Hollow fibre membrane separation equipment and its operation method

A separation device and fiber membrane technology, which is applied in the field of membrane separation, can solve the problems of imperfect external pipeline design and cannot be used for tea juice, etc., and achieve the effect of speeding up filtration and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

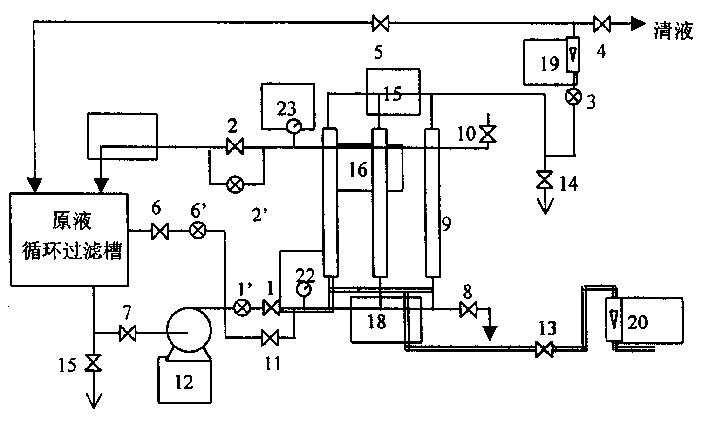

[0032] Some kind of amino acid fermented liquid, wet bacterial weight 13%, want to remove the impurity such as bacterial body in fermented liquid. Using the membrane separation device of the present invention, one Φ90 standard industrial membrane module is configured, and the filtration and refining are carried out according to the following process parameters:

[0033] 1), working status. Open valves 1', 2, 3, 4, 7, close valves 1, 2', 5, 6', 8, 14, 15, adjust valves 1, 2, half open valves 6, 11, so that the working pressure is P1 inlet 0.09MPa, outlet pressure P2 0.07MPa. The working time is 20 minutes.

[0034] 2), cleaning state 1. Close the automatic valves 1', 3, open the automatic valves 2', 6', adjust the valves 6, 11 to keep water in the membrane module, and the reading of the gas flow meter is 3Nm for each membrane module 3 / h. The cleaning time is 20 seconds.

[0035] 3), cleaning state 2. Turn off the compressed air, open valve 1' and close valve 6'. The ri...

Embodiment 2

[0038] Ibid amino acid fermented liquid, wet bacteria weight 13%, want to remove impurities such as thalline in the fermented liquid. Adopt the membrane separation device of the present invention, wherein dispose 1 Φ90 standard industrial type membrane module, the pipeline without valve 11, carry out filtration refining according to following process parameter:

[0039] 1), working status. Open valves 1', 2, 3, 4, 7, close valves 1, 2', 5, 6', 8, 14, 15, adjust valves 1, 2, half open valve 6, so that the working pressure is 0.09MPa at the inlet of P1 , Outlet pressure P2 0.07MPa. The working time is 20 minutes.

[0040]2), cleaning state 1. Close the automatic valves 1', 3, open the automatic valves 2', 6', and the reading of the gas flow meter is 3Nm for each membrane module 3 / h. The cleaning time is 20 seconds.

[0041] 3), cleaning state 2. Turn off the compressed air, open valve 1' and close valve 6'. The rinse time is 2 seconds.

[0042] 4), open the valve 3, an...

Embodiment 3

[0044] Some kind of amino acid fermented liquid, the weight of wet bacteria is 3%, and it is desired to remove impurities such as bacteria in the fermented liquid. Using the membrane separation device of the present invention, one Φ90 standard industrial membrane module is configured, and the filtration and refining are carried out according to the following process parameters:

[0045] 1), working status. Open valves 1', 2, 3, 4, 7, close valves 1, 2', 5, 6', 8, 14, 15, adjust valves 1, 2, half open valves 6, 11, so that the working pressure is P1 inlet 0.09MPa, outlet pressure P2 0.07MPa. The working time is 20 minutes.

[0046] 2), cleaning state 1. Close automatic valves 1', 3, open automatic valves 2', 6', adjust valves 6, 11 to keep water in the membrane module, and the reading of the gas flowmeter is 3Nm for each membrane module 3 / h. The cleaning time is 20 seconds.

[0047] 3), cleaning state 2. Turn off the compressed air, open valve 1' and close valve 6'. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com