Process for preparing gamma-chloropropylmethyldimethoxysilane

A technology of chloropropylmethyldimethoxysilane and chloropropylmethyldichlorosilane, which is applied in the field of preparation technology of γ-chloropropylmethyldimethoxysilane, can solve the problem of low conversion efficiency, reaction Low efficiency, high equipment investment and other problems, to achieve the effect of high production efficiency, stable operation and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

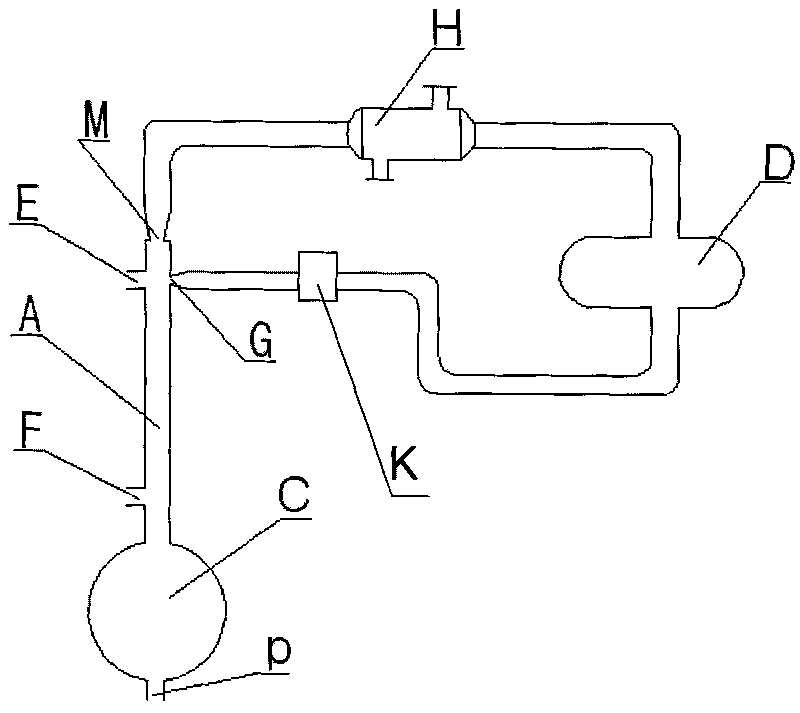

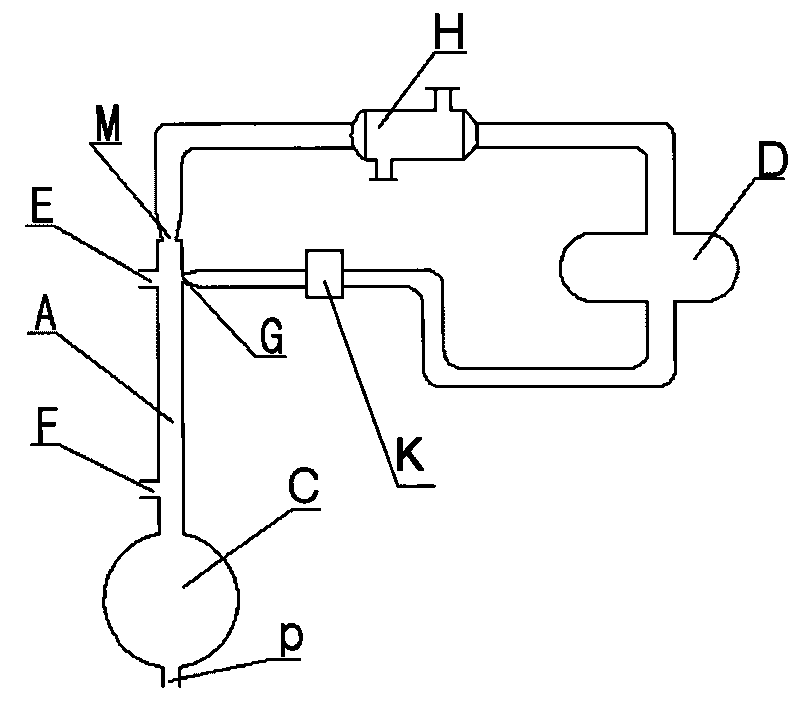

[0011] Embodiment 1, the preparation process of γ-chloropropylmethyldimethoxysilane, wherein: the bottom of the reaction tower A communicates with the inlet of the reaction kettle C, and one side of the top of the reaction tower A is provided with a first feeding port E, The other side of the top of the reaction tower A is provided with a reflux feeding port G which communicates with the bottom of the reflux tank D, and the top of the reaction tower A is provided with a steam rising port M which communicates with one end of the condenser H, and the other end of the condenser H communicates with the reflux tank The top of D is connected; the bottom of the reaction tower A is provided with a second feeding port F; the bottom of the reaction kettle C is provided with a discharge port P; the pipeline connecting the reflux tank D with the reflux feeding port G is provided with a control valve K;

[0012] Its technological process: uniformly add γ-chloropropylmethyldichlorosilane fro...

Embodiment 2

[0015] Embodiment 2, the preparation technology of γ-chloropropylmethyldimethoxysilane, wherein:

[0016] Evenly add γ-chloropropylmethyldichlorosilane at a rate of 3000g / 5h, and evenly add methanol at a rate of 1000g / 5h, and control the liquid reflux flow rate in the reflux tank D to 200g / 5h;

[0017] The reaction temperature in reaction tower A is 65-75°C, and the reaction temperature in reaction kettle C is 140-160°C; the packing layer in reaction tower A is 1-1.2 meters, and the material is glass or ceramic material. The porosity is 60-70%. All the other are with embodiment 1.

Embodiment 3

[0018] Embodiment 3, the preparation technology of gamma-chloropropylmethyldimethoxysilane, wherein:

[0019] Evenly add γ-chloropropylmethyldichlorosilane at a rate of 2500-3600g / 5h, and evenly add methanol at a rate of 900-1100g / 5h, and control the liquid reflux flow rate in the reflux tank D to 190-210g / 5h;

[0020] The reaction temperature in the reaction tower A is 65-75°C, and the reaction temperature in the reactor C is 140-160°C; the packing layer in the reaction tower A is 1-1.2 meters, and the material is glass or ceramic material. The porosity is 60-70%. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com