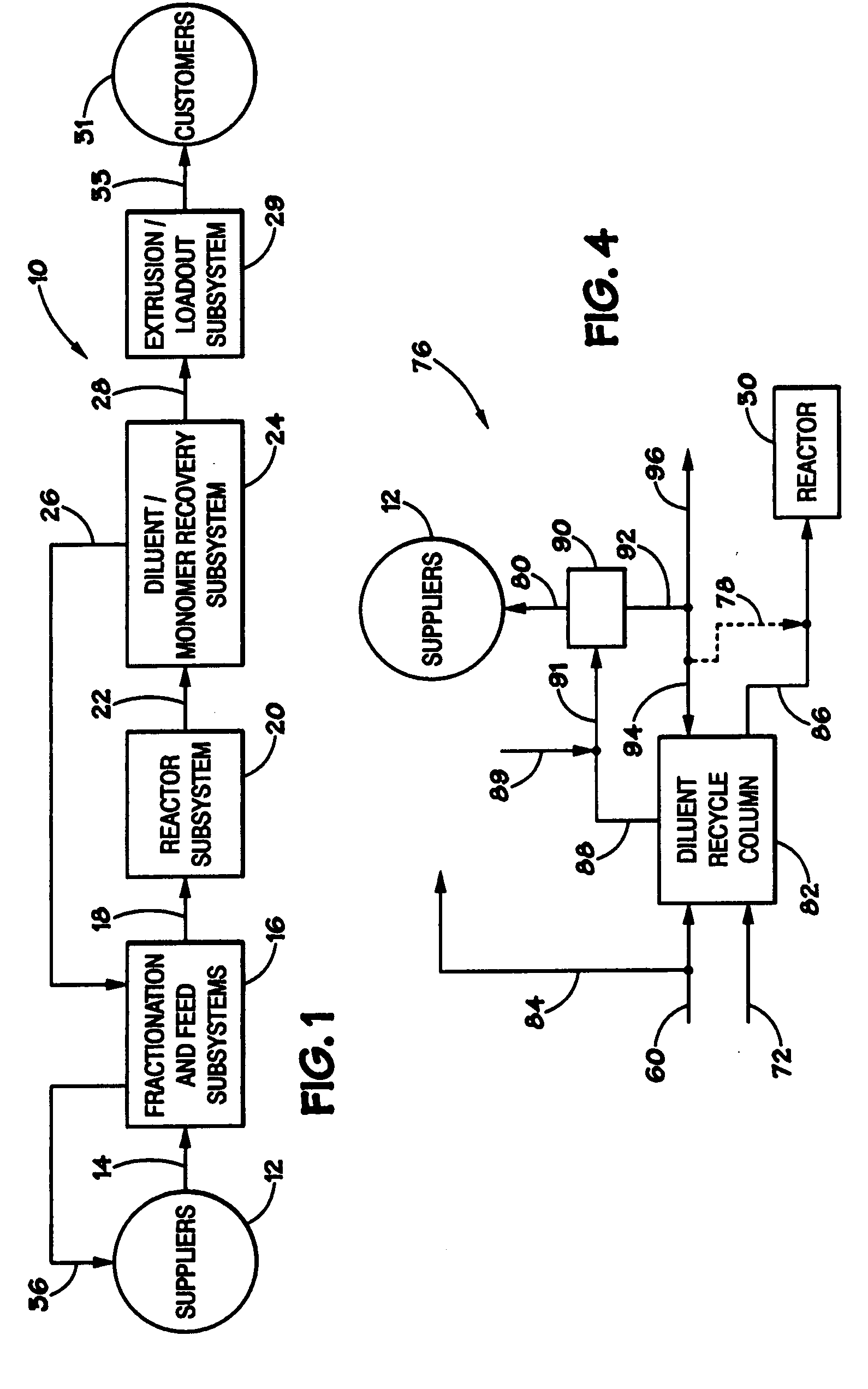

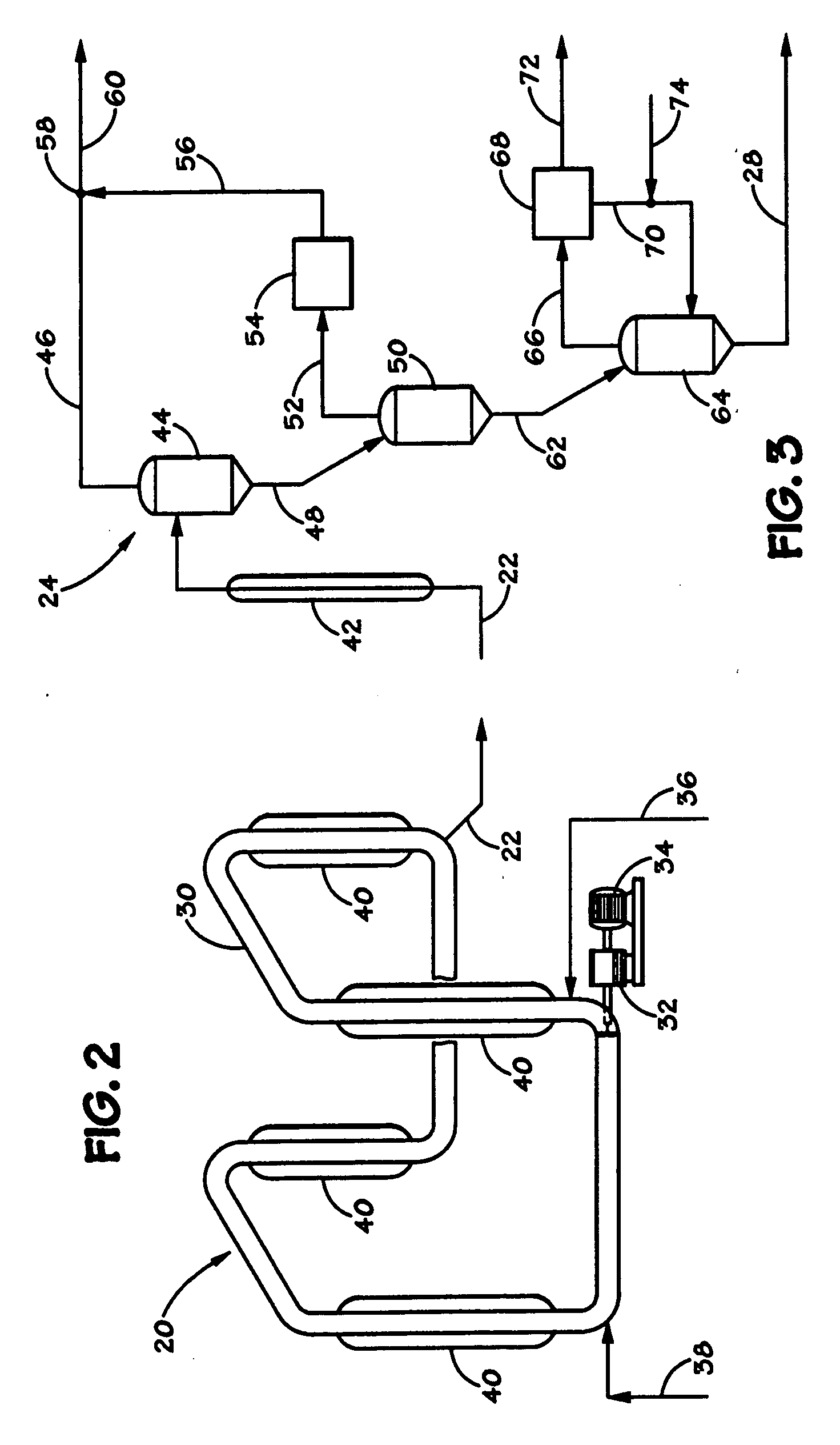

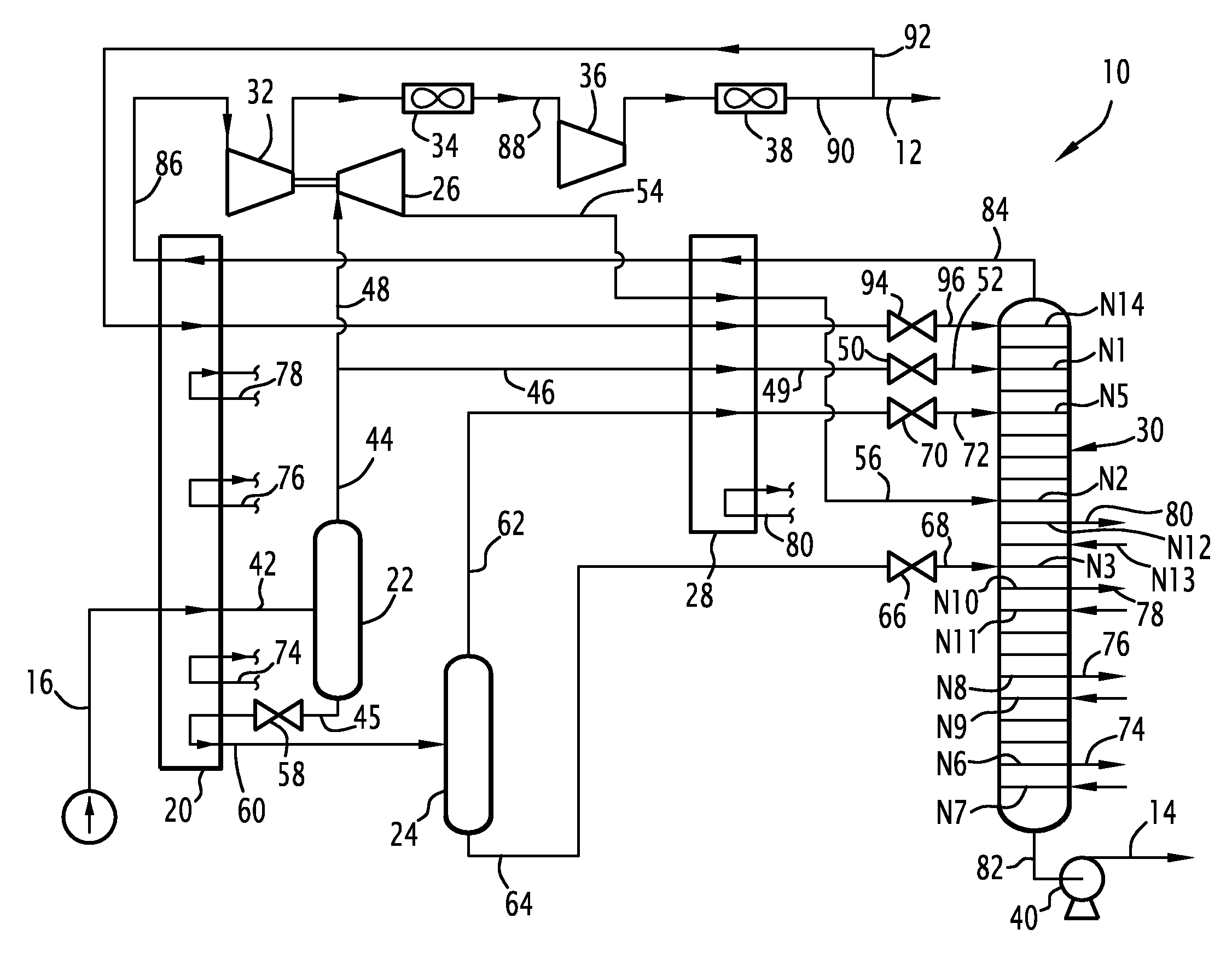

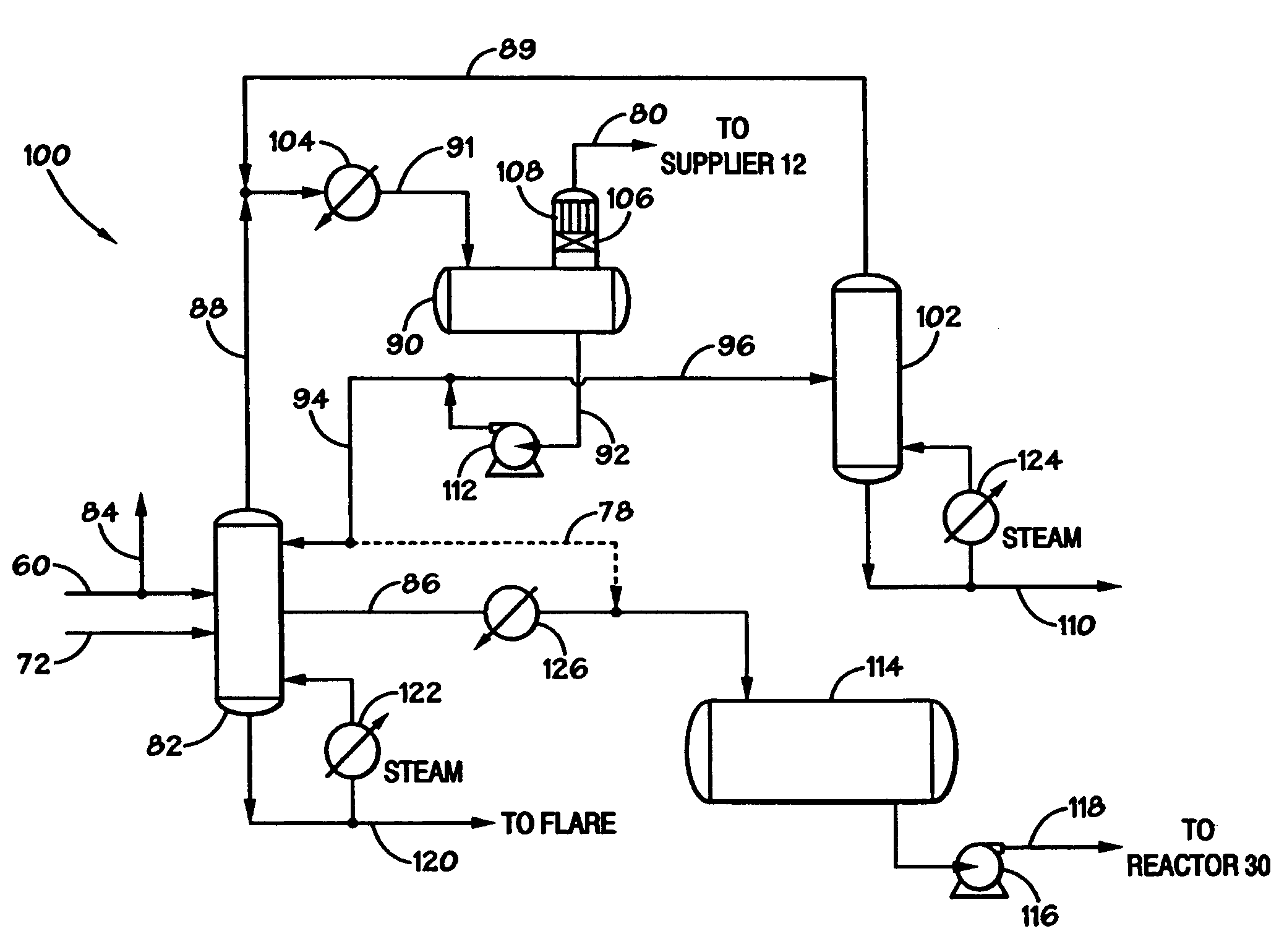

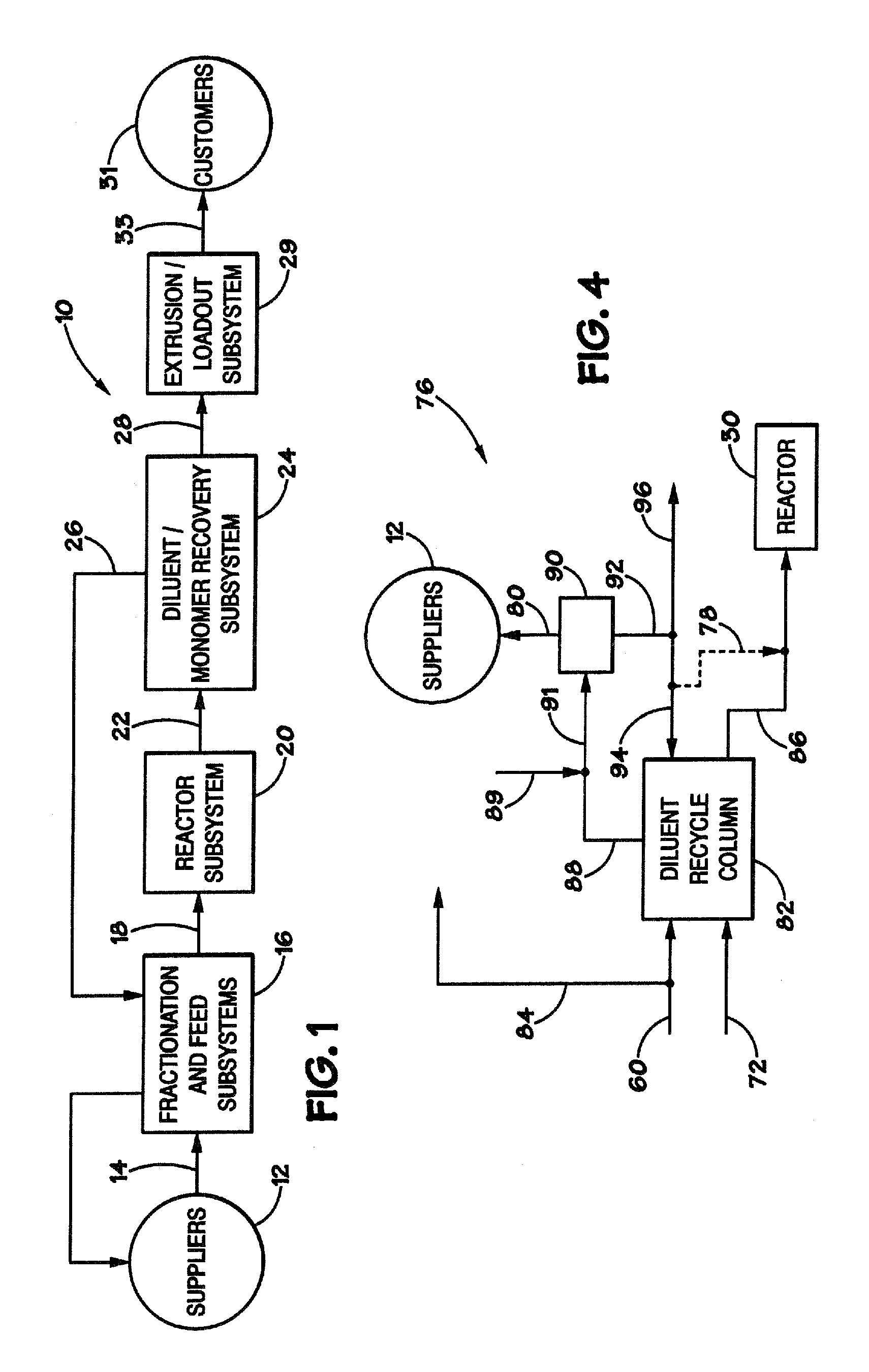

Monomer recovery by returning column overhead liquid to the reactor

InactiveUS20070142576A1Vacuum distillation separationChemical/physical/physico-chemical processesPolyolefinSlurry reactor

A polyolefin production system, comprising a polymerization reactor (such as a polyethylene loop slurry reactor) and a fractionation system that receives reactor effluent processed in a diluent / monomer recovery system for recycle to the reactor and to suppliers. A conduit diverts a portion of a reflux flow comprising monomer, such as ethylene, from within the fractionation system to the polymerization reactor, providing for less venting of monomer, such as ethylene, to the supplier. Accordingly, monomer yield is advantageously increased, as the monomer returned to the reactor displaces monomer feedstock to the reactor. The reflux flow may originate from a condensed overhead lights from a diluent recycle column disposed in the fractionation subsystem. The diluent recycle column may receive a stream comprising diluent and monomer as feed from the diluent / monomer recovery subsystem, and may receive the non-diverted portion of the reflux flow as reflux.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

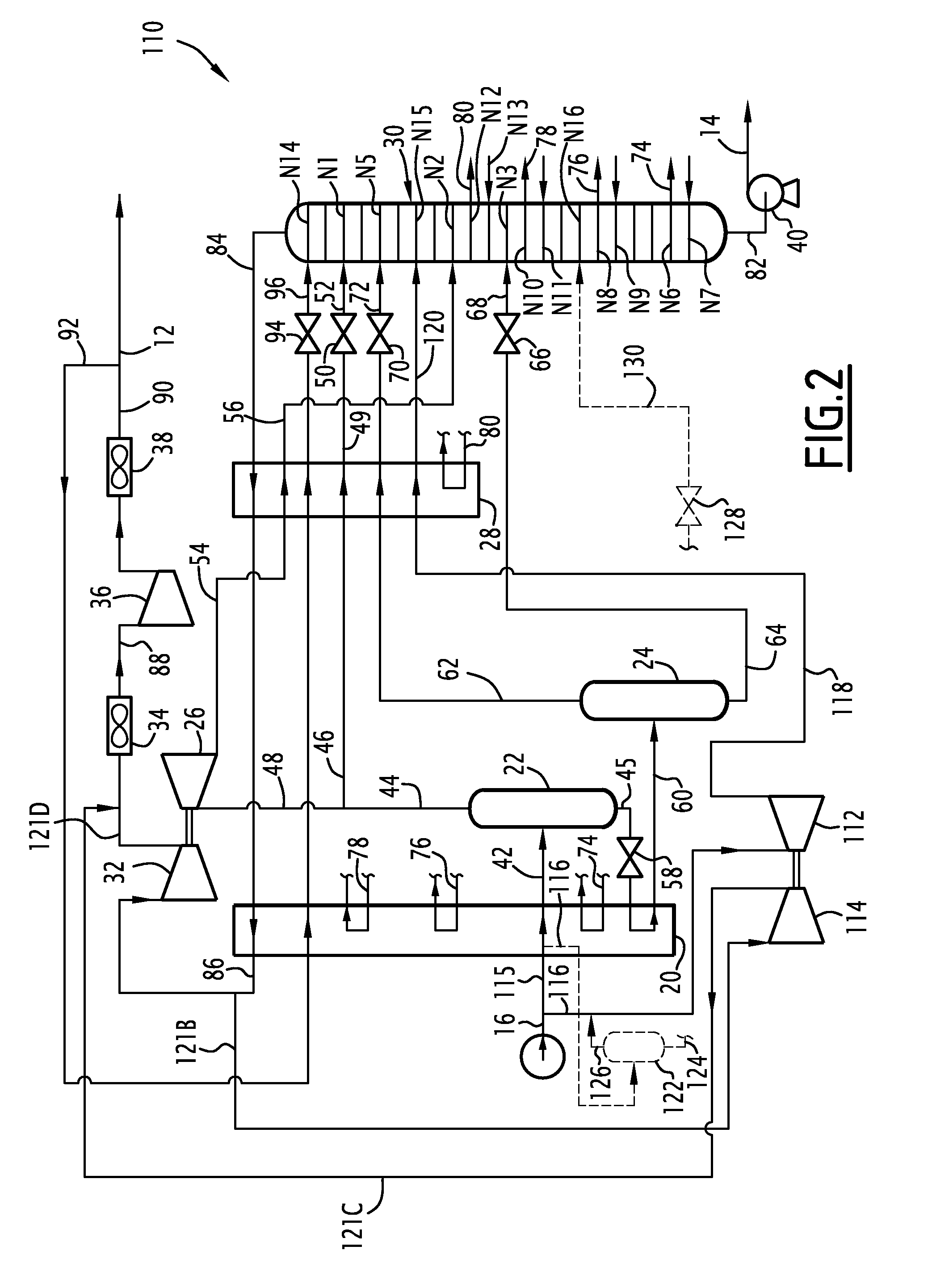

Method for producing a flow rich in methane and a flow rich in c2+ hydrocarbons, and associated installation

ActiveUS20110005273A1Economical and very efficient mannerSpace minimizationSolidificationLiquefactionFractionating columnProcess engineering

This method comprises cooling the supply flow in a first heat exchanger, separation in a first separation flask in order to produce a light upper flow and a heavy lower flow and dividing the light upper flow into a supply fraction of a dynamic pressure reduction turbine and a supply fraction of a first distillation column.The method comprises forming a cooled reflux flow from an effluent from a dynamic pressure reduction turbine, the portion of the effluent being cooled and at least partially liquefied in a heat exchanger.It comprises introducing the cooled reflux flow from the heat exchanger into the first distillation column.

Owner:TECH FRANCE SA

Liquid circulation system and ink-jet printer

An ink circulation system includes: an ink-jet head in which a shared ink flowing route is formed, an ink tank, a supply flowing route for supplying ink from the ink tank to the shared ink flowing route, a reflux flowing route for refluxing the ink from the shared ink flowing route to the ink tank, and a differential pressure generating unit for generating a differential pressure in the ink tank. The differential pressure generating unit is equipped with an impeller placed inside the ink tank, and a drive unit placed outside the ink tank. Then, the drive unit operates to turn the impeller, by means of remote driving, for generating a differential pressure between a supply port of the supply flowing route and a reflux port of the reflux flowing route so as to circulate the ink through the ink flowing route.

Owner:MIMAKI ENG

Method for preparing dipentaerythritol pentaacrylate

InactiveCN102146034AHigh purityHigh yieldOrganic compound preparationCarboxylic acid esters preparationPentaerythritolWastewater

The invention discloses a method for preparing dipentaerythritol pentaacrylate, which comprises the following steps of: (1) putting main materials of dipentaerythritol and crylic acid into an esterification reaction container, adding a solvent, adding a catalyst and a polymerization inhibitor A, and performing mixing reaction to obtain a reaction material; (2) controlling the pressure in the esterification reaction container to be -0.04 to -0.08MPa, raising the temperature in the esterification reaction container until reflux flows out, keeping the temperature, and beginning cooling to normal temperature until no reflux flows out or an acid value in reaction solution is detected to be 30-50mgKOH / g; (3) transferring the reaction material to a washing container, adding alkali liquor, controlling the pH value of the reaction material to be 7-8, standing until the reaction material is layered, and discharging wastewater on the lower layer; and (4) transferring the reaction material of which the wastewater is removed to a distillation container, adding a polymerization inhibitor B, vacuumizing the distillation container, and distilling to remove methylbenzene to obtain the product. The product is high in purity, good in color, and high in yield.

Owner:天津市天骄化工有限公司

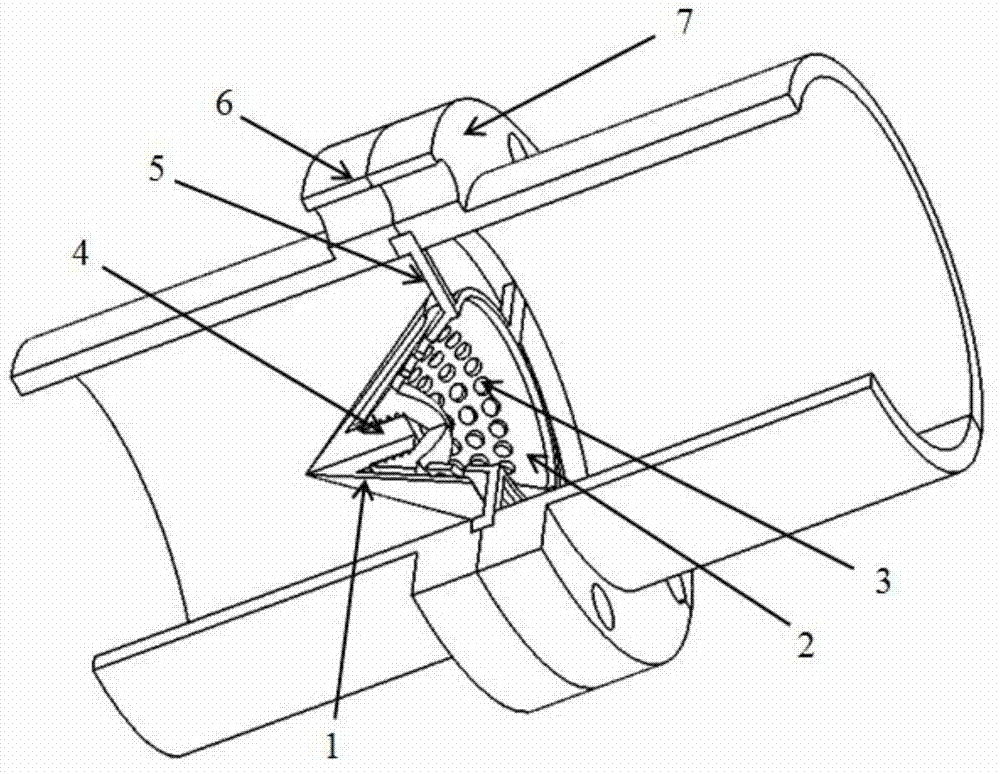

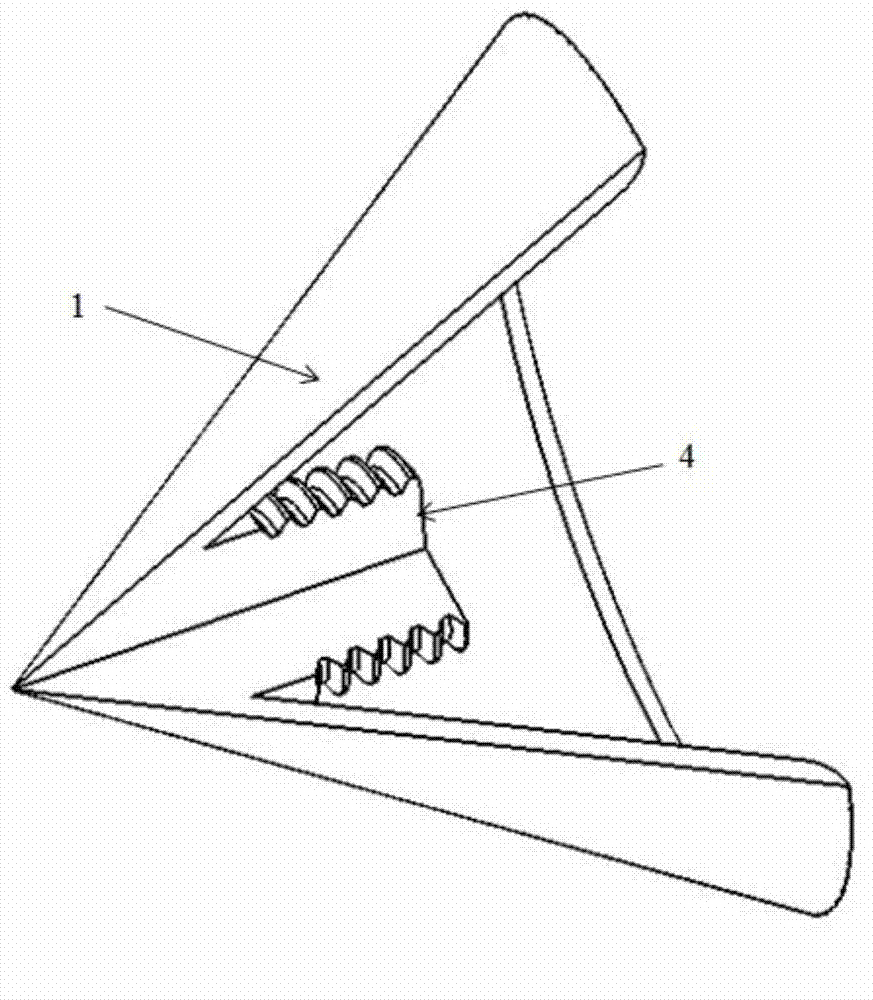

Structure for reducing back pressure of air inlet channel of inspiration type impulse knocking engine

InactiveCN103089444AIncrease thrustReduce pressureTurbine/propulsion air intakesShock waveCombustion

The invention provides a structure for reducing back pressure of an air inlet channel of an inspiration type impulse knocking engine. The structure is composed of a front cone and a rear cone, wherein the inner surface of the head of the front cone is provide with an axial column with an external thread, the inner surface of the head of the rear cone is provided with an axial boss, and the outer surface of the head of the rear cone is provided with an axial internal thread blind hole; the wall surface of the rear cone is provided with a plurality of drainage holes, the axial column of the external thread of the front cone and the blind hole of the internal thread of the rear cone are matched and fixed so as to form a conical ring cavity; pressure wave formed by combustion flame can reflect the pressure wave on the boss of the rear cone in use, and the transition from slow combustion to knocking is capable of accelerated; the knocking wave is formed, the knocking wave is spread on the rear cone, intense shock wave generated by the rear cone through reflecting is spread to the outlet, and the reflux total pressure is reduced; reflux enters the rear cone so as to enter the conical ring cavity through drainage holes and flow out along a ring cavity, and the flowing direction of part reflux is changed; and the reflux flowed from the ring cavity forms an annular jet, the reflux and the reflux through bypassing the rear cone are mutually acted, and the reflux discharge and total pressure of forward spread are reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

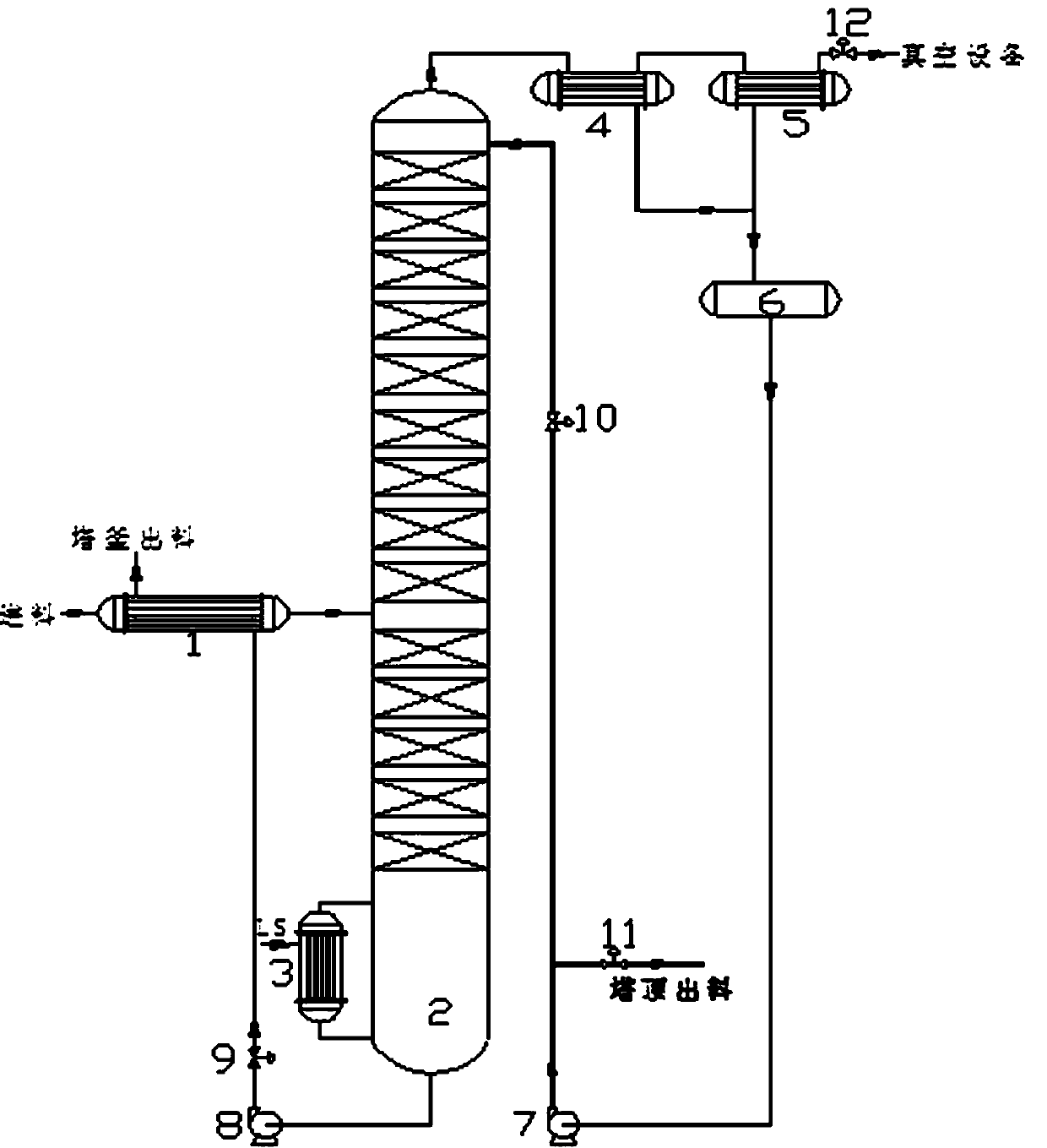

System and method for rectifying and purifying dimethyl oxalate synthesized through carbonylation of glycol from coal

InactiveCN110003007AHigh purityReduce consumptionOrganic compound preparationPreparation by carbon monoxide or formate reactionReboilerEvaporation

The invention relates to a system and method for rectifying and purifying dimethyl oxalate synthesized through carbonylation of glycol from coal. Through the system and method, the purity of the dimethyl oxalate product can be imprved, energy consumption is reduced, and the production cost is saved. The system comprises a dimethyl oxalate feeding heat exchanger and a vacuum rectification tower communicating with the dimethyl oxalate feeding heat exchanger, wherein a reboiler is arranged at the bottom of the tower, a tower-top condenser communicates with the top of the vacuum rectification tower through an evaporation vapor outlet, and the tower-top condenser communicates with a reflux tank and a tail cooler separately; the reflux tank communicates with a reflux pump, the reflux pump communicates with the top of the vacuum distillation tower and a tower-top extraction flow regulating valve, and the bottom of the rectification tower communicates with a heavy component discharge pump; andthe heavy component discharge pump passes through the dimethyl oxalate feeding heat exchanger and communicates with a material outlet of the tower through a pipeline and a tower liquid level regulating valve, a reflux flow regulating valve is arranged on the outlet pipeline of the reflux pump so as to remove light component impurities in a dimethyl oxalate mixed liquid and obtain a high-purity dimethyl oxalate intermediate product. Through vacuum operation, the boiling points of the components are reduced, the consumption of medium pressure steam is reduced, and the cost is reduced; and the tower components and the tower-top light components are taken out continuously, heat and materials are recycled and utilized effectively, and no outer emission of the materials occurs.

Owner:安阳永金化工有限公司

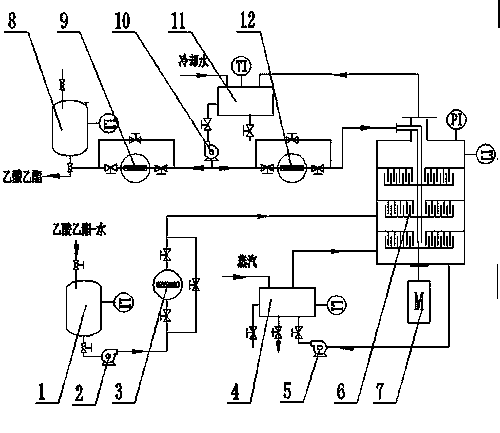

Technology for separating ethylene glycol monomethyl ether and water by use of continuous azeotropic distillation method

ActiveCN102952004ASolve the problem of high toxicity of the original processLow toxicityEther separation/purificationPhase splittingTower

Owner:HEBEI UNIV OF TECH

Method of producing ethyl acetate and equipment for carrying out this method

InactiveCN1433395ALow in ethanolEasy to purifyOrganic compound preparationOrganic chemistry methodsAcetic acidAcetic anhydride

The invention relates to a method of producing ethyl acetate by reaction of ethyl alcohol with acetic acid and / or acetic anhydride in presence of a solid acidic catalyst and during simultaneous distillatory separation of reaction components, in which acetic acid or acetic anhydride or their mixture and ethyl alcohol are introduced separately in molar ratio 2:1 to 1:2.5 and in a defined quantity, based on volume unit of catalyst, into the system separated into three zones, whereby, in the reaction zone, the reaction runs simultaneously with the distillatory separation of components, acetic acid feed is introduced into the reaction zone or above the zone and ethyl alcohol feed is introduced into the reaction zone or below this zone, in the upper separation zone, the volatile mixture is separated, thereafter, it is cooled to 5 to 70 DEG C and then separated to water and organic phases and this organic phase with high ethyl acetate content is drawn off and partially returned as reflux flow into this system, whereby, the ratio of the input components feed and the organic phase reflux flow is 1:1 to 1:20. A subject matter of this invention is also an equipment for carrying out this method.

Owner:SULZER CHEMTECH AG

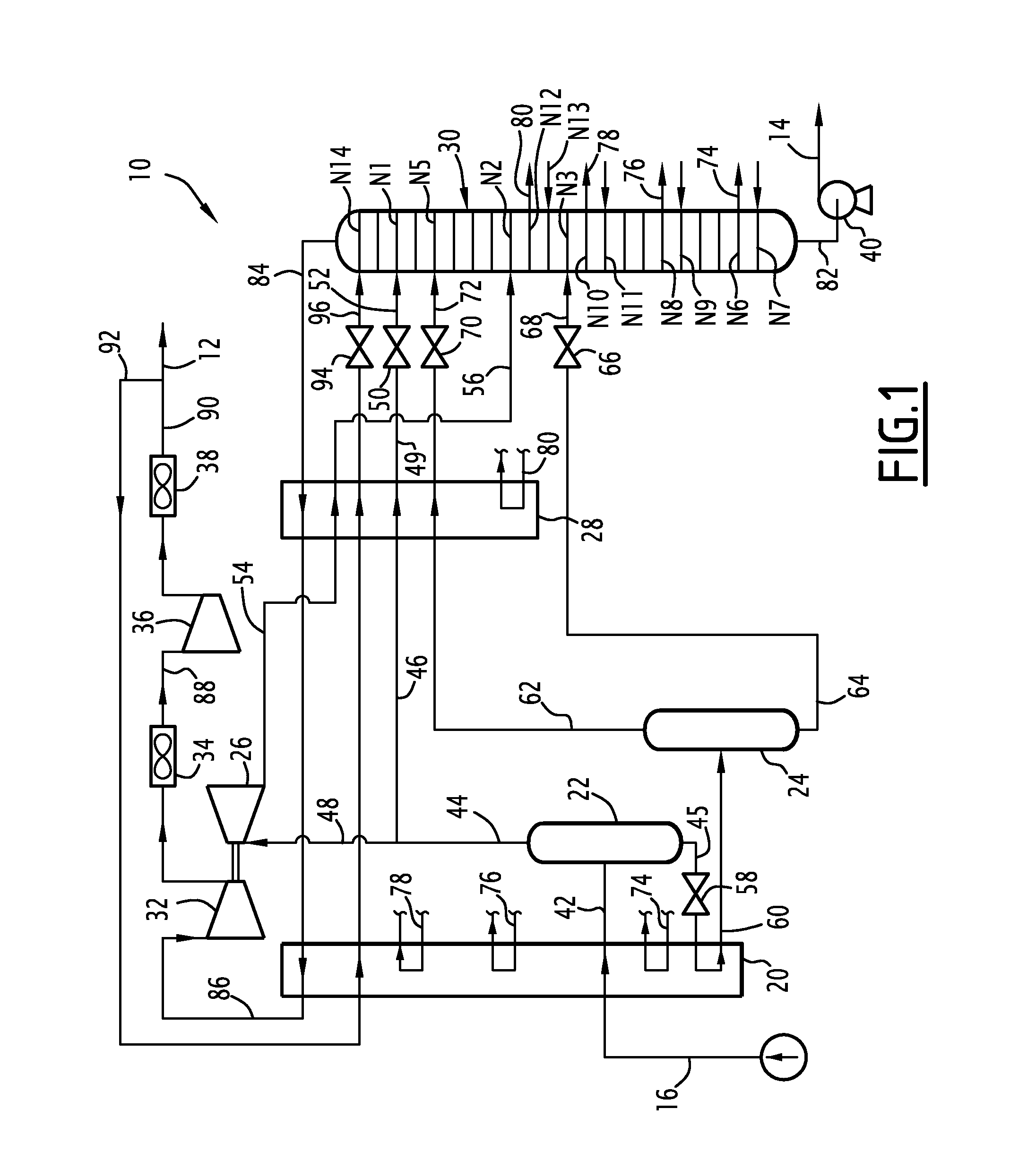

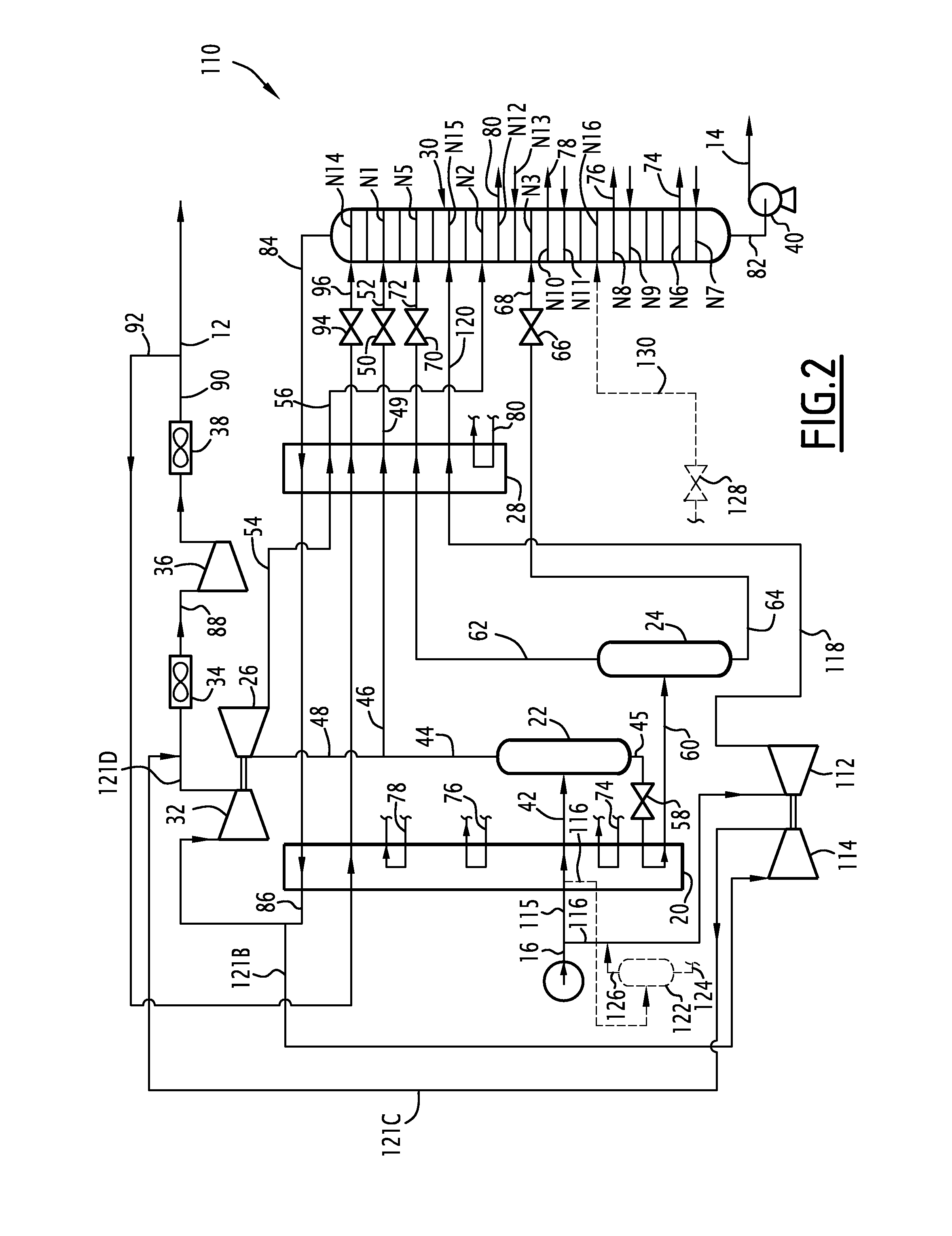

Monomer recovery by returning column overhead liquid to the reactor

A polyolefin production system, comprising a polymerization reactor (such as a polyethylene loop slurry reactor) and a fractionation system that receives reactor effluent processed in a diluent / monomer recovery system for recycle to the reactor and to suppliers. A conduit diverts a portion of a reflux flow comprising monomer, such as ethylene, from within the fractionation system to the polymerization reactor, providing for less venting of monomer, such as ethylene, to the supplier. Accordingly, monomer yield is advantageously increased, as the monomer returned to the reactor displaces monomer feedstock to the reactor. The reflux flow may originate from a condensed overhead lights from a diluent recycle column disposed in the fractionation subsystem. The diluent recycle column may receive a stream comprising diluent and monomer as feed from the diluent / monomer recovery subsystem, and may receive the non-diverted portion of the reflux flow as reflux.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

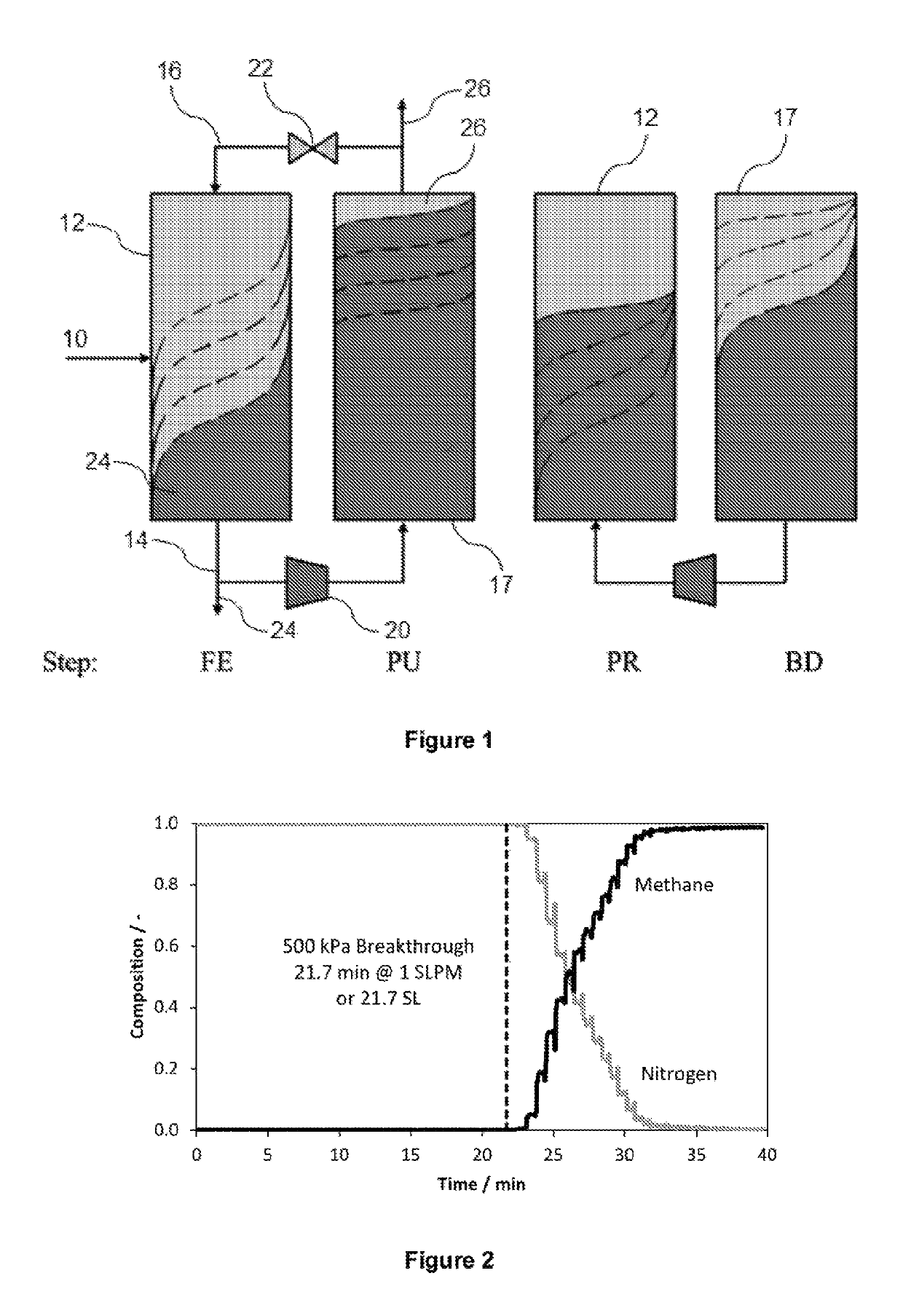

Method for preparing 2-methyl-2-propenoic acid 2-ethyl-2-[[(2-methyl-1-oxo-2-propenyl)oxy]methyl]-1,3-propanediyl ester

InactiveCN102146037AHigh purityHigh yieldOrganic compound preparationCarboxylic acid esters preparationWastewaterAcid value

The invention discloses a method for preparing 2-methyl-2-propenoic acid 2-ethyl-2-[[(2-methyl-1-oxo-2-propenyl)oxy]methyl]-1,3-propanediyl ester, which comprises the following steps of: (1) putting main materials of trimethylolpropane and methacrylic acid into an esterification reaction container, adding a solvent, adding a catalyst and a polymerization inhibitor A, and performing mixing reaction to obtain a reaction material; (2) controlling the pressure in the esterification reaction container to be -0.04 to -0.08MPa, raising the temperature in the esterification reaction container until reflux flows out, keeping the temperature, and beginning cooling to normal temperature until no reflux flows out or an acid value in reaction solution is detected to be 30-50mgKOH / g; (3) transferring the reaction material to a washing container, adding alkali liquor, controlling the pH value of the reaction material to be 7-8, standing until the reaction material is layered, and discharging wastewater on the lower layer; and (4) transferring the reaction material of which the wastewater is removed to a distillation container, adding a polymerization inhibitor B, vacuumizing the distillation container, and distilling to remove methylbenzene to obtain the product. The product is high in purity, good in color, and high in yield.

Owner:天津市天骄化工有限公司

Method for dewatering a mixture of mostly ethanol and water

ActiveUS20100270139A1Reduce energy consumptionSemi-permeable membranesFermented solutions distillation/rectificationAnhydrous ethanolThermodynamics

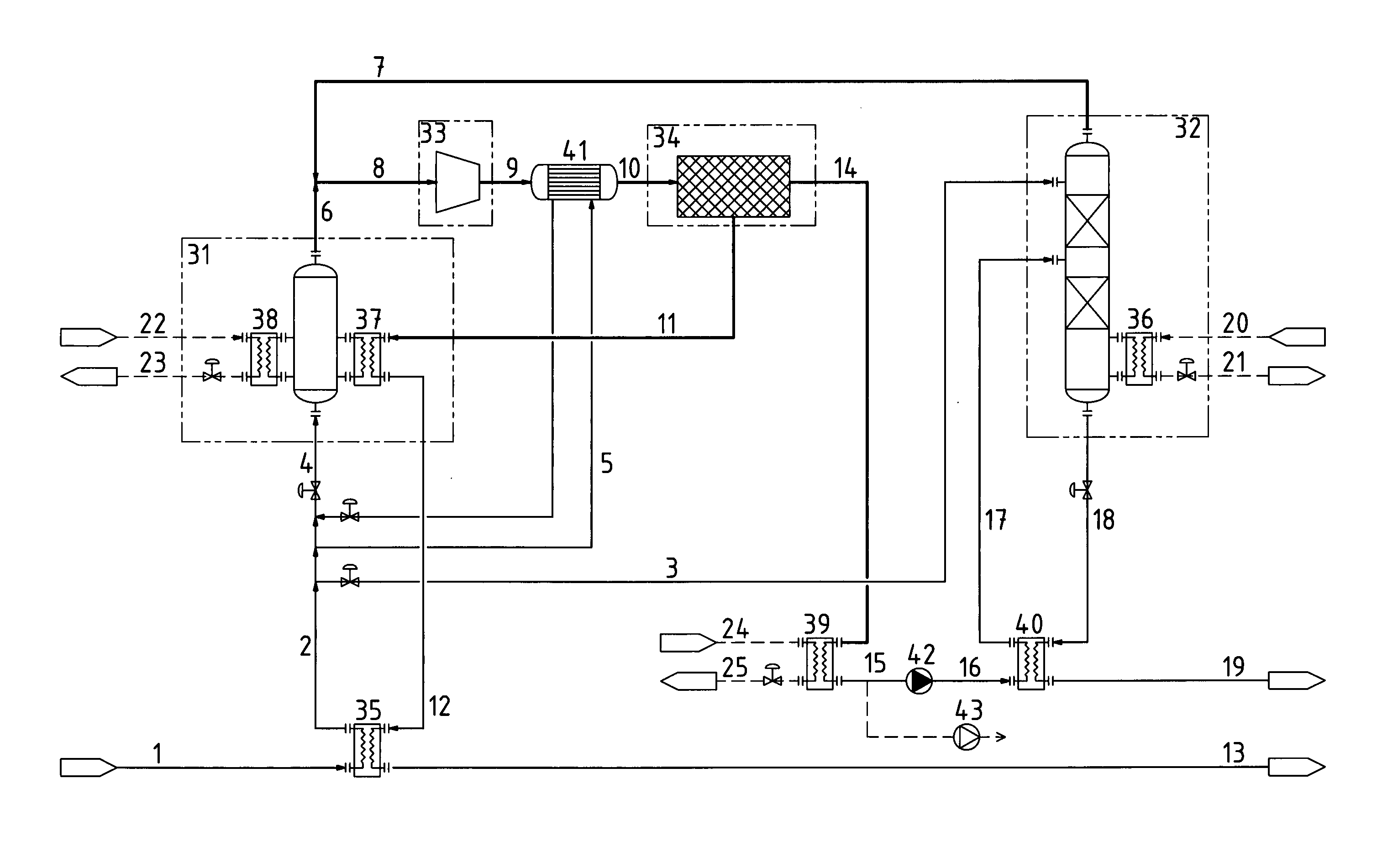

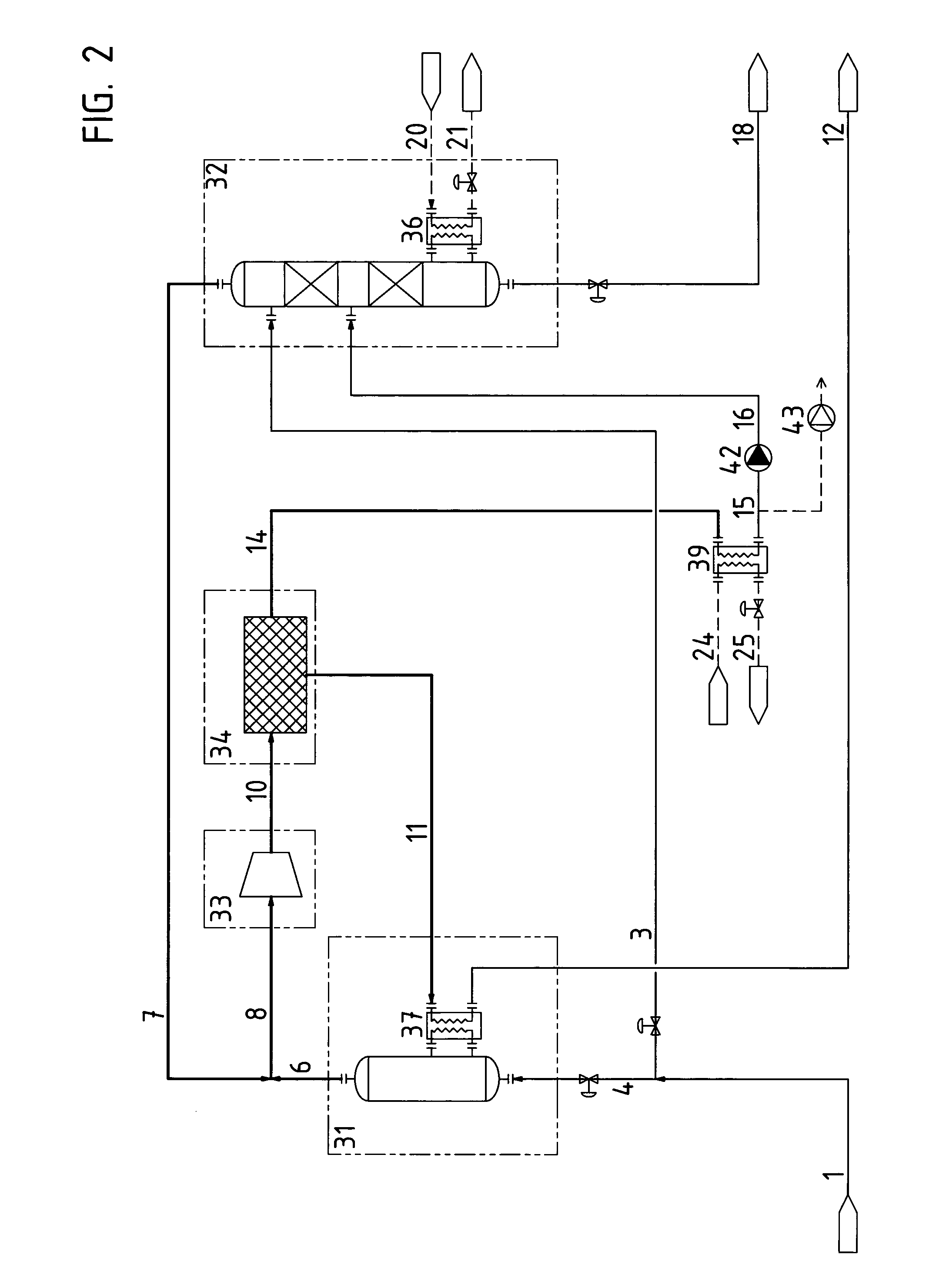

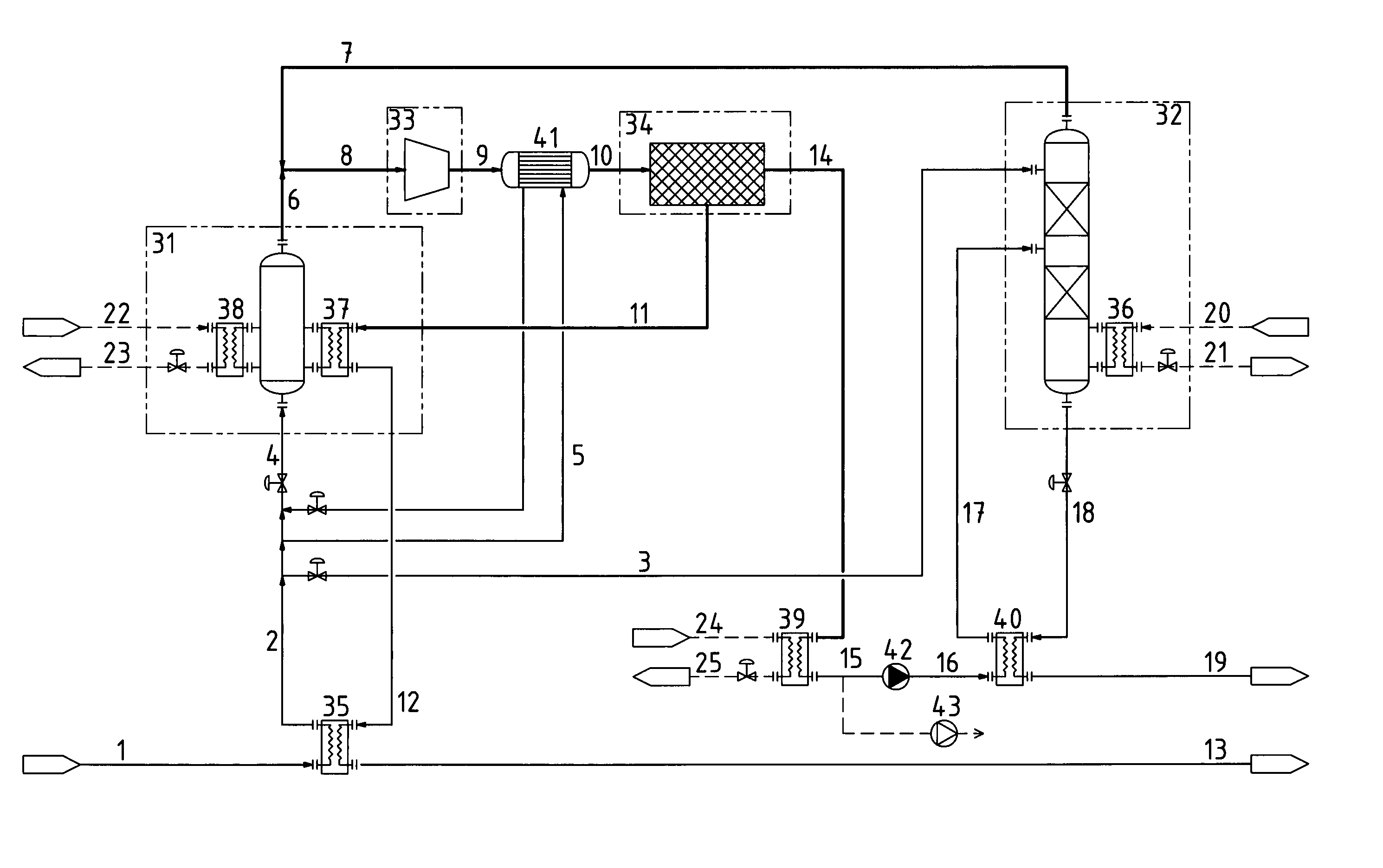

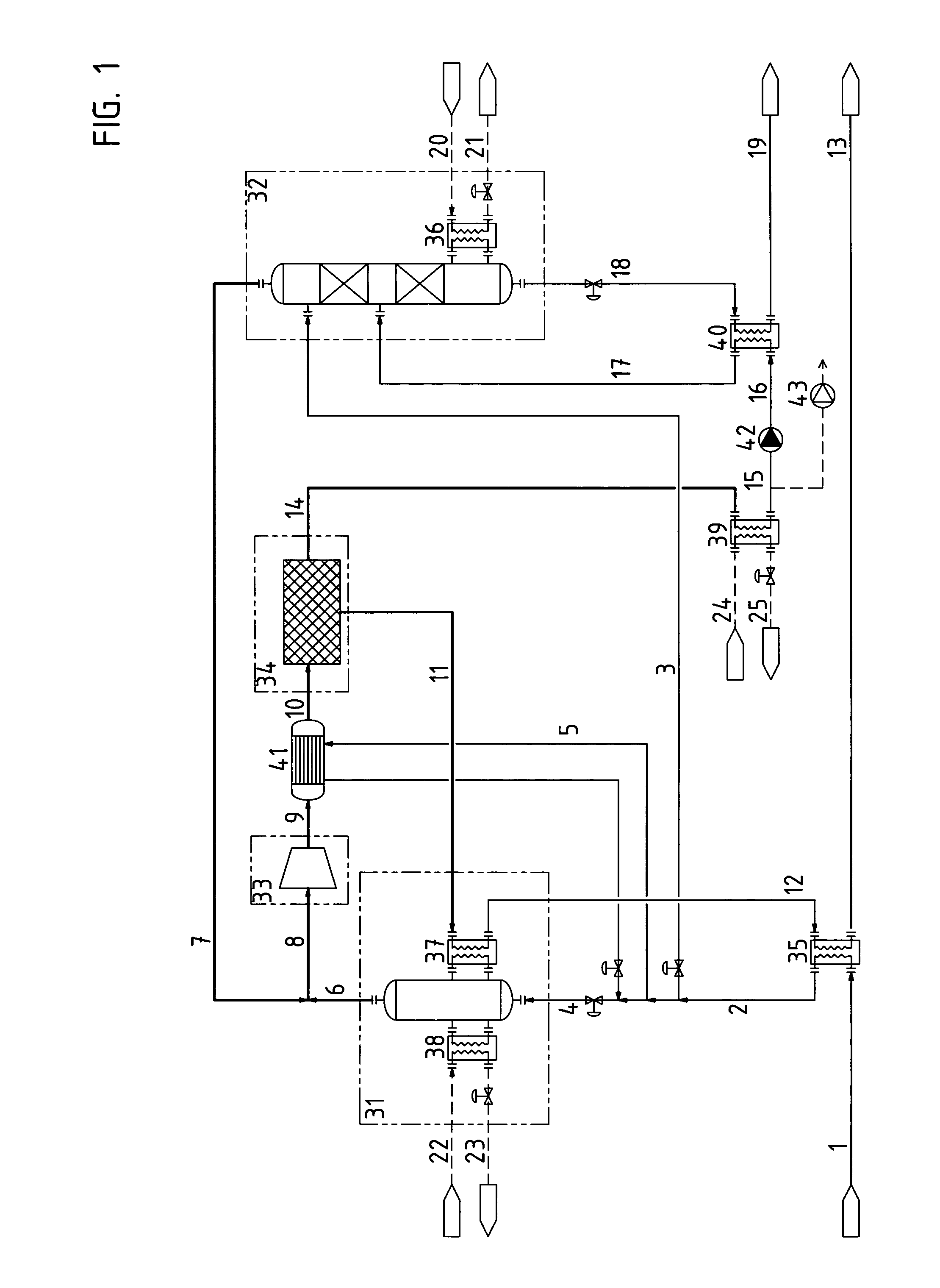

Method for dewatering a mixture of mostly ethanol and water which is split into a first partial feed flow (3) that is directed to a distillation column (32) as a reflux flow while a second partial feed flow (4) is directed to an evaporator unit (31) as an evaporator inlet flow and leaves the top of the evaporator unit as an evaporator outlet flow (6). A top discharge flow (7) from distillation column (32) is returned and combined with the evaporator outlet flow (6) to a combined flow (8) at an overpressure and which in a compressor unit (33) is compressed to a combined, compressed flow (10) which enters a dewatering unit (34) in which it is split into a water-rich permeate flow (14) and a retentate flow (11) in the form of substantially water free ethanol. The permeate flow (14) is condensed in a condenser (39) at an underpressure whereafter permeate flow (15) is pressurized by a pump (42) to a flow (16) which is fed to distillation column (32), which is supplied with external thermal energy by a heat exchanger (36), and there split into a water rich bottom discharge flow (18) and an ethanol-rich top discharge flow (7). The retentate flow (11) is used an energy source in a retentate heat exchanger (37) of evaporator unit (31) before leaving as a product flow (12).

Owner:EPCON ENERGY & PROCESS CONTROL

Method for dewatering a mixture of mostly ethanol and water

ActiveUS8425733B2Reduce energy consumptionFermented solutions distillation/rectificationSemi-permeable membranesThermal energyEngineering

Method for dewatering a mixture of mostly ethanol and water which is split into a first partial feed flow (3) that is directed to a distillation column (32) as a reflux flow while a second partial feed flow (4) is directed to an evaporator unit (31) as an evaporator inlet flow and leaves the top of the evaporator unit as an evaporator outlet flow (6). A top discharge flow (7) from distillation column (32) is returned and combined with the evaporator outlet flow (6) to a combined flow (8) at an overpressure and which in a compressor unit (33) is compressed to a combined, compressed flow (10) which enters a dewatering unit (34) in which it is split into a water-rich permeate flow (14) and a retentate flow (11) in the form of substantially water free ethanol. The permeate flow (14) is condensed in a condenser (39) at an underpressure whereafter permeate flow (15) is pressurized by a pump (42) to a flow (16) which is fed to distillation column (32), which is supplied with external thermal energy by a heat exchanger (36), and there split into a water rich bottom discharge flow (18) and an ethanol-rich top discharge flow (7). The retentate flow (11) is used an energy source in a retentate heat exchanger (37) of evaporator unit (31) before leaving as a product flow (12).

Owner:EPCON ENERGY & PROCESS CONTROL

A Fenton fluidized bed reactor and an operation method thereof

ActiveCN107098457AReduce yieldReduce invalid decompositionWater treatment compoundsSustainable biological treatmentFluidized bedDecomposition

A Fenton fluidized bed reactor and an operation method thereof are disclosed. The reactor includes a reactor shell, an inlet flow pattern distributor, a reflux flow pattern distributor, a hydrogen peroxide flow pattern distributor, a separating plate, a three-dimensional filter, a reflux pump, a water feeding pump, a pipeline mixer, an acid adding pump, a ferrous adding pump and a hydrogen peroxide adding pump. The reactor is uniform in water distribution and does not need additionally added power for stirring, thus saving the operation electric charge, reducing ineffective hydrogen peroxide decomposition caused by violent stirring and reducing the using amount of the hydrogen peroxide. The hydrogen peroxide and the ferrous sulphate are added separately, thus reducing ineffective consumption of agents. Active catalytic crystals are formed. The yield of iron-containing sludge is reduced.

Owner:DALIAN MARITIME UNIVERSITY +2

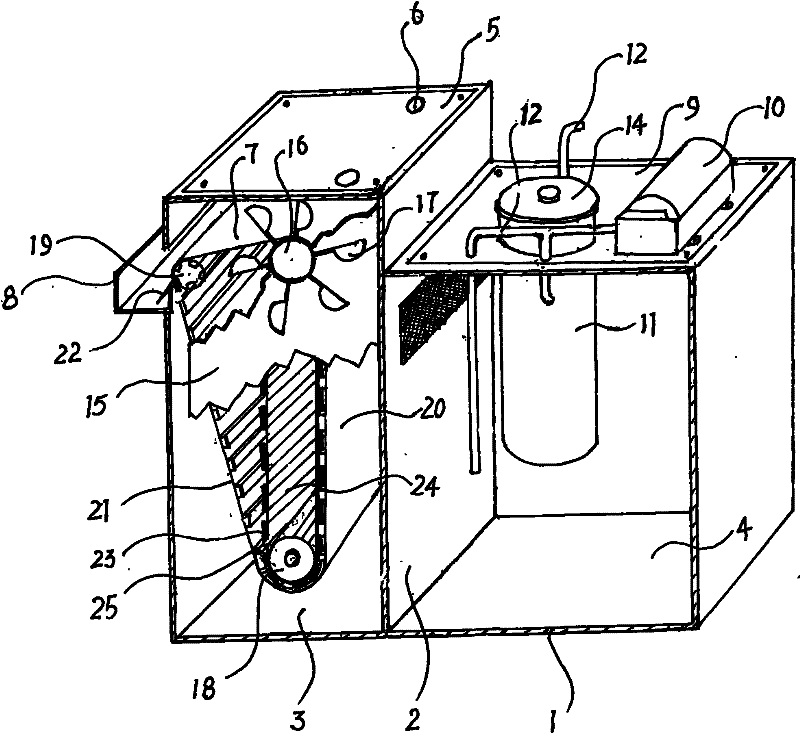

Residue automatic discharging filter

The invention relates to a residue automatic discharging filter. According to the device, a case body comprises a liquid inlet chamber and a liquid outlet chamber. An automatic discharging device is arranged in the liquid inlet chamber. A water pump and a filtering cylinder are arranged on the liquid outlet chamber. A shaft rotates under the driving of gravity of liquid buckets by reflux flowing. A driving belt and a conveyer belt rotate under the driving of the shaft. Magnetic teeth are arranged on the driving belt, and the conveyer belt is covered on the driving belt. With the magnetic force provided by the magnetic teeth, iron powder mixed in liquid can be absorbed on the surface of the conveyer belt. When the conveyer belt passes through the driving shaft, the conveyer belt is separated from the driving belt, such that the magnetic force is lost. Iron powder is detached and fell from the conveyer belt, and is discharged from a residue discharging groove.

Owner:NINGBO ZHENHAI YIFULAI CULTURE CREATIVE

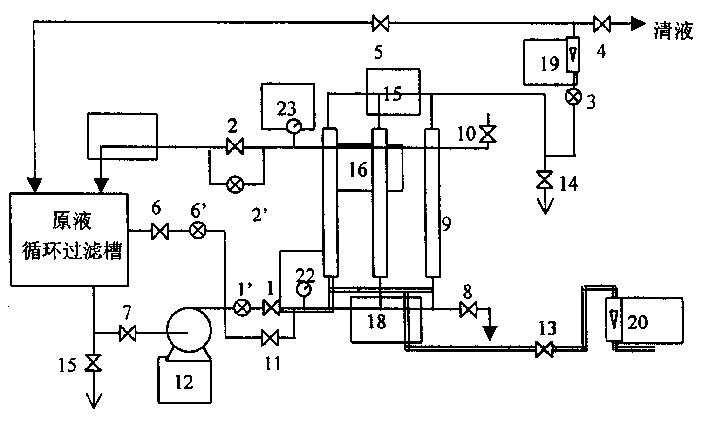

Hollow fibre membrane separation equipment and its operation method

InactiveCN1476923AIncrease productivitySpeed up filteringSemi-permeable membranesFiberHollow fibre membrane

The present invention provides a hollow fibrous membrane separation equipment and its operation method. Said membrane separation equipment includes membrane component, control valve, pressure gauge pump, air compressor, filter tank and connecting pipeline, liquid inlet pipeline and liquid outlet pipeline. The membrane separation equipment also includes working flow path, circulation reflux flow path, compressed air supplying pipeline, chemical cleaning reflux flow path and by-pass pipeline. Its operation method utilizes the valve on the pipeline to make said system implement switching-over between working state, first cleaning state, second cleaning state and chemical cleaning state.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

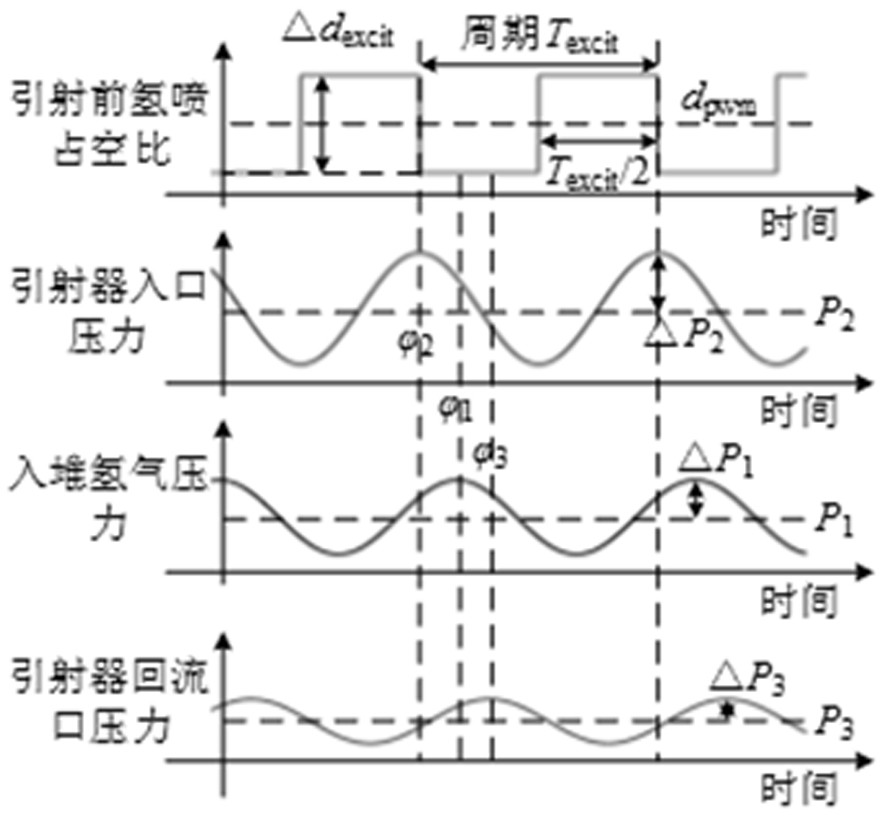

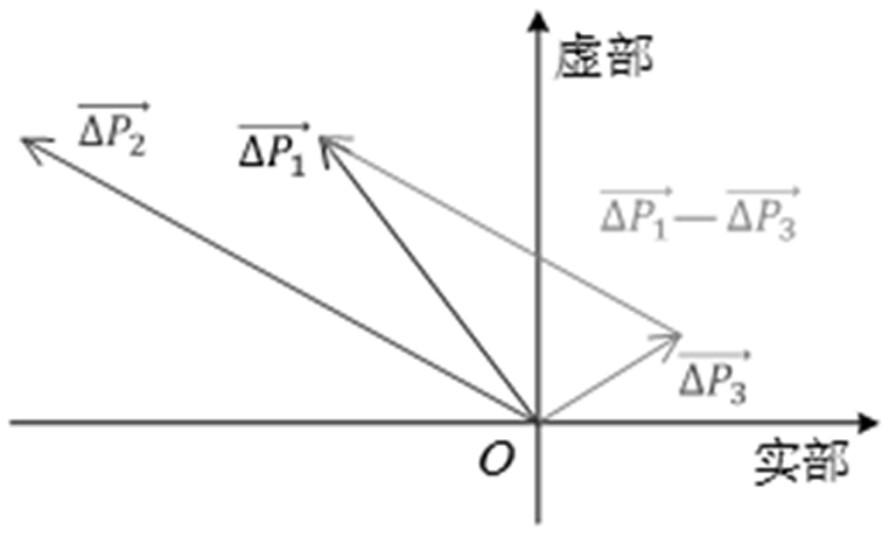

Method for calculating internal parameters of fuel cell system

The invention discloses a method for calculating internal parameters of a fuel cell system, and belongs to the field of fuel cells. The method comprises the following steps: enabling a controller to give disturbance instructions of different duty ratios of hydrogen injection, so that the in-pile pressure and the backflow pressure of the hydrogen injection fluctuate; based on the change of the gas pressure fluctuation frequency spectrum, obtaining the relationship between the reflux flow of the ejector and the reflux hydrogen pressure of the ejector, the hydrogen pressure at the inlet of the ejector, the in-pile hydrogen pressure and the radius of the gas pressure fluctuation frequency spectrum; and calculating the actual backflow flow of the ejector based on the relational expression and the gas pressure fluctuation spectrum radius. According to the method, the backflow flow of the ejector is calculated in a mode of generating system response by using pressure disturbance when the electric pile works stably. The backflow flow of the ejector can be calculated and evaluated on line by utilizing the ejector and system characteristics on the basis of an ejector body without adding extra acquisition equipment, so that the actual ejection backflow flow can be obtained on the basis of reducing the system cost.

Owner:BEIJING SINOHYTEC

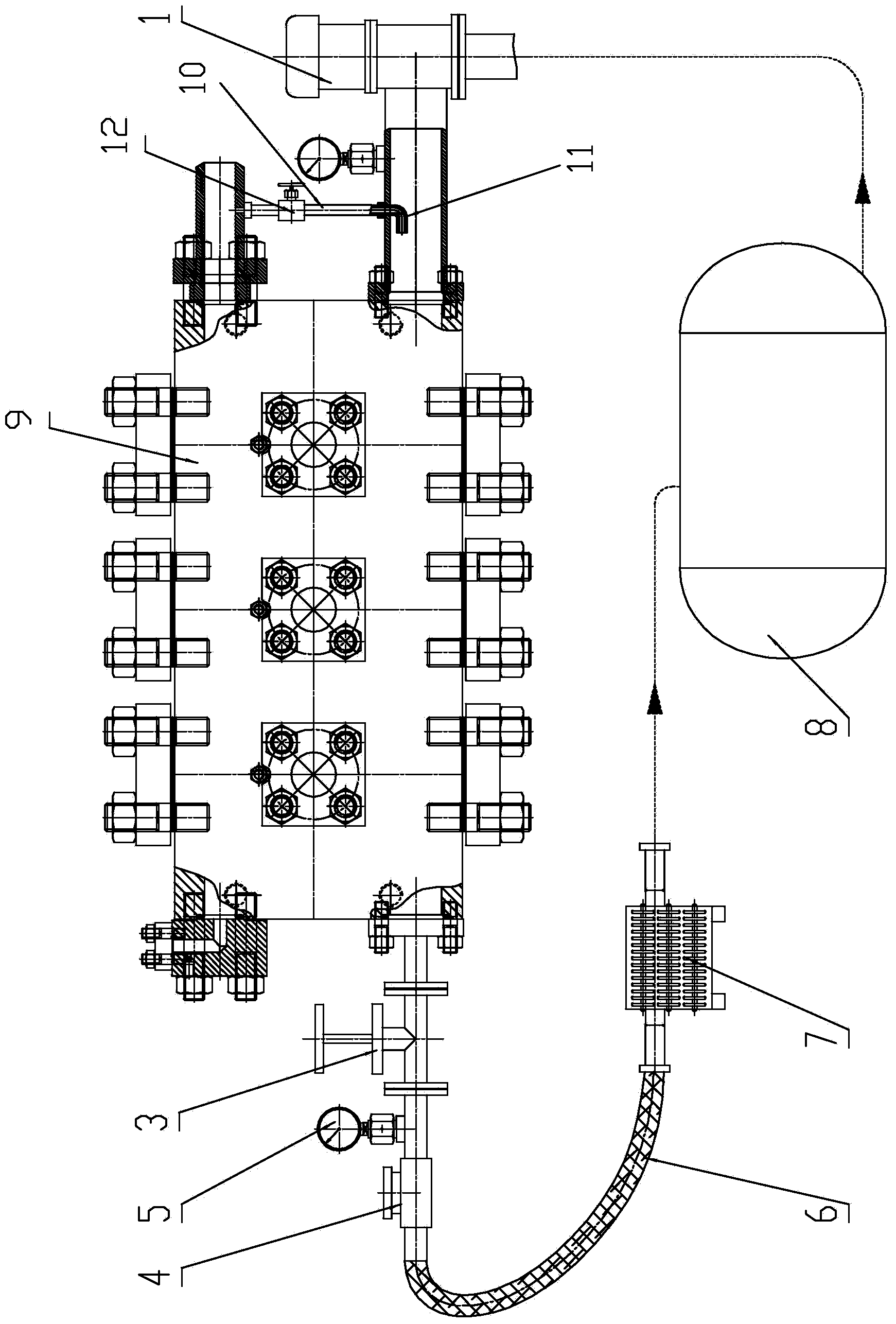

Ethyl acetate-water system supergravity distillation separation method

InactiveCN108147965AHigh purityImprove recycling efficiencyOrganic compound preparationCarboxylic acid esters preparationAcetic acidReboiler

The invention provides an ethyl acetate-water system supergravity distillation separation method. An ethyl acetate-water system supergravity distillation separation device is composed of an ethyl acetate-water storage tank, an ethyl acetate-water pump, an ethyl acetate-water flow meter, a reboiler, a separation liquid pump, a baffling supergravity distillation machine, a speed regulating motor, afinished product storage tank, a finished product flow meter, a finished product pump, a condenser, a reflux flow meter and corresponding connecting pipelines. A continuous separation recycling process using the baffling supergravity distillation machine is adopted, so that separation time can be shortened greatly, purity of recycled ethyl acetate and recycling efficiency are improved, and occupied space of conventional distillation separation equipment is saved. The method is simple in process, low in energy consumption and capable of realizing industrial production.

Owner:UNIV OF JINAN

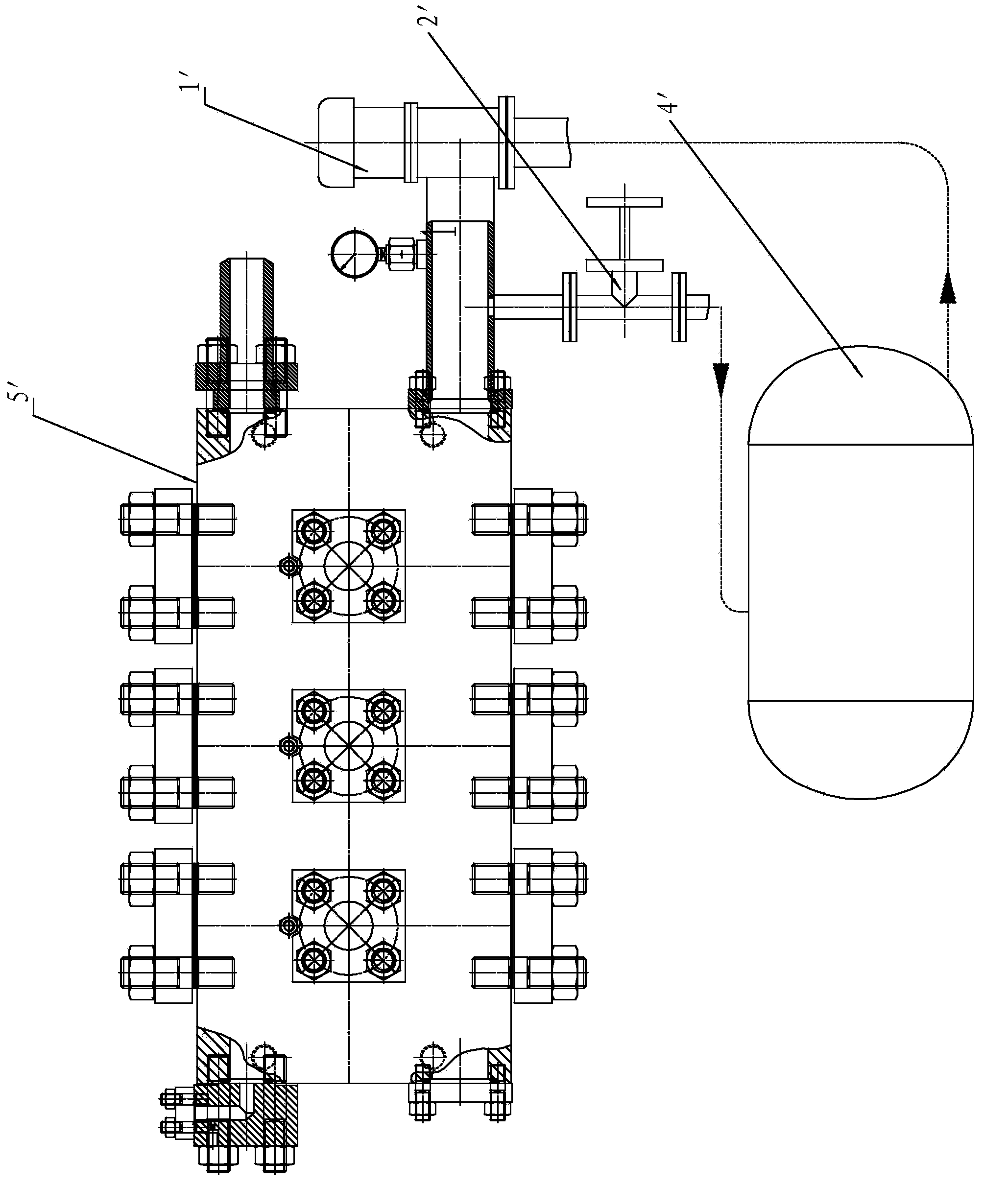

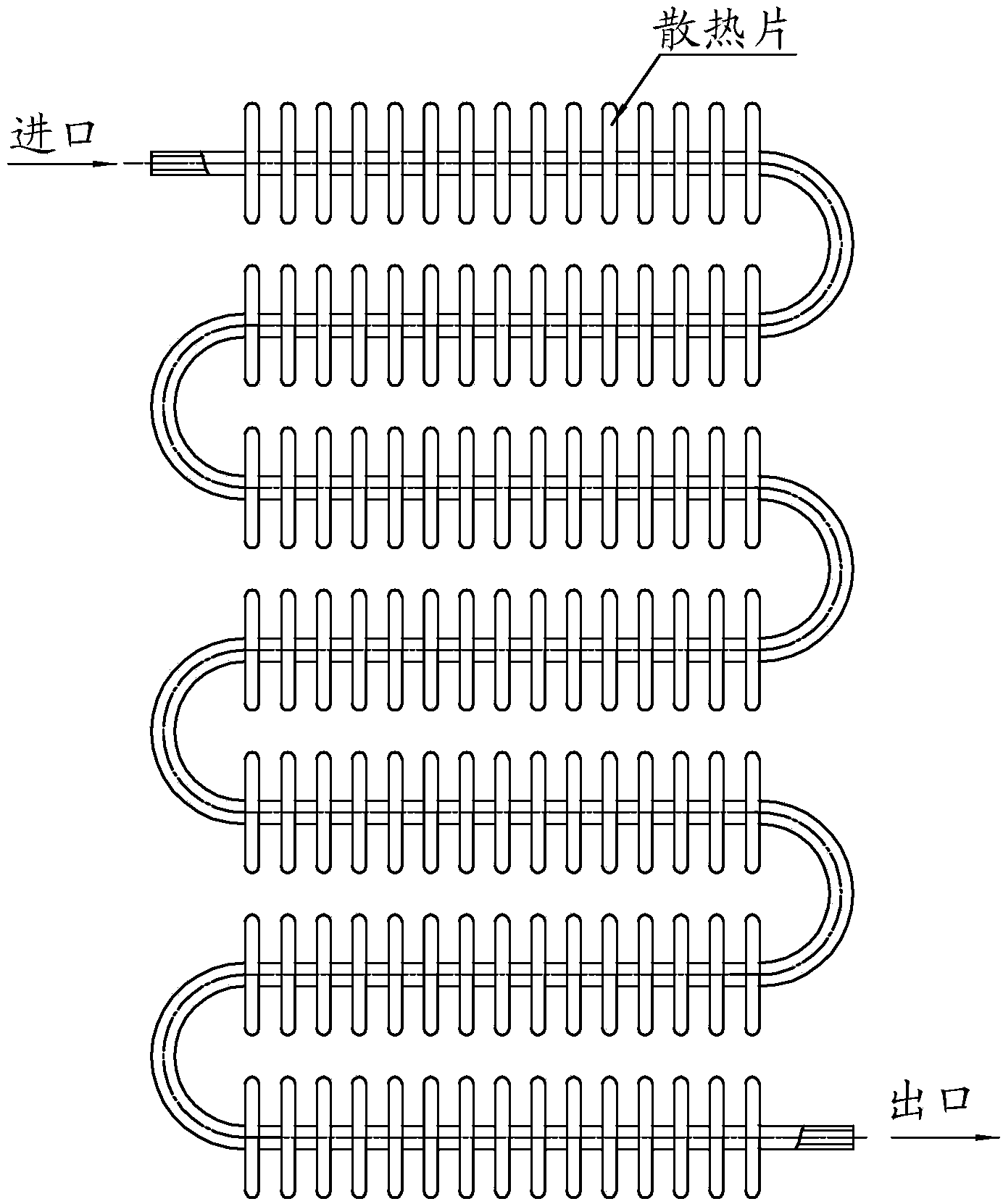

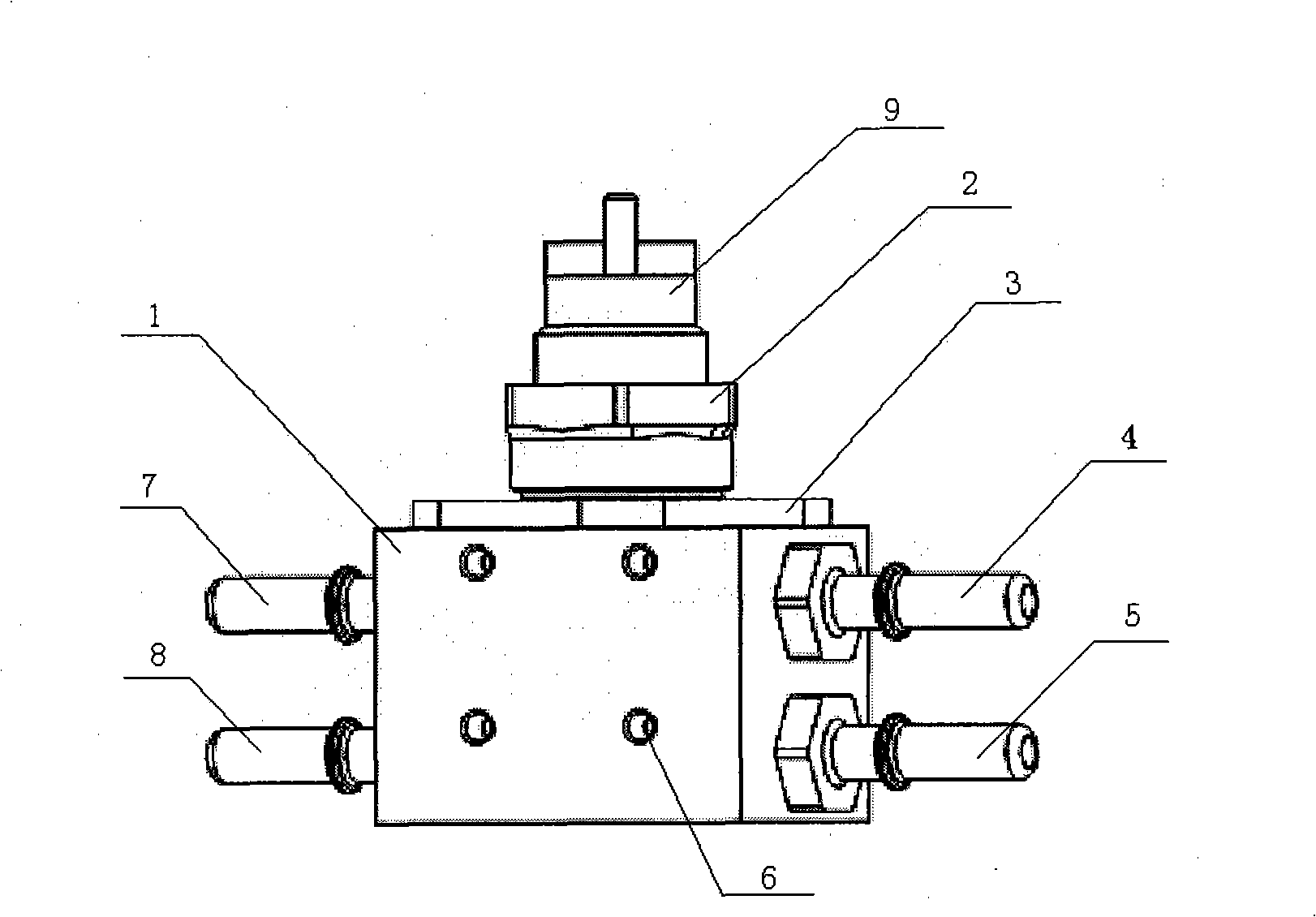

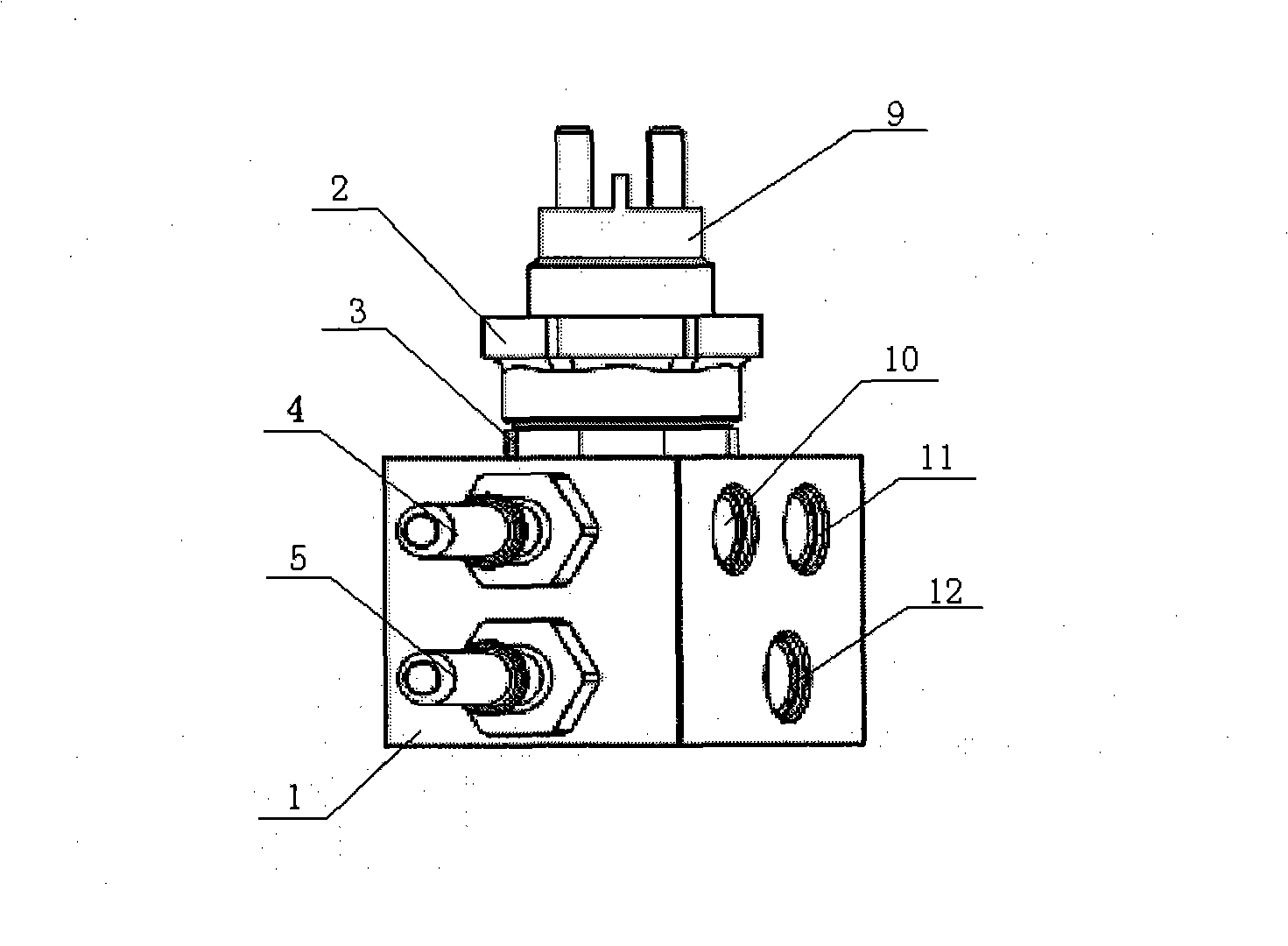

Device for resisting gasification of aerogenesis liquid medium of plunger pump

ActiveCN103644453AGasification overcomes and preventsOvercoming challenges in the gasification processContainer filling methodsPressure vesselsLiquid mediumEngineering

The invention relates to a device for resisting gasification of an aerogenesis liquid medium of a plunger pump, wherein the device for resisting gasification of the aerogenesis liquid medium of the plunger pump comprises an adjusting manifold; the adjusting manifold is used for adjusting a reflux flow and keeping a constant pressure and a constant temperature in a liquid inlet cavity of the plunger pump; the adjusting manifold comprises a throttle valve, a check valve, a reflux pipeline and a heat exchange booster; an inlet of the throttle valve is arranged in a channel of the liquid inlet cavity of the plunger pump or communicated with the liquid inlet cavity of the plunger pump; an outlet of the throttle valve is communicated with an inlet of the check valve; an outlet of the check valve is communicated with a liquid inlet of the heat exchange booster through the reflux pipeline; a liquid outlet of the heat exchange booster is communicated with a reflux end of an aerogenesis liquid medium storage tank. Compared with the prior art, the device for resisting gasification of the aerogenesis liquid medium of the plunger pump is simple to operate and strong in practicability; the device for resisting gasification of the aerogenesis liquid medium of the plunger pump is matched in a reciprocating plunger pump, so that the problem of a gasification process during conveying the aerogenesis liquid medium through the normal plunger pump can be avoided, thus reliable equipment support is provided for conveying other aerogenesis liquid mediums such as liquid CO2.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

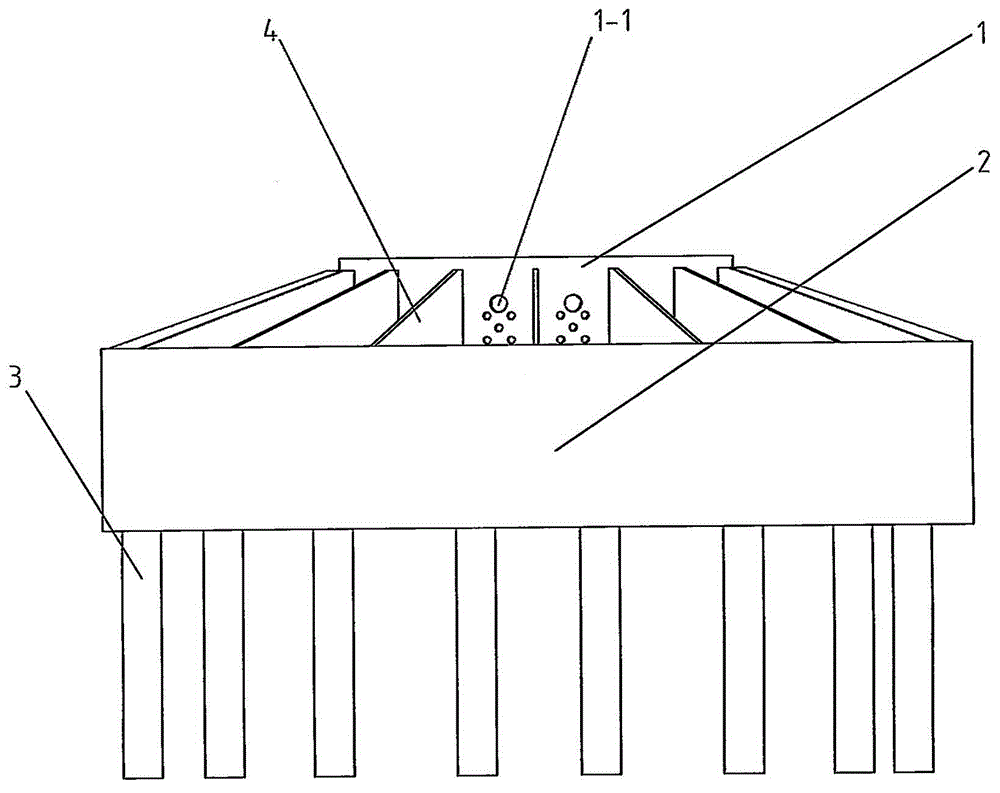

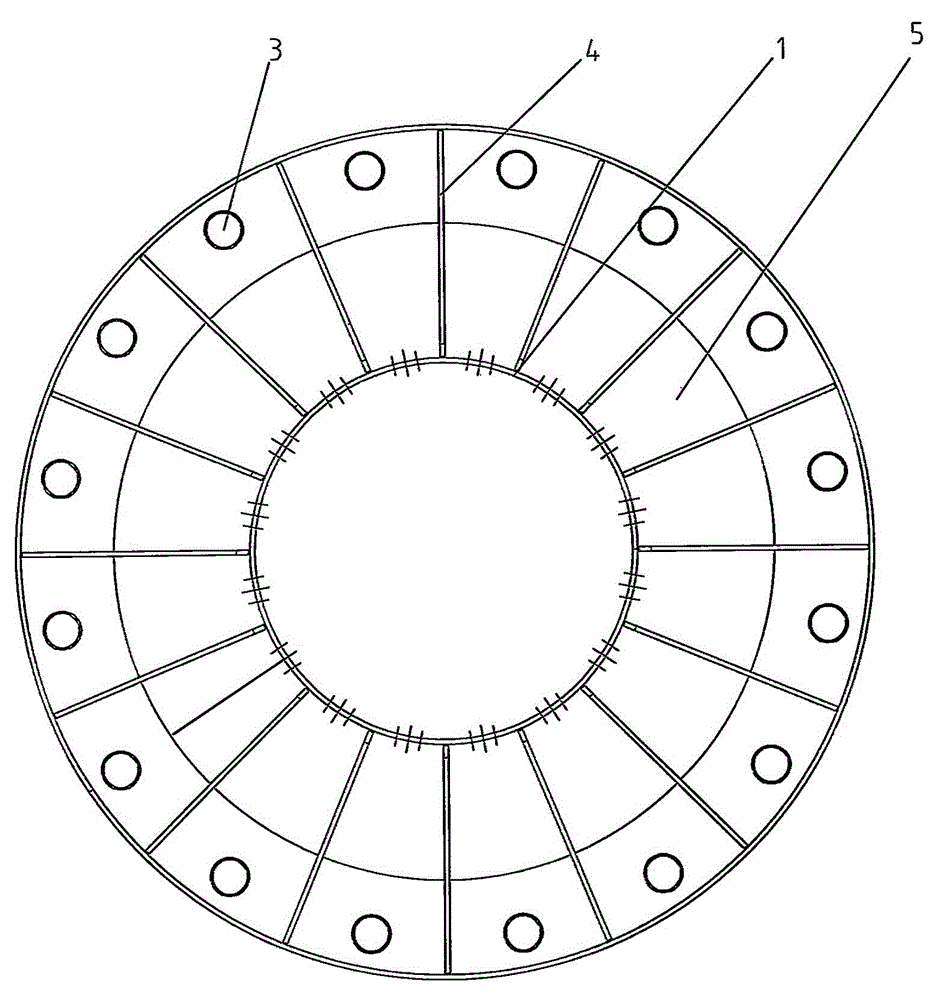

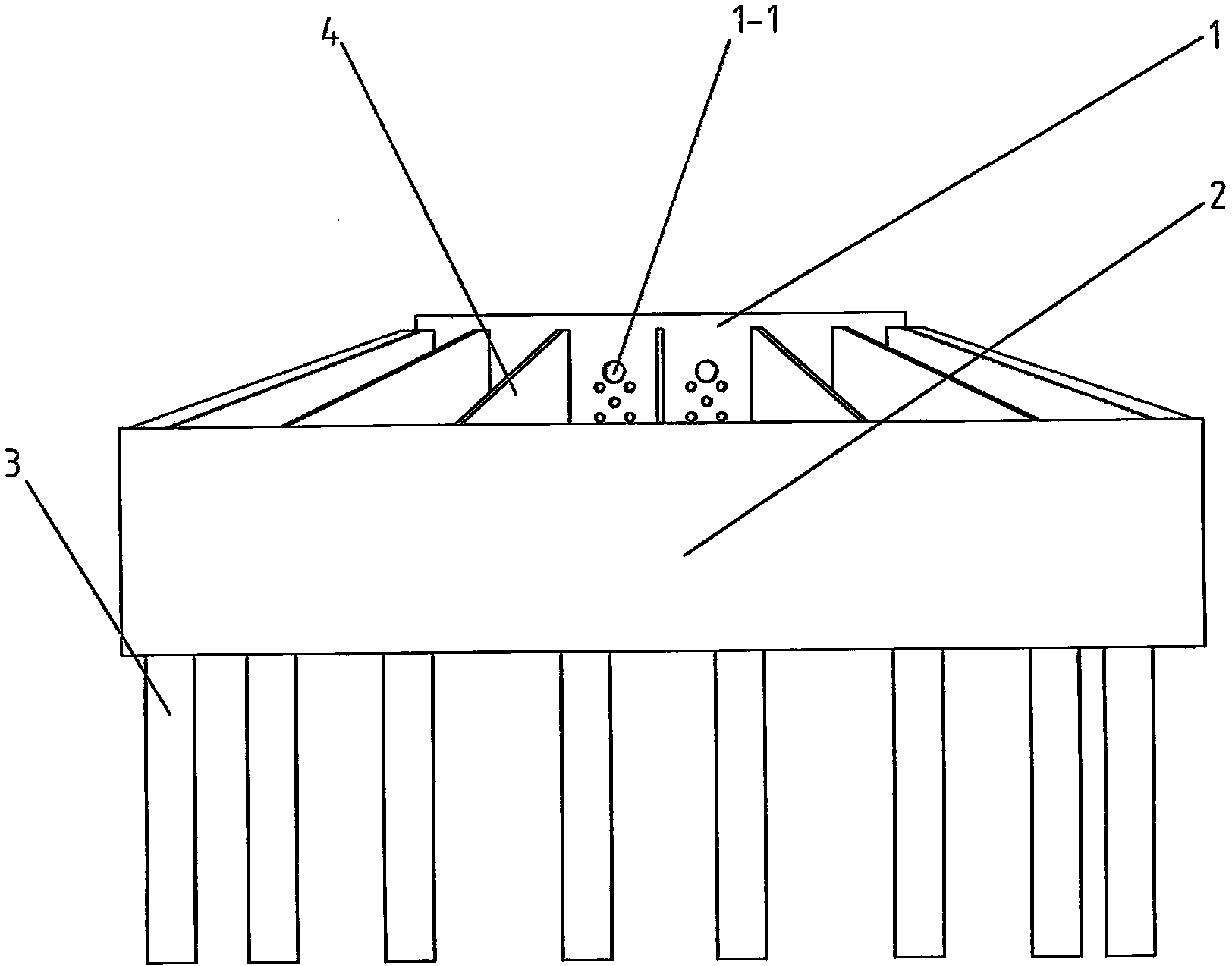

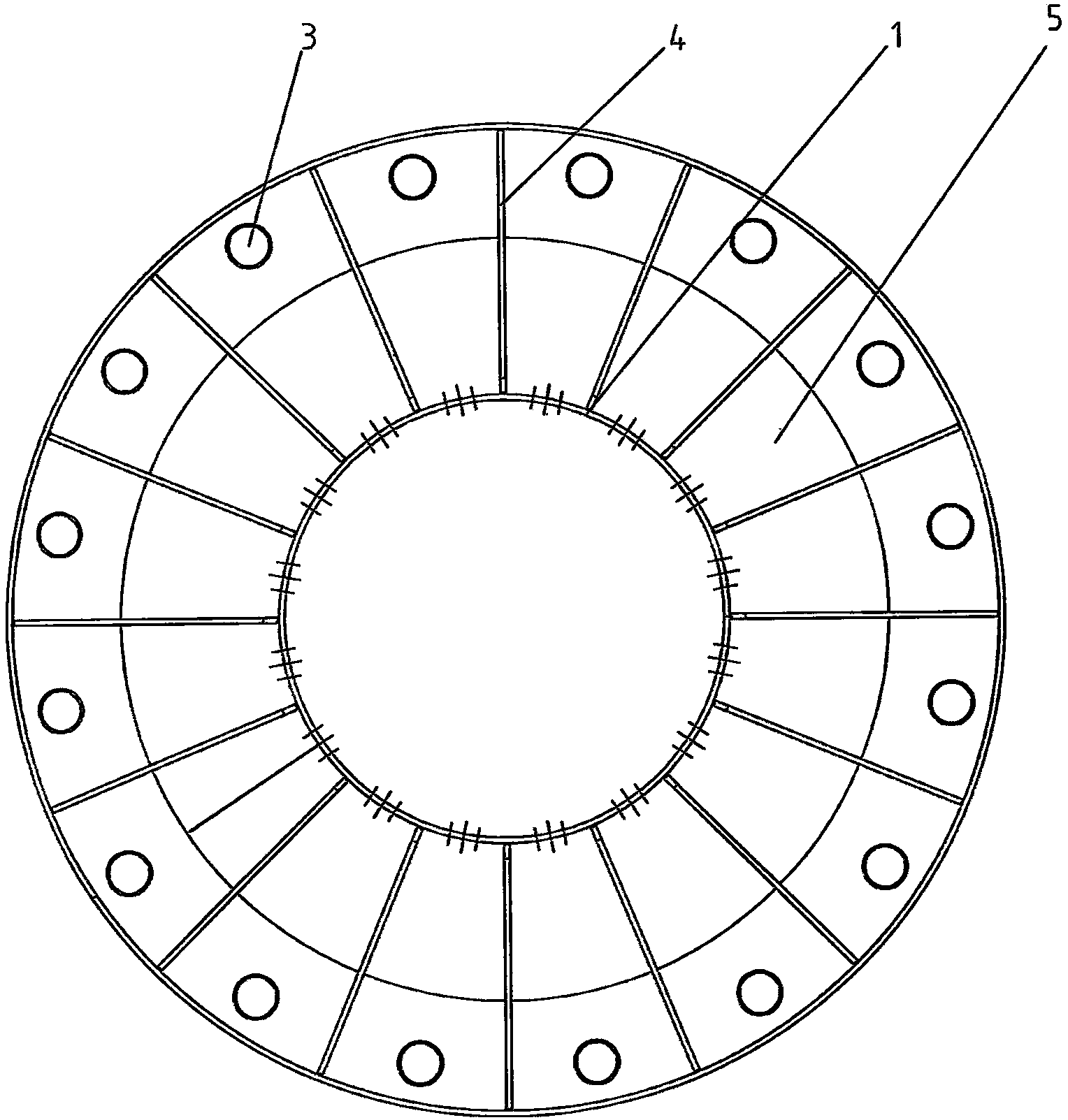

Automatic equal volume distribution device for cluster distillation reflux liquid

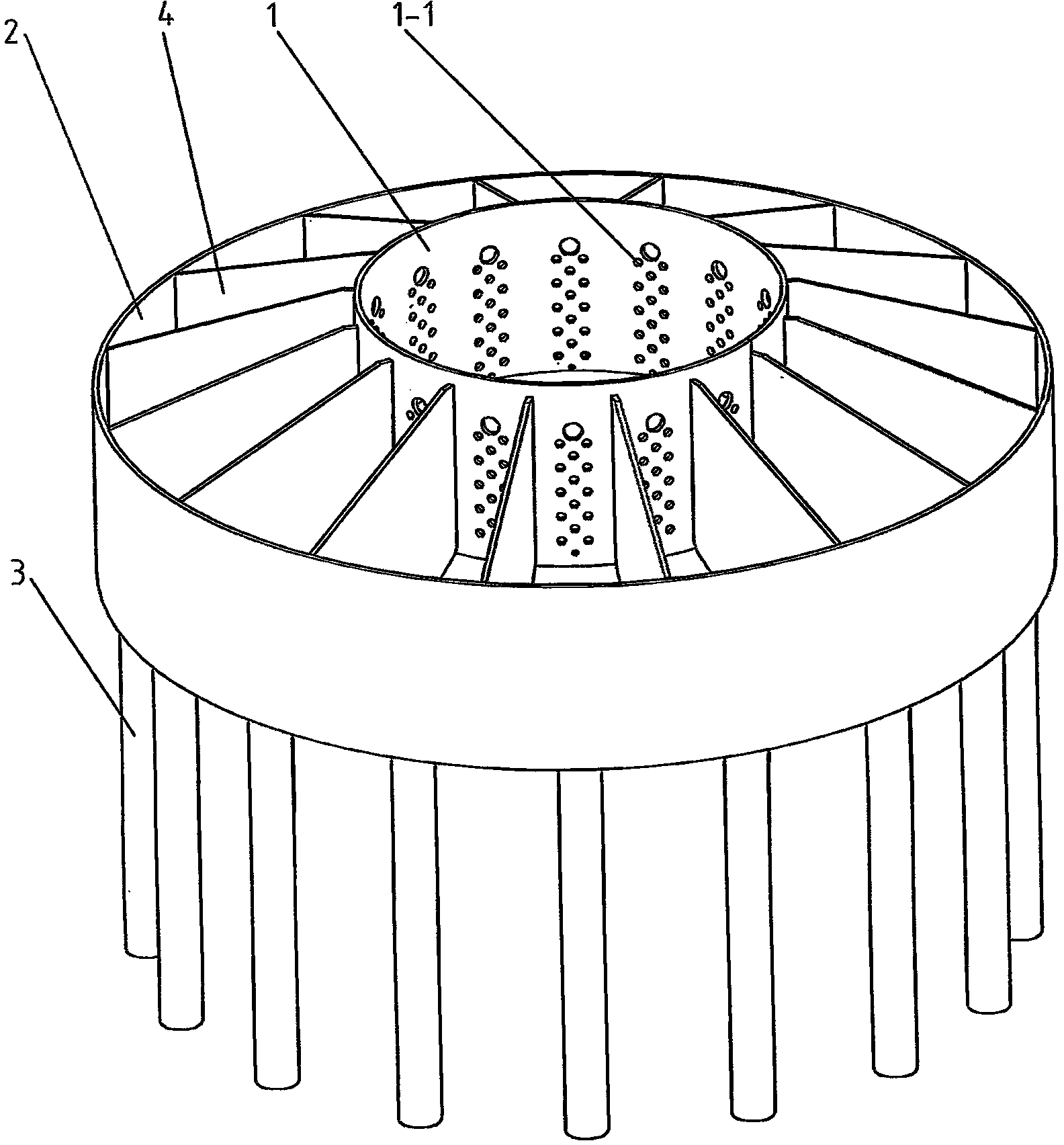

ActiveCN103920302BRealize automatic equal distributionGuarantee the normal operation of cluster distillationFractional distillationEngineeringTower

The invention discloses an automatic equivalent distributing device of cluster distillation reflux. The automatic equivalent distributing device of the cluster distillation reflux comprises an external groove wall, an inner reflux groove connected with a reflux discharge pipe, and a plurality of reflux flowing guide pipes; the external groove wall is positioned on the outer periphery of the inner reflux groove; a plurality of baffles which are distributed radially by taking the center of the inner reflux groove as a circle center is connected between the external groove wall and a wall plate of the inner reflux groove; reflux sub-grooves are formed between adjacent baffles; moreover, reflux flowing hole groups with the same arrangement are respectively formed in the wall plate of the inner reflux groove and corresponding parts of the corresponding reflux sub-grooves; additionally, the flow liquid hole groups are communicated with the inner sides of the corresponding reflux sub-grooves; the reflux flowing guide pipes are communicated with the bottoms of the outer side of the corresponding reflux inner groove. According to the device, the reflux is automatically and equivalently distributed to a plurality of distillation towers, so that the distillation effect is improved.

Owner:常州克罗蒂娜化工技术有限公司

Method for preparing lauryl methacrylate

InactiveCN102146035AHigh purityEasy aggregationOrganic compound preparationCarboxylic acid esters preparationWastewaterAcid value

The invention discloses a method for preparing lauryl methacrylate, which comprises the following steps of: (1) putting main materials of lauryl alcohol and methacrylic acid into an esterification reaction container, adding a solvent, adding a catalyst and a polymerization inhibitor A, and performing mixing reaction to obtain a reaction material; (2) controlling the pressure in the esterification reaction container to be -0.04 to -0.08MPa, raising the temperature in the esterification reaction container until reflux flows out, keeping the temperature, and beginning cooling to normal temperature until no reflux flows out or an acid value in reaction solution is detected to be 30-50mgKOH / g; (3) transferring the reaction material to a washing container, adding alkali liquor, controlling the pH value of the reaction material to be 7-8, standing until the reaction material is layered, and discharging wastewater on the lower layer; and (4) transferring the reaction material of which the wastewater is removed to a distillation container, adding a polymerization inhibitor B, vacuumizing the distillation container, and distilling to remove methylbenzene to obtain the product. The product is high in purity, good in color, and high in yield.

Owner:天津市天骄化工有限公司

Method for producing a flow rich in methane and a flow rich in c2+ hydrocarbons, and associated installation

ActiveUS20150292798A1Efficient and economical mannerSpace minimizationSolidificationLiquefactionFractionating columnEngineering

This method envisions cooling the supply flow in a first heat exchanger, separation in a first separation flask in order to produce a light upper flow and a heavy lower flow and dividing the light upper flow into a supply fraction of a dynamic pressure reduction turbine and a supply fraction of a first distillation column. A cooled reflux flow is formed from an effluent from a dynamic pressure reduction turbine, the portion of the effluent being cooled and at least partially liquefied in a heat exchanger. The cooled reflux flow is introduced from the heat exchanger into the first distillation column.

Owner:TECH FRANCE SA

Treatment apparatus and treatment method for wastewater produced during fumaric acid generation process

ActiveCN104773890ALower operating temperatureLow operating costMultistage water/sewage treatmentNature of treatment waterEvaporationCis-Butenedioic Acid

The present invention discloses a treatment apparatus and a treatment method for wastewater produced during a fumaric acid generation process. The treatment apparatus comprises a heating chamber, a crystallizer, a rectification tower, a cooler, a crystal receiving groove, a reflux flow meter, a distillate flow meter, a centrifuge and a condenser. According to the present invention, the components in the acid water of a phthalic anhydride tail gas absorption tower are more, wherein water is the light key component, maleic acid is the heavy key component, and the relative volatility is 6 under a normal pressure and is 14.9 under a vacuum degree of 10 KPa, such that the relative volatility is greatly increased; the rectification principle is utilized, and the crystallization, the evaporation and other operation units are integrated so as to greatly increase the separation efficiency and save the energy source and the manpower; and the treatment apparatus and the treatment method have the following beneficial effects that: the cheap low-pressure steam is used to treat at a lower temperature, the COD content in the effluent after the rectification is less than 100 PPM, the PH value of the effluent is greater than 6, the effluent can be directly discharged, and the apparatus has characteristics of simple structure, easy control process, low operating temperature, safety, reliability, low cost, and small occupation space.

Owner:ZHENJIANG KAIPU CHEM TECH CO LTD

Method for preparing triethylene glycol dimethacrylate

InactiveCN102146033AHigh purityEasy aggregationOrganic compound preparationCarboxylic acid esters preparationTriethyleneglycol dimethacrylateWastewater

The invention discloses a method for preparing triethylene glycol dimethacrylate, which comprises the following steps of: (1) putting main materials of triethylene glycol and methacrylic acid into an esterification reaction container, adding a solvent, adding a catalyst and a polymerization inhibitor A, and performing mixing reaction to obtain a reaction material; (2) controlling the pressure in the esterification reaction container to be -0.04 to -0.08MPa, raising the temperature in the esterification reaction container until reflux flows out, keeping the temperature, and beginning cooling to normal temperature until no reflux flows out or an acid value in reaction solution is detected to be 3-5mgKOH / g; (3) transferring the reaction material to a washing container, adding alkali liquor, controlling the pH value of the reaction material to be 7-8, standing until the reaction material is layered, and discharging wastewater on the lower layer; and (4) transferring the reaction material of which the wastewater is removed to a distillation container, adding a polymerization inhibitor B, vacuumizing the distillation container, and distilling to remove methylbenzene to obtain the product. The product is high in purity, good in color, and high in yield.

Owner:天津市天骄辐射固化材料有限公司

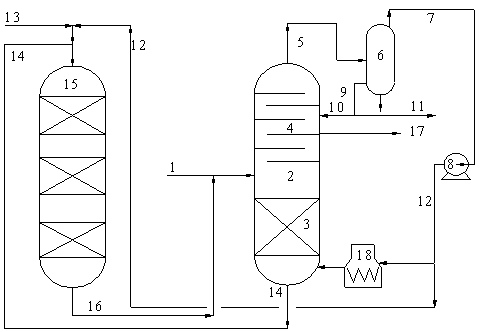

Method for producing jet fuel

ActiveCN108070403AHigh selectivityHigh yieldTreatment with hydrotreatment processesNaphthaFractionation

The invention discloses a method for producing jet fuel. The method comprises the following contents: a straight-run diesel oil raw material and hydrocracking generated oil are mixed, heated and / or subjected to heat exchange and enter a reaction rectification tower from the middle, and a product descends into a catalytic reaction zone filled with a hydrofining catalyst in the tower for hydrofiningreaction, wherein light components rise to the rectification section of the reaction rectification tower for fractionation, one part of the liquid phase as overhead reflux flows into the reaction rectification tower, and the other part comprising naphtha, jet fuel and the like as products is discharged out of the system; heavy components continue to descend in a stripping section, are dischargedfrom the bottom of the tower, and enter a hydrocracking reactor filled with a hydrocracking catalyst for hydrocracking reaction. According to the method, the straight-run diesel oil is taken as a mainraw material, the reaction process and the reaction depth are adjusted and controlled by selecting a proper process flow and catalyst system, more components in the straight-run diesel oil raw material are converted into jet fuel products, and accordingly, the yield of the jet fuel products is increased, and the quality of the jet fuel products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

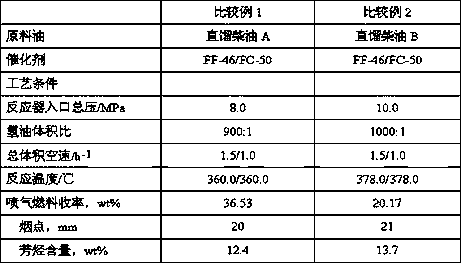

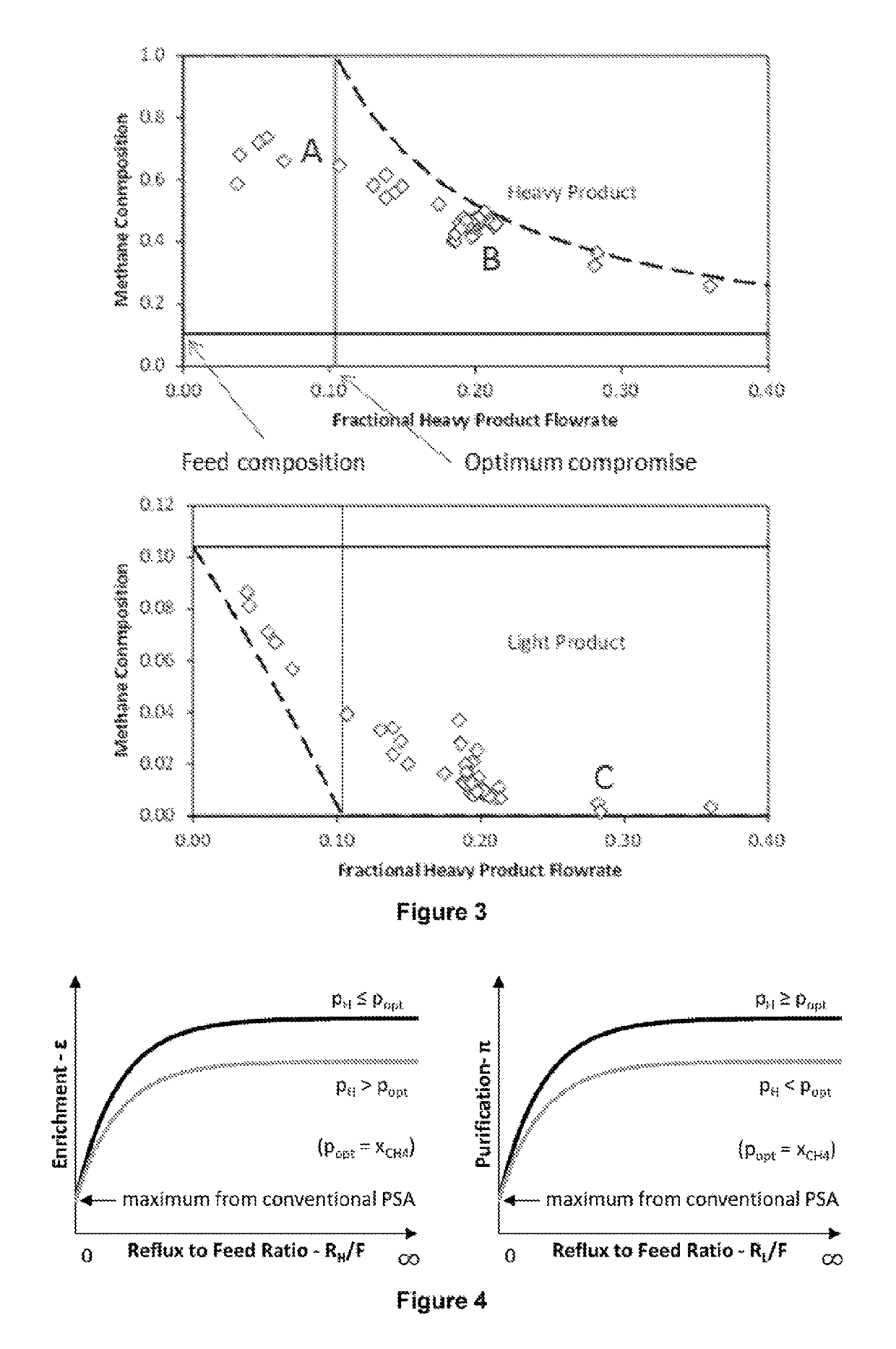

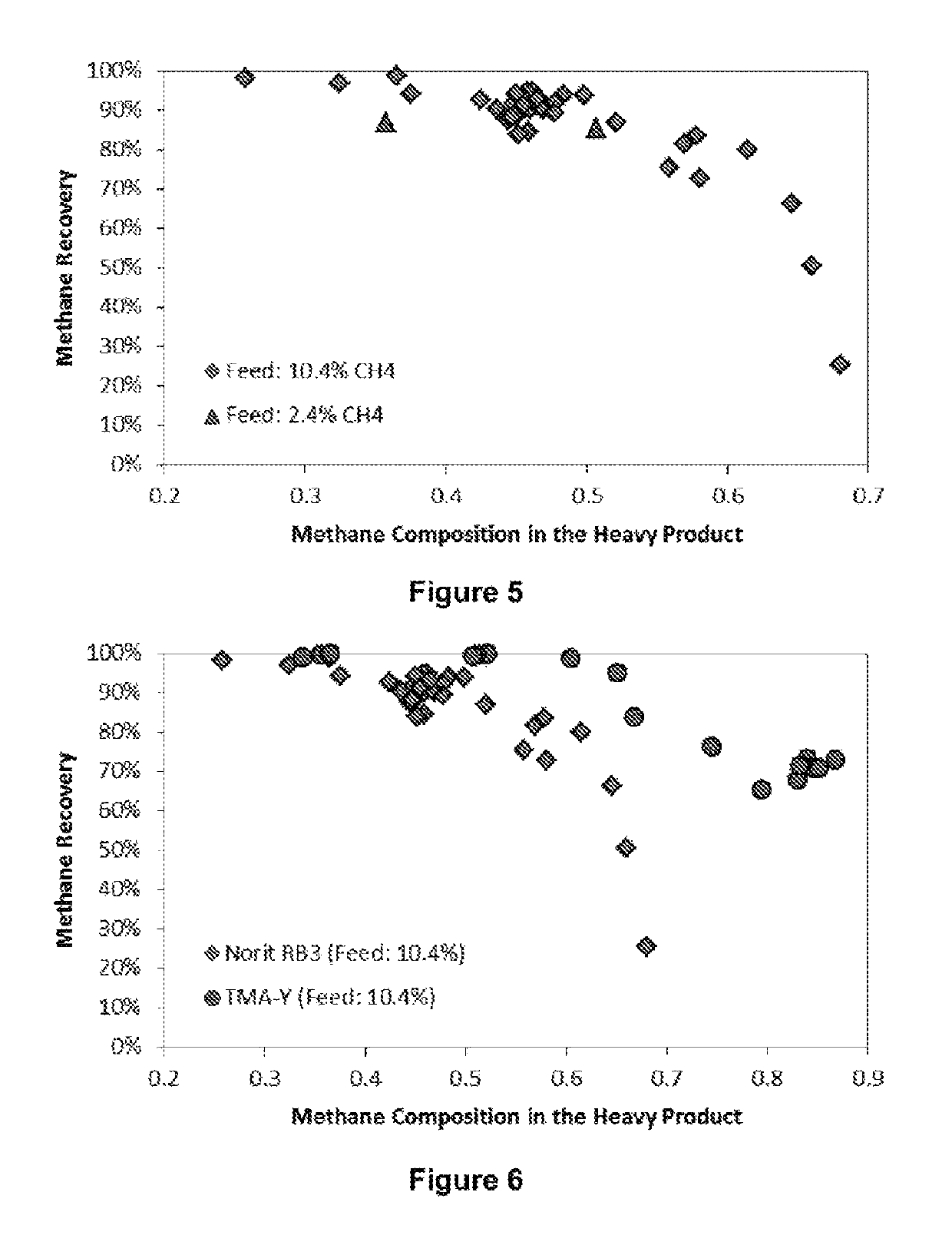

Method for gas separation

ActiveUS10279305B2Maximum degree of productivityHigh purity and recoveryGas treatmentDispersed particle separationSorbentProduct gas

A method for controlling gas separation of a gas mixture comprising a first component and a second component, the method comprising contacting a feed containing the gas mixture with an adsorbent in a bed in a column in a dual reflux swing adsorption process such that a first component of a gas mixture attains or exceeds a desired purity and a second component of the gas mixture attains or exceeds a desired purity, wherein the mathematical product of the cycle feed time and the sum of the molar feed flow rate and the molar reflux flow rate directed to the column does not exceed the maximum number of moles that can be treated per bed per cycle and wherein the ratio of the first product flow rate to the feed flow rate is less than or equal to the first component's fraction of the feed, and the ratio of the second product flow rate to the feed flow rate is less than or equal to the second component's fraction of the feed.

Owner:GAS CAPTURE TECH +1

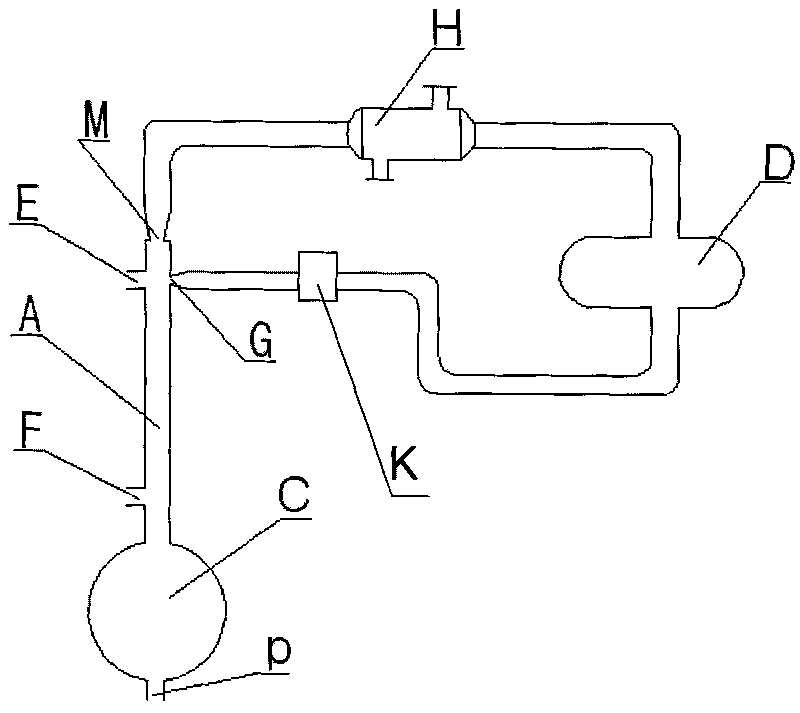

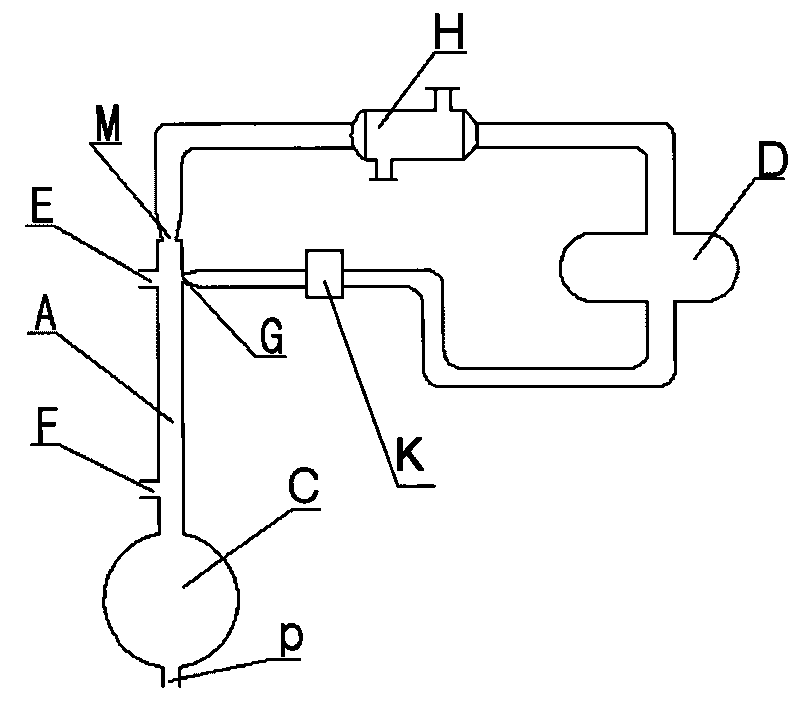

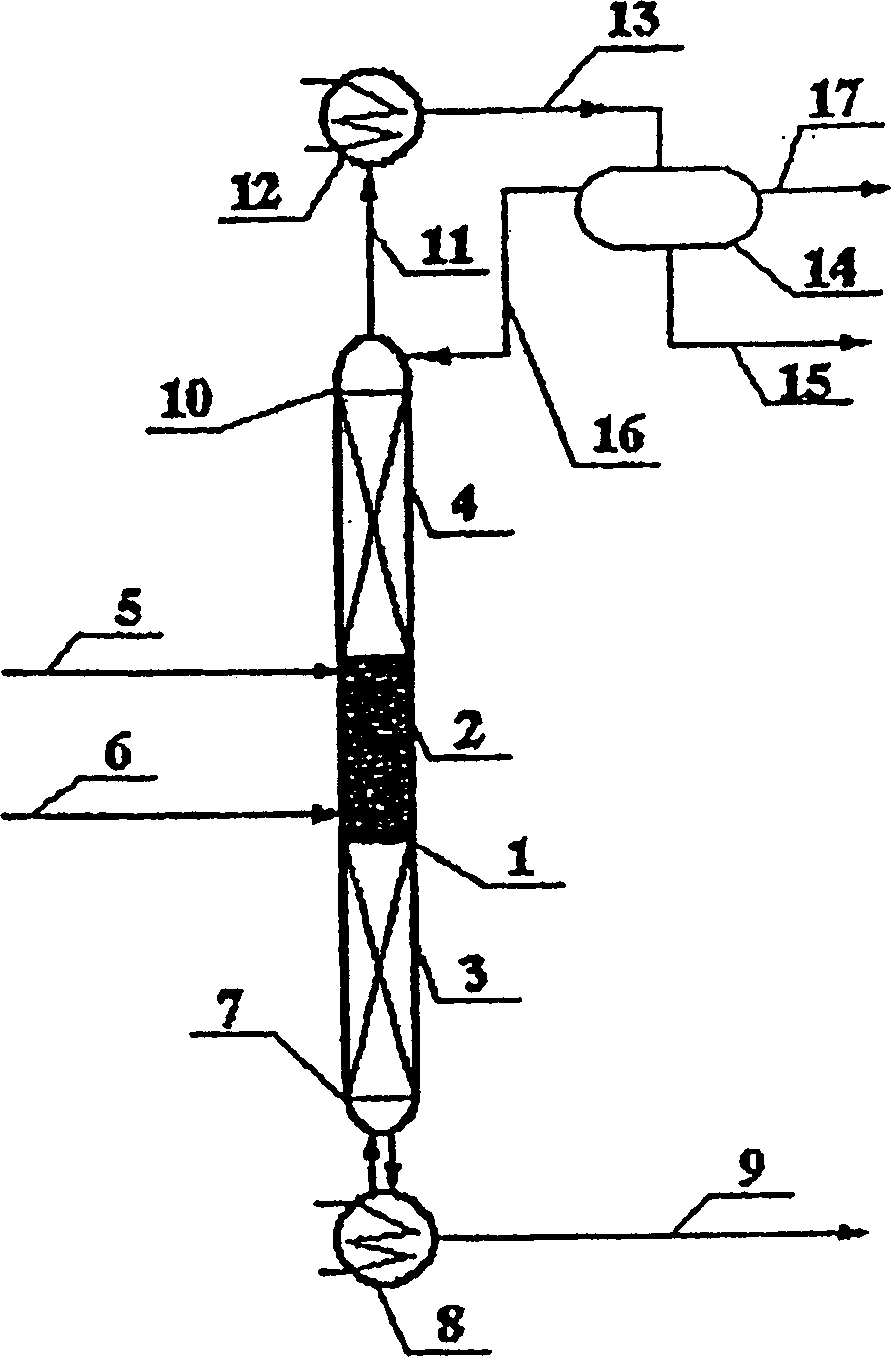

Process for preparing gamma-chloropropylmethyldimethoxysilane

ActiveCN101759714ARealize continuous productionGuaranteed uptimeGroup 4/14 element organic compoundsPorosityReaction temperature

The invention relates to a process for preparing gamma-chloropropylmethyldimethoxysilane. The gamma-chloropropylmethyldichlorosilane is uniformly added at the speed of 3,000g / 5h, the methanol is uniformly added at the speed of 1,000g / 5h, and the liquid reflux flow speed in a reflux tank D is controlled to be 200g / 5h; the reaction temperature in a reaction tower A is between 65 DEC and 75 DEG C, and the reaction temperature in a reaction kettle C is between 140 DEG C and 160 DEG C; a packing layer in the reaction tower A is between 1m and 1.2m, glass or ceramic material is adopted, the porosity in the packing layer is between 60 percent and 70 percent. The process is matched with needed equipment, can realize continuous production and has reasonable and compact device and stable running. Because an optimal technical parameter is matched, the yield can be as high as 98 percent, therefore, the pollution is small, and the production efficiency is high.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

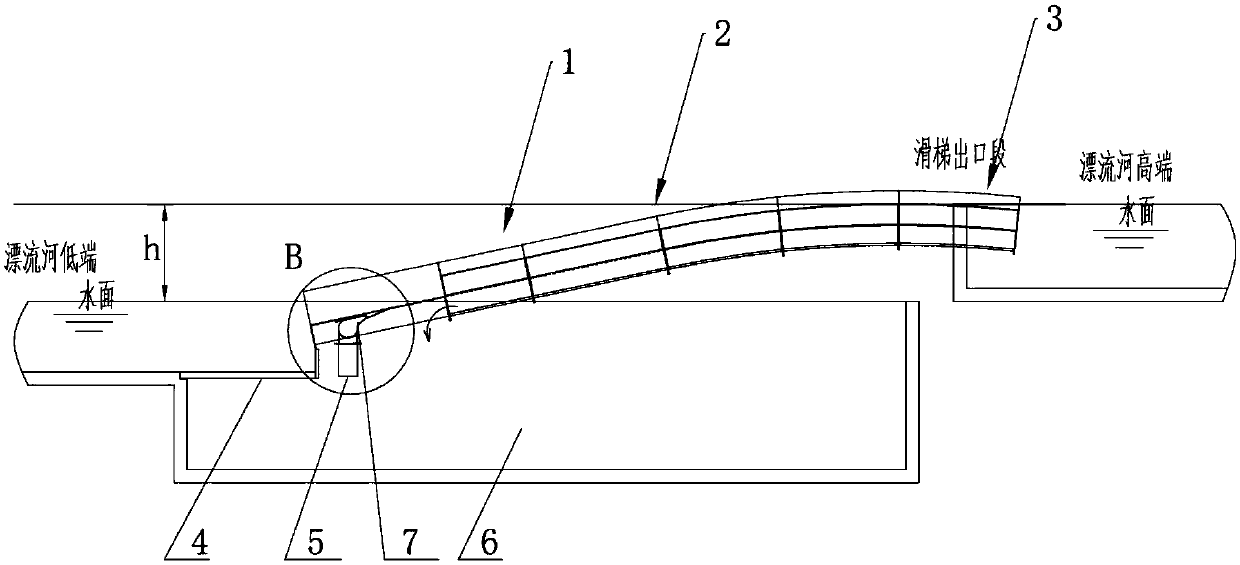

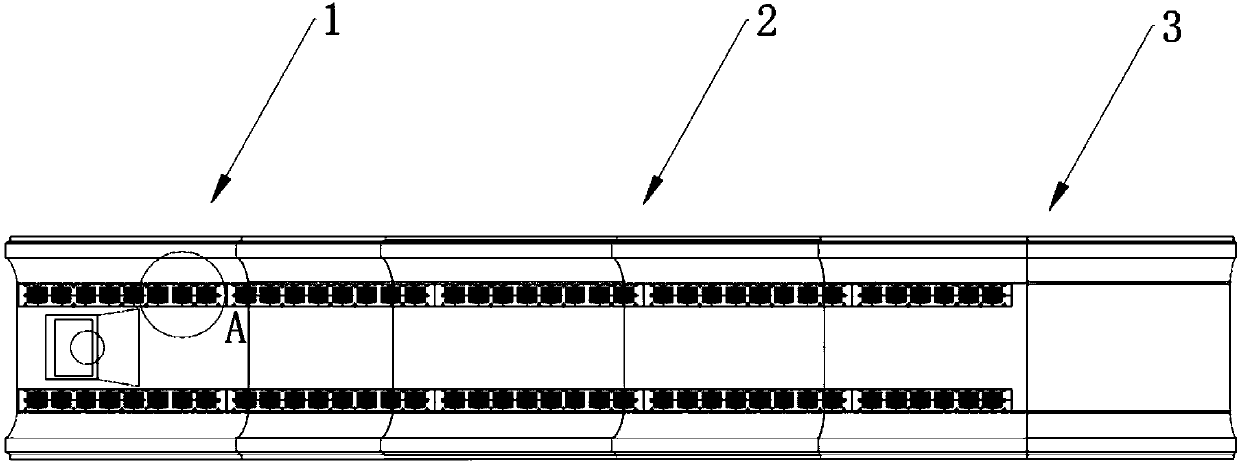

Lifting slide

The invention relates to a lifting slide which is formed by at least one single-section lifting slide way structure. Each single-section lifting slide way structure comprises a slide entrance section,a slide upward section and a slide exit section in connection from bottom to top, wherein each of the slide entrance section, the slide upward section and the slide exit section is formed by connection of multiple slide way sections, and a jet device for water jet is mounted in the head slide way section in the slide entrance section and connected with a water supply pipe through a flange. By arrangement of the jet devices on slide ways, rafts with tourists are enabled to slide from bottom to top under the action of water flow; by arrangement of water return tanks in the slide ways, water isenabled to flow back into a water pump pool to realize recycling; by arrangement of gratings in each slide way, water is enabled to flow into the water return tanks. By water jet for realizing slidingfrom bottom to top, drifting river forming forms are enriched while playing modes are increased, and playing amusement is greatly improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Automatic equivalent distributing device of cluster distillation reflux

ActiveCN103920302ARealize automatic equal distributionGuarantee the normal operation of cluster distillationFractional distillationEngineeringTower

The invention discloses an automatic equivalent distributing device of cluster distillation reflux. The automatic equivalent distributing device of the cluster distillation reflux comprises an external groove wall, an inner reflux groove connected with a reflux discharge pipe, and a plurality of reflux flowing guide pipes; the external groove wall is positioned on the outer periphery of the inner reflux groove; a plurality of baffles which are distributed radially by taking the center of the inner reflux groove as a circle center is connected between the external groove wall and a wall plate of the inner reflux groove; reflux sub-grooves are formed between adjacent baffles; moreover, reflux flowing hole groups with the same arrangement are respectively formed in the wall plate of the inner reflux groove and corresponding parts of the corresponding reflux sub-grooves; additionally, the flow liquid hole groups are communicated with the inner sides of the corresponding reflux sub-grooves; the reflux flowing guide pipes are communicated with the bottoms of the outer side of the corresponding reflux inner groove. According to the device, the reflux is automatically and equivalently distributed to a plurality of distillation towers, so that the distillation effect is improved.

Owner:常州克罗蒂娜化工技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2-methyl-2-propenoic acid 2-ethyl-2-[[(2-methyl-1-oxo-2-propenyl)oxy]methyl]-1,3-propanediyl ester Method for preparing 2-methyl-2-propenoic acid 2-ethyl-2-[[(2-methyl-1-oxo-2-propenyl)oxy]methyl]-1,3-propanediyl ester](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8eb46f11-a35b-4c5c-90ea-81bb57f1fca3/2010105571504100002DEST_PATH_IMAGE001.PNG)